Unlock your full potential by mastering the most common Heavy Lifting and Handling interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Heavy Lifting and Handling Interview

Q 1. Describe your experience with different types of lifting equipment.

My experience with lifting equipment spans a wide range, encompassing both manual handling aids and powered machinery. I’m proficient in using various types of cranes, including overhead cranes, mobile cranes, and tower cranes, understanding their load capacities, operational procedures, and safety protocols. I’m also experienced with forklifts, both sit-down and stand-up models, and am certified in their safe operation. Furthermore, my experience includes using specialized lifting equipment such as vacuum lifters for delicate or oddly shaped objects, and air hoists for precision lifting in confined spaces. In addition to powered machinery, I am highly skilled in the utilization of various manual handling aids, including hand trucks, pallet jacks, and lifting straps, always prioritizing safety and efficiency.

- Overhead Cranes: Used extensively for lifting heavy loads in warehouses and factories, requiring precise control and understanding of load charts.

- Forklifts: Essential for moving pallets and large quantities of materials, demanding adherence to strict safety regulations.

- Vacuum Lifters: Ideal for delicate materials like glass or sensitive machinery, needing a light touch and careful planning.

Q 2. What safety procedures do you follow when lifting heavy objects?

Safety is paramount in heavy lifting. My procedures always begin with a thorough risk assessment, considering the weight, size, shape, and fragility of the object, as well as the environment. This includes checking the surrounding area for obstacles and ensuring adequate space for maneuvering. I always select the appropriate lifting equipment for the task, ensuring it’s in good working order and within its safe working load (SWL). I then communicate the lifting plan clearly to my team, if applicable, and coordinate actions carefully. I maintain a proper lifting posture – keeping my back straight, bending at the knees and hips, and avoiding twisting movements. I always lift with my legs, not my back. Finally, I regularly inspect the equipment and report any deficiencies immediately.

- Pre-lift checks: Inspecting equipment and surroundings.

- Proper posture: Lifting with legs, keeping back straight.

- Communication: Clear instructions and coordination with team.

- Equipment maintenance: Regular inspections and reporting.

Q 3. Explain your understanding of weight distribution and balance.

Understanding weight distribution and balance is crucial for preventing injuries and ensuring safe lifting. It’s about maintaining a stable center of gravity during lifting. Poor weight distribution can lead to instability, making the load difficult to control and increasing the risk of accidents. For instance, lifting an object with its weight concentrated on one side will require more effort and strain, potentially causing back injuries. Imagine carrying a heavy backpack – if it’s evenly distributed, it’s much easier than if all the weight is concentrated on one strap. Similarly, when lifting heavier items, keeping the load close to the body and maintaining a balanced stance significantly reduces strain.

In practice, I ensure that the weight is evenly distributed across the lifting equipment. For manual lifting, this translates to holding the load centrally and keeping it as close to the body as possible. When using equipment like a forklift, it involves careful placement of the load on the forks, ensuring they’re evenly balanced.

Q 4. How do you assess the weight of an object before lifting?

Assessing the weight of an object before lifting involves a combination of techniques. For smaller items, I might be able to estimate their weight based on experience. For heavier items, I’ll utilize available scales or weighing equipment if available. If neither is accessible, I try to find an object of known weight for comparison – a reasonable estimation is better than a guess. Always err on the side of caution; if uncertain, I’ll use assistance, or opt for mechanical lifting equipment. For instance, if I’m unsure about a box’s weight, I might ask a colleague to lift with me, or I’d get a forklift or hand truck. Safety should always outweigh speed.

Q 5. What are the common causes of back injuries in heavy lifting?

Back injuries in heavy lifting are often caused by improper lifting techniques. These include twisting while lifting, lifting with a bent back, lifting objects that are too heavy, lifting objects that are too far from the body, and repetitive lifting without breaks. Poor posture and lack of physical fitness also contribute. Additionally, lifting objects with uneven weight distribution or using inappropriate lifting equipment can also lead to serious injuries. For example, repeatedly lifting heavy boxes improperly can lead to cumulative trauma and eventual disc herniation.

