Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Height Work and Rappelling interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Height Work and Rappelling Interview

Q 1. Describe your experience with different rope access techniques.

My rope access experience encompasses a wide range of techniques, from single-rope technique (SRT) which is the most common, relying on a single rope for ascent and descent, to double-rope technique (DRT) offering increased redundancy and safety, particularly in rescue scenarios. I’m proficient in various SRT variations, including ascending using ascenders like the Petzl Ascender or similar devices, and controlled descents using various braking devices. My experience also includes working with advanced techniques like deviation systems for complex rigging situations and multi-point anchor systems for redundancy and load distribution.

For instance, I’ve utilized SRT extensively in bridge inspections, accessing hard-to-reach areas efficiently and safely. In contrast, DRT proved invaluable during a wind turbine inspection where the extra security offered by two ropes was crucial given the height and potential for wind gusts. Each technique demands a specific skillset, and I’ve adapted my approach based on the unique challenges of each project.

Q 2. Explain the different types of rope access equipment and their uses.

Rope access equipment is meticulously chosen for its safety and performance. Essential gear includes ropes (static and dynamic), harnesses (specifically designed for rope access), ascenders (for ascent), descenders (for descent), carabiners (for connecting equipment), anchor systems (for securing the rope), and personal protective equipment (PPE) like helmets, gloves, and appropriate clothing. Beyond these basics, we frequently utilize:

- Self-braking descenders: Devices like the Petzl ID or Stop ensuring controlled descent and preventing runaway descents.

- Ascenders: Devices like the Petzl Ascender or Figure 8 ascenders facilitate efficient climbing.

- Anchor systems: These range from single-point anchors to complex multi-point systems for load distribution and redundancy, ensuring stability at the worksite.

- Prusik knots: Used in many SRT systems for creating friction and assisting in ascents and descents.

The selection of equipment depends entirely on the specific job requirements, environmental conditions, and potential hazards. For instance, working in icy conditions would require specialized gloves and potentially different types of ascenders and descenders.

Q 3. How do you perform a pre-use inspection of rope access equipment?

A thorough pre-use inspection is paramount before any rope access work. This involves a visual and hands-on check of all equipment, covering:

- Ropes: Checking for cuts, fraying, abrasions, kinks, and proper sheath integrity. We use specialized rope inspection tools such as a rope tester to check for core damage that may not be visible on the surface.

- Harnesses: Inspecting all buckles, straps, and stitching for any signs of wear, damage, or deformation. We check the integrity of the stitching at the attachment points for the ropes.

- Ascenders and descenders: Checking for smooth operation, wear on moving parts, and correct functionality. We check the camming mechanism and ensure smooth movement without any binding.

- Carabiners: Inspecting for damage to the gate, any signs of bending or deformation, and ensuring smooth gate operation. We check the gate closure mechanism to ensure it’s closing and locking properly.

- Anchor points: Assessing the structural integrity and load-bearing capacity of the anchor points. This is done by visually inspecting them, checking for any signs of corrosion, damage, and ensuring they’re rated for the intended load.

Any equipment showing any signs of damage or wear is immediately taken out of service and replaced. This proactive approach prevents accidents and ensures a safe work environment.

Q 4. What are the key safety regulations and standards you adhere to during rope access work?

My work adheres strictly to all relevant safety regulations and standards. These vary by region, but generally include adherence to guidelines set by organizations like ANSI, IRATA (Industrial Rope Access Trade Association), or similar national standards. Key areas of focus include:

- Risk assessment and method statements: A detailed risk assessment is performed for each project outlining potential hazards and mitigation strategies.

- Permit-to-work systems: Ensuring all work is authorized and properly documented.

- Regular equipment inspections: Thorough inspections before, during, and after each work session as previously described.

- Competency training and certifications: Possessing relevant training certifications and maintaining up-to-date knowledge of industry best practices.

- Emergency procedures: Having established and practiced rescue plans for various scenarios.

- Communication protocols: Maintaining clear and consistent communication with team members and ground support.

Compliance is not merely a checklist; it’s a continuous process of vigilance and professional responsibility. A commitment to safety is central to everything we do.

