Are you ready to stand out in your next interview? Understanding and preparing for Harvester Operations and Maintenance interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Harvester Operations and Maintenance Interview

Q 1. Describe your experience with different types of harvesters.

My experience encompasses a wide range of harvesters, from small-scale forage harvesters used for hay and silage to large-scale combine harvesters used for grain harvesting. I’ve worked extensively with various brands, including John Deere, Case IH, and Claas, gaining familiarity with their unique operational characteristics and maintenance requirements. For instance, I’ve operated self-propelled forage harvesters with different cutting systems – drum, disc, and knife – each requiring specific adjustments and maintenance based on the crop being harvested. Similarly, my experience with combines extends to different header types, such as corn heads, draper heads, and flex heads, which necessitates understanding the complexities of each header’s setup and maintenance procedures. This diverse experience allows me to quickly adapt to new harvesting equipment and troubleshoot a wide array of problems.

Q 2. Explain the preventative maintenance schedule for a combine harvester.

Preventative maintenance for a combine harvester is crucial for optimal performance and longevity. It’s best approached using a structured schedule, often broken down into daily, weekly, and seasonal tasks. Daily checks might include inspecting belts, hoses, and fluid levels (engine oil, hydraulic fluid, coolant); cleaning the grain tank and sieves; and checking the header for any damage. Weekly maintenance could involve lubricating bearings, checking tire pressure, and cleaning the radiator. Seasonal maintenance before the harvest season begins is far more extensive and might include a complete engine service (oil change, filter replacements), thorough inspection and cleaning of the entire machine, and replacing worn parts like belts and blades. A detailed checklist specific to the combine’s make and model is essential, and this is often provided by the manufacturer. Think of it like a regular health check-up for your machine – preventing minor issues from becoming major breakdowns.

Q 3. How do you troubleshoot a malfunctioning harvester header?

Troubleshooting a malfunctioning harvester header requires a systematic approach. First, I’d visually inspect the header for obvious problems: damaged knives or reel components, clogged augers, or any physical obstructions. I’d then check the hydraulic system for leaks or pressure issues using a pressure gauge. Next, I’d examine the electrical connections, ensuring proper power supply and functionality of sensors and actuators. A common issue is a jammed or damaged auger, which can be resolved by disassembling the auger and removing the obstruction. If the problem persists, checking the header’s hydraulic motor for proper function and looking for damaged belts or chains would be the next step. Finally, if none of the above reveals the source, a detailed consultation with a maintenance manual is necessary to diagnose more complex issues relating to the hydraulic or electrical components. Documenting every step with pictures or notes is crucial for future reference, especially during repetitive or complicated repairs.

Q 4. What are the common causes of engine overheating in a harvester?

Engine overheating in a harvester can stem from several causes. The most common are inadequate coolant levels, a malfunctioning cooling fan, a clogged radiator, or a faulty thermostat. Low coolant levels can be due to leaks in the system, so a visual inspection for leaks is paramount. A malfunctioning cooling fan might not be circulating enough air to dissipate heat, requiring repair or replacement. A clogged radiator restricts airflow, reducing cooling efficiency. This often needs cleaning or even replacement. A faulty thermostat prevents the coolant from circulating at the correct temperature, causing overheating. Additionally, problems like a restricted exhaust system or low engine oil levels can also contribute to overheating. In such cases, it’s always best to immediately shut down the engine to prevent serious damage. The situation should be thoroughly examined by skilled personnel.

Q 5. Describe your experience with repairing hydraulic systems in harvesters.

I have extensive experience repairing hydraulic systems in harvesters. This involves diagnosing leaks, replacing faulty components, and bleeding the system to remove air bubbles. Troubleshooting often starts with pinpointing the leak – this can be done using a combination of visual inspection and pressure testing. Common leaks occur in hoses, fittings, and seals. Replacing these components usually involves disconnecting the affected part, installing the new component, and carefully tightening the fittings to prevent future leaks. Bleeding the system afterwards is crucial to eliminate air bubbles that hinder the system’s efficiency and can cause damage. I am proficient in using hydraulic pressure gauges to identify any pressure drops indicating malfunctions within the hydraulic pumps, valves, or actuators. For complex issues, specialized hydraulic diagnostic tools might be necessary for accurate identification of the root cause.

Q 6. How do you ensure the safety of yourself and others during harvester operation?

Safety is paramount during harvester operation. Before starting work, I always perform a thorough pre-operational inspection, ensuring all guards are in place and safety interlocks are functioning. I always wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and sturdy work boots. I also maintain a safe distance from moving parts and ensure the area around the harvester is clear of obstructions and bystanders. Regular communication with other team members is key to coordinating safe operations. Following all safety regulations set by the manufacturer and local authorities is imperative. Understanding emergency procedures and knowing how to respond quickly to unexpected events is also critical, and regular refresher training is vital to reinforce safety consciousness and prevent accidents.

Q 7. Explain the process of calibrating a harvester’s yield monitor.

Calibrating a harvester’s yield monitor involves accurately measuring the harvested material to provide reliable yield data. The process typically starts with selecting the appropriate crop type and setting parameters on the yield monitor’s display. Then, a known quantity of material (e.g., a weighed amount of grain) is passed through the harvester, and the monitor’s readings are compared against the actual weight. Adjustments to the monitor’s settings are made to correct any discrepancies between the recorded and actual yield. This often involves adjusting sensor sensitivity and calibration factors. The process is repeated several times to ensure accuracy. Regular calibration is essential to maintain the yield monitor’s accuracy, especially when harvesting different crops or changing environmental conditions that might affect the sensor readings. Accurate yield data is crucial for making informed decisions regarding crop management and harvest efficiency.

Q 8. How do you handle a clogged grain tank?

A clogged grain tank is a common problem during harvest, often caused by damp grain, foreign materials, or simply an overload. Addressing this requires a systematic approach, prioritizing safety.

- Safety First: Always turn off the harvester and engage the parking brake before attempting any cleaning.

- Initial Assessment: Determine the extent of the clog. Is it a minor blockage or a complete stoppage? A visual inspection through access points can help.

- Clearing the Clog: For minor blockages, a grain auger or even a long, sturdy rod can often dislodge the material. For more serious clogs, you might need to access the tank from various points, potentially using a combination of tools like shovels and augers. Sometimes it might require removing the auger entirely to clear a particularly stubborn clog.

- Prevention: Regular checks of the tank’s fill level, using appropriate cleaning processes, and promptly addressing minor blockages are key to preventing major problems. Ensuring the grain is dry before harvesting significantly reduces the risk of clogging.

