Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Hay Bale Storage interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Hay Bale Storage Interview

Q 1. Describe the optimal conditions for long-term hay bale storage.

Optimal long-term hay bale storage hinges on maintaining dry, cool, and well-ventilated conditions to minimize spoilage and maximize nutritional value. Think of it like preserving a precious resource; the better you protect it, the longer it lasts.

- Dryness: Moisture is the enemy. Hay should have a moisture content below 15% before baling to prevent mold growth. Storing bales on a well-drained surface, away from ground moisture, is crucial. Consider using pallets or a concrete slab.

- Cool Temperatures: High temperatures accelerate spoilage and nutrient degradation. Shade is your friend. Ideally, store bales in a location shielded from direct sunlight and extreme weather conditions.

- Good Ventilation: Airflow prevents the buildup of moisture and gases produced during respiration, which can lead to heating and spoilage. This is why proper stacking and structure design are vital.

For example, imagine storing hay in a humid, poorly ventilated barn during a rainy summer. The combination of heat, moisture, and trapped air would create a perfect breeding ground for mold and fungi, ruining your hay supply.

Q 2. Explain different methods of hay bale stacking and their advantages/disadvantages.

Hay bale stacking methods influence ventilation and ease of access. Each method has trade-offs.

- Long Rows: Simple, requiring minimal space planning, but can lead to poor air circulation in the center of the stack, especially with large bales.

- Stacked Squares/Rectangles: Offers better ventilation than long rows by creating channels for air movement. However, requires more precise planning and space.

- Mushroom Stacks: A staggered method offering excellent ventilation, but it takes up significant space and can be challenging to construct and manage. Think of a stack of progressively smaller layers.

- Roofed Structures: Bales are stacked inside barns or sheds, offering the greatest protection from the elements and optimal ventilation, if the structure is designed well. However, construction cost is the major disadvantage.

Choosing the right method depends on factors such as bale size, available space, climate, and budget. A smaller operation in a dry climate might opt for long rows, whereas a large operation in a humid climate might invest in a barn with strategically placed ventilation.

Q 3. What are the common causes of hay spoilage and how can they be prevented?

Hay spoilage is primarily caused by moisture and heat, leading to mold, bacterial growth, and nutrient loss. Think of it as a recipe for disaster: moisture + heat = spoilage.

- Excessive Moisture: Rain, dew, or improper drying during harvest are leading causes.

- High Temperatures: Sunlight, poor ventilation, and fermentation within the bale contribute to heat buildup.

- Insect Infestations: Stored-product insects can damage and contaminate hay.

- Mold and Fungi: These thrive in damp, warm conditions, producing mycotoxins that are harmful to livestock.

Prevention strategies include proper field curing, baling at optimal moisture levels, using waterproof coverings (tarps are common but careful consideration must be given to ventilation) and ensuring adequate ventilation during storage. Regular monitoring for signs of heating or mold is also crucial.

Q 4. How do you assess the quality of hay bales before and after storage?

Assessing hay quality involves checking for key indicators before and after storage.

- Before Storage: Inspect bales for uniform color, texture, and absence of mold. A smell test can reveal signs of fermentation or spoilage. A hay probe can check internal moisture content.

- After Storage: Regular monitoring for heating (touching bales to feel for excessive warmth), mold growth, and insect activity is crucial. Examine bales for discoloration, musty odors, or excessive leaf loss. Consider laboratory testing for nutrient content and mycotoxin levels if you have concerns.

For instance, a bale that feels unusually warm to the touch might indicate internal heating, signifying potential spoilage. Regularly checking and addressing such issues is vital for maintaining hay quality.

Q 5. What safety precautions are crucial during hay bale handling and storage?

Safety is paramount when handling and storing hay bales. These precautions should always be implemented:

- Proper Equipment: Use appropriate machinery for handling and stacking, ensuring it’s in good working order. Never attempt to manually move bales beyond your physical capabilities.

- Protective Gear: Wear sturdy footwear, gloves, and eye protection when handling bales. Consider a hard hat when stacking.

- Safe Stacking Practices: Ensure bales are stable and evenly stacked to prevent collapse. Avoid overloading stacks or placing them near edges.

- Fire Prevention: Hay is highly flammable, especially during dry weather. Keep away from ignition sources, and have fire extinguishers readily available.

