Preparation is the key to success in any interview. In this post, we’ll explore crucial Harvest Season Management interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Harvest Season Management Interview

Q 1. Describe your experience managing harvest operations for various crops.

My experience spans over 15 years, encompassing a diverse range of crops including wheat, corn, soybeans, fruits (apples, cherries), and vegetables (potatoes, lettuce). I’ve managed harvest operations from small family farms to large-scale commercial operations, adapting my strategies to the unique challenges of each crop and environment. For instance, the delicate nature of cherry harvesting requires a different approach – focusing on hand-picking and careful handling – compared to the mechanized harvesting of wheat, which demands precise timing and efficient equipment operation. This experience has given me a deep understanding of the intricacies involved in maximizing yields and minimizing losses across various agricultural contexts.

- Wheat: Implementing precision harvesting techniques to optimize grain quality and minimize losses.

- Corn: Managing multiple harvesting crews and optimizing the use of combine harvesters to meet tight deadlines.

- Soybeans: Utilizing advanced sensor technology to determine optimal harvest timing and prevent yield reduction due to pod shattering.

- Fruits (Apples, Cherries): Implementing careful hand-picking strategies to maintain fruit quality and minimize damage.

- Vegetables (Potatoes, Lettuce): Utilizing specialized harvesting equipment and employing efficient post-harvest handling to extend shelf life.

Q 2. Explain your process for optimizing harvest yields.

Optimizing harvest yields involves a multi-faceted approach, starting long before the harvest season begins. It’s not just about the harvesting process itself; it’s about maximizing the potential of the crop throughout its entire life cycle. My process centers around these key areas:

- Pre-Harvest Planning: This includes thorough field scouting to assess crop maturity and uniformity, soil conditions, and potential challenges. We use this information to plan the harvest sequence and resource allocation effectively.

- Precision Harvesting Techniques: Utilizing GPS-guided machinery, yield monitors, and sensor technology allows for precise harvesting, minimizing losses and optimizing the use of resources. For example, variable-rate harvesting adjusts machine settings based on real-time yield data, ensuring consistent quality across the field.

- Optimal Harvest Timing: Precise timing is crucial to maximize yield and quality. We use a combination of visual inspection, maturity models, and sensor data to determine the ideal harvest window for each crop. This is especially important for crops susceptible to pre-harvest sprouting or spoilage.

- Post-Harvest Handling: Careful handling post-harvest is essential to prevent damage and maintain quality. This includes proper cleaning, drying, storage, and transportation techniques.

For example, in a corn harvest, we use yield monitors on the combines to track yield in real time. This data helps us identify areas with lower yields, allowing us to adjust harvesting parameters or investigate potential issues in those specific sections for improvements in the next growing season.

Q 3. How do you manage labor resources during peak harvest season?

Managing labor resources during peak harvest is a logistical challenge requiring meticulous planning and effective communication. My strategy involves:

- Accurate Labor Forecasting: We carefully estimate labor needs based on field size, crop type, and projected harvest timeline. This forecasting is often refined as the season progresses based on actual progress and weather conditions.

- Crew Scheduling and Management: We use specialized software to manage and track crew assignments, ensuring optimal workforce allocation and efficient workflow. Effective communication and clear work instructions are crucial to prevent delays and ensure high performance.

- Motivating and Training Employees: Providing competitive wages, clear expectations, and opportunities for training improves morale and productivity. We also focus on safety training to minimize risks and potential injuries.

- Strategic Partnerships: In certain circumstances, we engage with temporary labor agencies or contract with experienced harvest crews to meet peak demand.

For instance, during a particularly busy potato harvest, we coordinated with a local agricultural college to supplement our existing workforce with skilled student interns. This not only provided extra hands, but also gave the students valuable hands-on experience.

Q 4. What strategies do you employ to minimize harvest losses?

