The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Grip and Electric Equipment interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Grip and Electric Equipment Interview

Q 1. Explain the difference between a best boy grip and a key grip.

On a film set, both the Best Boy Grip and the Key Grip are crucial for managing the grip department, but their roles differ significantly. Think of it like an orchestra: the Key Grip is the conductor, setting the overall vision for rigging and grip equipment, while the Best Boy Grip is the first assistant conductor, ensuring everything runs smoothly and efficiently.

The Key Grip is the head of the grip department, responsible for the overall safety and functionality of all rigging and camera support. They work closely with the Director of Photography (DP) to design and execute complex camera moves and shots. They’re involved in pre-production planning, overseeing the grip crew, and troubleshooting on-set problems.

The Best Boy Grip is the Key Grip’s right-hand person. They manage the day-to-day operations of the grip department, overseeing equipment inventory, scheduling, and crew coordination. They often handle more of the hands-on aspects of rigging and problem-solving, freeing the Key Grip to focus on the bigger picture.

For example, the Key Grip might design the rigging for a complex crane shot, while the Best Boy Grip would supervise the crew setting it up and ensure all safety protocols are followed.

Q 2. Describe the process of rigging a camera for a complex shot.

Rigging a camera for a complex shot is a collaborative process that begins long before shooting. It involves careful planning, meticulous execution, and a strong understanding of safety protocols. Let’s say we need to rig a camera for a sweeping crane shot across a vast landscape.

- Planning & Pre-visualization: The DP and Key Grip discuss the shot’s requirements – camera movement, framing, speed, etc. They may use storyboards or pre-visualization software to plan the shot’s path.

- Equipment Selection: Based on the shot’s needs, they select appropriate equipment – a crane, jib arm, steadicam, or a combination. Factors like weight capacity, reach, and maneuverability are considered.

- Rigging: The grip crew, under the Best Boy’s supervision, assembles the chosen equipment, ensuring it’s stable and secure. This often involves attaching counterweights, using sandbags for stability, and carefully positioning the camera and lens.

- Testing & Adjustments: Before shooting commences, test runs are done to ensure smooth operation and accurate framing. Adjustments are made to counterweight distribution, camera position, and crane movement to achieve the desired effect.

- Safety Checks: Throughout the rigging process, rigorous safety checks are conducted. This includes ensuring all equipment is properly secured, weight limits are not exceeded, and the set is clear of any hazards.

For instance, a complex dolly track might require precise leveling and securing to the ground, along with safety measures to prevent accidental derailment.

Q 3. What are the safety procedures for working with high-voltage equipment?

Safety is paramount when working with high-voltage equipment. There’s no room for complacency. Before even touching anything, always assume the equipment is energized. The following are crucial safety procedures:

- Lockout/Tagout (LOTO): This is a critical procedure to prevent accidental energization. Before working on any high-voltage equipment, the power must be completely shut off and locked out using designated safety locks and tags, with multiple crew members involved in the verification process.

- Personal Protective Equipment (PPE): Appropriate PPE is essential, including insulated gloves, safety glasses, arc flash suits (depending on voltage), and safety shoes.

- Grounding: Equipment should be properly grounded to prevent electrical shock. This might involve connecting a grounding cable to the equipment casing.

- Testing for Voltage: Before touching any equipment, use a non-contact voltage tester to verify the absence of voltage. Even after lockout/tagout, this is a crucial double-check.

- Emergency Procedures: Every crew member should be familiar with emergency procedures in case of an electrical shock or other incident, including knowing the location of first-aid equipment and emergency contact numbers.

- Training & Competence: Only trained and authorized personnel should work with high-voltage equipment. Regular safety training and competency assessments are vital.

Ignoring these procedures can lead to severe injury or even fatality. A simple oversight can have devastating consequences.

Q 4. How do you troubleshoot a malfunctioning lighting fixture on set?

Troubleshooting a malfunctioning lighting fixture is a systematic process. First, assess the situation: Is the light completely out, flickering, or emitting an unusual sound? The following is a step-by-step approach:

- Check Power Source: Start by ensuring the light is plugged in securely and the power switch is on. Check the circuit breaker to see if it’s tripped. If a dimmer is used, check its functionality.

- Examine Bulbs/Lamps: If using replaceable bulbs, check for a blown bulb. This often requires switching off and waiting before replacing bulbs to ensure safety.

- Inspect Wiring and Connections: Carefully examine all wiring and connections for loose wires, damage, or corrosion. Ensure all connections are tight and secure. This might involve checking both within the fixture and at the power source.

- Test with Known Good Equipment: If possible, try swapping out the fixture with another known working fixture to rule out issues with the fixture itself versus the power source or wiring.

