Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Harvesting Oysters interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Harvesting Oysters Interview

Q 1. Describe the different methods used for oyster harvesting.

Oyster harvesting methods vary depending on the farming system and scale of operation. There are primarily two main approaches: hand harvesting and mechanical harvesting.

Hand Harvesting: This traditional method involves divers or workers wading through shallow waters to collect oysters. It’s often used for smaller-scale operations or in areas with complex bottom topography unsuitable for machinery. Think of it like a meticulous treasure hunt! Divers might use tongs or rakes to gently gather oysters, carefully selecting mature specimens while leaving smaller ones to grow.

Mechanical Harvesting: Larger-scale operations often utilize dredging or hydraulic harvesting. Dredges are large metal baskets dragged across the seabed, scooping up oysters. Hydraulic harvesting employs powerful water jets to dislodge oysters from the bottom, which are then collected by suction pumps. This method is more efficient but carries a higher risk of bycatch (unintentionally harvesting other species) and habitat damage if not carefully managed. It’s like using a giant vacuum cleaner, but with a much gentler approach to protect the ecosystem.

The choice of method hinges on factors like water depth, oyster density, environmental regulations, and the economic viability of each approach. Each method requires expertise and careful consideration of its impact on the environment.

Q 2. Explain the process of oyster depuration.

Oyster depuration is a process of purifying oysters to remove bacteria, viruses, and other contaminants. It’s a crucial step in ensuring food safety. Essentially, it’s like giving the oysters a spa treatment to cleanse them before they reach our plates!

The process typically involves holding oysters in controlled tanks with flowing, clean, seawater. This allows the oysters to naturally filter out contaminants. Parameters like water quality, temperature, and flow rate are meticulously monitored and adjusted to optimize the depuration process. The duration of depuration varies based on the initial level of contamination and the target standards. Regular testing ensures the oysters meet safety regulations before they’re released for sale. Think of it as a rigorous quality control check, making sure the oysters are perfectly clean and safe to eat.

Q 3. What are the common challenges faced during oyster harvesting?

Oyster harvesting presents several challenges, some environmental and some logistical:

Environmental factors: Severe weather conditions like storms and high tides can disrupt harvesting operations. Water quality issues, such as algal blooms or pollution, can affect oyster health and safety, impacting yields and potentially closing harvest areas.

Biological factors: Diseases and parasites can decimate oyster populations, reducing yields. Predation by other marine animals can also significantly impact harvests.

Economic factors: Fluctuating market prices and rising operating costs (fuel, labor, equipment maintenance) can affect profitability.

Regulatory hurdles: Navigating complex permits, licenses, and environmental regulations is crucial, but can be time-consuming and administratively challenging.

Addressing these challenges requires a combination of careful planning, adaptive strategies, and robust risk management. For example, having backup plans for weather disruptions, implementing sustainable farming practices to enhance oyster resilience, and proactive disease surveillance are vital for successful oyster harvesting.

Q 4. How do you ensure the quality and safety of harvested oysters?

Ensuring oyster quality and safety is paramount. It involves a multi-pronged approach:

Source Selection: Harvesting from clean, well-managed areas is fundamental. Regular monitoring of water quality and oyster health is essential. We are constantly evaluating the health of our oyster beds and the surrounding ecosystem.

Careful Handling: Oysters must be handled gently to minimize stress and damage. Proper storage and cooling immediately after harvesting are crucial for maintaining freshness and preventing bacterial growth. Imagine it like handling precious cargo!

Depuration: As discussed earlier, depuration is a critical step in removing contaminants.

Testing: Regular testing for bacterial contamination and other pollutants ensures the oysters meet safety standards. We use accredited laboratories to provide this essential testing.

By adhering to strict quality control measures throughout the entire process, from harvest to sale, we guarantee safe and high-quality oysters for consumers.

Q 5. What are the legal and regulatory requirements for oyster harvesting in your region?

Legal and regulatory requirements for oyster harvesting vary significantly by region. In my region, we must comply with numerous regulations related to:

Licensing and permits: We need specific licenses to harvest oysters from designated areas. These licenses are often subject to quotas and restrictions.