Minimizing harvest losses requires a proactive approach that begins well before harvest and continues through post-harvest handling. My strategies include:

- Proper Equipment Maintenance: Regularly scheduled maintenance of harvesting equipment is essential to ensure optimal performance and minimize mechanical losses. This includes regular inspections, lubrication, and timely repairs.

- Careful Field Preparation: Proper field preparation reduces pre-harvest losses by improving accessibility for harvesting equipment and preventing mechanical damage to plants. This includes considerations for soil conditions and weed control.

- Optimal Harvest Timing: Harvesting crops at the ideal maturity stage minimizes losses due to spoilage, shattering, or other quality issues. Using sensors and maturity models helps optimize timing.

- Efficient Post-Harvest Handling: Careful handling, cleaning, and storage practices minimize post-harvest losses due to damage, spoilage, or contamination.

- Loss Assessment and Analysis: Regularly assessing and analyzing harvest losses helps identify areas for improvement and refine strategies for future harvests. We often use data collected from yield monitors and post-harvest quality checks to identify trends and potential issues.

For example, we noticed significant losses in soybean yield due to pod shattering in one field. By analyzing the data from our yield monitors and conducting soil tests, we identified a nutrient deficiency as the primary cause and adjusted our fertilization practices for future planting seasons.

Q 5. Outline your approach to quality control during harvesting and post-harvest handling.

Quality control is paramount throughout the entire harvest and post-harvest process. My approach is multifaceted and includes:

- Pre-Harvest Assessment: Thorough pre-harvest field assessments are done to evaluate crop maturity, uniformity, and potential defects. This helps us anticipate potential quality issues and adjust harvesting procedures as needed.

- In-Field Quality Checks: During harvest, we conduct regular quality checks of harvested produce to monitor for damage, disease, and other quality factors. Samples are taken regularly and assessed against established standards.

- Post-Harvest Handling and Cleaning: Careful handling, cleaning, and sorting procedures are implemented to remove any damaged or substandard produce. This can include using automated sorting systems to quickly and accurately identify and separate defects.

- Storage and Transportation: Proper storage and transportation conditions are critical for maintaining quality. This involves careful temperature and humidity control, appropriate packaging, and prompt delivery to processing facilities or markets.

- Traceability: Implementing traceability systems allows for tracking the origin and handling of produce, making it possible to identify and address quality issues more quickly and efficiently. This is particularly useful in case of recalls or disputes.

For example, in apple harvesting, we use color-sorting machines to separate apples based on their maturity and color, ensuring a consistent product quality for different markets.

Q 6. Describe your experience with different harvesting equipment and their maintenance.

My experience encompasses a wide range of harvesting equipment, from traditional machinery to sophisticated precision technologies. I’m proficient in operating and maintaining various combines (for grains), harvesters (for vegetables and fruits), tractors, and other specialized equipment. This expertise includes:

- Routine Maintenance: This includes daily inspections, lubrication, cleaning, and minor repairs to prevent breakdowns and ensure optimal performance.

- Preventive Maintenance: Scheduled maintenance programs are implemented to prevent major repairs and extend the lifespan of equipment. This often includes overhauls, component replacements, and adjustments according to manufacturer guidelines.

- Troubleshooting and Repair: I possess the skills to diagnose and repair mechanical and electrical issues in harvesting equipment, minimizing downtime and ensuring efficient operations.

- Technological Proficiency: I’m familiar with the latest GPS-guided machinery, yield monitors, and sensor technology, which enables precision harvesting and improved efficiency.

For instance, I’ve successfully managed the transition from traditional harvesting techniques to the use of GPS-guided combines in a wheat farm, resulting in significant improvements in yield and reduced fuel consumption.

Q 7. How do you monitor and manage weather conditions during the harvest?

Monitoring and managing weather conditions during harvest is crucial for ensuring efficient and successful operations. My strategy involves:

- Weather Forecasting: We rely on accurate weather forecasts to anticipate potential weather events such as rain, wind, or extreme temperatures. This helps in planning daily operations and making necessary adjustments.

