The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Hazmat Handling and Disposal interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Hazmat Handling and Disposal Interview

Q 1. Describe your experience with handling different classes of hazardous materials.

My experience encompasses a broad spectrum of hazardous materials, spanning all nine classes defined by the Department of Transportation (DOT). This includes extensive hands-on work with Class 1 (explosives), ranging from handling small quantities of fireworks for disposal to managing the safe transport of commercial explosives. I’ve also managed Class 3 (flammable liquids) in industrial settings, overseeing the proper storage, handling, and transportation of solvents and paints. Experience with Class 4 (flammable solids), Class 5 (oxidizers and organic peroxides), Class 6 (toxic and infectious substances), Class 7 (radioactive materials), Class 8 (corrosives), and Class 9 (miscellaneous hazardous materials) is equally significant, ranging from managing chemical spills to ensuring the safe disposal of medical waste and overseeing the transport of batteries and other hazardous materials. Each class demands a unique approach, emphasizing precise adherence to safety protocols and regulatory compliance.

For instance, handling Class 7 materials necessitates specialized training, equipment (like radiation monitors), and stringent documentation to ensure worker safety and environmental protection. Similarly, managing Class 6 materials involves strict adherence to biohazard protocols and often utilizes specialized containment and disposal methods to prevent the spread of infectious agents. This diverse background enables me to approach any hazmat situation with a tailored strategy, prioritizing safety and compliance.

Q 2. Explain the process of identifying and classifying hazardous materials.

Identifying and classifying hazardous materials is a crucial first step in safe handling and disposal. This process typically involves a combination of visual inspection, referring to Safety Data Sheets (SDS), and utilizing specialized testing equipment when necessary.

- Visual Inspection: This involves carefully examining the material’s packaging, looking for labels, markings, and any signs of damage. For example, a container with a skull and crossbones symbol immediately indicates a highly toxic substance.

- Safety Data Sheets (SDS): The SDS provides comprehensive information on a material’s hazards, including its physical and chemical properties, health effects, and recommended handling procedures. This is the most important document to consult.

- Specialized Testing: In some cases, visual inspection and SDS information may be insufficient. This requires employing specialized tests to determine the exact composition and hazard class of the material, particularly for unknown substances. For example, a pH meter could be used to determine if a liquid is corrosive.

Once identified, the material is classified according to the relevant regulations (DOT, EPA, etc.). The classification dictates the appropriate handling, storage, transportation, and disposal methods. Proper classification is critical for ensuring safety and regulatory compliance. Misclassifying a hazardous material could lead to serious accidents and severe legal consequences.

Q 3. How do you ensure compliance with relevant regulations (e.g., DOT, EPA)?

Compliance with regulations like those from the Department of Transportation (DOT) and the Environmental Protection Agency (EPA) is paramount in hazmat handling. My approach to compliance involves a multi-faceted strategy:

- Staying Updated: I regularly review and stay abreast of changes in regulations and best practices. This often involves attending industry conferences and workshops, participating in professional development courses, and actively following updates from regulatory bodies.

- Thorough Documentation: Maintaining detailed records of all hazmat handling activities is crucial. This includes transportation manifests, waste disposal manifests, employee training records, and incident reports. This ensures traceability and facilitates audits.

- Regular Audits and Inspections: Conducting regular self-audits and actively participating in inspections by regulatory agencies helps identify potential compliance gaps proactively. This allows for timely corrective actions and prevents potential penalties.

- Employee Training: Regular, comprehensive employee training on hazmat handling procedures, safety protocols, and regulatory compliance is essential. Training should cover both theoretical knowledge and practical skills, including emergency response procedures.

For example, I ensure all shipments comply with DOT regulations, using the appropriate placards and packaging. Waste disposal follows EPA guidelines, using licensed facilities and submitting all required documentation. This ensures that my work not only protects workers but also safeguards the environment.

Q 4. What safety procedures do you follow when handling hazardous materials?

Safety procedures are the cornerstone of hazmat handling. My approach emphasizes a layered safety system, prioritizing prevention and mitigation:

- Risk Assessment: A thorough risk assessment is performed before any hazmat handling activity, identifying potential hazards and developing control measures. This includes evaluating potential exposure routes (inhalation, ingestion, dermal contact) and selecting appropriate PPE.

- Engineering Controls: Implementing engineering controls like ventilation systems, spill containment areas, and proper equipment design minimizes potential exposures. For instance, ensuring proper ventilation in a paint mixing room reduces the risk of flammable vapor accumulation.

- Administrative Controls: Administrative controls include establishing standard operating procedures (SOPs), providing comprehensive training, implementing work permits for high-risk tasks, and enforcing strict safety rules. Detailed SOPs ensure everyone follows the correct procedures.

