Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Harvesting and Vinification interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Harvesting and Vinification Interview

Q 1. Describe the ideal conditions for grape harvesting.

Ideal grape harvesting hinges on achieving optimal ripeness, balancing sugar accumulation with desirable acidity and phenolic compounds. This is a delicate balance, as overripe grapes can lack acidity and freshness, while underripe grapes will yield wines lacking in flavor and body. The ideal conditions involve careful consideration of several factors:

- Berry maturity: This is assessed through measurements of sugar (Brix), acidity (pH and TA), and phenolic ripeness (tasting the berries for tannins and color). We aim for a balance, not just maximum sugar.

- Weather conditions: Harvesting is best done during dry, cool periods to prevent rot and minimize microbial growth. Early mornings are preferred to avoid the heat of the day. Windy conditions should also be avoided to prevent damage.

- Grape health: Grapes must be free from disease, pests, and rot to ensure high-quality wine production. Careful vineyard management practices are crucial throughout the growing season.

For example, in Bordeaux, where Cabernet Sauvignon is prominent, achieving optimal phenolic ripeness often takes precedence over sugar levels, leading to later harvests compared to regions where earlier ripening varietals are grown. The specific optimal window is decided on a vintage-by-vintage basis, considering the weather patterns that year.

Q 2. Explain the different methods of grape sorting.

Grape sorting is crucial for producing high-quality wines by removing undesirable berries and material. Several methods exist:

- Manual sorting: This traditional method involves workers carefully inspecting the grapes on a conveyor belt and removing damaged, diseased, or unripe berries. It is labor-intensive but provides a high level of precision, particularly important for top-tier wines.

- Optical sorting: Sophisticated machines use sensors to detect and remove defects based on color, size, shape, and surface imperfections. This process is more efficient than manual sorting and can handle larger volumes of grapes.

- Density sorting: This technique utilizes differences in berry density to separate damaged or rotten grapes which generally have different densities due to water loss or decay.

Many wineries employ a combination of these methods, using optical sorting for large quantities and manual sorting for final quality checks. For example, a small boutique winery might rely almost exclusively on manual sorting, while a large commercial producer would use optical sorting for efficiency followed by manual checks.

Q 3. What are the key factors influencing the choice of yeast strains in fermentation?

Yeast strain selection significantly impacts wine aroma, flavor profile, fermentation kinetics, and the overall quality of the final product. The choice is influenced by several factors:

- Desired wine style: Different yeast strains produce distinct aroma and flavor compounds. For example, some strains contribute fruity esters, while others enhance spicy or earthy notes. A Chardonnay aimed for a buttery profile might use a yeast known for its production of diacetyl.

- Grape variety: Certain yeast strains are better suited for particular grape varietals. Their compatibility considers things like the grape’s inherent acidity and the amount of nutrients it provides.

- Climate and terroir: The climate and soil conditions influence grape composition, impacting the suitability of certain yeast strains. Hotter climates often require yeasts that are more tolerant to higher temperatures.

- Fermentation characteristics: Factors such as fermentation rate, temperature tolerance, and the production of by-products (like H2S) influence the choice. A sluggish fermentation might necessitate a more vigorous yeast strain.

Winery technicians often conduct trials with different yeast strains to find the optimal choice for a given vintage and grape variety. This ensures consistency and enhances the desired qualities of the wine.

Q 4. How do you monitor and control malolactic fermentation?

Malolactic fermentation (MLF) is a secondary fermentation where harsh malic acid is converted to softer lactic acid by lactic acid bacteria. Monitoring and controlling MLF is crucial to avoid off-flavors and ensure the desired wine character:

- Monitoring: We monitor pH, malic acid levels, and sensory evaluation (taste and smell) regularly to track the progress of MLF. Testing kits are used to quantify malic acid, and the sensory assessment identifies the development of diacetyl and other buttery aromas.

- Control: The onset of MLF can be induced or inhibited through temperature control. Cooler temperatures (around 18-20°C) typically delay or prevent MLF, while warmer temperatures promote it. The addition of specific bacterial cultures (inoculation) can also control the process. Conversely, sulfur dioxide (SO2) can be used to inhibit MLF if unwanted.

Proper management of MLF is particularly crucial in wines intended to age, as the softer lactic acid contributes to greater complexity and stability over time. For example, in many red wines, MLF is encouraged for its softening effect on tannins and development of desired flavors, while in some crisp white wines it is prevented to retain freshness and vibrancy.

Q 5. Describe the process of cold stabilization in winemaking.