- Real-Time Monitoring: During the harvest, we continually monitor weather conditions using on-site weather stations, mobile apps, and satellite imagery. This enables real-time decision-making.

- Contingency Planning: We develop contingency plans to address potential weather disruptions. This might include adjusting harvesting schedules, relocating equipment, or implementing protective measures to mitigate damage.

- Data-Driven Decision Making: We use historical weather data to analyze trends and patterns and improve forecasting accuracy. This helps in long-term planning and resource allocation.

For example, during a period of predicted heavy rain, we adjusted the harvesting schedule to prioritize fields at higher risk of waterlogging and utilized tarps to protect harvested produce waiting for transport.

Q 8. Explain your method for scheduling harvest activities based on crop maturity and weather forecasts.

Scheduling harvest activities requires a delicate balance between crop maturity and weather forecasts. My approach is a three-step process: First, I utilize precision agriculture technologies, such as yield monitors and remote sensing, to assess crop maturity across the fields. This allows for a field-by-field harvest plan rather than a blanket approach. Second, I meticulously analyze weather forecasts – not just daily predictions, but extended forecasts looking 5-7 days out, paying close attention to potential for rain, wind, and extreme temperatures. This data is crucial because untimely rain can cause significant yield loss, while strong winds can damage the crop during harvesting. Third, I integrate these two data sets into a sophisticated scheduling software that optimizes the harvest sequence, prioritizing the most mature fields with the most favorable weather windows. This might involve adjusting the harvest crew size and equipment based on the predicted weather and the area ready for harvest. For example, if a storm is predicted, we might prioritize the fields at highest risk of damage first.

Imagine it like a complex game of Tetris: each field is a block of varying shape and size (maturity level), and the weather forecasts dictate how much time you have to fit them in before the game ends (storm arrives). This software helps us find the optimal fit, maximizing yield and minimizing potential losses.

Q 9. How do you ensure the safety of your harvest crew?

Ensuring crew safety is paramount. My approach is multifaceted. We begin with comprehensive safety training, covering topics like operating machinery safely, recognizing and avoiding hazards (e.g., power lines, uneven terrain), and emergency procedures. We provide all necessary Personal Protective Equipment (PPE), including high-visibility clothing, safety helmets, gloves, and eye protection. Regular safety meetings reinforce these procedures, and we incorporate a ‘buddy system’ where workers pair up and check on each other throughout the workday. We also strictly enforce a zero-tolerance policy towards unsafe practices and provide regular health and wellness check-ins to address any fatigue or concerns. Finally, regular equipment maintenance and inspections prevent mechanical failures that could lead to accidents.

For instance, we might hold a dedicated training session on operating a combine harvester, demonstrating correct procedures for entering and exiting, safe use of controls, and what to do in the event of a malfunction. This proactive approach builds a strong safety culture and reduces the risk of incidents.

Q 10. What metrics do you use to evaluate the success of a harvest season?

Evaluating harvest success isn’t just about the total yield. I use a range of metrics to get a comprehensive view. Key indicators include yield per acre (tons/acre or bushels/acre), harvest efficiency (acres harvested per hour), post-harvest quality (percentage of damaged or diseased produce), and operational costs per unit harvested. We also track labor productivity (tons harvested per worker-hour) and equipment utilization (percentage of operational time). Beyond quantitative metrics, we assess the overall quality of the product, its market value, and the level of worker satisfaction. Analyzing these indicators allows for a thorough assessment of overall performance, identifying areas for improvement in subsequent seasons.

For example, a high yield per acre but low harvest efficiency could indicate a need for better equipment or more efficient field organization. Conversely, high harvest efficiency with a low yield might suggest an issue with crop management practices in the growing season.

Q 11. Describe your experience with post-harvest storage and handling of crops.

