The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Hand Truck Operation interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Hand Truck Operation Interview

Q 1. Describe your experience operating various types of hand trucks.

Throughout my career, I’ve extensively used various hand truck types, from basic two-wheel hand trucks for lighter loads to heavy-duty four-wheel models capable of carrying significantly more weight. I’m also proficient with specialized hand trucks like appliance dollies and stair climbers, each designed for specific tasks and load types. For instance, I’ve used two-wheel hand trucks for moving boxes in a warehouse setting, and four-wheel hand trucks for transporting heavier and bulkier items like furniture or equipment. My experience also includes the use of specialized hand trucks like those with pneumatic tires for navigating uneven terrain and those with straps for securing oddly shaped items. This diversity in experience allows me to adapt my technique and choose the right equipment for the job.

Q 2. What safety measures do you take when operating a hand truck?

Safety is paramount when operating hand trucks. My safety measures always begin with a thorough inspection of the equipment before each use, checking for worn wheels, damaged handles, and loose parts. I always ensure the load is balanced and properly secured to prevent shifting or tipping. Wearing appropriate footwear – sturdy, closed-toe shoes – is essential to protect my feet from potential injury. I also maintain awareness of my surroundings, paying close attention to obstacles, uneven surfaces, and other people. I avoid rushing and take my time, especially when navigating tight spaces or stairs. Finally, I always follow company safety protocols and use any required personal protective equipment (PPE).

Q 3. How do you properly load and secure items on a hand truck?

Proper loading and securing is crucial for safe hand truck operation. I begin by distributing the weight evenly across the platform. Heavier items should be placed lower and closer to the wheels for better stability. I always ensure the center of gravity is low to prevent tipping. For oddly shaped items, I may use straps or additional securing devices to keep them in place. If the load is excessively tall, I might consider using a second hand truck or seeking assistance to avoid overloading and potential accidents. For example, when moving stacks of boxes, I would interleave them with cardboard dividers to prevent shifting during transportation.

Q 4. What is your experience with different hand truck types (e.g., two-wheel, four-wheel)?

My experience encompasses a wide range of hand truck types. Two-wheel hand trucks are excellent for lighter loads and navigating narrow spaces, while their maneuverability makes them ideal for short distances. However, their stability can be compromised with heavy or uneven loads. Four-wheel hand trucks, on the other hand, provide greater stability and are better suited for heavier loads and longer distances. However, they are less maneuverable in tight spaces. I’ve also worked with specialized hand trucks, like those designed for specific materials – such as those with cushioned surfaces for delicate products – or for specific environments, like those with pneumatic tires for outdoor applications. Choosing the right type depends on the task, load, and the environment.

Q 5. Explain your approach to maneuvering hand trucks in tight spaces.

Maneuvering hand trucks in tight spaces requires a careful and methodical approach. I use smaller, more controlled movements, avoiding jerky motions that could cause a loss of balance. Short, deliberate steps, combined with careful steering, are key. I’ll often pivot or use a three-point turn to navigate corners efficiently. Planning the route beforehand and identifying potential obstacles is essential. For extremely confined areas, I might consider breaking down larger loads into smaller, more manageable units. It’s all about controlled movement and anticipating potential challenges.

Q 6. How do you handle heavy or awkward loads on a hand truck?

Handling heavy or awkward loads requires extra caution and potentially additional support. I’ll always assess the weight and dimensions before attempting to move the load. If the load is too heavy or unwieldy, I’ll seek assistance from a colleague or use appropriate lifting equipment. For awkward shapes, I use straps or other securing devices to prevent shifting or tipping. Proper lifting techniques are crucial to prevent back injuries. Remember, safety should never be compromised. If I have any doubt about my ability to safely handle the load, I always ask for help.

Q 7. How do you prevent tipping or accidents while operating a hand truck?

Preventing tipping or accidents involves a multifaceted approach. Maintaining a low center of gravity by properly loading the hand truck is crucial. Avoiding sudden stops or turns, particularly when carrying heavy loads, helps prevent tipping. Keeping a steady pace and maintaining awareness of the surroundings is equally important. I always use appropriate equipment for the task and ensure that the hand truck is in good working condition. Additionally, I remain vigilant and adjust my technique as needed based on surface conditions and environmental factors. Safety is a continuous process, not just a checklist.

Q 8. Describe your experience with hand truck maintenance and inspection.