Q 5. Describe your experience with rescue systems and procedures in rope access.

My experience with rescue systems is extensive. I am trained in various rescue techniques, including self-rescue, partner rescue, and multi-person rescue scenarios using different equipment and configurations. I’m proficient in using various devices including specialized rescue descenders, hauling systems, and raising systems. We regularly conduct practice drills to ensure efficient and safe responses to emergencies.

For example, during a recent training exercise, we simulated a scenario where a worker experienced a sudden medical emergency mid-descent. The team was able to quickly and effectively execute a rescue using a combination of ascenders and a specialized rescue descender to safely retrieve the simulated casualty. This constant training ensures our preparedness for any eventuality.

Q 6. How do you assess and mitigate risks associated with different work at height scenarios?

Risk assessment is the cornerstone of safe work at height. It’s a systematic process involving identification, analysis, and mitigation of potential hazards. This begins with a thorough site survey, considering factors like:

- Environmental factors: Wind speed and direction, temperature, precipitation, and visibility.

- Structural integrity: Assessing the condition of the structure, anchor points, and surrounding environment.

- Equipment suitability: Ensuring equipment is appropriate for the task and conditions.

- Human factors: Addressing fatigue, stress, and training levels of personnel.

Mitigation strategies are then developed and implemented. These may include selecting appropriate rope access techniques, using redundant systems, implementing fall protection, and having contingency plans for unforeseen circumstances. A risk assessment is not a one-time event but a living document, updated as needed throughout the project.

Q 7. Explain your understanding of fall protection systems and their application.

Fall protection systems are designed to prevent falls or minimize their consequences. In rope access, our primary fall protection is the rope itself, used in conjunction with appropriate harnesses and descenders. However, supplementary fall protection might be necessary depending on the specific circumstances. This can include:

- Self-retracting lifelines (SRLs): These devices automatically retract the lifeline in the event of a fall, minimizing the fall distance.

- Anchor systems with fall arresters: Robust anchor systems are used along with shock-absorbing systems and fall arresters that provide additional safety.

- Safety nets: Nets can be used in situations where a fall could result in a significant drop onto a potentially hazardous area.

The choice of fall protection system depends on several factors, including the height of the work, the potential fall distance, the type of work being performed, and the environmental conditions. The overriding principle is to select the most effective system that minimizes the risk of injury.

Q 8. How do you communicate effectively with your team during rope access operations?

Effective communication is paramount in rope access, where lives depend on clear and concise instructions. We utilize a combination of methods, prioritizing visual cues and pre-planned communication strategies. Before any operation, we conduct thorough briefings, outlining tasks, potential hazards, and emergency procedures. During the operation, we use a combination of hand signals, pre-agreed verbal commands, and radio communication, depending on the environment and the complexity of the task. For instance, a simple hand signal might indicate a ‘stop’ or ‘proceed with caution,’ while the radio is used for longer-range communications or to relay critical information to ground crews. Regular check-ins are crucial, ensuring everyone is aware of each other’s position and any changes in the situation. After each operation, we debrief to identify areas for improvement in communication and overall safety.

Q 9. Describe your experience with different types of anchors and their limitations.

My experience encompasses a wide range of anchors, including steel beams, reinforced concrete, and natural features like large, sturdy trees (after careful assessment). Each has its limitations. Steel beams, while strong, can be susceptible to corrosion, which significantly weakens them. We always thoroughly inspect for rust or damage before trusting our weight to them. Concrete anchors, while robust, require careful placement and consideration of the concrete’s integrity. Poorly placed anchors can easily pull out, leading to catastrophic failure. Natural anchors, such as trees, are assessed for their soundness, size, and the strength of the surrounding roots. They’re highly dependent on environmental factors and are less predictable than manufactured anchors. In all cases, redundancy is key. We never rely on a single anchor point; we always establish multiple independent anchor points to ensure safety and distribute the load effectively. This multi-point system provides a crucial backup in case one anchor fails.

Q 10. What are the signs of rope degradation and how do you address them?

