Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Ground Support Operations interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Ground Support Operations Interview

Q 1. Describe your experience with various Ground Support Equipment (GSE).

My experience with Ground Support Equipment (GSE) spans over a decade, encompassing a wide range of equipment crucial for aircraft operations. This includes everything from pushback tractors and aircraft tugs for maneuvering aircraft, to air start units for engine ignition, and ground power units (GPU) for supplying electrical power. I’m also proficient with lavatory service units for waste disposal, catering trucks for food and beverage loading, and various cargo loading equipment, including belt loaders and container lifts. Furthermore, my experience includes working with specialized GSE such as passenger stairs and aircraft maintenance stands. I’ve consistently prioritized safety and proper maintenance procedures across all these equipment types, conducting regular inspections and reporting any malfunctions promptly.

For instance, during my time at [Previous Company Name], I was responsible for troubleshooting a malfunctioning GPU which prevented an aircraft from receiving the necessary power for its pre-flight checks. Through systematic diagnostics, I identified the issue within the unit’s power converter and coordinated its prompt repair, minimizing disruption to the flight schedule.

Q 2. Explain the process of pre-flight aircraft inspection.

Pre-flight aircraft inspection is a crucial safety procedure that ensures the aircraft is airworthy before takeoff. It’s a meticulous process, typically following a standardized checklist and involving a visual examination of both the exterior and interior of the aircraft. The process begins with a walk-around inspection of the aircraft’s exterior, checking for any damage, fluid leaks, or foreign object debris (FOD). This includes examining the wings, fuselage, engines, landing gear, and control surfaces. Next, we check critical systems, including hydraulics, pneumatics, and electrical systems. We then move to the interior, verifying the functionality of safety equipment such as emergency exits, seatbelts, and oxygen masks. Finally, the pilot or flight crew will perform their own final checks based on their specific flight plans.

Think of it like a thorough car inspection before a long road trip. You wouldn’t leave without checking the tires, oil, and lights. Similarly, this pre-flight check ensures the aircraft’s readiness for safe and efficient operation.

Q 3. How do you ensure the safety of personnel and equipment during ground operations?

Ensuring the safety of personnel and equipment is paramount in ground operations. This starts with strict adherence to safety regulations and procedures, including the use of personal protective equipment (PPE) such as high-visibility vests and safety shoes. We maintain a clear communication system, using standardized hand signals and radio communication to coordinate movements and avoid collisions. We establish designated areas for personnel and equipment, ensuring safe distances between moving aircraft and personnel. Furthermore, we implement robust training programs for all personnel involved in ground operations, emphasizing risk assessment, emergency response procedures, and the safe operation of all GSE.

A real-world example would be implementing a ‘spotter’ system when towing an aircraft – someone guiding the tow operator and communicating with those around to prevent accidents. We also regularly conduct safety briefings and drills to refresh our knowledge and prepare for unexpected situations.

Q 4. What are the different types of aircraft towing techniques?

Aircraft towing techniques vary depending on aircraft size, type, and the available GSE. The most common methods include:

- Conventional Towing: Using a pushback tractor or a tug connected to the aircraft’s nose gear. This is common for smaller aircraft and involves careful maneuvering to avoid damage.

- Remote Towing: A more advanced method involving remote-controlled tugs, ideal for larger aircraft and tight spaces. It reduces the risk of human error.

- Taxiing (Self-Powered): Larger aircraft often taxi under their own power, guided by ground personnel. This requires careful coordination and communication.

Choosing the right technique depends on various factors like the aircraft type, available space, and the expertise of the ground crew. Safety is always the top priority. Each technique involves specific safety procedures, such as utilizing wheel chocks and ensuring the aircraft brakes are engaged when not taxiing under its own power.

Q 5. Describe your experience with aircraft fueling procedures.

Aircraft fueling is a highly regulated and safety-critical process. My experience involves handling various fuel types, from Jet-A to AvGas, adhering strictly to safety protocols to prevent fire hazards and fuel spills. This includes using properly calibrated fuel trucks and ground personnel trained in fuel handling procedures. Before fueling, a thorough pre-fueling inspection of the aircraft is conducted, verifying the aircraft’s fuel tank capacity and checking for any potential hazards. During the fueling process, we ensure proper grounding of the aircraft and fuel truck to prevent static electricity build-up. Once fueling is complete, a post-fueling inspection is performed to verify the accuracy of fuel quantity and the absence of any leaks. Throughout the process, communication is paramount to ensure coordination between ground personnel and the flight crew.

For example, I once handled a situation where a fuel truck malfunctioned during a fueling operation. Swift action, activating emergency procedures, and coordinating with other teams minimized the disruption and prevented any potential hazards. This situation highlights the importance of quick thinking, clear communication and a strong understanding of safety procedures.

Q 6. How do you handle unexpected delays or emergencies during ground operations?

Unexpected delays and emergencies during ground operations require calm, decisive action. My approach involves a systematic response, starting with immediate assessment of the situation. We determine the nature and severity of the delay or emergency and promptly inform relevant stakeholders, such as flight crew, air traffic control, and maintenance personnel. We implement contingency plans based on the established procedures, which might involve re-routing aircraft, deploying additional personnel, or contacting emergency services if necessary. Transparency and clear communication are key to maintaining composure and resolving issues effectively. Documentation of the incident and subsequent remedial actions is meticulously undertaken.

