The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Hide Selection and Preparation for Stamping interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Hide Selection and Preparation for Stamping Interview

Q 1. What are the key criteria for selecting hides for stamping?

Selecting hides for stamping involves a careful assessment of several key criteria to ensure the final product meets quality standards. Think of it like choosing the right wood for a fine piece of furniture – the wrong wood will ruin the project, no matter how skilled the craftsman.

- Thickness and Uniformity: The hide needs to be consistently thick to ensure even stamping and prevent breakage or uneven impressions. We use specialized measuring tools to check this across the entire hide.

- Fiber Structure: Strong, tightly packed fibers are essential for a crisp, clean stamp. Weak or damaged fibers will lead to poor results, like smudging or tearing. We examine the hide’s grain carefully to assess its strength.

- Surface Quality: A smooth, blemish-free surface is paramount. Scratches, holes, or other imperfections can hinder the stamping process and affect the aesthetic appeal of the finished product. We grade hides based on the number and severity of surface defects.

- Hide Type and Tanning Method: Different animal hides (e.g., cowhide, sheepskin) have different properties suitable for specific stamping techniques. The tanning method significantly impacts the hide’s durability and flexibility. We match the hide type and its tanning process to the stamping design and requirements.

Q 2. Explain the process of hide fleshing and its importance in stamping.

Hide fleshing is a crucial step in hide preparation where the remaining fatty tissues and muscle fibers are removed from the flesh side of the hide. Imagine it like cleaning a piece of raw meat before cooking – you wouldn’t start cooking without removing excess fat and connective tissue, right? The same applies to hides.

The process typically uses specialized fleshing machines, which employ rotating blades to efficiently remove the unwanted material. Improper fleshing can lead to uneven stamping, reduced durability of the stamped product, and potentially unpleasant odors.

Its importance lies in:

- Improved Stamping Quality: A clean, even surface ensures a crisp, clear impression and prevents the stamp from sticking or tearing.

- Enhanced Durability: Removal of excess flesh prevents decomposition and prolongs the hide’s lifespan.

- Better Dye Penetration: Proper fleshing allows for consistent dye absorption, creating vibrant and long-lasting colors.

Q 3. How do you identify and grade hides based on quality and defects?

Identifying and grading hides involves a thorough visual inspection and sometimes, the use of specialized tools. We assess the hide based on several factors, just like a gemologist grades a diamond. Each factor is assigned a score, and the overall grade determines the hide’s suitability for specific applications.

- Visual Inspection: We examine the hide for defects like scars, holes, insect damage, grain variations, and uneven thickness.

- Grading Scales: Industry-specific grading scales are used, considering factors like the hide’s area, thickness, and the presence of defects. For example, a common scale might use grades like ‘A’, ‘B’, ‘C’, with ‘A’ representing the highest quality.

- Measuring Instruments: Thickness gauges and area measuring devices ensure consistent and accurate assessment.

- Defect Classification: Defects are categorized by their severity and location, influencing the overall grade and its suitability for certain projects.

For instance, a hide with minor scratches might be graded ‘B’ and suitable for less demanding stamping projects, whereas a hide with numerous large scars would be graded ‘C’ or even rejected for stamping.

Q 4. Describe the different types of hide defects and their impact on stamping.

Several types of hide defects can significantly impact stamping. These flaws can affect the final product’s quality and aesthetics.

- Scars: These can create uneven surfaces, leading to inconsistencies in stamping.

- Holes: Holes of any size compromise the hide’s strength and can cause tearing during stamping.

- Insect Damage: Small holes or tunnels caused by insects weaken the hide and can be visible in the stamped product.

- Grain Variations: Uneven grain structure can lead to inconsistent dye penetration and stamping quality.

- Fleshing Defects: If fleshing is not properly performed, remaining fatty tissue can affect the stamping process and the overall look of the finished product.

The impact of these defects varies. For example, a small scar might be tolerable, while large holes or significant insect damage render the hide unsuitable for high-quality stamping.