Cold stabilization is a process used to remove potassium bitartrate crystals (cream of tartar) that can precipitate in wine during aging, leading to unwanted crystallization in the bottle. This process typically involves:

- Chilling the wine: The wine is cooled to near-freezing temperatures (typically around -4°C) for several days. This slows down the metabolic activities and lowers the solubility of potassium bitartrate.

- Crystallization: At these low temperatures, the excess potassium bitartrate precipitates out of solution and forms crystals.

- Filtration or settling: After chilling, the wine is either filtered to remove the crystals or allowed to settle, and then filtered or racked off of the sediment.

Cold stabilization is especially important for white wines and sparkling wines, which are more susceptible to tartrate instability. While it provides a visually appealing product, it doesn’t affect the wine’s flavor but might remove some beneficial compounds. Therefore, a balance should be sought depending on wine style.

Q 6. Explain the importance of SO2 in winemaking and its appropriate application.

Sulfur dioxide (SO2) is a crucial additive in winemaking, acting as an antimicrobial agent, antioxidant, and reducing agent. Its appropriate application is essential:

- Antimicrobial action: SO2 inhibits the growth of undesirable microorganisms (bacteria and yeasts) preventing spoilage and maintaining wine’s microbial stability.

- Antioxidant properties: SO2 protects wine from oxidation, preserving its color, aroma, and flavor. It protects against browning and the loss of fresh fruit characters.

- Reducing agent: SO2 helps to prevent undesirable reactions which might change the chemical balance of the wine, preventing unwanted discoloration or flavors.

SO2 is added at various stages of winemaking, including during crushing, fermentation, and aging. The amount added depends on the wine’s style, desired level of protection, and the free and total SO2 levels. Careful monitoring is crucial to ensure that the levels remain within legal limits, as excessive SO2 can negatively impact the wine’s flavor and aroma. For example, high levels might impart a harsh or medicinal note.

Q 7. How do you manage and prevent spoilage in wine during fermentation and aging?

Spoilage in wine can ruin the quality and even make it undrinkable. Preventing spoilage involves a multi-pronged approach:

- Sanitation: Maintaining impeccable hygiene throughout the entire winemaking process is vital. Equipment, tanks, and containers must be thoroughly cleaned and sanitized to eliminate potential sources of spoilage organisms.

- Careful handling of grapes: Preventing damage to the grapes during harvesting and transport minimizes the risk of introducing spoilage microbes.

- Controlled fermentation: Managing fermentation temperature and using appropriate yeast strains inhibits the growth of undesirable microbes.

- SO2 management: Careful addition of sulfur dioxide helps to control microbial growth throughout the winemaking process.

- Filtration and fining: Appropriate filtration and fining techniques can remove unwanted particles and microorganisms, contributing to improved stability.

- Regular monitoring: Close monitoring of wine throughout fermentation and aging enables early detection of spoilage indicators like off-odors or turbidity.

Spoilage microorganisms such as Acetobacter (leading to acetic acid spoilage and vinegar-like off-flavors) or Brettanomyces (producing undesirable phenolic compounds) are targeted through proper sanitation, SO2 use, and timely interventions.

Q 8. Describe the different methods of fining wine.

Fining wine is a crucial step in clarifying and stabilizing the wine, removing unwanted particles that can affect its clarity, taste, and stability. Several methods exist, each targeting specific issues.

- Egg whites: Traditionally used, egg whites bind to proteins and tannins, forming larger complexes that settle out. Think of it like a natural magnet pulling out impurities.

- Bentonite: A clay-based fining agent that effectively removes proteins, particularly beneficial for wines prone to haze. It’s like a tiny sponge absorbing the unwanted proteins.

- Isinglass: Derived from fish bladders, isinglass is excellent for removing haze and stabilizing the wine’s color. It’s a very gentle fining agent, ideal for delicate wines.

- PVPP (Polyvinylpolypyrrolidone): This is used to remove polyphenols, particularly responsible for browning and astringency. It’s frequently used in white wines to enhance brightness.

- Casein: A milk protein, casein is effective in removing tannins and improving the wine’s mouthfeel. However, it’s unsuitable for vegan wines.

The choice of fining agent depends on the wine’s specific needs and the winemaker’s preferences. For instance, a heavily tannic red wine might benefit from casein or egg whites, while a white wine prone to haze might require bentonite.

Q 9. What are the benefits and drawbacks of using oak barrels for aging wine?

Oak barrels significantly impact wine aging, imparting unique flavors and aromas, but also presenting some challenges.

- Benefits:

- Flavor and Aroma Complexity: Oak adds vanilla, spice, toasty, smoky, and coconut notes, depending on the type of oak (French, American, etc.) and the barrel’s toast level. Think of it like a spice rack for your wine.