- Personal Protective Equipment (PPE): Selecting and properly using appropriate PPE is critical. This choice depends on the specific hazard(s) involved. This may include respirators, gloves, eye protection, protective clothing, and more. Training on the correct use and limitations of the PPE is essential.

A critical aspect is emergency preparedness. This includes having readily available emergency response equipment (like spill kits) and ensuring everyone is trained in emergency procedures, including spill response, evacuation, and first aid.

Q 5. Describe your experience with personal protective equipment (PPE) selection and use.

Selecting and using PPE is not simply a matter of putting on the gear; it’s a crucial safety element requiring a deep understanding of the specific hazards and the limitations of the PPE. My approach begins with a comprehensive risk assessment to identify the potential hazards—chemical, biological, or physical.

For instance, when handling corrosive chemicals, I would select chemical-resistant gloves, eye protection, and a lab coat. The type of glove would depend on the specific chemical; some gloves are resistant to acids, while others are resistant to bases or solvents. If there’s a risk of airborne particulate matter, an appropriate respirator would be required, selecting the right filter based on the type of contaminant. For biological hazards, I would select protective gear designed to prevent contamination, such as gowns, gloves, and face shields, often following strict protocols for donning and doffing to avoid contamination. I always ensure the PPE is properly inspected before use, looking for damage or degradation that could compromise protection. Regular training reinforces proper usage and highlights limitations of the PPE.

Moreover, I always remember that PPE is a last line of defense. Prioritizing engineering and administrative controls to minimize the risk of exposure is far more effective than solely relying on PPE. It’s a layered approach to safety.

Q 6. How do you manage hazardous waste disposal according to regulations?

Managing hazardous waste disposal involves meticulous adherence to all applicable regulations, primarily those set forth by the EPA. This process requires a multi-step approach:

- Waste Characterization: Accurately identifying and characterizing the hazardous waste is paramount. This involves determining its composition, concentration of hazardous constituents, and the appropriate waste code as defined by the EPA.

- Proper Packaging and Labeling: Hazardous waste must be properly packaged and labeled according to EPA regulations. This includes using appropriate containers, ensuring proper closures, and using clear and unambiguous labels indicating the waste’s contents and hazards.

- Manifest System: A manifest system is used to track the waste from its generation to its final disposal. The manifest documents the waste’s origin, destination, and transportation details, ensuring accountability and traceability.

- Licensed Disposal Facilities: Hazardous waste must be transported to and disposed of at a licensed facility equipped to handle the specific type of waste. These facilities are authorized by the EPA and follow strict protocols to minimize environmental impact.

- Record Keeping: Detailed records are maintained throughout the process, including waste generation records, manifest copies, disposal invoices, and any associated documentation. These records must be maintained for a specific period as mandated by law.

Failure to comply with these procedures can result in significant environmental damage and hefty penalties. A real-world example would be improperly disposing of used solvents, potentially contaminating groundwater or releasing harmful vapors into the atmosphere. Strict adherence to regulations and diligent record keeping are crucial to prevent this.

Q 7. Explain your understanding of the Emergency Response Plan (ERP).

An Emergency Response Plan (ERP) is a crucial document outlining the procedures to follow in the event of a hazardous materials incident. A well-developed ERP minimizes the impact of an emergency, protects personnel and the environment, and facilitates a swift and effective response.

My understanding of an ERP includes its key components:

- Hazard Identification and Risk Assessment: This section details the potential hazards associated with the handled hazardous materials, including spill scenarios, fire, and explosion potential. It also outlines a detailed risk assessment of the probability and consequences of these incidents.

- Emergency Response Procedures: This section details specific step-by-step procedures for various emergency scenarios, including initial response actions, evacuation procedures, containment methods, and notification protocols.

- Emergency Contacts: This lists crucial emergency contact information including local emergency services, regulatory agencies (like the EPA and DOT), and internal emergency response personnel.

- Emergency Equipment and Supplies: This outlines the availability and location of all necessary emergency equipment, including spill kits, personal protective equipment, fire extinguishers, and decontamination equipment.

- Training and Drills: A comprehensive ERP includes a plan for regular employee training and emergency drills to ensure preparedness and proficiency in response procedures.

- Post-Incident Procedures: This section details the procedures to be followed after the incident, including cleanup, waste disposal, damage assessment, and reporting requirements.

A robust ERP is not a static document but a living document that should be regularly reviewed, updated, and tested through drills to ensure its effectiveness and relevance. The goal is to ensure a rapid and efficient response to any hazmat incident, minimizing harm and environmental damage.

Q 8. What is your experience with spill response and cleanup procedures?

Spill response and cleanup procedures are paramount in Hazmat handling. My experience encompasses a wide range of spills, from small leaks of solvents to major releases of corrosive chemicals. The process always begins with immediate isolation and containment of the spill, prioritizing personnel safety above all else. This includes establishing a safety perimeter, evacuating personnel from the immediate area, and calling emergency services if necessary.