- Call an Electrician: If the issue persists after these steps, it’s best to call a qualified electrician. Working with electricity can be dangerous, and it’s important to prioritize safety.

For instance, a flickering light might indicate a loose connection or a problem with the dimmer, requiring specific checks in those areas.

Q 5. What are the different types of grip equipment used for camera support?

A wide array of grip equipment is used for camera support, each serving a unique purpose. This equipment ensures stability, movement control, and safe camera operation:

- Tripods: The most basic support, offering stability for stationary shots.

- Dollies: Allow for smooth, controlled camera movement along tracks.

- Crane: Provides elevated shots and allows for dynamic, sweeping camera moves.

- Jib Arm: Similar to a crane but typically smaller and more portable.

- Steadicam: A body-mounted system for smooth, handheld shots, minimizing shake and allowing for fluid movement.

- Heads & Mounts: These connect the camera to the support system, allowing for precise panning, tilting, and focusing.

- Sandbags & Weights: Used to increase stability and prevent equipment from tipping over, especially crucial for larger, heavier equipment like cranes and jibs.

The choice of equipment depends heavily on the specific shot and its requirements. A low-budget short film might rely on tripods, while a big-budget feature could use complex crane systems and robotic heads.

Q 6. Explain your experience with various types of lighting instruments.

My experience encompasses a wide range of lighting instruments, from traditional tungsten fixtures to modern LED and HMI lighting.

- Tungsten lights (incandescent): These provide a warm, familiar light, but are energy-intensive and generate significant heat. I’ve used them extensively for creating a classic, cinematic look in various productions.

- HMI lights (Hydrargyrum Medium-arc iodide): These offer a brighter, daylight-balanced light output, but are also energy-intensive and require special handling due to their high intensity. I’ve used HMIs for outdoor scenes requiring strong, natural-looking daylight.

- LED lights: These are becoming increasingly popular due to their energy efficiency, relatively low heat output, and color temperature adjustability. I’ve found them versatile for both indoor and outdoor use, especially for situations requiring precise color matching or control.

- Fresnel lights: These are very versatile spotlights, adjustable with focus. I have worked with them in countless settings for lighting key actors, highlights, and even background accents.

- Softboxes & Diffusers: These are essential modifiers that soften harsh light, producing a more natural and flattering look. I use these frequently to manage light quality and avoid harsh shadows.

Understanding the characteristics of each lighting type is vital for achieving the desired look and feel, as well as managing energy consumption and safety on set.

Q 7. Describe your experience with different types of rigging hardware.

My experience with rigging hardware includes a comprehensive understanding of the various components needed for safe and effective rigging operations. I’m proficient in using a variety of materials and techniques.

- Steel Cable & Wire Rope: Essential for lifting and supporting heavy equipment. Proper inspection and care for this equipment are crucial, paying close attention to wear and tear.

- Chain: Another strong material used for hoisting and lifting, suitable for different load capacities.

- Carabiners & Shackles: These are critical connecting links that must be properly rated for the load they will carry. The selection and use of carabiners require a solid understanding of the equipment and safety procedures.

- Turnbuckles: Allow for precise adjustment of tension in cables or chains, ensuring proper alignment and stability. I regularly use these for fine-tuning rigging set-ups.

- Ratchets & Winches: Used for precise controlled movement of heavy objects. I’ve used these in situations requiring precise adjustments and smooth movements of rigging.

- Connectors & Fittings: A variety of connectors and fittings are used to secure equipment and maintain safety. I’m adept at selecting the appropriate connector for a specific load and application. Proper use avoids serious mishaps.

Rigging hardware should always be inspected before use, and proper maintenance is paramount for safety. Improper use can have disastrous consequences, therefore knowing strength limits, inspecting for damage and understanding proper connection techniques are key for my work.

Q 8. How do you ensure the safety of yourself and your crew while working with grip and electric equipment?

Safety on set is paramount. It’s not just about following rules; it’s about developing a safety-first mindset. For grip and electric, this means a multi-layered approach. Firstly, we meticulously check all equipment before use, ensuring proper grounding, insulation, and functionality. We use lockout/tagout procedures on electrical panels to prevent accidental energization. This is crucial. Think of it like this: before you drive a car, you check the tires and brakes; we do the same with our equipment. Secondly, we enforce a strict ‘two-person rule’ for many tasks, especially those involving heavy lifts or working at heights. One person operates, the other spots and ensures safety. Thirdly, we conduct regular safety briefings to reinforce safe practices and discuss potential hazards. We cover topics like arc flash safety, proper cable management, and emergency procedures. Finally, we maintain a clean and organized workspace; tripping hazards are a leading cause of accidents. We treat every day like we are responsible for everyone’s safety, and that’s how we should.