- Enhanced Structure and Texture: Oak’s porous nature allows oxygen to interact with the wine, softening tannins and adding complexity to the mouthfeel.

- Microbial Activity: Oak encourages beneficial microbial activity, further contributing to the wine’s aromatic profile.

- Drawbacks:

- Cost: High-quality oak barrels are expensive, representing a significant investment.

- Consistency Challenges: Even within the same barrel, the level of oak influence varies, making it tricky to control.

- Potential for Off-Flavors: Poorly made or improperly managed barrels can impart undesirable flavors to the wine, ruining the batch.

- Maintenance: Barrels require careful cleaning and maintenance between uses.

For example, a Chardonnay aged in new French oak will have distinct vanilla and buttery notes, different from one aged in stainless steel, which will highlight the fruit characteristics.

Q 10. How do you determine the optimal aging time for a particular wine?

Determining the optimal aging time is an art and science. It depends on several factors:

- Grape Variety: Certain grapes age better than others. Cabernet Sauvignon, for example, can age for decades, while Pinot Noir is often best enjoyed younger.

- Winemaking Techniques: Techniques like oak aging, malolactic fermentation, and fining impact aging potential.

- Wine’s Chemistry: The levels of acidity, tannins, and pH play a critical role. High tannins, for instance, generally indicate a longer aging potential.

- Sensory Evaluation: Professional tastings track the wine’s evolution over time. The winemaker searches for the optimal balance of fruit, tannins, acidity, and oak, indicating the peak aging point.

There’s no magic formula. It’s a blend of experience, science, and artful interpretation. For instance, a winemaker might bottle a Pinot Noir after one year to preserve its youthful fruitiness, while aging a Cabernet Sauvignon for five years or more to allow its tannins to mellow.

Q 11. Explain the different types of filtration used in winemaking.

Filtration in winemaking removes unwanted particles, improving clarity and stability. Several types are used:

- Coarse Filtration: Removes larger particles like grape skins, seeds, and yeast. It is often the first step in filtration.

- Fine Filtration: Removes smaller particles, improving the wine’s clarity and stability. Different filter types include membrane filters and pad filters, each with varying pore sizes to achieve specific levels of filtration.

- Sterile Filtration: Used as a final step to remove bacteria and yeast, ensuring long-term stability.

- Rotary Vacuum Filter: A highly efficient filtration system that uses a rotating drum to process large volumes of wine.

The choice of filtration method depends on the winemaker’s style and desired level of clarity. Some winemakers choose minimal filtration to retain more character in the wine, while others prefer a highly clarified product.

Q 12. Describe the process of bottling wine.

Bottling is the final stage, preserving the wine for enjoyment. It involves:

- Wine Preparation: The wine is clarified and filtered to ensure a pristine product. Any remaining sediment must be removed carefully.

- Bottling Line Setup: The bottling line is set up and sterilized to maintain hygiene.

- Filling: The wine is carefully filled into sterilized bottles, ensuring a consistent fill level.

- Corking/Closure: The bottles are sealed with corks or other closures, guaranteeing airtight sealing.

- Labeling and Packaging: Labels are applied, providing important information and adding the final touch.

- Quality Control Checks: Samples are drawn and tasted to ensure consistency and quality before release.

Imagine a well-oiled machine; every step must be precise and clean to prevent contamination and spoilage. Any hiccups in the bottling process could significantly impact the wine’s quality and shelf life.

Q 13. How do you ensure the quality and consistency of wine production?

Ensuring quality and consistency requires a multifaceted approach:

- Standardized Procedures: Following detailed protocols at every stage, from harvesting to bottling.

- Quality Control at Each Step: Regular checks throughout the process to identify and correct any deviations.

- Consistent Sourcing of Grapes: Working with reliable growers who consistently provide high-quality grapes.

- Advanced Technology: Utilizing modern equipment for precise temperature control, filtration, and bottling.

- Experienced Personnel: Employing skilled professionals with years of experience in winemaking.

- Regular Sensory Evaluation: Blind tastings by expert panels at each stage to assess the wine’s development and identify potential problems.

For example, implementing a strict temperature control system throughout fermentation prevents unwanted microbial growth and ensures consistent flavor profiles. Regular sensory evaluations are crucial in catching off-flavors early.

Q 14. What are the common quality control measures implemented during harvesting and vinification?

Quality control measures throughout harvesting and vinification are crucial. These include:

- Harvest Monitoring: Regular checks of grape ripeness (sugar levels, acidity, etc.) to determine the optimal harvest time.

- Grape Selection: Careful sorting of grapes to remove damaged or undesirable berries.

- Sanitation: Maintaining strict hygiene in all equipment and facilities to minimize the risk of microbial contamination.

