Cracking a skill-specific interview, like one for Handle and store materials properly, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Handle and store materials properly Interview

Q 1. Explain the importance of proper material handling techniques.

Proper material handling techniques are crucial for ensuring safety, efficiency, and minimizing costs within any operation involving materials. Think of it like this: a well-organized orchestra needs each musician to handle their instrument properly – if not, chaos ensues. Similarly, mishandling materials leads to damage, injuries, delays, and ultimately, financial losses.

The importance spans several key areas:

- Safety: Preventing injuries to workers through proper lifting techniques, using appropriate equipment, and maintaining a safe work environment.

- Efficiency: Streamlining workflows through optimized storage, quick retrieval, and efficient transportation methods, reducing downtime.

- Cost Reduction: Minimizing material damage, reducing waste, and lowering insurance premiums associated with accidents.

- Product Quality: Protecting materials from damage, ensuring they arrive at their destination in optimal condition, ready for use or sale.

For instance, improper stacking of pallets can lead to collapses, causing damage and injury. Conversely, utilizing appropriate lifting devices and employing correct techniques minimizes risks and maximizes efficiency.

Q 2. Describe your experience with various material handling equipment (e.g., forklifts, pallet jacks).

My experience with material handling equipment is extensive, encompassing both practical operation and safety protocols. I’m proficient in operating forklifts, pallet jacks, and conveyor systems. I hold all necessary certifications for forklift operation, including safe operating procedures and pre-shift inspections.

Specifically, I’ve used forklifts to efficiently move heavy pallets in warehouse environments, ensuring load stability and navigating tight spaces safely. With pallet jacks, I’ve handled smaller, lighter loads, prioritizing ergonomics to avoid strains and injuries. My experience with conveyor systems includes troubleshooting malfunctions and ensuring smooth material flow. I’m adept at matching the right equipment to the job based on factors like weight, size, and fragility of the materials.

One memorable instance involved troubleshooting a malfunctioning conveyor belt. By systematically identifying the problem – a broken roller – and promptly replacing it, I prevented significant delays and potential material damage. This highlights the importance of proactive maintenance and hands-on problem-solving skills.

Q 3. How do you ensure the safety of materials during storage and transportation?

Ensuring material safety during storage and transportation involves a multi-faceted approach. It’s about minimizing risks at every stage of the process.

- Proper Packaging: Using appropriate packaging materials to protect against damage during transit – think sturdy boxes, protective films, and padding for fragile items.

- Secure Storage: Implementing appropriate storage systems based on the material characteristics – utilizing racking systems, designated areas for hazardous materials, and maintaining proper stacking heights.

- Safe Transportation: Securing loads properly on vehicles to prevent shifting during transit, using tie-downs and other securing devices.

- Environmental Controls: Maintaining appropriate temperature and humidity levels for sensitive materials to prevent spoilage or degradation.

- Regular Inspections: Conducting routine inspections of storage areas and transportation vehicles to identify and address potential hazards promptly.

For example, we used specialized climate-controlled containers to transport temperature-sensitive pharmaceuticals, ensuring their integrity throughout the supply chain. This proactive approach minimized risks of spoilage and ensured product quality.

Q 4. What are the different types of storage systems you are familiar with?

I’m familiar with a variety of storage systems, each suited for different material types and operational needs. These include:

- Racking Systems: Selective racking, drive-in racking, push-back racking, cantilever racking – each optimized for different storage densities and material access requirements.

- Pallet Racks: Standard pallet racking is the most common, providing easy access to individual pallets.

- Shelving Systems: Various shelving units for smaller items and components.

- Bulk Storage: Systems like silos and bins for storing large quantities of homogenous materials.

- Vertical Storage: Utilizing vertical space efficiently, especially in areas with limited floor space.

The choice of storage system depends on factors like space availability, material characteristics, access frequency, and operational workflow. For instance, a high-density drive-in rack is ideal for storing large quantities of similar items with less frequent access, whereas selective racking provides easy access to each pallet.

Q 5. Explain your experience with inventory management systems.

