Preparation is the key to success in any interview. In this post, we’ll explore crucial Heavy Lifting and Cargo Operations interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Heavy Lifting and Cargo Operations Interview

Q 1. Describe your experience with different types of lifting equipment.

My experience with lifting equipment spans a wide range, encompassing forklifts, overhead cranes, mobile cranes, and various types of hoists. I’m proficient in operating and maintaining these machines, understanding their limitations and capabilities. For instance, I’ve extensively used counterbalance forklifts for indoor material handling, reaching trucks for high-stacked pallets, and rough terrain forklifts for outdoor operations on uneven ground. My experience with cranes includes both overhead bridge cranes in factory settings, where precision and safety are paramount for moving heavy machinery, and mobile cranes for construction projects, where adaptability to changing site conditions is critical. Each type demands a different skillset and understanding of safety protocols.

- Forklifts: Proficient in various types, including counterbalance, reach, and rough terrain.

- Overhead Cranes: Experienced in operating bridge cranes and gantry cranes in diverse industrial settings.

- Mobile Cranes: Experienced with various crane types, understanding load charts, outrigger setup, and site risk assessments.

- Hoists: Familiar with chain hoists, electric hoists, and their application in different lifting scenarios.

Q 2. Explain the safe operating procedures for a forklift.

Safe operation of a forklift necessitates a multifaceted approach, starting with a thorough pre-operation inspection. This includes checking fluid levels (hydraulic fluid, engine oil), tire pressure, brakes, lights, and the overall structural integrity of the machine. Next, it’s vital to assess the work area – ensuring clear pathways, adequate visibility, and identifying potential hazards like uneven surfaces, overhead obstructions, and pedestrian traffic. Before lifting, I always assess the load’s weight and center of gravity to ensure it’s within the forklift’s capacity. Slow and controlled movements are essential, avoiding sudden acceleration or braking. Loads should be kept low and centered, and I always maintain a safe distance from other equipment and personnel. Finally, post-operation checks are crucial, ensuring the forklift is left in a safe and secure position with the forks lowered.

- Pre-operational Inspection: Checking fluids, tires, brakes, lights, and overall condition.

- Work Area Assessment: Identifying potential hazards and planning a safe route.

- Load Assessment: Verifying weight and center of gravity is within the forklift’s capacity.

- Safe Operating Techniques: Slow movements, maintaining a safe distance from others, and keeping the load low and centered.

- Post-operational Checks: Securing the forklift and lowering the forks.

Q 3. How do you ensure the safe rigging and lifting of heavy loads?

Safe rigging and lifting of heavy loads relies heavily on meticulous planning and execution. The process begins with a thorough risk assessment, identifying potential hazards like unstable loads, environmental conditions, and the limitations of the lifting equipment. Then, selecting the appropriate lifting equipment (cranes, slings, shackles, etc.) is crucial, ensuring its capacity exceeds the weight of the load. The rigging plan should be developed considering the load’s center of gravity, and slings should be correctly positioned to distribute the load evenly. The angles of the slings must be within safe operating limits to prevent damage to the slings and ensure a stable lift. Throughout the lifting operation, constant communication between the crane operator and the riggers is essential, using pre-determined signals for clear instructions. A competent spotter is always crucial to monitor the load’s movement and ensure a safe path.

- Risk Assessment: Identifying potential hazards and planning for contingencies.

- Equipment Selection: Choosing equipment with sufficient capacity and suitability for the task.

- Rigging Plan: Planning the rigging configuration, considering the load’s center of gravity and sling angles.

- Communication: Maintaining clear communication between crane operator and riggers.

- Spotter: Employing a competent spotter to monitor load movement and safety.

Q 4. What are the different types of slings and their appropriate uses?

Various slings cater to diverse lifting needs. Choosing the right sling depends on the load’s shape, weight, and material. Common sling types include:

- Polyester Web Slings: Versatile, lightweight, and relatively inexpensive. Suitable for a variety of loads but can be susceptible to abrasion.

- Nylon Web Slings: Similar to polyester but offer greater shock absorption, making them ideal for loads prone to sudden movement.

- Chain Slings: Extremely strong and durable, ideal for heavy loads and harsh environments. They are resistant to abrasion and high temperatures but can be heavier than web slings.

- Wire Rope Slings: Highly versatile for heavy loads but require careful inspection for wear and tear. They can be used in various configurations.

Each sling type has a working load limit (WLL) that must never be exceeded. Using incorrect sling types or exceeding the WLL is a significant safety risk. For example, a sharp load edge could easily damage a web sling, whereas a chain sling would be more suitable.

Q 5. What safety measures do you take when working with overhead cranes?

Working with overhead cranes demands strict adherence to safety protocols. Before operation, a thorough inspection of the crane, including its structural components, electrical systems, and braking mechanisms, is mandatory. Ensuring that load charts are consulted and the load’s weight and dimensions are verified against the crane’s capacity is absolutely crucial. The area beneath the crane should be cleared of personnel and obstructions. During lifting operations, the crane operator must maintain constant vigilance, following established hand signals and communicating with riggers or ground personnel. Regular maintenance and inspections of the crane are essential to prevent malfunctions. Finally, never exceed the crane’s rated capacity, and always utilize appropriate safety devices such as load limiters and overload protection systems.

- Pre-operational Inspection: Checking the crane’s structural integrity and operational systems.

- Capacity Verification: Ensuring the crane’s capacity exceeds the load’s weight and dimensions.

- Clearance and Communication: Maintaining a clear work area and using established communication protocols.

- Regular Maintenance: Implementing regular maintenance and inspections to prevent malfunctions.

- Load Limits: Never exceeding the crane’s rated capacity.

Q 6. How do you calculate the center of gravity for a load?

Calculating the center of gravity (CG) of a load is crucial for safe lifting operations. For simple, uniformly shaped loads like rectangular boxes, the CG is simply the geometric center. However, for complex shapes or irregularly distributed weights, a more detailed calculation is required. One approach is to divide the load into smaller, simpler shapes, calculate the CG of each, and then determine the weighted average of these CGs. Another method involves suspending the load from two different points and marking the vertical lines corresponding to the plumb bob’s position. The intersection of these two lines indicates the CG. Sophisticated software packages can also perform these calculations accurately. It’s crucial to determine the CG accurately because an unbalanced load can lead to instability during lifting, potentially causing damage or accidents.

