Cracking a skill-specific interview, like one for Grading and Sorting Standards, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Grading and Sorting Standards Interview

Q 1. Describe your experience with different grading and sorting methodologies.

My experience spans a wide range of grading and sorting methodologies, encompassing both manual and automated systems. I’ve worked with various industries, including agriculture (grading produce by size, color, and ripeness), manufacturing (sorting components based on tolerances and defects), and the gemstone industry (grading diamonds based on the 4Cs: cut, clarity, color, and carat). Manual methods often involve visual inspection and simple tools like calipers or scales, while automated systems use advanced technologies such as machine vision, sensors, and AI-powered algorithms for high-throughput and objective grading. For example, in a fruit packing facility, I implemented a system that used cameras and computer vision to automatically sort apples based on size and color, significantly increasing efficiency and reducing labor costs. In the gemstone industry, I’ve been involved in developing grading standards to ensure consistency and transparency in diamond evaluation. This required a deep understanding of gemological principles and meticulous attention to detail.

Q 2. Explain the importance of standardized grading procedures.

Standardized grading procedures are crucial for ensuring fairness, transparency, and consistency across different operations. Without standards, subjective interpretations can lead to disputes, inconsistencies in product quality, and ultimately, damage to brand reputation. Consider the example of a coffee bean roaster. If there’s no standardized grading system for the beans based on size, density, and defects, the final product’s quality will vary greatly, impacting customer satisfaction and the roaster’s ability to maintain a consistent brand image. Standardized procedures also facilitate efficient communication between stakeholders (producers, buyers, consumers) and offer a common language for discussing and assessing product quality. These standards often involve defining clear grading criteria, specifying measurement tools, and outlining acceptable tolerances.

Q 3. How do you ensure consistency in grading across different teams or individuals?

Consistency in grading is maintained through rigorous training, detailed documentation, regular calibration checks, and the use of standardized tools and procedures. All graders receive comprehensive training on the specific grading criteria, with emphasis on practical exercises and proficiency tests. We utilize detailed grading manuals that include high-resolution images and precise descriptions of each grade category. Regular inter-rater reliability tests are conducted to identify and address any discrepancies between graders. This involves having multiple graders assess the same samples independently, and then comparing the results. Discrepancies are discussed and resolved through retraining or the refinement of the grading criteria. We also utilize calibration checks on measuring equipment, ensuring that scales, calipers, or other devices used remain accurate and consistent over time. A standardized scoring system, for instance, a numerical scoring system for each attribute, can help minimize subjectivity.

Q 4. What are the potential consequences of inconsistent grading?

Inconsistent grading can have severe consequences, ranging from financial losses to reputational damage. Inconsistent grading in manufacturing could result in defective products reaching the market, leading to recalls, warranty claims, and legal issues. In the food industry, inconsistent grading of produce might lead to price discrepancies, affecting both producers and consumers. Inaccurate grading of gemstones could lead to significantly overvalued or undervalued stones, causing financial losses to buyers or sellers and damaging consumer trust. Ultimately, inconsistent grading can erode consumer confidence, negatively impact brand reputation, and decrease overall profitability. It can also lead to conflicts between different stakeholders involved in the process.

Q 5. Describe your experience with quality control documentation and reporting.

My experience with quality control documentation and reporting involves meticulous record-keeping at every stage of the grading process. We maintain detailed logs of all graded items, including the date, time, grader’s identification, grade assigned, and any relevant observations or comments. This documentation is crucial for tracking performance, identifying trends, and investigating discrepancies. Regular reports are generated summarizing the grading results, highlighting any anomalies or deviations from established standards. These reports often include statistical analyses such as average grade, standard deviation, and the number of items in each grade category. We use specialized software to manage and analyze this data, making it easy to identify trends and areas for improvement.

Q 6. How do you identify and address grading errors or discrepancies?

Grading errors or discrepancies are addressed through a systematic process. First, the error is identified through regular quality control checks, including audits of grading records and inter-rater reliability tests. Once an error is detected, we investigate its cause. This may involve reviewing the grader’s training, re-examining the grading criteria, or checking the calibration of measuring equipment. If the error is due to human error, we provide additional training or retraining to the grader involved. If the error stems from ambiguous grading criteria, we revise the standards to ensure greater clarity and reduce ambiguity. Documentation of the error, its cause, and the corrective actions taken are meticulously maintained.

Q 7. What are some common challenges in grading and sorting, and how do you overcome them?

Common challenges in grading and sorting include subjective interpretations of grading criteria, grader fatigue and bias, and the difficulty of automating the grading process for complex items. Subjectivity can be mitigated by establishing clear, detailed, and objective grading standards with well-defined visual aids and numerical scoring systems. Grader fatigue and bias are addressed through regular breaks, rotation of tasks, and blind grading exercises. For complex items, automation may require advanced technologies like AI and machine learning, which can be costly and require specialized expertise. We overcome these challenges by combining the expertise of human graders with the efficiency of automation whenever possible. For instance, using automated systems for initial sorting, followed by human review for finer grading, creates a hybrid approach that balances efficiency and accuracy.