Q 5. What are the methods used for cleaning and pre-treating hides before stamping?

Cleaning and pre-treating hides before stamping are vital for optimal results. Think of it as preparing your canvas before painting – a clean surface creates a better result.

Methods include:

- Soaking and Washing: Hides are soaked to soften them and remove dirt, blood, and other impurities. Washing often involves detergents or enzymes to ensure thorough cleaning.

- Dehairing and Defleshing: Specialized machines are used to remove hair and flesh as described earlier.

- Pickling: This involves treating the hide with acid solutions to control pH and prevent bacterial growth.

- Bating: This step utilizes enzymes to soften the hide and make it more receptive to dyes and stamps.

- Neutralization: After pickling, the hides are neutralized to remove residual acid and prepare them for further processing.

The specific methods used depend on the hide’s condition, the desired end product, and the stamping technique employed.

Q 6. How do you ensure the proper thickness and consistency of hides for optimal stamping?

Ensuring proper thickness and consistency is crucial for uniform stamping. This is akin to a baker ensuring the dough is of uniform thickness for consistent baking. Variations in thickness can lead to uneven stamping, breakage, or inconsistencies in the final product.

Methods to achieve this include:

- Hide Selection: Careful selection of hides with consistent thickness, as discussed earlier.

- Splitting: A mechanical process to split thick hides into layers of desired thickness.

- Shaving: Removal of small amounts of material to achieve precise thickness.

- Thickness Measurement: Regular measurements using tools such as thickness gauges are essential during the entire process.

The required thickness varies greatly depending on the stamping design, the desired relief of the stamped image, and the hide type.

Q 7. What are the safety precautions associated with hide handling and preparation?

Safety is paramount in hide handling and preparation. Working with hides involves exposure to sharp tools, chemicals, and potentially hazardous materials. Proper safety measures are crucial.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves, eye protection, and protective clothing to prevent injuries from sharp tools, chemicals, or biological hazards.

- Machine Safety: Proper training and adherence to safety protocols are crucial when operating fleshing machines and other equipment to prevent accidents.

- Chemical Handling: Always follow the manufacturer’s instructions when handling chemicals like acids, bases, and dyes. Ensure adequate ventilation and proper disposal of chemical waste.

- Environmental Safety: Proper disposal of waste materials and the use of environmentally friendly processes are crucial to minimize environmental impact.

- Ergonomics: Pay attention to proper posture and body mechanics to avoid musculoskeletal injuries.

A safe work environment fosters productivity and prevents accidents, ensuring the well-being of workers and maintaining quality control.

Q 8. How do you determine the appropriate stamping pressure for different hide types?

Determining the appropriate stamping pressure for different hide types is crucial for achieving the desired outcome without damaging the material. It’s not a one-size-fits-all approach; it depends on several factors.

- Hide Thickness: Thicker hides require higher pressure to achieve a deep, clear impression. Thinner hides require less pressure to avoid puncturing or tearing. Imagine stamping a thick piece of wood versus a thin sheet of paper; you need more force for the wood.

- Hide Density: Denser hides, like those from older animals, may need more pressure. Less dense hides, such as those from younger animals, might require less.

- Hide Moisture Content: Slightly damp hides are often easier to stamp than completely dry hides. Dry hides can be brittle and more prone to cracking. Too much moisture can lead to uneven stamping and damage.

- Stamp Design: Intricate designs with fine details require more precise, often lower pressure to avoid distortion. Simpler, bolder designs can tolerate higher pressure.

We typically use a pressure gauge integrated into our stamping machines, coupled with trial-and-error adjustments for each batch of hides to find the optimal setting. For example, if we’re working with a batch of thick, dry cowhides, we would start with a higher pressure than what we’d use for thin, pliable calfskin.

Q 9. Explain the process of hide conditioning and its importance in the stamping process.

Hide conditioning is a critical pre-stamping process that ensures the hide is in optimal condition for stamping. This involves a series of steps that prepare the hide for the mechanical stress it will undergo during stamping.