My experience with inventory management systems includes both manual and automated systems. I’m proficient in using various software solutions like ERP (Enterprise Resource Planning) systems and WMS (Warehouse Management Systems) to track inventory levels, manage stock movements, and generate reports. My skills include data entry, reconciliation, and reporting.

I’ve used these systems to optimize stock levels, minimize waste through accurate forecasting, and identify slow-moving items. I also have experience with barcode scanning and RFID technologies for efficient tracking and location identification. In a previous role, I implemented a new WMS system, resulting in a 15% reduction in inventory discrepancies and a 10% improvement in order fulfillment speed.

Q 6. How do you identify and address potential hazards in a warehouse environment?

Identifying and addressing potential hazards in a warehouse environment requires a proactive and systematic approach. It’s about anticipating problems before they occur and having strategies to mitigate them.

- Regular Inspections: Conducting routine safety inspections to identify potential hazards, such as damaged flooring, poorly stacked materials, or electrical hazards.

- Hazard Assessments: Performing regular risk assessments to identify potential hazards and develop control measures.

- Employee Training: Ensuring all employees are properly trained on safe operating procedures and emergency protocols.

- Proper Housekeeping: Maintaining a clean and organized warehouse to prevent trips, falls, and other accidents.

- Emergency Preparedness: Developing and practicing emergency response plans to handle incidents like fires or equipment malfunctions.

For example, noticing a small crack in the warehouse floor, I immediately reported it to prevent a potential trip hazard, and it was repaired quickly, preventing a possible injury.

Q 7. Describe your experience with FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) inventory methods.

FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) are two common inventory methods that dictate the order in which inventory is used. Choosing between them depends heavily on the type of goods.

- FIFO (First-In, First-Out): This method prioritizes using the oldest inventory first. It’s ideal for perishable goods (e.g., food, pharmaceuticals) to minimize spoilage and ensure freshness. Think of it like a queue – the items that arrive first are the first to leave.

- LIFO (Last-In, First-Out): This method uses the newest inventory first. It’s often used for non-perishable goods where inventory doesn’t expire. This can be advantageous for tax purposes in certain scenarios, as the cost of goods sold reflects current market prices.

In my experience, I’ve used FIFO for managing perishable goods in a food processing facility and LIFO for managing raw materials in a manufacturing setting. Proper implementation requires rigorous tracking and attention to detail to ensure correct inventory rotation and prevent stock obsolescence.

Q 8. How do you handle damaged or obsolete materials?

Handling damaged or obsolete materials requires a systematic approach to minimize waste and ensure safety. First, we must identify the damaged or obsolete items through regular inventory checks and quality control processes. This often involves visual inspection and potentially testing for functionality. Then, we categorize the materials: some might be repairable, others may have salvage value (e.g., recyclable components), and some must be disposed of properly.

For repairable items, we initiate a repair process, documenting all steps and costs. For items with salvage value, we separate the reusable parts from the unusable and arrange for recycling or resale, adhering to all relevant environmental regulations. This might involve partnering with scrap metal recyclers or specialized e-waste disposal companies. For disposal, we strictly follow local and national regulations for hazardous waste, ensuring environmentally sound practices. Proper documentation, including waste manifests, is crucial throughout this process. For example, if we have damaged pallets, the usable wood could be salvaged and repurposed. Electronic waste, like old barcode scanners, needs special handling to avoid environmental contamination.

Q 9. What are your strategies for maintaining a clean and organized warehouse?

Maintaining a clean and organized warehouse is paramount for efficiency and safety. My strategies focus on a combination of preventative measures and consistent maintenance. This begins with clear labeling and designated storage locations for all materials. We utilize a systematic organization method, often by product category or frequency of use. Aisles are kept clear to ensure easy movement of equipment and personnel. Regular sweeping and cleaning are scheduled, and spills are addressed immediately. We also use color-coded systems for different material types, enhancing visual organization and quick identification.

Employee training is key; every team member is responsible for maintaining cleanliness in their work area. We use visual aids like checklists and signage to remind everyone of their responsibilities. Regular audits help identify areas for improvement and ensure consistent adherence to our cleanliness standards. Think of it like a well-organized kitchen – if everything has its place, you can find what you need quickly and safely, minimizing risks of accidents and improving workflow.