Q 8. How do you stay up-to-date with changes in grading and sorting standards?

Staying current in the dynamic field of grading and sorting standards requires a multifaceted approach. I actively participate in industry conferences and workshops, such as those hosted by organizations like the [Mention relevant industry organization]. These events provide invaluable insights into the latest advancements and regulatory changes. I also subscribe to specialized journals and newsletters, like [Mention specific publications], that publish research and updates on best practices. Furthermore, I maintain a network of colleagues and experts in the field, exchanging information and discussing evolving standards through regular communication and participation in online forums. Finally, I regularly review and update my knowledge base by consulting official standards documents issued by relevant governing bodies, ensuring I’m always working with the most current and accurate information.

Q 9. Explain your experience with different types of sorting equipment or technologies.

My experience encompasses a wide range of sorting equipment and technologies. I’ve worked extensively with optical sorters, which utilize advanced image processing and machine learning algorithms to identify and classify items based on various parameters like color, size, shape, and surface defects. For instance, in a food processing plant, I implemented a system that used near-infrared spectroscopy (NIRS) within an optical sorter to detect subtle variations in sugar content within batches of produce, ensuring consistent quality. I’ve also worked with mechanical sorters, including vibrating screens and roller sorters, which are effective for separating materials based on size and density. In a recycling facility, I optimized a system using a combination of these mechanical sorters to improve the efficiency of plastic separation. My experience also extends to the use of X-ray sorters for detecting foreign objects or internal defects, and air sorters which leverage differences in air density to separate items. Each technology presents unique challenges and benefits, requiring a thorough understanding of its capabilities and limitations for optimal implementation.

Q 10. Describe your experience with data analysis related to grading and sorting.

Data analysis is crucial for optimizing grading and sorting processes. I routinely use statistical process control (SPC) techniques to monitor process performance and identify areas for improvement. For example, I used control charts to track the rate of misclassifications in an optical sorting system, allowing us to pinpoint and address the cause of increased errors. I’m also proficient in using software like R and Python to perform data mining and machine learning. In one project, I utilized machine learning algorithms to build a predictive model that estimated the yield of a specific grade of product based on various input parameters like raw material quality and processing conditions. This allowed for better production planning and resource allocation. Furthermore, I employ data visualization techniques to present complex data in an easily understandable format for stakeholders, aiding in decision-making and performance evaluation.

Q 11. How do you manage large volumes of items requiring grading and sorting?

Managing high volumes requires a strategic approach that combines automation, efficient workflow design, and robust quality control. I typically start by analyzing the throughput requirements and identifying bottlenecks in the existing process. This often leads to the implementation of automated sorting systems, as mentioned earlier. But simply adding automation is insufficient. We also need efficient material handling systems, such as conveyor belts and automated stacking systems, to move items smoothly through the process. Furthermore, I implement strategies like batch processing and parallel processing to maximize throughput. For example, we might use multiple sorting lines running concurrently to handle large batches of products. Finally, robust quality control measures, including regular calibration of equipment and operator training programs, are essential to maintaining accuracy and consistency at high volumes.

Q 12. How do you prioritize tasks in a high-volume grading and sorting environment?

Prioritization in a high-volume environment hinges on a clear understanding of several factors. I utilize a combination of methods, including the prioritization matrix (urgency/importance), to classify tasks. Tasks with immediate impact on production or quality are prioritized first. For example, addressing a malfunction in a key piece of sorting equipment takes precedence over routine maintenance tasks. We also incorporate the concept of ‘lean’ principles, focusing on eliminating waste and improving workflow efficiency. This often involves optimizing the sequence of tasks to minimize idle time and maximize resource utilization. We frequently employ a Kanban system or similar visual management techniques to monitor task progress and identify potential bottlenecks before they impact overall output.

Q 13. How do you handle situations where grading criteria are ambiguous or unclear?

Ambiguous grading criteria are addressed through a systematic approach. The first step involves clarifying the criteria with stakeholders. This often necessitates reviewing the existing documentation, engaging in discussions with subject matter experts, and potentially conducting further testing to define more precise standards. For instance, if the criteria for ‘acceptable color’ is vague, we would define it using specific colorimetric values or create visual samples representing acceptable and unacceptable ranges. Once clear criteria are established, we communicate them effectively to all involved personnel through training materials and updated documentation. A well-defined grading standard, documented and accessible to all, minimizes inconsistencies and disputes.

Q 14. What are your strategies for ensuring the accuracy and efficiency of grading and sorting processes?

