The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Grommet and Hook Installation interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Grommet and Hook Installation Interview

Q 1. Explain the different types of grommets and their applications.

Grommets are reinforcing rings or washers inserted into holes to prevent fraying or tearing and provide a clean, finished look. Different types cater to specific needs.

- Metal Grommets: These are durable and commonly used for heavy-duty applications like tarps, banners, and industrial fabrics. They come in various metals like brass, aluminum, and steel, each offering different levels of corrosion resistance and strength.

- Plastic Grommets: Lighter and less expensive than metal, plastic grommets are suitable for lighter fabrics like canvas, paper, and thin plastics. They are often used in crafts and clothing.

- Eyelet Grommets: These have a loop or eyelet shape, particularly useful for attaching cords, straps, or chains.

- Snap-in Grommets: These are designed for quick and easy installation without the need for specialized tools. Often used in less demanding applications.

The choice depends on the material thickness, expected stress, and aesthetic requirements of the application. For instance, a heavy-duty tarp would need strong metal grommets, while a delicate fabric might only require small plastic ones.

Q 2. Describe the various types of hooks and their suitability for different materials.

Hooks serve various purposes, and their suitability depends on the material they’ll be attached to and the weight they’ll support.

- Screw-in Hooks: These are versatile and easy to install, ideal for wood, drywall, and other materials that can accept screws. They come in various sizes and designs for different load capacities.

- Adhesive Hooks: Convenient for temporary installations or where drilling isn’t an option, but they are only suitable for smooth, clean surfaces and have limited weight capacity. They’re perfect for lightweight items in the home.

- Toggle Bolts: These are strong and suitable for hollow walls, expanding inside the wall cavity for a secure hold. Excellent for heavier items in drywall.

- Eye Hooks: Often used in conjunction with chains or cords, they feature a loop for easy attachment. They can be screwed or welded.

- Rivet Hooks: These are permanently attached using rivets, offering exceptional durability and are often seen in leatherwork or outdoor equipment.

Selecting the right hook requires assessing the material’s strength, the expected load, and the permanence of the installation. A heavy picture frame on a drywall needs a toggle bolt, while a light towel on a tile wall might work with an adhesive hook.

Q 3. What safety precautions should be taken when installing grommets and hooks?

Safety is paramount when working with grommets and hooks. Always:

- Wear safety glasses: To protect your eyes from flying debris during punching or hammering.

- Use the right tools: Employing the correct tools for the job minimizes the risk of injury. Don’t force tools; using the wrong tool can damage materials and potentially cause injury.

- Work in a well-lit area: Good visibility reduces the chances of accidents.

- Be aware of sharp edges: Metal grommets and some hooks have sharp edges; handle them with care.

- Use caution with power tools: Power punches and rivet guns should be operated according to manufacturer instructions. Make sure the work area is clear.

- Proper ventilation: Some materials may release fumes during installation. Ensure adequate ventilation.

Taking these precautions minimizes the risk of injury and ensures a safe working environment.

Q 4. How do you select the appropriate grommet size for a given application?

Grommet size selection depends primarily on the hole size and material thickness.

First, measure the diameter of the hole you’ll be using. The grommet’s inside diameter should be slightly smaller than the hole to create a snug fit. The grommet’s outside diameter will determine the visible size of the grommet on the material.

Next, consider the material thickness. Thicker materials require grommets with a larger flange (the flat part that sits on top of the material) to provide adequate support and prevent tearing. Grommet manufacturers provide specifications that indicate appropriate grommet sizes for various material thicknesses. Always refer to these specifications to ensure proper fit and durability.

Choosing the wrong size can lead to loose grommets that pull out easily or tight grommets that damage the material. A test run on a scrap piece of the same material is always a good idea.

Q 5. What tools are commonly used for grommet and hook installation?

Common tools for grommet and hook installation include:

- Hand Grommet Punch: Used for manually installing grommets.

- Power Grommet Punch: A faster and more efficient option for high-volume installations.

- Hole Punch: To create the initial hole for the grommet.

- Drill and Drill Bits: Used for pre-drilling holes for hooks and other fasteners.

- Screwdriver: For installing screw-in hooks.

- Hammer and Setting Tool: Used for setting rivets in rivet hooks.

- Rivet Gun (optional): Provides a faster and more consistent method for installing rivet hooks.

- Measuring Tape and Ruler: For accurate measurements.

The specific tools you need will vary depending on the type of grommet and hook being installed and the material.

Q 6. Describe the process of installing a grommet using a hand punch.

Installing a grommet with a hand punch is straightforward.

- Prepare the material: Create a hole using a hole punch slightly smaller than the grommet’s inner diameter.

- Place the grommet: Insert the grommet into the hole, ensuring the washer is flat against the material.

- Position the punch: Place the hand punch over the grommet, aligning the die with the grommet.