Rope degradation is a serious concern in rope access. We regularly inspect ropes for several key signs: abrasions (cuts, scrapes), which weaken the fibers; cuts or nicks, which significantly reduce strength; unusual stiffening or softening, which could indicate chemical degradation or damage; and excessive wear at the ends or in frequently used sections. Any signs of melting or burning are cause for immediate replacement. We utilize a systematic inspection process, including visual checks and sometimes specialized testing equipment to assess strength. Addressing degradation involves immediate rope replacement. Damaged ropes are never repaired; they are immediately taken out of service. We maintain detailed records of rope inspections and replacements, adhering to strict manufacturer’s guidelines and industry best practices to ensure that we are always working with safe and reliable equipment.

Q 11. Explain your understanding of knot tying and its importance in rope access.

Knot tying is fundamental to rope access; it’s the foundation of safe and reliable anchoring and equipment management. A poorly tied knot can lead to catastrophic failure. We are proficient in a range of knots, including the figure-eight, clove hitch, bowline, and various specialized rope access knots. Each knot serves a specific purpose and has its own strengths and weaknesses. We choose the knot based on the specific application and load requirements. For instance, the figure-eight is a simple yet effective stopper knot, ideal for securing a rope to a harness, while the clove hitch is incredibly versatile and useful for attaching a rope to an anchor point. The importance lies in the precision and consistency of the knot’s execution. We practice regularly to maintain proficiency and consistency, ensuring a reliable and safe system. Regular training and certification reinforce our knowledge and skills.

Q 12. How do you handle emergency situations during rope access work?

Emergency preparedness is a cornerstone of rope access. We have established protocols for various scenarios, from equipment failure to medical emergencies. Our training includes advanced rescue techniques, self-rescue procedures, and efficient communication strategies. In case of an equipment failure, for instance, we’re trained to utilize backup systems and employ self-arrest techniques. For medical emergencies, we have established communication protocols to quickly alert emergency services and coordinate rescue efforts. We also carry comprehensive first-aid kits and are trained in administering first aid. Regular training exercises and drills help us refine our response times and coordination in emergency situations. The key is proactive risk assessment, redundant systems, and thorough training – planning for the worst while hoping for the best.

Q 13. Describe your experience working in confined spaces at height.

Working in confined spaces at height presents unique challenges. These environments often have limited access, restricted visibility, and potential hazards such as oxygen deficiency, hazardous materials, and limited escape routes. Before entering any confined space, we conduct a thorough hazard assessment, which includes atmospheric testing for hazardous gases and oxygen levels. We utilize appropriate personal protective equipment (PPE), including respiratory protection and specialized harnesses designed for confined space work. We establish communication systems to maintain contact with the ground crew and ensure a continuous flow of information throughout the operation. A rescue plan is always in place, tailored to the specific confined space and the nature of the work. Our experience encompasses working in various confined spaces, from water towers and chimneys to industrial tanks and silos, always adhering to strict safety regulations.

Q 14. What are the limitations of rope access techniques and when would you recommend alternative methods?

Rope access, while versatile, has limitations. It is not suitable for all situations. Access may be impossible if the structure is unstable, the anchor points are unreliable, or the weather conditions are too severe. Tasks requiring heavy loads or complex mechanical operations might also be better suited to alternative methods. For instance, we would not use rope access to lift heavy machinery to the top of a building, opting instead for a crane or other appropriate lifting equipment. If working in confined spaces, where there are risks of hazardous gases or limited escape routes, specialized confined space entry techniques would be preferred. The choice of method depends on a thorough risk assessment considering factors like structural integrity, weather conditions, access limitations, and the nature of the work being performed. Safety is always our priority.

Q 15. Explain your knowledge of different types of ascenders and descenders.

Ascenders and descenders are crucial pieces of equipment in rope access work, enabling controlled movement up and down a rope. Ascenders are devices that allow upward movement, while descenders control descent. There are various types, each with its own advantages and disadvantages.

Ascenders: Common types include the Petzl Ascender and the CMC Ascender. These typically use a camming mechanism that grips the rope as you pull upward. The Petzl Ascender is known for its smooth operation, while the CMC offers a more robust design. There are also variations designed for specific rope diameters and applications like the Figure 8 ascender, which is less efficient but often used as a backup.