Q 6. Describe your experience using hand trucks, dollies, or pallet jacks.

I have extensive experience using hand trucks, dollies, and pallet jacks. These tools are essential for efficient and safe material handling. Hand trucks are ideal for moving heavier items over shorter distances, while dollies are better suited for bulky, irregularly shaped objects. Pallet jacks are crucial for maneuvering pallets loaded with goods, often within a warehouse environment. My proficiency includes securing loads properly on each device, understanding weight limits, and maneuvering them safely through confined spaces. For example, when using a hand truck, I always ensure the load is balanced, and I use the appropriate technique to avoid strain on my back. Similarly, when using a pallet jack, I always check the load is stable, and I avoid abrupt movements.

Q 7. How do you handle unusual or awkwardly shaped objects?

Handling unusual or awkwardly shaped objects requires careful planning and the selection of appropriate equipment. A thorough risk assessment is paramount to understand the object’s center of gravity and potential hazards. For example, a long, slender object might require additional support to prevent it from tipping, perhaps using straps or multiple people for lifting. For irregularly shaped objects, specialized lifting equipment like vacuum lifters or custom slings might be necessary. In some situations, the object might need to be broken down into smaller, more manageable pieces. The key is to minimize the risk of injury and damage by using the right equipment, and by coordinating efforts carefully with others.

For example, when moving a large, oddly shaped piece of machinery, I’d carefully plan the route, considering potential obstacles and selecting appropriate lifting equipment like a crane with a specialized sling, ensuring all potential hazards are accounted for and mitigated.

Q 8. What is your experience with load securing techniques?

Load securing is paramount in heavy lifting and handling. It’s all about preventing movement during transportation, lifting, and lowering. Think of it like packing a fragile item for shipping – you need to ensure it won’t shift and break. My experience encompasses various techniques, including:

- Using appropriate securing devices: This includes chains, webbing slings, ratchets, and winches, each selected based on the load’s weight, shape, and material.

- Applying proper tension: Too little tension allows movement; too much can damage the load or securing equipment. I’m proficient in using tensioning tools and understanding the correct tension levels for different materials.

- Understanding load distribution: Distributing the load evenly across multiple securing points minimizes stress on any single point, preventing slippage or damage.

- Considering environmental factors: Weather conditions like wind or rain can impact securing techniques. For instance, additional securing may be needed in high winds.

- Documentation and inspection: Thorough documentation of the securing process, including the type and quantity of equipment used, is crucial for traceability and ensuring compliance with safety regulations. Regular inspections before and during transport are vital.

For example, securing a long steel beam requires multiple tie-down points, evenly spaced, with sufficient tension to prevent any movement or swing during transport. I’ve personally secured loads ranging from small machinery parts to large industrial equipment, always prioritizing safety and regulatory compliance.

Q 9. How do you ensure the safety of yourself and others during lifting operations?

Safety is my top priority. It’s not just about my own safety but also the safety of everyone in the vicinity. My approach involves:

- Pre-lift planning: This includes a thorough risk assessment, considering potential hazards and developing mitigation strategies.

- Using appropriate PPE (Personal Protective Equipment): This always includes hard hats, safety glasses, steel-toe boots, and, where appropriate, high-visibility clothing and fall protection harnesses.

- Clear communication: Establishing clear communication channels with the lifting team is crucial. This includes hand signals, radio communication, or a designated signal person.

- Maintaining a safe working environment: Ensuring the area is clear of obstructions and that traffic is managed effectively is key to prevent accidents.

- Regular inspections: Thorough inspections of equipment, including slings, hooks, and lifting machinery, are carried out before each lift to ensure everything is in safe working order.

- Following established procedures: Adhering strictly to company safety procedures and relevant regulations is non-negotiable.

I once prevented a potential accident by noticing a damaged sling during a pre-lift inspection. Replacing it before the lift averted a possible serious incident.

