Preparation is the key to success in any interview. In this post, we’ll explore crucial Ground support interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Ground support Interview

Q 1. Describe your experience with various types of Ground Support Equipment (GSE).

My experience with Ground Support Equipment (GSE) spans over ten years, encompassing a wide range of equipment used in aircraft handling and maintenance. This includes:

- Towing tractors: I’m proficient in operating various models, from small pushback tractors for smaller aircraft to heavy-duty tractors for large airliners, understanding their different capabilities and limitations.

- Aircraft stairs and passenger steps: I’ve extensively used both fixed and mobile units, ensuring safe and efficient passenger boarding and deplaning procedures, paying close attention to safe weight capacity and leveling on uneven terrain.

- Baggage carts and loaders: My experience covers various types, including belt loaders and container loaders. I’m adept at safely loading and unloading baggage, ensuring adherence to weight limits and proper cargo securing techniques.

- Power units (APUs): I’m familiar with connecting and disconnecting APUs, understanding their functionality in providing power for aircraft systems when engines are off. I’m aware of the safety protocols to avoid electrical hazards.

- Hydraulic and pneumatic service units: I have experience operating and maintaining these units to support aircraft systems such as brakes and landing gear. I understand the risks involved with high-pressure systems.

- De-icing and anti-icing equipment: I’ve worked with various de-icing trucks and spray equipment, adhering to strict safety procedures to prevent damage to the aircraft and environmental hazards.

This broad experience gives me a comprehensive understanding of the operational aspects and maintenance requirements for a variety of GSE, allowing me to contribute efficiently and safely to aircraft operations.

Q 2. Explain the safety procedures you follow when operating GSE.

Safety is paramount when operating GSE. My safety procedures always start with a thorough pre-operation inspection. This includes checking fluid levels, tire pressure, lights, and overall mechanical condition. I always ensure I have appropriate personal protective equipment (PPE), including high-visibility vests, safety glasses, and gloves. Before moving any equipment, I conduct a 360-degree visual check for obstructions and personnel.

During operation, I maintain a safe speed, avoid sudden movements, and always use appropriate signals when necessary. I never operate GSE beyond its rated capacity and always follow manufacturers’ instructions. Furthermore, I’m keenly aware of my surroundings, particularly in busy airport environments, ensuring I maintain adequate spacing from other aircraft and GSE. If any unusual noise or vibration occurs, I immediately shut down the equipment and report the issue. Regular training on updated safety protocols and equipment-specific procedures is crucial for me to maintain a high standard of safety.

Q 3. How do you troubleshoot malfunctions in GSE?

Troubleshooting GSE malfunctions requires a systematic approach. I usually start with a visual inspection to identify any obvious problems, such as fluid leaks, damaged components, or loose connections.

If the problem isn’t immediately apparent, I’ll consult the equipment’s operator’s manual, using the troubleshooting section to narrow down the possible causes. I’ll check circuit breakers, fuses, and other safety devices. If the issue persists, I might use diagnostic tools, such as multimeters or pressure gauges, to pinpoint the fault. For more complex issues, I’ll consult with experienced mechanics or supervisors. Documentation of all troubleshooting steps and outcomes is essential for maintenance records and to prevent similar future issues. For example, a tow tractor refusing to start might initially point towards a dead battery, but further investigation could reveal a faulty starter motor or even a problem with the fuel system.

Q 4. What is your experience with preventative maintenance on GSE?

Preventative maintenance is critical for ensuring GSE reliability and safety. My experience involves performing daily, weekly, and monthly inspections according to established checklists and manufacturer’s recommendations. This includes checking fluid levels, lubricating moving parts, inspecting tires and brakes, and verifying the functionality of all safety devices.

I’m also involved in more complex maintenance tasks such as filter changes, belt replacements, and minor repairs. I meticulously record all maintenance activities in the appropriate logs, noting any findings or issues. This proactive approach prevents costly repairs down the line and contributes to operational efficiency and safety. For instance, regularly checking the hydraulic fluid level in a baggage loader prevents potential leaks and costly repairs later on.

Q 5. Describe your familiarity with GSE documentation and maintenance logs.

I’m thoroughly familiar with GSE documentation and maintenance logs. I understand the importance of maintaining accurate and up-to-date records for both operational and legal compliance. This includes logging operational hours, maintenance performed, repairs undertaken, and any faults identified. I am proficient in reading and interpreting technical manuals, parts catalogs, and maintenance schedules.