Descenders: These devices control the speed of descent. Popular choices include the Petzl I’D, the Petzl RIG, and the ATC (Automatic Tension Control). The I’D offers self-braking capabilities, useful for controlled descents, while the RIG provides more versatility for various rope access techniques. The ATC is a simpler device requiring more user input for speed control and is often used in conjunction with a backup device. There are also rappelling devices which use friction, such as the 8-shaped descender.

Choosing the right ascender and descender depends on the specific job, rope type, and personal preference. Regular inspection and maintenance of these devices are paramount for safety.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage fatigue during prolonged rope access operations?

Fatigue management is critical in rope access work, as exhaustion significantly increases the risk of accidents. My strategy involves a multi-pronged approach:

Planning and breaks: Thorough pre-planning helps to minimize unexpected delays and strenuous activities. Regular, scheduled breaks are essential, allowing time for hydration, rest, and light stretches to combat muscle fatigue. I work with my team to ensure breaks are taken at safe and appropriate times.

Physical fitness: Maintaining a good level of physical fitness is paramount. This includes regular exercise focusing on strength, endurance, and flexibility, directly applicable to the demands of the job. This minimizes the risk of injury due to fatigue.

Hydration and nutrition: Staying adequately hydrated and consuming a balanced diet provides the energy needed for prolonged operations. This prevents energy crashes and helps to maintain focus and concentration.

Teamwork and communication: Working as part of a team allows for mutual support and monitoring of fatigue levels. Open communication ensures any concerns are addressed promptly before they escalate into a safety hazard. I actively encourage my teammates to communicate their fatigue levels.

Recognizing the signs of fatigue, such as decreased concentration, slow reaction times, or increased muscle soreness, is crucial. When I observe these in myself or my team, we take immediate steps to address the issue; often requiring a longer break or even a cessation of work until recovered.

Q 17. Describe your experience with working at night or in adverse weather conditions.

I have significant experience working at night and in challenging weather conditions. These scenarios demand additional precautions and specialized equipment.

Night work: This requires high-powered lighting systems for both illumination and visibility. I always ensure sufficient backup lighting sources, and we utilize communication systems designed for low-light conditions. Fatigue management is even more critical due to the disruption of the circadian rhythm.

Adverse weather: Working in rain, snow, or high winds necessitates extra vigilance. We use weather-resistant equipment and clothing, ensuring proper protection from the elements. The potential for increased slippage and reduced visibility demands extra care. We often have to adjust techniques to account for these risks. In extreme conditions, work is frequently suspended.

For both situations, detailed risk assessments are carried out prior to commencing work, outlining the potential hazards and appropriate mitigation strategies. Regular communication between the team and ground support is maintained to ensure safety and efficient operations.

Q 18. Explain your understanding of the hierarchy of hazard controls.

The hierarchy of hazard controls is a fundamental principle in safety management. It prioritizes control measures to minimize risks, starting with the most effective methods and progressing to less effective ones if necessary.

Elimination: This involves removing the hazard entirely. For example, if a task can be completed from the ground, eliminating the need for rope access, it’s the safest option.

Substitution: Replacing a hazardous substance or process with a safer alternative. For instance, switching to a less abrasive rope to prevent damage and wear.

Engineering controls: Implementing physical changes to control the hazard at its source. This could involve installing safety railings or improving lighting.

Administrative controls: Establishing procedures and training to mitigate risks. This includes thorough risk assessments, comprehensive training programs, and establishing clear communication protocols.

Personal protective equipment (PPE): Using protective equipment as a last resort, after all other controls have been implemented. This includes harnesses, helmets, gloves, and appropriate footwear.

This hierarchical approach ensures that the most effective and reliable methods are prioritized to minimize risk, always striving for the safest possible working conditions.

Q 19. How do you maintain accurate records and documentation of your work?

Maintaining accurate records and documentation is crucial for accountability and legal compliance. My record-keeping process involves several key steps:

Pre-work documentation: This includes a detailed risk assessment, method statement outlining the planned work, and a list of all equipment used, with its inspection details.

