The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Grinding and polishing blanks interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Grinding and polishing blanks Interview

Q 1. What types of grinding wheels are best suited for different materials?

Selecting the right grinding wheel is crucial for achieving the desired surface finish and preventing damage to the workpiece. The choice depends heavily on the material being ground. Think of it like choosing the right tool for the job – you wouldn’t use a hammer to screw in a screw!

- Hard and brittle materials (e.g., ceramics, hardened steel): These require wheels with harder abrasive grains like silicon carbide (SiC) or aluminum oxide (Al2O3) in a relatively hard bond. A softer bond might wear down too quickly, while a harder bond can reduce the risk of workpiece damage.

- Soft and ductile materials (e.g., aluminum, copper): Softer abrasive grains like silicon carbide (SiC) in a softer bond are generally preferred. This helps prevent loading (the clogging of abrasive particles) and ensures a smoother finish. Using too hard a wheel can lead to excessive tearing and poor surface quality.

- Tough materials (e.g., titanium alloys, superalloys): These materials often require CBN (Cubic Boron Nitride) or diamond wheels, which are significantly harder and can withstand the high forces involved. These wheels are more expensive but necessary for efficiently grinding these robust materials.

- Specific applications: The wheel’s structure (porosity) also plays a role. Open structures are beneficial for free-cutting operations and prevent loading, while denser structures are better for finer finishes.

For example, when grinding a hardened steel tool, a vitrified bond silicon carbide wheel with a medium hardness would be appropriate. However, for polishing aluminum, you might opt for a resinoid bond aluminum oxide wheel with a softer bond.

Q 2. Explain the difference between centerless and cylindrical grinding.

Both centerless and cylindrical grinding are used to achieve high-precision cylindrical surfaces, but they differ significantly in their setup and application.

- Cylindrical Grinding: This method uses a rotating workpiece held between centers (similar to a lathe) while a grinding wheel removes material. The workpiece rotates, and the grinding wheel traverses along its length, generating a cylindrical shape. It’s highly versatile, capable of grinding external or internal cylindrical surfaces and is commonly used for shafts, pins, and similar components. Think of it like sharpening a pencil, but on a much larger scale and with higher precision.

- Centerless Grinding: This method doesn’t require holding the workpiece between centers. Instead, it uses a regulating wheel to feed the workpiece against a grinding wheel. The regulating wheel controls the speed and the position of the workpiece. This allows for continuous grinding, enabling higher production rates. Centerless grinding is ideal for high-volume production of small, cylindrical parts like pins, needles, and rollers. It’s like a conveyor belt of parts constantly being sharpened.

In essence, cylindrical grinding offers greater versatility for a wider range of parts, while centerless grinding excels in speed and automation for mass production of smaller, simpler components.

Q 3. Describe the various polishing methods used for blanks.

Polishing blanks aims to achieve a highly refined surface finish, often exceeding the capabilities of grinding. Several methods are employed, each offering different levels of precision and surface quality:

- Abrasive Belt Polishing: Uses abrasive belts of varying grit sizes, progressively reducing the surface roughness. This is a fast method suitable for removing scratches left by grinding.

- Vibratory Polishing: Parts are placed in a container with abrasive media and a polishing compound. The container vibrates, causing the media to tumble and polish the surface. Excellent for complex shapes and producing a uniform finish but can be time-consuming.

- Chemical-Mechanical Planarization (CMP): A precise polishing technique commonly used in semiconductor manufacturing. Uses a chemical slurry and a rotating pad to planarize the surface to a high degree of flatness. It’s extremely accurate but specialized and expensive.

- Electrolytic Polishing: A chemical process where the workpiece is made an anode in an electrolyte solution. It removes a very thin layer of material, leaving a highly polished surface and is used for high-end applications.

- Hand Polishing: Using polishing compounds and various felts or cloths for manual finishing. This is ideal for small-scale operations, intricate parts, or achieving a highly specific finish but requires skill and patience.

The choice depends on the desired surface quality, part geometry, material, production volume, and cost considerations. A manufacturer might use abrasive belt polishing followed by vibratory polishing for a high-volume production of simple parts, while hand polishing might be chosen for a small, highly intricate component.

Q 4. How do you select the appropriate abrasive for a specific grinding or polishing task?

Abrasive selection is critical for both grinding and polishing. The ideal abrasive depends on several factors:

- Material Hardness: Harder abrasives are needed for harder workpieces, and vice-versa. Diamond is the hardest, followed by CBN, silicon carbide, and aluminum oxide.