My experience includes working with both paper-based and digital systems for maintaining GSE records. I know how to accurately fill out forms, record maintenance data, and ensure the information is readily accessible to other personnel. This detailed record keeping is essential for tracking equipment history, scheduling maintenance, and ensuring compliance with safety regulations.

Q 6. How do you ensure the safety of aircraft and personnel during GSE operations?

Ensuring the safety of aircraft and personnel during GSE operations is my top priority. I achieve this through diligent adherence to safety procedures, thorough pre-operation checks, and constant situational awareness. This involves maintaining a safe distance from aircraft, using appropriate signaling devices, following established procedures for maneuvering GSE around aircraft, and avoiding any actions that could cause damage or injury.

I’m trained to recognize potential hazards and take appropriate steps to mitigate them. This includes being aware of the aircraft’s position, potential blind spots, and the movements of other personnel and equipment. Communication is also key – I always communicate clearly with pilots, ground crew, and other personnel to ensure everyone is aware of my intentions and movements. I regularly participate in safety briefings and training to stay updated on best practices and emergency procedures.

Q 7. Explain your understanding of GSE weight and balance limitations.

Understanding GSE weight and balance limitations is crucial for safe operation. Each piece of GSE has specific weight and capacity limits that must be adhered to. Exceeding these limits can lead to equipment damage, instability, or even accidents.

Before using any GSE, I always check its weight and balance specifications. I carefully calculate the total weight of any cargo being transported, ensuring it does not exceed the GSE’s maximum load capacity. I also pay close attention to the center of gravity, to ensure the equipment remains stable during operation. For instance, when loading baggage onto a baggage cart, I ensure the weight is distributed evenly to maintain stability and prevent tipping. I’m trained to recognize signs of overloading or imbalance and take corrective actions to prevent accidents.

Q 8. How do you handle emergencies or unexpected situations involving GSE?

Handling emergencies with Ground Support Equipment (GSE) requires a calm, methodical approach prioritizing safety. My first step is always to assess the situation: identify the problem, determine the level of risk, and ensure the safety of personnel and aircraft. This might involve anything from a malfunctioning GPU (Ground Power Unit) to a sudden hydraulic fluid leak on a pushback tug.

For instance, if a GPU fails during engine start, I would immediately communicate with the pilot, shut down the power supply to prevent further damage, and call for a replacement unit. A checklist procedure is followed for each situation, ensuring safe disconnection. If there’s a fire, I would follow our established fire safety protocols, which includes activating the fire suppression systems (if applicable) and contacting emergency services immediately. Regular training in emergency response procedures is crucial in handling these situations efficiently.

- Immediate Assessment: Risk identification and safety prioritization.

- Communication: Alerting relevant personnel (pilots, maintenance, emergency services).

- Controlled Shutdown: Safely isolating the faulty GSE to avoid further hazards.

- Replacement/Repair: Initiating the process for replacement or repair as appropriate.

- Documentation: Creating a detailed report of the incident for analysis and improvement.

Q 9. What is your experience with different types of aircraft and their specific GSE requirements?

My experience spans a wide range of aircraft, from narrow-body jets like the Airbus A320 family and Boeing 737 to wide-body aircraft such as the Boeing 777 and Airbus A380. Each type has unique GSE requirements. For example, a larger aircraft needs higher capacity GPU for electrical power and a more robust pushback tug with greater towing capacity. Smaller regional jets have different requirements regarding the size and capacity of the equipment. I’m familiar with the specific requirements for air stairs, baggage loaders, catering trucks, and lavatory service units specific to each aircraft type. I’ve also worked with various cargo aircraft, understanding their unique loading and unloading equipment needs.

Understanding the Aircraft Maintenance Manual (AMM) and the GSE operator’s manual for each specific aircraft is critical. This ensures compatibility and avoids potential damage. For instance, using the wrong GPU could lead to an electrical surge, whereas an incorrectly connected air conditioning unit could damage the aircraft’s system. My experience has taught me the importance of precise adaptation of GSE to individual aircraft configurations.

Q 10. Describe your proficiency in using GSE checklists and operational procedures.

GSE checklists and operational procedures are fundamental to safe and efficient operations. I am proficient in using both manufacturer-specific and airport-specific checklists. These checklists guide me through pre-operational inspections, ensuring the GSE is functioning correctly and safely. They also detail operational sequences, including proper connections, safety measures, and emergency procedures. A typical checklist might include items like checking fluid levels, verifying electrical connections, and ensuring all safety mechanisms are engaged before operating the equipment.