Q 9. What are the common causes of electrical hazards on a film set?

Electrical hazards on film sets are unfortunately common, often stemming from a combination of factors. One major cause is damaged or improperly maintained equipment – frayed cables, faulty connectors, or overloaded circuits. Another significant issue is improper grounding, which can lead to dangerous voltage drops. Think of it as a leaky faucet – a small leak might seem harmless, but over time, it causes significant problems, and in this case, those problems are life-threatening. Improper use of extension cords, particularly overloading them or using them in unsuitable conditions, is another frequent hazard. We always ensure that the correct gauge is used for the amperage needed and that they’re in good working condition. Also, working near power lines without proper clearances is incredibly dangerous. And finally, a lack of awareness and training among crew members can contribute to accidents. So, thorough training and regular safety briefings are critical.

Q 10. Describe your experience with power distribution on a film set.

My experience with power distribution encompasses a wide range of projects, from small independent films to large-scale productions. I’m proficient in designing and implementing power distribution systems, considering factors like the total power draw, the number of circuits required, and the distance power needs to travel. I have extensive experience in using power distro boxes, managing different voltages (e.g., 120V, 220V), and ensuring a safe and efficient power supply for all equipment. For example, on a recent project involving numerous high-wattage lighting fixtures, I designed a system with multiple distribution points to minimize voltage drop and ensure consistent power delivery throughout the set. This involved detailed calculations, the selection of appropriate cables and breakers, and rigorous testing to guarantee the safety and reliability of the system. I know how to anticipate potential power surges and build fail-safes into the system to protect the equipment and personnel.

Q 11. How do you calculate the amperage needed for a specific lighting setup?

Calculating the amperage needed for a lighting setup is crucial for safe and efficient power distribution. The first step is to determine the wattage of each lighting fixture. Then, we add up the wattage of all fixtures to get the total wattage of the setup. To calculate the amperage (A), we use the formula: A = W / (V * PF) where ‘W’ is the total wattage, ‘V’ is the voltage (typically 120V or 220V), and ‘PF’ is the power factor (typically around 0.9 for most lighting equipment). For example, if we have a lighting setup with a total wattage of 3600W and a voltage of 120V, and using a PF of 0.9 the amperage required would be: A = 3600W / (120V * 0.9) = 33.33A. We always round up to the nearest whole number and add a safety margin, selecting a circuit breaker and cabling capable of handling at least 40 amps in this instance. Underestimating amperage can lead to overloaded circuits and potential fires, while overestimating ensures safety and prevents damage to equipment.

Q 12. What are your strategies for managing time and resources on a busy set?

Managing time and resources on a busy set requires meticulous planning and effective communication. I use a combination of strategies, including creating detailed shot lists and lighting plots in advance, coordinating with other departments (grip, camera, art), and employing efficient workflows. I always pre-rig equipment whenever possible, meaning preparing and setting up before actual shooting begins. This significantly reduces setup time during filming. Moreover, I prioritize tasks based on their urgency and impact, often using a Kanban-style system to visualize our workflow and manage tasks effectively. Effective communication with the director, cinematographer, and gaffer ensures we stay on schedule and optimize resource utilization. We anticipate potential delays and have contingency plans in place for unforeseen circumstances. Regular check-ins with my crew help identify any potential issues early on and prevent them from escalating. Flexibility is essential – being adaptable and ready to adjust to changing circumstances is a key component of success.

Q 13. Explain your knowledge of different types of lighting gels and their applications.

Lighting gels are crucial for shaping the look and feel of a scene. Different types of gels offer varying color temperatures and saturation. For instance, CTO (Color Temperature Orange) gels are used to warm up tungsten-balanced lighting to match daylight-balanced lighting, while CTB (Color Temperature Blue) gels cool down daylight-balanced lighting to match tungsten. Other gels, like half-CTO or half-CTB provide more subtle color shifts. Then you have color gels that provide a vast array of colors, from vibrant reds and blues to subtle pastels. The application of gels depends entirely on the creative vision for the scene. A film noir scene might utilize deep blues and greens, whereas a sunset might call for warm oranges and reds. Proper use of gels requires attention to color mixing and understanding their effect on the overall color balance of the scene. This is where understanding color theory is key, helping to create specific moods and atmospheres.

Q 14. How do you maintain and care for grip and electric equipment?