- Soaking: Hides are soaked in water to rehydrate them to an ideal moisture level, making them more pliable and less likely to crack.

- Tannage: This chemical process strengthens and preserves the hide, improving its durability and resistance to damage during stamping.

- Shaving: This process evens out the hide’s thickness for consistent stamping, removing any uneven parts that could cause problems.

- Fleshing: This removes any remaining fatty tissue or flesh from the hide, leaving a clean, smooth surface for stamping.

- Buffing/Sanding: This smooths the grain side of the leather to eliminate imperfections and ensure consistent imprint of the stamp.

Proper conditioning not only prevents damage during stamping but also leads to a cleaner, more consistent final product. Imagine trying to stamp a dry, brittle leaf versus a soft, damp one – the results would be drastically different.

Q 10. How do you manage and minimize waste during hide selection and preparation?

Waste management is a key aspect of sustainable leather production. We employ several strategies to minimize waste during hide selection and preparation:

- Careful Selection: We carefully inspect each hide for defects like scars, cuts, and holes. Hides with significant defects are earmarked for alternative uses (like trimmings for smaller leather goods) reducing the number that end up as total waste.

- Optimized Cutting Patterns: Computer-aided design (CAD) software helps us create cutting patterns that maximize the yield from each hide, minimizing waste from trimming. This is like using a jigsaw puzzle to get the most pieces out of a given shape.

- Recycling and Repurposing: Scraps and trimmings are collected and repurposed for other leather goods, or sometimes even sold to smaller businesses for various applications. Nothing goes to waste if we can help it.

- Wastewater Treatment: We have a robust wastewater treatment system that filters and treats water used in the tanning and cleaning processes, reducing environmental impact.

Regular monitoring of our waste output and continuous improvement strategies allow us to optimize resource usage and meet environmental sustainability goals. We constantly track our waste generation to identify areas where we can improve efficiency.

Q 11. Describe your experience with different types of stamping machinery.

My experience encompasses a range of stamping machinery, from traditional hand-operated presses to automated, high-speed systems. Each has its strengths and weaknesses.

- Hand-operated Presses: Ideal for smaller-scale operations or specialized, intricate designs, offering great control and precision. However, they’re labor-intensive and less efficient for large-scale production.

- Pneumatic Presses: These use compressed air to power the stamping action, offering more force and speed than hand-operated presses. They’re more efficient for medium-scale production runs.

- Hydraulic Presses: Employ hydraulic systems to generate extremely high pressure, suitable for thick hides and larger stamping areas. They are best suited for high-volume, heavy-duty applications.

- Automated Stamping Lines: These fully automated systems integrate multiple processes, from hide feeding to final product stacking. They’re highly efficient for mass production but require a substantial initial investment.

I’ve worked extensively with both pneumatic and hydraulic presses, and I’m familiar with the maintenance and operation of automated lines, allowing me to adapt to diverse production needs and optimize the stamping process for maximum efficiency and product quality.

Q 12. What are the common problems encountered during hide preparation and how do you resolve them?

Common problems encountered during hide preparation include:

- Uneven Hide Thickness: This leads to inconsistent stamping depth. Solution: Precise shaving and careful selection of hides.

- Hide Damage (tears, cuts): This renders the hide unusable for stamping. Solution: Careful handling and improved inspection procedures.

- Insufficient Moisture Content: Dry hides are brittle and prone to cracking. Solution: Optimized soaking procedures to achieve the ideal moisture level.

- Contamination: Dirt and debris can interfere with the stamping process and mar the final product. Solution: Thorough cleaning and sanitation procedures.

- Inconsistent Tannage: Unevenly tanned hides are prone to variations in color and texture after stamping. Solution: Improved tanning processes and quality control.

We address these problems through a combination of preventative measures – such as rigorous quality checks at each stage – and corrective actions when problems do arise, ensuring consistent high quality.

Q 13. How do you maintain the quality and consistency of stamped leather products?