Q 10. How do you ensure accurate inventory counts?

Accurate inventory counts are essential for efficient operations and informed business decisions. We use a multi-pronged approach to ensure accuracy. This starts with a robust inventory management system, often computerized, which tracks every item’s movement from receipt to shipment. Regular cycle counting, where a small portion of the inventory is counted and verified regularly rather than a complete count, is crucial for identifying discrepancies early on. We often use barcode scanners and RFID technology to enhance speed and accuracy during inventory checks. Additionally, we reconcile physical counts with our inventory management system frequently to detect any differences and promptly investigate their causes. This might involve reviewing picking lists, shipping documents, and potentially performing a full inventory recount if significant discrepancies are found.

For example, if a discrepancy occurs during cycle counting, we might investigate if there was a data entry error, a misplacement of the item, or even a potential loss or damage. Addressing these issues promptly is critical to maintain inventory accuracy and prevent further issues.

Q 11. Describe your experience with using barcode scanners and other inventory tracking technologies.

I have extensive experience using barcode scanners and other inventory tracking technologies. Barcode scanners significantly increase efficiency and accuracy in receiving, picking, and shipping processes. They reduce manual data entry errors, allowing for faster processing times. I am proficient in using various barcode scanner models and integrating them with different inventory management software (e.g., SAP, Oracle). Beyond barcode scanners, I’ve also worked with RFID (Radio-Frequency Identification) systems for tracking pallets and larger quantities of items. RFID technology allows for contact-less tracking, improving efficiency even further. We use the data collected by these technologies to generate real-time reports on inventory levels, helping us make data-driven decisions regarding stock replenishment and storage optimization.

In one past role, the implementation of RFID technology reduced our inventory discrepancies by 15%, a significant improvement in accuracy. The ability to track items remotely improved our warehouse efficiency significantly.

Q 12. How do you prioritize tasks in a fast-paced warehouse environment?

Prioritizing tasks in a fast-paced warehouse involves a structured approach. I typically use a combination of urgency and importance to prioritize tasks. Urgent and important tasks (e.g., fulfilling urgent customer orders) take precedence. Important but not urgent tasks (e.g., organizing a storage area) are scheduled strategically. Less important tasks are often delegated or deferred if necessary. We often use visual management tools, such as Kanban boards or task management software, to visualize the workflow and track progress. Effective communication within the team is crucial; we utilize daily huddles to discuss priorities and coordinate efforts.

For instance, if an urgent order needs to be shipped immediately, that task overrides all others until completed. This system, coupled with clear communication, maintains a productive workflow even under pressure.

Q 13. Explain your understanding of OSHA regulations related to material handling.

My understanding of OSHA regulations related to material handling is comprehensive. I am familiar with the requirements for safe lifting techniques, the use of appropriate personal protective equipment (PPE), such as safety shoes, gloves, and hard hats, and the proper use and maintenance of material handling equipment like forklifts and pallet jacks. I also understand the regulations regarding the safe storage of materials, preventing hazards like stack collapses, and maintaining safe working conditions, preventing hazards such as obstructed aisles. I am aware of the importance of regular inspections of equipment and the workplace, employee training programs on safe material handling practices, and the reporting procedures for accidents and near misses. Non-compliance with OSHA regulations can result in serious penalties, and my goal is always to maintain a safe and compliant workplace.

For example, we ensure all forklift operators are properly certified and undergo regular training, and we perform scheduled inspections of all equipment to maintain safety.

Q 14. Describe your experience with different types of packaging materials and their uses.

My experience encompasses various packaging materials and their uses. I’m familiar with corrugated cardboard boxes – the most common – used for their durability and affordability, suitable for a range of goods. I also work with plastic packaging, including shrink wrap, bubble wrap, and protective foam, offering varying levels of protection against damage. Wooden pallets are essential for transporting heavier goods, ensuring stability and ease of handling with forklifts. I’ve also worked with specialized packaging materials, such as climate-controlled containers for temperature-sensitive products or ESD (Electrostatic Discharge) protective packaging for electronics.

