Preparation is the key to success in any interview. In this post, we’ll explore crucial Grain Distilling interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Grain Distilling Interview

Q 1. Describe the process of mashing in grain distillation.

Mashing is the crucial first step in grain distillation, where we convert the complex starches in grains like barley, corn, rye, or wheat into simpler sugars that yeast can ferment. Think of it as preparing a feast for the yeast!

The process typically involves mixing the crushed grain (the ‘grist’) with hot water at a precisely controlled temperature. This creates a slurry called the ‘mash’. Enzymes naturally present in the grain, or added as an external source (like diastatic malt), break down the starches into fermentable sugars, primarily glucose and maltose. The temperature is carefully managed because different enzymes work optimally at different temperatures; achieving the right balance ensures maximum sugar yield.

For example, a common mashing schedule might involve a series of temperature rests: a protein rest (around 50°C) to activate enzymes that break down proteins, a saccharification rest (around 62-65°C) for optimal starch conversion, and a mash-out (around 75°C) to deactivate enzymes and halt the process. The mash is then transferred to a lauter tun (a vessel with a false bottom) to separate the sweet liquid, called ‘wort,’ from the spent grain (the ‘draff’). This wort is the raw material for the next stage: fermentation.

Q 2. Explain the role of yeast in fermentation.

Yeast is the magic ingredient that transforms the sugary wort into alcohol. These microscopic fungi are naturally occurring organisms, but specific strains are selected for their ability to efficiently ferment sugars and produce desirable flavor profiles. They consume the sugars, converting them into ethanol (alcohol), carbon dioxide, and various other byproducts which contribute to the final spirit’s character.

Different yeast strains produce different esters, higher alcohols, and other congeners, resulting in vastly different flavor profiles. A distiller might choose a specific yeast strain to enhance fruity notes, spice notes, or even create a more neutral spirit. Imagine it as choosing the right seasoning for your culinary dish! The yeast’s activity also needs careful control; factors like temperature, nutrient availability, and oxygen levels directly affect its fermentation performance and the resulting flavor profile.

Q 3. What are the different types of distillation columns used in grain distilling?

Grain distilleries use various distillation columns, each with its own characteristics, to refine the fermented wash (the mixture of alcohol, water, and congeners). The choice of column depends on the desired spirit’s character and production scale.

- Pot Stills: These are the traditional, batch-distillation systems. They produce spirits with richer, more complex flavor profiles because the congeners are less separated during distillation. Pot stills are common for whiskey and other specialty spirits.

- Column Stills (Patent Stills): These are continuous distillation systems utilizing multiple stages or plates to achieve higher levels of purification. They produce a more neutral spirit, ideal for vodka and gin production. Column stills are more efficient for large-scale production.

- Hybrid Systems: Some distilleries combine elements of both pot and column stills to achieve specific flavor profiles and production efficiencies.

The choice of column is a critical decision, as it significantly impacts the final product’s flavor and aroma. For example, a pot still will impart a more full-bodied character, while a column still will yield a cleaner, crisper profile.

Q 4. How do you control the temperature during fermentation?

Controlling fermentation temperature is paramount because yeast activity is highly temperature-sensitive. Optimal temperatures typically fall within a range of 18-25°C (64-77°F), depending on the yeast strain and desired outcome. Temperatures that are too high can kill the yeast, resulting in incomplete fermentation or the production of undesirable off-flavors. Conversely, temperatures that are too low will slow down the fermentation process significantly.

Methods for controlling fermentation temperature include:

- Temperature-controlled fermentation tanks: These tanks utilize sophisticated cooling systems to maintain the ideal temperature throughout the process.

- External cooling jackets: These jackets surround the fermentation vessel, allowing for precise temperature regulation.

- Cold water circulation: Cold water is circulated through the tank or within a coil inside the tank to regulate the temperature.

Monitoring temperature is continuous through the use of digital thermometers and often automated systems to alert the operators to any deviations outside the optimal range.

Q 5. What are the key factors influencing the flavor profile of a distilled spirit?

Many factors contribute to the final flavor profile of a distilled spirit, creating a complex interplay that makes each spirit unique. It’s akin to a symphony orchestra where each instrument plays its part to create a harmonious sound.

- Grain Type: Different grains (barley, corn, rye, wheat) impart unique flavor characteristics. For example, rye tends to contribute spiciness, while corn offers a sweeter profile.

- Yeast Strain: As mentioned earlier, yeast selection plays a crucial role in shaping flavor and aroma.

- Fermentation Conditions: Temperature, nutrient availability, and duration affect the production of various congeners (flavor compounds).

- Distillation Method: The type of still used and the distillation process determine which components are retained and which are removed.