Q 10. Explain your understanding of load capacity and limitations.

Load capacity and limitations are fundamental concepts in heavy lifting. It’s about understanding the maximum weight a lifting device or structure can safely handle without failure. This includes:

- Rated Capacity Limits: Every piece of lifting equipment (cranes, slings, chains, etc.) has a rated capacity, clearly marked by the manufacturer. Exceeding this limit is dangerous and illegal.

- Structural Limitations: The structure being lifted (e.g., a building component or a piece of machinery) also has its own limitations. Its weight distribution and structural integrity must be assessed to ensure it can withstand the lifting process.

- Environmental Factors: Wind, temperature, and ground conditions can affect load capacity. High winds can reduce the safe lifting capacity of a crane, for instance.

- Load Distribution: Evenly distributing the weight on the lifting device prevents uneven stress and potential failure.

Understanding these limitations allows for safe and efficient lifting operations. For example, I wouldn’t attempt to lift a load exceeding the rated capacity of a crane, even if it seems manageable. Safety always outweighs expediency.

Q 11. How do you identify and report unsafe lifting conditions?

Identifying and reporting unsafe lifting conditions requires vigilance and a proactive approach. I would:

- Visual inspections: Regular visual inspections of the work area, equipment, and load are crucial. Look for signs of damage, wear, or potential hazards (e.g., loose materials, uneven ground).

- Equipment checks: Checking the equipment’s certification, condition, and rated capacity before each lift is mandatory.

- Environmental assessment: Assessing weather conditions and the surrounding environment for any potential hazards (e.g., overhead obstructions, unstable ground).

- Risk assessment: A formal risk assessment helps to identify potential hazards and develop suitable control measures.

- Immediate reporting: Any unsafe condition should be reported immediately to the supervisor or safety officer. This ensures timely corrective action and prevents potential accidents.

In one instance, I noticed a crane’s hook was visibly damaged. I immediately halted operations and reported the issue, preventing a potentially catastrophic accident.

Q 12. Describe your experience with different types of slings and their applications.

I have extensive experience with various types of slings, each with specific applications:

- Wire rope slings: These are strong and durable, ideal for heavy loads and harsh environments. However, they can be prone to damage if not properly inspected and maintained. I always carefully inspect them for kinks, broken wires, or corrosion before each use.

- Web slings: These are made from synthetic materials, offering flexibility and less damage potential to the load’s surface. They are good for handling delicate or oddly shaped objects. Different types of webbing offer varying strength and durability.

- Chain slings: These are extremely robust, suitable for heavy and abrasive loads. However, they can damage delicate items. Regular inspections for elongation, kinks, or broken links are crucial.

The choice of sling depends on the load’s characteristics (weight, shape, material), the lifting environment, and regulatory requirements. For example, I’d choose a web sling for a polished steel component to avoid scratching, but a chain sling for a rough, heavy casting.

Q 13. What is your experience with using lifting harnesses and other safety gear?

Lifting harnesses and other safety gear are essential for high-risk lifting operations. My experience includes using:

- Full-body harnesses: These provide secure anchorage points for fall arrest systems, crucial for working at heights or near hazards.

- Safety helmets: Protecting the head from falling objects is paramount.

- Safety glasses: These protect eyes from debris and flying objects.

- Steel-toe boots: Protecting feet from dropped objects or crushing hazards.

- Gloves: Providing protection from abrasions, cuts, and other hand injuries.

Properly fitting and using this equipment is crucial. Regular inspections are necessary to ensure the gear is in good condition and correctly maintained. I always prioritize the correct application and condition of all PPE before commencing any lift.

Q 14. How do you plan a heavy lift to minimize risk?

Planning a heavy lift to minimize risk involves a systematic approach:

- Risk assessment: Identify all potential hazards involved, considering the load’s weight, shape, and material, the lifting equipment, the environment, and the personnel involved.

- Method statement: Develop a detailed plan outlining the lifting procedure, including equipment selection, personnel responsibilities, and safety precautions. This often includes drawings and diagrams.