Next, a proper assessment is critical. This involves identifying the spilled material through visual inspection and reference to labels or manifests, and evaluating the extent of the spill. We utilize specialized equipment to determine the nature and volume of the spill, and then develop a tailored cleanup strategy. This might involve the use of absorbent materials, neutralizers, or specialized equipment like vacuum trucks, depending on the substance’s properties. For example, I once responded to a spill of sulfuric acid where immediate neutralization with a base was crucial to prevent further damage.

Finally, post-spill procedures include proper disposal of contaminated materials, decontamination of equipment and personnel, and a thorough site assessment to ensure environmental safety. Documentation of the entire process is crucial for regulatory compliance and future reference.

Q 9. How do you handle unexpected incidents or emergencies involving hazardous materials?

Unexpected incidents are handled with a structured, methodical approach based on established emergency response plans. The first step is always to ensure the safety of personnel – activating emergency response procedures immediately and following a well-defined chain of command. Next, we isolate the area and try to contain the hazard, preventing further spread. I’ve been involved in several emergency situations where quick thinking was crucial. For instance, a fire involving flammable materials required immediate evacuation and utilization of fire suppression systems while simultaneously coordinating with the fire department.

Simultaneously, we initiate damage control and risk assessment. This often requires consulting the relevant MSDS sheets to understand the hazards and select appropriate protective measures. Communication is critical during emergencies; I ensure clear and concise communication is maintained amongst our team and external agencies like the EPA or local emergency responders. Post-incident analysis is crucial to identify areas of improvement in our emergency response procedures. Through regular drills and training, we ensure our response remains effective and efficient.

Q 10. Describe your experience with decontamination procedures.

Decontamination procedures are vital for protecting personnel and the environment after exposure to hazardous materials. The process is tailored to the specific substance involved and might involve several steps. It begins with removing contaminated clothing and personal protective equipment (PPE) in a controlled manner. Personnel then undergo a thorough wash-down using appropriate decontamination solutions. This may involve showers, specialized cleansing agents, and sometimes even physical scrubbing to remove particulate matter. I’ve overseen the decontamination of workers exposed to pesticides, requiring specialized procedures and careful monitoring of their health afterward.

The process also extends to equipment decontamination. This might involve washing, steam cleaning, or chemical treatment, depending on the nature of the contamination. Following decontamination, all materials and equipment are rigorously inspected to ensure complete removal of the hazardous substance. Proper disposal of contaminated waste materials is also a critical part of the decontamination procedure to prevent environmental contamination.

Q 11. Explain your familiarity with Material Safety Data Sheets (MSDS).

Material Safety Data Sheets (MSDS), now often referred to as Safety Data Sheets (SDS), are my constant companion. They are essential documents that provide comprehensive information about hazardous materials. My familiarity extends to interpreting the various sections, including identification, hazards, composition, first aid measures, fire-fighting measures, accidental release measures, handling and storage, exposure controls and personal protection, physical and chemical properties, stability and reactivity, toxicological information, ecological information, disposal considerations, and transportation information.

I use MSDS/SDS information extensively for risk assessment, selecting appropriate PPE, developing safe handling procedures, and planning emergency response strategies. For example, understanding the flash point of a flammable liquid from its MSDS helps determine safe storage conditions and appropriate fire suppression methods. Without readily accessible and clearly understood MSDS/SDS data, safe handling of hazardous materials would be impossible.

Q 12. How do you communicate hazards to others?

Communicating hazards effectively is critical in preventing accidents. My approach emphasizes clear, concise, and accessible communication tailored to the audience. For workers, this involves training sessions, clear labeling, and readily available MSDS/SDS documentation. I always use plain language, avoiding technical jargon unless necessary and providing clear instructions for handling and emergency procedures.

For emergency responders, communication involves providing precise information about the nature of the hazard, the extent of the spill, and any immediate actions required. Using standardized communication protocols and clear visual signals helps ensure everyone is on the same page during emergency situations. For the public, hazard communication may involve clear signage, public service announcements, or even door-to-door notifications, depending on the severity and extent of the hazard.

Q 13. What is your experience with hazardous materials transportation?

My experience with hazardous materials transportation includes both practical aspects and regulatory compliance. I’m familiar with the requirements for packaging, labeling, and documentation stipulated by the Department of Transportation (DOT) and other relevant agencies. I understand the importance of selecting appropriate containers and ensuring proper securing of materials during transportation to prevent spills and accidents.

I’ve been involved in the transportation of various hazardous materials, ensuring compliance with all relevant regulations. This includes completing shipping papers accurately, ensuring proper vehicle placarding and driver training, and implementing emergency response plans for incidents during transport. Understanding the specific regulations for different modes of transportation (road, rail, air, sea) is essential for safe and compliant hazardous materials transportation.

Q 14. Explain your knowledge of different hazardous waste treatment methods.