A specific example would be a sudden bird strike causing damage to an aircraft engine. The immediate response was to ground the aircraft, inform authorities, and arrange for maintenance personnel to assess the damage. Following protocol, alternative solutions were explored for affected passengers, ensuring minimal disruption to their travel plans.

Q 7. Explain your understanding of weight and balance procedures.

Weight and balance procedures are crucial for safe aircraft operation, ensuring the aircraft’s center of gravity remains within the approved limits. This involves calculating the total weight of the aircraft, including fuel, cargo, passengers, and crew, and determining the center of gravity location. We utilize weight and balance data provided by the aircraft manufacturer, along with the actual weights measured for each item. Accurate calculations are essential for safe takeoff and landing, and adherence to these limits is strictly monitored. Incorrect weight and balance can significantly impact flight performance and safety.

Imagine a seesaw; if the weight is not evenly distributed, it won’t balance. Similarly, an aircraft’s weight and balance must be carefully managed to maintain stability throughout the flight. Failure to adhere to these procedures can have severe consequences.

Q 8. What are the regulations concerning dangerous goods handling?

Regulations concerning dangerous goods handling are stringent and internationally standardized, primarily governed by the International Civil Aviation Organization (ICAO) Technical Instructions and national regulations mirroring these standards. These regulations dictate how hazardous materials, from lithium batteries to flammable liquids, are packaged, labeled, documented, and transported. Failure to comply can result in serious consequences, including fines, flight delays, and even accidents.

The key aspects include:

- Proper Packaging: Specific packaging requirements are defined for different classes of dangerous goods, ensuring containment and preventing leakage or damage during transit.

- Labeling and Marking: Clear and consistent labeling is crucial, indicating the hazard class and UN number of the dangerous goods. This allows ground crews and airline personnel to identify and handle the goods safely.

- Documentation: Detailed shipping documents, including the Shipper’s Declaration for Dangerous Goods (DGD), are essential, providing complete information about the dangerous goods being transported.

- Emergency Response Information: Contact details for emergency response teams are crucial for immediate action in case of spills or incidents.

- Training: Personnel handling dangerous goods must undergo specialized training to understand the risks associated with different classes and follow safe handling procedures.

For example, I once had to handle a shipment of lithium-ion batteries that were improperly packaged. This resulted in a delay in the flight until the packaging could be rectified to meet the stringent IATA regulations. This highlights the critical importance of following the regulations meticulously.

Q 9. Describe your experience with aircraft de-icing procedures.

Aircraft de-icing is a crucial process, especially during winter operations, to remove snow, ice, and frost from aircraft surfaces before takeoff. Improper de-icing can lead to significant performance issues and safety hazards. My experience encompasses various de-icing techniques and fluid types, along with strict adherence to safety protocols.

I’ve overseen operations utilizing Type I (water-based), Type II (glycol-based), and Type IV (inhibiting fluid) de-icing fluids. The choice of fluid depends on the type and severity of the ice accumulation and ambient temperature. The process typically involves:

- Visual Inspection: A thorough visual assessment of the aircraft to determine the type and extent of ice accumulation.

- Application of De-icing Fluid: Precise and even application of the chosen de-icing fluid using specialized equipment to ensure complete coverage.

- Holding Time: Allowing sufficient time for the de-icing fluid to work and loosen the ice before removing it.

- Removal of Ice and Fluid: Using high-pressure water spray, usually with specialized equipment, to remove the ice and de-icing fluid residue.

- Post-De-icing Inspection: Another thorough visual inspection to ensure all ice and fluid have been removed before the aircraft is cleared for takeoff.

I’ve also been involved in troubleshooting situations where de-icing equipment malfunctioned, requiring immediate action to minimize delays and ensure safety. For example, I once had to coordinate a replacement de-icing unit during a particularly busy period, demonstrating effective problem-solving under pressure.

Q 10. How do you manage communication with pilots and flight crew?

Effective communication with pilots and flight crew is paramount for smooth and safe operations. It requires clear, concise, and timely information exchange using various communication channels.

My approach involves:

- Pre-flight briefings: Providing pilots with relevant information about ground conditions, potential delays, and any special handling requirements for the aircraft.

- Radio communication: Utilizing standardized radio communication protocols to provide updates on ground operations, including taxi instructions, pushback, and any unforeseen issues.

- Face-to-face communication: Direct communication with flight crew to clarify any questions or concerns, ensuring complete understanding and coordination.

- Written communication: Documenting all communications, including any deviations from standard procedures or unexpected events.

A clear example of effective communication involved coordinating a last-minute change in the aircraft’s parking position due to a sudden operational change on the ramp. By quickly communicating with the pilot via radio and confirming the change through the flight operations department, we successfully avoided any delays or safety hazards.

Q 11. Explain the importance of maintaining accurate documentation.

Maintaining accurate documentation is critical in ground support operations for several reasons: safety, regulatory compliance, and operational efficiency. It forms a crucial audit trail, allowing for analysis, improvement, and accountability.

The importance includes:

- Safety records: Documenting all safety incidents, inspections, and maintenance activities, contributing to a safer work environment and identifying potential hazards.

- Regulatory compliance: Ensuring adherence to national and international regulations by maintaining records of all dangerous goods handling, weight and balance information, and aircraft maintenance.