- Equipment selection: Choose appropriate lifting equipment with sufficient capacity and suitable for the load and environment. Ensure all equipment is certified and properly maintained.

- Site preparation: Ensure the lifting area is clear of obstructions, the ground is stable, and adequate access is available. Consider traffic control and the establishment of exclusion zones.

- Personnel training: All personnel involved should be adequately trained and competent in the safe operation of the lifting equipment and procedures.

- Emergency procedures: Develop and communicate clear emergency procedures in case of equipment malfunction or accidents.

A well-planned lift reduces the likelihood of accidents and ensures the safe and efficient completion of the task. For example, a complex lift involving multiple cranes and rigging might require a detailed simulation or modeling exercise to optimize the plan and predict potential issues.

Q 15. Describe your experience working with different types of materials (e.g., fragile, hazardous).

My experience encompasses handling a wide variety of materials, each requiring a unique approach to ensure safety and prevent damage. For instance, I’ve worked extensively with fragile items like precision equipment and delicate glassware. This involves using specialized lifting equipment, padding, and techniques to minimize the risk of breakage. Think of moving a grandfather clock – you wouldn’t just grab it! You’d use straps, potentially a crane, and ensure a stable, slow movement. Conversely, I’m highly experienced in handling hazardous materials, including chemicals and radioactive substances. This requires strict adherence to safety protocols, such as wearing appropriate personal protective equipment (PPE) – including respirators, gloves, and specialized suits – and utilizing containment devices to prevent spills or exposure.

I’ve also worked with heavy construction materials like steel beams and concrete blocks, which demand a different set of skills and equipment, focusing on proper weight distribution and secure rigging to prevent accidents. Each material presents its own challenges and necessitates a tailored approach, prioritizing both safety and efficiency.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of lifting techniques you are familiar with?

I’m proficient in a range of lifting techniques, adapting my approach based on the specific load, environment, and available equipment. These include:

- Manual Lifting Techniques: This involves proper body mechanics, including using leg power, keeping the load close to the body, and avoiding twisting motions. Think of lifting a box – bending your knees, keeping your back straight, and lifting smoothly.

- Mechanical Lifting Techniques: This utilizes various equipment like forklifts, cranes, and hoists. Each piece of equipment has specific operating procedures and safety protocols that I strictly follow.

- Team Lifting Techniques: For exceptionally heavy or awkwardly shaped objects, coordinated team lifts are essential. This involves clear communication, designated roles, and synchronized movements to avoid injury and damage.

- Using Lifting Aids: This includes slings, straps, and other specialized equipment to secure the load and distribute its weight evenly. Choosing the right sling for the load is critical – a wrong choice could lead to a serious accident.

My expertise spans various lifting methodologies, prioritizing safety and efficiency in all scenarios.

Q 17. How do you deal with unexpected problems during a heavy lift?

Unexpected problems during a heavy lift can range from equipment malfunctions to unforeseen obstacles. My approach is systematic:

- Assess the Situation: Immediately stop the lift and evaluate the problem. Is it equipment failure, a change in the load’s center of gravity, or an environmental hazard?

- Communicate Clearly: Inform my team and any supervisors of the problem, ensuring everyone understands the situation and potential risks.

- Implement Corrective Actions: This may involve repairing equipment, adjusting the lifting plan, or seeking assistance from specialists. For example, if a sling breaks, immediately secure the load and replace the sling before resuming the lift.

- Prioritize Safety: Always prioritize safety. If the situation is unsafe, I will halt the lift completely until it can be safely resumed. Safety outweighs any schedule.

- Document the Incident: Thoroughly document the problem, corrective actions, and any resulting damage or delays.

My experience has taught me that a calm, methodical approach is crucial in resolving unexpected issues, emphasizing safety and problem-solving skills.

Q 18. What are your experience with using overhead cranes or hoists?

