Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Grain Cart Operation interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Grain Cart Operation Interview

Q 1. Describe your experience operating different types of grain carts.

My experience encompasses operating a wide variety of grain carts, from smaller, self-propelled units ideal for smaller fields to larger, pull-type carts requiring a tractor for maneuverability. I’ve worked with carts featuring different capacities, ranging from 300 bushels to over 1000 bushels. This experience includes carts with various auger systems, including those with vertical augers for faster unloading, horizontal augers for precise placement, and even some with specialized unloading systems for challenging terrains. For example, I’ve operated a 600-bushel pull-type cart behind a high-horsepower tractor in large wheat fields and a smaller, self-propelled 300-bushel cart in a field with tight turns and obstacles. Each cart presented unique operational challenges and required adaptation to its specific features and limitations.

Q 2. What safety procedures do you follow when operating a grain cart?

Safety is paramount. My standard operating procedures always begin with a pre-operation check, inspecting the cart’s tires, hydraulics, auger, and all safety mechanisms. I always ensure that the safety chains are properly connected when pulling a cart behind a tractor. During operation, I maintain a safe distance from the combine and other equipment, avoiding sudden movements. I wear appropriate personal protective equipment (PPE), including safety glasses and hearing protection, and I’m always mindful of potential hazards such as uneven terrain or moving traffic. Before unloading, I ensure the area is clear of personnel and obstacles. I treat the grain auger with respect, ensuring no limbs or clothing gets near the moving parts. Think of it like this: every precaution is a small investment to prevent a major accident.

Q 3. How do you ensure the accurate and efficient unloading of grain?

Accurate and efficient unloading hinges on several factors. First, I always check the grain bin level to estimate the remaining grain, preventing overfilling at the unloading site. Then, I adjust the unloading speed based on the receiving grain storage’s capacity and the condition of the auger. For example, if unloading into a truck, I’ll adjust the flow rate to match its filling capacity. Regular cleaning of the auger prevents clogging and ensures a smooth flow. I regularly check for any blockages. I often visualize the grain flow like water – a consistent, controlled flow prevents back pressure and ensures efficiency. Finally, I always conduct a post-unloading inspection to confirm complete unloading and to identify any potential issues for preventative maintenance.

Q 4. Explain your process for maintaining a grain cart in optimal condition.

Maintaining a grain cart requires a proactive approach. After each day’s operation, I thoroughly clean the cart, removing any spilled grain to prevent pest infestation and corrosion. I regularly grease all moving parts, such as the auger and hydraulic components. I check the tire pressure and condition. I also inspect the hydraulic system for leaks and damage, and I pay close attention to the structural integrity of the cart, looking for any signs of wear and tear. Think of this as preventative medicine for your machinery. Regularly addressing small issues prevents major breakdowns. A well-maintained cart not only improves efficiency but also extends its lifespan.

Q 5. What are the common problems encountered while operating a grain cart, and how do you troubleshoot them?

Common problems include auger blockages (often caused by damp grain or foreign materials), hydraulic leaks, and tire punctures. For auger blockages, I reverse the auger briefly, then use a cleaning rod to clear any obstruction. Hydraulic leaks require prompt attention and often necessitate a professional repair. Tire punctures are dealt with by changing the tire or using a tire repair kit. Electrical issues, such as a malfunctioning control panel, can sometimes arise and usually need a qualified technician’s assistance. My troubleshooting process involves systematically identifying the problem, attempting a fix based on my knowledge, and if the problem persists, calling in a mechanic. Knowing your limitations and seeking expert help is crucial.

Q 6. How do you adapt your operation to varying field conditions (e.g., terrain, crop density)?

Adapting to varying field conditions is crucial. In uneven terrain, I adjust my speed to maintain control and avoid tipping. I’m especially cautious around slopes. In areas with dense crop growth, I’m mindful of the combine’s operation and adjust my approach to prevent collisions. I might reduce speed or use a different unloading technique based on the surface’s condition—for example, avoiding sharp turns on soft ground to prevent getting stuck. My experience allows me to assess these situations quickly and make informed decisions to ensure safe and efficient operation. Understanding your equipment’s limitations and the environment is key.

Q 7. Describe your experience with different types of grain augers and unloading systems.