I follow a strict ‘no deviation’ policy unless a documented exception is made for reasons of safety or operational necessity. This meticulous approach minimizes risks and ensures operational compliance. I’m also adept at using digital GSE management systems that track maintenance, scheduling, and operational data – ensuring real-time monitoring and improved efficiency.

For example, before using a pushback tug, I’ll meticulously check the brakes, steering, and the tow bar attachment point to ensure a safe connection. After completing the checklist, I’ll perform a final visual inspection before initiating the operation.

Q 11. How do you communicate effectively with pilots and other ground crew members?

Effective communication is paramount in ground operations. I utilize clear, concise language, avoiding jargon whenever possible. When communicating with pilots, I use standardized phrases and terminology to ensure there’s no ambiguity. Before any operation, I confirm details verbally and, where appropriate, in writing, to avoid misunderstandings. Nonverbal communication, like hand signals, is also crucial for safety and efficiency in certain situations. This is especially important in high-noise environments. Active listening skills are essential for responding appropriately to any questions or concerns from pilots or ground crew members.

For instance, during pushback, I would use standard radio communication protocols, confirming the pushback direction, speed, and any obstacles before starting the maneuver. Following the pushback, I confirm the aircraft’s position before disconnecting the tow bar, ensuring the clearance for the aircraft’s movement and that the aircraft is safely ready for taxi.

Q 12. What is your experience with coordinating GSE operations with other airport services?

Coordinating GSE operations with other airport services, such as air traffic control, fueling, baggage handling, and catering, is vital for efficient airport operations. This often involves close collaboration and adherence to airport-specific procedures and schedules. I am experienced in using various communication tools, including radios and digital communication platforms to ensure that all parties are aware of GSE movements and potential conflicts. I will inform relevant parties of any delays or issues to prevent operational disruptions.

For example, I will coordinate with the fueling team to ensure the aircraft is fueled efficiently and without creating congestion on the ramp. Similarly, I will coordinate with baggage handlers to ensure their efficient operation without impeding GSE movements.

Effective communication and proactive planning are keys to ensuring that different airport services work together seamlessly.

Q 13. Describe your knowledge of relevant aviation regulations and safety standards.

I possess in-depth knowledge of relevant aviation regulations and safety standards, including those set by the FAA (Federal Aviation Administration) or equivalent international authorities. This includes regulations pertaining to GSE maintenance, operation, and safety. I’m familiar with regulations governing the use of dangerous goods, safety signage, and emergency procedures. I understand the importance of maintaining accurate records and documentation related to GSE operations.

I ensure all my actions adhere to these regulations. For example, I would be aware of and abide by weight and balance restrictions for tow tractors, ensuring I do not overload the equipment. Regular safety training keeps me updated on any changes or new safety regulations.

Q 14. Explain your understanding of GSE fuel and hydraulic systems.

Understanding GSE fuel and hydraulic systems is crucial for safe and efficient operation. I know the importance of regular inspections and maintenance of fuel tanks, lines, and pumps to prevent leaks and malfunctions. I’m familiar with different types of fuels used by GSE and their respective safety protocols, including the appropriate handling procedures and safety measures. I also understand the principles of hydraulic systems, including their function, pressure levels, and the dangers of leaks or system failures. I know how to identify potential leaks, interpret pressure gauges, and understand the potential consequences of hydraulic system malfunctions.

For example, before operating a hydraulically powered pushback tug, I would check the fluid level and inspect the lines for any leaks. During operation, I would monitor the pressure gauges to ensure the system operates within normal parameters. Any unusual readings would trigger an immediate shutdown and inspection.

Q 15. How do you maintain a clean and organized work area for GSE?

Maintaining a clean and organized GSE (Ground Support Equipment) work area is paramount for safety, efficiency, and preventing damage. Think of it like a well-organized kitchen – if everything has its place, you can work quickly and safely. My approach involves a multi-pronged strategy:

- Designated Storage: Each piece of equipment, from tow bars to baggage carts, has a clearly marked and easily accessible storage location. This minimizes clutter and makes it easy to locate items quickly.

- Regular Cleaning: Daily sweeps and periodic deep cleans remove debris, oil spills, and other hazards. This includes washing down equipment regularly to prevent corrosion and maintain functionality. I always prioritize cleaning after maintenance tasks, to prevent the spread of fluids or particles.