- Operational efficiency: Accurate documentation streamlines workflows, facilitating efficient resource allocation, tracking performance, and improving decision-making.

- Legal and insurance purposes: Providing evidence in case of accidents, incidents, or disputes, protecting the organization and employees.

In my previous role, precise documentation of fuel uplift quantities allowed us to identify a minor leak in a fuel hydrant system, preventing a larger and more costly problem down the line. This emphasized the value of detailed and accurate record-keeping in identifying and resolving issues proactively.

Q 12. What is your experience with troubleshooting GSE malfunctions?

Troubleshooting GSE (Ground Support Equipment) malfunctions requires a systematic approach, combining technical expertise with problem-solving skills. My experience includes diagnosing issues with various GSE, from pushback tractors to baggage loaders.

My approach involves:

- Safety first: Prioritizing safety by securing the area and ensuring the safety of personnel before commencing troubleshooting.

- Gather information: Collecting detailed information on the nature of the malfunction, including error codes, observed symptoms, and operational history.

- Visual inspection: Performing a thorough visual inspection of the equipment to identify any obvious problems, such as loose connections or physical damage.

- Systematic testing: Testing different components and systems to pinpoint the root cause of the malfunction, often utilizing diagnostic tools and manuals.

- Documentation: Recording all troubleshooting steps, findings, and corrective actions taken.

I remember an incident where a baggage loader’s hydraulic system failed. By systematically checking the hydraulic fluid levels, lines, and pumps, we isolated the problem to a faulty pressure relief valve, which was replaced, restoring the loader to full operation within an hour, minimizing disruption.

Q 13. How do you ensure the security of aircraft and cargo?

Ensuring the security of aircraft and cargo is a critical aspect of ground support operations, encompassing several layers of security measures.

Key strategies include:

- Access control: Restricting access to aircraft and cargo areas to authorized personnel only through identification checks, security passes, and surveillance systems.

- Perimeter security: Maintaining a secure perimeter around the aircraft and cargo areas with physical barriers, fences, and regular patrols.

- Cargo screening: Employing screening technologies, such as X-ray machines, to detect potential threats or contraband within cargo shipments.

- Personnel security: Background checks and security training for all personnel involved in aircraft and cargo handling.

- Incident reporting: Implementing robust procedures for reporting any security breaches or suspicious activities.

A significant aspect of this is maintaining a high level of awareness and proactively addressing potential vulnerabilities. This could include regularly reviewing security procedures, conducting security drills, and collaborating with law enforcement agencies.

Q 14. What safety measures do you implement to prevent bird strikes?

Bird strikes pose a significant threat to aircraft safety, and implementing effective measures to prevent them is crucial. My experience involves various techniques and strategies to mitigate this risk.

Strategies include:

- Habitat management: Working with airport authorities to manage the bird habitats around the airport, reducing the attraction of birds to the runways and taxiways. This includes removing food sources and nesting areas.

- Bird scaring techniques: Utilizing various bird scaring techniques, such as pyrotechnics, trained birds of prey, and noise deterrents to discourage birds from approaching the airport.

- Regular bird surveys: Conducting regular bird surveys to monitor bird activity and identify potential high-risk areas.

- Visual inspections: Thorough visual inspections of runways and taxiways before and after aircraft operations to remove any birds or debris that might attract them.

- Collaboration: Working collaboratively with wildlife management experts and airport authorities to develop and implement comprehensive bird strike prevention programs.

One successful example involved the implementation of a falconry program at the airport, which dramatically reduced bird strikes by deterring birds from approaching the runways. This highlights the effectiveness of integrating biological control methods into a broader bird strike prevention strategy.

Q 15. Describe your experience with baggage handling procedures.

Baggage handling is a critical aspect of ground operations, encompassing the entire journey of a passenger’s luggage from check-in to arrival at the baggage carousel. My experience covers all stages, from receiving and sorting bags using advanced conveyor systems like those found in modern airports, to loading and unloading them onto aircraft using specialized equipment like baggage carts and belt loaders. I’m proficient in using barcode scanners for accurate tracking and identifying mishandled baggage. I’ve also worked with fragile baggage procedures, ensuring delicate items are carefully handled and properly documented. For instance, I once had to personally escort a shipment of antique artifacts to a connecting flight, meticulously tracking every step to ensure their safe transfer. This involved coordinating with multiple teams across different terminals and airlines.

My expertise extends to addressing baggage discrepancies, resolving issues such as lost, damaged, or delayed bags. This requires meticulous record-keeping, effective communication with passengers and colleagues, and a keen understanding of airline baggage policies. We utilize sophisticated tracking systems that allow us to pinpoint a bag’s location throughout the entire process, and I am adept at navigating these systems to efficiently locate missing luggage.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you prioritize tasks during peak operational periods?

Peak operational periods demand a strategic approach to task prioritization. My approach is based on a combination of pre-emptive planning and dynamic adjustment. Before peak hours, I review flight schedules and potential bottlenecks, assigning personnel and resources accordingly. This includes prioritizing high-priority flights (e.g., international departures) and ensuring adequate staffing for critical areas like baggage handling and aircraft servicing.