I once had a situation where a farmer’s tank was completely clogged with wet, sticky corn. We had to access the tank through multiple access points, using a combination of tools and even a pressure washer with caution, to clear it. This experience highlighted the importance of preventative measures and meticulous cleaning processes.

Q 9. What are the different types of cutting heads used in harvesters and their applications?

Harvester cutting heads, also known as headers, are crucial for efficient and clean harvesting. The choice depends on the crop being harvested and field conditions. Here are some common types:

- Standard Grain Header: The most common type, designed for harvesting cereals like wheat, barley, and oats. Features a rotating reel to feed the crop into the cutter bar, which cuts the stalks and conveys them into the harvester.

- Corn Header: Specifically designed for corn harvesting. It features rows of rollers that strip the ears from the stalks. These headers often have various configurations depending on corn row spacing.

- Bean Header: Suitable for harvesting soybeans and other legumes. Typically uses a platform that picks up the plants, then threshing the beans from the plants within the header.

- Sunflower Header: Specifically designed to harvest sunflowers. It features a cutting mechanism that carefully cuts the sunflower heads, leaving the stalks in the field.

- Draper Header: This type gently cuts the crop and allows for more efficient harvesting in lodged (fallen) crops and varying crop heights.

The selection process often involves considering factors like crop type, yield, terrain, and operator preference. A farmer with hilly terrain, for instance, might prioritize a flexible header that contours to the uneven ground.

Q 10. Describe your experience with diagnosing electrical problems in harvesters.

Diagnosing electrical problems in harvesters requires a systematic and methodical approach, combining technical knowledge with problem-solving skills. My experience involves understanding schematics, utilizing diagnostic tools, and employing troubleshooting techniques.

- Safety First: Always disconnect the power source before working with electrical components.

- Visual Inspection: Begin with a careful visual inspection of wiring harnesses, connectors, and components for any signs of damage, loose connections, or corrosion.

- Schematic Review: Refer to the harvester’s electrical schematic to trace circuits and identify potential problem areas.

- Testing Equipment: Utilize multimeters, voltage testers, and other diagnostic equipment to measure voltages, currents, and resistances. This helps pinpoint the exact location of the fault.

- Component Testing: If a component is suspected to be faulty, test it independently using bench testing procedures or replacement to isolate the issue.

For example, I once resolved a situation where the harvester’s combine motor was not starting. Through systematic testing using a multimeter, I discovered a faulty relay switch in the starting circuit which was preventing current from reaching the motor. After replacing the relay, the harvester functioned correctly. This highlighted the importance of methodical diagnostic procedures, detailed schematic reading and use of quality testing equipment.

Q 11. How do you perform a pre-harvest inspection of a harvester?

A pre-harvest inspection is critical for ensuring safe and efficient operation. It should be a thorough process, covering key aspects of the harvester to prevent downtime and potential damage.

- Visual Inspection: Examine the cutting head, auger, and tank for any damage, loose bolts, or wear and tear. Inspect all belts and chains for tightness and signs of wear.

- Fluid Levels: Check engine oil, coolant, hydraulic fluid, and fuel levels and top up as required. Look for leaks and address them proactively.

- Operational Check: Test all operational components, such as the engine, transmission, hydraulic system, and cutting head. This ensures each component is functioning correctly.

- Safety Systems: Verify the functionality of safety systems like emergency stops and shields, ensuring they’re properly installed and operating effectively.

- Lubrication: Grease all appropriate lubrication points according to the manufacturer’s recommendations.

- Documentation: Record all findings and maintenance activities in a logbook for future reference.

A pre-harvest inspection is like a car’s pre-road trip check-up. It helps prevent unexpected issues during harvest, leading to higher productivity, reduced downtime and increased safety.

Q 12. Explain the importance of regular lubrication in harvester maintenance.

Regular lubrication is paramount for extending the life of the harvester and preventing costly repairs. Lack of lubrication leads to excessive wear and tear, friction, overheating, and ultimately, failure of critical components.

- Reduced Friction: Lubricants create a barrier between moving parts, significantly reducing friction and wear. This results in longer component lifespan.

- Heat Dissipation: Lubricants help in absorbing heat generated by friction, reducing the risk of overheating and damage to components.

- Corrosion Prevention: Lubricants protect metal surfaces from rust and corrosion caused by moisture and other elements.

- Improved Efficiency: Well-lubricated components function more efficiently, reducing energy loss and enhancing productivity.

Think of it like oiling a bicycle chain – without lubrication, the chain would quickly rust, wear, and eventually break. Similarly, regular lubrication in a harvester is essential for keeping everything running smoothly and preventing expensive breakdowns during the crucial harvest season.

Q 13. What are the common causes of loss of power in a harvester?

Loss of power in a harvester can stem from various sources, necessitating a systematic approach to diagnosis.

- Engine Problems: Issues like low fuel, clogged air filters, faulty fuel injectors, or engine component failure can lead to power loss.

- Transmission Issues: Problems within the transmission, such as low fluid levels, worn clutches, or internal damage, can restrict power transfer to the wheels or other components.

- Hydraulic System Problems: Leaks, low fluid levels, or issues with the hydraulic pump can affect the performance of hydraulically-driven components, reducing power.

- Electrical Problems: Faulty wiring, blown fuses, or problems with the electrical system can disrupt the flow of power to essential components.

- Driveline Problems: Problems with the driveline, such as worn universal joints or broken shafts, can impede power transfer.

A recent case involved a harvester experiencing intermittent power loss. Through careful diagnostics, we traced the issue to a faulty fuel injector causing inconsistent fuel delivery to the engine cylinders. Replacing the injector restored full power.

Q 14. How do you address fuel system issues in a harvester?

Addressing fuel system issues in a harvester requires careful attention to detail and safety. The steps typically follow this sequence:

- Safety First: Ensure the harvester’s engine is off and cooled down before attempting any repairs.

- Identify the Problem: Determine the nature of the fuel system issue. Is it fuel starvation, contamination, leaks, or a problem with the fuel pump or injectors? Observing symptoms, checking fuel levels, and inspecting for leaks are key.

- Check Fuel Quality: Ensure the fuel is clean and free of contaminants. Water in the fuel is a common culprit.

- Inspect Fuel Lines and Filters: Examine fuel lines for leaks, cracks, or blockages. Replace fuel filters if necessary, as clogged filters can restrict fuel flow.

- Test Fuel Pump: Check the fuel pump’s operation to ensure it’s supplying sufficient fuel pressure. This might involve using a pressure gauge.

- Inspect Fuel Injectors (if applicable): If the issue appears related to fuel injectors, specialized testing equipment or replacement may be required.