I have extensive experience operating overhead cranes and hoists of various capacities and types. My experience includes pre-lift inspections, load calculations, and safe operation procedures. I am familiar with different types of crane hooks, slings and load attachments, and their limitations. I understand the importance of load charts and the consequences of exceeding rated capacities, which can lead to catastrophic failures. Before operating any crane or hoist, I always ensure a thorough inspection to ensure safe operation. For example, I’d check for any wear and tear on cables, hooks, and other components. Operating these machines requires not only technical expertise but also a strong understanding of safety regulations and a commitment to careful operation. My experience covers everything from smaller chain hoists to large gantry cranes used in industrial settings.

Q 19. Describe your experience with forklift operation and safety.

I hold a valid forklift operator’s license and have years of experience operating various types of forklifts, from counterbalance to reach trucks. My experience includes pre-operational checks of the forklift, understanding load capacity limitations, and navigating safely in various environments, including warehouses, construction sites, and industrial facilities. Safety is paramount, and I always adhere strictly to company safety policies. I understand the importance of maintaining a clear view of the surroundings while operating the forklift, as well as the potential hazards of operating in confined spaces. I always prioritize safe load handling, ensuring that loads are balanced and secured correctly to avoid tipping or damage. Moreover, I am trained in recognizing and avoiding potential hazards, such as uneven surfaces or pedestrian traffic.

Q 20. How do you comply with relevant health and safety regulations during lifting tasks?

Compliance with health and safety regulations is non-negotiable. This involves:

- Risk Assessments: Participating in and conducting thorough risk assessments before any lifting operation to identify potential hazards and implement control measures.

- Permit-to-Work Systems: Following established permit-to-work procedures for high-risk lifting tasks, ensuring all necessary safety checks are completed before commencing work.

- PPE Usage: Consistent and correct use of personal protective equipment (PPE), including safety helmets, gloves, high-visibility clothing, and safety footwear.

- Training and Certification: Maintaining up-to-date training and certifications in relevant lifting techniques and equipment operation. This includes regular refresher courses.

- Reporting Incidents: Promptly reporting any accidents, near misses, or unsafe practices, contributing to a culture of continuous improvement.

I understand that adhering to regulations protects not only myself but also my colleagues and the surrounding environment. Safety is a collaborative effort, and I am committed to contributing to a safe work environment.

Q 21. How do you maintain accurate records of lifted items and their weight?

Maintaining accurate records of lifted items and their weights is crucial for traceability and safety. This involves:

- Pre-Lift Checklists: Using checklists to record details of each lift, including the item’s weight, dimensions, and any special handling requirements.

- Digital Logging Systems: Utilizing digital systems to record lift data, ensuring accurate and easily accessible records. This could include software specifically designed for lift management or even a simple spreadsheet.

- Weighing Equipment: Using calibrated weighing equipment to accurately determine the weight of the lifted item before commencing the lift.

- Documentation of Unusual Events: Documenting any unusual events, near misses, or incidents related to the lifting operation for analysis and future prevention. For example, if a load shifts unexpectedly, this needs to be recorded.

Accurate record-keeping is essential for safety analysis, liability management, and continuous improvement within the workplace.

Q 22. What is your experience with inventory management related to heavy items?

Inventory management for heavy items requires a meticulous approach, differing significantly from handling lighter goods. It involves optimizing storage space, considering weight distribution, and employing efficient tracking systems. My experience includes managing inventories of large industrial machinery, steel components, and oversized pallets. I’ve utilized warehouse management systems (WMS) to track the location and movement of these heavy items, ensuring proper stacking and preventing damage. For instance, in my previous role, we implemented a color-coded system for identifying weight classes, simplifying selection and reducing risk of stacking errors. This also optimized our forklift operations, minimizing unnecessary travel and maximizing efficiency.

Moreover, I’ve worked with specialized inventory software which integrates with our lifting equipment’s maintenance logs. This allows predictive maintenance and ensures that the correct equipment is available for specific items, preventing delays and potential accidents caused by using improperly maintained or unsuitable equipment.