During peak hours, I utilize a system that combines urgency and impact. Tasks are prioritized based on a matrix that weighs the urgency of completion against its impact on flight operations and passenger experience. For example, resolving a mechanical issue affecting a departing aircraft takes precedence over minor cleaning tasks. Clear communication and team collaboration are crucial, and I regularly update the team on priorities to ensure efficient workflow. We regularly practice emergency scenarios and have a robust incident management plan in place.

Q 17. What is your familiarity with different types of aircraft?

My familiarity with different aircraft types spans a wide range, encompassing narrow-body aircraft like the Airbus A320 family and Boeing 737s, as well as wide-body aircraft such as the Boeing 777 and Airbus A380. My understanding goes beyond mere identification; I’m knowledgeable about their operational specifics, such as loading procedures, baggage handling configurations, and ground support equipment compatibility. For example, the loading procedures for a Boeing 777 are different from those for an A320, requiring knowledge of the aircraft’s specific loading capacity, baggage compartment dimensions, and weight distribution requirements.

This includes understanding the differences in ground power unit (GPU) connections, pre-conditioned air (PCA) systems, and water servicing procedures. I’ve also worked with cargo aircraft, which involve additional safety protocols and specialized loading equipment for handling different types of freight. I constantly update my knowledge through manufacturer documentation and industry training to maintain my proficiency.

Q 18. Explain your understanding of aviation regulations related to ground operations.

I have a thorough understanding of aviation regulations related to ground operations, including those set forth by the FAA (Federal Aviation Administration) and ICAO (International Civil Aviation Organization). This includes adherence to safety regulations pertaining to aircraft ground handling, baggage handling, and the operation of ground support equipment (GSE). These regulations are critical to maintaining safety and preventing incidents.

My knowledge extends to regulations regarding the handling of hazardous materials (Hazmat), security protocols for aircraft and passenger screening, and environmental regulations relating to ground operations. For example, I am aware of the strict procedures for handling lithium-ion batteries in baggage and the implications of non-compliance. I also understand the importance of environmental regulations for fuel handling, waste disposal, and noise reduction.

Q 19. Describe your experience working within a team environment.

Throughout my career, I’ve consistently worked in highly collaborative team environments. Effective teamwork is paramount in ground operations, as successful completion of tasks requires seamless coordination between different teams, including baggage handlers, ramp agents, aircraft maintenance personnel, and air traffic controllers. I’ve been part of teams responsible for the successful ground handling of hundreds of flights daily. I believe in fostering a positive team spirit through clear communication, mutual respect, and a shared commitment to achieving common goals.

My role often involves delegating tasks, providing support to team members, and resolving conflicts effectively. For example, during a busy period with a series of delayed flights, I efficiently re-allocated personnel to prioritize critical tasks, ensuring minimal disruption to operations. I actively seek feedback from my colleagues and use it to improve team performance.

Q 20. How do you handle challenging customers or passengers?

Handling challenging customers or passengers requires patience, empathy, and strong communication skills. My approach is to listen actively to their concerns, validate their feelings, and attempt to find a solution that addresses their needs while adhering to company policies. I believe in treating every passenger with respect and understanding, even in stressful situations. Sometimes, a simple apology can go a long way in de-escalating tension.

For instance, I once had to deal with a passenger whose baggage was delayed. Instead of getting defensive, I listened to their frustration, apologized for the inconvenience, and promptly initiated the process of tracing their luggage, providing regular updates until it was located. By remaining calm, showing genuine concern, and proactively resolving the issue, I transformed a potentially negative interaction into a positive one.

Q 21. What are your problem-solving skills in handling ground equipment issues?

Problem-solving skills are crucial when dealing with ground equipment issues. My approach involves a systematic process. First, I identify the problem accurately through observation and using diagnostic tools when necessary. This might involve checking for fuel leaks, mechanical malfunctions, or electrical faults. Then, I assess the severity of the problem, determining whether it requires immediate action or can be scheduled for later repair.

Next, I follow established troubleshooting procedures, consulting technical manuals or contacting maintenance personnel for assistance if needed. For example, if a baggage tug malfunctions, I’ll first assess the type of failure – is it a hydraulic leak? An electrical short? Based on the diagnosis, I follow the designated troubleshooting steps from the equipment’s manual. If the issue is beyond my expertise, I immediately notify the maintenance team, providing clear details of the malfunction to expedite the repair process. I always prioritize safety, ensuring the equipment is secured and personnel are safe before initiating any repairs or contacting support.

Q 22. How do you ensure compliance with safety regulations?

Ensuring compliance with safety regulations in ground support operations is paramount. It’s not just about following rules; it’s about fostering a culture of safety. This involves a multi-faceted approach.

- Regular Training and Certification: All personnel undergo rigorous training on relevant safety regulations, including hazard identification, risk assessment, and emergency procedures. We regularly refresh this training to incorporate updates and best practices. For example, we conduct annual recurrent training on aircraft marshalling signals and emergency response procedures.

- Documentation and Record Keeping: Meticulous record-keeping is crucial. We maintain detailed logs of safety inspections, training records, incident reports, and any corrective actions taken. This allows for continuous monitoring and improvement of our safety procedures.

- Pre-Operational Checks: Before any ground operation commences, a thorough checklist is followed. This includes inspecting equipment for defects, verifying the operational readiness of vehicles, and ensuring adequate communication systems are in place. A failure in any pre-operational check immediately halts the operation until the issue is resolved.