- Punch the grommet: Firmly and evenly strike the punch with a hammer, driving the grommet through the material. Ensure the grommet is set securely and flush with the surface.

It’s crucial to use even pressure and avoid striking the punch off-center, which can damage the grommet or the material.

Q 7. How do you install a hook using a rivet?

Installing a rivet hook involves securing the hook with a rivet. The process is:

- Prepare the material: Drill a pilot hole that matches the rivet shank diameter.

- Insert the hook: Position the hook into the hole.

- Insert the rivet: Place the rivet through the hook and the material.

- Set the rivet: Use a hammer and a setting tool (or a rivet gun) to deform the rivet’s end, creating a secure bond between the hook and the material. The setting tool ensures even pressure, preventing damage to the rivet or hook.

Ensure the rivet is properly set to avoid the hook coming loose. Too much force can damage the material; too little force will result in a loose rivet.

Q 8. Explain the process of installing a hook into a wooden surface.

Installing a hook into wood depends on the hook type and the wood’s density. For lighter hooks and softer woods, a simple screw might suffice. For heavier hooks or harder woods, a pilot hole is crucial to prevent splitting.

- Step 1: Choose the right hook and screw. Select a hook with a screw appropriate for the wood’s thickness and the intended weight.

- Step 2: Mark the location. Use a pencil to mark the desired hook position.

- Step 3: (Optional) Drill a pilot hole. For harder woods or heavier hooks, pre-drilling a pilot hole slightly smaller than the screw diameter prevents splitting. The depth should be slightly less than the screw’s length.

- Step 4: Insert and secure the hook. Position the hook and gently screw it in. Avoid over-tightening, which can strip the wood.

Example: Installing a coat hook in a pine door. A small pilot hole is recommended to prevent splitting, using a screw approximately 1 inch in length.

Q 9. How do you install a hook into a metal surface?

Installing hooks into metal surfaces requires different techniques depending on the metal’s thickness and type. For thin metals, you might use self-tapping screws. For thicker metals or those prone to damage, you might need a drill and appropriate fasteners.

- Step 1: Assess the metal. Determine the metal’s thickness and material. Is it sheet metal, steel, or aluminum? This will dictate your fastener choice.

- Step 2: Choose appropriate fasteners. Self-tapping screws are ideal for thinner metals. For thicker metals, consider using machine screws with nuts and washers for better security. For softer metals like aluminum, you may need to use a specialized screw to prevent stripping.

- Step 3: (Optional) Pre-drill a pilot hole. Pre-drilling is especially important for harder metals to prevent damage. Use a drill bit slightly smaller than the screw diameter.

- Step 4: Install the hook. Securely fasten the hook using the chosen fasteners. For machine screws, use a wrench to tighten the nuts.

Example: Installing a heavy-duty hook on a steel garage door. A pilot hole and machine screws with appropriate washers and nuts would ensure a secure and damage-free installation.

Q 10. What are the common problems encountered during grommet and hook installation?

Common problems during grommet and hook installation include:

- Stripped threads: Over-tightening screws, especially in softer woods or metals, can easily strip the threads, rendering the fastener useless.

- Splitting wood: Failing to pre-drill a pilot hole in harder woods when installing hooks can lead to the wood splitting.

- Loose grommets: Incorrectly sized grommets can lead to a loose fit, potentially damaging the material or creating a snag hazard.

- Difficult insertion of grommets: Using improper tools or applying excessive force when inserting grommets can damage the material around the grommet hole.

- Incorrect grommet placement: Not centering the grommet or misaligning it with the hole before securing it.

These problems often stem from not properly assessing the materials or choosing the wrong tools and fasteners.

Q 11. How do you troubleshoot a grommet that is too loose or too tight?

Troubleshooting loose or tight grommets involves addressing the fit and the installation method.

- Too loose: If the grommet is loose, try using a grommet with a slightly larger outer diameter or a grommet specifically designed for thicker materials. You might also need to use a grommet setting tool to properly seat the grommet. In some cases, a slightly larger hole in the material may need to be made.

- Too tight: If the grommet is too tight, try using a grommet with a smaller outer diameter. You may have also used the wrong type of grommet, so check the material specifications. If the hole is too small, you might need to carefully enlarge it using a slightly larger hole punch or drill bit, ensuring a clean cut.

Remember to always use the appropriate tools and techniques to avoid damaging the material.

Q 12. How do you troubleshoot a hook that is not securely installed?

A hook that is not securely installed usually indicates a problem with the fastener or the installation method.

- Check the fastener: Ensure the screw or other fastener is appropriate for the material and the weight it needs to support. A bent or damaged fastener needs to be replaced.

- Re-evaluate the installation: If the hook is loose, it might be necessary to remove it, clean the hole of any debris or damaged material, and reinstall using a new fastener and potentially a pilot hole.