- Visual Management: Utilizing color-coded systems for different equipment types or identifying potential hazards (e.g., using red tags for malfunctioning equipment) makes identifying issues quickly and easily.

- 5S Methodology: I strongly advocate for the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to maintain a consistently clean and efficient workspace. This involves regularly decluttering, organizing tools, and establishing clear procedures for housekeeping.

- Preventive Maintenance Scheduling: Regularly scheduled maintenance prevents small problems from becoming big ones, keeps equipment running smoothly, and reduces the likelihood of spills or leaks that could compromise cleanliness.

For example, during my time at [Previous Company Name], I implemented a 5S system in our GSE hangar, resulting in a 15% reduction in equipment downtime due to improved organization and easier identification of maintenance needs.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with using specialized tools and equipment for GSE maintenance?

My experience with specialized GSE tools and equipment is extensive. I’m proficient in using diagnostic tools, hydraulic lifts, specialized wrenches, and other equipment necessary for preventative and corrective maintenance on a wide range of GSE, including pushback tugs, baggage loaders, and aircraft power units (APU) carts.

For example, I’m skilled in using diagnostic software to troubleshoot electrical and hydraulic systems. I’m experienced with hydraulic press testing and repair, and am trained in the safe use of lifting equipment and other heavy machinery. I’ve performed extensive preventative maintenance including oil changes, filter replacements, tire changes, and battery maintenance on various GSE. I’m also proficient in welding and fabrication, allowing for on-site repairs in certain situations.

Safety is paramount. I always adhere to strict safety protocols, including lock-out/tag-out procedures, wearing appropriate personal protective equipment (PPE), and following manufacturer’s instructions for each piece of equipment. A real-world example is how I used a specialized diagnostic scanner to pinpoint a faulty sensor on a baggage loader, preventing a potential operational failure during peak travel hours. By utilizing the diagnostic tool efficiently, I averted significant operational delays.

Q 17. How do you ensure the proper storage and security of GSE?

Proper storage and security of GSE are critical for maintaining operational readiness, preventing theft, and ensuring safety. My approach incorporates several key elements:

- Secure Storage Facilities: GSE should be stored in designated, secure areas, preferably fenced and locked, protected from the elements and unauthorized access. This minimizes the risk of theft, vandalism, and weather damage.

- Inventory Management: A robust inventory system is essential. This could involve barcodes, RFID tags, or a digital database to track the location and status of each piece of GSE.

- Regular Inspections: Regular inspections identify potential security risks, such as damaged locks or signs of tampering.

- Access Control: Access to storage areas should be restricted to authorized personnel only, using key cards, security cameras, or other control measures. This reduces the chances of unauthorized access and misuse.

- Regular Maintenance: Regular maintenance not only extends the lifespan of the equipment but also ensures that it’s in good working order and thus less likely to be compromised. Regular maintenance also improves the overall condition of stored equipment.

In a previous role, I implemented a new inventory system using RFID tags which reduced equipment loss by 20% and streamlined the process of locating specific equipment. This saved significant time and resources.

Q 18. Describe your experience with GSE performance monitoring and reporting.

GSE performance monitoring and reporting are crucial for identifying maintenance needs, optimizing operations, and ensuring safety. My experience involves:

- Data Collection: Utilizing various methods, such as digital maintenance logs, onboard diagnostics, and manual inspections, to collect data on GSE performance. This can include operational hours, fuel consumption, maintenance history, and any reported issues.

- Data Analysis: Analyzing the collected data to identify trends, patterns, and potential problems. This helps to predict future maintenance needs and prevent unexpected breakdowns.

- Reporting: Generating regular reports summarizing GSE performance, including key metrics such as downtime, maintenance costs, and operational efficiency. These reports are essential for management decision-making and resource allocation.

- Predictive Maintenance: Using data analysis to implement predictive maintenance strategies, which helps to proactively address potential issues before they escalate into major problems.

- KPI Tracking: Tracking key performance indicators (KPIs) such as Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR) to benchmark performance and identify areas for improvement.

For instance, through data analysis, I discovered a recurring issue with a specific type of tow tractor. This led to targeted maintenance, reducing downtime by 12% and lowering overall maintenance costs.

Q 19. How do you identify and report potential GSE hazards?