Q 23. How do you communicate effectively with colleagues during lifting operations?

Effective communication during lifting operations is paramount for safety. We use a standardized system of hand signals, verbal cues, and confirmation checks. Before any lift, we establish a clear communication plan, assigning roles and responsibilities. This includes identifying a spotter, responsible for observing the path of the lift and providing verbal guidance to the operator. We also use radio communication for larger projects or when visual contact is limited. A simple, but crucial, element is the use of clear, concise language, avoiding jargon and ensuring everyone understands the plan.

For example, before lifting a particularly large transformer, we held a pre-lift meeting where we reviewed the lifting plan, discussed potential hazards, and assigned roles. Each member verbally confirmed their understanding and commitment to the safety procedures before initiating the lift. We also practiced our hand signals to ensure consistent understanding amongst the team.

Q 24. Describe a time you had to lift an unexpectedly heavy object. What did you do?

During a warehouse relocation, I encountered a pallet of unusually heavy construction materials, heavier than initially indicated on the paperwork. Instead of attempting to lift it directly, I immediately assessed the situation. First, I confirmed the weight using a calibrated scale. Recognizing the risk, I didn’t try to lift it manually. I immediately secured additional assistance, and we used a forklift fitted with appropriate lifting attachments. Before moving the pallet, we performed a thorough inspection of the forklift and the securing straps to ensure they were in good working order. We also carefully planned the route to avoid obstructions. This careful approach, prioritizing safety over speed, ensured a successful and safe move.

Q 25. What is your experience with using lifting aids and mechanical assistance?

My experience with lifting aids and mechanical assistance is extensive. I’m proficient with various equipment, including overhead cranes, forklifts, pallet jacks, and specialized lifting slings and straps. I understand the limitations and operating procedures of each, emphasizing safety protocols in every case. I have experience selecting the appropriate equipment based on the weight, size, and fragility of the load. This includes calculating safe working loads (SWL) and ensuring compliance with all relevant safety regulations. I’m also trained in the use of vacuum lifters, air hoists, and other specialized lifting devices suitable for diverse lifting challenges and various load characteristics.

For example, I’ve used a specialized vacuum lifter to move large sheets of glass without risk of damage and employed a counterbalanced forklift to safely lift heavy rolls of steel.

Q 26. How familiar are you with different types of warehouse layout and their impact on lifting tasks?

Familiarity with various warehouse layouts is crucial for efficient and safe heavy lifting operations. Different layouts, such as U-shaped, I-shaped, and L-shaped, have different implications for material flow and lifting task efficiency. A poorly designed layout can significantly increase the risk of accidents. For instance, narrow aisles can hinder the maneuverability of forklifts, leading to congestion and potential collisions. Likewise, inefficient placement of heavy items can create unnecessary travel distances and increase the risk of worker fatigue.

I understand how to analyze layout designs, identifying potential bottlenecks and safety hazards. My experience includes working in different warehouse configurations, leading to the optimization of routes, improving safety, and contributing to reduced operational costs. I also consider factors like the proximity of loading docks, storage height, and traffic patterns when assessing a warehouse’s suitability for heavy lifting.

Q 27. What steps do you take to prevent injuries when lifting heavy objects repeatedly?

Preventing injuries when lifting heavy objects repeatedly requires a multi-faceted approach. This starts with proper training, emphasizing safe lifting techniques such as maintaining a straight back, bending at the knees, and keeping the load close to the body. We also use mechanical aids as much as possible, minimizing manual handling. Regular breaks are essential to avoid fatigue, which significantly increases the risk of injury. I advocate for job rotation to diversify tasks and prevent repetitive strain injuries (RSI). Implementing ergonomic principles is crucial, including using adjustable height workbenches and ensuring tools are within easy reach.

Furthermore, I always ensure that the workplace is kept clean and clutter-free to minimize tripping hazards and improve visibility. We also conduct regular safety audits to identify and mitigate potential risks. Personal protective equipment (PPE), such as safety shoes and gloves, is mandatory.