Water quality standards: We must adhere to strict water quality standards to ensure oyster safety and protect the environment. This includes regular monitoring and reporting of water quality parameters.

Harvesting methods and gear: The type of harvesting equipment and methods used are often regulated to minimize environmental impact and prevent overharvesting.

Size limits and quotas: There are regulations specifying minimum oyster size and harvest quotas to ensure sustainable populations.

Traceability: We are required to maintain detailed records of our harvests to ensure traceability from the harvesting location to the consumer.

Non-compliance with these regulations can lead to significant penalties. Understanding and following these regulations is crucial for ethical and legal oyster harvesting operations. We work closely with the relevant authorities to ensure we comply with all legal requirements.

Q 6. Describe your experience with different types of oyster harvesting equipment.

My experience encompasses several oyster harvesting equipment types:

Hand tongs: These are simple but effective for smaller-scale hand harvesting in shallow waters. They allow for selective harvesting, minimizing bycatch.

Hydraulic dredges: These are powerful machines employed in deeper waters and for larger-scale harvesting. They are efficient but demand careful operation to prevent damage to the seabed.

Suction dredges: These machines use powerful water jets to dislodge oysters and then collect them via suction. They are efficient but require careful management to avoid excessive seabed disturbance.

Diver-operated tools: Divers may use rakes, tongs, or specialized tools adapted for underwater use. This provides a degree of selective harvesting, protecting the environment.

The choice of equipment depends on several factors including water depth, bottom type, oyster density, and environmental considerations. Maintaining and repairing this equipment is a critical aspect of operations, ensuring safe and efficient harvests.

Q 7. How do you identify and handle diseased or contaminated oysters?

Identifying and handling diseased or contaminated oysters is a critical aspect of oyster harvesting. We employ several methods:

Visual inspection: During harvesting and processing, experienced workers visually inspect oysters for signs of disease or contamination, such as unusual coloration, lesions, or abnormal shell shape. This is like a rigorous quality check, identifying potential issues before they become a problem.

Laboratory testing: Samples of harvested oysters are sent to accredited laboratories for testing for bacterial contamination, parasites, and other pathogens. This allows for a precise assessment of the condition of the oysters.

Discarding affected oysters: Any oysters found to be diseased or contaminated are immediately discarded to prevent the spread of disease and protect consumer safety. This is a crucial step in ensuring product quality.

Notification of authorities: Any significant disease outbreaks or contamination events are reported to the relevant authorities for investigation and appropriate action. This helps protect the wider ecosystem and manage potential risks effectively.

Our approach focuses on proactive monitoring and quick response measures, minimizing the risk of spreading disease and ensuring the safety of both the oyster population and the consumers.

Q 8. What are the ideal environmental conditions for oyster harvesting?

Oysters thrive in specific environmental conditions. Salinity is crucial; they need a consistent saltwater environment with salinity levels generally between 15 and 30 parts per thousand. Temperature also plays a significant role, with optimal growth occurring within a range of 15°C to 25°C, though they can tolerate slightly broader ranges depending on the species and acclimatization. Water clarity is another important factor; excessive turbidity can reduce their feeding efficiency. Finally, a clean, well-oxygenated water column is essential for healthy oyster growth. Think of it like this: oysters are like picky eaters, demanding a comfortable and nutritious ‘table’ to thrive.

For example, the Chesapeake Bay, with its brackish waters and varying salinity levels, supports a robust oyster population, while areas with significantly higher or lower salinity often show decreased success. Similarly, warmer waters during summer months can accelerate growth but also increase susceptibility to disease if temperatures get too high.

Q 9. Explain the importance of sustainable oyster harvesting practices.

Sustainable oyster harvesting is paramount for maintaining healthy populations and ensuring the long-term viability of the industry. Unsustainable practices can lead to overfishing, habitat degradation, and the depletion of oyster stocks, impacting the entire ecosystem. Sustainable practices focus on several key areas: selective harvesting (taking only mature oysters), minimizing bycatch (unintentional capture of other species), protecting oyster reefs and their habitats, and implementing responsible aquaculture techniques.