Identifying and reporting potential GSE hazards is a critical aspect of ensuring safety. My approach involves proactive hazard identification and a clear reporting system:

- Regular Inspections: Conducting regular, thorough inspections of all GSE to identify potential hazards, such as damaged equipment, leaking fluids, or frayed wiring. A visual inspection is coupled with functional testing wherever possible.

- Hazard Reporting System: Implementing a clear and easy-to-use system for reporting hazards. This could involve a dedicated logbook, a digital reporting system, or a combination of both. Every reported hazard must be documented and its resolution tracked.

- Risk Assessment: Conducting risk assessments to evaluate the potential severity and likelihood of identified hazards. This helps to prioritize corrective actions and allocate resources accordingly.

- Corrective Actions: Implementing immediate corrective actions to mitigate identified hazards. This could involve removing the hazardous equipment from service, repairing the equipment, or implementing procedural changes.

- Training and Awareness: Providing regular training to all personnel on hazard identification, reporting procedures, and safe work practices.

In one instance, I noticed a crack in the hydraulic line of a baggage loader during a routine inspection. I immediately reported the issue, removed the loader from service, and prevented a potential hydraulic failure that could have caused serious damage and injury. Immediate action averted potential catastrophe.

Q 20. Explain your understanding of GSE environmental impact and sustainability practices.

Understanding the environmental impact of GSE and implementing sustainable practices is crucial for responsible operations. This involves considering factors such as fuel consumption, emissions, and waste generation:

- Fuel-Efficient Equipment: Prioritizing the use of fuel-efficient GSE, such as electric or hybrid vehicles, to reduce fuel consumption and greenhouse gas emissions. This will decrease the carbon footprint of the operation.

- Waste Reduction: Implementing waste reduction strategies, such as recycling used oil and other materials, to minimize environmental impact. Proper waste disposal is vital to environmental responsibility.

- Emission Control: Regular maintenance of GSE to minimize emissions and ensure compliance with environmental regulations. This also minimizes the environmental consequences of equipment malfunction.

- Alternative Fuels: Exploring the use of alternative fuels, such as biofuels or hydrogen, to reduce reliance on fossil fuels and lessen environmental consequences.

- Sustainable Practices: Implementing sustainable procurement practices, such as purchasing GSE from vendors who adhere to environmental standards. This encourages responsible manufacturing and use.

At [Previous Company Name], we implemented a program to transition our GSE fleet to electric vehicles, resulting in a significant reduction in carbon emissions and a positive impact on our environmental sustainability goals.

Q 21. What is your experience with training others on the safe operation of GSE?

Training others on the safe operation of GSE is a vital part of my role. My approach focuses on both theoretical and practical training:

- Classroom Training: Providing classroom instruction on GSE operation, safety procedures, and maintenance. This includes presentations, videos, and interactive exercises.

- Hands-on Training: Offering practical, hands-on training using real GSE. This allows trainees to gain experience and build confidence in operating different types of equipment.

- Mentorship and Observation: Mentoring new trainees and observing them during operation to ensure they understand and follow all safety procedures.

- Regular Refresher Courses: Providing regular refresher courses and updates on safety procedures, new equipment, and changes in regulations. Ongoing training is crucial for retention and improved practice.

- Documentation and Testing: Ensuring that all training is properly documented and that trainees demonstrate competency through practical tests and evaluations. This ensures a thorough understanding and safe practice of operating ground support equipment.

I’ve trained numerous personnel on various types of GSE, including pushback tugs, baggage loaders, and aircraft ground power units. My emphasis on practical, hands-on training has resulted in a significant improvement in safety performance and reduced incidents.

Q 22. Describe your familiarity with different types of towing equipment and procedures.

My experience encompasses a wide range of towing equipment, from small pushback tugs used for smaller aircraft to powerful tractors capable of handling the largest airliners. I’m familiar with both conventional towing methods, using tow bars and specialized connectors, and more advanced systems like electric towing vehicles that offer greater precision and control. Procedures vary depending on the aircraft type, the airport environment, and regulatory requirements. For instance, pre-towing inspections are crucial; this involves checking the tow bar connection, the aircraft brakes, and the surrounding area for obstructions. During the tow, maintaining proper speed and communication with the aircraft crew are paramount. Post-towing procedures include disconnecting the tow bar securely and performing a final visual check of the aircraft and the equipment.

- Pushback Tugs: Ideal for smaller aircraft, offering maneuverability in tight spaces.