- Compliance Audits and Inspections: Regular internal and external audits are conducted to evaluate our adherence to safety regulations and identify areas for improvement. These audits help us maintain a high level of safety and identify any potential hazards before they result in incidents.

- Reporting and Investigation of Incidents: Any incidents, no matter how minor, are thoroughly investigated to determine root causes and implement corrective actions. This proactive approach prevents similar incidents from occurring in the future. We use a formal incident reporting system with detailed analysis and follow-up actions.

In essence, safety compliance isn’t a checklist; it’s an ongoing process requiring continuous vigilance and a commitment from every member of the team.

Q 23. Describe your experience with load planning and cargo securing.

Load planning and cargo securing are critical aspects of ground support operations, directly impacting flight safety and efficiency. My experience encompasses various aspects of this process.

- Weight and Balance Calculations: I’m proficient in performing accurate weight and balance calculations to ensure the aircraft’s center of gravity remains within safe limits. This involves carefully documenting the weight and location of all cargo, passengers, and fuel.

- Cargo Securing Techniques: I’m experienced in using appropriate cargo securing techniques, employing various methods like netting, straps, and chocks to prevent shifting or damage during transit. This includes knowledge of different cargo types and their specific securing requirements. For example, I know the specific procedures for securing dangerous goods.

- Load Planning Software: I’m familiar with various load planning software programs that help optimize weight distribution and ensure compliance with safety regulations. This software helps to automate calculations and generate reports, improving efficiency and reducing the risk of errors.

- Hazard Identification and Mitigation: Before commencing loading, I always conduct a thorough risk assessment to identify potential hazards, such as incompatible cargo or unstable loading conditions. Appropriate mitigation strategies are then implemented to eliminate or reduce these risks.

I’ve successfully managed complex load planning scenarios involving oversized or heavy cargo, always prioritizing safety and efficiency. A specific example involved securing a large piece of machinery for an airfreight shipment. By careful planning and the use of specialized securing equipment, we ensured the safe and efficient transportation of the cargo.

Q 24. What is your understanding of pushback procedures and safety protocols?

Pushback procedures are a critical phase of ground operations, requiring precision and adherence to strict safety protocols to avoid accidents. My understanding encompasses both the practical execution and the underlying safety principles.

- Communication: Clear and concise communication is essential, especially between the pushback driver and the pilot or ground control. We use standardized hand signals and radio communication to ensure everyone is on the same page. For example, the use of standardized phraseology to confirm pushback direction is crucial.

- Pre-Pushback Checks: Before initiating the pushback, a series of checks are performed, including ensuring the brakes are engaged, the tow bar is correctly connected, and the area around the aircraft is clear of obstacles. A pre-pushback checklist is meticulously followed.

- Awareness of Surroundings: Maintaining awareness of the surroundings is crucial, particularly with regard to other aircraft, ground vehicles, and personnel. We always maintain a safe distance from other objects and prioritize the avoidance of collisions.

- Emergency Procedures: We are thoroughly trained on emergency procedures, such as engine start-up and immediate disconnection in case of unforeseen events. This is reinforced through regular simulations and training exercises.

- Use of Technology: Modern technology, such as pushback tractors with advanced guidance systems, can enhance safety and efficiency. I’m familiar with the operation and safety features of these systems.

The successful execution of pushback procedures relies on teamwork, precise execution, and constant vigilance. Any deviation from established protocols is immediately addressed to prevent accidents.

Q 25. How do you maintain a clean and organized work environment?

Maintaining a clean and organized work environment is crucial for safety and efficiency in ground support operations. It reduces the risk of accidents, improves workflow, and fosters a professional image.

- 5S Methodology: We employ the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to organize our workspace. This systematic approach ensures that all tools and equipment are in their designated places, reducing clutter and the risk of tripping hazards.

- Regular Cleaning: Regular cleaning schedules are in place to remove debris, spills, and other potential hazards. This includes sweeping, mopping, and cleaning equipment.

- Designated Storage Areas: Clearly designated storage areas for equipment and supplies are maintained to avoid clutter and ensure easy access to necessary items.

- Waste Management: Proper waste management procedures are followed, with designated containers for different types of waste. This helps keep the area clean and prevents environmental hazards.

- Team Responsibility: Maintaining a clean and organized workspace is a shared responsibility. Every team member is expected to contribute to keeping the area clean and organized. This shared responsibility fosters a sense of ownership and pride in the work environment.

A clean and organized environment is more than just aesthetically pleasing; it’s a critical safety precaution and promotes overall efficiency.

Q 26. Describe a time you had to adapt to a sudden change in ground operations.

During a severe snowstorm, our airport experienced significant delays and cancellations. Many of the scheduled pushback operations were halted due to the accumulating snow and icy conditions. This required immediate adaptation to maintain operational safety.

Our team swiftly implemented a revised protocol. This involved:

- Prioritizing operations: We focused on essential flights and those with the highest risk of being affected by the weather.

- Increased safety checks: More rigorous checks were performed to ensure aircraft and ground equipment were functioning safely in the adverse conditions.

- Enhanced communication: Communication with pilots, ground control, and maintenance teams was intensified to ensure coordinated efforts and prompt response to any emergent issue.

- Snow removal and de-icing: We collaborated with airport snow removal teams to quickly clear paths for aircraft movement and prevent icing of equipment.