- Desired Surface Finish: Finer grit sizes result in finer finishes. Grinding often uses coarser grits, while polishing employs finer grits.

- Material Removal Rate: Coarser grits remove material faster but create a rougher surface. Finer grits remove material slowly but produce a smoother finish.

- Cost: Diamond and CBN abrasives are expensive but essential for extremely hard materials.

Imagine you’re sanding wood. For rough shaping, you’d use coarse sandpaper, then progressively finer grits to achieve a smooth surface. Similarly, in grinding and polishing, selecting the appropriate grit progression is key to achieving the desired outcome. A systematic approach, starting with coarser abrasives and progressively moving to finer ones, is typically used.

Q 5. What are the common causes of surface defects in grinding and polishing?

Surface defects in grinding and polishing can significantly impact the quality and functionality of the workpiece. Common causes include:

- Improper Wheel Selection: Using the wrong type, bond, or grit size of grinding wheel can lead to surface cracking, burning, or tearing.

- Incorrect Grinding Parameters: Excessive grinding pressure, feed rate, or speed can cause burning, chatter marks, or surface waviness.

- Wheel Wear: A worn-out wheel can produce inconsistent finishes and surface defects.

- Insufficient Coolant: Lack of coolant can cause excessive heat generation, leading to burning and workpiece damage.

- Workpiece Defects: Existing flaws or irregularities in the workpiece can be exacerbated during grinding and polishing.

- Contamination: Particles in the coolant or abrasive can cause scratches and pits.

- Machine Vibration: Vibration in the grinding or polishing machine can cause chatter marks and uneven surfaces.

Careful attention to detail, proper machine maintenance, and rigorous quality control are crucial to minimize these defects.

Q 6. How do you measure surface roughness after grinding and polishing?

Surface roughness is measured using various instruments, the most common being:

- Profilometers: These instruments use a stylus that traces the surface profile, measuring the height variations. The resulting data provides a quantitative measure of surface roughness, typically expressed as Ra (average roughness) or Rz (maximum peak-to-valley height).

- Optical Profilometers: These instruments use optical techniques (e.g., confocal microscopy) to measure surface roughness without physical contact. This method is non-destructive and suitable for delicate surfaces.

- Surface Roughness Comparators: These provide a visual comparison of a surface to standard roughness samples. While less precise than profilometers, they offer a quick and simple assessment.

The choice of measurement technique depends on the required accuracy, surface characteristics, and budget. Profilometers are widely used for precise measurements, while optical profilometers are preferred for sensitive materials or delicate surfaces.

Q 7. Explain the importance of coolant in grinding operations.

Coolant plays a vital role in grinding operations. Its functions are critical for both process efficiency and workpiece quality:

- Cooling: Grinding generates substantial heat, which can soften the workpiece, burn the surface, and damage the grinding wheel. Coolant effectively dissipates this heat, maintaining optimal temperatures.

- Lubrication: Coolant reduces friction between the grinding wheel and workpiece, preventing excessive wear on both components and improving the surface finish.

- Chip Removal: Coolant flushes away the generated chips and debris, preventing clogging of the grinding wheel and ensuring consistent material removal.

- Corrosion Protection: Certain coolants also offer corrosion protection to prevent rusting or oxidation of the workpiece.

The absence of coolant can lead to workpiece burning, grinding wheel glazing (loss of sharpness), and poor surface quality. Choosing the right coolant for the material being ground is crucial to avoid adverse reactions or other issues. For example, oil-based coolants are sometimes preferred for grinding certain metals to provide better lubrication. Water-based coolants are common, often with added additives to enhance their performance.

Q 8. How do you troubleshoot common grinding machine problems?

Troubleshooting grinding machine problems requires a systematic approach. I typically start by visually inspecting the machine for any obvious issues like loose components, damaged belts, or coolant leaks. Then, I’ll check the machine’s operational parameters – is the power supply stable? Are the coolant flow and pressure correct? Are the grinding wheels properly mounted and dressed?

For example, if a surface grinder is producing inconsistent finishes, I’d first check the wheel’s condition for wear or glazing. If that’s not the problem, I’d then examine the workholding system for vibrations or misalignment, and finally consider the machine’s alignment itself. A systematic approach, starting from the simplest potential issue and moving to the more complex is key.

If the problem persists after these checks, I’d consult the machine’s manuals and potentially use diagnostic tools to pinpoint the fault. For instance, a faulty motor could be detected via electrical measurements, while vibration issues might indicate wear in bearings.