- Consider stronger fasteners: If the hook is still not secure even with a new fastener and a pilot hole, consider using stronger fasteners like toggle bolts for hollow materials or expansion anchors for concrete or brick.

Always prioritize safety; a poorly installed hook can be dangerous.

Q 13. What are the different types of materials used for grommets and hooks?

Grommets and hooks are made from a wide range of materials, depending on their intended use and environment.

- Grommets: Common grommet materials include metal (brass, steel, aluminum), plastic (nylon, polyethylene), and rubber. The choice depends on factors like durability, corrosion resistance, and the material being reinforced.

- Hooks: Hook materials include metal (steel, aluminum, brass), plastic, and even wood. Metal hooks are common for heavier applications, while plastic hooks are suitable for lighter loads and specific applications.

The selection of the material is crucial for longevity, strength and aesthetic appeal.

Q 14. What is the difference between eyelets and grommets?

While both eyelets and grommets reinforce holes, they differ in design and application.

- Eyelets: Generally smaller and are typically inserted into a pre-punched hole, creating a reinforced edge without a protruding flange. They often provide a cleaner, more subtle reinforcement.

- Grommets: Typically larger and feature a prominent flange which sits on the surface of the material. This flange provides a larger surface area for reinforcement and helps prevent fraying. They often have a more prominent, decorative appearance.

The choice between an eyelet and a grommet depends on the desired level of reinforcement, aesthetics, and the material’s thickness.

Q 15. How do you ensure the longevity of grommets and hooks?

Ensuring the longevity of grommets and hooks hinges on selecting the right materials and employing proper installation techniques. Think of it like building a house – you wouldn’t use cheap materials or shoddy workmanship, would you?

For grommets, high-quality metal grommets (brass or stainless steel) are far more durable than plastic alternatives, especially in harsh environments or with frequent use. Proper sizing is crucial; too small a grommet for the fabric will cause it to tear, while too large will lead to looseness and potential failure.

With hooks, the strength of the hook material and the securing method are key. Heavy-duty hooks made from sturdy metals like steel are far more reliable than lighter alternatives. The method of attaching the hook (e.g., riveting, screwing, welding) directly impacts longevity. Properly installed hooks will provide years of dependable service.

Regular inspection is also essential. Check for signs of wear and tear, such as corrosion, bending, or fabric fraying around grommets and hooks, and replace components as needed to prevent premature failure.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the industry standards for grommet and hook installation?

Industry standards for grommet and hook installation vary slightly depending on the application (e.g., banners, awnings, clothing), but several common threads exist. Safety is paramount. Proper personal protective equipment (PPE), such as safety glasses and gloves, is essential to prevent injuries.

Consistent installation is crucial, particularly in high-volume settings. This often involves using specialized tools to ensure uniform grommet placement and secure hook attachments. Quality control is key – regular inspections during the process help identify and correct defects early on.

Documentation is also important. Detailed procedures and checklists minimize errors and ensure consistent results. Finally, adherence to relevant safety regulations and building codes is non-negotiable, especially when working on large-scale projects.

Q 17. Describe your experience with different types of grommet and hook installation tools.

My experience encompasses a wide range of grommet and hook installation tools, from hand-operated punches for smaller jobs to automated machines used in industrial settings.

Hand-operated grommet setting tools are great for smaller projects and provide excellent control, allowing for precise placement. They consist of a die, a punch, and a setting anvil. You place the fabric over the die, insert the grommet, then use the punch to set it firmly.

For larger-scale projects, pneumatic and hydraulic grommet machines offer significant speed and efficiency advantages. These power tools handle high volumes quickly, ensuring consistent quality. Similarly, specialized hook-setting tools, such as rivet guns, speed up the installation process and ensure a strong, lasting bond.

I’m also proficient with various tools for different hook types, including screw guns for screw-in hooks, welding equipment for heavy-duty applications, and specialized tools for snap hooks.

Q 18. How do you determine the appropriate type of grommet for different fabrics or materials?

Choosing the right grommet depends heavily on the fabric’s weight, thickness, and material. Think of it as choosing the right screw for the right wood – using the wrong one will lead to problems.

For lightweight fabrics like cotton or polyester, smaller grommets with a thinner washer will suffice. Heavier materials like canvas or vinyl require larger, more robust grommets with thicker washers to prevent tearing.

The material of the grommet also matters. Brass grommets offer corrosion resistance and a classic look, while stainless steel offers superior strength and durability in harsher conditions. The color of the grommet should also be considered to match the fabric aesthetically.

I always consult specifications sheets or material data sheets to ensure proper grommet selection, preventing costly mistakes down the line.

Q 19. What are some common mistakes to avoid when installing grommets and hooks?

Several common mistakes can significantly impact the longevity and effectiveness of grommet and hook installations.

- Incorrect grommet size: Using grommets too small for the fabric will cause tears; those too large will be loose and ineffective.