Maintaining and caring for grip and electric equipment is essential to ensure its longevity and safety. Regular cleaning and inspection are key. We meticulously clean equipment after each use, removing dirt, debris, and any potential hazards. We carefully inspect cables for damage, looking for frays, cuts, or any signs of wear and tear. Damaged equipment is immediately tagged out of service and repaired or replaced. Proper storage is critical. Equipment is stored in designated areas, protected from moisture, extreme temperatures, and physical damage. We follow manufacturer recommendations for maintenance and servicing, ensuring regular checks of electrical components and mechanical parts. Preventative maintenance, like cleaning contacts and checking for loose connections, goes a long way in preventing failures. Proper documentation is also maintained to track maintenance procedures, repairs, and replacement of equipment. This is all part of our proactive commitment to safety and efficiency.

Q 15. Describe your experience with different types of dollies and tracks.

My experience encompasses a wide range of dollies and tracks, from basic two-wheeled dollies for lightweight cameras to complex motorized systems like the Techno Crane and specialized tracks for smooth, precise camera movements. I’m proficient with various track sizes and configurations, understanding the importance of track curvature and weight capacity for different shot requirements. I’ve worked with both straight tracks for straightforward shots and curved tracks for dynamic movements around obstacles. I am familiar with the intricacies of dolly grip, including precise speed control, maintaining camera level, and collaborating with the camera operator for seamless transitions. For instance, on a recent project, we utilized a Chapman/Miller dolly system on curved tracks to capture a sweeping shot of a character walking through a bustling marketplace, requiring careful coordination between the dolly grip, camera operator, and focus puller to maintain focus and composition throughout the move.

- Two-wheeled dollies: Ideal for lighter setups, offering maneuverability and quick setup.

- Three-wheeled dollies: Provide greater stability and smoother movement, particularly on uneven surfaces.

- Motorized dollies: Allow for precise, repeatable camera movements, controlled remotely or through pre-programmed sequences. This is invaluable for complex shots demanding accuracy.

- Track systems: Offer smooth, controlled camera movement along a predetermined path, minimizing bumps and ensuring consistent speed.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you collaborate effectively with other departments on set (camera, sound, etc.)?

Effective collaboration is paramount on set. My approach centers around proactive communication and a deep understanding of each department’s needs and workflow. Before the shoot, I attend pre-production meetings to coordinate with the camera, sound, and other departments, discussing shot plans, potential challenges, and safety protocols. On set, I maintain open communication channels, ensuring that my grip work doesn’t interfere with sound recordings or camera movement. I regularly check in with the camera operator and sound mixer to confirm that my rigging and dollies are not causing any issues, for example, by generating unwanted vibrations or blocking microphone positioning. For instance, during a recent shoot, I proactively repositioned a lighting stand to avoid it interfering with the boom microphone’s swing arc, preventing a costly and time-consuming reshoot. This proactive approach ensures a smooth and efficient production process.

Q 17. How do you handle unexpected problems or equipment failures on set?

Handling unexpected problems requires quick thinking, resourcefulness, and a methodical approach. My first step is always to assess the situation calmly and identify the problem’s root cause. Then, I quickly explore available solutions, utilizing my knowledge of alternative equipment and techniques. If a piece of equipment fails, I immediately communicate the problem to the relevant department head, proposing alternative solutions and timelines for repair or replacement. If time permits, I collaborate with other crew members to brainstorm solutions – often a simple workaround can resolve a complex problem. In one instance, a crucial grip head unexpectedly malfunctioned mid-shoot. By quickly swapping it with a spare and slightly adjusting the rigging configuration, we minimized downtime and avoided major disruptions. Problem-solving in this fast-paced environment requires a combination of technical expertise, teamwork, and decisive action.

Q 18. What are some common grip techniques used to stabilize a camera?

Stabilizing a camera involves a variety of techniques, depending on the shot and available resources. Common grip techniques include using:

- Tripods: Provides a stable base for static or slow-moving shots. The choice of tripod head (fluid head for smooth pans and tilts, geared head for precise movements) is crucial.

- C-Stands: Versatile supports for lighting and camera accessories, enabling flexible camera positioning.

- Camera dollies and tracks: As discussed earlier, these offer smooth and controlled movements.

- Steadycam or gimbal systems: These sophisticated systems provide exceptional stability during handheld shots, neutralizing unwanted camera movement.

- Sandbags and counterweights: Essential for stabilizing equipment and preventing accidental tipping or movement.

Often, a combination of these techniques is employed to achieve the desired level of stability. For example, a steadycam might be used in conjunction with a jib arm for dynamic, stabilized shots that combine smooth movement with varying heights.

Q 19. What is your experience with rigging heavy equipment?

Rigging heavy equipment is a critical aspect of my work, requiring a thorough understanding of weight distribution, load-bearing capacities, and safety protocols. I am experienced in calculating safe working loads, selecting appropriate rigging hardware (cables, shackles, clamps, etc.), and ensuring proper knot tying and securing techniques. I meticulously inspect all equipment before use, verifying its integrity and functionality. Safety is my paramount concern; I always utilize appropriate safety harnesses and follow established safety procedures. I’ve worked on rigging everything from lighting fixtures weighing several hundred pounds to complex camera systems for aerial shots. For example, I recently worked on a project involving a high-resolution camera system that needed to be rigged from a crane 100ft in the air. The entire rigging process required careful planning, precise calculations, and rigorous safety checks at every stage.