For instance, using methods like dredging judiciously, respecting size limits, and rotating harvesting areas allows for the regeneration of oyster populations and preserves the environment. Ignoring these principles could lead to a collapse of the oyster fishery, impacting both the economic viability and the ecological health of the region.

Q 10. How do you manage oyster stock levels to ensure consistent yields?

Managing oyster stock levels requires a multifaceted approach. Regular monitoring through surveys and sampling helps determine population density and growth rates. This data informs decisions on harvesting quotas and the implementation of conservation measures like creating artificial reefs or seeding areas with juvenile oysters (spat). We also need to consider factors like natural mortality rates and environmental conditions that can influence population size.

Imagine managing a farm; you wouldn’t harvest all your crops at once. Similarly, responsible oyster management involves leaving enough oysters behind to reproduce and maintain a healthy population for future harvests. This is often achieved through careful regulation and collaboration between researchers, harvesters, and regulatory bodies.

Q 11. Describe your experience with oyster grading and sizing.

Oyster grading and sizing are crucial for ensuring consistent product quality and meeting market demands. Oysters are typically graded based on their size, shape, and shell condition. Size is usually categorized into market-size oysters and smaller ones designated for further growth or other uses. We use calibrated sizing gauges to measure the length or width of the oysters, sorting them into different size categories. Shell condition is also assessed, discarding damaged or diseased oysters. This ensures consistent quality and meets consumer expectations.

For example, larger oysters are often preferred for the half-shell market, while smaller ones might be used for processing into other products like oyster stew. Maintaining consistent size grades is essential for fulfilling contracts and maintaining a positive reputation with clients.

Q 12. What are the common pests and predators affecting oyster growth and how do you manage them?

Oysters face numerous threats from pests and predators. Common predators include starfish, crabs, and certain species of fish, while diseases caused by various bacteria and parasites also significantly impact oyster growth and survival. We use several management strategies to mitigate these threats. This can include physical removal of predators from oyster beds, employing selective breeding to develop disease-resistant strains, and maintaining good water quality to minimize disease outbreaks. Sometimes, we use protective measures like mesh bags or cages to shield oysters from predators during their early life stages.

For instance, a sudden influx of starfish can devastate an oyster bed. Regular monitoring and swift removal of these predators can significantly reduce losses. Similarly, maintaining clean water helps reduce the risk of disease outbreaks, which can cause mass mortality events.

Q 13. How do you maintain water quality in an oyster farm?

Maintaining water quality in an oyster farm is critical for oyster health and productivity. This involves monitoring parameters like salinity, temperature, dissolved oxygen, and nutrient levels. We can use techniques such as water circulation systems to enhance oxygen levels and remove waste products. Effective water quality management also requires considering the surrounding environment and minimizing any impacts from land-based runoff or pollution sources.

For example, regular testing of water parameters allows us to identify potential problems early on, such as low oxygen levels, and take corrective actions before they affect oyster health. Implementing practices like buffer zones around the farm can help reduce the impact of land-based pollution.

Q 14. What are your strategies for preventing oyster mortality?

Preventing oyster mortality is a top priority. Strategies focus on minimizing stress factors that weaken oysters and make them vulnerable to disease or predation. This includes maintaining optimal water quality, managing predator populations, and selecting disease-resistant oyster strains. Regular monitoring and early detection of disease outbreaks are also crucial, enabling prompt intervention measures such as treatment or culling affected oysters to prevent widespread mortality. Good farm management practices, like ensuring adequate spacing between oysters to promote airflow and reduce stress, also play a significant role.

For instance, early detection of a disease outbreak through regular monitoring allows for swift response, potentially limiting the impact on the overall stock. The implementation of biosecurity measures, such as disinfection of equipment, helps prevent the introduction and spread of diseases within the farm.

Q 15. What are the different oyster species you have experience harvesting?