Maintaining the quality and consistency of stamped leather products requires attention to detail at every stage of the process.

- Quality Control Checks: Regular inspections of the hides, the stamping process, and the finished products are essential. This includes checking for defects, inconsistencies in stamping depth, and color variations.

- Calibration and Maintenance: Regular calibration of stamping machines ensures consistent pressure and accurate stamping. Proper maintenance minimizes downtime and ensures the equipment is functioning optimally.

- Consistent Materials and Processes: Using consistent types of hides, inks, and stamping techniques ensures uniformity in the final product. Any changes should be carefully documented and controlled.

- Environmental Control: Factors like temperature and humidity can affect the leather and the stamping process. Maintaining a controlled environment ensures consistent results.

By establishing and adhering to strict quality control protocols and maintaining our equipment, we can consistently produce high-quality, uniform stamped leather products that meet the standards we set.

Q 14. How do you ensure the efficient workflow in hide selection and preparation?

Efficient workflow in hide selection and preparation is essential for maximizing productivity and minimizing costs. This requires careful planning and coordination.

- Lean Manufacturing Principles: We apply lean principles to eliminate waste and optimize workflow. This includes streamlining processes, minimizing handling, and reducing lead times.

- Process Mapping and Optimization: Regularly reviewing and optimizing the process flow helps to identify bottlenecks and inefficiencies. This might involve rearranging workspaces or redesigning certain steps.

- Proper Equipment and Tools: Having the right tools and equipment for each stage of the process – from hide inspection to cleaning – significantly improves efficiency.

- Cross-Training of Staff: Cross-trained staff can perform multiple tasks, increasing flexibility and reducing downtime due to absenteeism or specialized skill shortages.

- Inventory Management: Careful management of hide inventory ensures a steady supply of materials, preventing delays or shortages that could disrupt the workflow.

By implementing these strategies, we ensure a smooth and efficient workflow that consistently delivers high-quality products on time and within budget. It’s about thinking of the entire process as an interconnected system.

Q 15. What are the different types of hides used in stamping and their properties?

The type of hide used significantly impacts the final stamped product’s quality and characteristics. We primarily work with bovine (cow), ovine (sheep), and caprine (goat) hides. Each has unique properties:

- Bovine Hides: These are the most common, known for their thickness, strength, and relatively large surface area, ideal for larger stamped items. Their grain (outer layer) can vary in texture, impacting the final look. Some bovine hides are specifically bred for their fine grain and are more expensive.

- Ovine Hides: These are thinner and more delicate than bovine hides, offering a softer feel and are often used for smaller, more intricate stamped designs where flexibility is crucial. They are also more prone to tearing during the stamping process, demanding extra care.

- Caprine Hides: Similar to ovine hides in terms of thickness and softness, caprine hides offer a unique grain pattern and are sometimes preferred for specific aesthetic effects in stamping. They require similar careful handling to ovine hides.

Understanding these differences allows us to choose the appropriate hide for the desired final product and stamping technique, optimizing both quality and cost-effectiveness.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different hide treatment chemicals and their applications.

Hide treatment is crucial for ensuring the hides are suitable for stamping. My experience encompasses a wide range of chemicals, each with specific applications:

- Soaking and Cleaning: We use enzymatic solutions to remove dirt, blood, and other contaminants. This step is vital for preventing bacterial growth and ensuring a clean base for further processing. Incorrect soaking can lead to hide damage.

- Bating: This process uses enzymes to soften the hide’s connective tissue, making it more pliable and receptive to stamping. The type of enzyme and its concentration must be carefully controlled to avoid over-softening or under-softening.

- Pickling: Acid solutions (often sulfuric acid) are used to adjust the pH of the hide, preparing it for tanning. This step is critical for the hide’s subsequent durability.

- Tanning: This crucial step converts the hide from a perishable material into a durable leather. We utilize both chrome and vegetable tanning methods, selecting the appropriate one based on the specific requirements of the final product. Chrome tanning offers greater durability, while vegetable tanning yields a more natural look and feel but may be less durable.