- Awareness of Hazards: Be mindful of potential hazards such as unstable stacks, sharp objects, and heavy machinery.

Following these precautions will greatly reduce the risk of accidents and injuries.

Q 6. Explain the importance of proper ventilation in hay bale storage.

Proper ventilation is essential for preventing hay spoilage. Think of it as the hay’s respiratory system. It needs to breathe!

Air circulation removes excess moisture and heat generated during respiration, preventing mold growth and fermentation. Insufficient ventilation can lead to significant losses of quality and quantity of hay. Proper ventilation maintains a suitable environment to extend hay’s lifespan and preserve its nutritional value.

Methods for enhancing ventilation include using stacked squares or mushroom stacks, creating air channels within the stack, and ensuring adequate air circulation around the storage structure. Structures may incorporate roof vents or other design features.

Q 7. What are the different types of hay storage structures, and when would you use each?

Hay storage structures vary depending on scale and climate.

- Outdoor Storage: Simple and cost-effective, suitable for small operations and dry climates. Risks include exposure to the elements.

- Pole Barns: Provide some protection from the elements and offer good ventilation if designed correctly. More expensive than outdoor storage.

- Hay Sheds/Barns: Offer optimal protection from weather and provide the best environment for long-term storage. Most expensive but provide the best hay preservation.

- Bale Shelters: These provide a roof, but leave the sides open, providing some protection from rain and sunlight.

The choice depends on budget, climate, bale volume, and desired storage duration. A farmer in a humid region will prioritize a well-ventilated barn over outdoor storage to avoid significant losses.

Q 8. How do you calculate the required storage capacity for a given quantity of hay?

Calculating hay storage capacity requires considering bale size and density. First, determine the volume of a single bale. For example, a standard large round bale might be approximately 4 feet in diameter and 6 feet long. We can approximate its volume using the formula for the volume of a cylinder: πr²h, where r is the radius (2 feet) and h is the height (6 feet). This gives us approximately 75.4 cubic feet per bale.

Next, account for bale density. Hay density varies based on the type of hay and baling conditions. A denser bale will occupy less space than a looser one. Let’s assume an average density. Then, multiply the volume of a single bale by the number of bales you need to store. Finally, consider the storage method. Stacking bales directly on the ground will require more space than using pallets or a raised structure.

Example: You need to store 100 large round bales. Each bale occupies approximately 75.4 cubic feet. Total storage needed is 100 bales * 75.4 cubic feet/bale = 7540 cubic feet. Add extra space (perhaps 10-20%) to allow for easier access and maneuvering.

Q 9. Describe your experience with different types of hay bale wrapping.

I’ve worked extensively with various hay bale wrapping techniques, each with its pros and cons. Net wrap is a common and relatively inexpensive option, offering good protection against weather and some pest damage. However, it can sometimes tear during transport or handling. Plastic wrap, typically in several layers, provides superior protection against moisture and pest infestation. It’s more expensive upfront, but the reduced spoilage can lead to significant cost savings in the long run. I’ve also used a combination approach, utilizing net wrap for initial containment and then adding plastic wrap for added protection. The choice often depends on factors like climate, hay type, and budget.

In one particular project, we were storing alfalfa in a high-humidity area. The client opted for the extra protection of multiple layers of plastic wrap and we saw significantly less spoilage than on a similar project which used only net wrap. This underscores the importance of carefully selecting the appropriate wrapping material based on specific conditions.

Q 10. Explain the role of pest control in hay bale storage.

Pest control is paramount in hay bale storage. Rodents, insects, and birds can cause significant damage and contaminate the hay. Effective pest control involves both preventative and reactive measures. Preventative measures include keeping the storage area clean and free of debris, ensuring proper ventilation to reduce moisture buildup (which attracts pests), and using proper bale wrapping. Structural barriers such as rodent-proof walls and sealed entry points can prevent infestations.

Reactive measures involve the strategic use of rodenticides or insecticides, always following label instructions and safety precautions. Monitoring for signs of pest activity, such as droppings or damaged bales, is crucial for early detection and intervention. In some cases, I’ve recommended employing pest control professionals for larger facilities to establish and maintain a comprehensive pest management plan.