Hand truck maintenance and inspection are crucial for safe and efficient operation. My experience encompasses regular visual checks for damage, such as bent wheels, cracked handles, or worn-out bearings. I also check for loose bolts and screws, ensuring all components are securely fastened. I lubricate moving parts like wheels and axles to minimize friction and extend the hand truck’s lifespan. I’ve developed a checklist to ensure consistency and thoroughness in my inspections. For instance, I always examine the condition of the wheels – are they inflated properly (for pneumatic wheels)? Are the bearings smooth and free of grinding noises? A damaged hand truck can lead to instability and accidents, hence proactive maintenance is non-negotiable.

- Visual Inspection: Checking for dents, cracks, rust, or loose parts.

- Functional Check: Testing the ease of wheel movement and handle operation.

- Lubrication: Applying lubricant to moving parts to reduce friction and wear.

- Documentation: Maintaining records of inspection dates and any repairs or replacements.

Q 9. What are the common causes of hand truck accidents and how to prevent them?

Hand truck accidents often stem from improper lifting techniques, overloading, and using the hand truck on unsuitable terrain. For example, lifting a heavy load without proper back support can lead to back injuries. Overloading compromises stability, and using a hand truck on uneven surfaces increases the risk of tipping. Prevention strategies involve proper training on lifting techniques and hand truck operation, including using the correct posture and footwork. Regular inspections to ensure the truck is in good working order are also vital. Furthermore, assessing the weight and stability of loads before moving them is crucial. I would also emphasize the importance of using appropriate safety gear, like steel-toed boots, in environments where falling objects are a risk.

- Improper Lifting Techniques: Training on proper lifting techniques, using legs and not back.

- Overloading: Adhering to the hand truck’s weight capacity.

- Uneven Surfaces: Avoiding ramps with steep inclines or rough terrain whenever possible.

- Lack of Training: Providing comprehensive training for all users.

Q 10. How do you assess the weight and stability of a load before using a hand truck?

Assessing weight and stability involves a multi-step process. Firstly, I visually estimate the load’s weight, considering the type of materials and their density. If unsure, I utilize a scale for precise measurement. I always check for the load’s center of gravity, ensuring it’s positioned centrally to maintain balance. I also inspect the load’s packaging, verifying its integrity and ensuring it’s securely fastened. If it is an unstable or oddly shaped load, I may need to use additional securing methods, like rope or straps, to maintain stability. Imagine trying to move a stack of oddly shaped boxes: securing them properly prevents slippage and tipping during transport.

- Visual Estimation: Assessing load weight based on experience.

- Scale Measurement: Using a scale for accurate weight determination.

- Center of Gravity: Ensuring the load is balanced and centered.

- Packaging Integrity: Checking if the load is properly packaged and secured.

Q 11. What is your experience with hand truck usage in various environments (e.g., ramps, uneven surfaces)?

My experience includes navigating various challenging environments. On ramps, I always proceed slowly, keeping the load centered and maintaining a firm grip on the handle. On uneven surfaces, I adjust my pace and footing to maintain stability. I avoid sharp turns and sudden movements. I’ve learned to utilize the hand truck’s features to my advantage—for instance, choosing a hand truck with larger, more robust wheels for navigating uneven terrain. I’ve also used specialized hand trucks, like those with wider bases for improved stability on inclines. One memorable instance involved using a heavy-duty hand truck with pneumatic wheels to maneuver large boxes across a gravel pathway. The pneumatic wheels provided superior traction and reduced vibrations compared to the hard rubber wheels of a standard hand truck.

Q 12. What is your experience working with different types of materials and their handling requirements?

I’ve handled a diverse range of materials, from fragile ceramics to heavy machinery parts. Each material necessitates a unique handling approach. Fragile items require careful padding and secure wrapping to prevent damage during transport. Heavy items require a sturdy hand truck with a sufficient load capacity. I always consider the material’s weight, size, and shape when selecting a hand truck and deciding on the best transport method. For example, I’d use a different technique and potentially a different type of hand truck to move a pallet of bricks compared to a single box of delicate glassware. Understanding the inherent characteristics of the material is paramount to safe and effective handling.

Q 13. Explain your understanding of load capacity and weight limitations for hand trucks.

Load capacity is the maximum weight a hand truck can safely support. This is usually printed on the hand truck itself. Exceeding this limit can lead to structural failure, resulting in accidents and injuries. Weight limitations are usually expressed in kilograms or pounds. I always check the hand truck’s load capacity before attempting to move any load. If the load exceeds the stated limit, I either use a heavier-duty hand truck or divide the load into smaller, manageable portions. Ignoring weight limits is a significant safety hazard; it’s essential to prioritize safe operation over expediency.