- Aging (if applicable): The type of barrel (oak, etc.), its char level, and the aging conditions (climate, etc.) significantly alter the spirit’s taste, introducing new characteristics over time.

Ultimately, the flavor profile is a result of a delicate balance of these elements. A master distiller carefully controls each factor to craft a spirit with the desired characteristics.

Q 6. Explain the process of aging spirits in barrels.

Aging in oak barrels is a crucial step for many spirits, imparting color, flavor, and complexity. The process involves storing the newly distilled spirit in oak barrels, typically for a period of several years, depending on the desired outcome and regulations.

During aging, a slow interaction occurs between the spirit and the wood. The oak releases compounds into the spirit, such as vanillin (contributing to vanilla notes), tannins (for astringency), and ellagic tannins (for complexity). Simultaneously, the spirit evaporates, causing a reduction in volume (the ‘angel’s share’). The barrels themselves can be new or used, and the char level (the intensity of the barrel’s interior toasting) greatly affects the imparted flavor. Heavily charred barrels contribute more smoky, spicy notes, while lightly charred barrels tend to be mellower.

Environmental conditions also influence aging. Temperature and humidity impact the rate of interaction between the spirit and the wood, influencing the final flavor profile. For example, warmer climates tend to yield faster-maturing spirits with more intense flavors.

Q 7. How do you ensure the quality of the grain used in the distillation process?

Ensuring grain quality is fundamental to producing high-quality spirits. It directly impacts the flavor profile, fermentation efficiency, and the overall yield. A thorough quality control system is needed throughout the supply chain.

- Grain Sourcing: Selecting reputable suppliers who adhere to strict quality standards and provide traceable grain is critical.

- Grain Inspection: Upon delivery, the grain is meticulously inspected for moisture content, foreign material contamination, and other defects. Samples are taken and tested to ensure adherence to the specified standards.

- Storage: Proper storage conditions are maintained to prevent degradation or spoilage of the grain before processing. This includes controlling moisture levels and preventing pest infestations.

- Cleaning: The grain is often cleaned before milling to remove any impurities, ensuring consistency in the mashing process.

Consistent grain quality minimizes variability in the final product, ensuring that the resulting spirit meets the desired specifications. Imagine baking a cake using poor quality ingredients – the result wouldn’t be ideal! The same logic applies to grain distillation.

Q 8. What are the common quality control checks performed during grain distillation?

Quality control in grain distilling is paramount, ensuring consistent product quality and safety. It’s a multi-stage process, beginning even before distillation. We conduct rigorous checks throughout the entire production lifecycle.

- Raw Material Analysis: We test incoming grains for moisture content, protein levels, and the presence of any unwanted contaminants. This ensures we’re starting with high-quality ingredients that will yield the desired flavor profile.

- Fermentation Monitoring: Regular checks of temperature, pH, and sugar levels during fermentation are crucial. We monitor for off-flavors or signs of bacterial infection. For example, an unexpectedly high pH might indicate a problem with the yeast, resulting in a stalled or sour fermentation.

- Distillation Monitoring: We carefully monitor the distillation process itself, paying attention to the ‘heads’, ‘hearts’, and ‘tails’ fractions. ‘Heads’ contain volatile compounds like methanol, which are toxic and must be carefully separated. ‘Hearts’ represent the desirable middle fraction, and ‘tails’ contain heavier compounds that can affect the final product’s flavor. Precise cuts are essential.

- Sensory Evaluation: Trained personnel conduct regular sensory evaluations, assessing aroma, taste, and mouthfeel. This subjective analysis, combined with instrumental measurements, allows us to identify subtle variations in quality and make adjustments.

- Final Product Testing: Before bottling, the final product undergoes testing for alcohol content, congeners (flavor compounds), and the absence of harmful substances. This ensures compliance with regulations and product consistency.

A consistent, structured approach to QC is crucial for the production of high-quality spirits.

Q 9. Describe your experience with different types of distillation equipment.

My experience encompasses a variety of distillation equipment, from traditional pot stills to modern, highly efficient column stills. Each has its strengths and weaknesses.

- Pot Stills: These are batch stills, known for producing spirits with rich, complex flavor profiles due to their slower, gentler distillation. I’ve worked with various sizes, from small, copper pot stills ideal for craft distilleries to larger, stainless steel versions used for higher production volumes. The batch nature requires careful control and understanding of the process. The challenge lies in consistency across batches.

- Column Stills: These are continuous stills, characterized by their high efficiency and ability to produce large quantities of neutral spirits. I’ve worked with both packed and plate column stills, each offering different levels of control and separation efficiency. Column stills are excellent for producing high-purity spirits but might lack the nuanced flavor complexity of pot still spirits. They are incredibly precise and allow for excellent control over the purity of the distillate.