I once dealt with a harvester suffering from fuel starvation. After careful investigation, we discovered a faulty fuel pump. Replacing the pump resolved the issue, demonstrating the critical role of component-level diagnostics and timely replacement.

Q 15. Describe your experience working with different types of harvesting attachments.

My experience encompasses a wide range of harvesting attachments, from grain platforms of varying widths (from 12 feet to 40 feet) designed for different crops like wheat, barley, soybeans, and corn, to specialized headers for canola and rice. I’ve also worked extensively with corn heads, both row-crop and draper-style, each requiring unique setup and adjustments based on crop conditions and yield. Beyond grain harvesting, I’m proficient with forage harvesters and their various attachments like various types of chopping heads and different kernel processor configurations depending on the desired particle size of the chopped forage. The key to efficient harvesting lies in selecting the right attachment and configuring it appropriately for optimal performance and minimal crop loss. For example, a poorly adjusted header can lead to significant yield loss, which translates directly to economic consequences for the farmer. Therefore, a thorough understanding of each attachment’s mechanics and adjustment points is crucial.

- Grain Platforms: Experience with various header widths and configurations for different crops.

- Corn Heads: Proficiency with row-crop and draper-style heads, including adjustments for row spacing and crop height.

- Forage Harvesters: Expertise in using various chopping heads and kernel processors for optimal forage quality.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the process of changing a combine harvester’s rotor.

Replacing a combine rotor is a complex procedure requiring specialized tools and safety precautions. It’s not a task for the inexperienced. First, the combine must be completely shut down and the power source disconnected. Then, safety guards and access panels are removed to expose the rotor. The next steps involve carefully removing the rotor components, often working in tandem with a second mechanic for heavier parts. The old rotor is then removed, cleaned, and inspected for damage before being replaced with a new or reconditioned rotor. The new rotor is carefully installed, ensuring proper alignment and engagement with all components. All components are then reinstalled, and the machine is reassembled. A thorough check-up after installation is essential before restarting the harvester. Each step has to be executed precisely, missing a step or improperly fitting a part can damage the harvester components, leading to costly repairs. The entire process can take several hours and requires detailed knowledge of the combine’s mechanical components. For example, on a Claas Lexion, specific tools and procedures are required, and the manual needs to be consulted throughout the operation. Proper maintenance and regular inspections can predict rotor failures and prevent unexpected downtime.

Q 17. How do you handle emergency situations during harvester operation?

Emergency situations during harvester operation require quick thinking and decisive action. My approach involves prioritizing safety and minimizing damage. For instance, if a fire breaks out, the first priority is to evacuate the operator and any personnel nearby. Then, engage the fire extinguisher system or call for emergency services. If a mechanical failure occurs, such as a broken belt or jammed rotor, I would first shut down the harvester to ensure safety before troubleshooting and making the necessary repairs. If there’s a blockage in the threshing unit, the safe procedure is to completely shut down and unload the combine before attempting to clear the obstruction. Detailed documentation of each event and the subsequent actions taken is crucial for future preventative maintenance. Understanding the warning signs of the harvesters, using available monitoring systems and preventative maintenance to predict problems are key parts of minimizing emergency situations.

- Fire: Immediate evacuation, fire suppression, emergency services.

- Mechanical Failure: Shutdown, troubleshooting, repairs.

- Blockages: Shutdown, clearing of obstructions.

Q 18. What safety regulations are you familiar with regarding harvester operation?

I’m thoroughly familiar with all relevant safety regulations concerning harvester operation, including OSHA standards and manufacturer’s guidelines. This includes, but isn’t limited to, proper personal protective equipment (PPE) such as hearing protection, eye protection, and safety footwear; pre-operational checks before each use (including visual inspections of mechanical parts); maintaining safe operating speeds and distances from hazards; the importance of regular maintenance schedules to prevent mechanical failures; safe refueling procedures; the required training to operate heavy machinery; and following all lockout/tagout procedures when performing maintenance. Ignoring these regulations can lead to serious accidents resulting in injury or fatalities. Regular safety training and refresher courses are a vital part of ensuring a safe work environment and efficient operation.

Q 19. Describe your experience with GPS-guided harvesting.

My experience with GPS-guided harvesting is extensive. I’ve used various systems, including RTK GPS, to achieve high levels of precision during harvesting operations. This technology allows for automated steering, optimizing header placement, which significantly reduces overlap and minimizes crop losses. This also allows for optimized harvesting of varied crops across uneven terrains. It’s proven very beneficial in areas with varying crop yields. I can use the data collected to map and generate detailed yield maps, providing valuable insights for future field management decisions, such as variable rate fertilizer application. For example, using GPS guidance, we managed to improve harvesting efficiency by 15% on a challenging field with undulating terrain. The integration of GPS with yield monitoring systems allows for the real-time monitoring and optimization of the harvest process.

Q 20. How do you maintain accurate records of harvester maintenance and repairs?

Accurate record-keeping is crucial for efficient harvester maintenance and repair. I utilize a combination of digital and physical methods. I use computerized maintenance management systems (CMMS) to track all maintenance activities, including preventative maintenance schedules, repairs, parts replacements, and costs. This ensures comprehensive documentation of all maintenance and repair activities. Physical records, such as service manuals and operation logs, are also kept for reference. This combination provides a comprehensive and easily accessible audit trail. A detailed record-keeping system helps predict potential problems, optimizes preventative maintenance schedules, reduces downtime and maximizes machine lifespan. For example, by tracking fuel consumption and yield data, we identified a faulty fuel injector, which was repaired proactively, preventing costly downtime during the peak harvest season.

Q 21. Explain your experience with using diagnostic software for harvesters.

I’m proficient in using diagnostic software for harvesters from various manufacturers. This software provides access to real-time data from the machine’s various sensors and systems, allowing for prompt identification of potential issues before they escalate into major problems. For example, I can use diagnostic software to identify problems such as sensor failures, hydraulic leaks, and electrical malfunctions. Early detection allows for proactive maintenance, extending the lifespan of the harvester and preventing costly downtime. The software generates error codes, which, when cross-referenced with the manufacturer’s service manuals, allows for precise diagnosis and facilitates repair work. Moreover, some diagnostic software allows for remote diagnostics, which is incredibly valuable for resolving issues quickly, especially during peak harvest seasons.

Q 22. Describe your experience with different types of harvester engines.

My experience encompasses a wide range of harvester engines, from older, less efficient models using naturally aspirated diesel engines to the latest generation employing sophisticated turbocharged and aftercooled diesel engines, and even some incorporating biofuel capabilities. I’ve worked extensively with both Caterpillar and John Deere engines, becoming familiar with their unique characteristics, maintenance requirements, and troubleshooting procedures. For instance, I’ve handled the complete overhaul of a John Deere PowerTech engine, including replacing worn piston rings and rectifying injector issues, and have experience diagnosing and resolving performance issues stemming from faulty fuel systems in Caterpillar engines. The newer engines often feature advanced electronic control systems requiring specialized diagnostic tools and knowledge, a skillset I’ve diligently cultivated.