Q 9. Describe your experience with different types of grinding machines (e.g., surface grinders, cylindrical grinders).

My experience encompasses a wide range of grinding machines. I’ve extensively worked with surface grinders, cylindrical grinders (both centerless and center-type), and also have experience with specialized grinders like internal and tool grinders.

Surface grinders, for instance, are ideal for creating flat, parallel surfaces on workpieces. I’ve used them extensively for precision flatness requirements on various materials, like steel and aluminum. With cylindrical grinders, I’ve honed my skills in achieving precise cylindrical dimensions and surface finishes on shafts and similar components. The difference in setup and operation between centerless and center-type cylindrical grinders requires understanding of the unique advantages of each. Centerless is incredibly efficient for high volume production of parts of the same size, while center-type offers more flexibility and control for smaller batch sizes and more intricate parts. Internal grinders require a high level of precision and understanding of wheel selection for those hard to reach areas.

Q 10. What safety precautions are essential when working with grinding and polishing equipment?

Safety is paramount when operating grinding and polishing equipment. The most crucial precautions involve appropriate personal protective equipment (PPE). This includes safety glasses or a face shield to protect against flying debris, hearing protection to mitigate the noise, and work gloves to protect hands from cuts or abrasions. Long sleeves and closed-toe shoes are also a must.

Furthermore, proper machine guarding is essential. Ensure all guards are in place and functioning correctly before starting any operation. Regular checks of guards and equipment for damage are also necessary. Never operate a machine if you’re unsure about its safe operation, always seek guidance.

Additionally, proper handling of grinding wheels is critical. Wheels should be inspected before mounting for any cracks or damage and mounted correctly, avoiding excessive force that might cause fracturing. The work area should be clean and well-lit to reduce the risk of accidents. Finally, understanding the machine’s specific safety features and procedures is crucial.

Q 11. How do you maintain and clean grinding and polishing equipment?

Maintaining and cleaning grinding and polishing equipment is crucial for ensuring accuracy, longevity, and safety. Regular cleaning after each use removes debris and prevents clogging, ensuring consistent performance. This usually involves brushing away loose debris from the machine, particularly around the wheel and work area. Coolant systems require regular flushing and cleaning to remove accumulated sludge.

Scheduled maintenance depends on the type of machine and its usage frequency, but it typically involves lubrication of moving parts, checking and tightening loose components, and inspecting belts and pulleys for wear. Grinding wheels should be inspected for wear and damage, and replaced or dressed as needed.

For example, with a cylindrical grinder, I’d regularly check the alignment of the work head and the tailstock, ensuring they’re perfectly aligned to avoid inaccuracies. Proper cleaning and maintenance not only extends the lifespan of the equipment but also improves the quality and consistency of the finished product.

Q 12. Explain the process of calibrating and maintaining grinding wheels.

Calibrating and maintaining grinding wheels is critical for maintaining accuracy and surface finish. Wheel calibration ensures the wheel’s trueness, which is its concentricity or balance. An unbalanced wheel can lead to vibration and poor finish.

Truing a grinding wheel is usually done using a diamond dresser or other appropriate tool. This removes any irregularities on the wheel’s surface, restoring its profile. Dressing, on the other hand, sharpens the wheel and maintains its cutting edges by removing glazing and dulling. The frequency of both operations depends on the material being ground and wheel wear but will always be part of the regular maintenance. Precise measurement and control is essential to accurately maintain desired specifications.

Wheel storage is also important. Grinding wheels should be stored properly to prevent damage or cracking. They need to be kept clean and dry and stored in a safe and secure area. A poorly stored wheel is both unsafe and likely to become useless.

Q 13. What are the different types of surface finishes achievable through grinding and polishing?

The surface finish achievable through grinding and polishing depends on the abrasive used, the grinding parameters, and the final polishing stage. A wide range of finishes is possible, from coarse, rough surfaces to extremely smooth, mirror-like finishes.

For example, a coarse grinding wheel might produce a relatively rough surface with a high Ra (average roughness) value, while finer grinding wheels followed by polishing can produce smoother surfaces with a much lower Ra value. Specific surface finish requirements are often specified using various standards, such as Ra, Rz (ten-point height), and surface texture designations. The choice of abrasive, lubricant, and polishing compounds will greatly influence this.

Q 14. How do you determine the optimal grinding parameters (speed, feed, depth of cut)?

Determining optimal grinding parameters (speed, feed, and depth of cut) is crucial for achieving the desired surface finish, minimizing wear on the wheel and machine, and maximizing efficiency. These parameters are interconnected and must be balanced.