- Finishing: Various chemicals are employed to achieve the desired surface finish, including dyes, pigments, and coatings. The selection depends on the aesthetic requirements and intended use of the stamped product.

Precise control over the concentration and application of these chemicals is paramount, as incorrect usage can damage the hide and affect the quality of the stamped product. We have strict protocols and regular quality checks in place to maintain consistency and prevent inconsistencies.

Q 17. How do you manage inventory of hides effectively?

Effective hide inventory management is critical for maintaining smooth operations and minimizing waste. We employ a First-In, First-Out (FIFO) system, ensuring that older hides are processed first to prevent spoilage. This is particularly important considering hides are a perishable commodity.

Our inventory tracking system utilizes barcodes and a dedicated database, allowing us to monitor each hide’s origin, processing stage, and quality attributes. This allows for efficient stock rotation and timely identification of any potential problems. We regularly conduct physical inventory checks to validate our database records and identify any discrepancies.

Predictive modelling, based on past consumption and anticipated orders, helps us optimize our purchasing and storage strategies. This approach reduces storage costs while minimizing the risk of stockouts.

Q 18. How do you inspect hides for diseases or other health issues?

Inspecting hides for diseases or health issues is a crucial step, both for quality control and to prevent the spread of infectious agents. The inspection process typically begins at the receiving stage.

We meticulously examine each hide for any signs of disease, including:

- Physical signs: Scars, lesions, punctures, unusual discoloration, and abnormal thickness.

- Smell: An unpleasant or unusual odor can indicate bacterial contamination or decomposition.

- Visual Inspection: Checking for evidence of parasites or other infestations.

Any hide showing signs of disease or damage is immediately quarantined and disposed of according to established safety protocols to prevent cross-contamination and ensure the health and safety of our employees. Regular training and adherence to strict guidelines are implemented to maintain a consistently high standard of inspection.

Q 19. What are the environmental considerations in hide processing?

Environmental sustainability is a top priority in our hide processing operations. We aim to minimize our environmental footprint by:

- Wastewater Treatment: Implementing robust wastewater treatment systems to remove pollutants before discharge. This involves biological treatment processes followed by filtration to meet regulatory standards.

- Waste Management: Implementing effective waste management strategies for solid waste materials (e.g., trimmings, offcuts) including recycling or responsible disposal.

- Energy Efficiency: Using energy-efficient equipment and processes to reduce energy consumption and greenhouse gas emissions.

- Chemical Management: Careful selection and responsible handling of chemicals, aiming for low-impact alternatives and minimizing waste generation.

Regular audits and compliance with environmental regulations are integral to our operations, and we actively seek opportunities to improve our environmental performance.

Q 20. What is your experience with quality control procedures for hides?

Quality control is a continuous process, beginning with hide selection and extending throughout the entire processing chain. Our procedures encompass:

- Incoming Inspection: Rigorous checks on received hides for quality, disease, and damage.

- In-Process Control: Regular monitoring of various parameters at each stage of processing, including pH, temperature, and chemical concentrations.

- Sampling and Testing: Random sampling of hides at different stages to verify compliance with quality standards.

- Final Inspection: A thorough inspection of finished hides to assess their physical properties, surface quality, and adherence to specifications.

- Documentation: Detailed records are maintained for each hide, tracking its journey through the entire process and providing traceability.

We use statistical process control (SPC) techniques to monitor and control process variability, ensuring consistent product quality. Our quality control system aims for zero defects and prompt corrective action for any identified non-conformances.

Q 21. How do you handle and resolve customer complaints regarding hide quality?

Customer satisfaction is paramount. When handling customer complaints regarding hide quality, we follow a systematic approach:

- Acknowledge and Investigate: We promptly acknowledge the complaint and thoroughly investigate the issue, gathering all relevant information.

- Analyze the Complaint: We analyze the complaint to identify the root cause of the problem, determining whether it stems from hide defects, processing errors, or other factors.