The selection of packaging material depends on factors such as the fragility of the product, transportation method, storage conditions, and environmental concerns. The goal is always to provide optimal protection while minimizing waste and costs. For example, we’d use sturdy wooden crates for fragile antiques, while lightweight bubble wrap suffices for electronics already encased in protective packaging.

Q 15. How do you handle discrepancies between physical inventory and system records?

Discrepancies between physical inventory and system records are a common challenge in material handling. Identifying the root cause is crucial. My approach involves a systematic investigation. First, I’d verify the accuracy of the physical count, often employing double-checking and potentially using barcode scanners for larger inventories. Then, I’d meticulously review the system records, checking for data entry errors, potential system glitches, or outdated information.

If the discrepancy remains, I’d investigate potential areas of loss or gain. This could include damaged goods not properly accounted for, items misplaced within the warehouse, or potential theft. I’d analyze inventory movement data to pinpoint the time frame of the discrepancy and identify any related transactions. This might involve comparing delivery receipts to system entries or reviewing employee activity logs. A clear documentation trail is maintained throughout the investigation, ultimately leading to corrective actions and prevention strategies. For example, if I find consistent errors in a specific area, it might highlight a need for better training or improved inventory management processes.

Ultimately, resolving discrepancies requires a combination of detailed investigation, attention to detail, and a proactive approach to prevent future errors. It’s like solving a puzzle, carefully examining all the pieces to understand the bigger picture.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with cycle counting?

Cycle counting is a crucial inventory control technique that involves regularly counting a small portion of your inventory, rather than performing a full inventory count infrequently. My experience spans several years, including leading cycle counting initiatives in fast-paced warehouse environments. I’ve successfully implemented various cycle counting methodologies, adapting strategies based on the specific characteristics of the inventory items and the warehouse layout.

For instance, I’ve used A-B-C analysis to prioritize higher-value items for more frequent counting. I’ve also employed zone-based counting, dividing the warehouse into sections and assigning counting responsibilities accordingly. Crucially, I ensure the process integrates seamlessly with the warehouse management system (WMS). Data from cycle counts are regularly analyzed to identify trends, address discrepancies, and refine inventory management processes. For example, consistently low counts of a specific item may indicate theft or damage, requiring immediate attention. Cycle counting is more than just a task; it’s a proactive measure to improve inventory accuracy, reduce losses, and enhance operational efficiency.

Q 17. How do you prevent material theft or loss?

Preventing material theft or loss requires a multi-layered approach encompassing security measures, procedural controls, and employee engagement. Physical security is paramount, involving secure access control to the warehouse, utilizing surveillance cameras, and implementing robust alarm systems. Procedural controls are equally vital, such as regular inventory checks, strict protocols for receiving and issuing materials, and documented chain-of-custody procedures. This might involve using barcode scanners to track every movement of inventory.

Moreover, fostering a culture of accountability and integrity is crucial. This includes thorough background checks during the hiring process, regular employee training on security protocols, and clearly defined consequences for theft or negligence. Random audits and surprise inventory checks can also deter theft. Regularly reviewing security measures and adapting to changing circumstances ensures the system remains effective and robust. It’s about creating a ‘fortress mentality’ around your valuable materials, deterring potential threats at every level, and building a culture of responsibility.

Q 18. Explain your experience with receiving and inspecting incoming shipments.

My experience in receiving and inspecting incoming shipments involves meticulous attention to detail and a strong understanding of quality control procedures. Upon arrival, I verify the shipment against the purchase order, ensuring the quantity and item descriptions match. I then thoroughly inspect the condition of the goods, looking for damage, defects, or discrepancies. Documentation is key – I meticulously record any discrepancies, damaged goods, or shortages. This includes taking photographs as evidence and promptly notifying the supplier. I’ve worked with various shipping documents, including bills of lading, packing slips, and certificates of origin. Understanding these documents is key to ensure smooth and accurate processing.