By adapting our procedures and working collaboratively, we were able to successfully navigate the challenging situation, minimizing disruptions and ensuring the safety of personnel and equipment. This experience highlighted the importance of flexibility and adaptability in ground support operations.

Q 27. How do you contribute to a positive safety culture?

Contributing to a positive safety culture requires active participation and a commitment to safety beyond simply following rules. My contribution involves:

- Proactive Hazard Identification: I actively identify and report potential hazards, no matter how insignificant they may seem, promoting a culture of vigilance.

- Open Communication: I encourage open communication and feedback regarding safety concerns, ensuring that everyone feels comfortable expressing their observations and recommendations.

- Mentorship and Training: I actively mentor newer team members, sharing my knowledge and experience to promote safe working practices and foster a shared understanding of safety procedures.

- Leading by Example: I demonstrate a commitment to safety in all my actions, following procedures meticulously and always prioritizing safety over expediency.

- Promoting Teamwork: I emphasize the importance of teamwork and collaboration in maintaining a safe work environment, fostering mutual respect and trust among team members.

A positive safety culture is not simply mandated; it’s cultivated through consistent effort, proactive participation, and a shared commitment to safety among all team members.

Q 28. What are your salary expectations?

My salary expectations are in line with my experience and qualifications in ground support operations, considering the responsibilities and demands of the role. I am open to discussing a competitive compensation package that fairly reflects my contributions to the organization. I would be happy to provide further details once I have a better understanding of the specific requirements of the position and the company’s compensation structure.

Key Topics to Learn for Ground Support Operations Interview

- Safety Procedures and Regulations: Understanding and applying relevant safety protocols, including hazard identification and risk mitigation strategies in various ground support scenarios. This includes familiarity with industry-standard operating procedures and emergency response plans.

- Aircraft Handling and Servicing: Practical knowledge of aircraft towing, pushback procedures, baggage handling, fueling, de-icing, and cabin servicing. Be prepared to discuss specific techniques and potential challenges encountered during these operations.

- Ground Support Equipment (GSE): Familiarity with the operation and maintenance of various GSE, including tow tractors, baggage carts, and fueling equipment. Understanding their limitations and safety precautions is crucial.

- Communication and Coordination: Effective communication with pilots, flight crew, and other ground personnel is essential. Discuss your experience with radio communication, standardized terminology, and teamwork in a high-pressure environment.

- Logistics and Operations Management: Understanding the flow of operations within an airport, including flight scheduling, passenger flow, and cargo handling. Be prepared to discuss optimizing efficiency and problem-solving in dynamic situations.

- Troubleshooting and Problem Solving: Describe your approach to resolving unexpected issues during ground operations, highlighting your ability to think critically and make informed decisions under pressure. Examples of past challenges and their solutions will be valuable.

- Regulatory Compliance: Demonstrate your understanding of relevant aviation regulations and compliance procedures. This includes knowledge of international and local standards related to safety and operations.