Ensuring accuracy and efficiency involves a multi-pronged strategy. Regular calibration and maintenance of equipment is paramount, preventing inaccuracies caused by malfunctioning equipment. We implement rigorous quality checks at various stages of the process, including random sampling and audits to verify the accuracy of the sorting and grading. Comprehensive operator training programs ensure that personnel are well-versed in the established standards and operating procedures. Continuous improvement methodologies, such as Six Sigma or Lean, are employed to identify and eliminate sources of error and waste. Regular data analysis, as previously mentioned, helps us track performance, identify trends, and proactively address potential issues. Finally, a culture of continuous learning and improvement helps foster a team dedicated to maintaining high standards of accuracy and efficiency.

Q 15. Describe a time you had to troubleshoot a problem with a grading or sorting system.

One time, we experienced a significant drop in the accuracy of our automated citrus grading system. The system, which uses optical sensors to assess fruit size and color, suddenly started misclassifying a large percentage of oranges. My initial troubleshooting involved checking the most obvious culprits: sensor calibration, lighting consistency, and conveyor belt speed. These checks revealed no immediate issues.

However, after a more thorough investigation, I discovered that recent changes to the software algorithm designed to detect minor blemishes had become overly sensitive, misinterpreting natural variations in orange peel texture as defects. This resulted in perfectly good oranges being downgraded. The solution involved adjusting the algorithm’s parameters to be less sensitive and recalibrating the system using a broader sample of fruits. We also instituted a more robust quality control check, comparing the automated grading with manual spot checks to catch such errors early.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure compliance with relevant regulations and standards?

Ensuring compliance is paramount in grading and sorting. We adhere to several key regulations and standards, depending on the product type. For example, when dealing with agricultural products, compliance with relevant food safety regulations (e.g., GMPs, HACCP) is essential. This involves maintaining meticulous records of all processes, including calibration logs, quality control data, and product traceability information. We also regularly audit our processes to ensure ongoing compliance and identify potential gaps.

Furthermore, industry-specific standards (e.g., those set by agricultural organizations or governing bodies) provide a framework for consistent grading practices. These standards often define specific criteria for classifying products based on size, quality, and other relevant attributes. We use these standards as a benchmark for developing and evaluating our grading systems and procedures, regularly updating our protocols to reflect the latest standards. This includes staying informed about any revisions or changes through continuous professional development and industry publications.

Q 17. What metrics do you use to measure the effectiveness of grading and sorting processes?

Measuring the effectiveness of our grading and sorting processes requires a multi-faceted approach. We focus on several key metrics:

- Accuracy: This measures the percentage of correctly graded items. For example, in a batch of 1000 apples, how many were correctly sorted into their respective size categories? A high accuracy rate (e.g., above 98%) signifies an effective system.

- Throughput: This measures the volume of material processed per unit of time. A high throughput indicates efficiency, but it’s crucial to balance throughput with accuracy.

- Efficiency: This considers both accuracy and throughput. It’s calculated by comparing the total correctly sorted items against the total processing time.

- Waste Reduction: This measures the amount of correctly graded material that is rejected or discarded due to errors. A lower waste percentage shows optimized sorting accuracy and efficiency.

- Cost per Unit: This considers the operating costs of the grading process against the volume processed, helping to optimize resource utilization.

Regular monitoring of these metrics provides valuable insights for process improvement and helps us identify areas needing optimization.

Q 18. How do you train new employees on grading and sorting procedures?

Training new employees is crucial. We use a multi-stage approach that combines theoretical learning and hands-on experience:

- Classroom Training: New hires receive comprehensive training on the relevant standards, grading procedures, and use of equipment. This involves presentations, videos, and interactive sessions.

- On-the-Job Training: Experienced graders mentor new hires, guiding them through the process and providing immediate feedback. This allows for practical application of the theoretical knowledge.

- Simulated Exercises: We use practice sessions with sample materials to allow trainees to hone their skills before working on actual production lines. This minimizes the risk of errors during live operations.

- Regular Assessments: Throughout the training period, we conduct regular assessments to track progress and identify areas needing additional training. This ensures consistency in grading across all team members.

- Ongoing Feedback and Development: Continuous feedback and coaching are provided, focusing on both skill improvement and adherence to safety and quality standards.

This comprehensive approach ensures new employees possess the necessary skills and knowledge to perform accurately and efficiently.

Q 19. Describe your experience with different types of materials requiring grading and sorting.

My experience spans various materials requiring grading and sorting, including agricultural products (fruits, vegetables, grains), industrial materials (e.g., nuts, bolts, recycled plastics), and even consumer goods (e.g., sorted clothing in a donation center). Each material presents unique challenges. For instance, grading apples requires attention to size, color, and blemish detection, while sorting bolts demands precise measurement of dimensions and quality control checks for defects.