Moreover, I’m proficient in using barcode scanners and handheld devices to efficiently record the receipt of items and update the inventory management system. This ensures timely updating of inventory levels. Effective communication with suppliers is also crucial – clearly stating any issues or discrepancies expedites resolution and reduces delays. For instance, I’ve successfully negotiated credits or replacements for damaged goods, minimizing the financial impact on the organization.

Q 19. How do you ensure the efficient loading and unloading of trucks?

Efficient loading and unloading of trucks is critical for timely delivery and operational efficiency. My approach involves careful planning and coordination. Before the truck arrives, I ensure the designated loading/unloading area is clear and organized. This includes appropriate equipment, like forklifts and pallet jacks, being readily available and in good working order. I utilize a pre-planned loading sequence optimized for the truck’s capacity and the destination of the goods. This could involve loading heavier items at the bottom and lighter ones on top to ensure stability and prevent shifting during transit.

Effective communication with the truck driver is crucial – clarifying the delivery instructions and verifying the correct number of pallets and items. I also make sure proper documentation, such as delivery receipts, is completed accurately and timely. Regularly reviewing and improving loading/unloading procedures is vital. By analyzing data on truck turnaround times, we can identify bottlenecks and implement solutions to increase efficiency. For instance, optimizing the placement of goods in the warehouse can reduce travel time and improve the overall process. It’s about optimizing the flow of goods to ensure efficient operation and reduce downtime.

Q 20. Describe your experience with using warehouse management systems (WMS).

I’m proficient in using various Warehouse Management Systems (WMS), including [mention specific WMS systems if comfortable – e.g., SAP EWM, Oracle WMS, etc.]. My experience extends from data entry and inventory management to advanced features such as order fulfillment, cycle counting integration, and reporting. I can effectively utilize the system for tracking inventory, managing orders, and generating various reports. I’ve used WMS to optimize picking routes, improve inventory accuracy, and streamline the overall workflow.

For example, I’ve utilized the WMS reporting tools to identify slow-moving items, enabling proactive adjustments to inventory levels and preventing stock obsolescence. I understand the importance of data integrity within the WMS, ensuring accurate and timely updates to maintain reliable inventory information. Moreover, I’m adept at troubleshooting common issues and identifying system errors. My experience with WMS has significantly contributed to improvements in warehouse efficiency, inventory accuracy, and overall operational effectiveness.

Q 21. What are your strategies for optimizing warehouse space?

Optimizing warehouse space requires a strategic approach that considers both the physical layout and the operational flow. I employ several strategies to maximize space utilization. Firstly, I conduct a thorough assessment of the current space usage, identifying areas of inefficiency and underutilized space. This might involve analyzing storage patterns and identifying opportunities to consolidate inventory or relocate less frequently accessed items to higher or less accessible areas.

Secondly, I explore different storage methods, such as implementing high-bay racking systems, using vertical space efficiently, or utilizing narrow-aisle forklifts. Thirdly, I optimize the layout to minimize travel distances for picking and put-away operations. Implementing lean principles, such as 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain), ensures efficient organization and prevents wasted space. This could involve regularly cleaning and organizing the warehouse to maintain a streamlined layout. Regularly reviewing and adjusting the layout based on operational changes and inventory adjustments is crucial for maintaining optimal space utilization. It’s an ongoing process of fine-tuning to keep the warehouse working effectively and prevent wastage.

Q 22. How do you handle rush orders or unexpected changes in demand?

Handling rush orders requires a flexible and adaptable approach. My strategy centers around prioritization and clear communication. First, I’d immediately assess the order’s specifics: quantity, required materials, and delivery deadlines. Then, I’d collaborate with the team to identify any potential bottlenecks in our existing workflow. This might involve adjusting our scheduling, prioritizing specific tasks, and potentially even temporarily reallocating resources. For example, if a rush order requires a specific type of packaging material we’re low on, I’d immediately contact our supplier to expedite delivery. Transparency is key; I’d keep all relevant parties informed of the progress, managing expectations and proactively addressing any challenges that arise. Unexpected demand changes are tackled similarly, leveraging our inventory management system to quickly identify stock levels and adjust production or procurement accordingly. This involves analyzing historical data to anticipate future trends and having contingency plans in place for scenarios like sudden surges in demand. We might implement overtime shifts or explore alternative sourcing options if necessary to meet the increased demand without compromising quality or delivery timelines.