- Temperature Monitoring: Precise temperature control during fermentation and aging to prevent spoilage.

- Sensory Evaluation: Regular tastings to monitor the wine’s development and identify potential problems.

- Laboratory Analysis: Regular chemical analysis to ensure the wine meets quality standards.

- Documentation: Meticulous record-keeping of all procedures and results for traceability.

Think of it like a doctor checking a patient’s vital signs. Regular monitoring and analysis ensure the wine remains healthy and meets the standards expected.

Q 15. How do you handle deviations from expected wine quality parameters?

Handling deviations from expected wine quality parameters requires a systematic approach combining preventative measures with corrective actions. We constantly monitor parameters throughout the winemaking process – from grape arrival to bottling. This includes assessments of pH, titratable acidity (TA), sugar levels, phenolic ripeness, and sensory evaluation at key stages. Deviations are often identified through routine laboratory analysis and sensory panels.

For example, if a batch shows unexpectedly high volatile acidity (VA), indicating spoilage, we might investigate the source. This could be due to issues during fermentation, such as insufficient sanitation or elevated temperatures. Corrective actions may involve treatments such as acid blend adjustment or, in severe cases, discarding the affected batch. Similarly, low color intensity in red wines might signal a need to adjust maceration time in future vintages or experiment with techniques like micro-oxygenation to enhance pigment extraction. The key is to meticulously document every step, analyze the root cause of the deviation, and implement appropriate adjustments to avoid recurrence.

Data analysis and statistical process control (SPC) charts are crucial tools for tracking quality parameters over time and detecting trends. This allows us to identify potential problems before they significantly impact wine quality. Addressing deviations is a continuous learning process, refining our techniques based on experience and analysis.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the environmental factors that influence grape quality?

Environmental factors significantly influence grape quality, affecting both the quantity and quality of the harvest. These factors interact in complex ways, impacting the grape’s sugar accumulation, acidity levels, and the concentration of aromatic compounds. Key environmental influences include:

- Sunlight (solar radiation): Adequate sunlight is essential for photosynthesis, directly influencing sugar accumulation. Insufficient sunlight can lead to underripe grapes with low sugar and poor aroma development. Excessive heat can lead to sunburned grapes and reduced quality.

- Temperature: Temperature profoundly impacts the rate of ripening and the balance between sugars and acids. Warm days and cool nights are generally ideal, promoting optimal ripening and retaining acidity.

- Rainfall: Appropriate rainfall is crucial; however, excessive rain can dilute sugar concentration and promote fungal diseases like powdery mildew or botrytis. Drought conditions can also negatively impact yield and quality, causing smaller berries and reduced aroma complexity.

- Wind: Wind can assist with disease prevention by drying foliage, but strong winds can cause physical damage to vines and grapes.

- Altitude: Higher altitudes often experience greater diurnal temperature variation, leading to more concentrated grapes with enhanced flavors.

Understanding these factors is critical for vineyard site selection and management practices. For example, choosing a site with good sunlight exposure and appropriate drainage helps prevent water stress and fungal diseases. Careful canopy management can optimize sunlight penetration and airflow within the vineyard.

Q 17. Explain the role of pH and TA in winemaking.

pH and titratable acidity (TA) are crucial parameters in winemaking, influencing several aspects of wine quality and stability. pH measures the hydrogen ion concentration, indicating the wine’s acidity level on a scale of 0-14 (lower pH indicates higher acidity). TA, on the other hand, represents the total amount of acids present in the wine, expressed as tartaric acid equivalents.

pH’s role: pH affects the microbial activity during fermentation, influencing the activity of yeasts and bacteria. A proper pH is essential for optimal yeast performance and to prevent spoilage. It also affects the color extraction in red wines and the stability of the wine’s color and aroma compounds over time.

TA’s role: TA provides the wine’s structure and freshness, contributing to its taste and mouthfeel. It’s a crucial factor influencing the wine’s overall balance, impacting both taste and preservation. High TA wines are typically more resistant to microbial spoilage.

The ideal balance between pH and TA varies depending on the wine style and grape variety. For example, a balanced white wine may have a pH around 3.3 and a TA around 6 g/L, whereas a red wine might have slightly higher pH (3.4-3.6) and TA (4-7 g/L). We may adjust either the pH or TA through various techniques such as acidification or deacidification, depending on the need. Careful monitoring and control are vital for crafting quality wines with optimal flavor profiles and long-term stability.

Q 18. What are the common grape diseases and how are they managed?