- Uneven grommet placement: Inconsistent spacing can create a messy and unprofessional look.

- Improper tool usage: Using the wrong tool or applying excessive force can damage the fabric or the grommet itself.

- Insufficient hook security: Improperly fastened hooks can easily pull out, leading to failure.

- Neglecting fabric preparation: Not properly cleaning or preparing the fabric before installation can compromise the strength of the bond.

Careful planning, proper tool selection, and attention to detail are crucial to avoid these issues. A bit of extra care at the beginning saves a lot of time and frustration later.

Q 20. Explain your experience with installing grommets and hooks in high-volume production settings.

I’ve extensive experience in high-volume grommet and hook installation settings, primarily within the banner and awning manufacturing industries.

This involved working with automated machinery, optimizing workflows for maximum efficiency, and implementing quality control measures to maintain consistent standards across large production runs.

In these environments, the focus shifts from individual skill to process optimization. This includes things like optimizing tool placement, implementing standardized procedures, and ensuring proper training of personnel. Lean manufacturing principles play a crucial role, reducing waste and maximizing throughput.

I’ve successfully managed projects involving thousands of grommets and hooks, meeting tight deadlines while maintaining the highest quality standards.

Q 21. How do you manage your time effectively during grommet and hook installation projects?

Effective time management during grommet and hook installation projects relies on careful planning and efficient execution.

I always begin by breaking down the project into smaller, manageable tasks. This includes estimating the time required for each step, such as fabric preparation, grommet placement, and quality control.

Prioritizing tasks based on urgency and importance ensures that crucial steps are completed on time. Using checklists and visual aids helps keep the team on track and reduces the risk of overlooking critical steps. Regular communication with the team and stakeholders ensures that everyone remains informed and any potential issues are addressed promptly.

Maintaining a clean and organized workspace improves efficiency and reduces the likelihood of errors. Finally, continuous improvement practices help identify bottlenecks and refine processes for better time management in future projects.

Q 22. Describe a time you had to troubleshoot a challenging grommet or hook installation problem.

One particularly challenging installation involved a large banner requiring hundreds of grommets in a precise grid pattern. The material was a thick, heavy-duty vinyl that proved difficult to punch through cleanly with our standard grommet machine. The initial attempts resulted in torn material around several grommets.

To troubleshoot, I first experimented with different grommet sizes and settings on the machine. I found that a slightly larger grommet size with a lower pressure setting created a cleaner hole without tearing the vinyl. Next, I created a template with precisely measured grid markings to ensure consistent spacing. Finally, I used a backing board underneath the vinyl to provide extra support during the punching process. By systematically addressing each potential issue, we successfully completed the installation without further damage.

This experience highlighted the importance of understanding material properties and adjusting techniques accordingly. A one-size-fits-all approach doesn’t always work, and adaptability is key to successful grommet installation.

Q 23. How do you ensure the quality of your grommet and hook installations?

Quality control in grommet and hook installations begins with careful preparation. This involves selecting the right tools and fasteners for the specific material and application. For example, using the wrong size grommet or the wrong type of hook could lead to damage or failure. It is important to always check the material’s thickness and composition before choosing your tooling.

During installation, I meticulously inspect each grommet or hook to ensure it’s properly seated and secure. Visual checks are essential for detecting any misalignments, loose connections, or material damage. I also periodically test the strength of the installed fasteners, especially in high-stress applications.

Post-installation, a final thorough inspection is performed, checking for any defects or potential issues. Accurate record-keeping of materials and techniques used is crucial for future reference and quality assurance.

Q 24. How familiar are you with different types of fastening systems?

My familiarity with fastening systems extends beyond grommets and hooks. I have extensive experience with various types, including:

- Rivets: Solid and tubular rivets, used for permanent fastening in applications requiring high strength.

- Snaps and Fasteners: Pressure snaps, magnetic snaps, and zippers, useful for temporary or easily removable connections.

- Velcro: A versatile fastening system ideal for quick and reusable attachments.

- Sewing: Traditional stitching, using various threads and needles, for strong and durable connections, especially for textiles.

- Adhesives: Various types of glues and tapes, ranging from instant-bonding cyanoacrylates to stronger epoxies depending on the material and needed strength.

Understanding the strengths and limitations of each system allows me to recommend the most appropriate option for a given project, ensuring both functionality and durability.

Q 25. What is your experience with automated grommet and hook installation equipment?

I have significant experience operating automated grommet and hook installation equipment, including both pneumatic and electric-powered machines. My experience encompasses troubleshooting these machines, performing routine maintenance (like cleaning and lubrication), and understanding the settings required for different materials and grommet/hook types.

For instance, I’ve worked with machines capable of placing thousands of grommets an hour with high precision. Using these machines requires a thorough understanding of their operation and safety protocols, from setting the correct pressure and depth to ensuring proper material alignment. I’m also proficient in programming and adjusting settings on computerized machines to accommodate various material thicknesses and grommet styles. This automated approach significantly improves speed and consistency in large-scale projects.