In agricultural settings, I’ve dealt with variations in quality related to seasonal factors and environmental conditions, needing to adapt grading parameters accordingly. In industrial settings, the focus has been more on high-speed automated sorting systems and ensuring consistent quality control across large production volumes. The key to success across all applications involves understanding the specific requirements for each material and selecting or developing the appropriate grading and sorting techniques.

Q 20. Explain your experience with statistical process control (SPC) in grading and sorting.

Statistical Process Control (SPC) is integral to maintaining consistent grading quality. We use control charts (e.g., X-bar and R charts, p-charts) to monitor key metrics like size, weight, or color deviation during the grading process. This allows us to identify trends, patterns, and anomalies early on, preventing small variations from escalating into larger quality issues.

For example, if a control chart indicates a significant shift in the average size of oranges being graded, it alerts us to a potential problem with the harvesting or handling process. We can then investigate the cause (e.g., a malfunctioning machine, a change in the supply of oranges) and implement corrective measures to bring the process back under control. Using SPC enhances our ability to identify and prevent inconsistencies, ensuring product quality and reducing waste.

We also employ capability analysis to determine whether our grading system is capable of meeting the specified requirements and identify areas for improvement in precision and efficiency. Data analysis plays a pivotal role, giving us quantifiable evidence of process performance that aids in decision-making and continuous improvement.

Q 21. How do you handle customer complaints regarding grading inconsistencies?

Customer complaints regarding grading inconsistencies are handled with utmost seriousness. Our first step is to thoroughly investigate the complaint, gathering all relevant information, including details about the specific batch, photographs, and any supporting documentation. We then review our internal quality control records to ascertain if the complaint is justified.

If the complaint is deemed valid, meaning we identify an error in our grading process, we take immediate corrective action to address the root cause and prevent future occurrences. This may involve recalibrating equipment, refining our grading protocols, or providing additional training to our staff. We strive for transparency and keep the customer informed every step of the way.

To compensate for any inconvenience caused, we offer a suitable resolution, which may include a refund, replacement of the affected product, or a discount on future purchases. Our aim is to retain customer trust and continuously improve our grading processes to minimize such situations in the future.

Q 22. How do you contribute to process improvement in grading and sorting operations?

Process improvement in grading and sorting hinges on continuous evaluation and refinement. My approach involves a multi-faceted strategy focusing on data analysis, technology integration, and team training.

Data Analysis: I meticulously track key performance indicators (KPIs) such as throughput, accuracy rates, and error types. Identifying trends in errors helps pinpoint bottlenecks or inconsistencies in the process. For instance, if a high percentage of errors occur during a specific stage, it signals a need for improved training, equipment recalibration, or process redesign in that area.

Technology Integration: I advocate for leveraging automated systems wherever possible. This could range from automated optical sorters for visual grading to sophisticated machine learning algorithms for more complex classification tasks. For example, implementing a vision system to automatically detect defects in produce can drastically increase both speed and accuracy compared to manual inspection. The data generated by these systems further informs the data analysis process, creating a virtuous cycle of improvement.

Team Training and Development: Consistent and thorough training is crucial. This includes both initial training on grading standards and ongoing refresher courses to ensure everyone is up-to-date on best practices and any changes in procedures. Regular feedback sessions and performance reviews are key to fostering continuous skill development and addressing any performance gaps. For example, I might implement a peer-review system where graders cross-check each other’s work, leading to improved consistency and learning opportunities.

By combining these approaches, I can systematically identify areas for improvement, implement effective solutions, and ensure consistent, high-quality results across grading and sorting operations.

Q 23. Describe your understanding of various grading scales and systems.

Grading scales and systems vary widely depending on the product being graded. Some common examples include:

Numerical Scales: These use numerical values (e.g., 1-10, 1-5) to represent quality levels. A higher number usually indicates better quality. This is commonly seen in evaluating things like the quality of gems (clarity, cut, color, carat). A diamond might be graded from D (highest) to Z (lowest) for color.

Descriptive Scales: These use descriptive terms to categorize items based on attributes such as size, color, shape, or defects. For example, in fruit grading, you might have categories like ‘extra fancy,’ ‘fancy,’ ‘No. 1,’ and ‘No. 2,’ each describing a range of quality attributes.

Standard Grades: Many industries have established standard grading systems defined by regulatory bodies or industry associations. For example, the USDA has specific standards for grading agricultural products like meat and eggs.

Visual Grading Charts: These charts often accompany descriptive scales, providing visual examples of different grade levels. This is particularly useful for subjective attributes like color or texture.

The choice of grading scale depends on several factors including the product’s characteristics, the intended market, and regulatory requirements. The key is to ensure the scale is clear, consistent, and easily understood by everyone involved in the process.