- Hybrid Systems: I’ve also had experience with hybrid systems that combine elements of pot and column stills, allowing for a degree of customization in flavor and production volume. This flexibility is particularly beneficial for meeting diverse market demands.

Choosing the right equipment depends heavily on the desired spirit style, production scale, and budget. My expertise lies in adapting my knowledge and techniques to work efficiently with various equipment types.

Q 10. How do you manage potential hazards and safety concerns in a distillery?

Safety is paramount in a distillery environment, given the presence of flammable materials and high-pressure equipment. We adhere to a comprehensive safety program to mitigate potential hazards.

- Fire Safety: This is the most crucial aspect. We have an extensive fire suppression system, regular fire drills, and strict regulations regarding the handling of flammable materials. All staff receive comprehensive training in fire safety procedures.

- Chemical Handling: We utilize proper personal protective equipment (PPE) when handling chemicals and follow stringent procedures for storage and disposal. Proper ventilation is critical to mitigate the risk of exposure to harmful fumes.

- Equipment Maintenance: Regular inspection and maintenance of all equipment are crucial. This includes pressure testing of vessels and regular checks of electrical systems to prevent malfunctions and potential accidents.

- Emergency Response Plan: A detailed emergency response plan is in place, addressing various scenarios, including fires, chemical spills, and equipment malfunctions. Regular drills ensure preparedness.

- Employee Training: All staff receive extensive safety training, covering hazard recognition, safe work practices, and emergency procedures. Regular refresher courses keep everyone updated on safety protocols.

Our proactive approach to safety ensures a safe working environment for all employees and minimizes the risk of accidents.

Q 11. What are the regulatory requirements for grain distilling in your region?

(Note: This answer will vary depending on the specific region. The following is a general example and should be replaced with information relevant to the specific region in question.)

Regulatory requirements for grain distilling are stringent and vary depending on the location. In my region, key requirements include:

- Licensing and Permits: We require various licenses and permits from both federal and state/local authorities, covering production, distribution, and sales.

- Product Labeling: Strict regulations govern product labeling, including alcohol content, ingredients, and warning statements.

- Alcohol Content and Purity: We are subject to regulations specifying the permitted range of alcohol content and limitations on harmful impurities. Regular testing is required to demonstrate compliance.

- Environmental Regulations: Regulations cover wastewater discharge, air emissions, and the safe disposal of byproducts. We need to maintain accurate records and adhere to environmental standards.

- Taxation: Accurate record-keeping is crucial for tax compliance. The process of excise tax payment and reporting is complex and requires careful attention to detail.

Maintaining compliance is an ongoing process that demands meticulous record-keeping, regular inspections, and close cooperation with regulatory authorities.

Q 12. Explain your understanding of different types of grains used in distilling (e.g., corn, rye, wheat, barley).

Different grains impart distinct characteristics to distilled spirits, impacting flavor, aroma, and mouthfeel. Understanding these differences is crucial for crafting specific spirits.

- Corn: Corn is a versatile grain, often used for producing neutral spirits and bourbons. It contributes a sweet, slightly creamy character.

- Rye: Rye delivers a spicy, robust flavor profile, often characterized by notes of pepper and spice. It is commonly used in rye whiskies.

- Wheat: Wheat adds a soft, smooth, and sometimes slightly sweet character to spirits. It is frequently used in blends or in wheat-based whiskies.

- Barley: Barley is a key ingredient in Scotch whisky production. It contributes to a malty, earthy character, with the potential for subtle smoky notes depending on malting processes.

The choice of grain significantly impacts the final product’s flavor and is often tailored to the style of spirit being created. Grain bills (the blend of different grains used) are carefully designed to achieve specific flavor profiles.

Q 13. How do you troubleshoot common problems encountered during fermentation?

Troubleshooting fermentation issues requires a systematic approach, combining observation, testing, and corrective action.

- Slow or Stalled Fermentation: This can be due to insufficient yeast, low temperature, or high acidity. We’d check yeast viability, adjust temperature, and possibly add nutrients to stimulate fermentation.

- Off-Flavors: Off-flavors might indicate bacterial contamination or an undesirable yeast strain. Microscopic analysis and sensory evaluation help identify the cause. Possible solutions include discarding the batch or employing specific treatments depending on the nature of the contamination.

- High Acidity: High acidity can inhibit yeast activity. Measuring pH and adjusting it with appropriate agents (e.g., lactic acid bacteria) might be necessary.

- Infection: Signs of infection (e.g., unpleasant smells, unusual foaming) necessitate immediate action. This may involve adding sanitizers to control the infection. In severe cases, discarding the entire batch is necessary to prevent contamination of other batches.

Careful monitoring and prompt action are critical to maintaining the quality and safety of the fermentation process. Good sanitation practices from the outset are the best preventative measure.