Daily logs: These record daily activities, any incidents or near misses, weather conditions, and personnel involved. Any issues or observations are noted meticulously.

Photographs and videos: Visual documentation of the work site, the process, and the equipment is vital, particularly for documenting incidents or near misses. Time-stamped images and videos provide crucial evidence.

Post-work reports: These summarize the work completed, any challenges encountered, and lessons learned. Equipment condition checks are documented.

All documentation is stored securely, both digitally and in hard copy, ensuring accessibility and longevity. This meticulous record-keeping is essential for demonstrating compliance, facilitating continuous improvement, and providing valuable data for future projects.

Q 20. Describe your experience with different types of harnesses and their components.

Harnesses are the cornerstone of rope access safety, providing the crucial connection between the worker and the rope system. Various types exist, each suited to different tasks.

Full-body harnesses: These provide complete protection, encompassing the legs, waist, and chest. They typically have attachment points for ascenders, descenders, and fall arrest systems. They are designed to distribute forces during a fall.

Sit harnesses: These are more streamlined, focusing on waist and leg support, primarily used for work positioning rather than fall arrest. They are lighter and more comfortable for prolonged work.

Components: Key components include the leg loops, waist belt, chest strap (for full body), gear loops for holding equipment, and attachment points for connecting to ropes and safety systems.

Regular inspections of harnesses, checking for wear and tear, stitching damage, and correct functioning of buckles, are crucial. Always ensure the harness fits properly and is appropriately maintained. Different manufacturers have varying designs, each with its own strengths and weaknesses, so choosing the right harness for the specific job is crucial.

Q 21. What are the key differences between single rope technique (SRT) and double rope technique (DRT)?

Single Rope Technique (SRT) and Double Rope Technique (DRT) are two primary methods for rope access. They differ significantly in their setup, functionality, and application.

SRT (Single Rope Technique): Uses a single rope for both ascent and descent. It relies heavily on ascenders and descenders for controlled movement. It’s efficient for accessing single points but can be more challenging and risky in complex situations. SRT is often used for solo work, requiring a high level of expertise. A self-braking descender is essential for safety.

DRT (Double Rope Technique): Employs two ropes, one for ascent and the other for descent, providing redundancy. Generally considered safer than SRT, especially in situations with greater risks or for less experienced personnel. It offers increased safety in case of equipment failure on one rope. However, it involves more equipment and can be less efficient than SRT.

The choice between SRT and DRT depends on factors like the complexity of the access point, the experience of the rope access technician, and the specific risk assessment of the project. Understanding the advantages and disadvantages of both techniques is essential for choosing the most suitable approach, always prioritizing safety.

Q 22. How do you ensure compliance with relevant health and safety legislation?

Ensuring compliance with health and safety legislation in height work and rappelling is paramount. It’s not just about ticking boxes; it’s about fostering a safety culture. This involves a multi-faceted approach.

- Understanding Legislation: Thoroughly familiarizing myself with relevant regulations, such as OSHA (in the US) or equivalent legislation in other countries, is crucial. This includes understanding specific requirements for working at height, rope access techniques, and the use of personal protective equipment (PPE).

- Risk Assessments: Before any job, a comprehensive risk assessment is mandatory. This involves identifying potential hazards, evaluating the risks associated with each hazard, and implementing control measures to mitigate those risks. This assessment is documented and reviewed regularly.

- Method Statements: Detailed method statements outline the specific procedures for each task, incorporating the risk assessment findings and specifying the safety precautions to be followed. These statements are reviewed and approved by supervisors before work commences.

- Regular Inspections: Equipment inspections are conducted before, during, and after each job. This includes checking ropes, harnesses, carabiners, and other PPE for wear and tear, damage, or defects. Any issues are immediately reported and rectified.

- Training and Competency: Ensuring that all team members are adequately trained and competent in rope access techniques and safety procedures is non-negotiable. Regular training, refresher courses, and competency assessments are essential.