Post-harvest handling is critical to maintain product quality and extend shelf life. Our process starts with careful handling during harvest to minimize damage. We employ appropriate cleaning and sorting procedures at the collection points, removing any damaged or diseased produce. Then the crops are transported to storage facilities equipped with climate-controlled environments. This minimizes spoilage and reduces losses. Storage conditions are tailored to the specific crop, maintaining optimal temperature and humidity levels. We regularly monitor storage conditions, including temperature and humidity, and use pest control measures to prevent infestation. Inventory management systems track storage location and quality, ensuring efficient stock rotation and preventing spoilage.

For example, apples require cooler temperatures and controlled humidity to prevent browning and rotting, whereas potatoes need a slightly higher temperature to prevent sprouting. Our storage facilities are specifically designed to cater to these varied needs.

Q 12. How do you manage logistics and transportation during the harvest season?

Harvest logistics are crucial, especially during peak season. We optimize transportation by carefully planning routes, coordinating with trucking companies, and utilizing efficient loading and unloading procedures. Real-time tracking of vehicles and inventory ensures timely delivery to processing plants or storage facilities. We strategically locate temporary holding areas near fields to reduce transportation distances and prevent bottlenecks. Efficient communication and coordination between field crews, transportation teams, and processing plants are essential for smooth operation.

For example, we might use route optimization software to plan the most efficient truck routes, minimizing travel time and fuel consumption. This allows us to respond swiftly to changes in the harvest schedule or unexpected delays.

Q 13. What is your approach to managing inventory levels during harvest?

Inventory management during harvest requires a dynamic approach. We use sophisticated software systems to track harvested quantities in real-time, updating inventory levels continuously. This system integrates data from yield monitors and weighing scales, providing an accurate picture of available stock. This allows for precise forecasting of storage needs, timely allocation of resources, and informed decisions regarding sales and processing. We continuously monitor market demands to prevent overstocking or stockouts.

This might involve adjusting our harvesting schedule in response to market demand. For instance, if a particular variety is in high demand, we may prioritize its harvest to meet that demand, while potentially slowing down harvesting of a lower-demand variety.

Q 14. How do you handle unexpected challenges during the harvest (e.g., equipment breakdowns, weather delays)?

Unexpected challenges are inevitable. Our strategy revolves around preparedness and adaptability. We maintain a robust maintenance program for all equipment, minimizing breakdowns. We have backup equipment and personnel on standby to respond quickly to malfunctions. Our contingency plans include alternative transportation arrangements and a system for communicating effectively with crews in case of delays caused by inclement weather. We have a dedicated team responsible for identifying and addressing issues promptly, minimizing downtime. We use data analysis to anticipate potential issues and proactive measures to mitigate risks.

For instance, a sudden heavy rainfall might necessitate a temporary halt in harvesting. Our contingency plan would involve re-routing trucks already en route, contacting the processing plant to coordinate, and repositioning crews to fields less affected by the rain. The data analysis would then be used to inform future decisions regarding weather-related harvest schedules.

Q 15. Describe your experience with implementing sustainable harvest practices.

Sustainable harvest practices are crucial for long-term profitability and environmental stewardship. My experience encompasses implementing a range of strategies, from optimizing machinery to minimize soil compaction and fuel consumption, to adopting precision agriculture techniques for targeted harvesting and reduced waste.

For example, in one project, we transitioned from traditional tillage methods to no-till farming, significantly reducing soil erosion and improving water retention. This led to higher yields and lower input costs. We also implemented crop rotation strategies to improve soil health and reduce pest and disease pressure, further enhancing sustainability. We carefully monitor soil health indicators and adjust practices as needed. Another key element is the responsible management of agricultural waste, utilizing methods such as composting and anaerobic digestion to reduce landfill waste and generate valuable by-products.