Next Steps

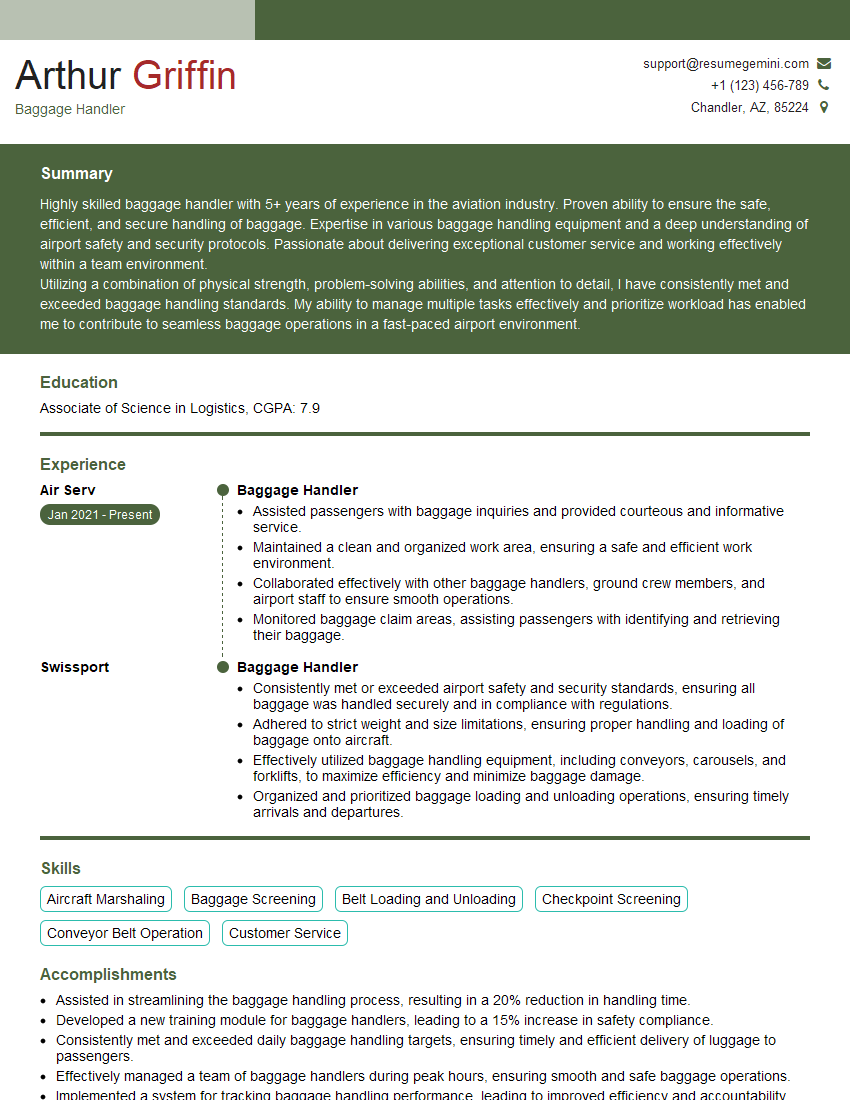

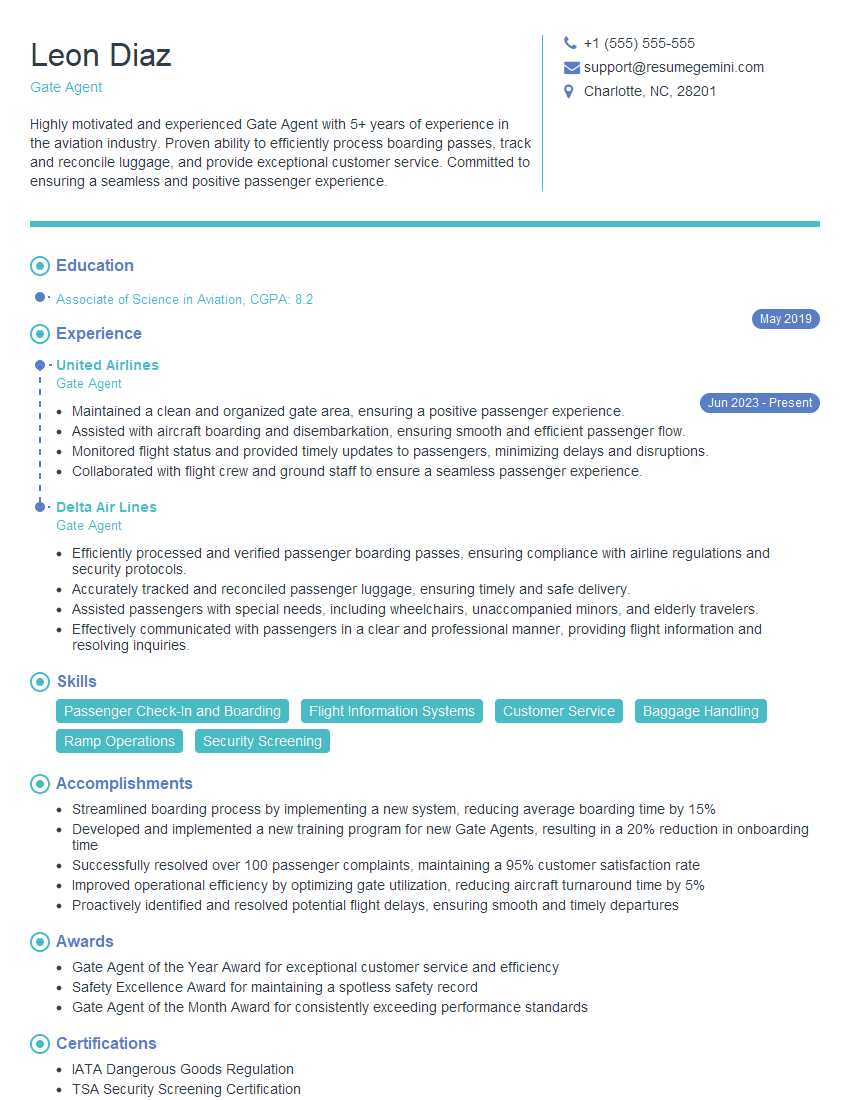

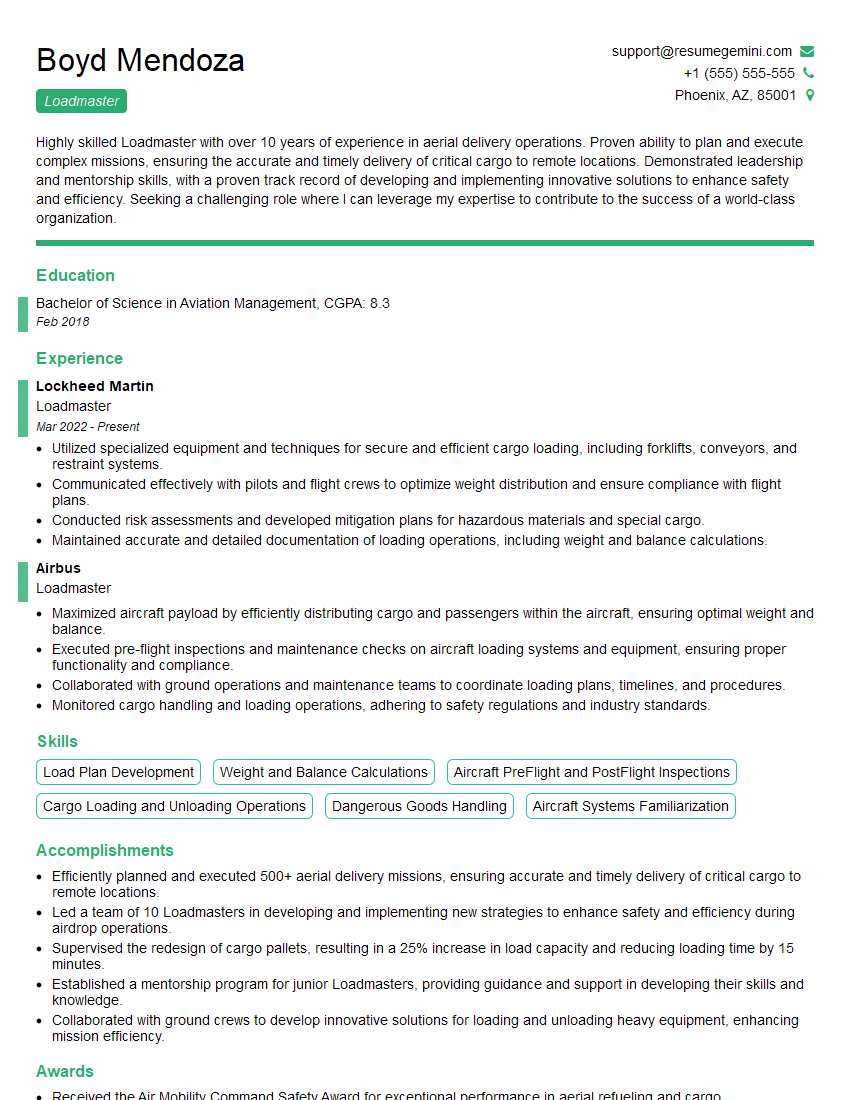

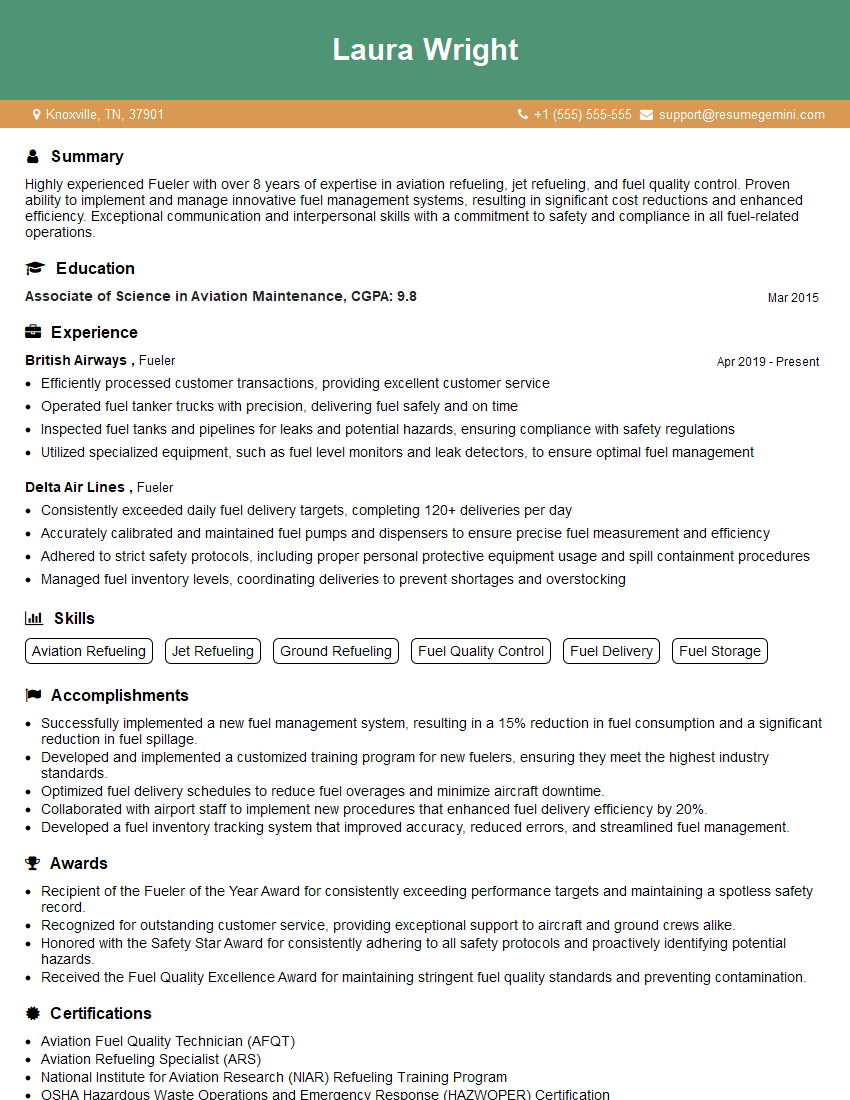

Mastering Ground Support Operations opens doors to a rewarding career with significant growth potential within the aviation industry. A strong understanding of these crucial aspects significantly enhances your job prospects. To maximize your chances of landing your dream role, it’s vital to present your skills and experience effectively. Building an ATS-friendly resume is key to getting noticed by recruiters. We highly recommend utilizing ResumeGemini, a trusted resource, to craft a professional and impactful resume that showcases your expertise. ResumeGemini offers examples of resumes tailored to Ground Support Operations to help you get started. Invest time in crafting a compelling resume; it’s your first impression and a critical step in securing your next opportunity.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good