My experience includes working with various grain auger types, including vertical augers known for their speed, and horizontal augers, which offer more precise placement during unloading. I’ve also encountered carts with different unloading systems, such as those with a high-capacity unloading system optimized for large-scale operations versus those with a smaller, more versatile auger for smaller operations. Some systems use hydraulics for precise control, while others are more basic, relying on gravity. Understanding the strengths and weaknesses of each system is essential for efficient and safe operation. I choose the right auger and unloading system depending on the specific job requirements and environmental conditions. It’s like choosing the right tool for the right job.

Q 8. How do you ensure the grain cart is properly weighed and documented?

Accurate grain cart weighing and documentation are crucial for efficient harvest management and financial accountability. We use a combination of on-board scales and independent weigh systems. The on-board scales provide a real-time weight reading during filling, allowing for efficient management of the cart’s capacity. However, we always rely on an independent weigh system at the unloading point (grain bin or truck) for final, verified weights. This ensures accuracy and prevents discrepancies. Documentation is meticulously maintained, typically using farm management software or spreadsheets, recording date, time, field location, grain type, weight, and moisture content. This detailed record-keeping is essential for tracking yields, calculating input costs, and facilitating grain sales.

For example, if the on-board scale shows 500 bushels but the final weight is 495 bushels, this minor difference is documented and noted. This ensures that any discrepancies are accounted for, and we can identify potential issues with the weighing equipment or filling process.

Q 9. What is your experience with GPS guidance systems in grain cart operation?

GPS guidance systems are indispensable for modern grain cart operation. They significantly improve efficiency and reduce overlaps or missed areas, maximizing time and minimizing fuel consumption. I have extensive experience with both RTK (Real-Time Kinematic) and other GPS systems, using them to navigate precisely between the combine and the unloading point. This accuracy ensures smooth, uninterrupted unloading, and greatly reduces the risk of spillage or damage. Moreover, many systems provide data logging features that allow for precise tracking of cart movement and harvest progress, useful for future planning and optimization.

In one instance, using RTK GPS enabled me to maintain consistent accuracy of within 2 inches, minimizing overlaps and ensuring that no grain was left uncollected. This translates to increased yield and reduced wasted time and fuel.

Q 10. How do you manage communication and coordination with the combine operator?

Clear and constant communication with the combine operator is paramount. We use a combination of visual signals (hand signals, lights) and two-way radios for efficient coordination. Prior to starting, we establish clear protocols regarding filling levels, unloading locations, and any special instructions. During operation, constant communication ensures that the combine doesn’t overfill the cart, and that the cart is ready to unload promptly. This prevents delays and minimizes the risk of downtime. We establish a system of signals for various situations – e.g., a slow wave of the hand signifies ‘almost full’, while a raised hand might mean ‘stop’. The use of radios allows for more complex information exchange, such as reporting unexpected issues or changes in plan.

Effective communication is more than just avoiding accidents. It’s a core element for a smoothly running harvest and maximizing yield. In a past harvest, quick communication via radio helped us avoid a major delay when a field unexpectedly had a wet patch that the combine was struggling with.

Q 11. Describe your experience with pre-harvest checks and maintenance of grain carts.

Pre-harvest checks and maintenance are vital to prevent costly breakdowns during the crucial harvest season. This includes a thorough inspection of all mechanical components, such as the auger, conveyor belts, hydraulics, tires, and electrical systems. We check for wear and tear, lubricate moving parts, and tighten any loose bolts or connections. We also inspect the scales for accuracy, ensuring proper calibration. Cleaning and preparation are equally important; clearing out any residual grain or debris prevents clogging and ensures smooth operation. This preventative maintenance approach minimizes downtime and extends the lifespan of the equipment. A well-maintained grain cart is an efficient grain cart.

For example, checking the auger flighting for wear before harvest prevents potential clogging during operation, which could result in significant delays and potential damage. This proactive approach ensures smooth operation and minimizes downtime.

Q 12. How do you handle unexpected equipment malfunctions during operation?

Handling unexpected equipment malfunctions requires a quick, calm, and methodical approach. The first step is assessing the severity of the problem. Minor issues like a minor belt slippage can often be addressed on the spot with basic tools and maintenance procedures. However, more significant malfunctions, like a hydraulic leak or electrical failure, require a more comprehensive strategy. This often involves contacting a mechanic, using spare parts if available, or temporarily suspending operation until the issue is resolved. Effective communication with the combine operator and other team members is critical to minimize disruption. We also have emergency contact numbers readily available to expedite repairs.