Finally, a focus on efficient water usage is critical. This includes the use of drip irrigation systems, targeted fertilization, and weather-based irrigation scheduling to reduce water waste. By meticulously tracking water usage and yield, we continually refine our water management strategies.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you track and analyze harvest data to improve future operations?

Data-driven decision-making is paramount in modern harvest management. We utilize various technologies, including yield monitors on harvesting machinery, GPS mapping systems, and farm management software to track key metrics such as yield per acre, harvest speed, fuel consumption, and machinery downtime. This data is then analyzed using statistical software and data visualization tools to identify trends, bottlenecks, and areas for improvement.

For instance, by analyzing yield maps, we can pinpoint areas with lower yields and investigate the underlying causes, such as soil deficiencies or pest infestations. This allows for targeted interventions in future growing seasons. We also analyze machinery performance data to identify potential maintenance needs and optimize harvesting routes, reducing fuel consumption and improving efficiency. This data-driven approach allows us to continuously refine our operations and maximize profitability while minimizing waste.

Q 17. How do you communicate effectively with your harvest team and other stakeholders?

Effective communication is the backbone of a successful harvest operation. I employ a multi-faceted approach involving regular team meetings, clear and concise task assignments, open communication channels (both verbal and written), and regular feedback sessions. We use various communication tools, including mobile apps for real-time updates and project management software for task tracking and progress monitoring.

Building strong relationships with the team is also crucial. I emphasize a collaborative and supportive work environment, ensuring that everyone feels valued and heard. Transparent communication with stakeholders, including landowners, buyers, and regulatory agencies, is also paramount. This includes regular updates on progress, potential challenges, and any necessary adjustments to the harvesting plan. Clear and proactive communication ensures a smooth and efficient operation and mitigates potential conflicts.

Q 18. Explain your knowledge of various crop varieties and their specific harvesting requirements.

My expertise encompasses a wide range of crop varieties, each with unique harvesting requirements. For example, grains like wheat and barley require careful consideration of moisture content at harvest to ensure optimal quality and storage. Legumes such as soybeans and peas need to be harvested at the right maturity stage to balance yield and seed quality. Fruits and vegetables have even more stringent requirements regarding ripeness, handling, and storage conditions. Knowledge of optimal harvesting techniques for different crops, including mechanical vs. hand harvesting methods, is essential.

I have extensive experience with various harvesting equipment and techniques optimized for different crop types and conditions. This includes understanding the impact of weather conditions on harvest timing and adjusting harvesting strategies accordingly. Furthermore, I am knowledgeable about different varieties within crop types, taking into account their specific maturity dates, susceptibility to disease, and optimal harvesting windows.

Q 19. How do you ensure compliance with relevant regulations during harvesting?

Compliance with relevant regulations is a non-negotiable aspect of harvest operations. This involves staying updated on all applicable federal, state, and local regulations concerning pesticide use, water quality, labor laws, and worker safety. We maintain meticulous records of all harvesting activities, including pesticide applications, water usage, and worker hours. We conduct regular safety training sessions for our team, ensuring they are well-versed in safe operating procedures and emergency response protocols.

We also actively engage with regulatory agencies and seek clarification when needed. We maintain comprehensive documentation to demonstrate our compliance efforts and proactively address any potential issues. By prioritizing compliance, we minimize risks and maintain a strong reputation in the industry.

Q 20. Describe your experience with budget management in the context of harvest operations.

Budget management is crucial for successful harvest operations. I have extensive experience in developing and managing detailed budgets that encompass all aspects of harvesting, from labor costs and equipment maintenance to fuel and transportation expenses. We utilize budgeting software to track expenditures against planned allocations and identify any potential cost overruns.

In one instance, we implemented a system of predictive analytics to forecast potential equipment downtime and budget accordingly for repairs and maintenance, significantly reducing unexpected costs. This proactive approach allows for efficient resource allocation and helps avoid financial surprises during the harvest season. We also carefully analyze historical data to refine our budgeting process and improve cost control in subsequent years.