Over my two decades in oyster harvesting, I’ve worked extensively with several species. The most common are the Eastern oyster (Crassostrea virginica), known for its robust flavor and adaptability, and the Pacific oyster (Magallana gigas), prized for its larger size and faster growth rate. I also have experience with the Olympia oyster (Ostrea lurida), a smaller native species that requires more specialized cultivation techniques due to its sensitivity to environmental changes. Each species presents unique challenges and rewards in terms of harvesting, with differences in growth rates, preferred habitats, and market demand influencing harvesting strategies.

- Eastern Oyster: The workhorse of the industry, requiring a balance between sustainable harvesting and maintaining healthy populations.

- Pacific Oyster: Often farmed in more controlled environments, requiring different techniques for harvesting.

- Olympia Oyster: Restoration efforts and careful management are paramount, making sustainable harvesting crucial.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with oyster seed collection and cultivation.

Oyster seed collection and cultivation are critical first steps. We typically collect oyster spat (larvae) from natural oyster beds or utilize hatchery-produced spat. For natural spat collection, we deploy collectors – materials like oyster shells or specially designed substrates – in areas with known oyster populations. After a period of larval settlement, these collectors are retrieved, and the attached spat are carefully removed and nurtured in nurseries. These nurseries provide a controlled environment, protecting the young oysters from predators and ensuring optimal growth before being transferred to grow-out areas, typically intertidal zones or floating rafts. Hatchery techniques allow for greater control over oyster genetics, disease resistance and growth, and can improve the efficiency of seed production. The process involves carefully monitoring water quality, salinity, temperature, and food availability for optimal larval development.

For example, we once experienced a significant spatfall failure due to unexpectedly high water temperatures. This highlighted the importance of close environmental monitoring and the need for contingency plans, such as having a diverse collection of spat from different locations or using hatchery-produced spat as a backup.

Q 17. How do you assess the market demand for oysters and adjust your harvesting schedule accordingly?

Market analysis is crucial for efficient oyster harvesting. We closely monitor wholesale and retail prices, seasonal demand fluctuations (higher demand during holidays, for example), and any shifts in consumer preferences (e.g., growing interest in specific oyster varieties). This information, combined with forecasts from market research firms, allows us to adjust our harvesting schedule to meet market needs. For instance, during peak seasons like summer, we increase harvesting frequency to meet higher demand, while during slower periods, we might reduce harvesting to allow for oyster growth and maintain stock levels for later months. We also consider transportation logistics and storage capabilities when planning our harvest schedule to ensure optimal freshness and reduce waste.

Q 18. Describe your experience with post-harvest handling and processing of oysters.

Post-harvest handling and processing are critical for maintaining oyster quality and safety. After harvesting, oysters are immediately cleaned to remove debris and sorted by size. They are then either immediately shucked (opened) for immediate market or placed in specialized containers for live storage. Live oysters are kept in chilled, flowing seawater tanks to maintain their freshness and viability. Shucking requires skill to minimize damage and maximize yield. After shucking, oysters are typically rinsed, packed, and quickly chilled for distribution. Strict adherence to food safety standards, including temperature control and proper hygiene, is paramount throughout the entire process. Any oysters showing signs of disease or poor quality are immediately discarded to prevent contamination.

Q 19. What safety measures do you implement during oyster harvesting?

Safety is our top priority. Our harvesting teams are trained in safe boating practices, including proper use of life jackets and communication equipment. We use designated harvesting areas to minimize risks associated with navigation. We also provide safety training that covers the handling of harvesting tools, the recognition and avoidance of hazardous marine life (e.g., stinging jellyfish, sharp shells), and emergency procedures. Regular equipment inspections are carried out, and all staff are equipped with appropriate Personal Protective Equipment (PPE), such as gloves and protective footwear to prevent injuries from sharp shells or other hazards.

Q 20. How do you monitor and record oyster harvest data?

We maintain detailed records of our oyster harvests using a combination of digital and manual methods. Harvest data includes the date, location (using GPS coordinates), quantity harvested (by weight or number), oyster size distribution, and any observations about oyster condition and water quality. This data is entered into a computerized database, which allows for efficient analysis and tracking of harvest trends. We also maintain manual logs, useful as a backup and for recording qualitative observations not easily captured digitally. This data is essential for evaluating the success of our farming practices, tracking oyster growth rates, and complying with regulatory requirements. Regular data analysis helps to optimize our operations and improve sustainability.