Grapevines are susceptible to several diseases, impacting yield and quality. Effective disease management requires a combination of preventative and curative measures. Some common grape diseases include:

- Powdery Mildew (Erysiphe necator): This fungal disease creates a white, powdery coating on leaves, shoots, and fruit, hindering photosynthesis and reducing fruit quality. Management involves preventative fungicide applications, resistant cultivars, and proper vineyard sanitation.

- Downy Mildew (Plasmopara viticola): Another fungal disease, downy mildew, affects all green parts of the vine, leading to leaf spots and reduced fruit set. Control methods include copper-based fungicides and integrated pest management (IPM) strategies.

- Botrytis bunch rot (Botrytis cinerea): This fungus causes grey rot, affecting grapes particularly during wet conditions. It can lead to significant yield loss and negatively affect wine quality. Careful vineyard management to ensure good air circulation and timely harvest are crucial for control.

- Pierce’s disease (Xylella fastidiosa): This bacterial disease is spread by insects and can cause significant vine decline. Management involves vector control (insect management) and removal of infected vines.

Disease management relies on a holistic approach, employing integrated pest management techniques that minimize pesticide use while maximizing effectiveness. Regular vineyard monitoring, precise timing of treatments, and accurate disease identification are key to successful disease management. Proactive approaches, such as selecting disease-resistant cultivars and implementing cultural practices to promote healthy vines, are critical for long-term vineyard health and sustainable viticulture.

Q 19. How do you manage pest control in the vineyard?

Pest control in the vineyard requires a multifaceted approach that prioritizes sustainable practices and minimizes environmental impact. Our strategy focuses on integrated pest management (IPM), combining various methods to effectively control pests while preserving biodiversity.

Methods include:

- Monitoring: Regular scouting for pest presence and population levels allows for timely intervention, avoiding unnecessary treatments.

- Biological control: Introducing natural predators or parasites to control pest populations, like using beneficial insects to control aphids or mites.

- Cultural controls: Implementing vineyard practices to discourage pest establishment, such as proper pruning, weed control, and maintaining good vineyard hygiene.

- Targeted pesticide application: Only using pesticides when necessary and targeting specific pests, employing the lowest effective dose and choosing products with the least environmental impact.

- Resistant cultivars: Planting grape varieties with inherent resistance to common pests reduces the reliance on chemical controls.

For instance, we might use pheromone traps to monitor and manage grapevine moths, utilizing this information to optimize the timing and scope of any necessary interventions. By carefully assessing each pest and employing a combination of methods, we aim for effective pest control while minimizing environmental impact and promoting long-term vineyard sustainability. Record-keeping is essential to track pest pressures and the efficacy of various control measures. This approach is crucial for optimizing resources and maximizing the long-term health of the vineyard.

Q 20. Explain different methods of irrigation and their impact on grape quality.

Irrigation methods significantly impact grape quality, influencing yield, sugar accumulation, acidity, and overall flavor profile. The choice of irrigation method depends on several factors, including climate, soil type, and vineyard topography. Common methods include:

- Drip irrigation: This method delivers water directly to the root zone, minimizing water waste and promoting efficient water use. It’s particularly suitable for arid or semi-arid regions and can help maintain consistent soil moisture. Drip irrigation often leads to better fruit quality with higher sugar concentrations and better flavor development.

- Overhead irrigation: This involves spraying water over the entire canopy. While simpler to install, it can lead to higher water loss through evaporation, increased disease incidence (due to wet foliage), and potential for sunscald. It is generally less efficient than drip irrigation.

- Micro-sprinkler irrigation: This method combines aspects of drip and overhead, applying water in a more localized manner than overhead, but with less precision than drip.

The impact on grape quality stems from the precise control over soil moisture that irrigation offers. Consistent water availability throughout the growing season promotes optimal vine growth and fruit development. However, over-irrigation can dilute sugar concentrations and negatively affect flavor development. Careful management of irrigation scheduling is crucial, considering factors like rainfall, evapotranspiration rates, and vine development stages to optimize water use efficiency and grape quality. Monitoring soil moisture levels using sensors allows for data-driven decision-making regarding irrigation schedules, helping to avoid both water stress and over-irrigation.

Q 21. Describe the impact of different soil types on grape growth and wine quality.

Soil type significantly impacts grapevine growth and wine quality. Different soil properties affect water retention, drainage, nutrient availability, and root development, all influencing the grapes’ composition and the resulting wine’s character.

Examples of soil types and their influence:

- Clay soils: These soils retain water well but can be poorly drained, leading to waterlogging and oxygen deficiency, potentially impacting root health. They can be rich in nutrients but their high water retention capacity might dilute the concentration of sugars and aroma compounds in the grapes.