Q 20. What are your knowledge of different types of grip heads and their uses?

Grip heads are essential for attaching camera equipment to stands and other support systems. I’m familiar with a variety of grip heads, including:

- Standard grip heads: Offer basic pan and tilt functionality, suitable for simpler setups.

- Fluid heads: Provide smooth, controlled pan and tilt movements, essential for professional cinematography.

- Geared heads: Allow for precise, repeatable movements, perfect for time-lapses or other shots demanding extreme accuracy.

- Mitchell heads: Robust, heavy-duty heads often used for larger cameras and demanding applications.

- Gimbal heads: Allow for 360-degree rotation, offering greater versatility for capturing complex camera movements.

The choice of grip head depends on the specific requirements of the shot, considering factors like camera weight, desired movement fluidity, and the overall setup’s stability.

Q 21. Explain your knowledge of different types of lighting modifiers.

Lighting modifiers shape and control the quality and direction of light, influencing the overall mood and aesthetic of a scene. My experience encompasses a wide range of lighting modifiers, including:

- Softboxes: Diffuse harsh light, creating softer, more flattering illumination.

- Umbrellas: Similar to softboxes, but generally less expensive and more portable.

- Reflectors: Bounce light back onto the subject, adding fill light and shaping shadows.

- Snoots: Focus light into a narrow beam, ideal for highlighting specific areas.

- Gels: Change the color temperature or tint of the light, adding creative effects or matching different light sources.

- Diffusers: Soften and spread the light, reducing harshness and creating a more even illumination.

Understanding how different modifiers interact with light sources and affect the final image is crucial for creating the desired look. For example, using a softbox with a diffusion material can create a soft, ethereal light, while a snoot can be used to create a dramatic spotlight effect. The choice of modifier depends on the scene’s needs, the desired lighting quality, and the overall aesthetic vision of the director.

Q 22. How familiar are you with various types of power cables and connectors?

My familiarity with power cables and connectors is extensive, encompassing various voltage ratings, amperages, and applications. I’m proficient in identifying and selecting appropriate cables for specific tasks, considering factors like conductor material (copper, aluminum), insulation type (PVC, XLPE, EPR), shielding, and overall cable construction. This includes understanding the implications of different cable constructions on things like flexibility, durability, and resistance to environmental factors.

- Low-voltage cables: These are commonly used for lighting circuits, data communication, and control systems. I have experience with various types like SOOW (Service-Outdoor-Oil-resistant-Weather-resistant), THHN (Thermoplastic High Heat-resistant Nylon), and SJT (Service-Junior-Thermoplastic) cables.

- Medium-voltage cables: Used in larger power distribution systems, these cables require more robust insulation and often include features like metallic shielding for grounding and interference protection. Examples include shielded medium voltage cables, used in power distribution infrastructure, and are often specialized for different operating environments.

- High-voltage cables: These are used in high-power applications such as power transmission lines, and they require meticulous handling and specialized installation procedures. Safety protocols are paramount here, focusing on appropriate safety equipment, procedures, and awareness of potential dangers such as high-voltage arcs.

- Connectors: My experience includes working with a wide range of connectors, from simple twist-on wire connectors to more complex industrial-grade connectors like Anderson Powerpoles, XLR connectors, and various types of heavy-duty industrial plugs and sockets suitable for high amperage requirements. I understand the critical importance of proper connector selection and installation to ensure safe and reliable electrical connections.

For example, on a recent project involving the installation of a large lighting rig, I had to carefully select and install heavy-duty multi-core cables with appropriate connectors to ensure the system could handle the high current demands. This required careful attention to proper grounding and bonding techniques to prevent hazards.

Q 23. What safety measures do you take when working at heights?

Safety is paramount when working at heights. My approach always follows a strict hierarchy of controls, prioritizing elimination or substitution of hazards before resorting to administrative or personal protective equipment (PPE) controls.

- Planning and Risk Assessment: Before commencing any work, a thorough risk assessment is conducted to identify all potential hazards, such as falls, electrical hazards, and equipment failures. This assessment dictates the specific safety measures required.

- Fall Protection: This is the cornerstone of height safety. This includes using appropriate fall arrest systems, such as harnesses, anchor points, and lanyards, ensuring they are properly inspected and rated for the task and the worker’s weight. We never rely solely on guardrails, preferring comprehensive fall protection systems.