- Tractor Units: High-powered vehicles used for larger aircraft, often featuring adjustable tow bars for different aircraft types.

- Electric Towing Vehicles: Environmentally friendly and offer precise control, minimizing the risk of damage to aircraft.

I understand the importance of adhering to strict safety protocols throughout the entire towing process, including using checklists and following established procedures meticulously.

Q 23. How do you manage multiple tasks and priorities during busy ground support operations?

Managing multiple tasks during busy ground support operations requires a structured approach. I utilize prioritization techniques like the Eisenhower Matrix (urgent/important), focusing on time-sensitive tasks first while delegating appropriately when possible. Effective communication is key; I maintain clear lines of communication with my team and other ground support personnel to ensure everyone is aware of priorities and potential delays. Proactive planning and anticipating potential bottlenecks are also crucial. For instance, if I know a particular gate will be congested, I’ll adjust schedules proactively to minimize delays. I also rely heavily on technology – using GSE management systems to track equipment location and availability, improving efficiency and reducing the chance of conflicts.

Think of it like conducting an orchestra – each musician (ground crew member) has a specific role, and the conductor (me) ensures everyone plays in harmony to achieve the overall goal (efficient aircraft turnaround).

Q 24. What are your strategies for resolving conflicts or disagreements during GSE operations?

Conflict resolution is a crucial skill in ground support. My approach is based on open communication and collaborative problem-solving. I first aim to understand the perspectives of all involved parties, actively listening to their concerns and identifying the root cause of the disagreement. Then, I facilitate a discussion, focusing on finding mutually acceptable solutions. If the conflict involves safety concerns, those take immediate precedence. Documentation is important – keeping records of the disagreement, the proposed solutions, and the outcomes.

For example, if there’s a disagreement about the priority of servicing two aircraft, I’d work with both teams to assess the urgency of each request, considering factors like flight schedules and potential delays. Compromise might involve adjusting schedules slightly to accommodate both.

Q 25. How do you adapt to changing operational demands and priorities?

Adaptability is essential in ground support. I embrace change by maintaining flexibility in my approach and staying informed about operational updates. This includes regularly reviewing flight schedules, weather reports, and any notifications about GSE availability. I actively seek feedback from colleagues and supervisors to understand potential challenges and adjust accordingly. For example, if a sudden influx of flights necessitates a change in priorities, I’ll immediately communicate the changes to my team, explaining the rationale and ensuring everyone understands the revised plan.

It’s about being agile and responsive. Think of it like navigating a dynamic environment; you need to be prepared to adjust your course to reach your destination efficiently and safely.

Q 26. Explain your problem-solving skills in a scenario involving a GSE malfunction.

My problem-solving skills were recently tested when a baggage tug experienced a hydraulic failure. My steps were:

- Assessment: I first assessed the situation, ensuring the safety of personnel and the aircraft. The tug was secured, and the area was cordoned off.

- Diagnosis: I checked the tug’s diagnostic system for error codes, indicating the specific hydraulic component malfunction. I also visually inspected the system for any obvious leaks or damage.

- Solution: Based on the diagnosis, I contacted maintenance for assistance. While awaiting maintenance, I developed a contingency plan, involving manual baggage handling if necessary to minimize disruption to flight schedules.

- Repair/Replacement: Maintenance personnel repaired the hydraulic system. I oversaw the testing to ensure functionality before the tug was returned to service.

- Documentation: I thoroughly documented the entire incident, including the cause of the malfunction, the actions taken, and the time taken to resolve the issue.

This systematic approach ensured minimal downtime and prevented further issues.

Q 27. How do you prioritize safety considerations in fast-paced ground operations?

Safety is my top priority. I integrate safety considerations into every aspect of ground support operations. This starts with pre-operational checks of all GSE, ensuring proper functioning and adherence to maintenance schedules. I strictly enforce safety regulations, such as using appropriate Personal Protective Equipment (PPE) and maintaining awareness of the surroundings. I conduct regular safety briefings with my team, highlighting potential hazards and best practices. Furthermore, I encourage a safety-conscious culture where reporting near-misses is encouraged to prevent future incidents. I implement and rigorously follow established safety procedures, including those pertaining to aircraft proximity, emergency response protocols, and communication procedures. I continually review and update safety procedures based on best practices and lessons learned.

Safety is not just a checklist; it’s a mindset and an ingrained part of our operational culture.