- Sandy soils: These soils drain quickly, requiring more frequent irrigation. They offer excellent aeration but have poor nutrient retention, often resulting in smaller berries with intense flavors but potentially lower yields. Wines from sandy soils often display more minerality.

- Loamy soils: These soils are considered ideal, offering a good balance of water retention, drainage, and nutrient availability. They provide a consistent environment for grapevine growth, resulting in consistently high-quality grapes.

- Gravelly soils: These well-drained soils are known for producing grapes with concentrated flavors and intense aromas. They often have limited water retention, so efficient irrigation is needed.

Understanding the soil’s physical and chemical properties is crucial for site selection and vine management. Soil analysis helps determine nutrient deficiencies and allows for targeted fertilization to optimize vine health and grape quality. Soil management practices such as cover cropping and organic matter additions can improve soil structure, water retention, and nutrient availability, leading to better grape production and quality wines.

Q 22. How do you determine the optimal harvest date for different grape varieties?

Determining the optimal harvest date is crucial for wine quality. It’s not simply about calendar dates; it’s about achieving the perfect balance of sugar, acidity, and phenolic ripeness in the grapes. This balance varies significantly depending on the grape variety, the specific vineyard site (including soil type and climate), and the vintage. We use a multi-pronged approach:

- Sugar levels (Brix): Measured with a refractometer, this indicates potential alcohol content. Different varieties have optimal Brix ranges. For example, Cabernet Sauvignon might need higher Brix than Pinot Noir.

- Acidity (TA): Titratable acidity, measured in grams per liter of tartaric acid, is essential for freshness and balance. High acidity can lead to harshness, while low acidity can result in flabby wines. We monitor TA throughout the growing season.

- Phenolic ripeness: This refers to the development of tannins (in red grapes) and other flavor compounds. We assess this through sensory evaluation (tasting) and laboratory analysis of the grapes’ color, seed color, and tannin levels. For instance, we might wait for seed color change in Cabernet Sauvignon before picking.

- Weather forecasting: Predicting rain or extreme temperatures can influence the harvest decision. A pre-harvest rain can lead to dilution and rot, so we may need to harvest earlier than planned.

Ultimately, we make decisions based on a combination of these factors, using historical data, current vineyard observations, and laboratory results. It’s an art and a science. Each year presents unique challenges and opportunities, requiring a flexible and adaptable approach.

Q 23. Explain the difference between red and white winemaking processes.

Red and white winemaking differ significantly, primarily due to the handling of grape skins. In white winemaking, the juice is separated from the skins immediately after crushing, preventing the extraction of color and tannins. Fermentation then takes place without the skins.

Red winemaking, conversely, involves fermenting the juice along with the skins. This extended contact allows for the extraction of color, tannins, and flavor compounds from the skins, contributing to the red wine’s characteristics. This process often includes a phase called ‘maceration’ which determines the intensity of color and tannin extraction.

Here’s a simplified comparison:

- White Wine: Crushing, pressing (separation of juice from skins), fermentation, aging.

- Red Wine: Crushing, fermentation (with skins), pressing, aging.

Beyond this fundamental difference, techniques like malolactic fermentation (MLF), which softens acidity, may be used in both red and white winemaking, but the timing and application vary significantly depending on the wine’s style and the grape variety.

Q 24. How do you assess the maturity of grapes prior to harvest?

Assessing grape maturity before harvest is a critical step. We combine several methods:

- Berry sampling and tasting: Tasting berries from various parts of the vineyard provides a sensory evaluation of ripeness, sugar, acidity, and phenolic development. This subjective assessment is vital.

- Refractometer readings (Brix): This tool measures the sugar content, indicating potential alcohol levels.

- Titratable acidity (TA) measurement: This determines the level of acidity, which impacts the wine’s freshness and balance. We use a titration method in the laboratory.

- pH measurement: pH level influences the microbial stability and flavor profile of the wine. We employ a digital pH meter.

- Seed analysis: In red grapes, seed color and hardness are indicators of phenolic ripeness. Fully ripe seeds are typically brown and soft.

- Berry firmness: We assess the berry’s texture; overripe berries can be prone to splitting and rot.

Combining these methods allows for a comprehensive assessment of grape maturity, ensuring we harvest at the optimal time for the desired wine style.

Q 25. What are the potential challenges of organic or biodynamic winemaking?

Organic and biodynamic winemaking present unique challenges compared to conventional methods. The core challenge lies in minimizing synthetic inputs while maintaining vineyard health and consistent yields.

- Pest and disease management: Organic viticulture relies on natural methods like beneficial insects and cover crops for pest control. This can be challenging in years with high disease pressure, requiring vigilance and potentially more labor-intensive interventions.