- Record Keeping: Maintaining accurate and detailed records of all safety procedures, inspections, training, and incidents is crucial for demonstrating compliance and identifying areas for improvement.

For example, on a recent project involving façade inspection, we meticulously followed all OSHA regulations regarding fall protection, ensuring that our method statement included specific details about anchor points, rope management, and emergency procedures. This proactive approach ensured a safe and compliant operation.

Q 23. Describe a time you had to overcome a challenging situation during a rope access job.

During a high-rise building inspection, we encountered unexpectedly strong winds at the summit. The planned access route, which involved a single rope technique, became dangerously unstable. The wind was gusting significantly, affecting my ability to maintain a stable position and increasing the risk of pendulum swing.

My immediate response was to halt the operation and reassess the situation. We couldn’t simply wait for the wind to die down; the project had tight deadlines. After a thorough reevaluation, we decided to employ a more robust technique: a twin-rope system with redundant safety lines. This would greatly enhance stability and reduce the impact of the wind. The team worked together to re-rig the system, carefully securing the new anchor points and checking all the equipment before proceeding. The project was slightly delayed, but safety was prioritized. This demonstrated the importance of adaptability and having alternative plans in place to overcome unforeseen circumstances.

Q 24. What are the key considerations for selecting appropriate PPE for rope access work?

Selecting appropriate PPE for rope access work is critical for safety. The choice depends on several factors:

- The specific task: Different tasks necessitate different levels of protection. For example, façade inspection might require different PPE than window cleaning.

- Environmental conditions: Weather conditions such as wind, rain, and temperature will influence the choice of protective clothing.

- Risk assessment: The risk assessment identifies potential hazards and determines the necessary level of protection.

- Individual needs: PPE should be properly fitted to ensure comfort and effectiveness.

Essential PPE typically includes:

- Full-body harness: Must meet appropriate safety standards and be properly fitted.

- Helmet: To protect against falling objects.

- Gloves: To protect against cuts, abrasions, and chemical exposure.

- Ropes and Carabiners: Certified and regularly inspected.

- Appropriate footwear: Providing good grip and ankle support.

- Fall arrest system: Depending on the work, this may include a self-retracting lifeline (SRL) or other fall protection devices.

For instance, working on a damp, slippery surface would require gloves and footwear with enhanced grip, while working near electrical hazards necessitates insulated gloves and specialized safety equipment.

Q 25. How do you develop and implement a safe system of work for rope access tasks?

Developing a safe system of work for rope access tasks involves a systematic approach:

- Planning and Risk Assessment: Conduct a thorough risk assessment, identifying all potential hazards and evaluating the associated risks. This assessment forms the basis of the safe system of work.

- Method Statement: Develop a detailed method statement outlining the specific procedures for each task, including the use of equipment, communication protocols, and emergency procedures. This should incorporate the findings of the risk assessment and specify the control measures to be implemented.

- Competency Assessment: Ensure that all team members possess the necessary skills, knowledge, and experience to carry out the tasks safely. Regular competency assessments are crucial.

- Equipment Selection: Select appropriate PPE and equipment, ensuring that it is correctly inspected and maintained. This selection is based on the risk assessment and the specific tasks to be performed.

- Communication Plan: Establish clear communication protocols to maintain effective communication between team members, supervisors, and other stakeholders. This might involve the use of two-way radios or other communication devices.

- Emergency Procedures: Develop and implement detailed emergency procedures to address potential incidents. This includes rescue plans and procedures for contacting emergency services.

- Supervision and Monitoring: Provide adequate supervision to ensure that the safe system of work is being followed correctly. Regularly monitor the work environment and the performance of team members.

For example, a system for working on a bridge would include detailed plans for anchor point selection, rope management, and fall arrest systems, along with clear communication strategies using radio communication and designated hand signals.

Q 26. Explain your understanding of the importance of regular training and competency assessments.

Regular training and competency assessments are the cornerstones of a safe rope access program. They’re not just a formality; they’re vital for maintaining proficiency and identifying potential skill gaps. The human element is crucial; even the best equipment is ineffective without well-trained personnel.