Q 11. How do you manage inventory and track hay bale usage?

Inventory management and hay bale tracking are critical for efficient operation. I typically use a combination of physical inventory checks and a computerized inventory system. Physical checks involve regular counting of bales, noting their condition and location. This data is then input into a database, which can be a simple spreadsheet or a dedicated farm management software. The system tracks bale type, quantity, date received, and location within the storage facility. This data allows for accurate forecasting of hay needs, efficient ordering, and identification of potential spoilage or waste.

For example, using barcodes on each bale and a handheld scanner allows for rapid and accurate inventory counts. This data can then be linked to a software system that helps track usage as bales are moved or fed out, giving a real-time view of remaining inventory.

Q 12. What are the best practices for loading and unloading hay bales?

Safe and efficient loading and unloading of hay bales necessitates careful planning and the use of appropriate equipment. This includes using forklifts or bale handlers designed for the size and weight of the bales. Always ensure the equipment is in good working condition and operators are properly trained. Prioritize safety by clearing the area of obstacles and ensuring adequate space for maneuvering. Bales should be stacked securely, avoiding unstable configurations that could cause toppling.

When unloading, carefully assess the receiving area to ensure it can handle the weight and volume of the bales. Employing a staged unloading process, where bales are strategically placed for easy access and minimizes unnecessary handling, increases efficiency. Regular maintenance of handling equipment, and training for safe operation, are crucial aspects to avoid accidents and maximize efficiency.

Q 13. What are the common equipment malfunctions related to hay handling, and how do you troubleshoot them?

Common equipment malfunctions in hay handling often involve hydraulic systems (leaks, pump failures), engine problems (starting issues, overheating), and issues with the bale handling mechanisms (forks, clamps). Troubleshooting involves a systematic approach. First, assess the safety of the situation; ensuring that the equipment is shut down and secured before any inspection or repair is attempted. Check fluid levels, inspect for visible damage, and listen for unusual noises. If the problem is simple, like a low fluid level or a loose connection, it can often be resolved on the spot. For more complex issues, obtaining professional repair services is recommended.

For example, if a bale handler is not lifting correctly, checking hydraulic fluid levels, inspecting hoses for leaks, and verifying proper operation of the hydraulic pump are the first steps. A record-keeping system to document maintenance activities is crucial for both preventative and corrective actions.

Q 14. How do you ensure the structural integrity of hay storage facilities?

Maintaining the structural integrity of hay storage facilities is essential to protect the hay from the elements and to ensure worker safety. This begins with the initial design and construction. The building’s foundation should be strong enough to support the weight of the hay, and the structure must be able to withstand the forces of wind and snow. Regular inspections are crucial for identifying potential problems such as structural damage from settling, deterioration due to weather exposure, or rodent activity.

Structural support elements such as beams, posts, and walls need to be inspected for signs of stress or damage. Proper ventilation is key to preventing moisture buildup which can lead to structural decay and hay spoilage. Maintaining the integrity of the roof and walls is equally important to prevent water damage and pest infestation. Addressing any issues promptly minimizes the risk of collapse or significant damage.

Q 15. What are the environmental considerations for hay bale storage?

Environmental considerations in hay bale storage are crucial for minimizing negative impacts on the surrounding ecosystem. These considerations primarily revolve around runoff, erosion, and air quality.

Runoff: Rainwater running off a hay bale storage area can carry fertilizers, pesticides, and soil contaminants into nearby water bodies. Proper site selection, utilizing impervious surfaces where possible (like concrete pads), and implementing effective drainage systems are vital to mitigate this. For example, creating a berm around the storage area can help contain runoff.

Erosion: Unprotected soil around the storage area is susceptible to wind and water erosion, leading to sedimentation in waterways and loss of topsoil. Implementing vegetative buffers (planting grass or other erosion-control vegetation) around the storage area is a common solution. This provides a natural barrier against erosion and also improves the aesthetic appeal of the area.

Air Quality: Mold and dust from improperly stored hay can negatively impact air quality. Ensuring proper ventilation, minimizing dust during handling, and choosing storage locations away from residential areas and sensitive ecosystems are key to maintaining good air quality. Regular monitoring of mold growth can also alert to potential issues that can lead to higher levels of spores in the air.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with using technology to manage hay storage (e.g., sensors, software).