Q 21. What are your strategies for dealing with labor shortages during peak harvest season?

Labor shortages during peak harvest season are a common challenge. My strategies for mitigating this involve a multi-pronged approach. This includes proactive recruitment efforts well in advance of the harvest season, offering competitive wages and benefits packages, and fostering a positive and supportive work environment to attract and retain skilled workers.

In addition, we leverage technology to increase efficiency and reduce labor demands. This involves using advanced harvesting machinery and precision agriculture techniques. We also explore alternative labor solutions, such as partnerships with temporary staffing agencies and utilizing student labor programs when feasible. Open communication with the team and flexibility in scheduling can also significantly aid in addressing labor needs during peak harvest periods. Effective planning and proactive strategies are key to mitigating labor shortages.

Q 22. Explain your familiarity with different harvesting techniques (e.g., mechanical vs. hand harvesting).

Harvesting techniques vary greatly depending on the crop, scale of operation, and terrain. Mechanical harvesting utilizes machinery like combines, harvesters, and pickers for large-scale operations, significantly increasing efficiency and speed. This is ideal for crops like wheat, corn, and soybeans, where the yield is high and the crop is relatively uniform. Think of a combine as a mobile processing plant, cutting, threshing, and cleaning the grain all in one go.

Hand harvesting, on the other hand, involves manual labor and is often preferred for delicate crops like grapes, berries, and certain fruits and vegetables. It allows for selective picking, ensuring only the ripe and high-quality produce is harvested, minimizing damage. This method is more labor-intensive and expensive, but crucial for maintaining superior product quality and often used for specialty markets. For example, premium wine grapes are almost exclusively hand-harvested to prevent bruising.

A hybrid approach, combining both methods, is also common. For example, a large orchard might use mechanical shakers to dislodge fruit from trees, followed by hand-picking to collect the produce and remove any damaged pieces.

Q 23. How do you mitigate the risk of crop damage during harvesting?

Mitigating crop damage during harvesting requires a multi-pronged approach. Firstly, choosing the right harvesting equipment and adjusting settings based on crop maturity and conditions is vital. For instance, setting the combine’s drum speed too high can lead to grain breakage in wheat harvesting. Secondly, proper training of harvesting crews is crucial. Whether it’s operating machinery or hand-picking, careful handling minimizes physical damage. Regular maintenance of machinery is also non-negotiable – broken parts can damage crops. Thirdly, harvesting at the optimal time is critical. Harvesting too early can yield immature produce, while harvesting too late can lead to spoilage or pest infestation. Finally, careful post-harvest handling prevents further damage during transport and storage.

For example, in a grape vineyard, using padded harvesting bins and avoiding dropping the fruit prevents bruising, a common cause of quality loss. Properly calibrated machinery helps avoid crop damage during mechanical harvesting of crops like potatoes.

Q 24. Describe your experience with pest and disease management during the harvest season.

Pest and disease management during the harvest season is critical to preserving yield and quality. This starts long before harvest with proactive strategies. Regular scouting for pests and diseases throughout the growing season allows for early detection and timely intervention. This could involve applying appropriate pesticides or fungicides, or employing biological controls like introducing beneficial insects. Proper sanitation practices, such as removing diseased plants promptly, limit the spread of pathogens.

During harvest, careful monitoring is crucial to identify any emerging issues. This might involve checking for pest damage in the field before commencing harvesting, or inspecting the harvested produce for signs of disease or insect infestation. Any infected produce must be removed immediately to prevent contamination of the entire harvest. Post-harvest treatments such as cold storage or fumigation might be necessary to control pests and diseases that might still be present.

Q 25. How do you ensure timely delivery of harvested crops to processing facilities?

Timely delivery of harvested crops is essential to maintain quality and market value. Effective planning and coordination are key. This includes having sufficient transport capacity, establishing efficient routes to processing facilities, and scheduling harvesting activities to match processing plant availability. Real-time tracking systems, using GPS and communication technology, can monitor the location and condition of the harvested goods during transit. This allows for immediate response to delays or potential issues.