Q 14. Describe your experience with different types of stills (e.g., pot still, column still).

My experience with different still types has provided valuable insights into their unique capabilities and limitations.

- Pot Stills: I’ve worked extensively with pot stills, appreciating their ability to produce richly flavored spirits. The process involves careful monitoring of temperatures and cuts to isolate the ‘hearts’ fraction. The batch-wise nature requires more hands-on management, but the results are often highly rewarding. This is where you develop your relationship with the nuances of the specific still.

- Column Stills: Column stills offer higher efficiency and precision. I’ve used these to produce neutral spirits with high purity, ideal for vodka or gin production. The ability to control the vapor path and fractionation allows for precise control over the composition of the final product. The tradeoff is the potential loss of some of the flavor complexity found in pot-still spirits.

Understanding the strengths and weaknesses of each type allows for informed decisions about equipment selection based on the desired spirit style and production goals. The choice often comes down to the balance between flavor complexity and production efficiency.

Q 15. How do you calculate the yield of a distillation run?

Calculating distillation yield involves determining the amount of alcohol recovered compared to the initial amount present in the feedstock. It’s usually expressed as a percentage. We use a simple formula: Yield (%) = (Total Alcohol in Distillate / Total Alcohol in Feedstock) x 100. For example, if we start with 100 liters of wash containing 10 liters of pure alcohol (10% ABV) and after distillation, we recover 8 liters of pure alcohol in our distillate, the yield is (8 liters / 10 liters) x 100 = 80%. This yield is crucial for assessing the efficiency of the entire process and identifying areas for improvement. Factors like column design, reflux ratio, and the quality of the feedstock all influence the final yield.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of the different stages of distillation (e.g., stripping, rectification).

Grain distillation typically involves two main stages: stripping and rectification. Stripping is the initial distillation where the fermented mash (wash) is heated, and the alcohol is separated from the other components, resulting in a high-alcohol content liquid called ‘low wines’. Think of it like a rough separation – we’re primarily focused on getting the alcohol concentrated. Rectification is the subsequent distillation of the low wines, aiming for a purer spirit with a higher alcohol concentration and desirable flavor profile. This stage involves multiple fractional distillations within a column, separating the alcohol from congeners (flavor compounds) with differing boiling points. A good analogy is refining crude oil into gasoline – stripping is like getting the initial fuel mixture, while rectification is the fine-tuning to achieve the desired product.

Q 17. How do you monitor and control the alcohol content during distillation?

Monitoring alcohol content is crucial for controlling the distillation process and ensuring product quality. We use several methods:

- Hydrometers measure the specific gravity of the liquid, which is directly related to alcohol content using readily available conversion tables.

- Alcohol meters, also called alcoholometers, are specialized hydrometers calibrated directly to percentage alcohol by volume (ABV).

- Online analyzers provide continuous readings of alcohol concentration, enabling real-time adjustments to the distillation parameters. These are more expensive but offer significant control advantages.

Q 18. What are the key factors that affect the efficiency of a distillation process?

Several factors influence the efficiency of a distillation process.

- Column Design: The type and design of the still (pot still, column still) significantly impacts separation efficiency.

- Reflux Ratio: The amount of condensed vapor returned to the column (reflux) directly affects the purity and strength of the distillate. A higher reflux ratio leads to better separation but reduces the yield.

- Heating Rate: Even and controlled heating prevents bumping and uneven fractionation.

- Feedstock Quality: The quality and composition of the fermented mash greatly impact the overall yield and the quality of the final product. Impurities in the feed can lead to off-flavors and reduce efficiency.

- Packing Material (in column stills): The type and quality of packing material within a column still influence the surface area available for vapor-liquid contact, impacting separation.

Q 19. How do you ensure the purity of the final product?

Ensuring purity involves a multi-step approach.

- Careful Distillation: Precise control over the distillation parameters (as discussed earlier) is essential for separating alcohol from other components.

- Filtering: After distillation, filtration helps remove any remaining solids or impurities.

- Aging (for some spirits): Aging in oak barrels can further refine the spirit, removing some volatile compounds and enhancing the flavor profile. This is often used to smooth the spirit.

- Quality Control Testing: Regular testing (e.g., sensory evaluation, gas chromatography) ensures the final product meets quality standards and legal requirements for purity and alcohol content.

Q 20. What are your strategies for optimizing the distillation process?

Optimizing the distillation process requires a systematic approach.

- Data Logging: Tracking key parameters (temperature, pressure, alcohol content) helps to identify trends and areas for improvement.

- Process Modeling: Using simulation software can help to predict the behavior of the system and optimize parameters before making physical changes.

- Experimentation: Controlled experiments, changing one parameter at a time, are crucial to understanding the effect of each variable.