- Weed control: Organic practices often rely on mechanical methods like tillage or mowing, which can be costly and less precise than herbicides. Careful vineyard management is essential.

- Yield variability: Organic vineyards can experience greater year-to-year yield fluctuations due to their greater susceptibility to pests and diseases.

- Higher labor costs: Organic methods generally require more labor than conventional methods, due to hand-harvesting and more involved pest and disease management techniques.

- Certification and regulation: Meeting the strict standards for organic and biodynamic certifications can be complex and requires adherence to rigorous guidelines and inspections. There are various standards worldwide.

Despite these challenges, many winemakers find the benefits of producing healthy, sustainable wines outweigh the increased effort and complexity.

Q 26. Explain the importance of sanitation in winemaking.

Sanitation is paramount in winemaking. Contamination by unwanted microorganisms (bacteria and wild yeasts) can ruin a batch of wine, leading to off-flavors, spoilage, and even vinegar production. Our sanitation protocols are meticulous and cover every stage:

- Equipment cleaning: All tanks, pumps, hoses, and other equipment are thoroughly cleaned and sanitized with appropriate solutions (e.g., hot water, sodium metabisulfite) after each use. We adhere to stringent SOPs.

- Vineyard sanitation: Maintaining hygiene in the vineyard helps prevent contamination during harvest. We employ meticulous harvesting techniques, avoiding bruised or rotten grapes.

- Barrel sanitation: Oak barrels are carefully cleaned and sterilized before use, ensuring the wood doesn’t impart unwanted flavors.

- Bottling sanitation: The bottling process requires sterile conditions to avoid spoilage, ensuring the final product remains stable.

Regular monitoring and testing are performed to ensure effective sanitation. We use laboratory analysis to detect any microbial contamination in various stages of wine production.

Q 27. Describe your experience with different winemaking equipment and technologies.

My experience encompasses a range of equipment, from traditional to state-of-the-art technologies. I’ve worked with:

- Traditional basket presses: These offer gentler pressing, minimizing oxidation and extracting more delicate flavors. They’re particularly useful for high-quality white wines.

- Pneumatic presses: These modern presses are more efficient, allowing for consistent and controlled pressing.

- Stainless steel tanks: These are the workhorse of modern winemaking, offering inert environments for fermentation and aging. Their sizes range from small to massive depending on the winery’s scale.

- Oak barrels: I’ve used French, American, and Hungarian oak barrels of various toast levels, each imparting different characteristics to the wine.

- Temperature-controlled fermentation tanks: Precision temperature control is essential for optimizing yeast activity and maintaining wine quality.

- Spectrophotometers and other analytical instruments: Precise laboratory analysis is crucial for quality control throughout the winemaking process.

This diverse experience has broadened my understanding of different approaches to winemaking and their impact on the final product. I’m adept at adapting my techniques to different equipment and optimizing their use to achieve the best results.

Q 28. What are your strategies for improving wine quality year after year?

Improving wine quality year after year requires a holistic approach:

- Vineyard management: Careful canopy management, soil health optimization (through cover crops and sustainable practices), and disease prevention are fundamental. We adapt our practices based on annual climate conditions.

- Harvest optimization: Refining our understanding of optimal harvest timing and techniques based on data analysis and experience is crucial. We constantly refine our protocols based on past vintages.

- Winemaking techniques: We experiment with different fermentation and aging techniques, adapting our approaches based on each year’s grape characteristics. Data analysis guides our decisions.

- Quality control: Rigorous laboratory analysis throughout the winemaking process ensures quality and consistency. We employ sensory evaluation at each stage, complemented by chemical analysis.

- Continuous learning: Staying updated on the latest research, technologies, and winemaking practices is vital for improvement. We attend conferences and collaborate with other wine professionals.

- Documentation and data analysis: Detailed records of each step in the process allow for analysis and optimization. We analyze data from previous vintages to improve our decision-making.

By consistently applying these principles, we strive for continuous improvement and produce wines that consistently reflect the unique characteristics of each vintage while maintaining our high quality standards.

Key Topics to Learn for Harvesting and Vinification Interview

- Harvest Timing and Techniques: Understanding optimal harvest dates based on sugar levels, acidity, and phenolic ripeness. Practical application: Explain your experience with different harvesting methods (manual vs. mechanical) and their impact on grape quality.

- Pre-Fermentation Handling: Explore sorting techniques, destemming, crushing, and the impact of these processes on wine characteristics. Practical application: Discuss the challenges of handling different grape varieties and how you’ve addressed them to maintain quality.