- Maintaining Proficiency: Rope access techniques require constant practice and refinement. Regular training keeps skills sharp, ensuring safe and efficient work practices. This covers everything from knot tying and equipment handling to rescue techniques and emergency procedures.

- Adapting to Changes: New technologies, improved techniques, and changes in legislation necessitate continuous updates to knowledge and skills. Regular training keeps practitioners informed about best practices and industry standards.

- Identifying Skill Gaps: Competency assessments objectively evaluate an individual’s skill level. This helps to identify areas where additional training or support might be necessary.

- Risk Mitigation: Well-trained personnel are less likely to make mistakes that could lead to accidents. Regular assessment ensures that team members are proficient in all aspects of rope access work, minimizing risks.

- Legal Compliance: Many jurisdictions require regular training and competency assessments as part of their health and safety regulations for working at height.

For instance, we conduct annual refresher training for all our rope access technicians, including practical exercises and written examinations to ensure they maintain their certification and stay up-to-date with the latest safety standards and best practices.

Q 27. Describe your experience with using various types of communication devices during rope access operations.

Effective communication is vital during rope access operations, especially when working at height where visual contact may be limited. Various communication devices have their place, depending on the job and environment.

- Two-Way Radios: These are essential for maintaining constant communication between team members, particularly when working in different locations. We use radios with long-range capabilities, ensuring clear communication even at considerable distances.

- Hand Signals: Pre-agreed hand signals provide a backup communication system and are especially useful in noisy environments or when radio communication is unavailable. This is critical for safety.

- Visual Signals: Simple, universally understood visual signals (e.g., waving a brightly colored flag) can alert others to potential issues.

- Mobile Phones (with backup): While not the primary means of communication during rope access, a reliable mobile phone with a backup system can be used for communicating with ground crews or emergency services in case of an emergency.

On a recent project involving bridge inspection, we used two-way radios for constant communication between the technicians on the bridge and the ground crew. Hand signals served as a backup in case of radio interference. We also ensured all team members had fully charged mobile phones as an additional safety measure.

Q 28. How do you manage potential conflicts between safety regulations and project deadlines?

Managing conflicts between safety regulations and project deadlines requires a balanced approach that prioritizes safety without compromising the project entirely. Safety is never negotiable.

- Open Communication: Maintain open communication with all stakeholders (clients, supervisors, team members) to transparently discuss any potential conflicts between deadlines and safety requirements.

- Risk Assessment Review: If a deadline jeopardizes safety, reassess the risks and explore alternative solutions, such as adjusting the work schedule, bringing in additional resources, or modifying the work plan. This may involve accepting a delay in completion.

- Prioritize Safety: If a conflict cannot be resolved without compromising safety, the project timeline must be adjusted to ensure adherence to safety regulations. This approach prevents accidents and potential legal issues.

- Documentation: Maintain detailed records of all discussions, decisions, and risk assessments to demonstrate that safety was prioritized. This can be vital for legal purposes if issues arise.

- Alternative Solutions: Seek creative solutions. Could certain tasks be expedited? Are there alternative methods that maintain safety while improving efficiency? This requires careful planning and detailed knowledge of the equipment and techniques available.

For instance, on a recent project, a tight deadline was causing pressure to accelerate the work. However, a crucial safety check on a critical piece of equipment was delayed. We chose to delay the entire project until the safety check was completed, demonstrating our unwavering commitment to safety above all else. While the delay was frustrating, it was a necessary step.

Key Topics to Learn for Height Work and Rappelling Interview

- Safety Regulations and Procedures: Understanding OSHA regulations, industry best practices, and company-specific safety protocols is paramount. This includes detailed knowledge of personal protective equipment (PPE) and its proper use.

- Rope Access Techniques: Mastering various rappelling techniques, ascending methods, and anchor system setups is crucial. Be prepared to discuss different knot tying techniques and their applications in diverse situations.

- Equipment Knowledge: Demonstrate a thorough understanding of various ropes, harnesses, carabiners, ascenders, descenders, and other specialized equipment. This includes knowing their limitations and proper maintenance.