Q 26. How do you maintain your tools and equipment to ensure efficient operation?

Maintaining tools and equipment is crucial for efficient and safe operation. My routine involves regular cleaning, lubrication, and inspection of all tools. This includes checking for wear and tear, damaged parts, and ensuring all moving parts function smoothly. I keep a detailed log of maintenance performed on each piece of equipment.

For example, I clean and lubricate pneumatic tools regularly to prevent rust and ensure consistent air pressure. I also frequently inspect grommet dies for sharpness and wear, replacing them as needed to prevent damage to the material. Proper tool maintenance extends the lifespan of the equipment and minimizes downtime caused by unexpected failures.

Q 27. How do you adhere to workplace safety regulations during installation?

Workplace safety is paramount. I strictly adhere to all relevant safety regulations, including the use of appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection, as needed. I understand and follow all lockout/tagout procedures when working with machinery.

Before starting any installation, I ensure the work area is clear of obstacles and properly illuminated. I always keep a tidy workspace to minimize the risk of accidents. If working at heights, I use appropriate fall protection equipment. My commitment to safety not only protects me but also ensures the safety of my colleagues.

Q 28. Describe your experience working in a team environment during installation projects.

I thrive in team environments. Effective teamwork during installations requires clear communication, task delegation, and mutual respect. I actively participate in planning sessions, contributing ideas and insights to optimize workflows. I believe in open communication among team members to solve challenges collaboratively.

On a recent large-scale project, we worked as a coordinated team. One member focused on material preparation and measurement, another on operating the automated grommet machine, and I handled quality control and final inspection. This division of labor allowed for increased efficiency and ensured a flawless final product. Successfully completing the project together was very rewarding.

Key Topics to Learn for Grommet and Hook Installation Interview

- Understanding Grommet: Grasp the core concepts of Grommet’s design system, including its component library, accessibility features, and responsive design principles. Explore the benefits of using Grommet for building user interfaces.

- Grommet Installation Methods: Become proficient in various Grommet installation techniques, including using npm or yarn package managers. Understand how to configure Grommet within different project setups (e.g., React, Vue, standalone).

- Working with Grommet Components: Gain hands-on experience using key Grommet components such as Buttons, Forms, Grid, and Charts. Practice implementing these components to build functional and visually appealing interfaces.

- Understanding Hooks in React (if applicable): If the role involves React, deeply understand React Hooks (useState, useEffect, useContext, etc.) and how they integrate with Grommet components to manage application state and side effects.

- Styling with Grommet: Master Grommet’s styling capabilities, including theme customization, theming options, and applying custom CSS. Understand how to create visually consistent and branded user interfaces.

- Troubleshooting and Debugging: Develop your problem-solving skills by tackling common issues during Grommet and Hook installation and usage. Practice debugging techniques to efficiently resolve errors.

- Accessibility Considerations: Understand Grommet’s built-in accessibility features and how to ensure your applications are inclusive and accessible to users with disabilities.

- Performance Optimization: Explore techniques to optimize the performance of your Grommet applications, focusing on efficient rendering and minimizing unnecessary re-renders (especially relevant when using Hooks).