- Access Equipment: When using ladders or scaffolding, we meticulously ensure they are stable, properly secured, and fit for purpose. The equipment’s weight rating, appropriate use and conditions for safe deployment are always checked prior to commencing operations.

- Electrical Safety: When working near energized equipment, lockout/tagout procedures are strictly enforced. Live-line work is avoided whenever possible; otherwise, only trained and qualified personnel use appropriate insulated tools and PPE.

- Communication: Clear and consistent communication is crucial amongst team members. Designated spotters and communication protocols are employed to minimize risks.

For instance, during a recent outdoor event, we erected a substantial lighting structure. We used a comprehensive fall protection system including a designated anchor point for each worker, routinely inspected harnesses and lanyards, and employed spotters at all times. This ensured that the crew maintained a high level of safety while working at heights.

Q 24. Describe your experience working with generators and power distribution.

I possess extensive experience with generators and power distribution, covering various aspects from initial setup and commissioning to troubleshooting and maintenance. My experience ranges from small, portable generators to large, industrial-scale systems.

- Generator operation and maintenance: I’m skilled in safely operating and maintaining various generator types, including diesel, gasoline, and natural gas generators. This involves regular inspections, fuel management, load balancing, and preventive maintenance.

- Power distribution systems: I have hands-on experience with designing and implementing power distribution systems, including the selection of appropriate transformers, circuit breakers, and protective devices. This involves an understanding of power factor correction, load calculations, and proper grounding practices.

- Troubleshooting: I have successfully resolved a wide range of generator and power distribution issues, from minor electrical faults to major system failures. My problem-solving approach is systematic, using diagnostic tools and procedures to identify the root cause and implement the most effective solution.

- Safety compliance: I am fully aware of all relevant safety regulations and standards associated with the operation of generators and power distribution systems. This includes ensuring proper grounding, using appropriate PPE, and enforcing lockout/tagout procedures for safe access to equipment.

For example, during a large-scale outdoor concert, we experienced a sudden power outage. I quickly diagnosed the problem as a tripped circuit breaker in the main power distribution panel. By safely restoring power to the affected circuit, minimizing downtime and preventing potential damage to equipment and safety to personnel. My swift response prevented a significant disruption to the event.

Q 25. What is your experience with lighting design and execution?

My experience in lighting design and execution spans diverse applications, from small-scale events to large-scale productions. I am comfortable working with both traditional and modern lighting technologies.

- Design: I’m proficient in using lighting design software to create lighting plans that meet the specific needs of the project. This involves considering factors such as ambient light levels, color temperature, light intensity, and desired mood or atmosphere.

- Implementation: I have hands-on experience in installing and configuring lighting fixtures, including LED, HMI, and tungsten lights. This involves understanding the electrical requirements of each fixture, proper wiring techniques, and safety protocols.

- Troubleshooting: I effectively troubleshoot lighting issues, such as blown bulbs, faulty ballasts, and wiring problems. This includes using testing equipment to identify the source of the problem and implementing the necessary repairs.

- Technology familiarity: I’m familiar with various lighting control systems and dimming techniques. This ranges from simple dimmer switches to advanced DMX control systems allowing for sophisticated lighting effects.

In a recent theater production, I was responsible for designing and executing the lighting scheme. I used lighting design software to create detailed plans that ensured that every scene was lit to perfection, enhancing the visual storytelling and immersing the audience in the play. The lighting scheme used both traditional and modern lighting techniques and a DMX controlled system for dynamic scenes.

Q 26. How do you assess risk and implement safety protocols on set?

Risk assessment is a fundamental aspect of my approach. It’s an iterative process involving proactive identification, analysis, and mitigation of hazards. On any set, the process is detailed and follows a clear methodology.

- Hazard identification: A comprehensive walkthrough of the set is performed to identify potential hazards, including electrical hazards, trip hazards, fire hazards, and any environmental hazards.

- Risk assessment: Each identified hazard is assessed based on its likelihood and potential severity. This determines the appropriate control measures.

- Control measures: The appropriate safety protocols are implemented. This might involve implementing engineering controls (e.g., using safer equipment), administrative controls (e.g., work permits, safety training), or personal protective equipment (PPE) controls (e.g., providing appropriate protective clothing and eyewear).

- Communication: Regular safety meetings are conducted to communicate identified hazards, implemented controls, and any necessary changes to procedures. Clear communication protocols are essential.

- Monitoring and review: The effectiveness of the safety protocols is continuously monitored, and adjustments are made as needed. Post-event reviews are vital to identify areas for improvement.

For instance, on a film set, I noticed a potential electrical hazard near a water source. Through risk assessment we decided to relocate the power source and add additional GFCI protection. This proactive approach mitigated the risk of electrocution and ensured the safety of the crew.