Q 14. How do you prioritize safety when working under pressure or with tight deadlines?

Even under pressure, safety remains my top priority. I never compromise safety for speed. Instead, I prioritize careful planning and execution. I might break down a large task into smaller, more manageable steps to maintain control and avoid rushing. If I’m unsure about the safest approach, I consult with a supervisor or colleague for guidance. Rushing often leads to mistakes, so it’s far better to take the extra time to ensure a safe and efficient operation. For example, if I am given a tight deadline to unload a truck, I will first ensure I have the correct equipment, assess the loads properly, and then methodically move each item rather than attempting to rush through the task.

Q 15. Describe a time you encountered a problem while using a hand truck. How did you solve it?

One time, I was moving a heavy pallet of boxes using a hand truck across an uneven warehouse floor. The pallet shifted unexpectedly, causing the hand truck to tilt dangerously. The load was near the tipping point and I needed to quickly regain control.

My immediate response was to carefully lower the load to the ground using controlled movements. I avoided any jerky movements that could have caused further instability. Then, I re-evaluated the situation. The uneven floor was the root cause. I secured the load more tightly using straps, then took a more cautious route, avoiding the worst bumps and dips. Finally, I took smaller, more controlled steps with the hand truck, ensuring stability throughout the process. This incident reinforced the importance of assessing the environment before moving loads and using appropriate safety measures, like securing heavy items. A slight adjustment in technique and careful planning prevented a potentially serious accident.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you adhere to company safety regulations regarding hand truck use?

Company safety regulations regarding hand truck use are paramount. My adherence is comprehensive and proactive, encompassing several key areas:

- Pre-use Inspection: Before each use, I inspect the hand truck for any damage, such as bent wheels, loose screws, or worn-out components. If any issues are found, I immediately report them to my supervisor and take it out of service.

- Proper Lifting Techniques: I always utilize proper lifting techniques. This includes bending at my knees, keeping my back straight, and using my legs to lift the weight, minimizing strain. I never attempt to lift anything heavier than what is safe for me or the hand truck’s capacity.

- Safe Loading Practices: I ensure the load is balanced and centered on the hand truck platform. Overloading the truck is never done. Using straps to secure heavy or unstable items is a standard practice.

- Environmental Awareness: I assess the environment before moving – ensuring the route is clear of obstacles, uneven surfaces, and other hazards. I’m aware of the potential for slipping, tripping and collisions.

- Personal Protective Equipment (PPE): Depending on the work, I always use appropriate PPE such as safety shoes.

Following these procedures consistently ensures both my safety and the safety of others around me.

Q 17. What is your understanding of proper hand truck storage and organization?

Proper hand truck storage and organization are crucial for safety and efficiency. Hand trucks should be stored in designated areas, away from walkways and other potential hazards. They shouldn’t obstruct traffic flow or create tripping hazards.

I advocate for a system that promotes easy access while maintaining order. This might involve designated racks or designated storage spaces. Hand trucks should be stored upright to prevent damage and to make them easily retrievable without causing congestion in the work area. Regular cleaning of the storage area and the hand trucks themselves is vital to maintain a safe and efficient workplace. A clean and organized storage area makes it easier to spot any damage or wear and tear on the hand trucks themselves.

Q 18. How would you train a new employee on safe hand truck operation?

Training a new employee on safe hand truck operation involves a structured approach combining theory and hands-on practice.

- Classroom Instruction: I would begin with classroom instruction covering the hand truck’s components, safe lifting techniques, load balancing, appropriate loading capacity, and hazard identification (e.g., uneven surfaces, obstacles). I’d also cover the importance of pre-use inspection and reporting any damage.

- Demonstration: A practical demonstration of proper hand truck usage, including loading, maneuvering, and unloading, is crucial. This would highlight the correct body mechanics and posture for safe handling.

- Hands-on Practice: Supervised hands-on practice is essential. The new employee would practice using the hand truck under my watchful eye to correct improper technique and ensure the understanding of safe operating procedures. This should involve moving loads of varying weights and navigating different terrain conditions.

- Safety Regulations: Company and OSHA regulations relevant to hand truck operation would be explained and reinforced.

- Assessment: A final assessment would evaluate the new employee’s competence, making sure they can operate the hand truck safely and efficiently before working independently.

Ongoing mentorship and reinforcement of safety procedures are also important aspects of effective training.

Q 19. Describe your proficiency in lifting and carrying techniques related to hand truck usage.