Wheel speed is usually determined by the wheel’s type and material being ground; manufacturer guidelines should be followed closely. Feed rate refers to the rate at which the workpiece advances into the wheel. A higher feed rate may increase productivity but can lead to excessive wear and a poor surface finish. Depth of cut defines the material removed in each pass; a deeper cut removes more material but puts more stress on both the wheel and the workpiece. These variables must be carefully considered for the chosen workpiece material and the desired outcome. Optimizing these parameters often involves trial-and-error, starting with conservative settings and iteratively adjusting them until the desired results are achieved. This frequently requires experience with different materials and extensive knowledge of the properties of grinding wheels.

For instance, grinding a hard steel requires a slower feed rate and shallower depth of cut compared to a softer aluminum workpiece.

Q 15. Describe your experience with different types of polishing compounds.

My experience with polishing compounds spans a wide range of materials, each chosen based on the specific workpiece material and the desired surface finish. For instance, diamond compounds are excellent for achieving extremely fine finishes on hard materials like ceramics or hardened steels. Their abrasive particles are incredibly hard and provide a fast cut rate. I’ve extensively used them for precision optical components. Conversely, alumina compounds are more versatile and are suitable for a broader range of materials, from softer metals to some plastics. They are often used in multi-stage polishing to progressively refine the surface. Then there are cerium oxide compounds, frequently used for final polishing of glass and lenses, producing exceptional clarity and smoothness. Selecting the right compound involves considering factors like particle size (which impacts the final scratch depth), concentration, and the polishing method itself – whether it’s vibratory, lapping, or conventional polishing.

In my experience, I also consider the type of polishing pad or media used alongside the compound, which can significantly impact results. A soft felt pad will produce a different finish compared to a harder felt or a polyurethane pad. The combination of compound and pad must be carefully chosen to optimize the final surface finish and minimize defects.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the dimensional accuracy of the finished blanks?

Ensuring dimensional accuracy of finished blanks is paramount. We achieve this through a combination of precise pre-grinding and polishing operations with precise monitoring at each stage. Before grinding, the blanks are carefully inspected for initial dimensions. During grinding, we utilize CNC controlled grinders that allow for precise control of material removal, depth, and shape. We use calibrated measurement tools such as micrometers, dial indicators and optical comparators to monitor the dimensions continuously. Regular checks are performed to ensure we stay within the allowed tolerances. The grinding process is often followed by a lapping process, a finer form of grinding used to achieve high precision and flatness, and finally polishing brings the surface finish to its finest standard, again monitored for dimensional accuracy using advanced techniques like interferometry if required. In-process gauging and statistical process control (SPC) helps to identify and address any deviations early on, thus preventing scrap and rework.

Q 17. What is the role of surface preparation before grinding and polishing?

Surface preparation is critical and significantly impacts the grinding and polishing process. It’s like preparing a canvas before painting; a poorly prepared surface will lead to an uneven and unsatisfactory end product. This involves a series of steps depending on the material and desired surface finish. First, we usually start with cleaning to remove any contaminants such as oil, grease, or scale. This could involve ultrasonic cleaning, solvent degreasing or other specialized methods. Then, often a pre-grinding stage is employed to remove heavy imperfections and generate a relatively flat surface. This may involve using coarser grit abrasive materials. Finally, prior to finer grinding and polishing, a thorough cleaning is crucial to remove any residual grinding debris which would otherwise be embedded in the surface during finer stages, leading to scratches. This initial surface preparation ensures consistent material removal rates and a superior final finish.

Q 18. What quality control measures do you implement during the grinding and polishing process?

Quality control is integrated throughout the entire process, not just at the end. We use various tools and techniques. We start with incoming material inspection; ensuring the blanks are free of defects before they even reach the grinding stage. Throughout the grinding and polishing, regular checks are performed using optical instruments to assess surface quality, including smoothness, flatness, and the presence of scratches or other defects. Dimensional measurements are taken at each stage using calibrated instruments. Statistical Process Control (SPC) charts are used to track key parameters and identify any trends that may indicate a problem. Regular calibration and maintenance of our equipment are performed to ensure accuracy and consistency. Furthermore, we use automated inspection systems which are especially helpful in mass production scenarios. We document all these checks meticulously, providing a detailed history for every workpiece. This rigorous approach minimizes defects and ensures consistency.

Q 19. Explain the concept of material removal rate (MRR) in grinding.