Q 28. Describe your experience with GSE technology and computerized maintenance systems.

I have extensive experience with GSE technology and computerized maintenance management systems (CMMS). I am proficient in using various GSE diagnostic tools to identify and troubleshoot equipment malfunctions. My experience with CMMS includes entering maintenance records, scheduling preventative maintenance, and tracking equipment history. This allows for efficient management of the GSE fleet, minimizing downtime and optimizing maintenance costs. I’m familiar with various software systems used for GSE tracking and management, facilitating efficient allocation and scheduling. For instance, I’ve used systems that provide real-time location tracking of equipment, allowing for proactive identification of potential bottlenecks or equipment shortages.

Technology significantly improves efficiency and safety in ground support, ensuring that equipment is properly maintained and deployed effectively.

Key Topics to Learn for Ground Support Interview

- Aircraft Handling: Understanding procedures for pushback, towing, and aircraft movement; knowledge of various aircraft types and their specific handling requirements.

- Safety Regulations and Procedures: Familiarity with ground support equipment (GSE) safety protocols, emergency response plans, and regulatory compliance (e.g., FAA regulations).

- Ground Support Equipment (GSE) Operation and Maintenance: Practical knowledge of operating and troubleshooting common GSE, including pushback tugs, baggage carts, and loading equipment; basic maintenance procedures and safety checks.

- Passenger and Baggage Handling: Efficient and safe procedures for passenger boarding and disembarkation, baggage loading and unloading, and handling of special baggage.

- Communication and Teamwork: Effective communication skills for coordinating with pilots, flight crew, and other ground support personnel; understanding the importance of teamwork in a fast-paced environment.

- Logistics and Planning: Understanding the logistical aspects of ground support operations, including scheduling, resource allocation, and efficient workflow management.

- Problem-Solving and Decision-Making: Demonstrating the ability to identify and resolve issues quickly and effectively in high-pressure situations; applying critical thinking skills to operational challenges.

- Aviation Security: Awareness of security protocols and procedures related to ground support operations, including baggage screening and access control.

- Environmental Awareness: Understanding environmentally responsible practices in ground support, such as fuel conservation and waste management.