Hazardous waste treatment methods vary depending on the nature of the waste. Common methods include physical treatment, chemical treatment, and biological treatment. Physical treatment might involve methods like filtration, sedimentation, or incineration. Chemical treatment often involves neutralization reactions, oxidation, or reduction processes to transform hazardous substances into less harmful forms.

Biological treatment utilizes microorganisms to break down hazardous substances, often used for biodegradable organic waste. The selection of the most appropriate method is crucial and depends on several factors including the type of hazardous waste, the volume, its physical and chemical properties, and regulatory requirements. For example, incineration is effective for destroying many organic hazardous wastes, but it requires strict air pollution controls. Selecting the right method is essential for minimizing environmental impact and ensuring compliance with all applicable regulations.

Q 15. Describe your experience with risk assessment and mitigation strategies.

Risk assessment is the cornerstone of safe hazmat handling. It involves identifying potential hazards, analyzing their likelihood and severity, and determining the potential consequences. Mitigation strategies are the actions we take to reduce or eliminate those risks. My experience encompasses a multi-step process starting with a thorough site survey, identifying all potential hazards – from spills and leaks to improper storage and employee handling practices. We then use established methodologies like HAZOP (Hazard and Operability Study) or what-if checklists to systematically analyze scenarios. For example, in one project involving the transportation of corrosive chemicals, we identified the risk of an accident during transit. Our mitigation strategy included specialized transportation vehicles with secondary containment, rigorous driver training on emergency procedures, and real-time GPS tracking to monitor the shipment’s progress and location. Finally, we create a documented plan which outlines emergency response procedures, including communication protocols and protective measures in case of an incident. This ensures everyone understands their role in managing risk.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How familiar are you with OSHA regulations related to hazmat handling?

I’m intimately familiar with OSHA’s HazCom standard (29 CFR 1910.1200), which mandates comprehensive hazard communication programs. This includes the proper labeling of containers, the creation of safety data sheets (SDS), employee training, and emergency response procedures. I’m also well-versed in OSHA’s regulations pertaining to specific hazardous materials, including those covering respiratory protection, personal protective equipment (PPE), emergency response planning (29 CFR 1910.38), and waste disposal (29 CFR 1910.120). Beyond this, my experience includes staying updated on updates and interpretations, which is crucial considering the dynamic nature of OSHA standards. I’ve participated in numerous OSHA compliance audits, and used this knowledge to implement changes that ensure consistent compliance. For instance, I recently helped a client transition their hazardous waste management practices to comply with a new state-specific regulation that reflected stricter EPA guidelines.

Q 17. What is your experience with container integrity checks?

Container integrity checks are fundamental to preventing leaks and spills. My experience involves visual inspections for damage, corrosion, leaks, and proper closure mechanisms. Beyond visual checks, I’m proficient in using specialized equipment like leak detectors for gaseous materials or pressure gauges for pressurized containers. The specific methods depend on the type of container and the hazardous material it holds. For instance, a drum of flammable liquid will require different checks than a tank car of chlorine. I also verify the integrity of secondary containment structures, ensuring that they can handle potential spills without compromising environmental safety. A comprehensive check includes reviewing the container’s history – checking previous inspection reports and any recorded damage incidents. For example, if a chemical drum shows signs of rust or dents, I’d flag it for immediate replacement or repair rather than risk a dangerous incident.

Q 18. How would you handle a situation where a hazmat container is damaged?

Handling a damaged hazmat container requires immediate and decisive action. First, I’d isolate the area, preventing unauthorized access. This may involve cordoning off a larger perimeter depending on the nature of the hazard and weather conditions. The next step is to assess the extent of the damage and the nature of the hazardous material. This informs the selection of appropriate PPE for personnel involved in the cleanup or containment. We would then contact the appropriate emergency response teams, including local fire departments, hazmat teams, and potentially the material’s manufacturer for specific guidance. Depending on the severity, we might use specialized equipment such as spill containment booms, absorbent pads, or vacuum trucks. For instance, if a tank truck carrying sulfuric acid suffers a significant leak, we’d immediately notify emergency services and use neutralizing agents to minimize the risk of a larger spill or reaction with surrounding materials. Documentation of every step is essential, including photographs, measurements of the spill, and a detailed incident report.

Q 19. Describe your experience with incident reporting and documentation.

Accurate and thorough incident reporting is crucial for preventing future incidents and ensuring compliance. My experience includes creating detailed incident reports following a structured format, including date, time, location, nature of the incident, personnel involved, equipment used, and actions taken. This is complemented by photographic or video evidence, and samples of the hazardous material if appropriate and safe to collect. I use specific software to log incidents, maintaining a centralized database that supports trend analysis. This aids in identifying patterns and recurring issues, enabling us to improve safety procedures and prevent similar occurrences. Reports are also utilized for regulatory compliance reporting requirements to regulatory bodies. For example, a spill of a regulated substance needs to be reported promptly to the EPA, along with documentation of the actions taken for remediation. Each step is documented meticulously to showcase complete transparency and proactive response to the situation.