Q 27. Describe your experience with troubleshooting electrical issues and repairs.

My experience in troubleshooting electrical issues and repairs is extensive and spans a wide range of scenarios. My systematic troubleshooting approach ensures quick and effective solutions while prioritizing safety.

- Systematic approach: I follow a structured approach involving visual inspection, use of testing equipment (multimeters, insulation testers), and systematic elimination of potential causes.

- Testing equipment proficiency: I’m proficient in using various electrical testing instruments, such as multimeters to measure voltage, current, and resistance, and insulation testers to verify the integrity of insulation.

- Electrical code compliance: All repairs are carried out in strict accordance with relevant electrical codes and safety standards, ensuring the work is both safe and compliant.

- Documentation: Accurate documentation of all repairs and maintenance performed is crucial. This ensures traceability and accountability.

For example, during a live television broadcast, a lighting fixture suddenly malfunctioned. Using my multimeter, I quickly identified a short circuit in the wiring. By carefully isolating the faulty section and making the necessary repairs, we restored the lighting without disrupting the ongoing broadcast. My quick diagnosis and precise repair skills prevented significant delays and ensured the broadcast ran smoothly.

Key Topics to Learn for Grip and Electric Equipment Interview

- Electrical Safety and Regulations: Understanding OSHA standards, lockout/tagout procedures, and safe work practices is paramount. Consider the practical application of these regulations in various workplace scenarios.

- Grip Equipment Mechanics: Explore the principles of leverage, force, and torque as they relate to different types of gripping mechanisms (e.g., clamps, vices, etc.). Understand the limitations and potential failure points of various grip systems.

- Electric Motor Principles: Familiarize yourself with different types of electric motors (AC/DC, synchronous/asynchronous), their operating principles, and applications in industrial settings. Be prepared to discuss motor efficiency and maintenance.

- Power Transmission and Distribution: Grasp the concepts of voltage, current, resistance, and power. Understand how electricity is safely transmitted and distributed within industrial equipment and systems.

- Troubleshooting and Diagnostics: Develop your problem-solving skills by practicing identifying and resolving common issues in grip and electric equipment. This includes understanding diagnostic tools and techniques.

- Hydraulic and Pneumatic Systems (if applicable): If the role involves hydraulic or pneumatic components alongside electric and grip systems, familiarize yourself with their principles and integration.

- Control Systems and Automation: Understand basic PLC (Programmable Logic Controller) programming or other automation systems used to control grip and electric equipment. Practical experience or theoretical knowledge will be beneficial.

- Maintenance and Repair Procedures: Be prepared to discuss preventative maintenance schedules, common repair techniques, and the importance of record-keeping for equipment longevity.