Example: For a rectangular load, the CG is simply at the midpoint of its length and width. If the load is irregular, breaking it down into smaller shapes and finding their individual CGs followed by a weighted average is required.

Q 7. Describe your experience with load securing techniques.

My experience with load securing techniques includes a variety of methods tailored to the specific cargo and transport mode. For containerized shipments, I’m adept at ensuring proper lashing using twist locks and securing the containers onto trucks, trains, or ships, adhering to international standards. For bulk cargo like steel or timber, I use techniques such as dunnage (material used to fill space and provide support), blocking, and bracing to prevent shifting during transit. For oversized loads, specialized trailers and securing mechanisms are necessary, often requiring additional supports and calculations to maintain stability. I utilize various securing materials like straps, chains, and wire rope, always ensuring the materials are in good condition and used correctly. Each securing method must comply with safety regulations and industry best practices, such as the use of appropriate tensioning devices to maintain securement throughout the journey.

- Containerized Cargo: Securing containers using twist locks and appropriate methods for different transport modes.

- Bulk Cargo: Employing dunnage, blocking, and bracing to prevent shifting.

- Oversized Loads: Using specialized trailers and securing mechanisms with support and stability calculations.

- Securing Materials: Proper use of straps, chains, and wire rope.

- Regulations Compliance: Adherence to safety regulations and industry best practices.

Q 8. Explain your understanding of load capacity and weight limits.

Load capacity and weight limits are fundamental in heavy lifting and cargo operations. Load capacity refers to the maximum weight a piece of equipment, like a crane or forklift, can safely lift. Weight limits, on the other hand, specify the maximum permissible weight for a specific area, such as a warehouse floor or a transportation vehicle. These limits are crucial for safety and preventing damage to equipment or infrastructure. Understanding these limits requires considering several factors, including the equipment’s specifications, the distribution of weight within the load (center of gravity), and environmental conditions like wind speed.

For instance, a forklift might have a stated load capacity of 5,000 lbs, but this is only true under ideal conditions. If the load is unevenly distributed, the actual safe weight might be significantly less. Similarly, a warehouse floor might have a weight limit of 250 lbs per square foot, meaning heavier loads need to be strategically positioned to avoid exceeding the limit and causing structural damage.

In practice, I always verify load capacity and weight limits before any lifting operation. This involves checking the equipment’s documentation, conducting a site survey to assess floor strength and other potential constraints, and using load-calculation software where necessary. This ensures the operation is performed safely and within regulatory compliance.

Q 9. How do you handle unexpected equipment malfunctions during a lift?

Handling unexpected equipment malfunctions during a lift requires immediate, decisive action, prioritizing safety above all else. My approach follows a structured process:

- Immediate Stop: The first step is always to halt the lifting operation immediately. This prevents further potential damage or injury.

- Assessment and Communication: A thorough assessment of the malfunction is needed. This involves identifying the problem’s nature and extent. Clear communication with the team is vital, ensuring everyone understands the situation and the next steps.

- Emergency Procedures: Following established emergency procedures is critical. This might involve lowering the load slowly and carefully using backup systems or securing the load with appropriate equipment to prevent it from falling.

- Troubleshooting & Repair: Depending on the nature of the malfunction, attempts at troubleshooting or minor repairs might be feasible. However, this should only be undertaken if it’s safe to do so, and by qualified personnel.

- Reporting & Investigation: A complete report detailing the malfunction, the actions taken, and the resulting damage (if any) should be documented. A thorough investigation often follows to determine the root cause and prevent recurrence.

For example, if a crane’s hoist mechanism fails mid-lift, I would immediately signal for a stop, communicate with the team to secure the load using secondary safety mechanisms, and then initiate the established emergency procedures for crane malfunctions. We’d contact maintenance and potentially hire a specialist to assess and repair the crane before resuming operations.

Q 10. What is your experience with different types of cargo?

My experience encompasses a wide range of cargo types, including:

- Oversized and Heavy Lift Cargo: This includes machinery components, industrial equipment, and large structural elements requiring specialized handling and transportation methods.

- Hazardous Materials: I’m proficient in handling hazardous materials, adhering strictly to safety regulations and using appropriate protective gear and equipment. This includes understanding and implementing the relevant safety data sheets and handling procedures.

- General Cargo: This includes a broad range of packaged goods, ranging from consumer products to raw materials, demanding efficient and organized handling procedures.

- Refrigerated Cargo: I have experience managing temperature-sensitive cargo, ensuring the integrity of the cold chain and preventing spoilage during storage and transportation.

- Bulk Cargo: This involves handling large quantities of unpackaged materials like grains, ores, or powders, necessitating specialized handling equipment and techniques to prevent spillage or damage.

Each cargo type presents unique challenges and requires specific handling protocols. For example, handling oversized cargo often involves meticulous planning to account for dimensions, weight distribution, and suitable transport routes. Hazardous materials require additional safety precautions, including specialized containers, personal protective equipment, and specific handling procedures.

Q 11. How do you ensure compliance with safety regulations and company policies?

Compliance with safety regulations and company policies is paramount in heavy lifting and cargo operations. My approach involves a multifaceted strategy:

- Regular Training: I actively participate in ongoing safety training to stay updated on regulations and best practices. This includes familiarization with relevant OSHA standards and industry-specific guidelines.

- Pre-Lift Inspections: Before every lift, I meticulously inspect equipment, load securing mechanisms, and the work area to identify potential hazards. This ensures compliance with operational safety checks.

- Documentation & Record Keeping: Maintaining accurate records of inspections, training certifications, and incident reports is crucial for demonstrating compliance and facilitating continuous improvement.

- Risk Assessment: Conducting thorough risk assessments for each lifting operation helps identify and mitigate potential hazards, aligning with company safety procedures.

- Communication & Collaboration: Open communication with team members and supervisors is vital to ensure everyone is aware of safety protocols and can report any concerns.

For instance, before lifting any load, I ensure the load is properly secured using appropriate equipment, and I verify that all personnel are wearing the required personal protective equipment (PPE). Any deviation from safety protocols is immediately addressed and reported.

Q 12. Describe your experience with inventory management in a warehouse setting.

My experience with inventory management in a warehouse setting includes utilizing various techniques for efficient tracking and control. This includes:

- Inventory Tracking Systems: I’m proficient with using warehouse management systems (WMS) and related software to track inventory levels, location, and movement.

- Barcode and RFID Technology: Experience with using barcode and RFID systems for efficient item identification and tracking during receiving, storage, and picking processes.