For example, a grower might contract with multiple trucking companies to ensure sufficient transport capacity during peak harvest times. Regular communication with the processing facility ensures the smooth flow of harvested goods, preventing bottlenecks and spoilage.

Q 26. What is your approach to managing waste and by-products from the harvest?

Managing waste and by-products from the harvest is crucial for environmental sustainability and economic efficiency. This includes minimizing waste at each stage of the process, from careful harvesting techniques to efficient processing methods. Strategies involve exploring different avenues for utilization of by-products. For instance, crop residues can be used as animal feed, compost, or biofuel. Processing waste can be utilized as a source of nutrients for other crops or for industrial applications.

For example, in a fruit processing plant, fruit peels and cores can be used to produce juice or jam, minimizing waste and creating value-added products. Similarly, leftover grain after threshing might be used for animal feed, rather than being discarded.

Q 27. Explain your understanding of the impact of climate change on harvest operations.

Climate change significantly impacts harvest operations. More frequent and intense extreme weather events, such as droughts, floods, heatwaves, and unexpected frosts, directly affect crop yields and harvesting schedules. Changes in rainfall patterns can lead to uneven crop maturation, making harvesting more challenging. Higher temperatures can accelerate ripening, shortening the harvest window and increasing the risk of spoilage. It’s important to adopt climate-smart agriculture practices. This might include choosing drought-resistant crop varieties, implementing efficient irrigation systems, and improving soil health to enhance resilience to climate change.

Farmers need to adapt to these changes by diversifying crops, adopting more resilient varieties, and integrating technology like weather forecasting and precision agriculture to optimize harvest timing and resource management.

Q 28. How do you use technology to improve the efficiency of harvest operations?

Technology plays a crucial role in improving the efficiency of harvest operations. GPS-guided machinery allows for precise navigation and reduces overlap, minimizing fuel consumption and increasing harvesting speed. Yield monitors on combines provide real-time data on crop yield, enabling adjustments to harvesting strategies to optimize efficiency. Remote sensing technologies like drones and satellite imagery provide valuable information on crop health and maturity, aiding in making informed decisions regarding harvest timing.

Precision agriculture technologies, combined with data analytics, allow for precise application of inputs such as fertilizers and pesticides, minimizing waste and improving crop quality. Automated systems for sorting and grading harvested produce improve efficiency and reduce manual labor. Finally, supply chain management software facilitates efficient transportation and logistics, streamlining the entire harvest process.

Key Topics to Learn for Harvest Season Management Interview

- Yield Optimization Strategies: Understanding and applying techniques to maximize crop yield, considering factors like weather patterns, soil conditions, and pest management.

- Harvest Planning & Logistics: Developing efficient harvesting schedules, managing equipment allocation, and coordinating labor resources for timely and cost-effective harvesting.

- Quality Control & Post-Harvest Handling: Implementing procedures to maintain product quality throughout the harvesting and post-harvest processes, minimizing losses and ensuring optimal market value.

- Inventory Management & Forecasting: Accurately predicting harvest yields, managing storage capacity, and optimizing inventory levels to meet market demands and minimize spoilage.

- Risk Management & Mitigation: Identifying and assessing potential risks associated with harvest season (e.g., weather events, equipment failures, labor shortages) and developing strategies to mitigate their impact.

- Data Analysis & Reporting: Utilizing data to track key performance indicators (KPIs), identify areas for improvement, and make informed decisions to enhance efficiency and profitability.

- Team Management & Communication: Effectively leading and motivating harvest teams, fostering collaboration, and ensuring clear communication to achieve common goals.

- Budgeting & Cost Control: Developing and managing harvest budgets, monitoring expenses, and identifying opportunities for cost reduction while maintaining quality and efficiency.