Next Steps

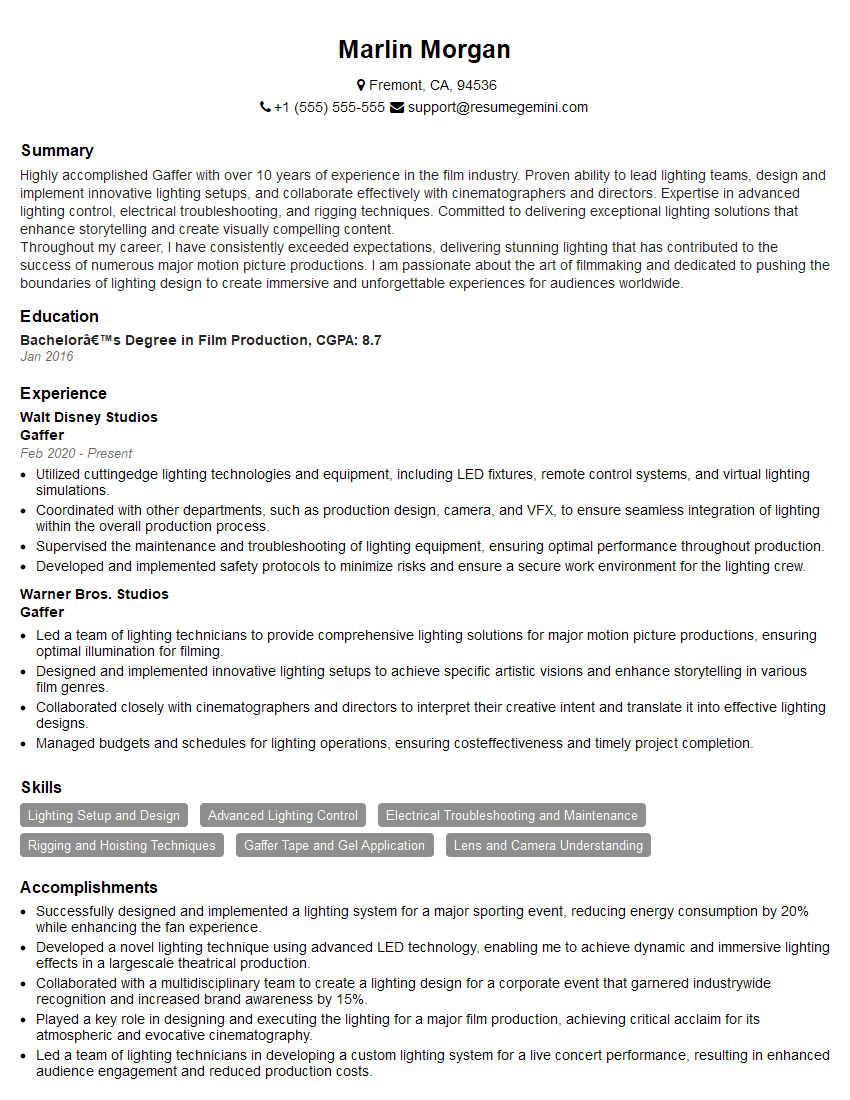

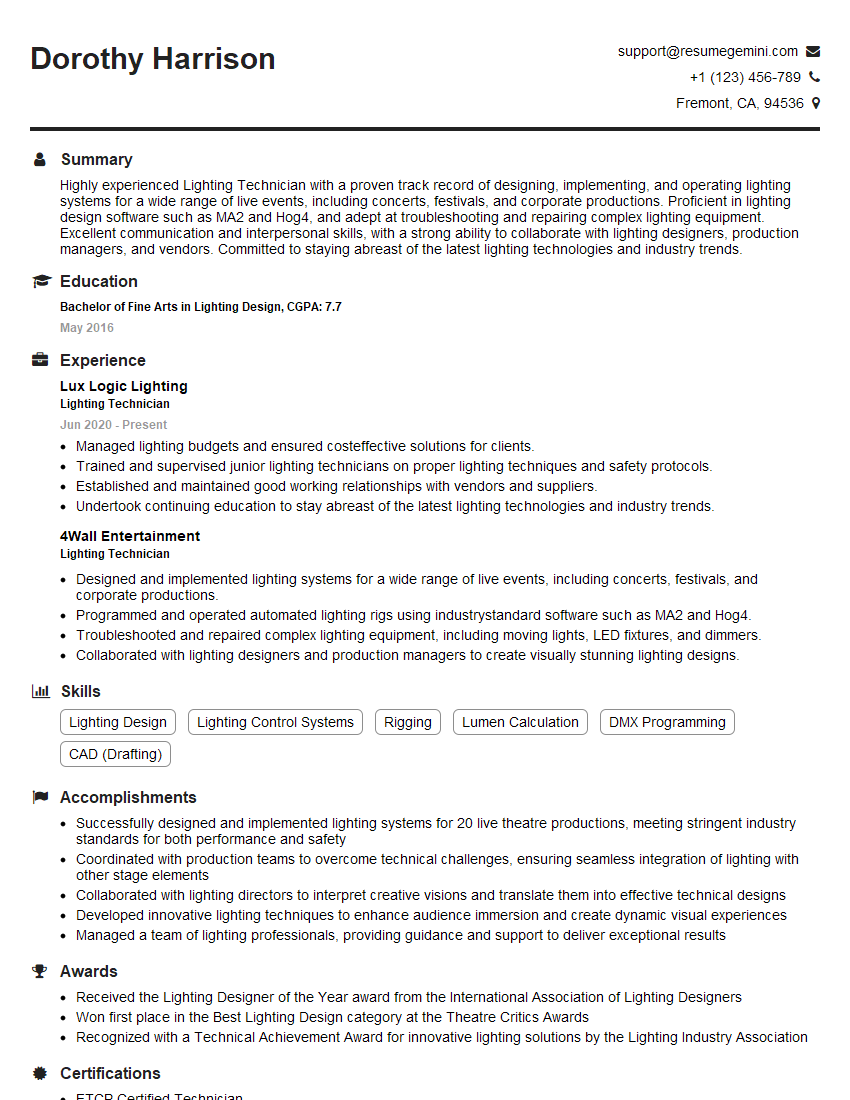

Mastering the principles of grip and electric equipment is crucial for a successful and rewarding career in many industries. A strong understanding of these topics will significantly enhance your job prospects and allow you to contribute effectively from day one. To maximize your chances, crafting a compelling and ATS-friendly resume is essential. We highly recommend using ResumeGemini to build a professional resume that showcases your skills and experience effectively. ResumeGemini provides examples of resumes tailored to the Grip and Electric Equipment industry to help you create a standout application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good