Q 20. What are the different types of hazardous waste and their disposal methods?

Hazardous wastes are broadly categorized based on their chemical properties and potential health or environmental effects. They include:

- Flammable wastes: These materials readily ignite and require careful storage and disposal, often involving incineration or special landfills.

- Corrosive wastes: These substances chemically attack materials and necessitate specialized containers and neutralization processes before disposal.

- Reactive wastes: These materials are unstable and readily react violently with other substances. They often require specific stabilization techniques before disposal, frequently involving chemical treatment.

- Toxic wastes: These pose significant health risks, even at low concentrations. Their disposal involves stringent regulations and often includes secure landfills or specialized treatment methods.

Disposal methods vary depending on the waste type and local regulations. Common methods include incineration, landfilling (in specialized hazardous waste landfills), chemical treatment, biological treatment, and recycling where feasible. Proper disposal is critical to protecting human health and the environment, avoiding pollution of soil, water, and air.

Q 21. Explain the concept of segregation and compatibility of hazardous materials.

Segregation and compatibility are essential principles in hazmat handling. Segregation means separating incompatible materials to prevent dangerous reactions or contamination. Compatibility refers to the ability of materials to coexist safely without adverse effects. Think of it like sorting laundry – you wouldn’t wash your whites with your reds! Incompatible materials can react violently when mixed, creating fires, explosions, or toxic gases. For example, acids and bases are incompatible and must be stored separately. Similarly, oxidizing agents and flammable materials are a dangerous combination and should never be stored together. My experience involves creating detailed segregation plans for storage areas and transportation routes, ensuring that incompatible materials are physically separated by sufficient distance or barriers. This includes considering the potential for leaks or spills and designing a system that minimizes the risk of dangerous mixing, even in an emergency scenario. Proper segregation and compatibility protocols are key in preventing accidents and keeping personnel safe.

Q 22. What is your experience with using specialized equipment for hazmat handling?

My experience with specialized hazmat handling equipment is extensive. I’m proficient in operating and maintaining a wide range of equipment, from basic personal protective equipment (PPE) like respirators and hazmat suits to more complex tools such as spill containment booms, vacuum trucks, and neutralization systems. For instance, I’ve used specialized pumps to transfer corrosive liquids safely during a chemical spill at a manufacturing plant, ensuring minimal environmental impact. I also have experience with decontamination equipment, including showers and specialized cleaning agents, crucial for protecting personnel after exposure incidents. Proper training and regular maintenance checks are fundamental to my approach to using this equipment safely and effectively. Understanding the limitations of each piece of equipment is crucial – knowing when to call for specialized support is as important as knowing how to operate the equipment itself.

Q 23. How do you ensure the proper labeling and packaging of hazardous materials?

Proper labeling and packaging of hazardous materials is paramount to preventing accidents. It’s governed by strict regulations, primarily the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). This system uses standardized pictograms, signal words (like ‘Danger’ or ‘Warning’), hazard statements, and precautionary statements to clearly communicate the risks associated with a given material. Packaging must be compatible with the material’s properties. For example, corrosive chemicals require containers made of materials that won’t be degraded by the substance. Each package must be labeled according to the GHS, including the product identifier, supplier information, and the hazard pictograms. The packaging itself must also be robust enough to withstand the rigors of transport and handling. Improper labeling or packaging can lead to severe consequences, ranging from fines and legal repercussions to accidents causing injury or environmental damage. In my experience, double-checking every label and package is crucial, even if the process seems repetitive. It’s about preventing even the slightest error that could escalate into a significant problem.

Q 24. Describe your experience with training others on hazmat handling procedures.

I have extensive experience training personnel on hazmat handling procedures. My approach emphasizes hands-on learning and scenario-based training. I’ve developed and delivered numerous training programs for various industries, focusing on topics such as hazard identification, risk assessment, emergency response, and proper use of PPE. I’ve taught everything from basic awareness training to advanced response procedures. For example, I conducted a multi-day training program for a team of first responders, teaching them how to handle different hazardous materials incidents, including chemical spills, radioactive leaks, and biological contamination. The program included classroom instruction, simulations, and hands-on practice using specialized equipment. Effective training involves constant assessment and adjustments to meet the specific needs of the audience. I often use real-world case studies to illustrate the importance of following safety protocols and the potential consequences of non-compliance. Regular refresher courses are also essential to maintain proficiency and address evolving regulatory changes.

Q 25. How do you stay updated on changes in hazmat regulations and best practices?