Q 24. Explain the difference between objective and subjective grading.

The difference between objective and subjective grading lies in the measurability of the criteria.

Objective Grading: This relies on quantifiable measurements and clearly defined standards. For example, grading lumber based on its dimensions (length, width, thickness) and moisture content is objective. There is little room for interpretation; a piece of wood either meets the specified dimensions or it doesn’t.

Subjective Grading: This involves evaluating qualities that are open to interpretation, such as color, taste, texture, or appearance. Grading the ripeness of fruit is subjective, as different people may have slightly different perceptions of what constitutes ‘ripe.’ Similarly, assessing the aesthetic appeal of a piece of art is largely subjective.

Many grading processes involve a mix of both objective and subjective elements. For example, grading coffee beans might involve objective measurements of size and weight, but also subjective assessment of aroma and flavor.

Q 25. How do you balance speed and accuracy in grading and sorting tasks?

Balancing speed and accuracy in grading and sorting is a constant challenge. My approach involves:

Optimizing workflows: This includes streamlining the process, eliminating unnecessary steps, and ensuring efficient material flow. For example, using conveyor belts and automated sorting systems can significantly increase throughput without compromising accuracy.

Training and technology: Well-trained graders are essential. Investing in automation, such as image recognition systems, can increase speed while maintaining or improving accuracy. Regular calibration and maintenance of equipment are also critical.

Quality control checks: Incorporating multiple quality control checkpoints throughout the process helps identify and correct errors early. Random sampling and audits can ensure consistent quality. For example, a supervisor might randomly check a certain percentage of the sorted items to verify the accuracy of the grading.

Data-driven decision-making: Tracking KPIs like throughput, accuracy, and error rates provides insights into process performance. This data can inform decisions about workflow optimization, training needs, and technology upgrades.

Finding the optimal balance often involves a trade-off. In some cases, prioritizing accuracy might necessitate a slightly slower process, while in other cases, a higher throughput might be acceptable with a slightly higher error rate, provided the error rate remains within acceptable limits.

Q 26. What are your experience with different inspection methods (visual, automated, etc.)?

My experience encompasses a range of inspection methods, each with its own strengths and weaknesses:

Visual Inspection: This remains a cornerstone of many grading processes, particularly for products with complex or subtle quality attributes. It requires trained personnel with keen observational skills and a thorough understanding of grading standards. The main drawback is that it’s subjective and prone to human error, especially during prolonged tasks. For example, manually sorting gemstones requires experienced graders to identify subtle variations in color and clarity.

Automated Optical Sorting: Technologies like color sorters, near-infrared (NIR) sorters, and hyperspectral imaging systems automate many aspects of visual inspection. These systems can significantly increase speed and consistency. However, they may not be suitable for all products or require specialized training to operate and maintain. For example, an automated system could sort beans based on color and size, removing damaged or discolored ones.

X-ray Inspection: This is often used for inspecting products where internal defects are critical, such as detecting blemishes inside fruits or identifying foreign objects within packaged food. X-ray systems provide objective measurements but can be more expensive and require specialized training.

Other Sensors: Other sensors may be used depending on product requirements. For example, weight sensors are common for sorting products by weight, while size sensors can help sort products by dimensions.

The choice of inspection method depends on the product, required accuracy, throughput demands, and budget constraints. Often, a combination of methods is used for optimal results.

Q 27. How do you handle disputes over grading decisions?

Handling disputes over grading decisions requires a clear, transparent, and well-defined appeals process. My approach involves:

Reviewing the grading criteria: The first step is to ensure all parties understand and agree on the relevant grading standards and procedures. If a dispute arises, we carefully review the grading criteria to confirm that the decision aligns with established guidelines.

Independent review: In cases of significant disagreement, an independent review by a senior grader or a designated expert is conducted. This review involves a fresh examination of the product and a comparison to the grading standards.

Documentation: Maintaining thorough documentation throughout the grading process is crucial. This includes records of the grading decision, any supporting evidence (e.g., photos), and details of the appeals process. This documentation ensures accountability and transparency.

Escalation procedures: Clearly defined escalation procedures should be in place. This could involve referring the dispute to a supervisor, quality manager, or even an external arbitrator, depending on the nature and severity of the disagreement. For example, a dispute could be escalated to a higher authority if the financial implications of the disagreement are substantial.

Mediation (if necessary): In some cases, mediation may be necessary to facilitate a resolution. A neutral third party can help the involved parties communicate effectively and reach a mutually agreeable solution.

The goal is to resolve disputes fairly and efficiently, maintaining confidence in the grading process and preserving positive relationships with all stakeholders.

Key Topics to Learn for Grading and Sorting Standards Interview

- Understanding Grading Systems: Explore various grading scales (e.g., numerical, letter, percentile), their applications in different industries, and the implications of choosing the right system for specific contexts. Consider the impact of bias and fairness in grading design.