Technology is transforming hay storage management, enhancing efficiency and reducing losses. I’ve extensively used sensor-based monitoring systems in my work. These systems employ temperature and humidity sensors placed within hay bales or throughout the storage structure. Data is transmitted wirelessly to a central monitoring system, either a computer or a mobile app. This allows me to remotely track conditions and receive alerts about potential problems, like excessive heating which is a strong indicator of spontaneous combustion.

One example of software I use integrates with these sensors. It provides visual representations of data, allowing for trend analysis and prediction of potential issues. For example, if humidity levels consistently exceed optimal ranges, the software may project a high probability of mold growth, prompting preventative measures. The software also enables me to generate reports for insurance purposes, demonstrating proactive management of stored hay.

Example data point: Temperature = 75°F, Humidity = 60%, Location = South Stack, Bale ID: 1234Q 17. How do you deal with damaged or spoiled hay bales?

Dealing with damaged or spoiled hay bales requires a systematic approach prioritizing animal safety and minimizing losses. The first step is to visually inspect the bales for signs of damage, such as mold growth, discoloration, or excessive heating.

Segregation: Damaged bales are immediately separated from undamaged ones to prevent contamination. This prevents the spread of mold and reduces the risk of spoilage among the good quality bales.

Assessment: The extent of damage is assessed. Lightly damaged bales might be suitable for lower-quality animal feed, whereas heavily damaged or moldy bales are unsuitable for animal consumption.

Disposal: Unsuitable hay is disposed of responsibly. Options include composting (following local regulations), landfilling, or, in some cases, using it as bedding for animals (depending on the nature of the damage).

Prevention is key. Proper curing, handling, and storage significantly reduce the risk of damage. This includes using appropriate equipment and techniques during baling and storage and ensuring optimal environmental conditions in the storage facility.

Q 18. What are the financial implications of inefficient hay storage practices?

Inefficient hay storage practices translate directly into financial losses. These losses manifest in several ways:

Spoilage: Hay spoilage due to improper storage represents a direct loss of the investment in the hay itself. This can amount to significant losses, especially for large operations.

Reduced Nutritional Value: Improperly stored hay experiences a decrease in its nutritional value, impacting animal health and potentially requiring supplementary feed which adds to the operational costs.

Increased Labor Costs: Handling and managing spoiled hay requires additional labor, increasing operational costs. This includes activities such as sorting, disposal, and purchasing replacement hay.

Damage to Equipment: Improperly stacked hay can damage storage structures or equipment. This can lead to costly repairs or replacements.

For example, a 10% loss of a 1000-bale harvest at an average bale cost of $50 would amount to a $5000 direct loss. This, combined with potential veterinary bills due to poor feed quality, can quickly escalate costs.

Q 19. Explain your experience with different types of hay bale movers.

My experience encompasses a variety of hay bale movers, each with its own strengths and weaknesses. I’ve worked with:

Front-End Loaders: These are versatile and powerful, ideal for loading and unloading large quantities of hay. However, they require significant space for maneuverability and can be less efficient for smaller operations.

Telehandlers: These offer excellent reach and maneuverability, making them suitable for loading and unloading in tight spaces. They are also useful for stacking hay bales to significant heights.

Skid Steer Loaders: Compact and maneuverable, skid steers are suitable for smaller operations and working in confined areas. Their lifting capacity might be limited compared to larger machines.

Specialized Bale Handling Equipment: Some farms utilize equipment like bale clamps and grapples specifically designed for efficient handling of large numbers of bales. This can dramatically increase handling speeds.

The choice of equipment depends on factors like farm size, storage layout, and budget. Consideration should be given to factors like fuel efficiency and maintenance costs when making purchasing decisions.

Q 20. How do you plan for and manage the seasonal changes in hay storage requirements?

Seasonal changes significantly impact hay storage requirements. Planning and management must adapt accordingly.

Harvest Season: This period focuses on efficient baling and immediate storage. This involves ensuring adequate storage space is prepared in advance. Overcrowding needs to be avoided, as this can lead to increased spoilage.

Winter Months: Focus shifts to protecting the hay from the elements. This includes ensuring proper roofing and sidewalls on barns, and inspecting for any structural weaknesses to prevent damage from snow or high winds.