In one instance, a sudden hydraulic leak necessitated immediate action. Using a spare hydraulic line and our knowledge of hydraulic systems, I was able to temporarily repair the leak, allowing operation to resume while arranging for a proper repair once the day was completed. The key is having a prepared response, not panicking.

Q 13. Explain your understanding of grain quality and handling best practices.

Understanding grain quality and handling best practices is crucial to maintaining the value of the harvest. Factors such as moisture content, temperature, and cleanliness directly impact the quality and market price. Moisture content must be carefully monitored to prevent spoilage and fungal growth. Proper aeration and storage techniques are employed to maintain grain quality after harvest. Cleanliness is vital to prevent contamination and maintain high standards. This includes regularly cleaning the grain cart to remove debris and prevent cross-contamination between different grain types. We also adhere strictly to industry best practices for handling, transportation, and storage, to maximize grain quality and profitability.

For example, knowing that high moisture content in corn can lead to mold growth and significant losses in value makes proper drying and storage critical to the overall profitability of the harvest.

Q 14. What are the different types of grain you have experience handling?

My experience encompasses a wide variety of grains, including corn, soybeans, wheat, barley, and oats. I’m also familiar with handling different types of grain sorghum, canola and sunflowers. Handling each grain type requires a slightly different approach due to variations in size, density, and susceptibility to damage. Understanding these differences is critical for optimizing the harvest process and minimizing losses. For instance, handling delicate grains like oats requires a gentler approach to minimize damage compared to the more robust corn kernels.

Each grain has unique characteristics that must be addressed during harvesting, storage and handling. Understanding the needs of each type of grain ensures the best outcome.

Q 15. Describe your experience with grain cart cleaning and sanitation procedures.

Grain cart cleaning and sanitation are crucial for preventing cross-contamination and maintaining grain quality. My procedure always begins with a thorough visual inspection to identify any leftover grain or debris. I then use a high-pressure air hose to remove loose material from the auger, tank, and any other components. Following this, I’ll use a stiff brush to scrub all surfaces, paying particular attention to areas where grain tends to accumulate. For a deeper clean, I might employ a specialized cleaning agent designed for agricultural equipment, always following the manufacturer’s instructions carefully. Finally, I ensure everything is completely dry before storing the grain cart to prevent mold growth. For example, during a particularly wet harvest last year, I noticed a build-up of damp grain residue in the auger. Thorough cleaning using a brush and cleaning agent, followed by complete drying, prevented any spoilage or cross-contamination with the next crop.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you prioritize safety while working in a fast-paced harvest environment?

Safety is paramount in the fast-paced harvest environment. My approach involves several key strategies. Before starting work each day, I always perform a pre-operational inspection of the grain cart, checking fluid levels, tire pressure, and the overall condition of the equipment. I also wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and sturdy work boots. During operation, I maintain a safe distance from moving parts and remain aware of my surroundings, especially when working near other equipment or personnel. Clear communication with the combine operator is vital – we use hand signals and radio communication to coordinate efficiently and avoid accidents. I also regularly inspect the grain cart during operation for any signs of damage or malfunction and address them immediately. For example, if I notice a loose bolt or a leaking hose, I immediately halt operations and address the issue before continuing. This proactive approach has helped prevent many potential accidents over the years.

Q 17. What is your experience with different types of grain cart attachments or accessories?

I have experience with a variety of grain cart attachments and accessories. These include different sized augers for varying grain types and harvest conditions; weighing systems which provide real-time updates on the amount of grain in the cart, improving efficiency; and GPS-guided auto-steer systems that allow for precise maneuvering and reduced operator fatigue. I’ve also worked with unloading augers of different capacities and designs, optimizing the unloading process depending on the storage facility. For example, during a harvest where we had particularly wet grain, a larger-diameter auger helped to minimize grain bridging and clogging. The experience with different attachments allowed me to adapt to a wider range of harvesting scenarios and improve overall efficiency.

Q 18. How familiar are you with the regulations and safety standards for operating agricultural equipment?