- Sorting Algorithms and their Efficiency: Familiarize yourself with common sorting algorithms (e.g., bubble sort, merge sort, quicksort) and their time and space complexities. Be prepared to discuss the strengths and weaknesses of each algorithm and how to choose the appropriate algorithm for a given dataset size and characteristics.

- Data Integrity and Validation in Grading and Sorting: Understand the importance of data accuracy and consistency. Learn about data validation techniques used to ensure the reliability of grading and sorting processes, and how to handle errors or inconsistencies.

- Practical Applications Across Industries: Explore the applications of grading and sorting standards in diverse sectors like manufacturing (quality control), agriculture (yield assessment), education (performance evaluation), and logistics (inventory management). Be ready to discuss real-world examples and how different industries adapt grading and sorting methodologies.

- Statistical Analysis and Interpretation: Develop a strong understanding of descriptive statistics (mean, median, mode, standard deviation) and their relevance in analyzing graded data. Learn how to interpret statistical summaries to draw meaningful conclusions about the data being assessed.

- Automation and Technology in Grading and Sorting: Explore the role of technology in automating grading and sorting processes. Discuss the use of software, specialized equipment, and machine learning techniques for enhanced efficiency and accuracy.

Next Steps

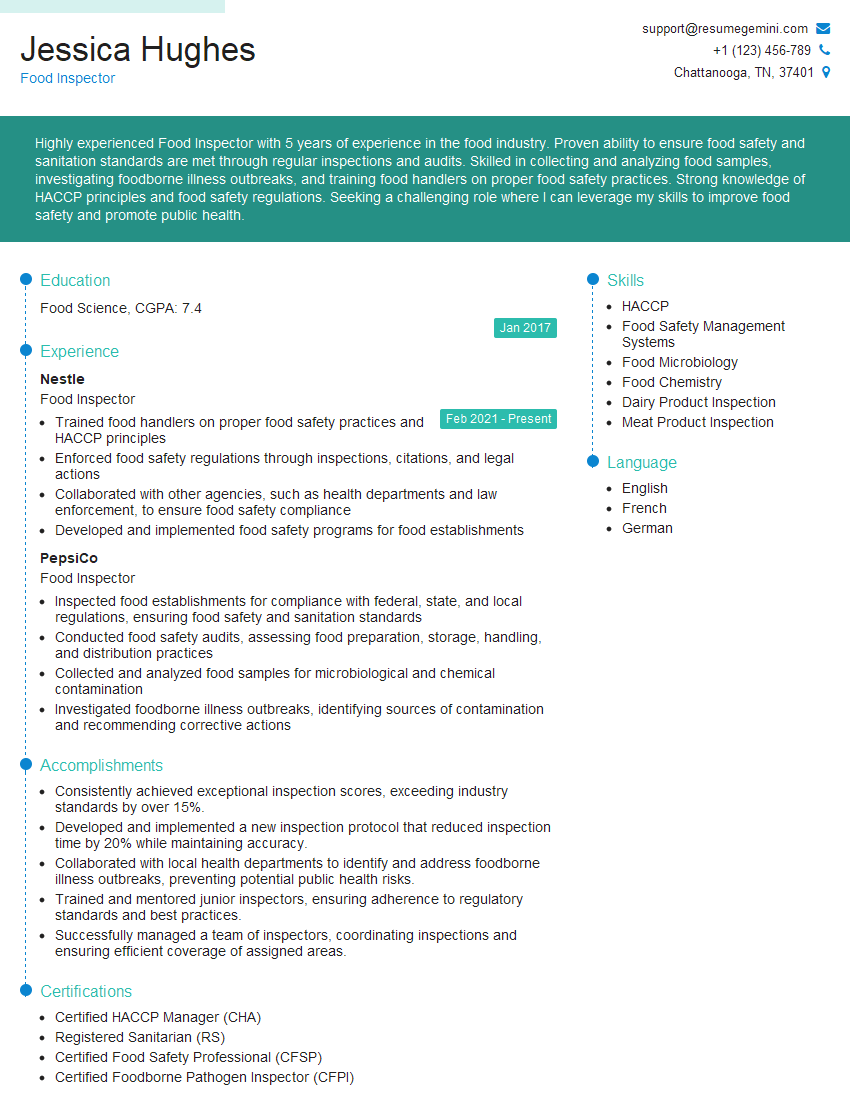