Spring/Summer: Regular monitoring of temperature and humidity is crucial during these months. Mold can become a significant concern, requiring close inspection and ventilation adjustments to maintain optimal conditions. Hay may need to be moved for better air circulation during periods of high humidity.

A well-defined seasonal management plan, incorporating regular inspections, adjustments to ventilation, and addressing potential issues promptly, ensures hay quality and reduces losses throughout the year.

Q 21. How do you handle the disposal of spoiled hay bales?

Disposal of spoiled hay bales must adhere to environmental regulations and safety standards. Options vary depending on local regulations and the extent of spoilage.

Composting: Suitable for bales with minor spoilage, composting involves controlled decomposition, transforming the hay into valuable organic matter for soil amendment. However, regulations must be followed to prevent environmental contamination.

Landfilling: Heavily contaminated or moldy hay is often disposed of in landfills. This method necessitates adherence to local waste management guidelines and may involve specific handling and transportation requirements.

Animal Bedding (with caution): In some situations, spoiled hay (with minimal mold and no evidence of toxins) can be used as animal bedding, however, care should be taken to prevent ingestion and to thoroughly monitor animal health.

It’s crucial to research and comply with all applicable local, state, and federal regulations regarding the disposal of agricultural waste. Failing to do so can result in penalties and environmental damage.

Q 22. Explain the importance of regular maintenance of hay storage equipment.

Regular maintenance of hay storage equipment is crucial for ensuring its longevity, preventing accidents, and maintaining the quality of your hay. Neglecting maintenance can lead to costly repairs, inefficient storage, and even safety hazards.

- Equipment Inspection: Regularly inspect all equipment, including tractors, bale handling equipment, and barn structures, for wear and tear, loose parts, and any potential malfunctions. This might involve checking hydraulic systems, belts, chains, and structural integrity.

- Preventative Maintenance: Develop a preventative maintenance schedule including lubrication, tightening bolts, replacing worn parts, and cleaning equipment after each use. This is far more cost-effective than emergency repairs.

- Storage: Proper storage of equipment during off-season protects it from the elements, extending its lifespan. For example, covering machinery, storing in a dry shed, and draining fluids are good practices.

- Professional Service: Schedule annual professional inspections and servicing for more complex equipment to catch potential problems early on. This can involve a mechanic specializing in agricultural equipment.

For example, a farmer neglecting to regularly lubricate his bale handling equipment could lead to a breakdown during harvest, resulting in delays and potential financial losses. Regular maintenance ensures smooth operations and minimizes downtime.

Q 23. How do you ensure compliance with all relevant safety regulations during hay storage?

Ensuring compliance with safety regulations during hay storage is paramount to protect both personnel and property. This involves adherence to both local and national standards related to fire prevention, structural integrity of storage facilities, and safe handling practices.

- Fire Safety: This includes maintaining adequate distances between hay piles, ensuring proper ventilation to minimize spontaneous combustion, and having readily accessible fire extinguishers appropriate for Class A fires (ordinary combustibles). Regular inspections are vital.

- Structural Integrity: Hay storage structures (barns, sheds) must be properly designed and maintained to withstand the weight of the hay and potential weather conditions. This includes regular inspections for structural weaknesses, pest infestation, and adequate roof support.

- Safe Handling Procedures: Establish and enforce safe operating procedures for handling hay bales, including using appropriate equipment (e.g., bale spears, loaders), wearing protective gear (e.g., gloves, eye protection), and training personnel on safe working practices to prevent accidents.

- Emergency Planning: Develop an emergency plan outlining procedures in case of fire or other emergencies, including clear evacuation routes and contact information for emergency services.

Failing to follow safety regulations can lead to severe consequences, including injuries, property damage, and significant financial losses. For example, a fire caused by inadequate ventilation could completely destroy a hay storage facility and its contents.

Q 24. Describe your experience with different types of hay storage facilities (barns, sheds, outdoor piles).

My experience encompasses a range of hay storage facilities, each with its own advantages and disadvantages:

- Barns: Traditional barns offer excellent protection from the elements and pests, but require significant upfront investment and ongoing maintenance. They offer good control over environmental factors, minimizing spoilage. The type of barn – pole barn, gambrel roof, etc. – also affects cost and suitability.