I am very familiar with the regulations and safety standards for operating agricultural equipment. This includes adhering to all relevant Occupational Safety and Health Administration (OSHA) standards, as well as complying with manufacturer’s recommendations for the specific equipment I operate. I understand the importance of proper maintenance, regular inspections, and safe operating procedures to prevent accidents. I’m also aware of regulations concerning the transportation of grain, including load securement and weight limitations. Staying updated on these regulations is crucial for safe and compliant operation. For instance, I know that proper lighting and signage are vital for operating at night or in low visibility conditions and maintain awareness of any local laws or requirements concerning equipment operation.

Q 19. Explain your understanding of fuel efficiency and its impact on grain cart operation.

Fuel efficiency is a significant factor in grain cart operation, directly impacting operating costs. Understanding factors like tire pressure (properly inflated tires reduce rolling resistance), maintaining the engine in optimal condition, and avoiding unnecessary idling significantly influences fuel consumption. Efficient driving practices, such as smooth acceleration and deceleration, also contribute to fuel savings. Using technologies like yield monitoring can indirectly impact fuel consumption by optimizing routes and minimizing unnecessary travel. For example, during one harvest, I noticed a significant improvement in fuel efficiency by optimizing tire pressure, leading to a noticeable reduction in fuel costs. The cumulative effect of these efficiency measures can lead to significant long-term savings.

Q 20. Describe your experience with using technology to improve grain cart efficiency (e.g., yield monitoring).

Technology significantly enhances grain cart efficiency. Yield monitoring systems provide real-time data on grain yield, allowing for better decision-making regarding unloading locations and minimizing unproductive travel time. GPS guidance systems enable precise maneuvering and reduce overlap and wasted time, resulting in increased efficiency and reduced fuel consumption. Data collected from these technologies can be analyzed to identify areas for further optimization. For instance, yield maps from one harvest highlighted areas of lower yield, helping us adjust planting strategies for the following season. Incorporating this technological data improves decision-making and streamlines the entire harvesting operation.

Q 21. How do you adapt to changing weather conditions while operating a grain cart?

Adapting to changing weather conditions is essential for safe and efficient grain cart operation. In wet conditions, I reduce speed to prevent soil compaction and minimize wheel slippage. I may also need to adjust unloading strategies to avoid delays due to muddy access roads. In strong winds, I need to be cautious, especially when unloading, to prevent grain spillage. During periods of extreme heat, I take regular breaks to stay hydrated and prevent overheating. I always monitor weather forecasts closely and adapt my work schedule accordingly, prioritizing safety and efficiency. For instance, I’ve learned to identify the early signs of an approaching storm and take appropriate shelter, including ensuring the grain cart is parked safely, well away from potential hazards.

Q 22. What are your strategies for preventing grain spillage or loss during transport?

Preventing grain spillage is paramount for efficiency and minimizing losses. My strategy involves a multi-pronged approach focusing on careful loading, secure transport, and regular maintenance.

Proper Loading Techniques: I ensure the grain auger is positioned correctly to avoid overloading the cart and minimize spillage during the filling process. I also monitor the grain level to prevent overfilling, which can lead to significant losses during transport. Think of it like carefully packing a suitcase – you want to maximize space without overflowing.

Regular Inspection: Before each trip, I meticulously inspect the grain cart for any damage or leaks. This includes checking the auger, the unloading system, and the cart body itself. A small crack can lead to substantial losses over time.

Careful Driving: I maintain a safe and steady driving speed to avoid sudden movements that could cause grain to shift and spill. I also take extra care when navigating uneven terrain or sharp turns. Imagine driving with a delicate cargo – you’d want to drive smoothly.

Auger Management: I ensure the auger is correctly aligned and functioning optimally to efficiently move grain without causing blockages or spilling. Regular lubrication and maintenance are key to avoiding problems.

Q 23. How do you ensure the longevity and optimal performance of your grain cart?

Ensuring the longevity of a grain cart involves proactive maintenance and proper storage. It’s an investment that pays off in the long run.

Regular Cleaning: After each harvest season, I thoroughly clean the grain cart to remove any remaining grain and debris. This prevents build-up and corrosion.

Lubrication: Regular lubrication of moving parts like the auger, wheels, and hydraulic systems is essential. It reduces wear and tear and prevents costly breakdowns.

Scheduled Inspections: I perform regular inspections, checking for wear and tear on the body, wheels, tires, and other components. Any issues are addressed promptly to prevent further damage.

Proper Storage: During the off-season, the grain cart is stored in a covered area to protect it from the elements. This prevents rust and damage from rain, snow, or sun.