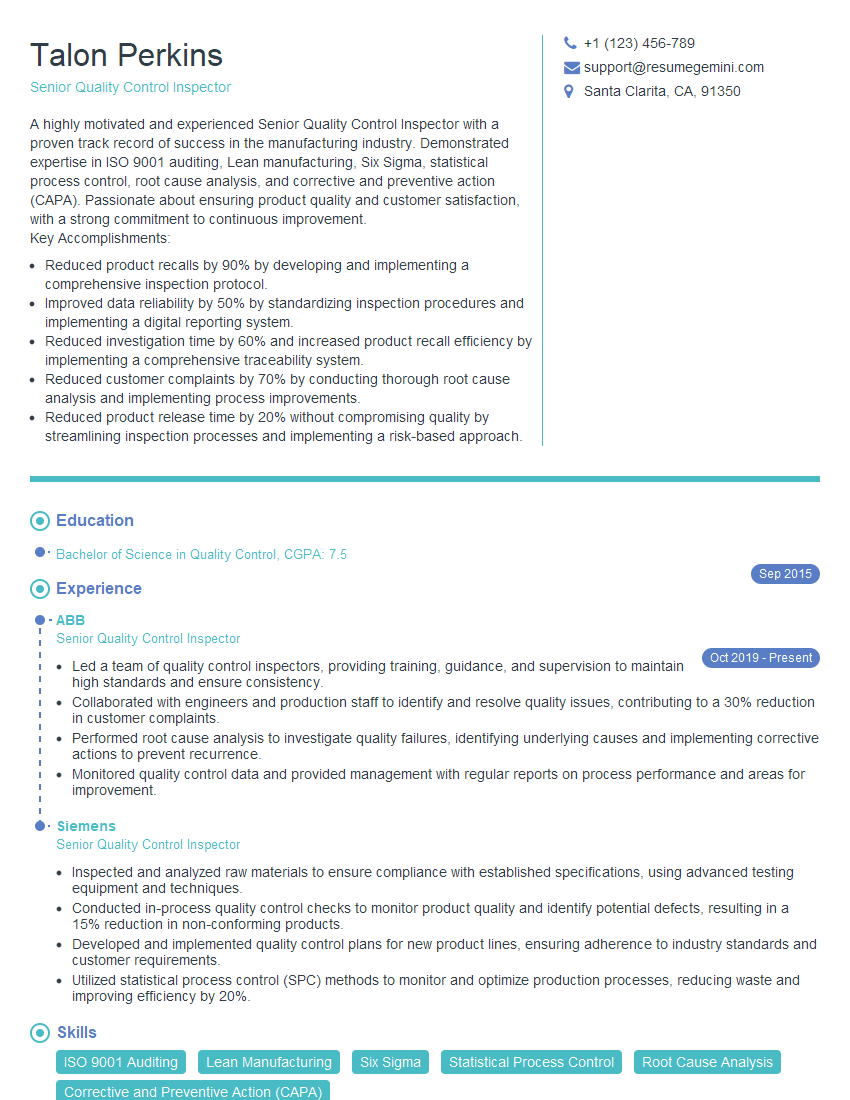

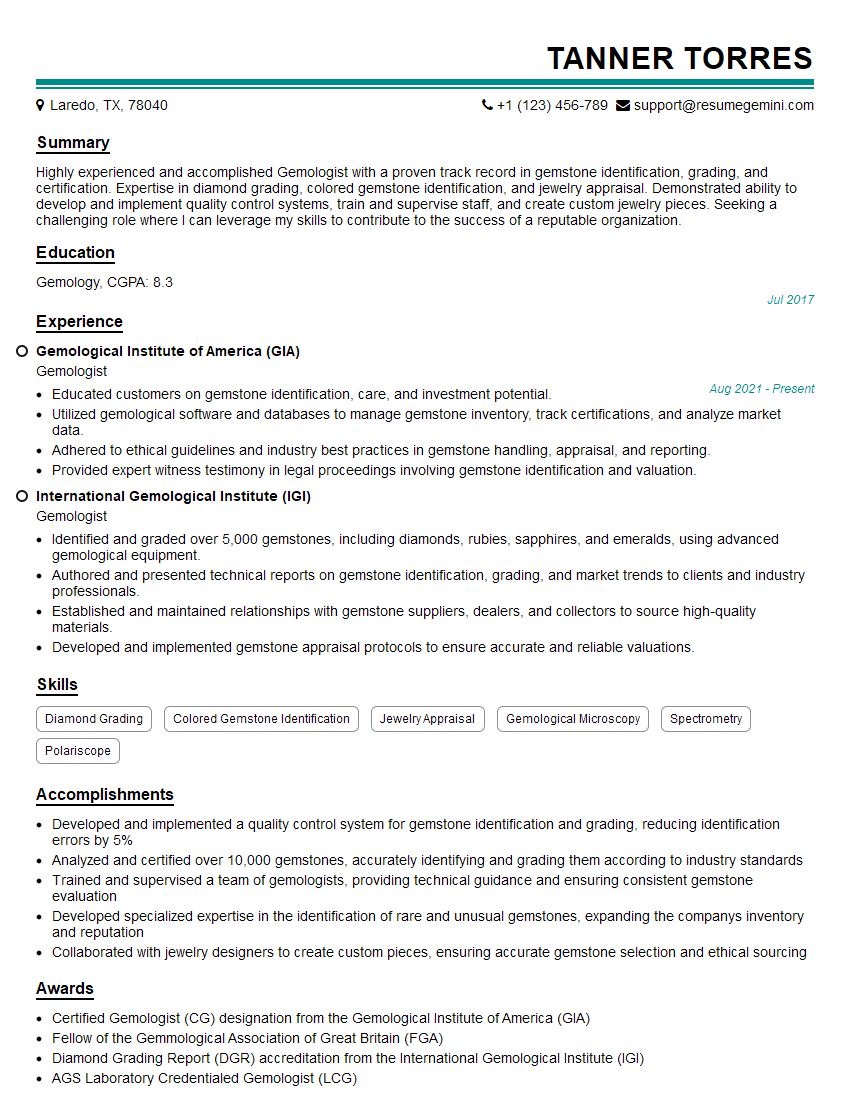

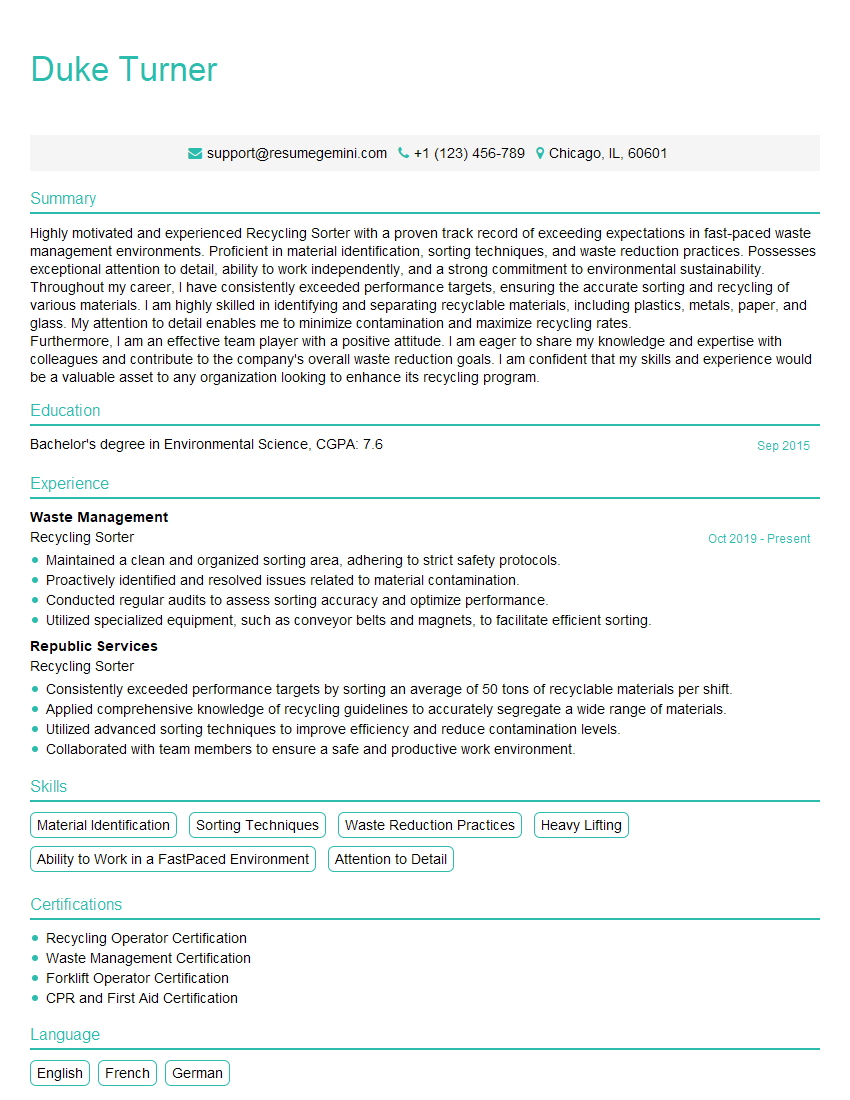

Mastering Grading and Sorting Standards is crucial for career advancement in many fields, showcasing your analytical skills and attention to detail. A well-crafted resume is your key to unlocking these opportunities. Building an ATS-friendly resume significantly improves your chances of getting noticed by recruiters. We recommend leveraging ResumeGemini, a trusted resource for creating professional and impactful resumes. Examples of resumes tailored to Grading and Sorting Standards are available to help you create a compelling application that highlights your skills and experience.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good