My proficiency in lifting and carrying techniques in relation to hand truck usage is high. I am well-versed in proper body mechanics to prevent injury. This includes:

- Assessing the Load: Before attempting to lift or move anything, I always evaluate the weight and stability of the load, ensuring it’s within safe limits for both myself and the hand truck.

- Proper Lifting Posture: I always bend at the knees, keeping my back straight, and using my leg muscles to lift the load. I never twist my body while lifting.

- Balanced Load: I ensure the load is evenly distributed on the hand truck’s platform. I avoid overloading it and always secure any unbalanced or unstable items.

- Controlled Movements: I maintain a firm grip on the hand truck handles and avoid sudden jerky movements that might cause the load to shift or tip.

- Seeking Assistance: If a load is too heavy or awkward for safe handling by myself, I never hesitate to ask for help from a colleague.

This understanding and application of proper lifting techniques ensures both the efficient movement of goods and my personal safety. It is a habit ingrained from years of consistent, safe practice.

Q 20. How familiar are you with hand truck-related OSHA regulations?

I am very familiar with OSHA regulations concerning hand truck operation. While I don’t have the regulations memorized verbatim, I understand the core principles focusing on hazard prevention, safe operating procedures, and employee training. These regulations emphasize the importance of proper training, pre-use inspection, proper load securing, and the use of appropriate personal protective equipment (PPE).

My understanding of these regulations allows me to anticipate and prevent potential hazards, ensuring safe and compliant hand truck operations in any setting.

Q 21. Explain how you maintain efficiency while ensuring safety when using a hand truck.

Maintaining efficiency while ensuring safety when using a hand truck requires a balanced approach. It’s not a matter of choosing one over the other – they are mutually reinforcing.

My strategy focuses on:

- Planning the Route: Before starting a task, I plan the most efficient route while also considering potential hazards. This helps to eliminate unnecessary movements and potential delays caused by obstacles.

- Proper Loading Techniques: Correctly loading and securing the load ensures stability during movement. A well-balanced load requires less effort to maneuver, increasing efficiency while reducing the risk of accidents.

- Using the Right Equipment: Choosing the appropriate hand truck for the task (e.g., the right wheel type for the terrain) greatly enhances efficiency and safety.

- Appropriate Pace: Maintaining a consistent, steady pace is key. Rushing increases the risk of accidents, while excessively slow movement decreases efficiency. Finding the right balance is crucial.

- Regular Maintenance: Properly maintained equipment operates smoothly and efficiently. Regular inspection and prompt reporting of any issues prevents delays and reduces accident risk.

This integrated approach ensures both speed and safety are prioritized, leading to a more productive and risk-free work environment.

Q 22. Describe your experience documenting hand truck usage or incidents.

My experience documenting hand truck usage and incidents involves meticulous record-keeping. I’ve developed a system that includes detailed descriptions of the incident or task, the type of hand truck used, the load weight and dimensions, the environment (e.g., surface type, incline), and any contributing factors like poor lighting or obstructions. I use both written reports and photographic evidence to document the details objectively. For example, if a hand truck wheel broke during transport, my report would detail the model of the hand truck, the condition of the wheel before and after the incident, the weight of the load, and the surface the hand truck was on. This level of detail is crucial for identifying trends, improving safety protocols, and potentially facilitating any necessary repairs or replacements.

In addition to incident reporting, I regularly document hand truck usage patterns within our warehouse. This includes tracking the frequency of usage per hand truck, the types of loads transported, and the routes taken. This data helps in identifying potential areas of improvement, such as optimizing routes or investing in more appropriate equipment for specific tasks.

Q 23. How would you handle a situation where a hand truck malfunctioned?

If a hand truck malfunctions, my immediate priority is safety. I would first secure the load to prevent it from falling or shifting. This might involve using additional support like straps or finding a stable surface to temporarily rest the load. Next, I would assess the nature of the malfunction – is it a broken wheel, a bent frame, or a loose component? Depending on the severity, I might attempt a minor repair if I’m trained and equipped to do so (like tightening a bolt), but I would never compromise safety. If the damage is significant or if I’m unsure about the repair, I’d immediately report the incident to my supervisor and remove the damaged hand truck from service, marking it clearly as unusable.

I have previous experience where a wheel became detached from a hand truck mid-transport. After securing the load, I reported the incident and the hand truck was inspected. The investigation determined that it was due to routine maintenance being overlooked, and I now emphasize proactive checks before each use. This incident reinforced the importance of regular inspections and prompt reporting of any deficiencies.