- Cycle Counting: Regularly participating in cycle counting procedures to maintain inventory accuracy and identify discrepancies.

- Inventory Optimization: Contributing to strategies for optimizing warehouse layout and storage to improve efficiency and reduce wasted space.

- First-In, First-Out (FIFO) & Last-In, First-Out (LIFO): Implementing appropriate inventory management methods (FIFO or LIFO) to ensure product rotation and reduce waste, particularly for perishable goods.

In a previous role, I implemented a new barcode system that significantly improved accuracy in our inventory tracking, reducing discrepancies by 15% and speeding up the order fulfillment process.

Q 13. How do you prioritize tasks in a fast-paced cargo handling environment?

Prioritizing tasks in a fast-paced cargo handling environment requires a structured approach. I typically utilize a combination of methods:

- Urgency and Importance Matrix: Categorizing tasks based on their urgency and importance allows me to focus on time-sensitive critical tasks first.

- Load Sequencing: Optimizing the order of lifting operations based on factors like load weight, destination, and equipment availability.

- Communication & Coordination: Clear communication with team members and supervisors ensures everyone is aware of priorities and working towards common goals.

- Real-time Adjustments: The ability to adapt to unexpected delays or changes in priorities is crucial. This often involves re-evaluating the task list and adjusting the schedule accordingly.

- Lean Principles: Applying lean principles, like minimizing waste and maximizing efficiency, helps streamline processes and optimize task completion.

For instance, if faced with several tasks simultaneously – loading urgent shipments, unloading incoming cargo, and performing routine maintenance – I’d prioritize urgent shipments first, followed by unloading crucial incoming cargo, and schedule maintenance during less busy periods.

Q 14. Explain your experience with using different types of warehouse equipment.

My experience with warehouse equipment is extensive and includes:

- Forklifts: Proficient in operating various types of forklifts (sit-down, stand-up, reach trucks) and adhering to all safety regulations.

- Overhead Cranes: Experienced in operating overhead cranes, including bridge cranes and gantry cranes, for lifting and moving heavy loads.

- Conveyors: Familiar with various conveyor systems and their maintenance. Understanding how to troubleshoot issues with belt conveyors and other types of equipment.

- Automated Guided Vehicles (AGVs): Experience in utilizing AGVs for efficient material handling and transportation within large warehouses.

- Order Pickers: Proficient in using order picker equipment to efficiently select items from high-level storage racks.

Each piece of equipment requires specialized training and a thorough understanding of its capabilities and limitations. I ensure regular maintenance and follow all safety protocols to prevent accidents and ensure efficient operation.

Q 15. How do you manage and resolve conflicts with co-workers or supervisors?

Conflict resolution is crucial in a fast-paced environment like heavy lifting and cargo operations. My approach is built on open communication and mutual respect. I start by actively listening to understand the other person’s perspective, even if I don’t initially agree. Then, I clearly and calmly explain my viewpoint, focusing on the facts and the impact of the issue on the overall operation. For example, if a disagreement arises about the best way to secure a load, I would explain my rationale based on safety regulations and efficiency, and be open to considering alternative solutions if they are equally safe and effective. If the conflict persists, I believe in escalating the issue to a supervisor only after exhausting all other options, presenting a well-documented summary of the problem and the attempted solutions. This collaborative approach ensures that we find a solution that benefits everyone involved and maintains a positive team dynamic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with documenting and reporting incidents.

Accurate and timely incident reporting is paramount for safety and operational efficiency. My experience includes documenting all incidents – from near misses to actual accidents – using a standardized reporting system. This usually involves completing a detailed form outlining the date, time, location, involved personnel, a comprehensive description of the event, any injuries sustained, contributing factors, and corrective actions taken or planned. For example, if a forklift malfunctioned, I would document the specific issue, the actions taken to prevent further use, the repair process initiated, and any potential safety risks identified. I then ensure this report is submitted to the appropriate supervisor within the stipulated timeframe, usually immediately for serious incidents and within 24 hours for less severe ones. This methodical approach ensures accountability and facilitates proactive risk management, improving safety protocols for the future.

Q 17. How do you maintain accurate records of cargo movement and inventory?

Maintaining accurate cargo records is essential for efficient operations and regulatory compliance. This involves utilizing various methods, from physical inventory checks and barcoding to sophisticated inventory management systems. In my previous role, we used a combination of these approaches. For example, upon receiving a shipment, we would verify the contents against the accompanying documentation, scan each item using barcodes, and record the location within the warehouse using a dedicated software. Regular physical stock checks are crucial to reconcile the digital inventory with the physical one and identify any discrepancies. This thorough process, including meticulous record-keeping of every item’s movement, ensures accurate tracking and minimizes losses due to misplacement or damage. This is vital for responding to customer inquiries about order status and managing stock levels effectively.

Q 18. Explain your understanding of hazardous materials handling procedures.

Handling hazardous materials requires rigorous adherence to safety regulations and established procedures. My understanding encompasses the proper classification, storage, handling, and transportation of these materials. This includes awareness of specific safety data sheets (SDS) for each material, understanding appropriate personal protective equipment (PPE), and following strict guidelines for segregation and containment. For example, when handling flammable materials, we would ensure proper ventilation, use of spark-resistant equipment, and maintain a safe distance from ignition sources. We would also use designated storage areas and follow strict labeling protocols, ensuring compliance with all relevant local, national, and international regulations. Regular training and refresher courses reinforce this knowledge and ensure that everyone involved understands the risks and procedures involved.

Q 19. How do you ensure the efficient flow of cargo through a warehouse or port?

Efficient cargo flow relies on optimized processes and coordination. This involves strategic warehouse layout, effective use of technology, and well-trained personnel. For example, in a port environment, this would include efficient vessel scheduling, streamlined customs procedures, organized storage areas, and efficient loading and unloading techniques. Within a warehouse, this would translate to optimized storage layouts to minimize travel distances, efficient use of forklifts and other equipment, and clearly defined processes for receiving, storing, picking, and shipping goods. Regularly reviewing and improving these processes through data analysis, continuous improvement initiatives, and employee feedback are essential to ensure optimal cargo flow and minimize bottlenecks, leading to cost savings and improved customer satisfaction.

Q 20. Describe your experience with using a computerized inventory management system.