Material Removal Rate (MRR) in grinding refers to the volume of material removed from the workpiece per unit time. It’s a crucial parameter in determining grinding efficiency and process optimization. A higher MRR generally implies faster processing. However, it’s not always desirable as it can lead to increased surface roughness or even damage to the workpiece if not carefully controlled. MRR is influenced by several factors: the type and size of the abrasive grains, the grinding wheel speed, the feed rate (how fast the workpiece is advanced into the wheel), the depth of cut, and the workpiece material’s properties. For example, a harder workpiece material will generally result in a lower MRR. The formula often used is an approximation, as it doesn’t capture the complexities of the grinding process fully. A practical example would be optimizing the MRR for a particular workpiece material by adjusting the grinding wheel speed and feed rate until we obtain the desired surface finish within an acceptable processing time.

MRR ≈ (Wheel Speed * Feed Rate * Depth of Cut) / (Workpiece Hardness) (This is a simplified approximation)

Q 20. How do you interpret and react to quality control reports in relation to grinding?

Quality control reports are essential feedback mechanisms. I carefully review them to identify trends, anomalies, and potential process issues. For example, a sudden increase in surface roughness might indicate a problem with the grinding wheel, coolant supply, or improper workpiece clamping. Similarly, if dimensional accuracy consistently falls outside the specified tolerances, this could indicate problems with machine calibration, incorrect programming, or wear of grinding components. The reports also help in preventative maintenance by highlighting areas where equipment is nearing the end of its useful life or where preventative maintenance might be needed. If problems are detected, we immediately investigate the root cause and implement corrective actions, which may involve adjusting machine parameters, replacing worn components, or refining the grinding process. This might include adjusting the feed rates, changing the grinding wheel, or modifying the coolant parameters. The process is then monitored until the issue is resolved and quality returns to the expected levels.

Q 21. How do you address issues of chatter during grinding operations?

Chatter, the high-frequency vibration during grinding, is a significant problem leading to poor surface finish, dimensional inaccuracy, and even damage to the machine. We address it through a multi-pronged approach. First, we ensure the workpiece is securely clamped to minimize vibration. Second, we carefully select and maintain grinding wheels to ensure they are free from defects and correctly balanced. Improper balancing can exacerbate chatter significantly. Third, we optimize grinding parameters, like wheel speed and feed rate, to reduce the likelihood of chatter. Experimentation and fine-tuning these parameters are crucial. Fourth, we focus on the rigidity of the entire grinding system; a flexible system is more susceptible to chatter. Lastly, if chatter persists, we might explore using specialized damping systems or vibration isolation techniques to reduce the transmission of vibrations to the workpiece. In some cases, using different grinding fluids with appropriate viscosity and damping properties may also help dampen the vibrations and reduce chatter.

Q 22. Describe your experience working with different types of blank materials (e.g., metals, ceramics, plastics).

My experience spans a wide range of blank materials, encompassing various metals, ceramics, and plastics. Each material presents unique challenges and requires a tailored approach to grinding and polishing. For instance, working with hardened steels necessitates using diamond-based grinding wheels and precise control of parameters like feed rate and depth of cut to avoid cracking or chipping. In contrast, softer materials like aluminum or plastics require gentler techniques to prevent excessive material removal or surface damage. Ceramics demand specialized tooling and slower speeds to handle their brittle nature and prevent fracture. I’ve worked extensively with stainless steels (304, 316, etc.), titanium alloys, aluminum alloys (e.g., 6061, 7075), silicon carbide ceramics, and polymers such as acetal and polycarbonate, each requiring specific grinding wheel selection, coolant choices, and process parameters.

- Metals: Experience with various metal alloys, including understanding their hardness, machinability, and thermal properties to optimize the grinding process.

- Ceramics: Expertise in handling the brittle nature of ceramic materials to prevent chipping and cracking, requiring careful selection of abrasive materials and grinding parameters.

- Plastics: Familiarity with the different characteristics of various plastics and their tendency to deform under pressure, leading to the use of specialized tooling and grinding techniques.

Q 23. What software or systems have you used to program or control grinding machines?

Throughout my career, I’ve utilized several software systems for programming and controlling grinding machines. My experience includes using both Computer Numerical Control (CNC) systems and more advanced systems with adaptive control capabilities. I’m proficient in using FANUC and Siemens CNC control systems, programming G-code and M-code to define intricate grinding paths. Furthermore, I’ve worked with software packages that simulate the grinding process, allowing for the optimization of parameters before actual machining. These simulations help to predict surface finish, material removal rates, and potential issues, leading to a more efficient and effective grinding operation. A recent project involved using a system with real-time monitoring of wheel wear and workpiece temperature, enabling adaptive adjustments to maintain consistent quality.