- Fermentation Management: Mastering yeast selection, temperature control, and inoculation techniques for both red and white wine fermentation. Practical application: Describe your experience monitoring fermentation parameters and troubleshooting potential issues (e.g., stuck fermentation).

- Malolactic Fermentation (MLF): Understanding the process, its impact on wine flavor profile, and managing MLF initiation and completion. Practical application: Explain how you’ve ensured successful MLF in different wine styles.

- Post-Fermentation Processes: Familiarize yourself with techniques like racking, fining, filtration, and their effects on wine stability and clarity. Practical application: Discuss your experience with different clarification methods and their impact on wine quality.

- Oak Management: Understand the use of oak barrels for aging, its impact on wine flavor and aroma, and the selection of appropriate oak types. Practical application: Describe your experience with different oak treatments and their effect on the final product.

- Wine Stabilization and Bottling: Mastering techniques for preventing spoilage and ensuring long-term wine stability. Practical application: Explain your understanding of different stabilization methods and their application in a production setting.

- Quality Control and Assurance: Understand the importance of sensory evaluation, analytical testing, and maintaining consistent quality throughout the winemaking process. Practical application: Describe your experience implementing quality control measures and resolving quality-related issues.

Next Steps

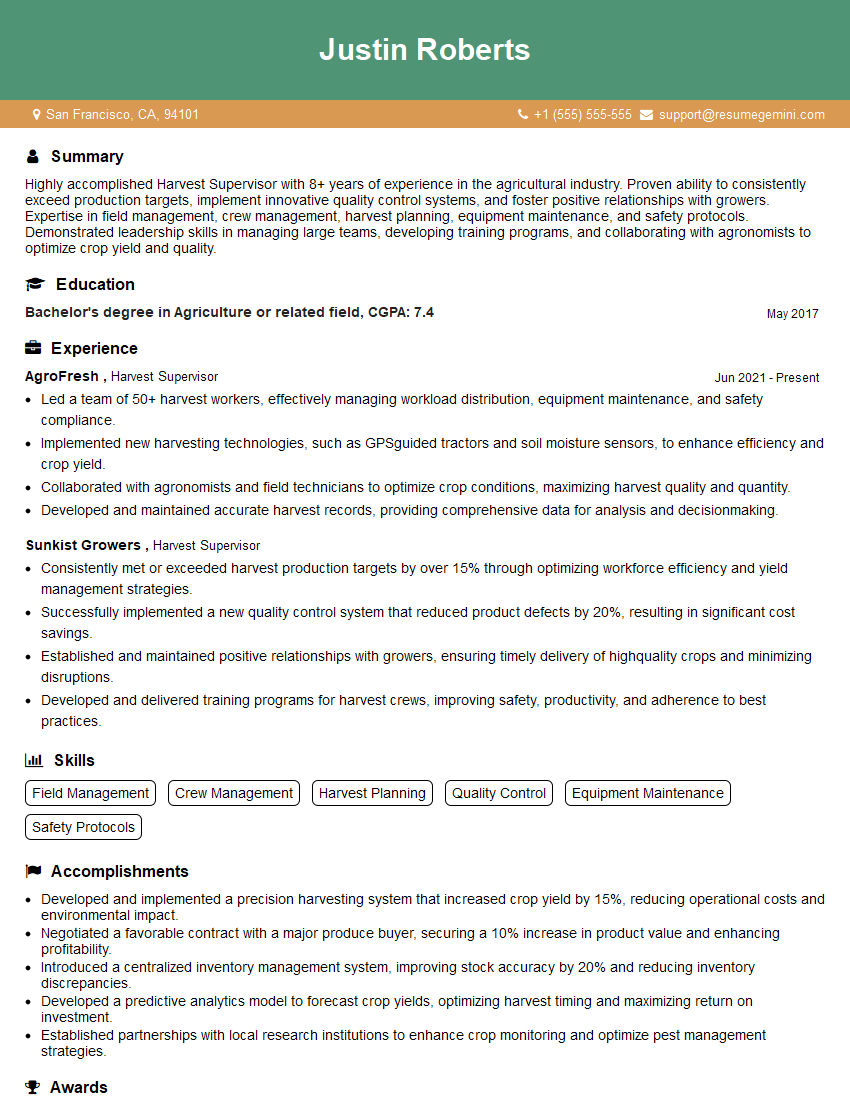

Mastering Harvesting and Vinification is crucial for career advancement in the wine industry, opening doors to specialized roles and increased responsibilities. An ATS-friendly resume is your key to unlocking these opportunities. To make your application stand out, invest time in crafting a strong resume that highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and effective resume. They offer examples of resumes tailored to the Harvesting and Vinification field to guide you through the process. Take the next step towards your dream career – build your winning resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good