Key Topics to Learn for Heavy Lifting and Handling Interview

- Ergonomics and Body Mechanics: Understanding proper lifting techniques, posture, and movements to prevent injuries. Practical application includes demonstrating safe lifting procedures and explaining the principles behind them.

- Load Assessment and Planning: Evaluating the weight, size, and stability of loads before lifting. Practical application involves describing methods for determining safe lifting limits and strategies for managing unusually shaped or heavy objects.

- Equipment and Machinery: Familiarity with various lifting equipment (e.g., forklifts, cranes, hoists) and their safe operation. Practical application could be explaining pre-operational checks or demonstrating understanding of load capacity limits.

- Safety Regulations and Procedures: Knowledge of relevant health and safety regulations and company-specific procedures for heavy lifting and handling. Practical application includes describing incident reporting procedures and explaining the importance of risk assessments.

- Hazard Identification and Risk Mitigation: Identifying potential hazards associated with heavy lifting and handling and implementing appropriate risk mitigation strategies. Practical application involves describing methods for preventing common lifting injuries and addressing specific workplace hazards.

- Teamwork and Communication: Understanding the importance of teamwork and clear communication during heavy lifting operations. Practical application includes describing how to effectively communicate with colleagues during lifting tasks to ensure safety.

Next Steps

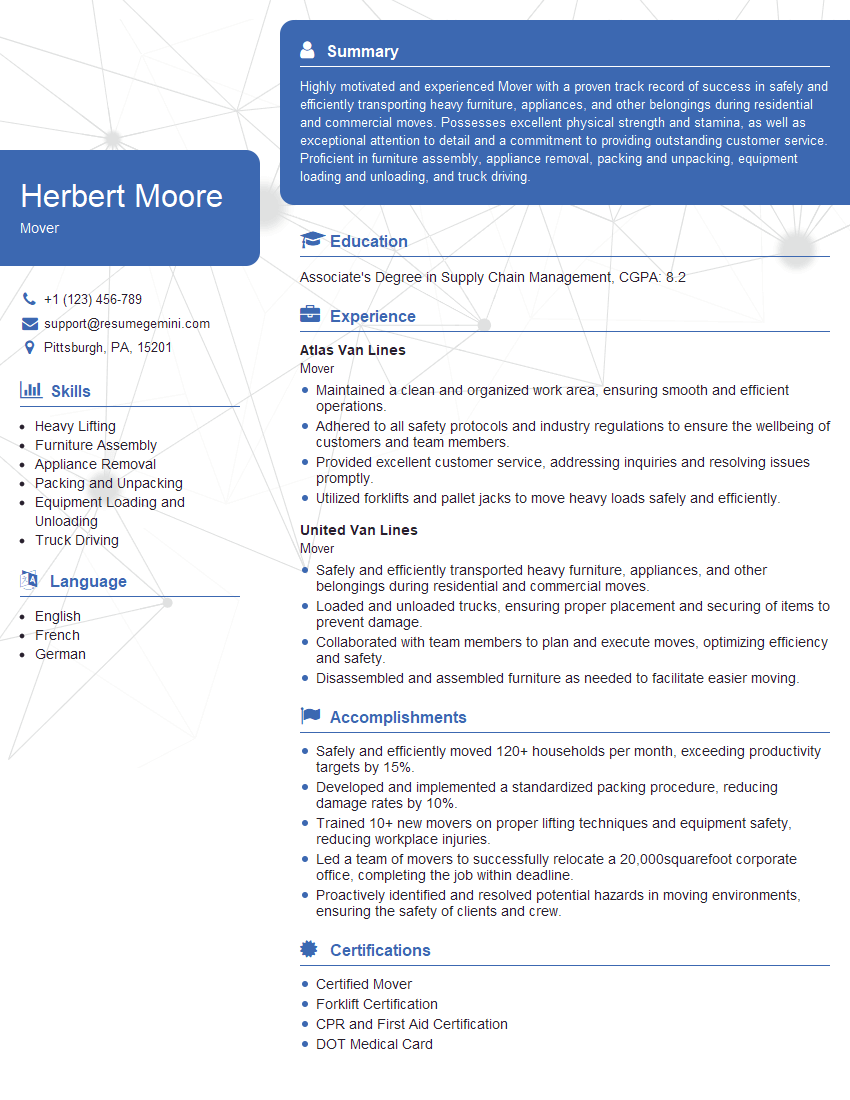

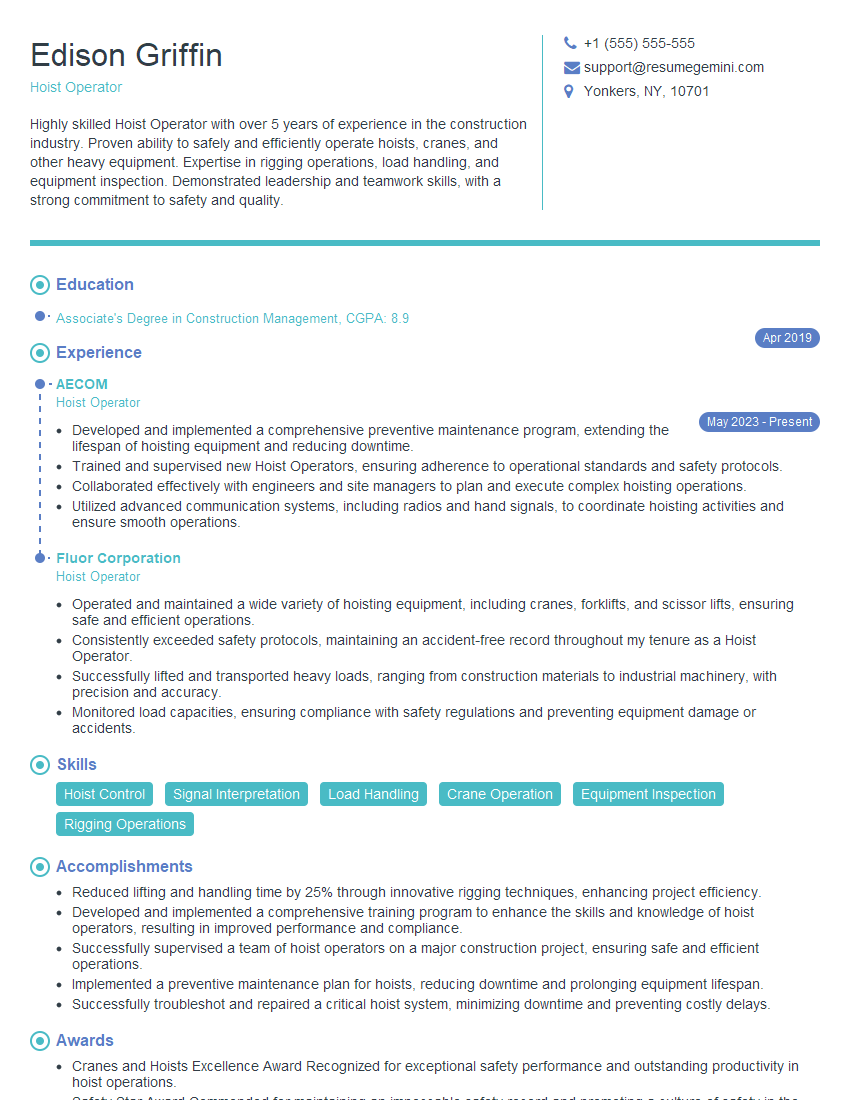

Mastering heavy lifting and handling techniques is crucial for career advancement in numerous industries, demonstrating your commitment to safety and efficiency. A strong resume is your key to unlocking these opportunities. Creating an ATS-friendly resume is essential for getting your application noticed by potential employers. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience. We provide examples of resumes tailored specifically to Heavy Lifting and Handling to guide you. Take the next step towards your dream job!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good