- Sheds: Sheds provide a more cost-effective alternative to barns, offering basic protection from rain and wind. However, they often provide less protection from pests and are generally smaller than barns. The type of material (metal, wood) impacts durability and longevity.

- Outdoor Piles: Outdoor piles are the simplest and least expensive option but provide minimal protection from the elements and pests. They are highly susceptible to spoilage, fire hazards, and weather damage. Proper covering is crucial.

The choice of storage facility depends on factors such as budget, climate, hay volume, and level of protection required. For instance, in a rainy climate, outdoor piles are risky, while in a dry climate, they may be acceptable for short-term storage with proper precautions.

Q 25. How do you assess the risk of fire or other hazards associated with hay storage?

Assessing the risk of fire and other hazards in hay storage requires a multi-faceted approach. Hay is naturally susceptible to spontaneous combustion due to its biological activity.

- Moisture Content: High moisture content is a major contributor to fire risk. Hay with moisture content above 15% significantly increases the likelihood of spontaneous combustion. Regular monitoring is essential.

- Temperature Monitoring: Hay bales can generate heat during storage. Monitoring bale temperatures using infrared thermometers or temperature probes can detect potential hotspots indicating impending fire hazards.

- Ventilation: Proper ventilation helps to dissipate heat and moisture, reducing the risk of spontaneous combustion. Good airflow is critical, especially in enclosed storage facilities.

- Pest Control: Rodents and insects can contaminate hay and increase the risk of fire through nesting and chewing. Implementing rodent control measures is necessary.

- Regular Inspections: Regular visual inspections for any signs of heating, smoke, or unusual odors are essential. Prompt attention to any anomalies can prevent a small incident from escalating into a major fire.

Example: A farmer noticed a slightly warm bale during a routine inspection. Immediate action, including moving the bale to a well-ventilated area, prevented a potential fire.

Q 26. How do you determine the moisture content of hay bales and its impact on storage?

Determining the moisture content of hay bales is crucial for safe storage and maintaining quality. High moisture content promotes mold growth, spoilage, and increases fire risk. Several methods can be employed:

- Moisture Meter: A moisture meter is the most accurate method, providing a direct measurement of moisture content in the hay. Different meters are available for different bale types.

- Feel Test: An experienced hay handler can often estimate moisture content by feeling the hay. However, this is subjective and less accurate than using a meter.

- Visual Inspection: Observing the color and texture of the hay can provide some indication of moisture content. Darker color and a slimy texture usually indicate high moisture.

The ideal moisture content for storage is generally considered to be below 15%, although the target may vary depending on the type of hay and storage method. High moisture content can lead to significant losses due to spoilage and fire, while very low moisture can lead to excessive dust and nutrient loss.

Q 27. Describe your experience with different types of hay bales (round, square, rectangular).

My experience includes handling various types of hay bales:

- Round Bales: Round bales are large and cylindrical, generally requiring specialized equipment for handling. They are efficient for large-scale operations but require more space for storage.

- Square Bales: Square bales are smaller and easier to handle manually or with smaller equipment. They are suitable for smaller operations and can be stacked more efficiently in storage.

- Rectangular Bales: Rectangular bales are a variation of square bales, often larger and denser. They are suitable for large operations and often require specialized equipment for efficient handling.

The choice of bale type depends on factors such as farm size, equipment availability, and storage space. Round bales are favored for large operations with ample space, while square bales are suitable for smaller farms. The density and size significantly impact handling and storage efficiency.

Q 28. How do you use data analytics to improve hay storage efficiency?

Data analytics can significantly improve hay storage efficiency and reduce losses. Collecting and analyzing data on various factors can provide valuable insights for better decision-making.

- Moisture Sensors: Deploying moisture sensors within the storage facility can provide real-time data on hay moisture levels, alerting to potential problems before they escalate. This allows for proactive intervention to prevent spoilage or fire.

- Temperature Monitoring: Installing temperature sensors within hay piles can detect early signs of heating, enabling prompt action to prevent spontaneous combustion. Data analysis can help identify patterns and potential risks.

- Inventory Management: Tracking hay inventory using software or spreadsheets can optimize storage space and facilitate efficient retrieval. This prevents waste from spoilage due to long storage.