Staying updated on hazmat regulations and best practices is an ongoing process. I actively participate in professional organizations such as the National Fire Protection Association (NFPA) and the International Association of Emergency Managers (IAEM). I regularly review updates from regulatory bodies like OSHA and EPA. I subscribe to industry publications and attend conferences and webinars to stay informed on new technologies and best practices. These resources offer a combination of official updates and industry perspectives. Attending conferences offers networking opportunities that help in understanding and sharing best practices. Online resources provide immediate access to the latest information. The regulatory landscape is constantly evolving, particularly with new chemical compounds and emerging technologies, so continuous learning is non-negotiable. A proactive approach to learning is necessary to maintaining compliance and ensuring safety.

Q 26. What is your experience with auditing and inspections related to hazmat compliance?

I have significant experience conducting audits and inspections for hazmat compliance. This involves reviewing safety programs, inspecting storage facilities, and evaluating emergency response plans. I use checklists and standardized procedures to ensure a thorough assessment. I’ve conducted numerous audits for various clients, identifying areas of non-compliance and recommending corrective actions. For example, during an audit of a chemical storage facility, I discovered several deficiencies in their spill containment procedures. I provided detailed recommendations on improving their systems and ensuring compliance with EPA regulations. Audits aren’t just about identifying problems; they’re about helping organizations improve their safety programs. A crucial part of this is providing constructive feedback and guidance so they can enhance their safety protocols proactively.

Q 27. Describe a time you had to make a critical decision related to hazmat safety.

During a transportation accident involving a tanker carrying highly flammable materials, I had to make a critical decision. The tanker was leaking, and there was a significant risk of ignition. Evacuating the surrounding area was the first priority. This involved coordinating with local emergency services, establishing a safety perimeter, and ensuring residents were safely relocated. Then, I had to decide between attempting to contain the leak immediately or waiting for specialized hazmat teams to arrive. Given the imminent danger of ignition, I opted to deploy the readily available spill containment booms to slow the spread, buying crucial time before the specialized teams arrived. This involved a calculated risk, but the potential consequences of inaction outweighed the risks associated with immediate intervention. Thorough risk assessment and making quick, informed decisions are crucial in high-pressure hazmat situations. The safety of the public and the hazmat response teams was the top priority throughout the incident.

Q 28. How do you prioritize safety measures when faced with time constraints?

Prioritizing safety measures under time constraints requires a systematic approach. I utilize a risk assessment matrix to evaluate the potential hazards and their associated risks. The highest-priority risks, those posing the most significant immediate danger, are addressed first. While speed is necessary in many hazmat situations, compromising safety is never an option. For example, if there’s a leak of a toxic substance, securing the area and protecting personnel would be the immediate priorities, even if it delays other aspects of the response. This often means delegating tasks efficiently to multiple teams to expedite the process while maintaining safety standards. Using pre-established emergency response plans is essential; they provide a framework for efficient action, ensuring that critical steps aren’t overlooked. The key is to balance speed with safety through careful planning, efficient delegation, and a disciplined approach to risk management.

Key Topics to Learn for Your Hazmat Handling and Disposal Interview

- Hazmat Identification and Classification: Understanding the different classes of hazardous materials, their properties, and associated risks. This includes practical application of the DOT’s Hazardous Materials Table and the Globally Harmonized System of Classification and Labelling of Chemicals (GHS).

- Emergency Response Procedures: Knowing the appropriate response protocols for spills, leaks, and other incidents involving hazardous materials. This includes practical knowledge of personal protective equipment (PPE) selection and use, emergency shutdown procedures, and containment strategies.

- Safe Handling and Transportation: Mastering the techniques for safely handling, storing, and transporting hazardous materials, adhering to all relevant regulations and safety protocols. Practical application includes understanding placarding, shipping papers, and vehicle inspection procedures.

- Waste Management and Disposal: Understanding the legal and environmental regulations surrounding the disposal of hazardous waste, including proper packaging, labeling, and transportation to licensed disposal facilities. This includes practical knowledge of waste manifests and record-keeping.

- Regulatory Compliance: Familiarity with relevant federal, state, and local regulations governing the handling and disposal of hazardous materials. This encompasses understanding OSHA regulations, EPA guidelines, and DOT requirements, and the ability to apply them to real-world scenarios.

- Personal Protective Equipment (PPE) and Decontamination: Thorough understanding of the selection, use, and limitations of various PPE, as well as proper decontamination procedures for personnel and equipment. This includes practical knowledge of different types of PPE and their appropriate application based on the hazard.

- Incident Investigation and Reporting: Understanding the process of investigating incidents involving hazardous materials, documenting findings, and reporting to relevant authorities. This involves understanding root cause analysis and preventative measures.