Preventative Maintenance: I regularly replace worn-out parts proactively, preventing larger, more expensive repairs down the line. It’s like changing the oil in your car – it’s a small investment for a much larger return.

Q 24. What is your experience with different types of grain bin unloading systems?

I’ve worked with several types of grain bin unloading systems, each with its strengths and weaknesses.

Gravity Discharge: This is the simplest system, relying on gravity to move grain out of the cart. It’s reliable but can be slower than other methods. This system is perfect for smaller operations or when speed isn’t the primary concern.

Auger Unloading Systems: These systems use a powered auger to transfer grain from the cart to the storage bin. They are more efficient than gravity discharge, allowing for faster unloading times. I’m very comfortable operating carts with auger systems of various sizes.

Cross Auger Systems: These use multiple augers to move grain efficiently to multiple bins simultaneously. They offer increased efficiency, especially in large-scale operations. I find this system ideal for speed and efficiency in large harvests.

My experience spans across various systems, enabling me to adapt quickly to any situation and optimize unloading time based on specific conditions and bin configuration.

Q 25. Describe your experience with night operation of grain carts and associated safety considerations.

Night operation of grain carts requires extra caution and careful planning. Safety is paramount.

Adequate Lighting: Sufficient lighting is crucial for safe navigation and operation. This includes powerful cart lights and potentially additional lighting on the field. I use high-visibility vests and reflective gear to increase visibility.

Communication: Clear communication with the combine operator and other team members is essential. Radios and pre-determined hand signals are often used to coordinate movements and avoid collisions. It’s like having a well-coordinated dance, each person knows their steps.

Fatigue Management: Extended night shifts can lead to fatigue. I make sure I have adequate rest before operating the grain cart at night to maintain alertness and prevent accidents. Taking breaks and ensuring ample sleep is vital.

Weather Considerations: Adverse weather conditions at night can further complicate operations, increasing the risk of accidents. I carefully assess weather conditions before starting a night shift and exercise extra caution when necessary.

Q 26. How do you manage your time effectively to maximize harvesting efficiency?

Maximizing harvesting efficiency requires meticulous time management. My approach focuses on several key strategies.

Preparation: I ensure all necessary equipment is in top working order before starting the day. This reduces downtime and maximizes operational hours.

Route Planning: I plan efficient routes between the combine and storage bins to minimize travel time. I optimize the path, like a delivery driver ensuring each stop is optimized.

Communication: Continuous communication with the combine operator is crucial to ensure a seamless flow of grain and avoid delays. The synergy between us is a key factor.

Problem-Solving: I address any issues or delays promptly to minimize disruptions and keep the harvesting process running smoothly. Quick problem solving is important to maintain pace.

Q 27. Describe your approach to working effectively as part of a harvesting team.

Effective teamwork is the backbone of a successful harvest. My approach emphasizes communication, cooperation, and mutual respect.

Clear Communication: I maintain open and clear communication with all team members, particularly the combine operator, to ensure everyone is aware of the plan and any changes.

Problem-Solving: When problems arise, I actively participate in finding solutions and collaborate with other team members to address them effectively. A problem shared is a problem halved.

Flexibility: I’m adaptable and willing to adjust my approach to accommodate changing conditions or unforeseen challenges. Working as a team requires flexibility and a willingness to adjust.

Support: I support my teammates and offer assistance whenever needed. A strong team relies on support and trust.

Q 28. What are your salary expectations for this grain cart operator position?

My salary expectations are commensurate with my experience, skills, and the responsibilities of this position. I am open to discussing a competitive compensation package that reflects my value to your operation. I’m confident my skills and experience will make me a valuable asset to your team and I’m happy to review specific salary ranges based on market data and the specific details of this role.

Key Topics to Learn for Grain Cart Operation Interview

- Understanding Grain Cart Mechanics: Learn the intricacies of grain cart components, including augers, unloading systems, and safety mechanisms. Be prepared to discuss maintenance and troubleshooting procedures.

- Efficient Operation Techniques: Master the practical skills of loading, transporting, and unloading grain efficiently and safely. Consider discussing strategies for minimizing grain loss and maximizing productivity.

- Safety Procedures and Regulations: Demonstrate a thorough understanding of all relevant safety protocols, including pre-operation checks, hazard identification, and emergency procedures. Highlight your commitment to safe work practices.