Q 21. What is your experience with using GPS and other mapping tools during oyster harvesting?

GPS and mapping tools are indispensable for efficient oyster harvesting and farm management. We use GPS devices to accurately mark the location of our oyster beds, enabling precise navigation and efficient harvesting. Mapping software allows us to create detailed maps of our oyster farms, showing the distribution of oyster beds, water depths, and other relevant information. This helps in planning harvesting routes, optimizing resource allocation, and monitoring the overall health of the oyster beds. For example, we might use GIS (Geographic Information System) software to overlay environmental data (e.g., water temperature, salinity) with our oyster farm maps to identify areas where oysters might be at greater risk of disease or stress. This precise location data contributes to sustainable harvesting practices, helping us minimize environmental impact while maximizing productivity.

Q 22. Describe your experience with oyster transportation and logistics.

Oyster transportation and logistics are critical for maintaining the quality and safety of the product. It’s a delicate process, as oysters are highly perishable. My experience encompasses every stage, from harvesting to delivery to the end consumer.

We begin by carefully hand-selecting oysters, ensuring they’re free from damage. They are then immediately chilled to around 4°C (39°F) to slow down metabolic processes and prevent spoilage. For short distances, we use refrigerated trucks, meticulously monitoring the temperature throughout the journey. For longer distances, we utilize specialized refrigerated containers with ice packs or, increasingly, temperature-controlled systems that monitor and log the temperature constantly. This data is crucial for traceability and meeting food safety standards.

Efficient logistics also involve route planning to minimize transit time, and appropriate packaging to protect the oysters from damage during transport. We often use specially designed oyster trays that keep them secure and prevent crushing. Finally, clear communication with our buyers regarding delivery schedules and any potential delays is vital.

Q 23. What are your knowledge of oyster diseases and their prevention?

Oyster diseases are a significant concern for oyster farmers. Understanding and preventing them is crucial for maintaining healthy stocks and ensuring product quality. Common diseases include Dermo (Perkinsus marinus) and MSX (Haplosporidium nelsoni), both parasitic diseases that can cause significant mortality. Other issues include bacterial infections and viral diseases.

Prevention strategies focus on maintaining good water quality. This includes regular monitoring of water parameters like salinity, temperature, and dissolved oxygen levels. We also employ selective breeding programs to develop oyster strains that exhibit greater resistance to diseases. Careful site selection, choosing areas with good water circulation and lower disease prevalence, is also critical. Regularly culling affected oysters and practicing proper sanitation techniques on harvesting equipment help minimize the spread of infection.

Furthermore, we regularly consult with researchers and regulatory agencies to stay informed about emerging diseases and best practices for disease management. It’s a continuous learning process crucial for long-term sustainability.

Q 24. How do you maintain accurate records of oyster harvests, sales, and inventory?

Maintaining accurate records is essential for efficient business management and meeting regulatory requirements. We use a combination of digital and physical record-keeping methods. Every harvest is documented using a detailed log that records the date, location, quantity harvested, and size distribution of oysters. Sales records track the volume and value of oysters sold, the buyer, and the date of sale. Inventory records provide a real-time overview of oysters in storage, their location, and their condition.

We employ a custom-designed database which allows us to easily input and access this information. This allows for generation of reports on harvest yield, sales trends, and inventory levels. This data is crucial for planning future harvests, managing costs, and identifying trends. We also retain physical copies of all important documents to ensure redundancy.

Regular audits of our records are conducted to ensure accuracy and compliance with relevant regulations. This ensures transparency and accountability in our operations.

Q 25. How do you adapt harvesting methods based on environmental factors?

Environmental conditions heavily influence oyster harvesting. Adapting to these factors is key to successful and sustainable harvesting. For example, strong currents or storms make harvesting dangerous and sometimes impossible; we postpone harvesting until conditions improve.