- Develop a Solution: Based on the root cause analysis, we develop a suitable solution that satisfies the customer, whether it’s a replacement, refund, or a revised processing procedure.

- Implement Corrective Actions: If the complaint reveals a process flaw, we implement corrective and preventative actions to prevent similar issues from recurring.

- Follow-up: We follow up with the customer to ensure their satisfaction and to confirm that the issue has been effectively resolved. We also use customer feedback to improve our quality control procedures.

Our goal is to turn negative experiences into opportunities for improvement and to maintain strong, trusting relationships with our customers.

Q 22. Describe your experience with different types of stamping dies.

My experience encompasses a wide range of stamping dies, from simple, single-piece dies used for basic branding to complex, multi-part dies capable of intricate designs and embossing. I’m familiar with dies made from various materials, including hardened steel, tool steel, and even tungsten carbide for extremely durable applications. The choice of die material depends heavily on the hide’s thickness, desired design complexity, and the expected production volume. For example, a simple logo on thin leather might use a hardened steel die, while a detailed embossed pattern on thick hides would require a more robust tungsten carbide die to prevent premature wear.

- Single-piece dies: These are simpler, less expensive, and suitable for basic stamping. Think of a simple company logo pressed onto a wallet.

- Multi-piece dies: These allow for more complex designs, including multiple levels of depth and texture. This is commonly seen in intricate patterns on high-end leather goods.

- Rule dies: Used for creating repetitive patterns, often seen in decorative elements on upholstery or belts.

Beyond material, I understand the importance of die maintenance, including sharpening, cleaning, and proper storage to prolong their lifespan and ensure consistent stamping quality. A dull die will lead to inconsistent impressions, potentially damaging the hides and wasting materials.

Q 23. Explain the role of temperature and humidity in hide preparation.

Temperature and humidity play a crucial role in hide preparation, significantly impacting its pliability and suitability for stamping. Imagine trying to stamp a dry, brittle piece of leather – it’s likely to crack! Conversely, a hide that’s too wet will be difficult to handle and might not receive a clean impression.

Ideal conditions usually involve a controlled environment with moderate temperature and humidity levels. Too much humidity can lead to mold growth and deterioration, while low humidity results in a stiff, inflexible hide prone to cracking. The specific ideal range varies depending on the type of hide and the intended stamping process but is often maintained within a specific range – such as 65-75°F and 40-60% relative humidity.

We use hygrometers and thermometers to constantly monitor conditions and adjust them as needed, often through climate control systems (HVAC) and humidity regulation. Prior to stamping, the hides are often conditioned to reach the optimal moisture content for the best stamping results.

Q 24. How do you troubleshoot problems with stamping machines?

Troubleshooting stamping machines requires a systematic approach. I typically start by visually inspecting the machine for any obvious issues like loose parts, damaged components, or obstructions. Then, I check the die itself for wear, damage, or misalignment. A misaligned die will cause inconsistent stamping, while a worn die will produce blurry or incomplete impressions. Further troubleshooting might involve checking the machine’s power supply, hydraulics (if applicable), and control systems.

Here’s a step-by-step approach I follow:

- Visual inspection: Look for loose connections, damaged parts, or any signs of wear.

- Die inspection: Check the die for damage, wear, or misalignment. Replace or repair as needed.

- Pressure check: Verify that the stamping pressure is properly calibrated. Inconsistent pressure can lead to uneven impressions.

- Hydraulic system check (if applicable): Check for leaks, low fluid levels, or other issues within the hydraulic system.

- Electrical system check: Ensure power supply is stable and check for faulty wiring or components.

- Testing: After making adjustments, test the machine with a sample hide to ensure the problem is resolved.

Detailed records are kept on all maintenance and repairs conducted on the stamping machines. This allows us to track performance, predict potential issues, and optimize maintenance schedules.

Q 25. What are the regulatory requirements related to hide handling and processing?