Next Steps

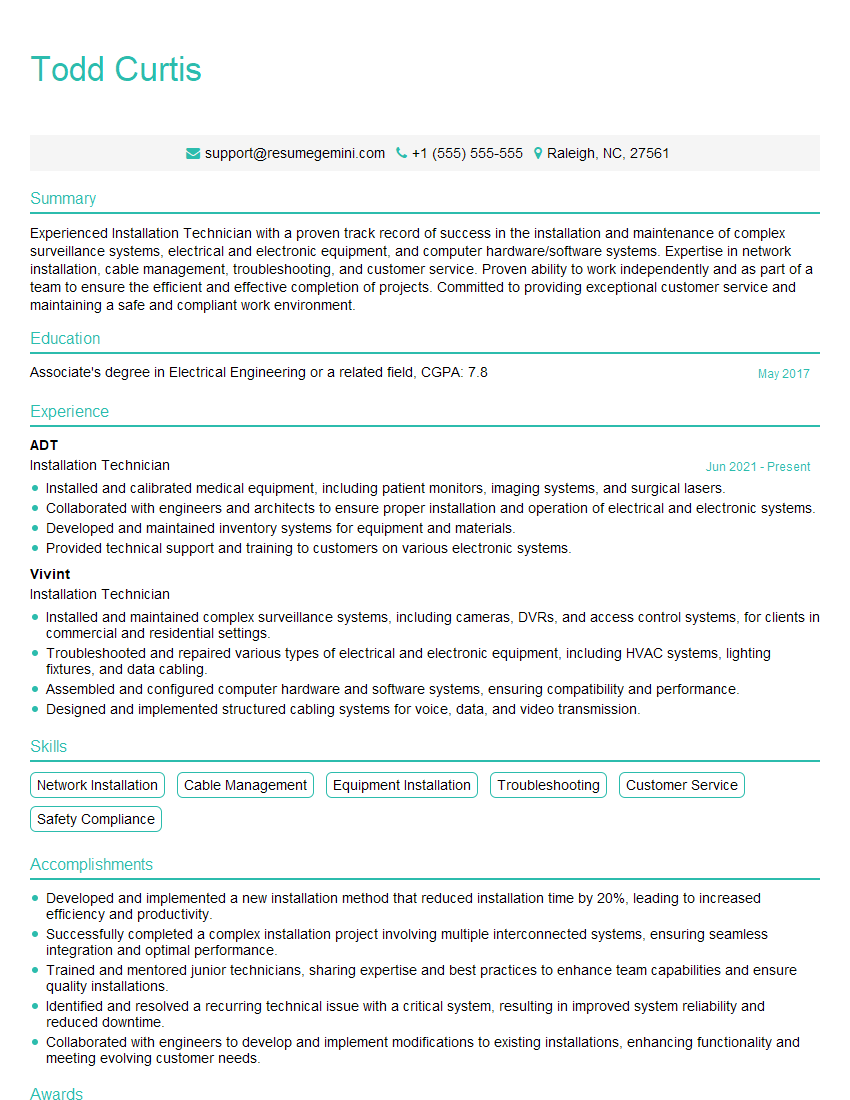

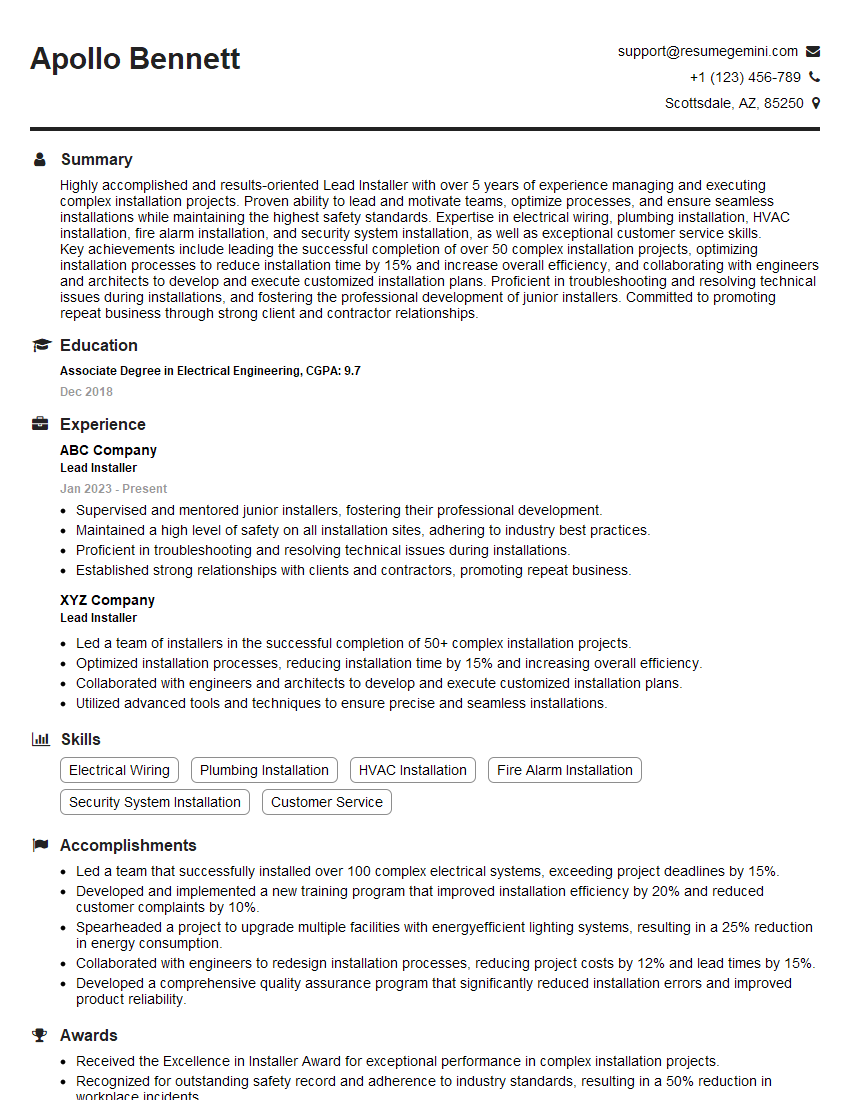

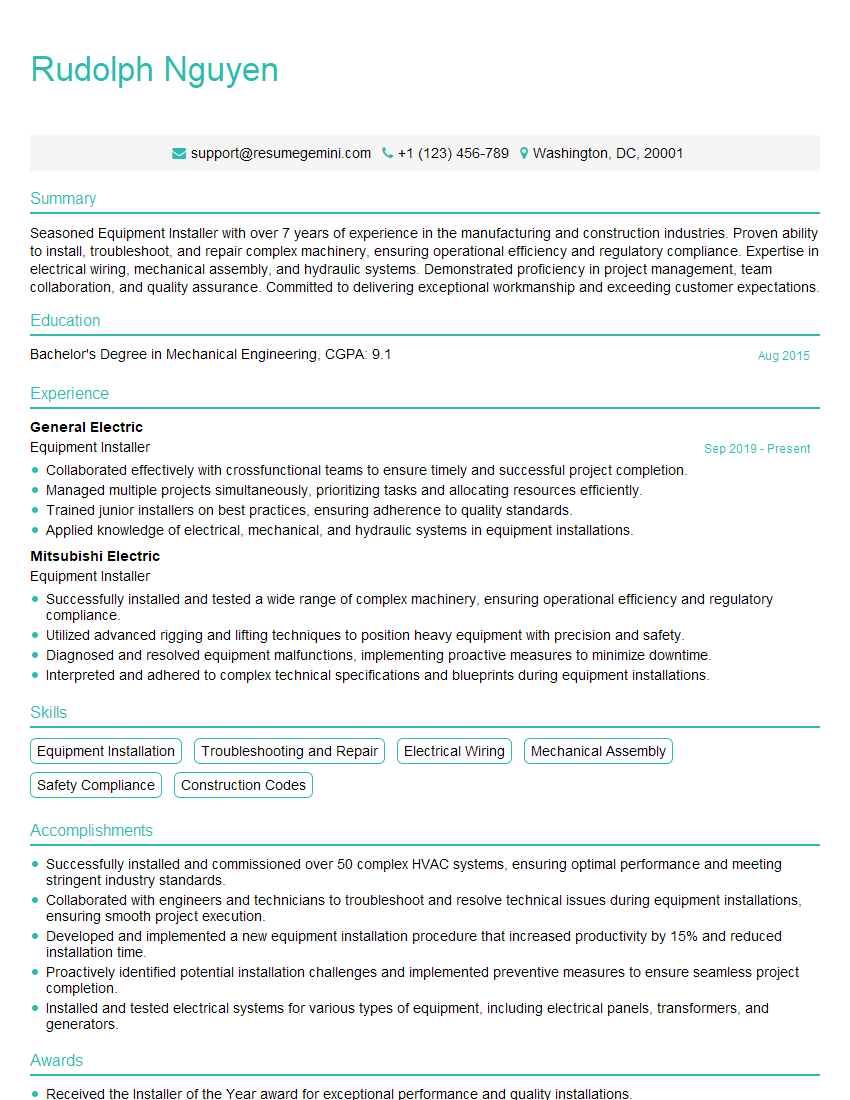

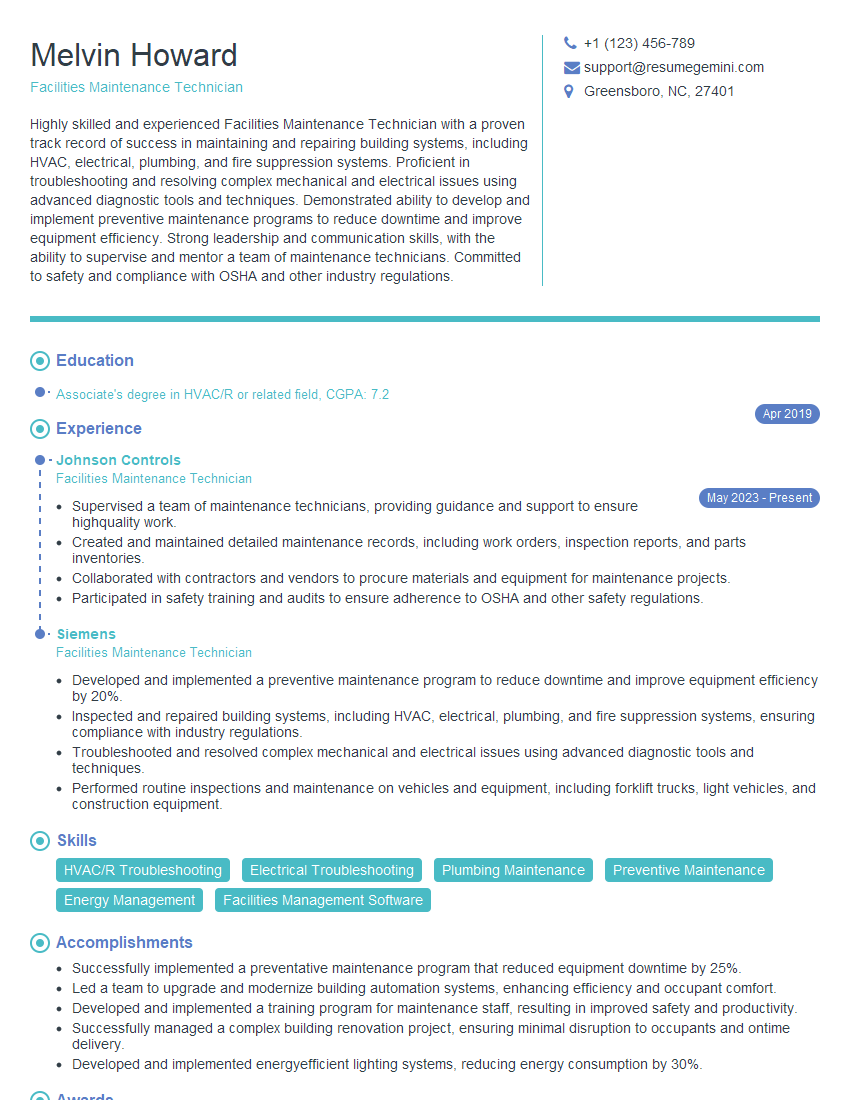

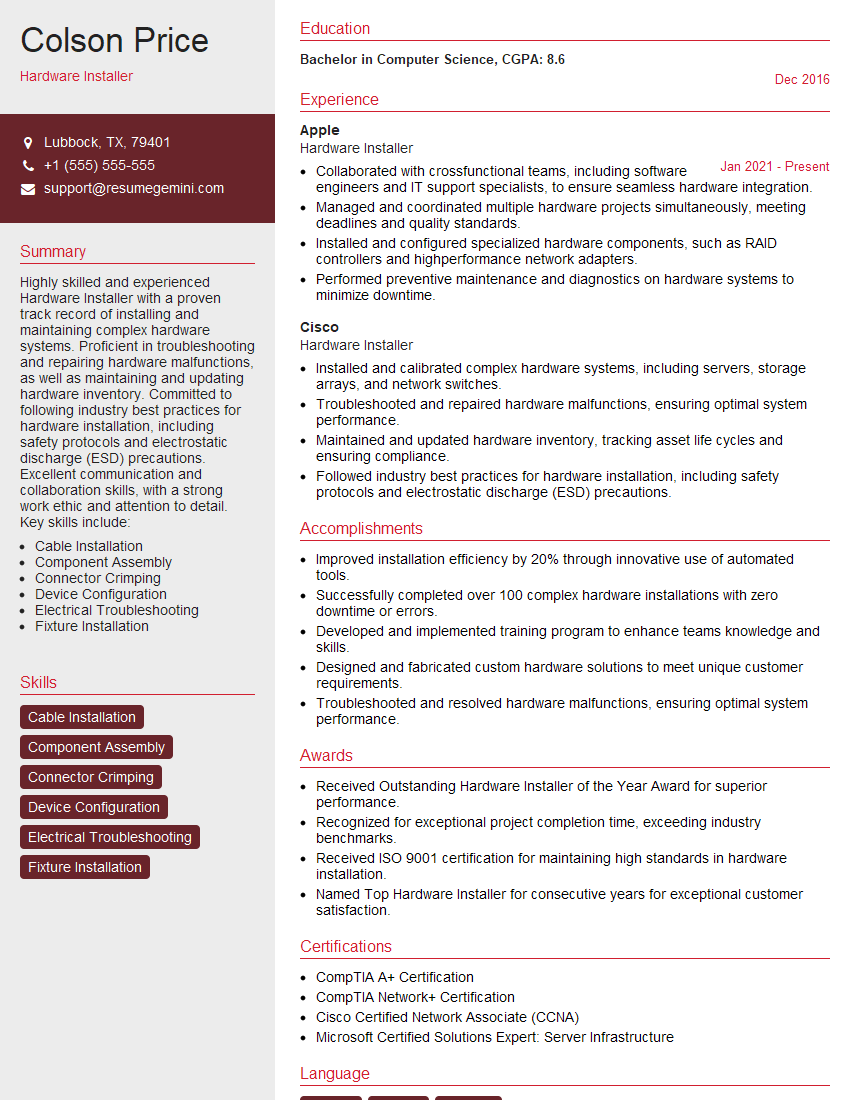

Mastering Grommet and Hook installation is crucial for securing roles in modern front-end development. A strong understanding of these technologies demonstrates your proficiency in building accessible, user-friendly, and performant applications. To significantly boost your job prospects, create a well-crafted, ATS-friendly resume that highlights your skills and experience. ResumeGemini is a valuable resource to help you build a professional and impactful resume. Examples of resumes tailored to Grommet and Hook Installation expertise are available to further guide your preparation.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good