- Sustainability & Environmental Practices: Implementing environmentally friendly harvesting practices, minimizing environmental impact, and promoting sustainable agriculture.

- Technological Advancements in Harvest Management: Staying updated on the latest technologies and innovations impacting harvest operations, such as precision agriculture and automation.

Next Steps

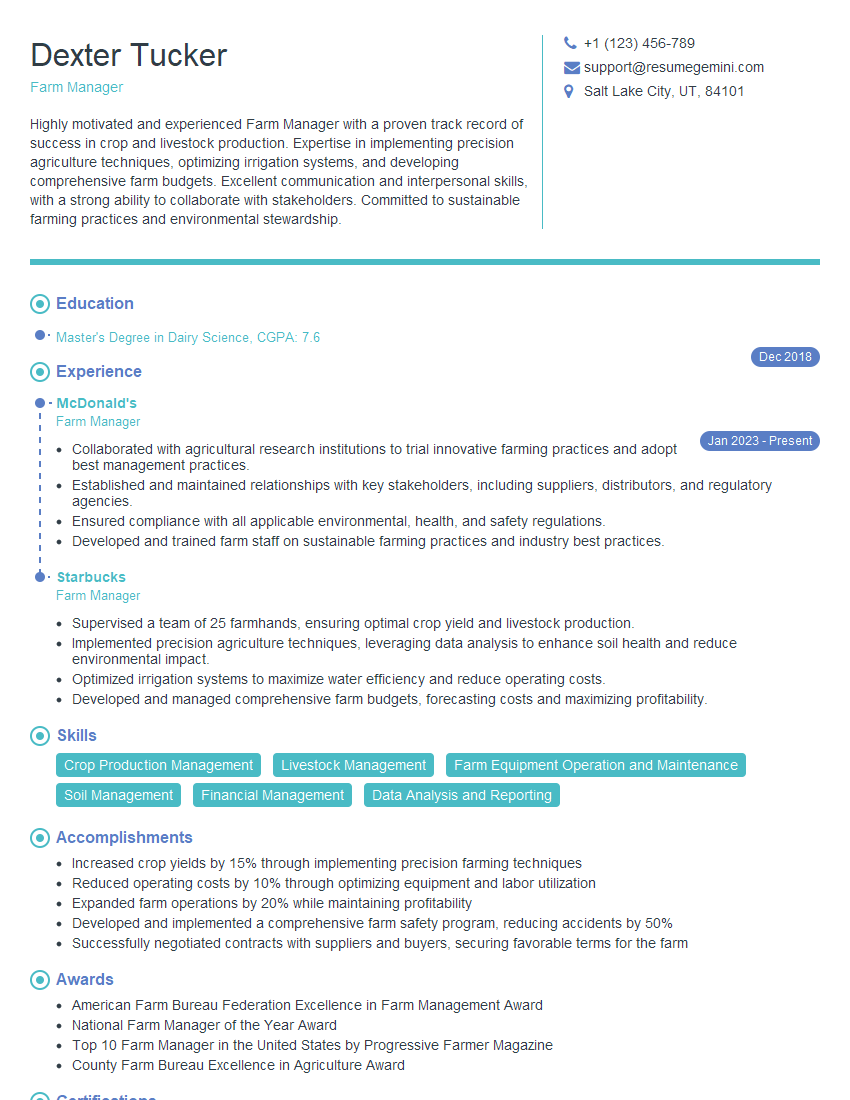

Mastering Harvest Season Management is crucial for career advancement in the agricultural sector, opening doors to leadership roles and increased responsibilities. A strong resume is essential for showcasing your skills and experience to potential employers. Building an ATS-friendly resume significantly increases your chances of getting your application noticed. To create a compelling and effective resume, we recommend using ResumeGemini, a trusted resource for building professional resumes. Examples of resumes tailored specifically to Harvest Season Management are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good