Q 23. What is your experience with different types of racking systems?

My experience encompasses a variety of racking systems, each suited to different needs and materials. I’m proficient with selective pallet racking, which is ideal for high-volume storage of palletized goods, offering easy access to individual pallets. I’ve also worked extensively with cantilever racking, perfect for long, bulky items like lumber or pipes. Drive-in/drive-through racking is another system I’ve used, optimizing space in high-density storage situations, although it has limitations in accessibility. Finally, I have experience with push-back racking, a space-saving solution suited for FIFO (First-In, First-Out) inventory management. The choice of racking system always depends on the specific characteristics of the materials stored—their size, weight, fragility, and turnover rate—as well as the overall warehouse layout and budget. For example, a warehouse storing delicate electronics would benefit from a system offering better protection against damage, while a warehouse with a high volume of fast-moving consumer goods might prioritize easy access over maximum space efficiency.

Q 24. Describe a time you had to solve a problem related to material handling.

In a previous role, we experienced a significant backlog in our shipping department due to an unforeseen issue with our labeling system. The automated label printer malfunctioned, causing delays in processing orders and leading to potential shipping errors. My initial response involved assessing the damage and identifying the root cause of the malfunction. We then implemented a temporary solution: manually labeling shipments using pre-printed labels while technicians repaired the printer. To prevent this situation from recurring, we reviewed our backup systems and upgraded the printer’s software to improve its reliability. We also implemented a more robust quality control process to ensure that all labels were accurate before shipment. This incident highlighted the importance of having contingency plans and effective communication during emergencies. The collaborative effort to implement a temporary solution, coupled with long-term preventative measures, minimized the impact on our customers and improved our overall operational efficiency.

Q 25. How do you ensure materials are stored correctly according to their specific requirements (e.g., temperature, humidity)?

Ensuring correct material storage requires a meticulous approach that considers the specific requirements of each item. For temperature-sensitive materials, we utilize climate-controlled storage areas with precise temperature and humidity monitoring systems. These areas are regularly calibrated to maintain optimal conditions and prevent spoilage or degradation. For instance, pharmaceuticals or perishable goods need rigorous temperature control, often within very narrow ranges. Materials sensitive to humidity are stored in areas with dehumidifiers or in sealed containers with desiccant packs. Flammable or hazardous materials are kept in designated areas following strict safety regulations, far from ignition sources and properly labelled with appropriate hazard warnings. Proper racking and stacking techniques are vital to prevent damage and ensure safe access. We use inventory management software to track the location and condition of each item, alerting us to any potential storage issues. Regular inspections and audits are vital to ensure our systems remain effective and that materials are stored according to specifications.

Q 26. How do you stay up-to-date on best practices for material handling and storage?

Staying current in material handling and storage best practices is an ongoing process. I actively participate in industry conferences and workshops, attending seminars and webinars offered by professional organizations. I subscribe to relevant industry publications and journals to keep abreast of new technologies and regulatory changes. Furthermore, I actively engage with online professional networks, participating in forums and discussions to exchange knowledge with peers and industry experts. I also actively seek out certifications and professional development courses to enhance my skill set and demonstrate my commitment to professional excellence. For example, recent advancements in warehouse automation, such as the use of automated guided vehicles (AGVs) and robotics, require continuous learning to effectively integrate these technologies into our operations.

Q 27. Describe your experience with implementing new material handling procedures.

I recently led the implementation of a new warehouse management system (WMS) to improve our inventory tracking and order fulfillment process. The project involved a thorough needs assessment to identify areas for improvement, including selecting the right WMS software that aligned with our needs and budget. This was followed by a comprehensive training program for all warehouse staff to ensure smooth adoption of the new system. We also developed detailed implementation plans, phased rollout strategies to minimize disruption, and a robust testing process to identify and resolve any bugs or compatibility issues. Key to success was the establishment of clear communication channels and consistent monitoring of performance metrics post-implementation. The new WMS resulted in a significant reduction in order processing time, minimized errors, and optimized our warehouse space utilization. This project involved managing a team, coordinating with vendors, and overseeing technical implementation, demonstrating my ability to handle complex projects effectively.