- Regular Maintenance: Maintaining the equipment (cleaning, inspecting) is vital for consistent performance and optimal results.

Q 21. How do you manage waste and byproducts from the distillation process?

Managing waste and byproducts is crucial for environmental responsibility and cost-effectiveness. The primary byproduct is ‘spent grains’ – the remaining mash after distillation. These can be:

- Used as animal feed: A valuable source of nutrients for livestock.

- Composted: Returning nutrients to the soil.

- Used in biogas production: Generating renewable energy.

Q 22. Describe your experience with different methods of spirit maturation.

Spirit maturation is a crucial step in grain distilling, profoundly impacting the final product’s flavor profile. Different methods influence the rate and nature of wood interaction, impacting the spirit’s color, aroma, and taste. My experience encompasses both traditional and innovative approaches.

- Traditional methods rely on the slow, natural extraction of compounds from oak barrels. This can range from simple aging in ex-bourbon barrels to more complex practices involving different barrel toasting levels and charring (heavily toasted barrels impart more intense flavors).

- Accelerated aging techniques are becoming increasingly popular. These methods, such as using smaller barrels, higher-proof spirits, or employing ultrasonic technology, can dramatically reduce maturation time, although the resulting flavor profile may differ from traditionally aged spirits. I’ve worked with both traditional and accelerated methods, understanding their advantages and drawbacks based on the desired final product.

- Finishing is another method where the spirit is transferred to a different type of barrel after initial aging. For instance, a whiskey aged in bourbon barrels might be finished in sherry casks to add unique notes of sweetness and complexity. I’ve extensively explored finishing techniques, experimenting with various secondary barrels like port, rum, or even maple syrup barrels to introduce distinctive flavor profiles.

For example, in one project we compared aging a rye whiskey in new American oak with aging the same whiskey in a used French oak barrel. The American oak imparted bolder vanilla and spice notes, while the French oak contributed more subtle, nuanced flavors of fruit and spice. Understanding these differences allows me to choose the best maturation method for a specific spirit.

Q 23. What are the different types of barrels used for aging spirits?

The type of barrel significantly impacts the aging process and the final character of the spirit. The most common types are:

- American oak: Characterized by its pronounced vanilla, caramel, and coconut notes, frequently used for bourbon and rye whiskey.

- French oak: Known for its more subtle flavors of spice, fruit, and toast, often preferred for finer whiskeys and cognacs.

- Ex-Bourbon barrels: Previously used for bourbon, these barrels provide a rich canvas of vanilla, caramel, and oak notes, often reused for other spirits like Scotch or Irish whiskey.

- Sherry casks: Used for sherry wine, they impart sweetness, nuttiness, and dried fruit flavors to spirits.

- Port casks: Similar to sherry casks, they offer rich fruit notes, often plum and raisin, alongside a darker, more intense character.

- Other options: Many other types of barrels can be employed creatively, including those previously holding wine (like Cabernet Sauvignon or Pinot Noir) or even unique vessels like rum casks or maple syrup barrels.

The choice of barrel depends on the desired flavor profile, budget, and the specific spirit being aged. Each barrel type introduces a unique set of flavors and aromas into the spirit.

Q 24. How do you select appropriate barrels for aging different types of spirits?

Selecting the right barrel is an art and a science. The process involves carefully considering the desired taste profile of the finished spirit and matching it with the characteristics imparted by various barrel types.

- Spirit type: For a robust, spicy rye whiskey, new American oak barrels might be preferable. For a smoother, more delicate single malt Scotch, seasoned French oak could be the better choice.

- Barrel age and history: The age and previous use of the barrel are significant. New barrels impart bolder flavors, whereas used barrels contribute subtler notes. The history of a barrel (e.g., previously holding bourbon, sherry, or wine) adds unique nuances.

- Toasting and charring levels: This process affects the intensity of flavor extraction. Heavily toasted barrels provide more intense flavors compared to lightly toasted ones.

- Climate and storage conditions: The environment plays a crucial role, impacting the rate of maturation. Temperature and humidity influence the interaction between the spirit and the wood.

For example, if I’m aiming for a whiskey with a strong vanilla and caramel profile, I would choose new American oak barrels. However, if I prefer a more nuanced, complex profile with notes of fruit and spice, I’d opt for well-seasoned French oak. This selection often involves extensive tasting and experimentation, balancing factors like budget and desired aging time.

Q 25. What is your experience with blending different spirits?

Blending different spirits is a critical skill in crafting a consistent and high-quality product. It requires a deep understanding of the individual components’ flavor profiles and how they interact. My experience with blending encompasses various techniques and stages:

- Sensory evaluation: Thorough tasting and evaluation of each component to understand its strengths and weaknesses.