Water temperature impacts oyster growth and quality. In warmer months, oysters grow faster, but may also be more susceptible to diseases. We adjust harvesting frequency accordingly, harvesting more frequently in periods of optimal growth but being extra cautious during periods of high temperature and disease risk. Similarly, we modify our harvesting techniques based on water clarity. In murky water, visibility is reduced, requiring slower and more careful methods to prevent damage to both oysters and the seabed.

We also consider tidal cycles when scheduling harvests. Lower tides expose more of the seabed, allowing for more efficient harvesting, but we must also ensure that the exposed oysters don’t dry out.

Q 26. Explain the impact of climate change on oyster farming and harvesting.

Climate change poses significant challenges to oyster farming and harvesting. Rising sea temperatures are a major concern. Higher temperatures can cause oyster mortality, accelerate disease outbreaks, and alter the species’ distribution. Ocean acidification, caused by increased CO2 absorption, reduces the ability of oysters to form their shells, impacting growth and survival.

Changes in weather patterns, such as increased frequency and intensity of storms, can damage oyster beds and disrupt harvesting activities. Sea level rise can inundate oyster farms and alter salinity levels, further impacting oyster health and productivity. In response, we are exploring various adaptation strategies, such as selective breeding for heat-tolerant oyster strains, implementing improved water management techniques, and developing resilient farming infrastructure.

Collaboration with researchers and other stakeholders is essential to develop effective strategies for mitigating the impacts of climate change on oyster farming and ensuring the long-term viability of this valuable industry.

Q 27. Describe your knowledge of different oyster farming techniques (e.g., bottom culture, raft culture).

Different oyster farming techniques cater to diverse environmental conditions and oyster species. Bottom culture is the simplest method, involving seeding oyster spat directly onto the seabed. This relies on natural settling and growth, requiring less infrastructure but potentially higher risk of predation and disease.

Raft culture is an alternative where oysters are grown suspended in the water column on rafts or longlines. This reduces the risk of seabed-related problems, provides better water circulation, and facilitates easier harvesting and monitoring. Other techniques include hanging-on-rope culture and tray culture, each suited to specific environmental and economic considerations. The choice of technique depends on factors such as water depth, current strength, substrate type, and the species of oyster being cultivated. For example, in areas with strong currents, raft culture might be preferred to reduce the risk of oysters being dislodged from the seabed, while bottom culture might be more suitable in calm, shallow waters with a suitable substrate.

Q 28. How do you ensure traceability and compliance with food safety regulations?

Traceability and food safety are paramount. We meticulously maintain records at every stage, from spat collection and grow-out to harvesting and distribution. This includes identifying the origin of the oysters, tracking their growth conditions, and documenting all handling processes. This detailed record-keeping allows us to trace any oyster back to its origin and identify potential sources of contamination should a problem occur.

We adhere strictly to all relevant food safety regulations and undergo regular inspections by regulatory agencies. Our facilities are maintained to high sanitation standards, and our staff receive thorough training in food safety protocols. We employ regular testing to ensure our oysters are free from harmful bacteria or other contaminants, ensuring the product reaches the consumer safely.

The use of technology, such as RFID tags or blockchain technology, is being explored to improve traceability and ensure transparency throughout the supply chain, providing further assurance to consumers.

Key Topics to Learn for Harvesting Oysters Interview

- Oyster Biology and Life Cycle: Understanding oyster growth, reproduction, and environmental factors influencing their development is crucial. This includes knowledge of different oyster species and their specific needs.

- Sustainable Harvesting Practices: Explore environmentally responsible techniques, including gear selection, size limits, and minimizing habitat disruption. Consider the impact of different harvesting methods on oyster populations and the ecosystem.

- Water Quality and Oyster Health: Learn about the importance of clean water for oyster growth and the identification of potential contaminants. Understand how to assess water quality and its effect on oyster health and marketability.

- Harvesting Techniques and Equipment: Familiarize yourself with various harvesting methods (e.g., tongs, rakes, diving) and the equipment used. Analyze the efficiency and suitability of different techniques for various environments and oyster types.

- Post-Harvest Handling and Processing: Understand the proper procedures for cleaning, sorting, storing, and transporting harvested oysters to maintain quality and prevent spoilage. Learn about different oyster grading and sizing standards.