Key Topics to Learn for Handle and store materials properly Interview

- Material Identification and Classification: Understanding different material types (e.g., hazardous, fragile, perishable) and their specific handling requirements.

- Storage Techniques and Best Practices: Proper stacking, racking, labeling, and rotation methods to prevent damage and ensure efficient retrieval. This includes understanding FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) inventory management.

- Safety Procedures and Regulations: Adhering to OSHA guidelines and company-specific safety protocols for handling various materials, including the use of appropriate Personal Protective Equipment (PPE).

- Inventory Management Systems: Familiarity with different inventory tracking methods (manual or automated) and their impact on material handling and storage efficiency. This also includes understanding potential software solutions used for managing inventory.

- Damage Prevention and Control: Implementing strategies to minimize material damage during handling and storage, including proper packaging, climate control (if necessary), and pest control.

- Waste Management and Disposal: Understanding procedures for proper disposal of waste materials, complying with environmental regulations and minimizing environmental impact.

- Technological Applications: Exploring the use of technology in material handling and storage, such as automated guided vehicles (AGVs), conveyor systems, and warehouse management systems (WMS).

- Problem-Solving and Troubleshooting: Developing strategies for addressing potential issues related to material handling and storage, such as damage, loss, or inefficiencies. This involves the ability to analyze situations, identify root causes, and implement effective solutions.