Example G-Code snippet: G01 X10.0 Y20.0 F100; (Linear interpolation move)Q 24. How familiar are you with different types of grinding fluids and their properties?

Grinding fluids play a crucial role in the grinding process, influencing factors such as surface finish, material removal rate, and wheel life. My experience encompasses a variety of fluids, including oil-based emulsions, synthetic fluids, and water-based coolants. The choice of fluid depends heavily on the material being ground. Oil-based emulsions are effective for many metals, providing good lubrication and cooling. Synthetic fluids often offer superior performance in terms of reduced friction and improved surface finish, especially in high-precision grinding. Water-based coolants are environmentally friendly but may require additives for optimal performance and corrosion inhibition. I understand the importance of fluid properties such as viscosity, lubricity, cooling capacity, and environmental impact when selecting the best option for a specific application. For example, when grinding titanium, a synthetic coolant with excellent lubricity helps prevent galling and improves surface quality.

Q 25. How do you handle variations in workpiece materials and their effect on grinding?

Variations in workpiece materials significantly affect the grinding process. Different materials have varying hardness, toughness, thermal conductivity, and chemical reactivity. These properties influence the selection of grinding wheels, the choice of grinding fluids, and the optimal process parameters. For example, grinding a hard material like hardened steel requires a harder grinding wheel and lower feed rates to prevent wheel wear and workpiece damage. Softer materials might require a softer wheel and higher feed rates for efficient material removal. My approach involves careful material characterization – determining hardness, tensile strength etc. – before selecting the appropriate grinding parameters. I regularly use hardness testing equipment and consult material datasheets to ensure the optimal settings are used, preventing damage to the workpiece and maintaining consistent product quality. Adaptive control systems in modern CNC grinders help compensate for variations in material properties during the process, further enhancing consistency.

Q 26. Describe a time you had to troubleshoot a complex grinding problem. What was your approach?

During a project involving the grinding of a complex aerospace component made of a titanium alloy, we experienced inconsistent surface roughness on the final product. Initial investigation revealed that minor variations in the workpiece’s microstructure were affecting the grinding process. My approach involved a systematic troubleshooting process:

- Data Analysis: We meticulously reviewed the process parameters, including spindle speed, feed rate, depth of cut, and coolant flow rate. We also analyzed the surface roughness data from multiple runs.

- Material Characterization: We performed additional material analysis on the titanium alloy to identify the source of the microstructural variations. This involved microscopic examination and hardness testing across multiple samples.

- Process Optimization: Based on the analysis, we adjusted the grinding parameters, such as implementing a slower feed rate and optimizing the coolant flow for better heat dissipation. We also experimented with different grinding wheel types and grits.

- Adaptive Control Implementation: To further mitigate the effect of material variations, we implemented an adaptive control strategy into our CNC system. This allowed the machine to automatically adjust the grinding parameters based on real-time feedback from sensors monitoring surface roughness.

This multi-faceted approach resolved the problem, resulting in consistent surface roughness and meeting the stringent quality requirements of the aerospace component. The key was combining data-driven analysis with a deep understanding of both the material and the grinding process itself.

Q 27. What are the key differences between fine grinding and superfinishing?

Fine grinding and superfinishing are both advanced grinding techniques aimed at achieving extremely smooth surfaces, but they differ significantly in their objectives and processes. Fine grinding focuses on achieving a specific surface roughness within a certain range (e.g., Ra 0.2-0.8 µm), removing the majority of machining marks left by previous operations. It employs finer grits of abrasive wheels and focuses on removing material efficiently while maintaining surface quality. Superfinishing, on the other hand, aims to achieve an exceptionally smooth surface finish with very low roughness values (e.g., Ra < 0.05 µm) by using very fine abrasives, often within a polishing compound, and very light pressure. It's about refining the surface at a molecular level removing very fine surface irregularities rather than significant material removal. Superfinishing is less about material removal and more about microstructural manipulation of the surface. Think of fine grinding as sanding wood down to a smooth finish, whereas superfinishing is akin to polishing that same wood to a glass-like sheen. The result is a significantly improved surface quality and reduced friction in applications requiring high precision and exceptional surface smoothness.

Q 28. What are your experience with automated grinding systems and their benefits?