Next Steps

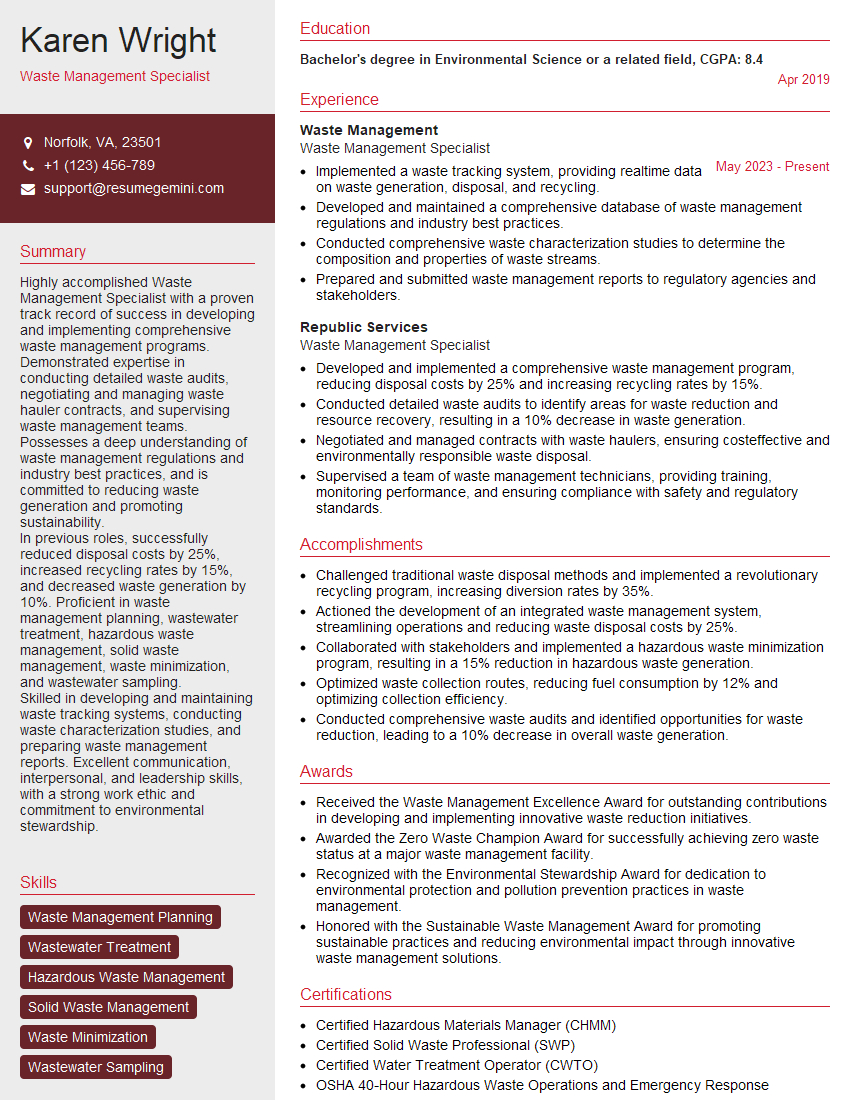

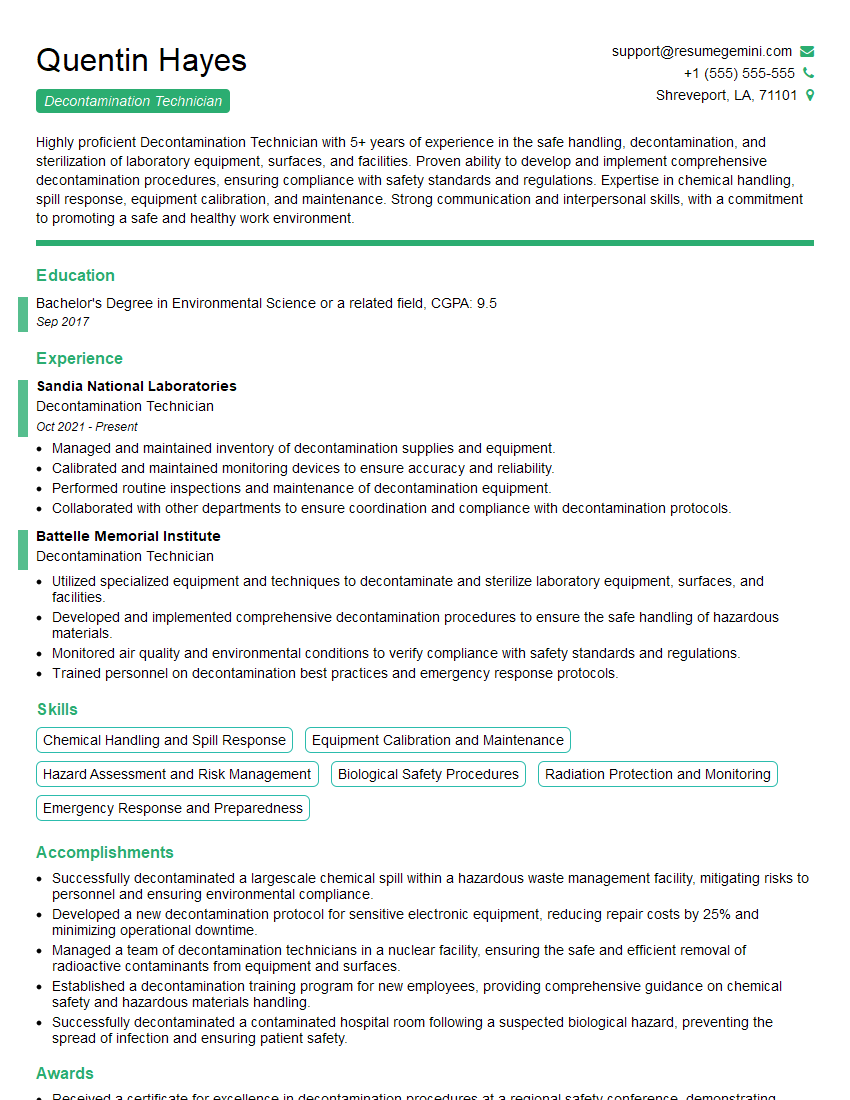

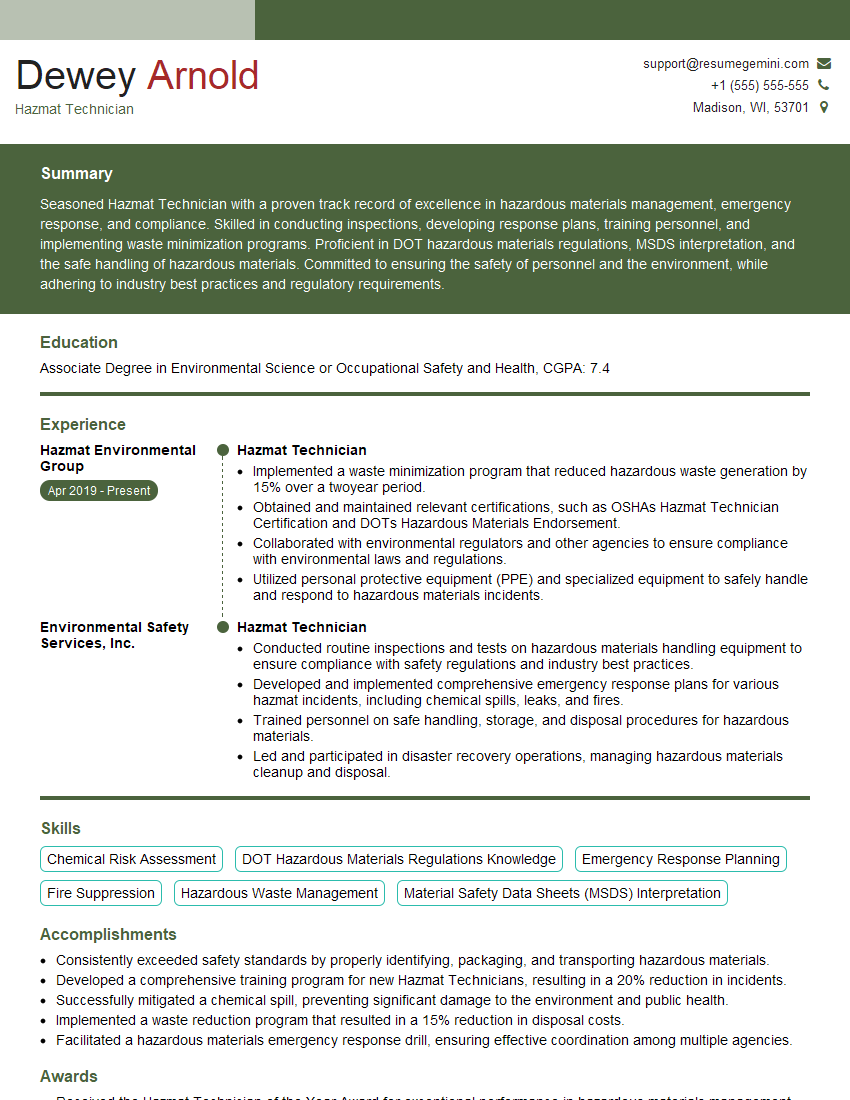

Mastering Hazmat Handling and Disposal opens doors to rewarding and impactful careers in various sectors. Demonstrating your expertise through a well-crafted resume is crucial for securing your dream role. An ATS-friendly resume, optimized for Applicant Tracking Systems, significantly increases your chances of getting noticed by recruiters. To build a powerful, ATS-optimized resume that showcases your skills and experience in Hazmat Handling and Disposal, we highly recommend using ResumeGemini. ResumeGemini provides a streamlined process and offers examples of resumes tailored to this specific field, helping you present yourself effectively and stand out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good