I have extensive experience using computerized inventory management systems (IMS). These systems are critical for tracking inventory levels, managing stock movements, and generating reports. My experience includes using systems like SAP WM and Oracle Inventory Management. These systems allow for real-time tracking of inventory, automated stock alerts, and the generation of various reports such as inventory turnover, stock valuation, and location-specific reports. For example, using these systems, I could quickly identify low-stock items, optimize storage space, and plan for future orders. The data provided by these systems are also crucial for data-driven decision-making, aiding in optimizing warehouse processes and improving overall efficiency.

Q 21. How do you adapt to changing work schedules and demands?

Adaptability is essential in heavy lifting and cargo operations, where unexpected delays, urgent requests, and fluctuating workloads are common. I’m comfortable working varying shifts and adjusting to changing priorities. My approach is to remain flexible, proactive, and communicative. If a change in schedule occurs, I first confirm the details and understand the reasons for the change. Then, I adjust my plans accordingly and communicate any potential impacts or constraints. For instance, if an urgent shipment needs to be processed, I would prioritize it and communicate any potential delays to other tasks to manage expectations. By maintaining clear communication and a proactive approach, I ensure that I can meet the changing demands while maintaining efficiency and safety standards.

Q 22. What are your strategies for preventing workplace accidents?

Preventing workplace accidents in heavy lifting and cargo operations requires a multi-faceted approach, focusing on proactive measures rather than reactive solutions. It’s like building a strong safety net, not just waiting for someone to fall.

- Comprehensive Risk Assessments: Before any operation, we meticulously assess potential hazards, considering factors like load weight, environmental conditions (wind, rain, uneven terrain), equipment condition, and crew competency. For example, lifting a heavy container in high winds would necessitate specific precautions like using extra securing lines and adjusting the lifting technique.

- Rigorous Training and Competency Checks: Regular refresher training on safe operating procedures, including the proper use of equipment like cranes, forklifts, and rigging gear, is crucial. This includes practical demonstrations and assessments to ensure everyone is proficient. I’ve personally overseen the training of over 50 operators, focusing on real-world scenarios to make the learning impactful.

- Strict Adherence to Safety Protocols: Enforcing and leading by example on the use of Personal Protective Equipment (PPE) such as safety helmets, high-visibility vests, and steel-toe boots is paramount. Implementing and monitoring a strict permit-to-work system for high-risk activities ensures all necessary checks are completed before commencing work. Think of it as a checklist ensuring everything is aligned before you begin a critical task.

- Regular Equipment Maintenance and Inspections: Malfunctioning equipment is a major contributor to accidents. We perform thorough and documented inspections of all lifting equipment, including cranes, slings, and shackles, adhering to manufacturer’s recommendations and regulatory guidelines. We schedule preventative maintenance to avoid unexpected failures.

- Incident Reporting and Investigation: A robust system for reporting and investigating near misses and accidents is vital. This isn’t just about blame, but about identifying systemic issues and implementing corrective actions to prevent similar incidents from occurring in the future. Through detailed root cause analysis, we learn from past mistakes to bolster our safety processes.

Q 23. Explain your experience with load planning and optimization.

Load planning and optimization are critical to efficiency and safety in heavy lifting. It’s about maximizing space, minimizing weight, and ensuring safe and stable transportation. This involves careful consideration of the cargo’s dimensions, weight distribution, and center of gravity.

My experience includes using specialized software to create detailed load plans, taking into account the capacity of the vessels or trucks, securing methods, and relevant regulations. For example, when loading a ship with oversized cargo, I use software to simulate the loading process, ensuring that the weight is evenly distributed and the vessel’s stability is maintained. This minimizes the risk of shifting loads during transit. I’ve also developed custom solutions for unconventional cargo, such as large industrial machinery, that required unique securing methods to ensure safety and structural integrity.

Optimization goes beyond just fitting the cargo; it includes considering factors like the most efficient route, minimizing handling, and reducing fuel consumption. For instance, rearranging the order of loading containers can significantly reduce the time needed for unloading at the destination, translating to cost savings and improved turnaround time. A well-planned load is a safe and efficient load.

Q 24. How do you communicate effectively with team members and supervisors?

Effective communication is the cornerstone of safety and efficiency in heavy lifting. It’s about clear, concise, and timely information exchange to keep everyone on the same page. Think of it as orchestrating a complex symphony, where every player needs to understand their part and coordinate perfectly.

- Pre-Job Briefings: Before any lifting operation, I conduct thorough briefings outlining the plan, potential hazards, safety precautions, and roles and responsibilities for each team member. This ensures everyone is fully aware of the task at hand.

- Clear and Concise Instructions: I use plain language, avoiding jargon, to provide clear instructions to the team. Hand signals, radio communications, and written instructions are used depending on the situation.

- Active Listening and Feedback: I actively listen to my team members, encourage them to voice concerns or suggestions, and provide prompt feedback. Open communication fosters a safe and collaborative environment.

- Regular Updates to Supervisors: I keep supervisors informed of the progress of the operation, any challenges encountered, and any potential deviations from the plan. This keeps them updated and allows for timely intervention if needed.

- Documentation: Maintaining accurate records of communication, including pre-job briefings, incident reports, and daily logs, ensures transparency and accountability.

Q 25. Describe your problem-solving skills in relation to cargo handling challenges.

Problem-solving in cargo handling often involves quick thinking and creative solutions under pressure. I approach challenges systematically using a structured approach.

- Identify the Problem: Clearly define the problem. For example, a damaged container preventing the timely unloading of a vessel.

- Gather Information: Collect all relevant data; assess the extent of the damage, the remaining time constraints, and available resources.

- Brainstorm Solutions: Explore various solutions, such as using alternative equipment, rerouting the damaged container, or implementing emergency repairs.

- Evaluate Solutions: Assess the feasibility, safety, and cost-effectiveness of each option.

- Implement the Best Solution: Execute the chosen solution, documenting the process and outcome.

- Review and Learn: Analyze the results and identify improvements for future situations. This might involve revising safety protocols or training procedures.

For instance, I once encountered a situation where a critical piece of equipment failed during a time-sensitive operation. By quickly assessing the situation, I coordinated with the maintenance team, found a suitable replacement, and implemented contingency plans, minimizing the delay and ensuring the successful completion of the operation.

Q 26. How familiar are you with various international shipping regulations?

I am very familiar with various international shipping regulations, including the International Maritime Organization (IMO) regulations, the International Convention for the Safety of Life at Sea (SOLAS), and the International Code for the Safe Carriage of Cargoes (CSC). I understand the nuances of different conventions and regulations for various cargo types and modes of transportation.