Hide handling and processing are subject to various regulations, primarily focused on worker safety, environmental protection, and the prevention of disease transmission. These regulations vary depending on location and often involve permits, licensing, and adherence to specific handling procedures. For example, regulations might specify:

- Waste disposal: Proper disposal of waste materials, such as scraps and contaminated water.

- Chemical handling: Safe storage and handling of chemicals used in tanning and other processing steps.

- Personal protective equipment (PPE): Mandatory use of PPE to protect workers from hazards.

- Worker safety: Safe operating procedures for machinery and equipment.

- Traceability: Maintaining accurate records of hide origin and processing to ensure compliance and prevent fraudulent activities.

We comply strictly with all relevant regulations, maintaining up-to-date documentation and undergoing regular inspections to ensure our operations are fully compliant. Failure to comply can result in substantial fines and legal repercussions.

Q 26. How do you maintain hygiene and cleanliness in the hide preparation area?

Maintaining hygiene and cleanliness is paramount in hide preparation. Contamination can lead to spoilage, damage the hides, and create health hazards for workers. Our procedures include:

- Regular cleaning: Daily cleaning of all work surfaces, equipment, and tools using appropriate disinfectants.

- Waste disposal: Immediate and proper disposal of waste materials to prevent contamination.

- Pest control: Regular pest control measures to prevent infestations.

- Personal hygiene: Strict adherence to personal hygiene protocols by all personnel.

- Protective clothing: Use of appropriate protective clothing, including gloves and aprons, to prevent contamination and protect workers.

We also implement a rigorous cleaning schedule after each batch of hides is processed. This includes thorough cleaning of all stamping dies and machinery to remove any residual hide particles or contaminants.

Q 27. What are your methods for tracking and tracing hides throughout the process?

We employ a robust tracking and tracing system for hides throughout the entire process, using a combination of barcode scanning and specialized software. Each hide is assigned a unique identification number at the point of receipt. This number is then tracked through every stage of preparation, stamping, and packaging. We utilize barcode scanners at each stage to record the movements and processing of the hides. This system helps to ensure accuracy and prevent any errors or mix-ups.

The software we use integrates with our ERP system, which allows us to maintain a comprehensive database of all hide movements and processing details. This facilitates efficient inventory management, quality control, and provides a detailed audit trail for regulatory compliance.

This traceability is not only important for efficient operations but also for addressing potential issues, such as identifying the source of a damaged hide or tracking the origins of a batch for recall purposes (if necessary).

Q 28. Describe your experience with different software used in hide management and production.

My experience includes working with various software applications designed for hide management and production. This includes ERP (Enterprise Resource Planning) systems for managing inventory, production scheduling, and tracking costs, and specialized software packages for managing the workflow from hide receiving to finished goods. We also utilize quality control software for monitoring and analyzing data collected during each stage of the process, enabling us to identify and address potential quality issues early on.

Examples of software I have experience with include [Mention Specific ERP and Hide Management Software Names if possible – avoiding specifics to protect proprietary information is also acceptable, substitute with general examples such as ‘Industry-standard ERP system X’ and ‘Hide Management Software Y’]. These systems offer valuable tools for optimizing the overall process, improving efficiency, and ensuring the highest quality product.

Key Topics to Learn for Hide Selection and Preparation for Stamping Interview

- Hide Assessment and Grading: Understanding different hide qualities (thickness, grain, defects), and methods for grading hides based on industry standards. This includes practical knowledge of visual inspection and potential use of measuring tools.

- Preparation Techniques: Familiarize yourself with various pre-treatment processes like soaking, fleshing, and liming. Understand the impact of each process on hide quality and the final stamped product. Be prepared to discuss the challenges and solutions associated with each step.

- Defect Identification and Remediation: Learn to identify common hide defects (e.g., scars, holes, wrinkles) and explain strategies for minimizing their impact on the stamping process. This might include trimming, patching, or selecting alternative hide sections.

- Material Selection for Stamping: Understand the relationship between hide characteristics and the suitability for different stamping techniques and designs. Consider factors like hide thickness, flexibility, and grain pattern.