- Flavor profiling: Identifying the key flavor attributes (e.g., sweetness, spice, fruitiness) of each spirit.

- Trial blends: Creating and tasting multiple blends to experiment with different ratios and combinations.

- Refinement: Adjusting the blend to achieve the desired balance and complexity.

- Maturation after blending: In some cases, the final blend is further matured to allow the flavors to integrate.

For instance, in blending a bourbon, I might combine different barrels to create a complex profile. One barrel might be rich in vanilla, while another offers a bolder spice. By carefully balancing these components, we create a final product that is more nuanced and enjoyable than any single barrel could provide on its own. This skill necessitates extensive knowledge of the aging process and the resulting flavor profiles.

Q 26. Explain your understanding of the sensory evaluation of spirits.

Sensory evaluation of spirits involves using all five senses—sight, smell, taste, touch, and even hearing (in some cases)—to assess a spirit’s quality. It’s an integral part of quality control and product development.

- Appearance: Observing the color, clarity, and viscosity of the spirit.

- Aroma: Identifying the different aromas, their intensity, and complexity. Techniques like swirling the spirit in a glass to release volatile aromas are employed.

- Taste: Evaluating the flavor profile, including sweetness, sourness, bitterness, saltiness, umami, and astringency. The palate is used to detect the intensity and harmony of different flavor notes.

- Mouthfeel: Assessing the texture, body, and weight of the spirit on the palate.

- Finish: Evaluating the lingering sensations after swallowing or spitting out the spirit. The length and character of the finish are important indicators of quality.

During sensory evaluation, I use standardized methods and scorecards to ensure objectivity and consistency. This involves tasting multiple samples blind, documenting observations meticulously, and comparing findings with other tasters to validate results. A well-trained palate allows one to detect subtle nuances and identify defects, ultimately improving product quality.

Q 27. How do you maintain accurate records and documentation in a distillery?

Maintaining accurate records and documentation is crucial for traceability, quality control, and regulatory compliance in a distillery. This involves a comprehensive system encompassing every stage of production, from grain selection to bottling.

- Production records: Detailed logs of each production run, including the type and quantity of grain used, fermentation parameters, distillation details (cut points, yields), and aging information.

- Barrel management: A system for tracking individual barrels, including the type of wood, char level, fill date, and location. This often involves digital databases and barcodes for efficient tracking.

- Inventory management: Monitoring the inventory of grains, spirits, barrels, and packaging materials. Real-time tracking prevents stockouts and ensures efficient resource allocation.

- Quality control data: Recording the results of sensory evaluations, chemical analyses, and other quality control tests. This data is essential for identifying trends, resolving issues, and ensuring consistent product quality.

- Regulatory compliance: Maintaining records to meet all applicable laws and regulations. This typically includes records related to alcohol content, production volume, and tax payments.

Our distillery utilizes a combination of paper-based logs (for immediate records) and a sophisticated digital database to manage these records efficiently. The data is backed up regularly to ensure its security and accessibility. This rigorous documentation system ensures transparency, enables continuous improvement, and allows us to meet all legal requirements.

Key Topics to Learn for Your Grain Distilling Interview

- Grain Selection and Milling: Understanding the impact of different grains (e.g., corn, rye, wheat, barley) on the final spirit’s flavor profile, and the principles of efficient milling for optimal mashing.

- Mashing and Fermentation: Mastering the process of converting starches into fermentable sugars and the role of enzymes. Understanding various fermentation techniques and their influence on flavor development and yeast strain selection.

- Distillation Principles: Grasping the fundamentals of distillation, including the different types of stills (pot, column), and the impact of reflux and stripping on the final product’s quality and alcohol content.

- Quality Control and Testing: Familiarize yourself with standard methods for measuring alcohol content, pH, and other crucial parameters. Understanding quality control procedures throughout the entire distilling process.

- Spirit Maturation and Aging: Learn about the principles of barrel selection, the impact of wood type and char on flavor development, and the influence of aging time on spirit character.

- Safety and Regulatory Compliance: Understanding relevant health and safety regulations, as well as legal requirements concerning alcohol production and distribution.

- Troubleshooting and Problem Solving: Develop your ability to identify and address potential issues during each stage of the distillation process, from raw materials to finished product.

- Yield Optimization and Cost Control: Explore strategies to maximize efficiency and minimize waste throughout the production process. Understand the economic aspects of grain distilling.