- Predictive Modeling: Using historical data on weather patterns, hay moisture content, and storage conditions, predictive modeling can help anticipate potential risks and optimize storage strategies.

For example, by analyzing historical data on temperature and moisture levels, a farmer can determine optimal ventilation strategies to minimize fire risk and spoilage. This data-driven approach is a more proactive and efficient way to manage hay storage compared to traditional methods.

Key Topics to Learn for Hay Bale Storage Interview

- Hay Bale Types and Characteristics: Understanding different types of hay (alfalfa, grass, etc.), their moisture content, and how these factors influence storage needs.

- Storage Structures and Design: Analyzing the pros and cons of various storage methods (barns, sheds, outdoor piles), considering factors like climate, pest control, and ventilation.

- Hay Bale Handling and Transportation: Safe and efficient methods for moving and stacking hay bales, minimizing damage and spoilage. This includes machinery knowledge and safety protocols.

- Inventory Management and Tracking: Developing systems to track hay bale quantities, quality, and location, ensuring efficient stock management and minimizing waste.

- Pest and Spoilage Control: Identifying common threats to stored hay (insects, rodents, mold) and implementing preventative measures and mitigation strategies.

- Quality Assurance and Preservation: Understanding techniques for maintaining hay quality throughout the storage period, including monitoring temperature and humidity.

- Safety Regulations and Best Practices: Familiarity with relevant safety standards and regulations related to hay storage and handling, including fire prevention.

- Cost Optimization and Efficiency: Analyzing storage costs (building maintenance, labor, potential losses) and identifying strategies for improved efficiency and profitability.

- Environmental Considerations: Understanding the environmental impact of hay storage practices and exploring sustainable solutions.