Q 24. What is your experience working independently and as part of a team using hand trucks?

I’m comfortable working both independently and as part of a team using hand trucks. When working independently, I focus on efficient task completion, prioritizing safety protocols. In team settings, I collaborate effectively, ensuring clear communication and coordination to prevent accidents and optimize workflow. For instance, when moving large, heavy items as a team, we establish clear roles – one person steers, another supports the load, and a third clears the path. This prevents collisions, strain injuries and improves overall efficiency.

My experience includes leading a small team in a warehouse setting where we were responsible for moving hundreds of boxes daily. Effective communication and teamwork were key to maintaining a safe and productive working environment. We developed a system where we rotated responsibilities to avoid fatigue and promote fairness, enhancing teamwork and morale.

Q 25. How do you adapt your hand truck operation technique to different work environments?

Adapting hand truck operation to different work environments requires careful observation and adjustment of technique. I assess factors like the surface type – smooth concrete requires less effort than uneven ground or ramps. Incorporating appropriate safety measures like wearing safety shoes is crucial on uneven or slippery surfaces. The presence of inclines requires altered posture and potentially a different hand truck technique to avoid losing balance or tipping the load. Ramps, for example, demand a slower, more controlled approach, with a focus on maintaining stability. The presence of obstacles such as doorways or corners necessitates maneuvering skills and careful planning to prevent collisions.

For example, I’ve worked in a construction site with uneven terrain and a busy environment. My approach involved using a hand truck with larger pneumatic wheels designed for rough terrain. I adjusted my pace and maintained extra awareness of surroundings to avoid obstacles and potential hazards to my co-workers.

Q 26. What are your strategies for minimizing strain and fatigue while using a hand truck?

Minimizing strain and fatigue when using a hand truck involves employing proper lifting techniques, maintaining good posture, and taking regular breaks. Proper lifting techniques emphasize bending at the knees, keeping the back straight, and lifting with the legs. Maintaining a balanced posture throughout the task distributes the workload evenly across the body. Avoiding jerky movements or twisting and making sure the load is balanced on the truck is important as well. Taking short breaks allows the body to recover and prevents muscle fatigue. Proper hydration also helps to combat fatigue.

I often use the analogy of a marathon runner: pacing is key. Consistent, steady movements are more sustainable than bursts of intense effort. In a fast-paced environment, this is even more critical. Breaking down large tasks into smaller, manageable units and taking short breaks can prevent unnecessary fatigue.

Q 27. Describe your experience using hand trucks with specialized attachments or accessories.

I have experience using hand trucks with various specialized attachments and accessories, including ramps, straps, and specialized wheel attachments for different terrain. Ramps are essential for navigating stairs or loading docks, increasing safety and efficiency. Straps are crucial for securing unstable or oddly shaped loads, preventing accidents. Specialized wheels, such as pneumatic tires for uneven terrain or non-marking wheels for cleanroom environments, improve maneuverability and protect the floor surfaces.

For instance, I utilized a hand truck with a ramp attachment to move heavy equipment up a flight of stairs during a warehouse relocation. The ramp attachment significantly reduced the risk of injury and made the task considerably easier and safer.

Q 28. How do you prioritize safety and efficiency when operating a hand truck in a fast-paced environment?

Prioritizing safety and efficiency in a fast-paced environment requires a systematic approach. I always begin by conducting a thorough risk assessment, identifying potential hazards and developing strategies to mitigate them. This includes checking the hand truck’s condition, assessing the load, and planning the route. Effective communication is crucial – I ensure clear communication with colleagues to coordinate movements and avoid collisions. This proactive approach ensures that tasks are completed safely and efficiently, even when under pressure.

For example, while working in a distribution center during peak season, I implemented a system of visual cues and clear communication with my team to manage the high volume of shipments. This ensured that all members of the team remained informed of the movement of hand trucks to prevent any unexpected collisions or accidents. This system improved both the safety and the efficiency of the operation.

Key Topics to Learn for Hand Truck Operation Interview

- Safe Operating Procedures: Understanding and adhering to all safety regulations, including proper lifting techniques, load securing methods, and workplace hazard awareness.

- Equipment Knowledge: Familiarity with different types of hand trucks (e.g., two-wheel, four-wheel, specialized trucks), their capabilities, and limitations. Knowing how to perform basic maintenance checks.

- Load Management: Properly assessing load weight and distribution to ensure safe and efficient transport. Techniques for balancing uneven or awkward loads.