- Naturally Aspirated Diesel Engines: Simpler design, easier maintenance, but lower power output.

- Turbocharged and Aftercooled Diesel Engines: Higher power output, improved fuel efficiency, but more complex maintenance and diagnostics.

- Biofuel Engines: Environmentally friendly alternative fuel, however, may require specialized engine modifications and maintenance procedures.

Q 23. How do you adjust the harvester’s settings for different crops?

Adjusting a harvester’s settings for different crops is crucial for optimal yield and minimal crop damage. This involves modifying several parameters depending on the crop’s characteristics (e.g., height, density, fragility). Think of it like adjusting the settings on a camera to capture the best possible image – the wrong settings will ruin the shot.

- Header Height: Adjusted to match the crop height. Too low, and you risk damaging the crop; too high, and you’ll miss a lot.

- Concave Setting: This controls the aggressiveness of the threshing mechanism. A delicate crop like soybeans needs a gentler setting than a robust one like wheat. Imagine this as the pressure you apply when extracting juice from an orange – delicate for an orange, firm for a lemon.

- Cylinder Speed: Affects the speed at which the crop is threshed. Faster speeds can increase throughput, but may also lead to increased crop damage. It’s like adjusting the speed of a blender – slow for soft ingredients and fast for hard ones.

- Separator Settings: Adjusting the air flow and sieve settings helps to effectively separate grain from chaff and other materials. It’s like using a sifter with different sized holes to separate various ingredients.

These adjustments are typically made through a combination of manual controls and, in modern harvesters, sophisticated computer interfaces. Experience and understanding of the specific crop’s requirements are essential for making the correct adjustments.

Q 24. Explain the process of cleaning and storing a harvester after use.

Thorough cleaning and storage are vital for extending the life of a harvester. Neglecting this can lead to costly repairs and reduced efficiency in the next season. Think of it as the difference between regularly servicing a car versus never doing so – one ensures longevity, the other guarantees eventual breakdowns.

- Initial Cleaning: Immediately after harvesting, remove all accumulated material from the header, threshing cylinder, cleaning system, and auger. Use compressed air, brushes, and water (as applicable) to clean thoroughly.

- Detailed Cleaning: Disassemble parts where possible to remove stubborn debris and check for any damage. Pay close attention to the grain tank and elevator areas.

- Lubrication: Apply fresh lubricant to all moving parts and grease points. Regularly check the oil levels in the engine and transmission.

- Storage: Store the harvester in a dry, well-ventilated location to prevent rust and corrosion. Cover it with a protective tarp.

- Preventative Maintenance: Check and replace worn parts as needed. Batteries should be removed and stored in a climate-controlled environment to prevent freezing or overheating.

Q 25. What are the environmental considerations when operating a harvester?

Environmental considerations are paramount in harvester operations. Minimizing the machine’s environmental footprint ensures sustainable agricultural practices. This includes considerations like fuel efficiency, soil compaction, and minimizing noise pollution.

- Fuel Efficiency: Selecting the right engine speed and utilizing technologies that improve fuel consumption helps reduce greenhouse gas emissions.

- Soil Compaction: Operating on dry soil and using wide tires helps reduce the impact on soil structure. Excessive compaction reduces crop yields and can lead to soil erosion.

- Noise Pollution: Following noise reduction guidelines and using appropriate sound dampening technologies minimizes noise levels which protects both the operator and surrounding communities.

- Waste Management: Proper handling and disposal of lubricants and other hazardous materials is essential to protect the environment.

- Crop Residue Management: The correct management of crop residues (straw, etc) minimizes soil erosion.

Q 26. How do you identify and report malfunctions in a harvester’s safety systems?

Safety systems in harvesters are critical for protecting the operator and others. Regular inspection and prompt reporting of any malfunctions are essential. This is not just about legal compliance, but about saving lives.

Identifying malfunctions involves a combination of regular visual inspections and functional tests. For example, checking the emergency stop button, fire suppression system, and rotor shields are routine tasks. Malfunctions might range from a faulty sensor to a completely failed system.

Reporting procedures typically involve documenting the issue, reporting it to the appropriate supervisor or mechanic, and taking the harvester out of service until the issue is resolved. The documentation is usually done via work order forms, detailing the nature of the failure and its location. Strict adherence to safety protocols is non-negotiable. In case of a serious malfunction or accident, emergency services must be notified immediately.

Q 27. Explain the importance of timely repairs for maximizing harvester efficiency.

Timely repairs are crucial for maintaining harvester efficiency and preventing larger, more costly problems. A stitch in time saves nine, as the saying goes. Neglecting small issues can lead to catastrophic failures that result in significant downtime and repair expenses.

Regular maintenance, including lubrication, inspection, and replacement of worn parts, prevents many potential breakdowns. This proactive approach extends the harvester’s lifespan and keeps it operating at peak performance. Early detection of problems, even minor ones, significantly reduces repair costs and downtime.

For example, ignoring a small oil leak could lead to engine seizure, a much more expensive repair. Similarly, delaying the replacement of a worn-out cutting blade could lead to harvest delays and crop damage.

Q 28. Describe your experience with working on both older and newer model harvesters.

My experience spans both older and newer model harvesters, providing me with a unique perspective on the evolution of harvesting technology. Older models require a more hands-on, mechanical approach to maintenance and repair. Troubleshooting often involves a deeper understanding of mechanical systems and the ability to diagnose problems using traditional methods. For example, I’ve spent many hours meticulously adjusting carburetors and manually cleaning fuel injectors on older machines. This involved a more intimate understanding of the inner workings of the engine.

Newer harvesters incorporate advanced electronics and sophisticated computer systems. Diagnosing problems necessitates the use of specialized diagnostic tools and software. While this technology simplifies certain aspects of maintenance, it also introduces a new level of complexity, requiring proficiency in computer systems and software. This includes diagnosing electronic control unit (ECU) malfunctions and interpreting diagnostic trouble codes (DTCs). The combination of both experiences provides me with a solid foundation in both traditional and modern approaches to harvester maintenance and repair.

Key Topics to Learn for Harvester Operations and Maintenance Interview

- Harvester Mechanics: Understanding the intricate workings of various harvester components, including engines, hydraulic systems, cutting mechanisms, and powertrains. Consider the principles of preventative maintenance and troubleshooting common mechanical issues.