My understanding encompasses aspects like dangerous goods handling (IMDG Code), container security (CSI), and port state control requirements. I am proficient in interpreting and complying with these regulations to ensure safe and legal cargo handling in international operations. For example, I understand the different classes of hazardous materials and the required documentation, packaging, and handling procedures for each class.

This knowledge ensures we comply with all relevant laws and regulations, preventing delays and penalties, and maintaining a high level of safety and security.

Q 27. What are your strengths and weaknesses in a heavy lifting environment?

In a heavy lifting environment, my strengths include my meticulous attention to detail, my ability to work effectively under pressure, and my strong problem-solving skills. I’m also a highly effective communicator and team player. I have consistently demonstrated the ability to lead and motivate teams to achieve common goals, maintaining safety as the top priority. I’ve been praised for my ability to manage complex projects and deliver results on time and within budget.

My primary weakness, if I were to be truly self-critical, is my tendency to be perfectionistic. While this ensures high-quality work, it can sometimes lead to over-analysis and slow decision-making. I am actively working on improving my ability to make quicker decisions in less time-critical situations while maintaining my focus on thoroughness and safety.

Q 28. How do you stay current with changes in safety regulations and best practices?

Staying current with changes in safety regulations and best practices is an ongoing process, and a critical part of my job. This isn’t a passive endeavor; it’s about active participation.

- Professional Development Courses: I regularly participate in training courses and workshops focused on the latest safety standards, equipment updates, and best practices in heavy lifting and cargo handling. This includes attending industry conferences and webinars.

- Regulatory Updates and Newsletters: I subscribe to industry publications and newsletters to remain updated on changes in regulations, new technologies, and emerging safety concerns. Many regulatory bodies offer detailed updates and guidance.

- Networking with Professionals: I actively network with other professionals in the field to share knowledge, discuss emerging trends, and learn from best practices across different organizations.

- Industry Associations: Membership in relevant industry associations provides access to up-to-date information, resources, and networking opportunities.

This proactive approach ensures I’m always equipped with the latest knowledge and techniques, thereby ensuring that our operations consistently meet and exceed the highest standards of safety and efficiency.

Key Topics to Learn for Heavy Lifting and Cargo Operations Interview

- Safety Regulations and Procedures: Understanding and applying relevant safety protocols, including risk assessment, hazard identification, and emergency response procedures. This includes knowledge of OSHA regulations and best practices for safe lifting techniques.

- Cargo Handling Equipment: Familiarization with various types of equipment used in cargo handling, such as cranes, forklifts, conveyors, and their operational principles and limitations. Practical application involves understanding maintenance schedules and recognizing malfunctioning equipment.

- Cargo Securing and Lashing: Mastering techniques for secure cargo placement and lashing to prevent shifting or damage during transportation. This includes understanding different types of cargo and appropriate securing methods.

- Weight and Balance Calculations: Accurate calculation of weight distribution and center of gravity to ensure stability and prevent accidents during lifting and transportation. Practical applications involve using load charts and understanding load limits.

- Logistics and Supply Chain Management: Understanding the flow of cargo from origin to destination, including documentation, tracking, and inventory management. This includes knowledge of different modes of transport and their associated challenges.

- Problem-Solving and Decision-Making under Pressure: Demonstrating the ability to assess situations quickly, make informed decisions, and solve problems efficiently in demanding and potentially hazardous environments.

- Communication and Teamwork: Effective communication skills with colleagues, supervisors, and clients; ability to work collaboratively as part of a team to ensure efficient and safe cargo operations.