- Maneuvering Techniques: Mastering efficient navigation in various environments (e.g., narrow aisles, ramps, uneven surfaces). Understanding how to safely negotiate obstacles.

- Ergonomics and Physical Fitness: Recognizing and minimizing risks of musculoskeletal injuries. Understanding the importance of proper posture and lifting techniques to prevent strain and injury.

- Problem-Solving Scenarios: Preparing for potential challenges like damaged equipment, unexpected obstacles, or difficult load configurations. Thinking through solutions while prioritizing safety.

- Teamwork and Communication: Understanding the importance of collaboration with colleagues, communicating load information effectively, and working safely within a team environment.

Next Steps

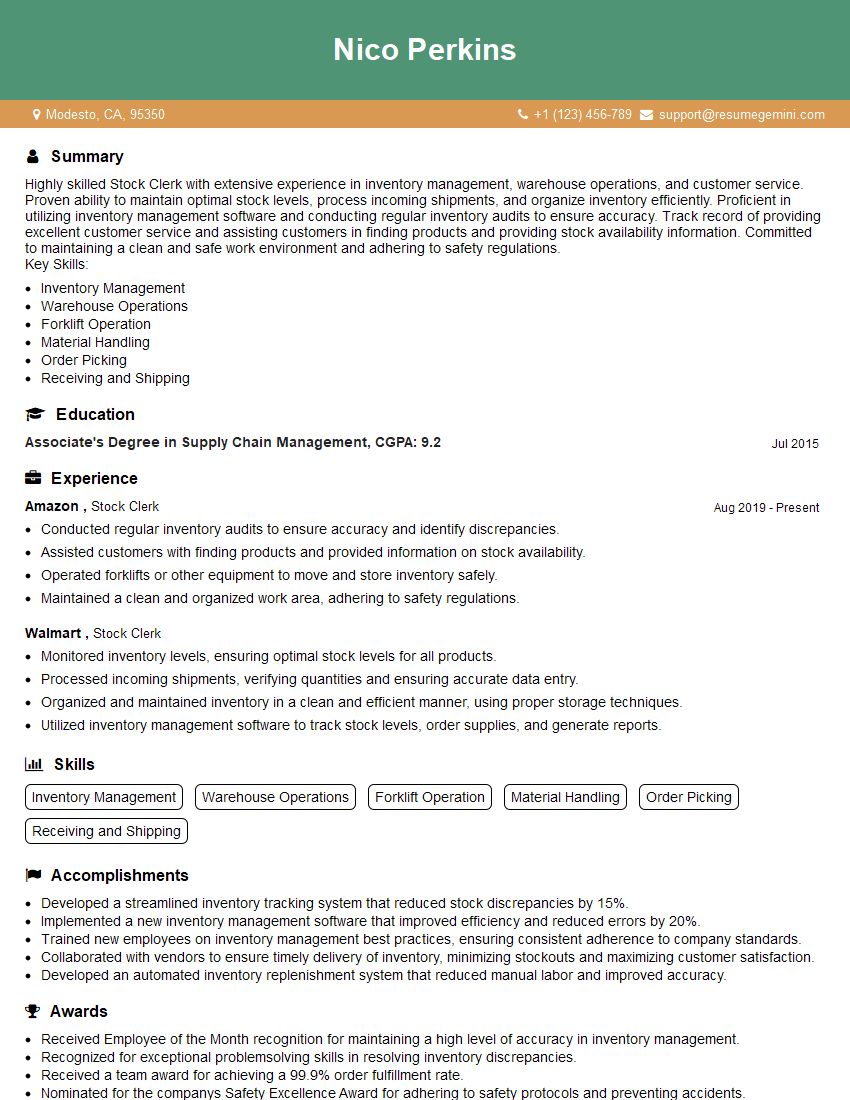

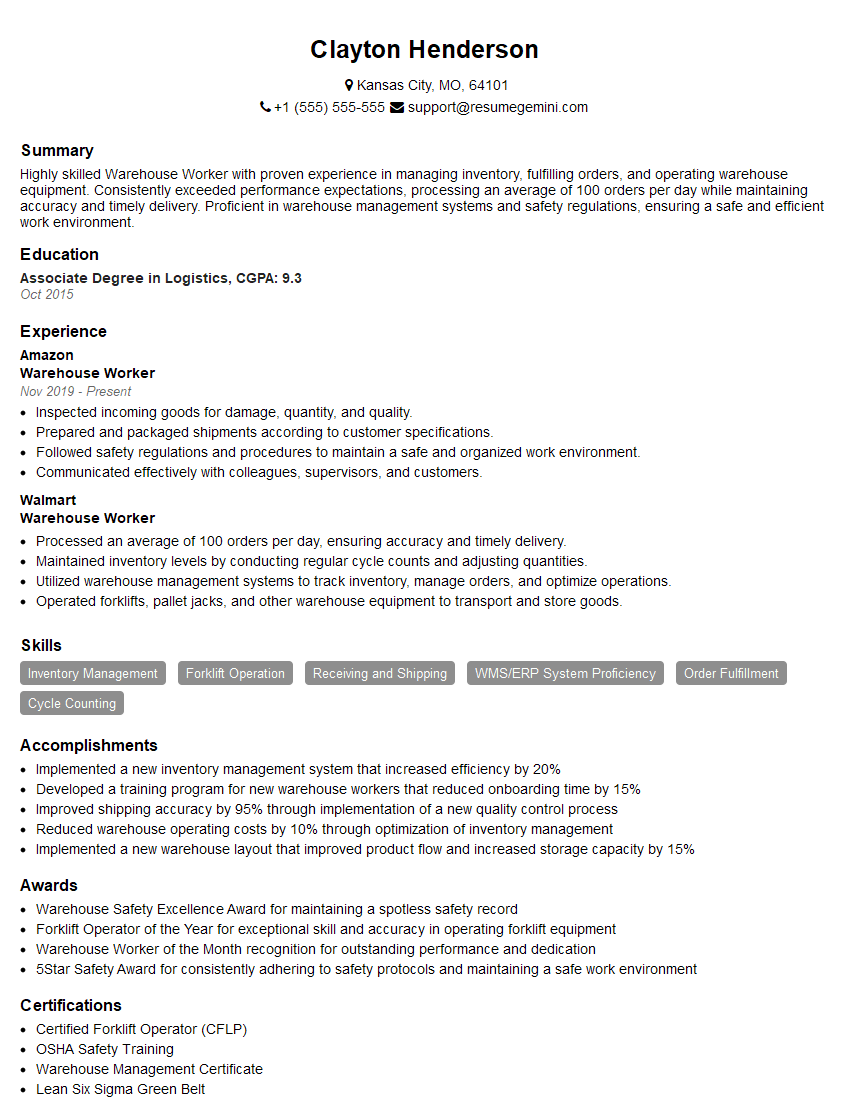

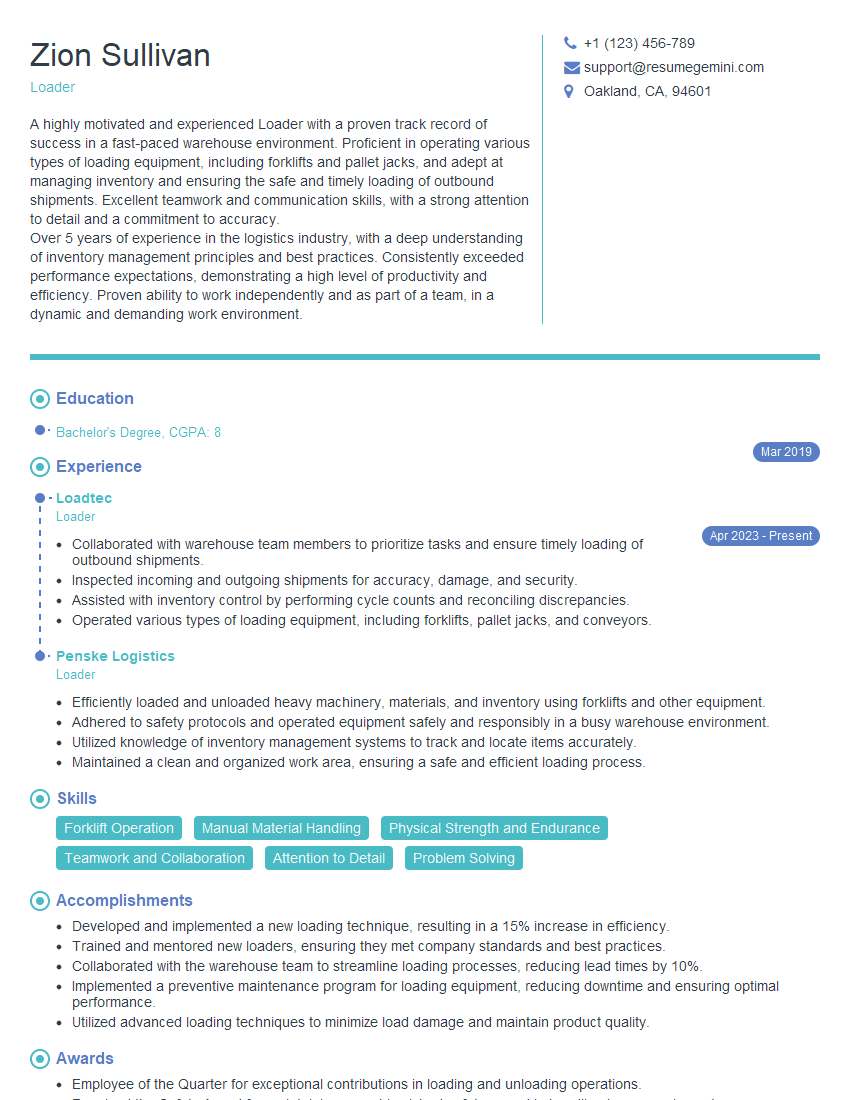

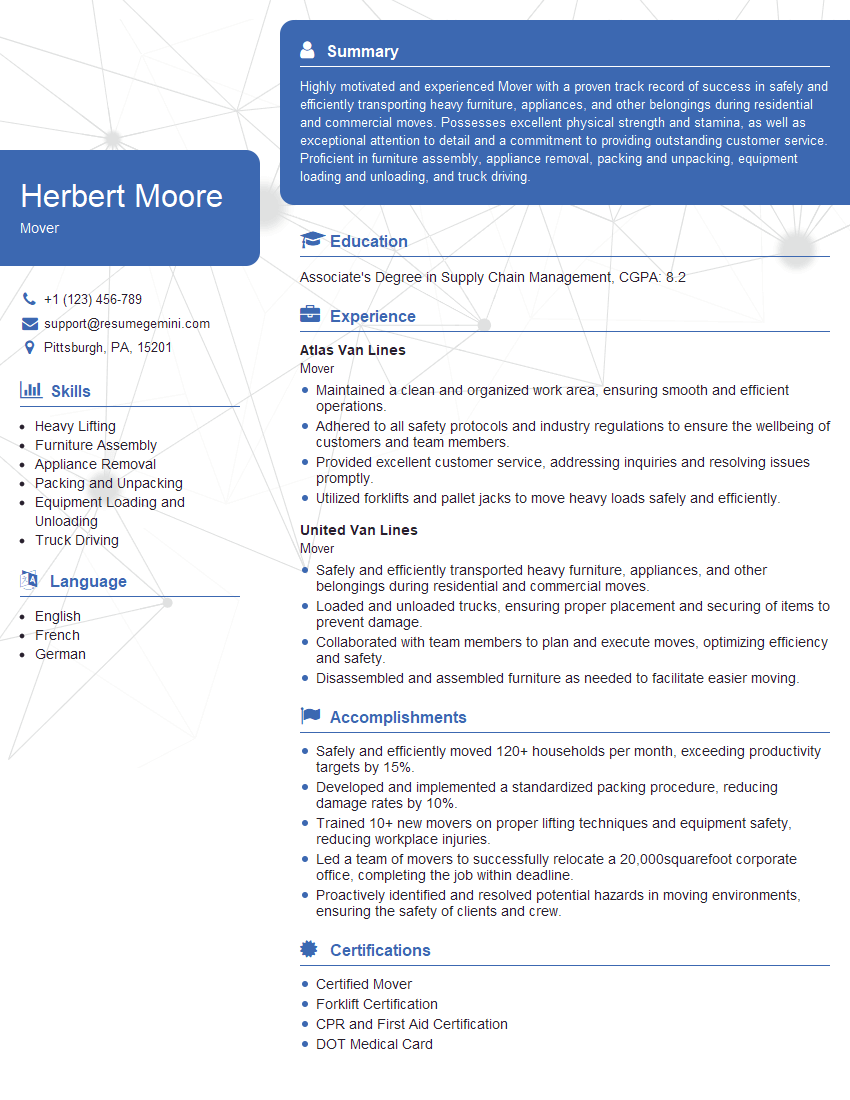

Mastering hand truck operation is a valuable skill that opens doors to various opportunities within logistics, warehousing, and transportation. Developing proficiency in this area demonstrates your commitment to safety, efficiency, and attention to detail – highly sought-after qualities in many industries. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We provide examples of resumes tailored to Hand Truck Operation to help you showcase your skills and experience effectively. Take the next step in your career journey – build your best resume with ResumeGemini.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good