Next Steps

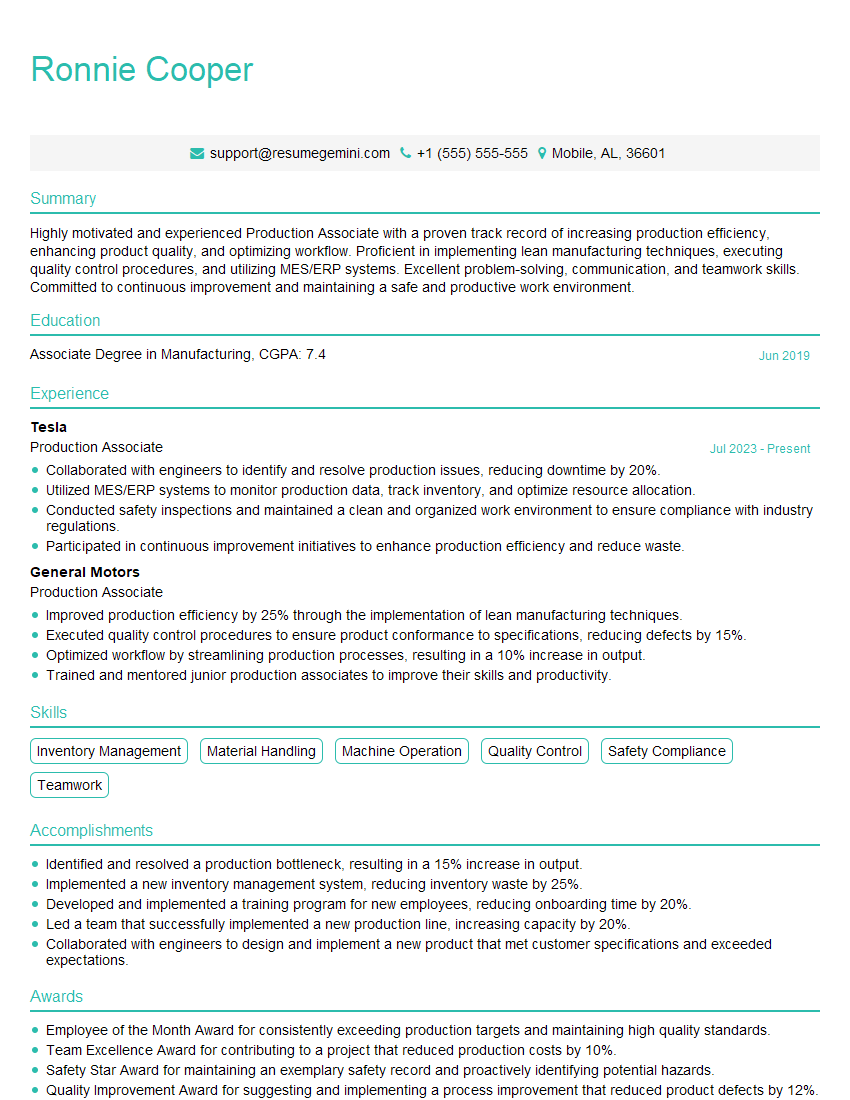

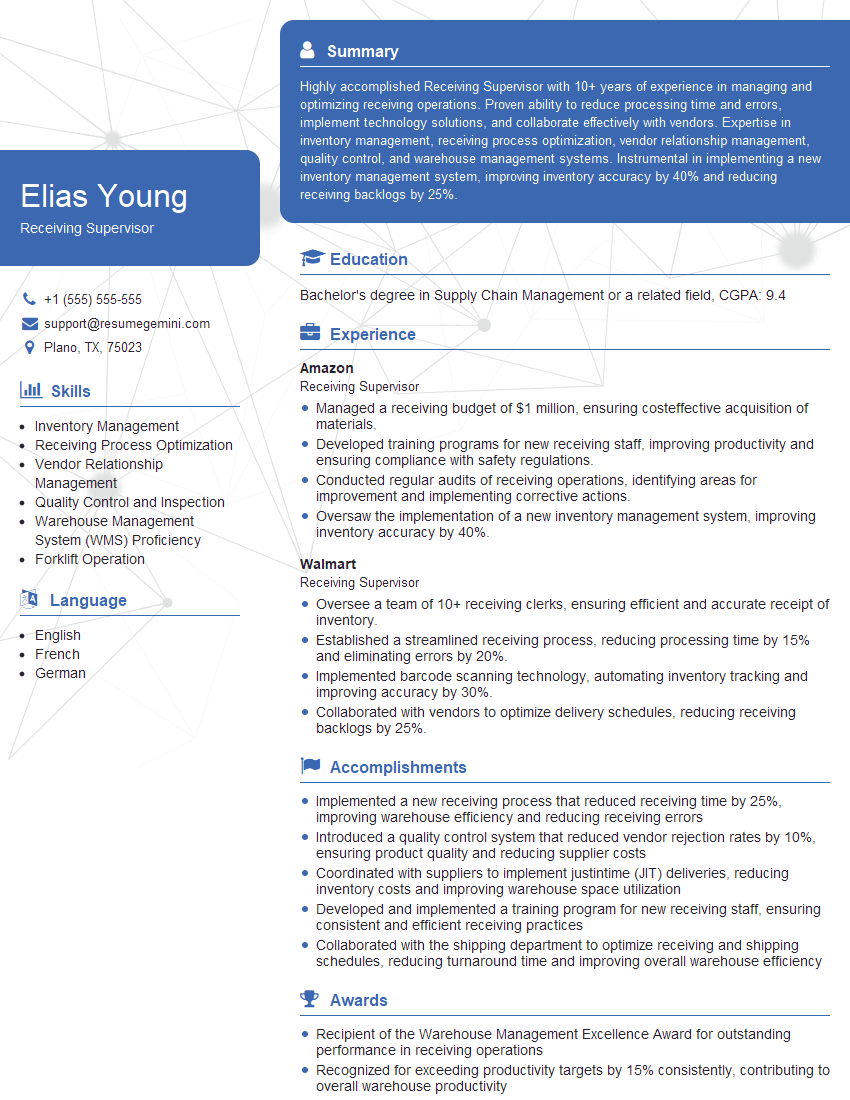

Mastering proper material handling and storage techniques is crucial for career advancement in numerous industries. It demonstrates your commitment to safety, efficiency, and responsible practices. To highlight these skills effectively to potential employers, focus on building an ATS-friendly resume that clearly showcases your relevant experience and expertise. ResumeGemini is a trusted resource to help you create a professional and impactful resume that stands out from the competition. Examples of resumes tailored to highlight experience in material handling and storage are available, helping you present your qualifications in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good