Next Steps

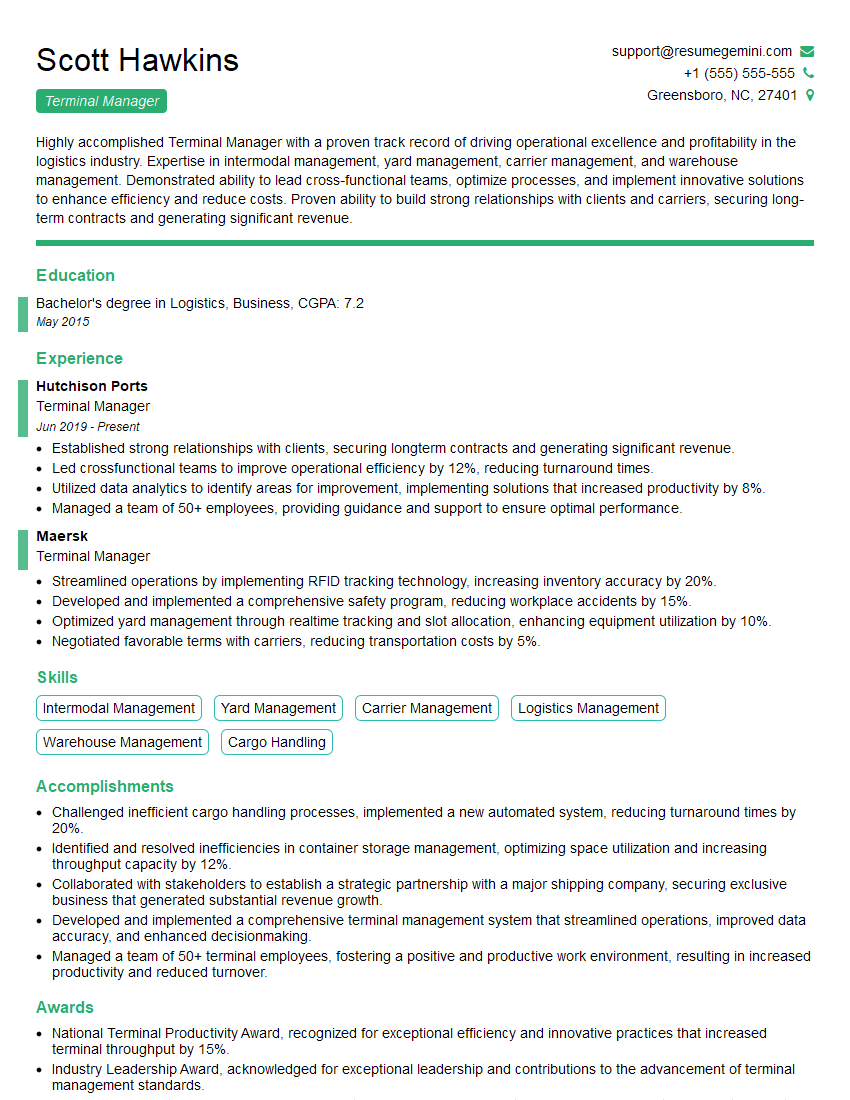

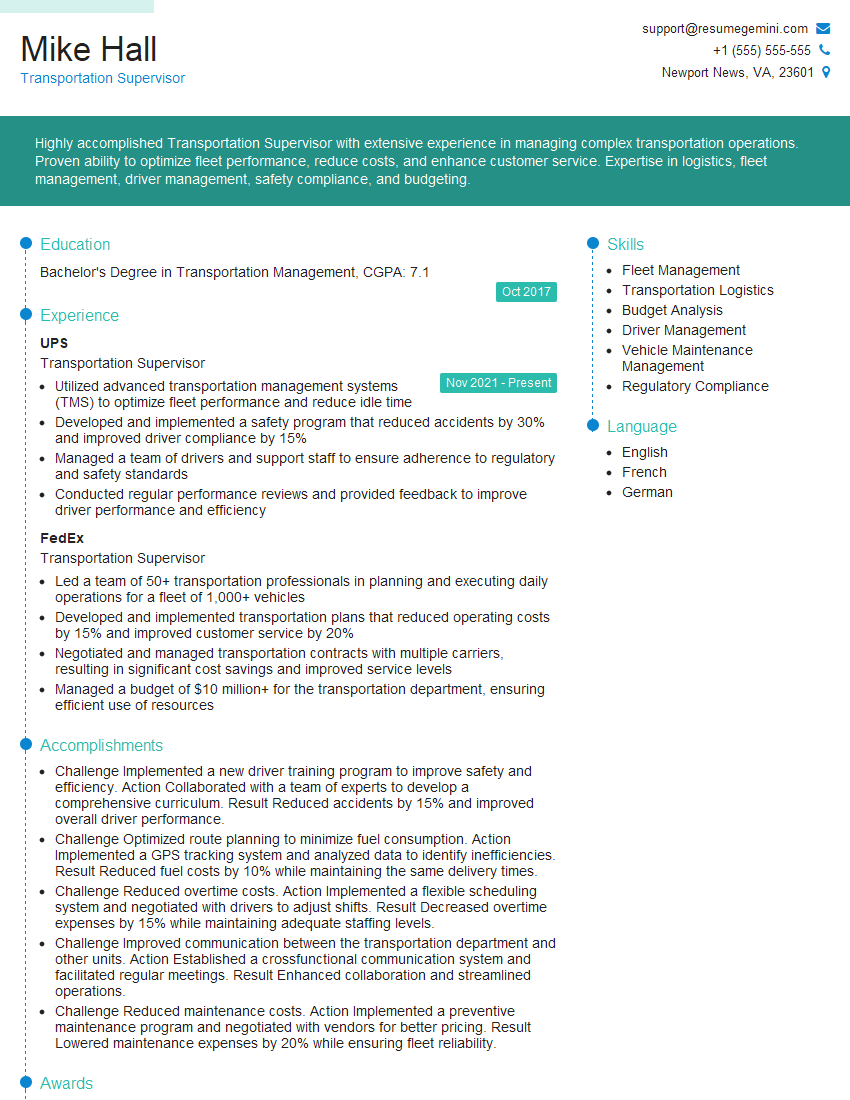

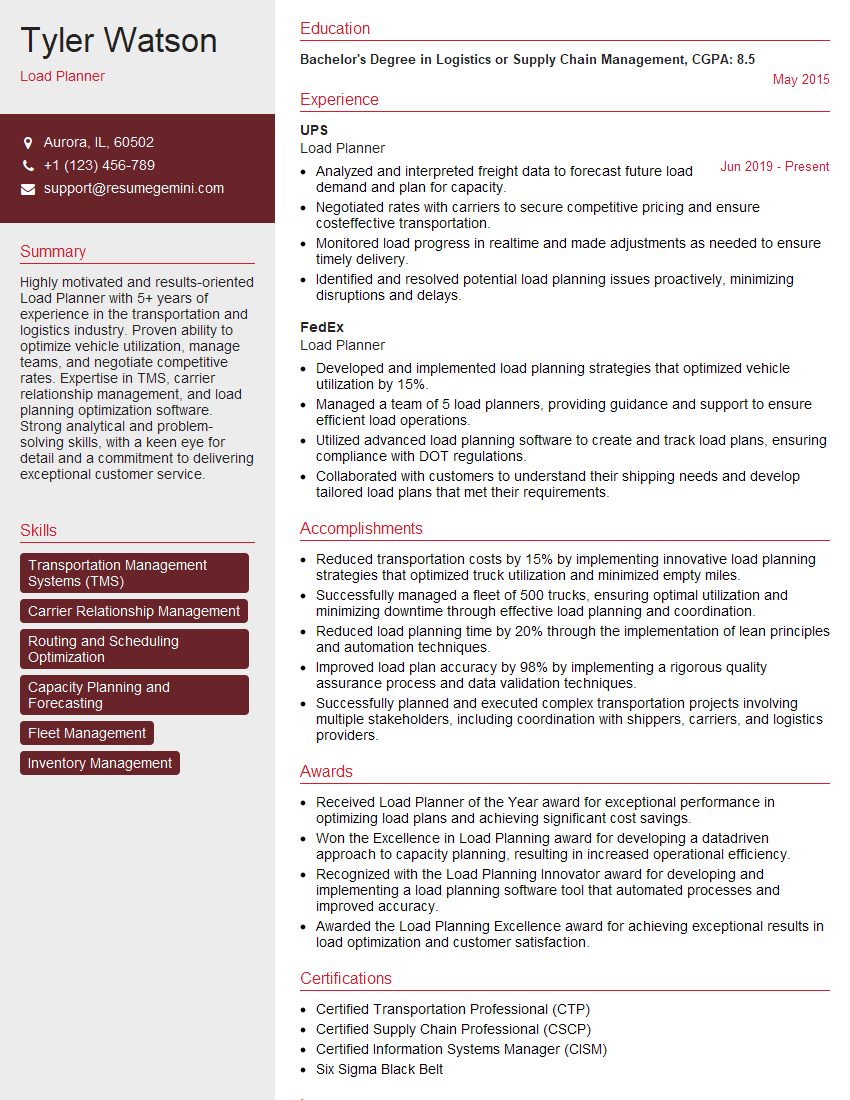

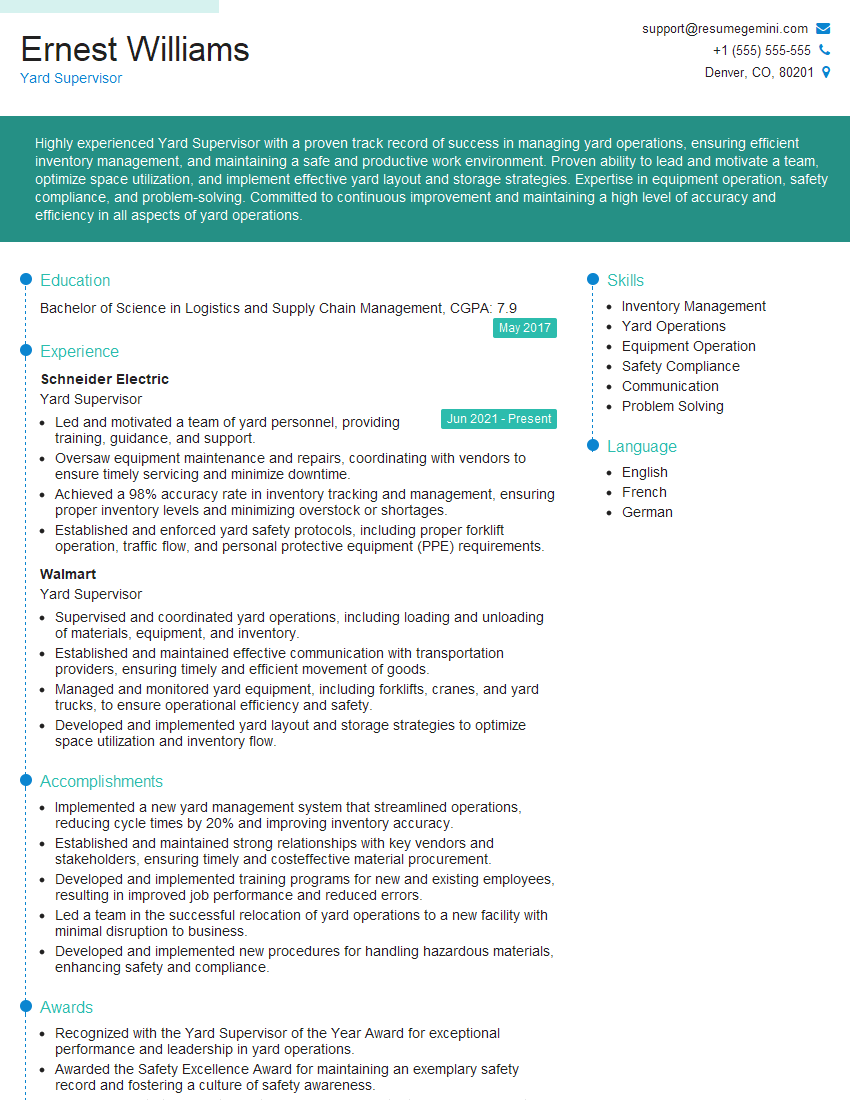

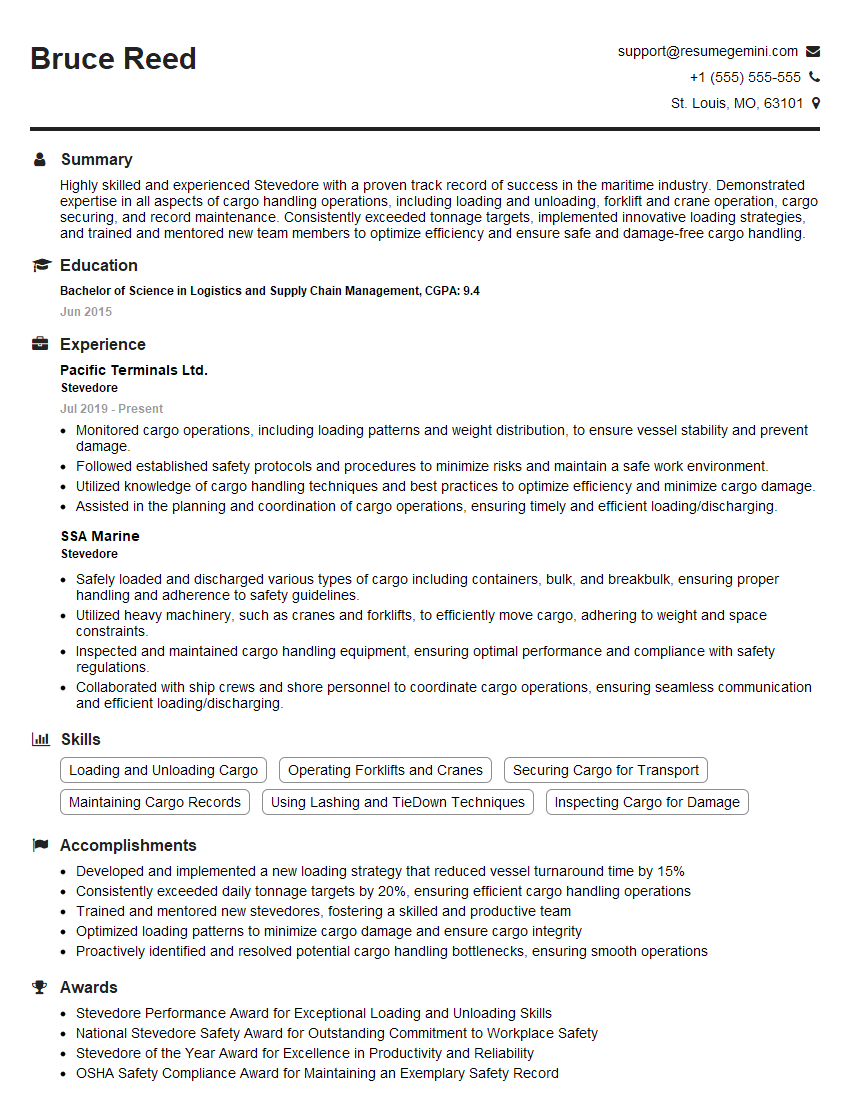

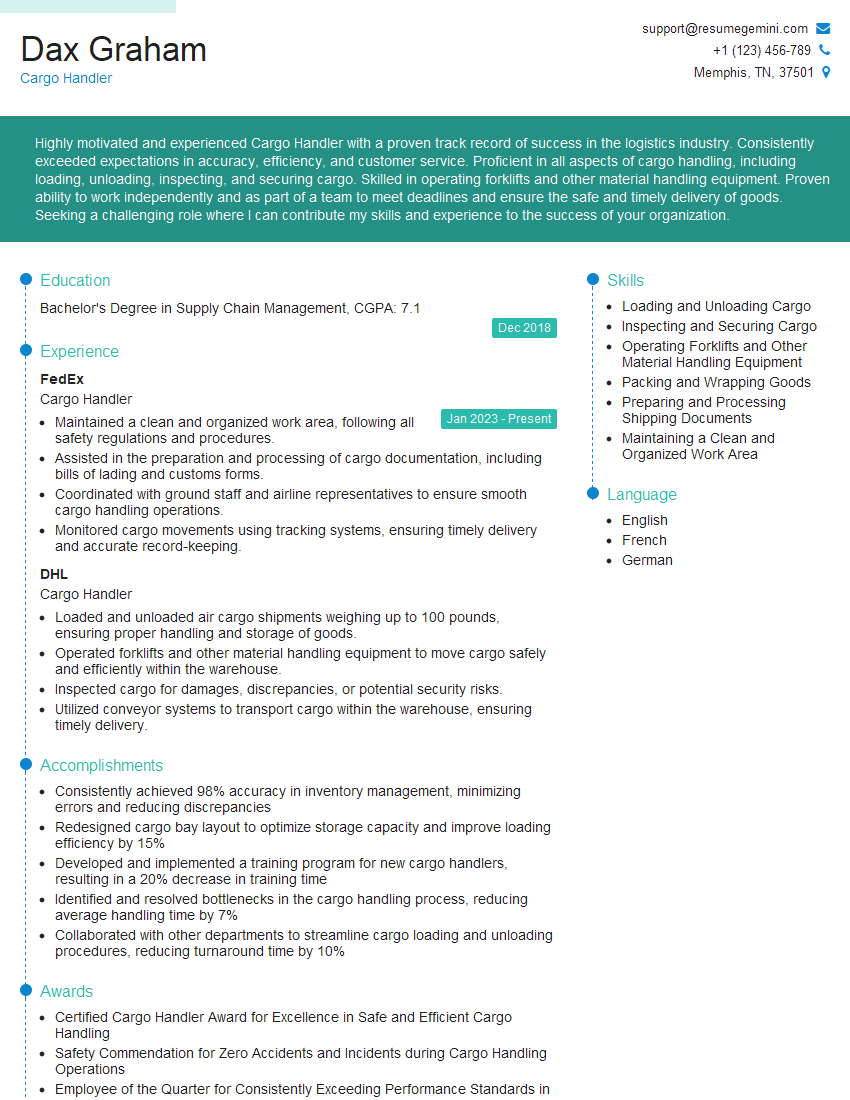

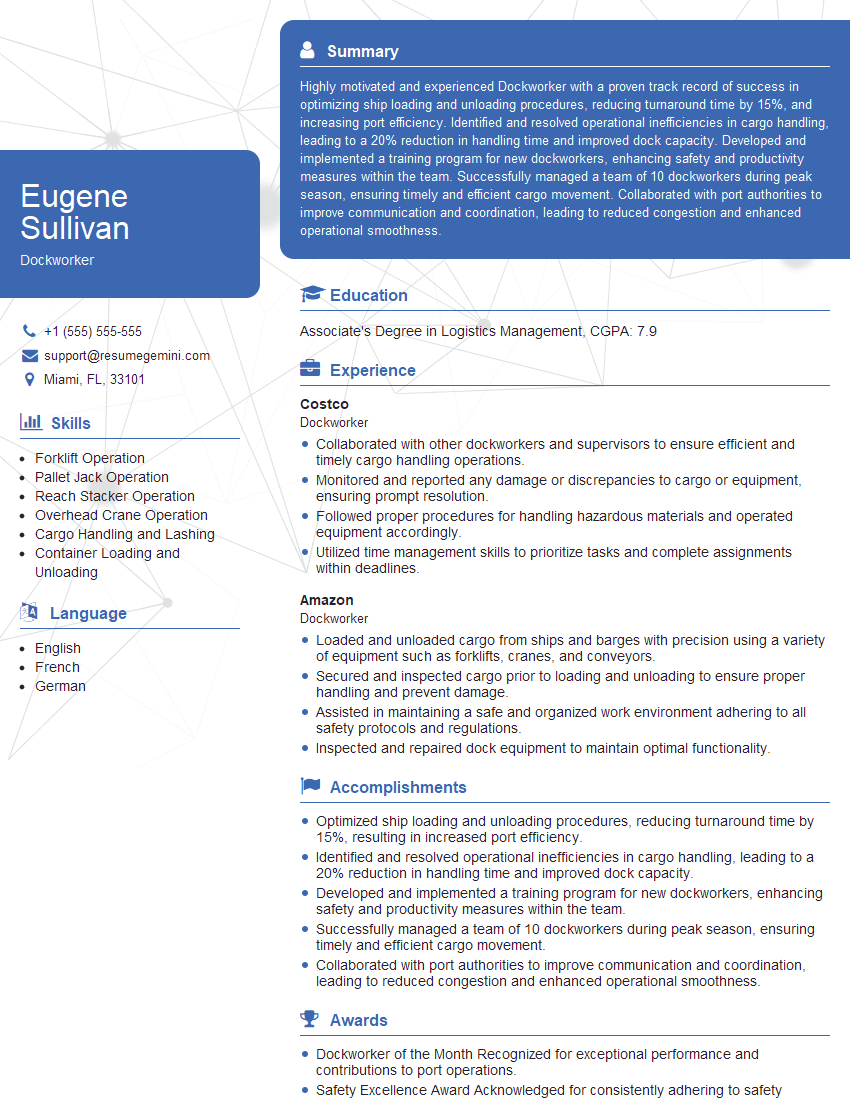

Mastering Heavy Lifting and Cargo Operations opens doors to rewarding careers with excellent growth potential. This field demands skilled professionals who prioritize safety and efficiency. To significantly increase your job prospects, it’s crucial to present your qualifications effectively. Creating an ATS-friendly resume is paramount in getting your application noticed. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience in a way that Applicant Tracking Systems (ATS) can easily understand. Examples of resumes tailored to Heavy Lifting and Cargo Operations are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good