Next Steps: Unlock Your Distilling Career

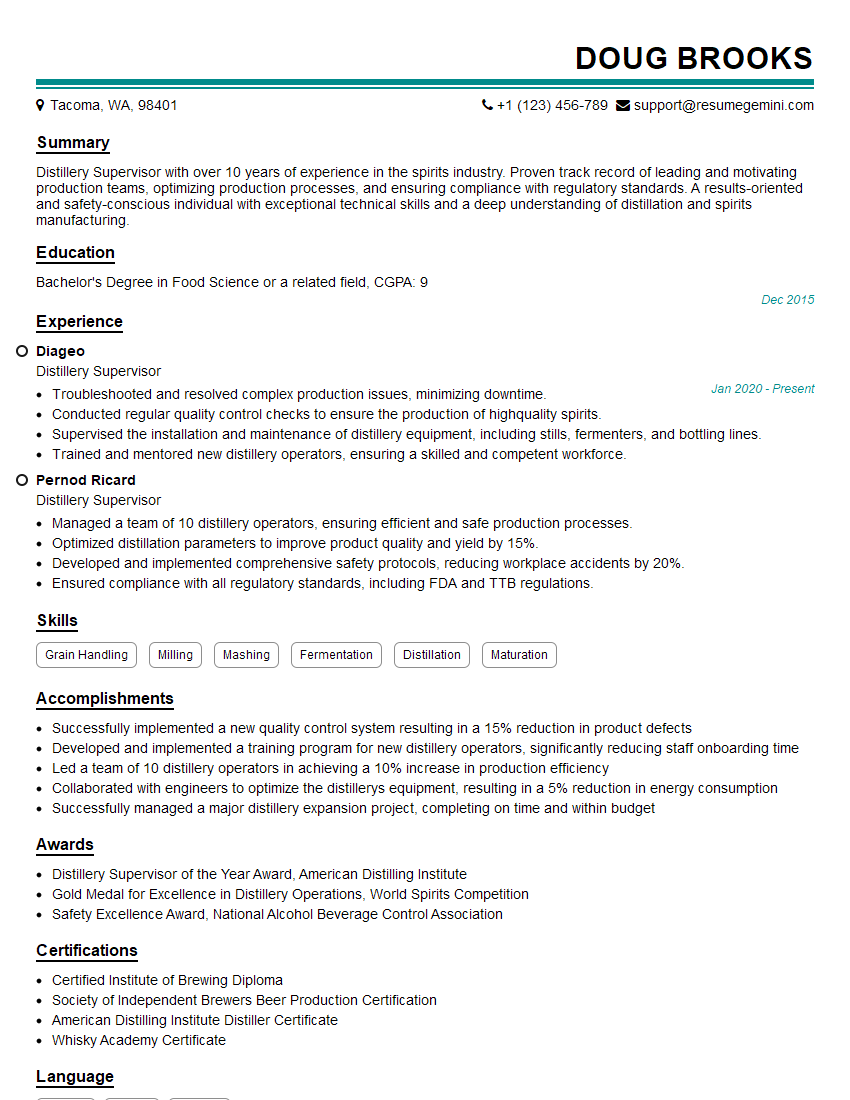

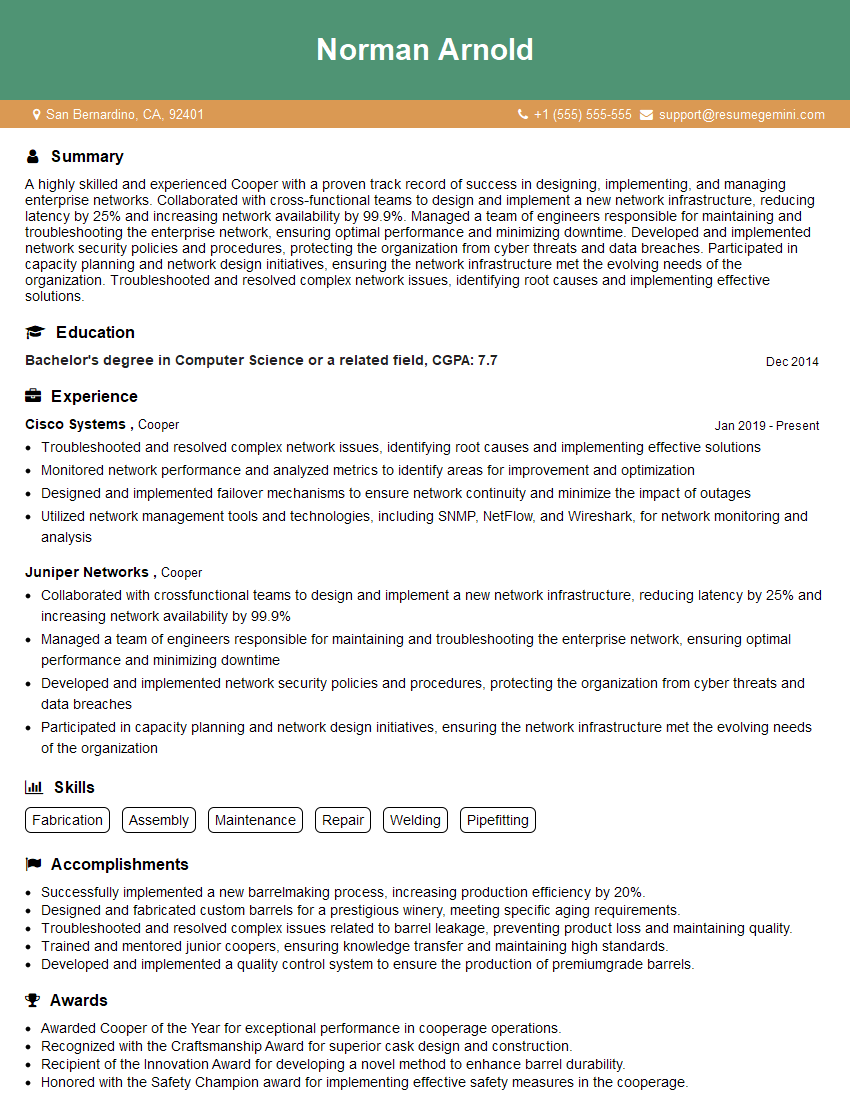

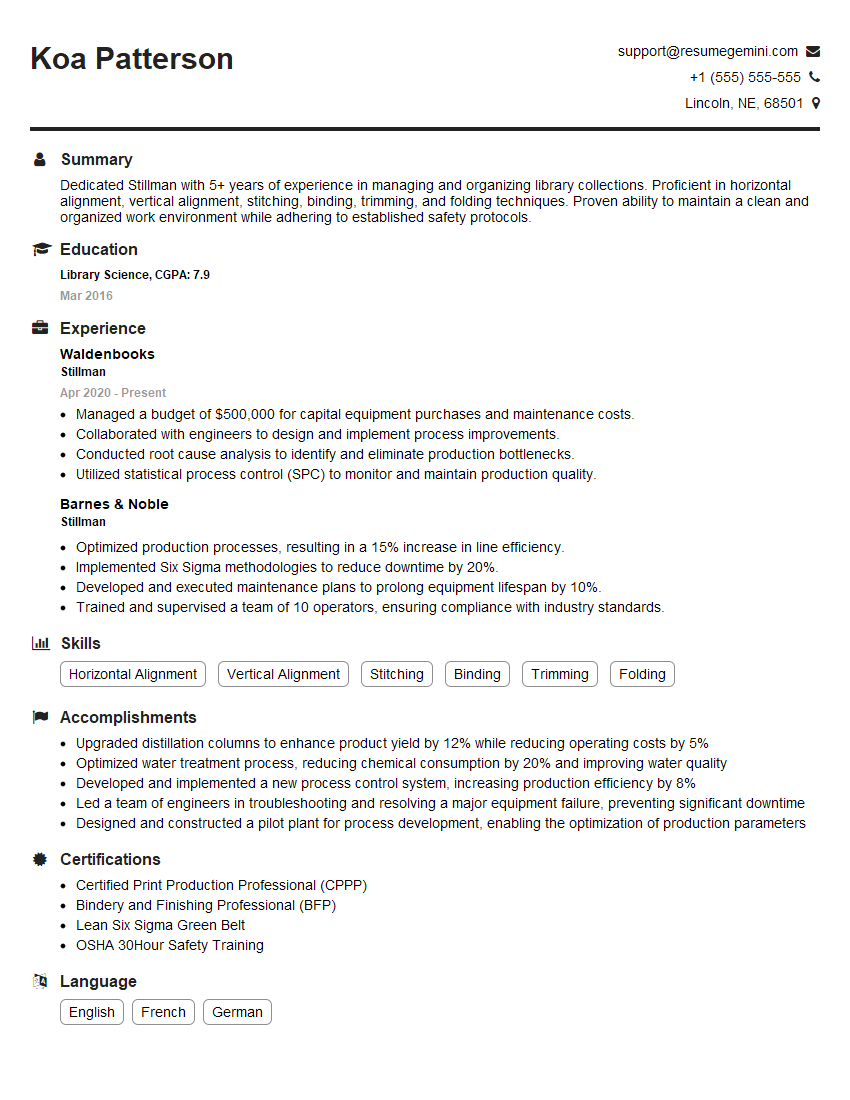

Mastering the art and science of grain distilling opens doors to exciting career opportunities in a dynamic and growing industry. To significantly enhance your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you craft a compelling resume tailored to highlight your skills and experience in grain distilling. Take advantage of their expertise and explore examples of resumes specifically designed for this field. A well-structured resume is your first step toward securing your dream job in the world of grain distilling.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good