- Safety Regulations and Procedures: Be prepared to discuss relevant safety regulations and best practices for working in aquatic environments. This includes understanding potential hazards and preventative measures.

- Regulations and Licensing: Understand the legal framework surrounding oyster harvesting, including licensing requirements, quotas, and seasonal restrictions. This showcases your awareness of industry compliance.

- Market Trends and Demand: Research current market trends, consumer preferences, and price fluctuations in the oyster industry. This demonstrates your understanding of the broader economic context.

Next Steps

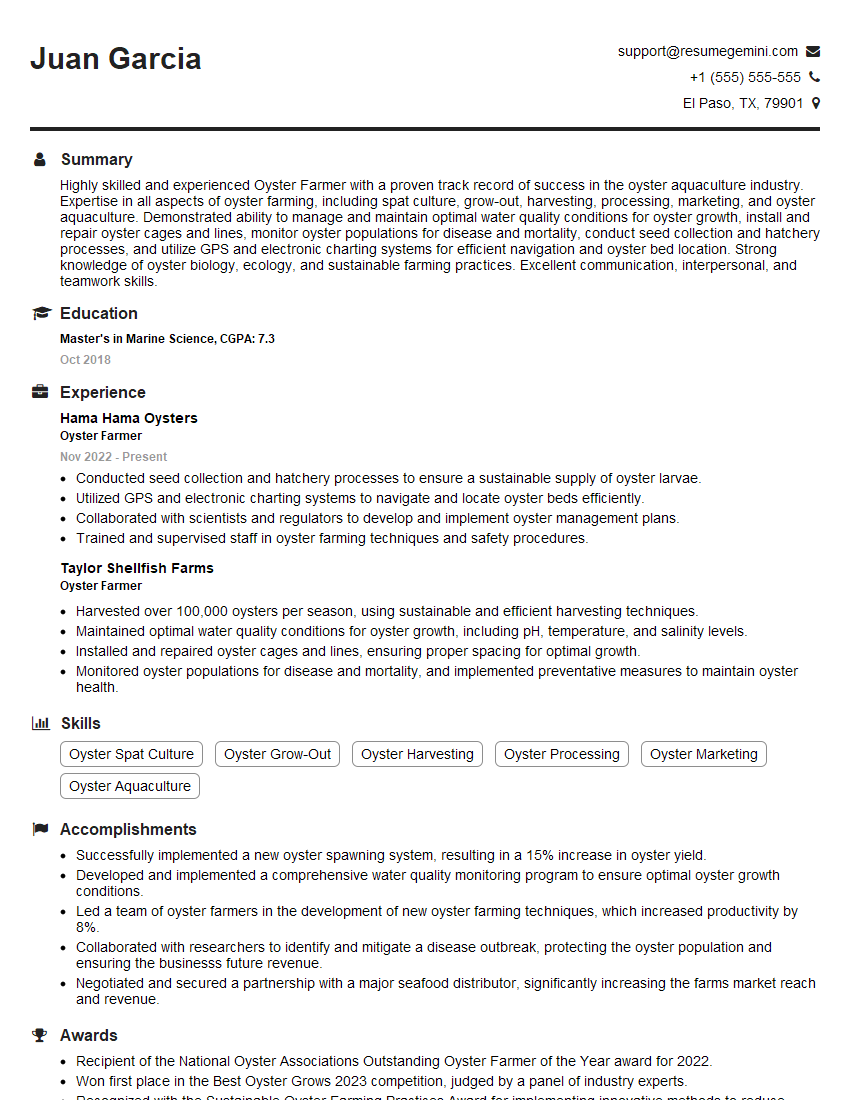

Mastering the intricacies of oyster harvesting positions you for a successful and rewarding career in a growing industry. A strong understanding of these key areas will significantly enhance your interview performance and demonstrate your commitment to sustainable and efficient practices. To further boost your job prospects, create an ATS-friendly resume that highlights your relevant skills and experience. We highly recommend using ResumeGemini, a trusted resource, to build a professional and impactful resume. Examples of resumes tailored to the oyster harvesting industry are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).