- Process Optimization: Discuss strategies for improving efficiency and reducing waste in the hide selection and preparation process. This could include waste reduction techniques, process flow optimization, and the implementation of quality control measures.

- Safety and Regulatory Compliance: Demonstrate awareness of safety protocols and industry regulations concerning hide handling, chemical usage, and waste disposal.

- Technological Advancements: Research and understand any modern technologies or automated systems used in hide selection and preparation (e.g., automated grading systems, robotic fleshing machines).

Next Steps

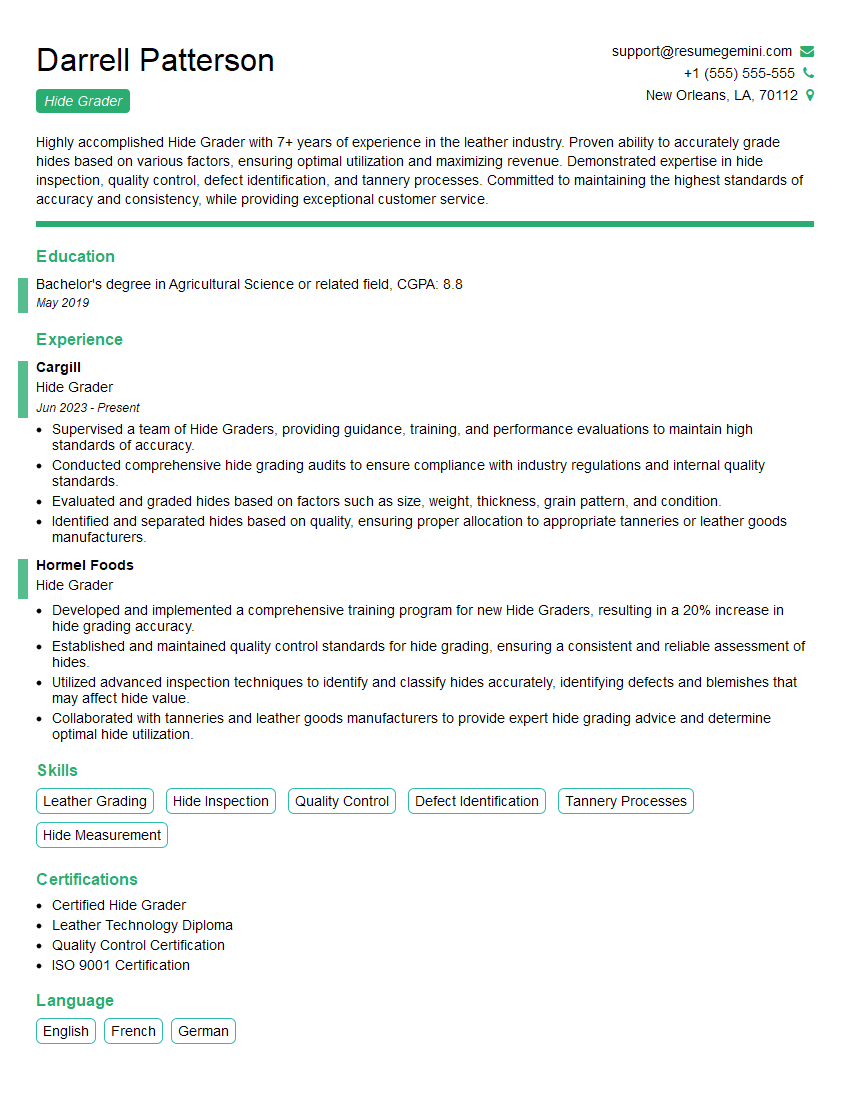

Mastering Hide Selection and Preparation for Stamping is crucial for career advancement in the leather industry, opening doors to specialized roles and increased earning potential. A strong understanding of these processes demonstrates valuable skills in quality control, efficiency, and material science. To maximize your job prospects, create an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume that grabs the attention of recruiters. Examples of resumes tailored to Hide Selection and Preparation for Stamping are available to further guide your preparation.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good