Next Steps

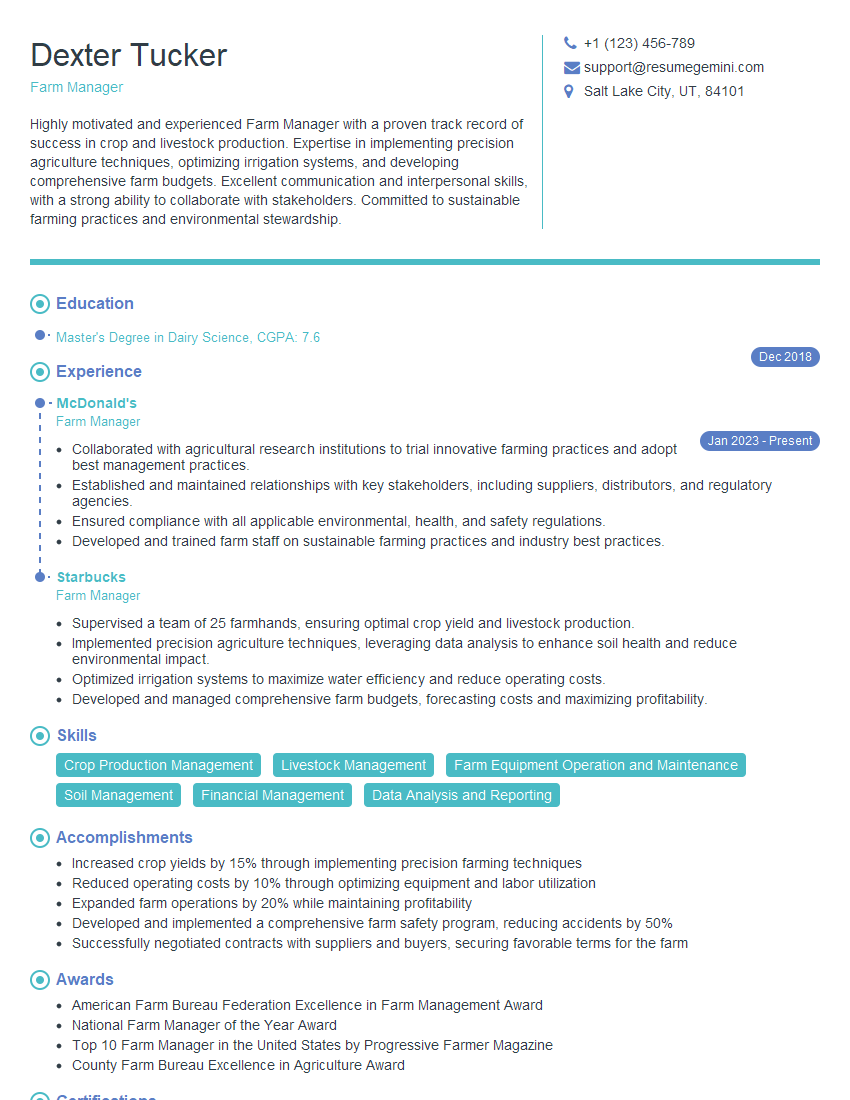

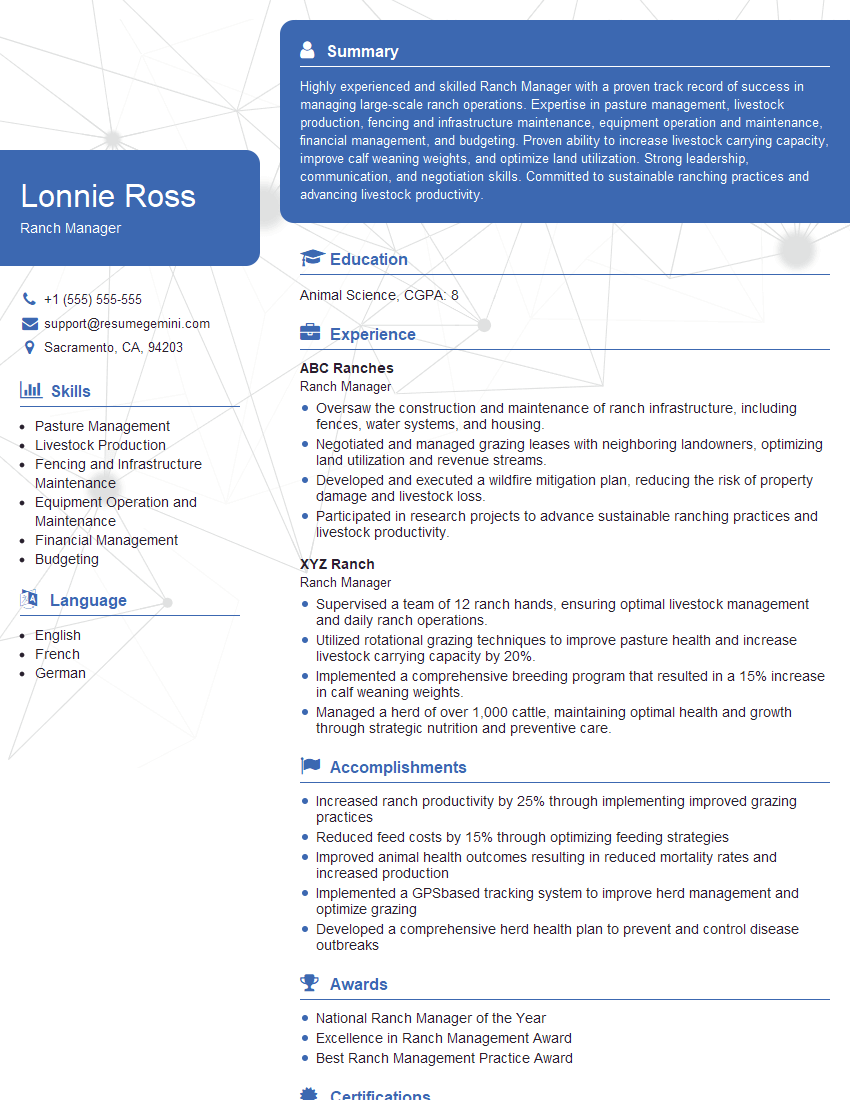

Mastering Hay Bale Storage techniques is crucial for career advancement in agriculture and related industries. A strong understanding of these principles demonstrates practical skills and problem-solving abilities highly valued by employers. To enhance your job prospects, create an ATS-friendly resume that effectively highlights your relevant skills and experience. We recommend using ResumeGemini, a trusted resource, to build a professional and impactful resume. Examples of resumes tailored to Hay Bale Storage are available for your review, providing valuable guidance for crafting your application materials.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good