My experience with automated grinding systems is extensive, and I’ve witnessed firsthand their numerous benefits. Automated systems enhance productivity dramatically through increased throughput, reduced labor costs, and improved consistency. CNC-controlled machines, equipped with automatic workpiece loading and unloading systems, can operate continuously with minimal human intervention, boosting production rates significantly. This is particularly crucial in high-volume manufacturing applications. Furthermore, automated systems often incorporate advanced sensors and control algorithms, leading to better process control and reduced variability. This results in a consistent level of surface quality and dimensional accuracy that is difficult to achieve manually. For example, in a recent project involving the automated grinding of cylindrical parts, we achieved a 25% increase in production efficiency and a 15% reduction in surface roughness compared to the previous manual process. The consistency ensured that we eliminated the variability present in manual processes and reduced our defect rate. The automated system also enabled us to utilize more sophisticated adaptive control strategies to precisely tailor the grinding process to each workpiece.

Key Topics to Learn for Grinding and Polishing Blanks Interview

- Material Science Fundamentals: Understanding the properties of various materials (metals, ceramics, plastics) used in blanks and how these properties influence grinding and polishing techniques.

- Grinding Processes: Familiarize yourself with different grinding methods (e.g., centerless grinding, surface grinding, cylindrical grinding), their applications, and the selection criteria for each.

- Abrasive Selection: Learn about various abrasives (e.g., diamond, CBN, silicon carbide), their characteristics, and how to choose the appropriate abrasive for different materials and desired surface finishes.

- Polishing Techniques: Explore different polishing methods (e.g., vibratory polishing, lapping, buffing), their advantages and disadvantages, and how to achieve specific surface finishes.

- Process Parameters: Understand the impact of various parameters like speed, feed rate, depth of cut, and coolant selection on the grinding and polishing process.

- Quality Control and Measurement: Learn about surface roughness measurement techniques (e.g., profilometry, optical microscopy) and the importance of quality control in ensuring consistent results.

- Troubleshooting and Problem-Solving: Develop your ability to identify and solve common problems encountered during grinding and polishing, such as chatter, burning, and surface defects.

- Safety Procedures: Understand and be prepared to discuss the essential safety precautions and regulations related to grinding and polishing operations.

- Automation and CNC Technology: Familiarize yourself with the role of automation and CNC machines in modern grinding and polishing processes.

- Dimensional Tolerances and Specifications: Understand the importance of meeting precise dimensional tolerances and specifications in the finished blanks.