- Communication and Teamwork: Discuss your ability to communicate effectively with combine operators and other team members. Explain how you contribute to a smooth and coordinated harvesting process.

- Problem-Solving and Adaptability: Be ready to describe scenarios where you faced challenges during grain cart operation and how you effectively solved them. This demonstrates your problem-solving skills and ability to adapt to unexpected situations.

- GPS and Technology Integration: If applicable to the role, discuss your experience using GPS systems and other technologies commonly used in modern grain cart operations. This showcases your technical skills and ability to utilize technology to improve efficiency.

- Grain Quality and Handling: Demonstrate an understanding of proper grain handling techniques to prevent damage and maintain quality throughout the harvesting and transportation process.

Next Steps

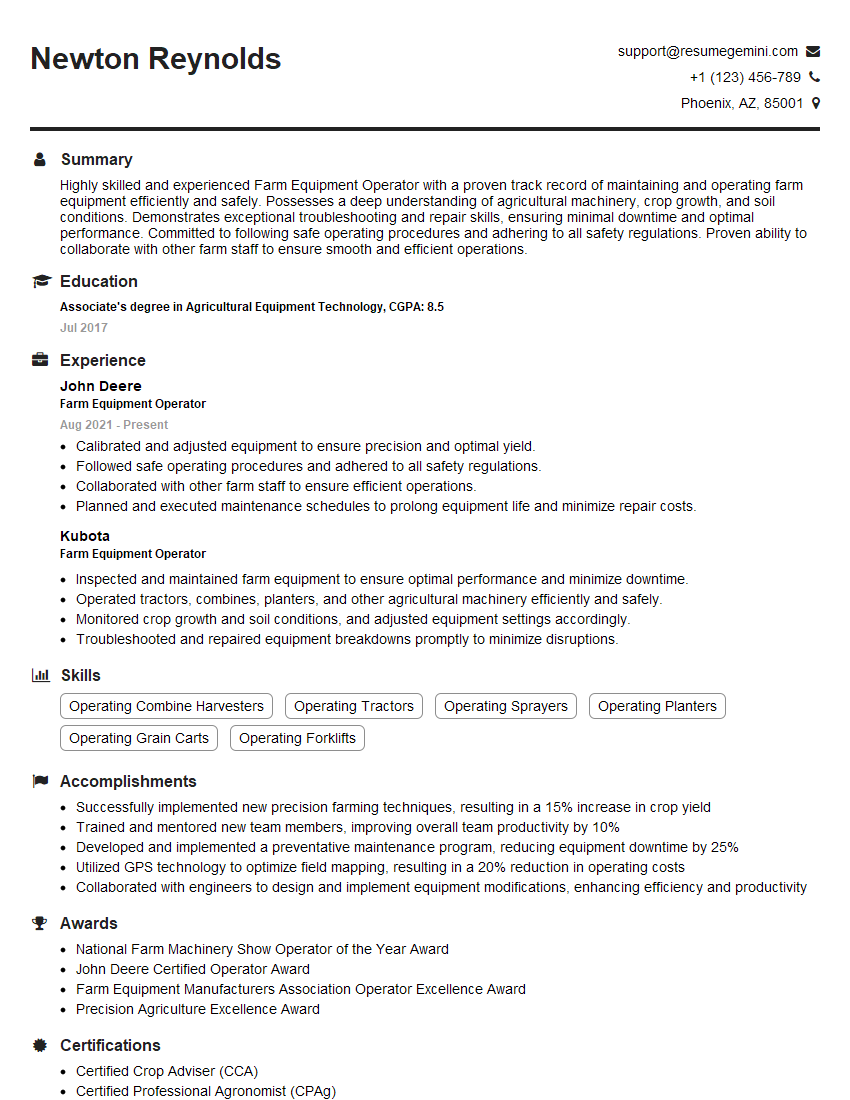

Mastering grain cart operation is a valuable skill that opens doors to rewarding careers in agriculture, offering opportunities for advancement and specialization. To significantly boost your job prospects, create a professional and ATS-friendly resume that showcases your skills and experience effectively. We highly recommend using ResumeGemini to build a compelling resume tailored to the specific requirements of grain cart operation jobs. ResumeGemini provides valuable tools and resources to create a strong application, and examples of resumes tailored to Grain Cart Operation are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good