Next Steps

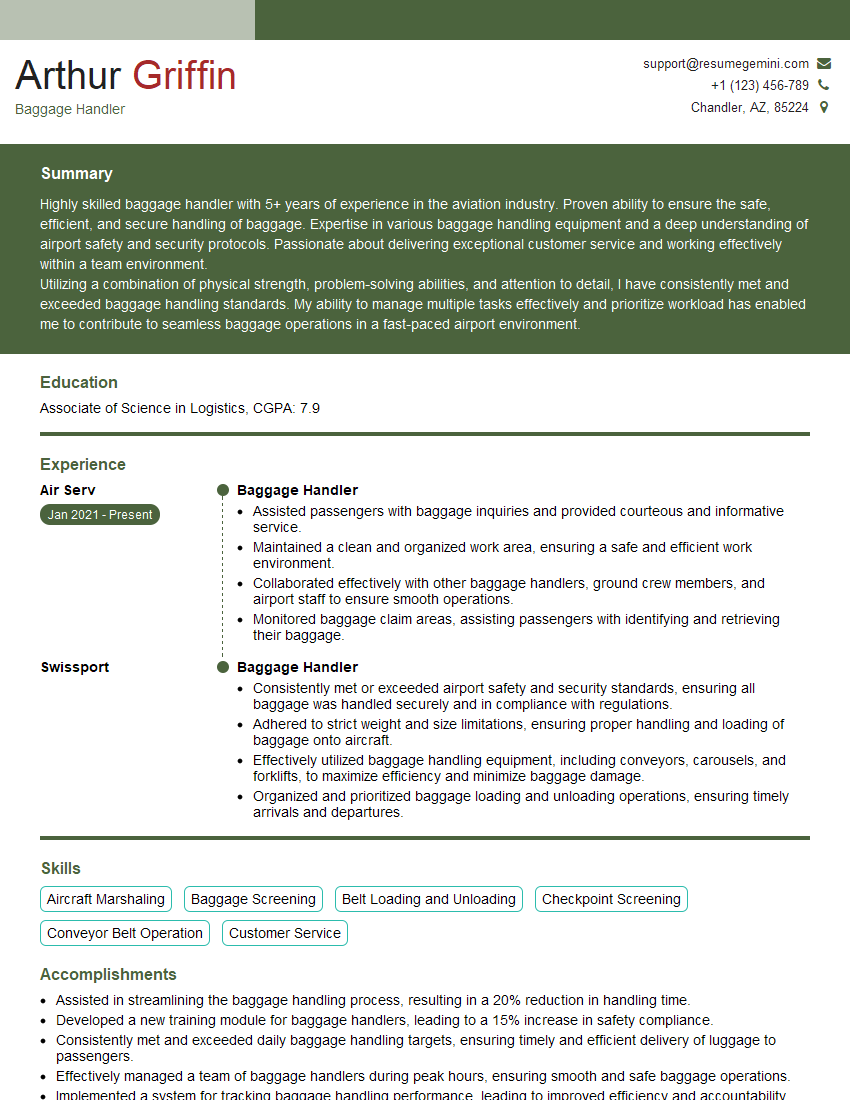

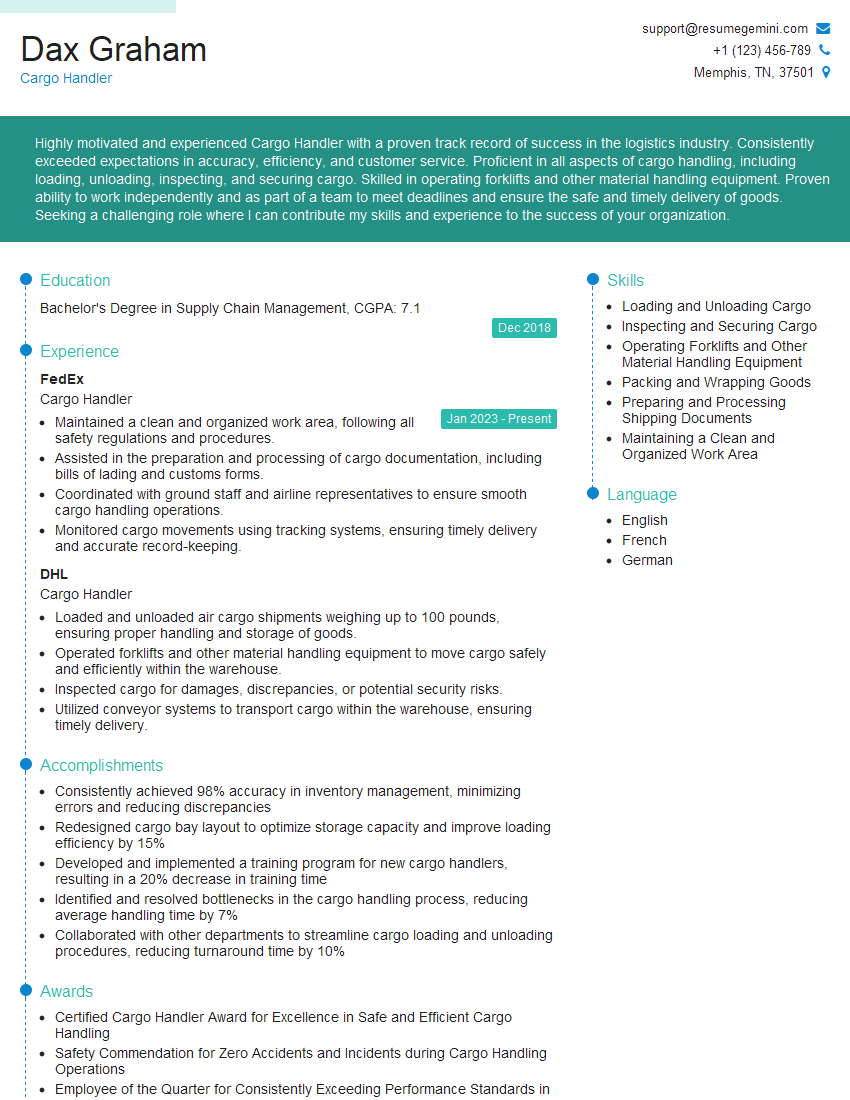

Mastering ground support opens doors to a rewarding career in aviation, offering opportunities for advancement and specialization. A strong resume is crucial for showcasing your skills and experience to potential employers. To increase your chances of landing your dream job, focus on creating an ATS-friendly resume that highlights your relevant qualifications and achievements. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, ensuring your application stands out. Examples of resumes tailored to ground support roles are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good