- Electrical Systems: Familiarize yourself with the electrical architecture of harvesters, including wiring diagrams, sensor technologies, and control systems. Practice diagnosing electrical faults and applying safe repair procedures.

- Hydraulic Systems: Gain a strong grasp of hydraulic principles, including pressure, flow, and component functionality within harvester systems. Be prepared to discuss troubleshooting leaks, pressure loss, and component failures.

- Safety Procedures and Regulations: Demonstrate a deep understanding of relevant safety protocols, emergency procedures, and regulatory compliance for operating and maintaining harvesters. This includes both personal safety and environmental considerations.

- Preventive Maintenance: Explain the importance of scheduled maintenance, lubrication, and inspection routines for maximizing harvester uptime and minimizing breakdowns. Discuss the use of maintenance logs and documentation.

- Troubleshooting and Diagnostics: Practice identifying and resolving common harvester malfunctions. Be prepared to discuss your approach to problem-solving, including diagnostic tools and techniques.

- Data Acquisition and Analysis: Understand how data from harvester sensors and monitoring systems are used for performance evaluation, maintenance scheduling, and operational optimization.

- Harvesting Techniques and Optimization: Demonstrate knowledge of efficient harvesting practices, including optimizing cutting height, speed, and yield while minimizing damage to crops and equipment.