- Risk Assessment and Mitigation: Discuss your approach to identifying potential hazards in height work and rappelling scenarios, and explain your strategies for mitigating those risks. This includes pre-job planning and on-site risk management.

- Emergency Procedures: Be prepared to explain your knowledge of emergency response protocols, including rescue techniques, communication strategies, and first aid in height work environments.

- Practical Applications: Discuss real-world applications of height work and rappelling, such as in construction, inspection, maintenance, and rescue operations. Be ready to provide specific examples of your experience or knowledge.

- Problem-Solving and Decision Making: Interviewers will assess your ability to think critically and make sound judgments under pressure. Be ready to describe how you’ve overcome challenges in height work scenarios.

Next Steps

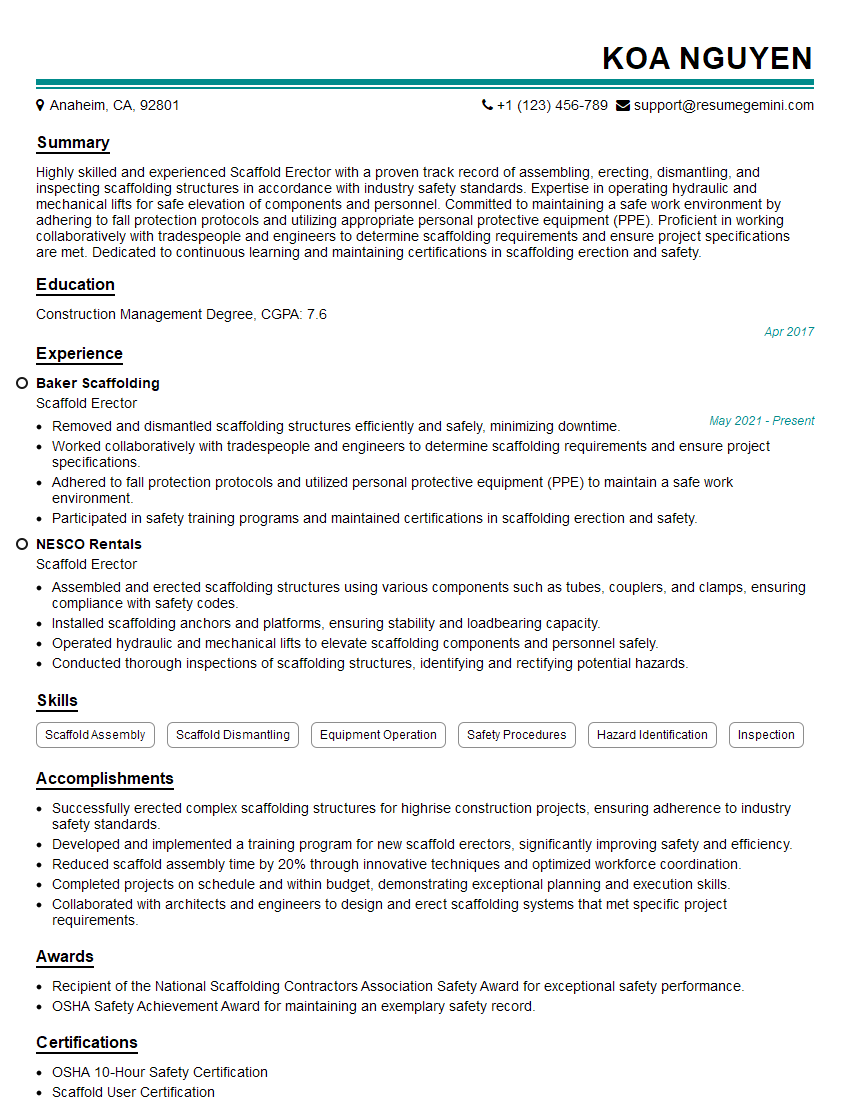

Mastering height work and rappelling opens doors to exciting and rewarding career opportunities in various industries. Your expertise in this specialized field is highly valuable, offering excellent earning potential and career growth. To significantly enhance your job prospects, creating a compelling and ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume tailored to showcase your skills and experience effectively. Examples of resumes specifically designed for Height Work and Rappelling professionals are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good