Next Steps

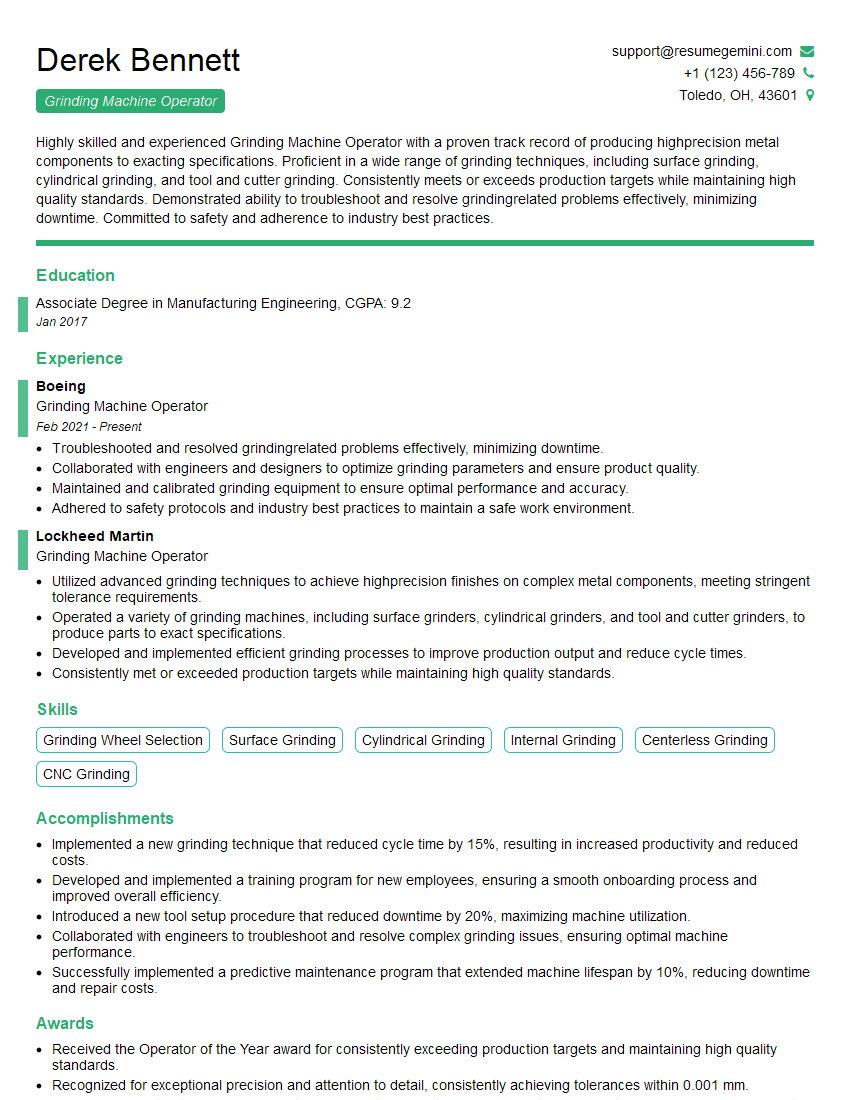

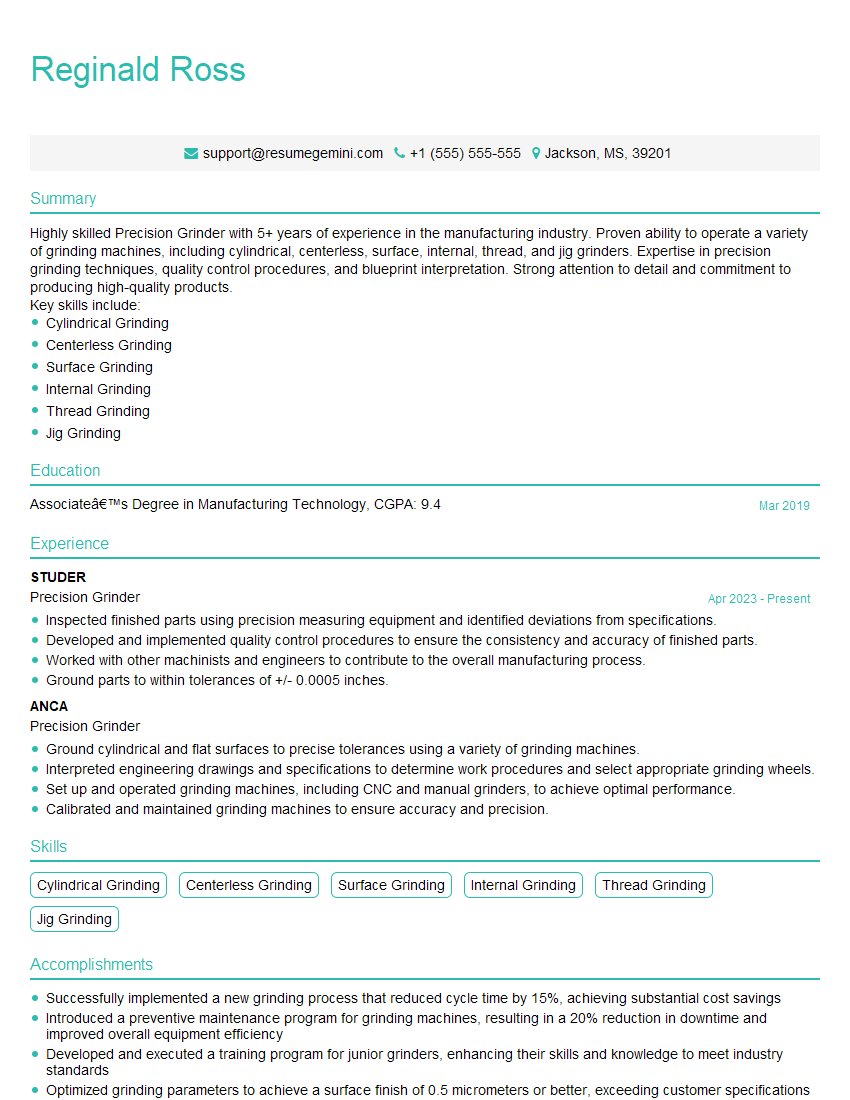

Mastering grinding and polishing blanks opens doors to exciting career opportunities in manufacturing, engineering, and precision machining. To maximize your job prospects, invest time in creating a strong, ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and effective resume. Examples of resumes tailored to the grinding and polishing blanks industry are available to guide you. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good