Next Steps

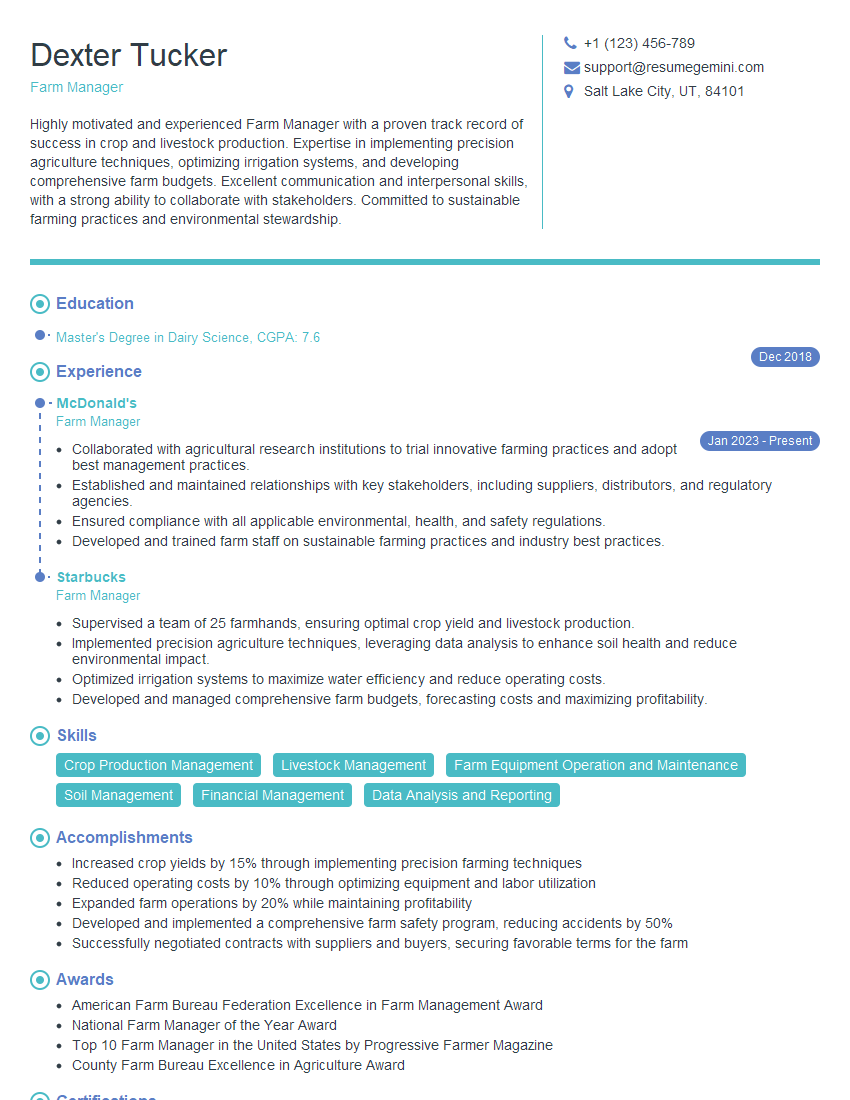

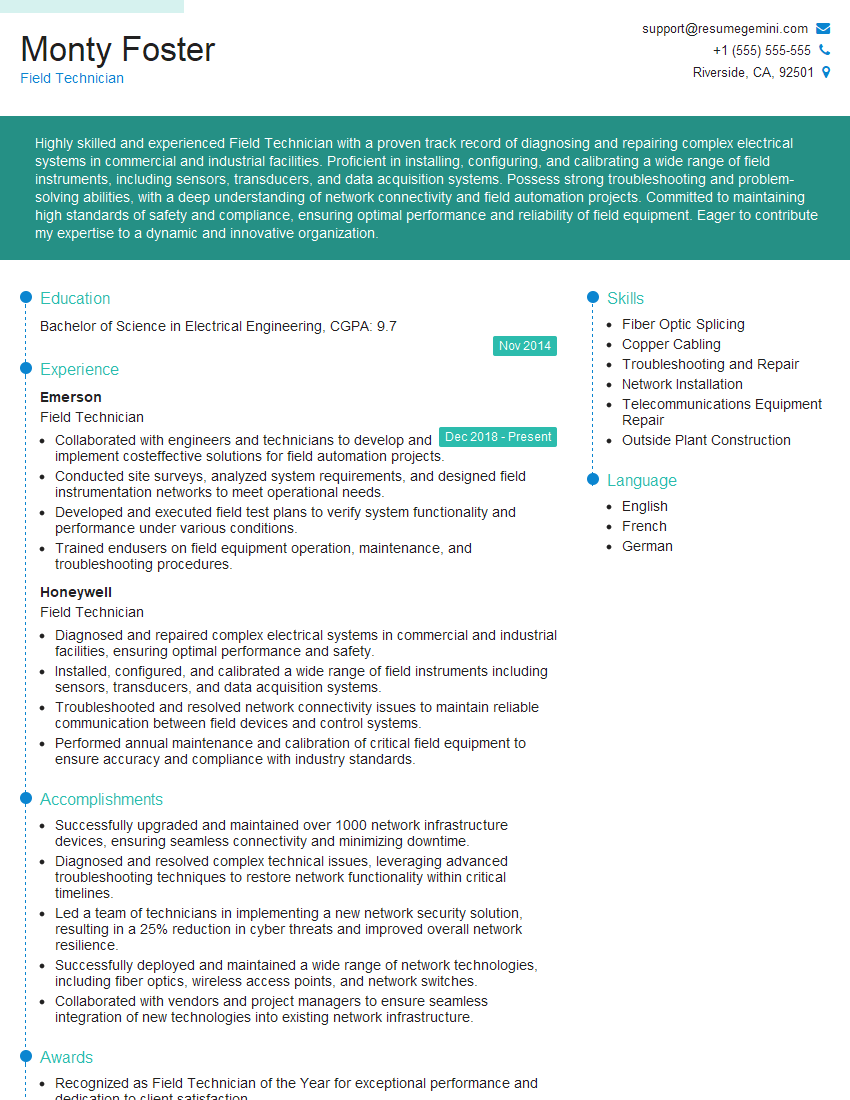

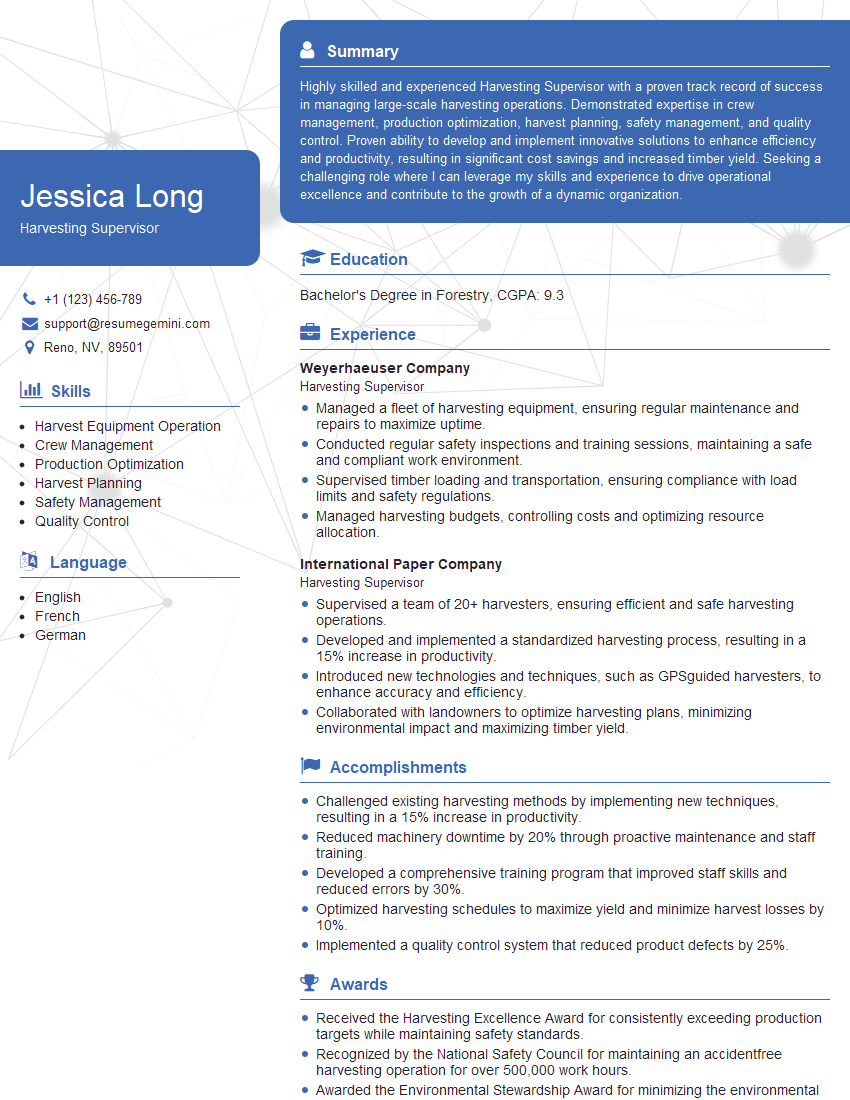

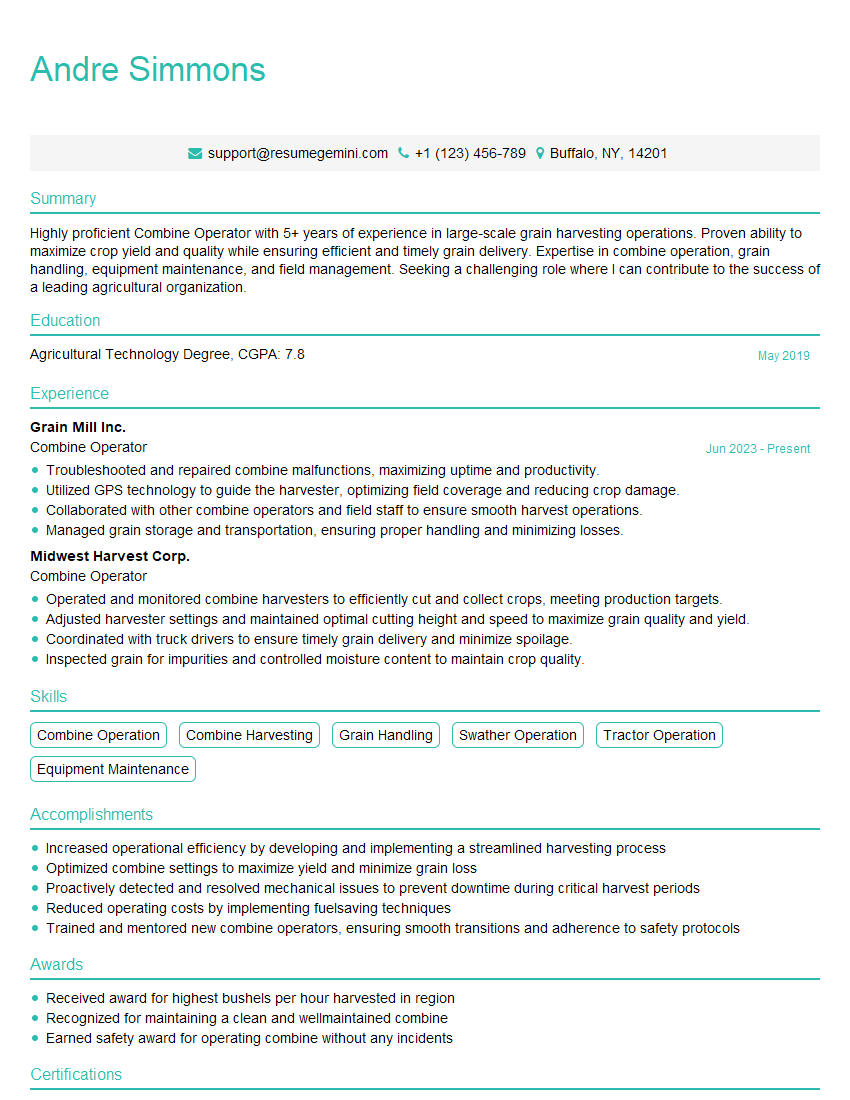

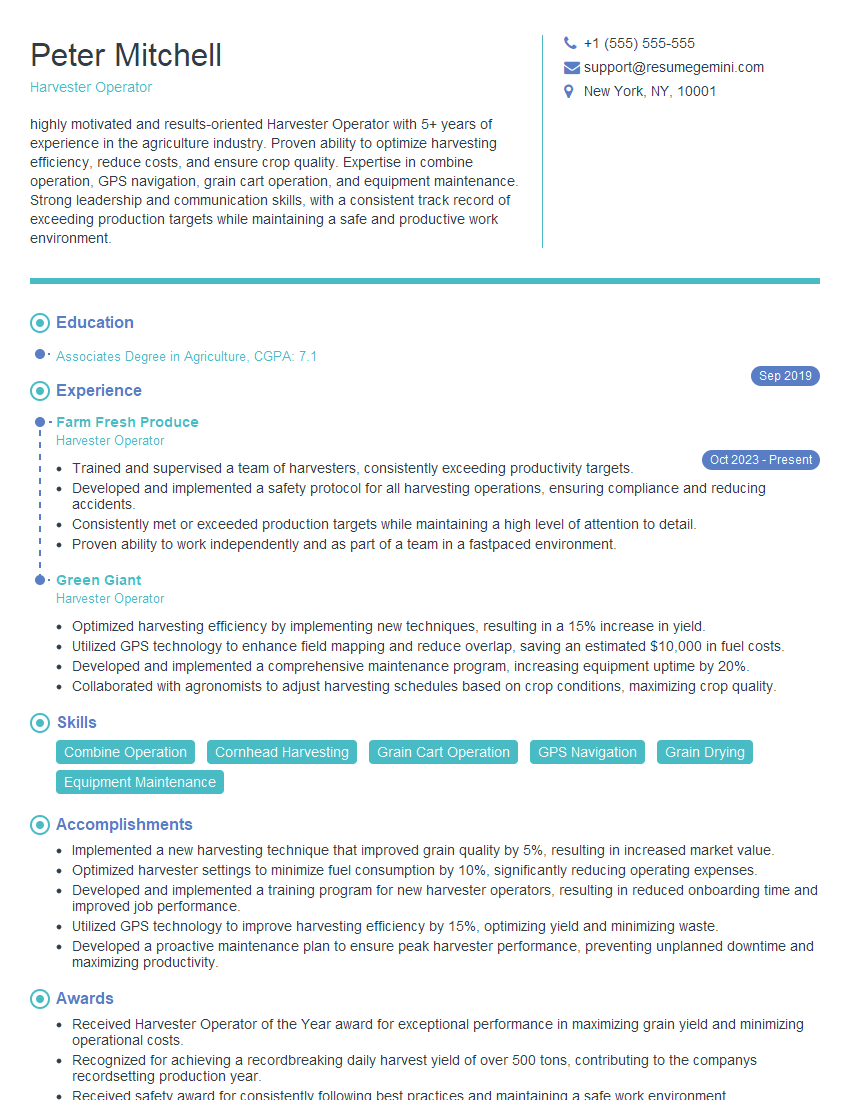

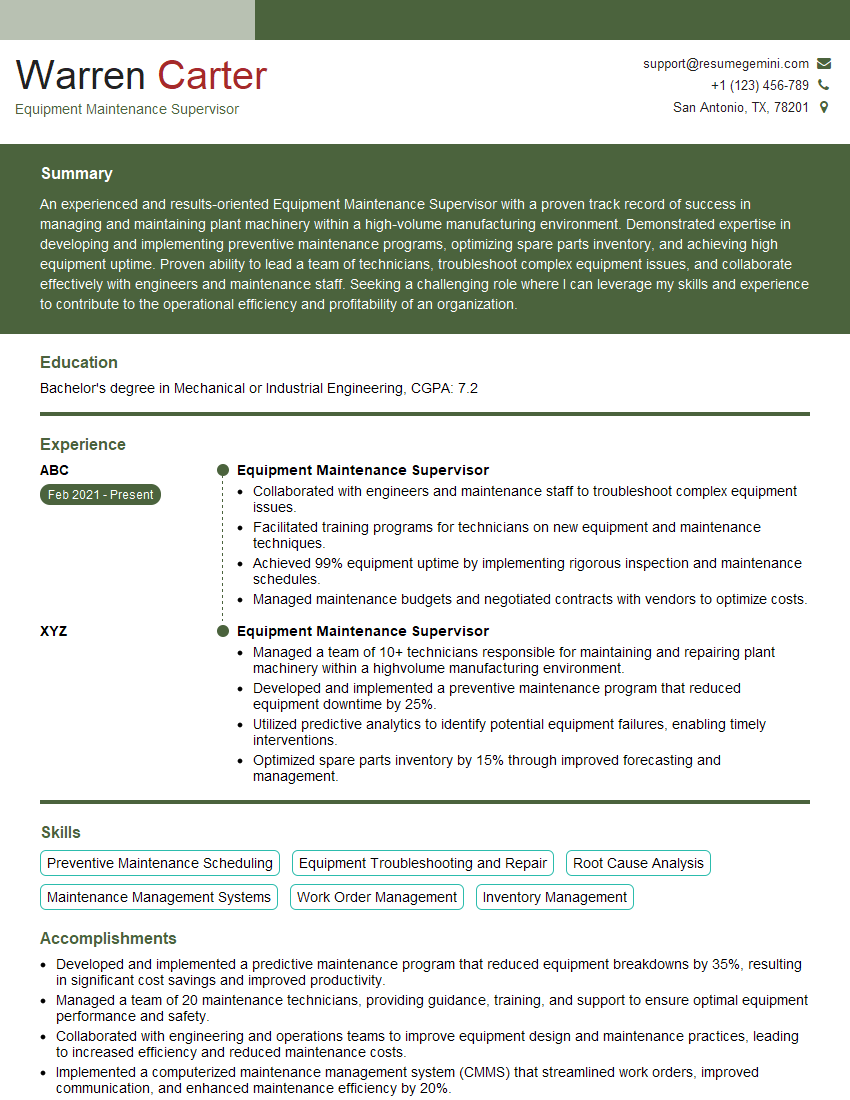

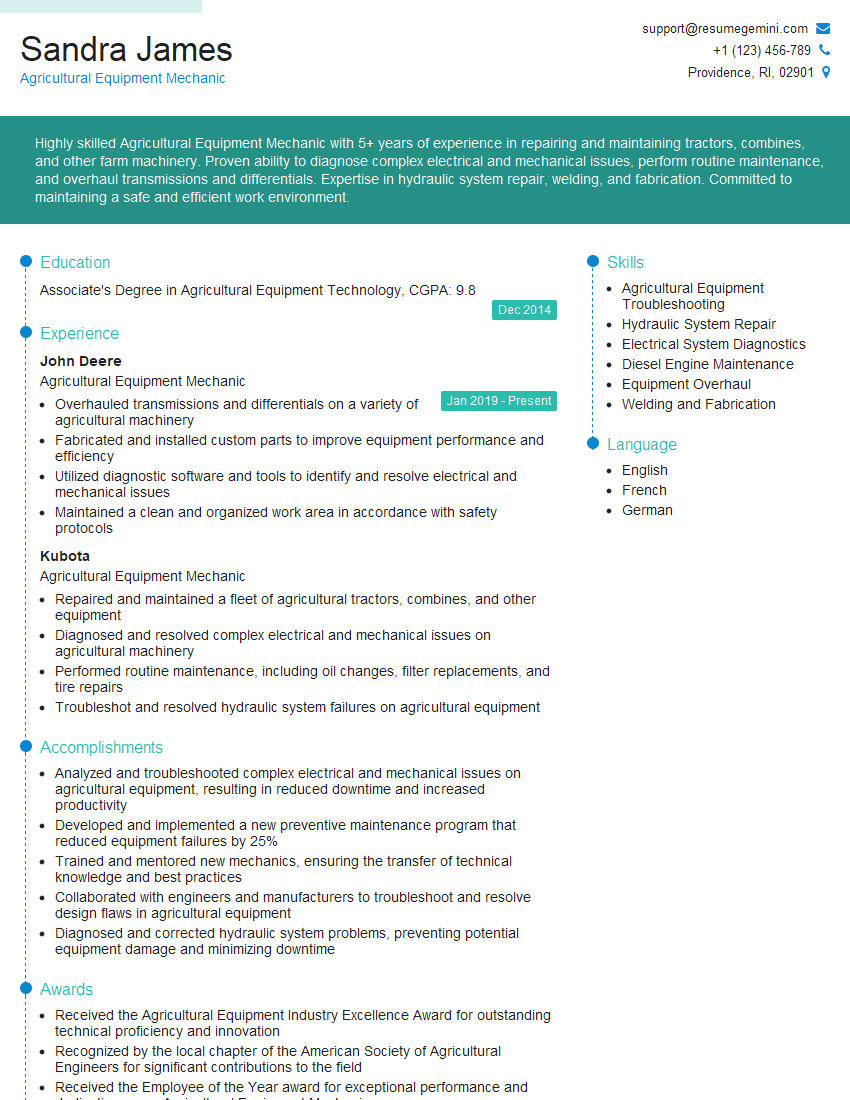

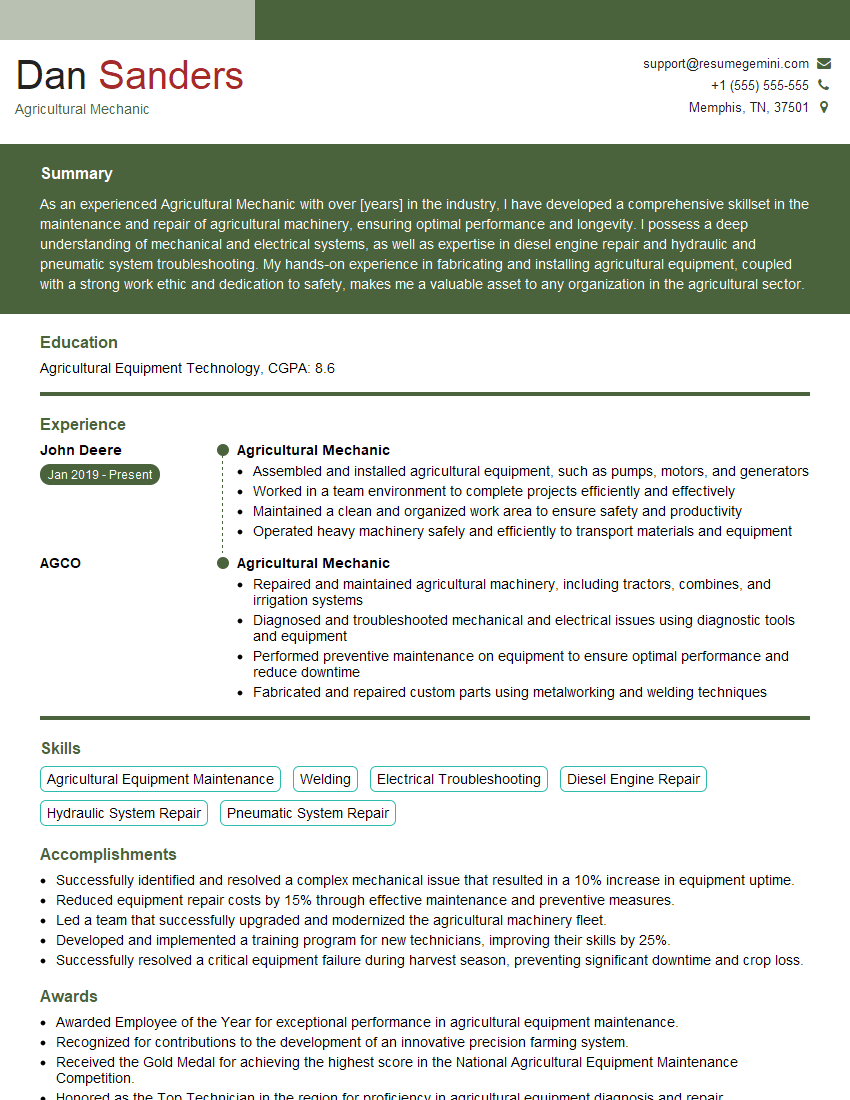

Mastering Harvester Operations and Maintenance is crucial for a successful and rewarding career in the agricultural technology sector. This expertise opens doors to specialized roles, higher earning potential, and increased responsibility. To significantly improve your job prospects, create a compelling and ATS-friendly resume that highlights your skills and experience effectively. We strongly encourage you to utilize ResumeGemini, a trusted resource for building professional resumes. ResumeGemini provides examples of resumes tailored specifically to Harvester Operations and Maintenance roles, offering you a head start in crafting a document that showcases your unique qualifications.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good