Cracking a skill-specific interview, like one for Hide Trimming, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Hide Trimming Interview

Q 1. Describe your experience with different types of hides (e.g., cowhide, sheepskin).

My experience encompasses a wide range of hides, primarily cowhide and sheepskin, but also including goat, pig, and even some more exotic options. Cowhide, the most common, presents unique challenges due to its thickness and variations in texture. I’ve worked with everything from heavy-duty hides destined for upholstery to thinner, more delicate hides intended for leather goods. Sheepskin, on the other hand, is much finer and requires a gentler approach to trimming. Its variations in density and the presence of wool also necessitate specialized techniques. Understanding these differences is crucial for achieving the best possible outcome. For example, a heavy-duty trimming tool might damage a delicate sheepskin, while a gentle touch might not be sufficient for removing defects from thick cowhide. Each hide type demands a tailored approach, adapting both tool selection and trimming intensity.

Q 2. What are the common defects found in hides that require trimming?

Common defects requiring trimming include:

- Holes and Tears: These can range from small punctures to large tears, often caused during the animal’s life or the flaying process.

- Scars and Brand Marks: Scars left by injuries and brand marks from cattle ranches can affect the hide’s aesthetic quality.

- Insect Bites and Damage: Holes and damaged areas resulting from insect infestations.

- Grub Holes: Small, round holes created by insect larvae.

- Flesh and Fat Attachments: Excess flesh or fat adhering to the hide.

- Damaged Edges: Frayed or uneven edges from the flaying process.

- Stretches and Wrinkles: Areas of the hide that are uneven, making for less uniform leather products.

Identifying and addressing these defects efficiently and precisely is critical for maximizing the usable area of the hide and preserving its value.

Q 3. Explain your knowledge of various trimming tools and their applications.

My expertise spans various trimming tools, each with specific applications:

- Hand Trimming Knives: These offer precision and control, ideal for detailed work on delicate hides or around intricate defects. I use different blade types based on the hide and the specific task, from smaller curved blades for fine work to larger, straighter blades for removing larger sections.

- Rotary Trimming Machines: These increase efficiency significantly for large-scale trimming, particularly with heavy hides. Different blade configurations (e.g., circular knives, oscillating blades) are used to manage different hide thickness and textures. They require skillful operation to maintain consistent quality and avoid damaging the hide. I routinely adjust the cutting depth and speed to suit each specific situation.

- Shears: These are useful for trimming edges, removing loose pieces, and performing finer detail work. I frequently use these in conjunction with knives and rotary machines.

- Automated Trimming Systems (if applicable): Advanced technologies utilize computer vision and automated cutting mechanisms for high-volume trimming operations, guaranteeing consistency and speed. While I haven’t had extensive experience with these, I’m familiar with their functionalities and potential benefits.

Selecting the right tool depends on the hide’s type, the nature of the defects, the desired level of precision, and the scale of the operation.

Q 4. How do you ensure consistent quality in hide trimming?

Consistent quality in hide trimming relies on a multi-faceted approach:

- Standardized Procedures: Adhering to pre-defined trimming guidelines for each hide type and defect ensures uniformity. This includes detailed instructions for trimming margins, tool selection, and techniques.

- Regular Tool Maintenance: Sharply honed knives and well-maintained machines are essential for clean, precise cuts and prevent damage to the hide. I frequently inspect and sharpen my tools and perform routine maintenance on the rotary machines.

- Quality Control Checks: Regular inspections during and after trimming, often involving multiple team members, guarantee adherence to standards and early detection of issues. A second pair of eyes often catches flaws that I might miss, which enhances overall quality.

- Operator Training and Skill Development: Experienced and well-trained personnel are crucial for consistent results. I regularly participate in training sessions to enhance my skills and stay updated on best practices.

- Consistent Work Environment: Maintaining a well-lit and organized workspace contributes to increased accuracy and reduces errors.

By focusing on these aspects, we minimize variations in the trimming process, leading to a consistent output that meets our quality standards.

Q 5. What are the safety procedures you follow while using trimming tools?

Safety is paramount in hide trimming. My procedures include:

- Proper Personal Protective Equipment (PPE): This includes cut-resistant gloves, safety glasses, and close-toed shoes at a minimum. For machine trimming, I also use hearing protection.

- Safe Tool Handling: I always handle knives and other sharp tools with care, ensuring they are stored safely when not in use. I never leave tools unattended.

- Machine Safety Procedures: When using rotary machines, I strictly follow all manufacturer’s safety guidelines, including proper locking mechanisms and emergency stop procedures. Regular machine inspections are part of our safety protocols.

- Regular Training: Safety training is mandatory, and I participate regularly to stay up-to-date on safe operating procedures.

- Clean Workspace: Maintaining a clean and organized workspace helps reduce the risk of accidents. We dispose of sharp objects properly and regularly clean the equipment.

Safety is not just a procedure; it’s an ingrained mindset, and it’s everyone’s responsibility to ensure a safe work environment.

Q 6. How do you determine the appropriate trimming margin for different hide sections?

Determining appropriate trimming margins depends on several factors:

- Hide Section: Different parts of the hide have varying quality and thickness. For example, the belly area often requires more trimming due to thinner leather and more defects, while the butt area might have less trimming due to its thicker and more uniform nature.

- Defect Severity: The size and type of defect dictate the necessary margin. A small scar may only require a narrow trim, while a large tear would require a wider margin to remove the affected area completely.

- End Use: The intended application of the leather influences the trimming margin. Leather for high-quality shoes might have tighter trimming tolerances compared to leather for upholstery where minor imperfections might be less critical.

- Hide Quality Grade: Higher-grade hides generally allow for tighter trimming margins since they have fewer defects.

It’s often a balancing act between maximizing usable leather and ensuring the final product meets quality standards. Experience plays a critical role in making these judgment calls. I use templates and visual guides to ensure consistency in trimming margins across similar defects. Also, regular inspection and feedback helps refine this process.

Q 7. Describe your experience with different trimming techniques (e.g., hand trimming, machine trimming).

I’m proficient in both hand trimming and machine trimming techniques.

Hand trimming requires precision and a keen eye for detail. It’s indispensable for delicate hides or when dealing with complex defects requiring fine control. This method allows for a personalized and highly adaptable approach, enabling corrections and adjustments as needed throughout the process. For example, I might use hand trimming to carefully remove a scar while preserving as much of the surrounding undamaged hide as possible.

Machine trimming offers significant speed advantages, especially for high-volume production or trimming large, heavy hides. However, it demands expertise in machine operation and adjustments to guarantee consistent quality and prevent damage. It is essential to select the right blade configuration and cutting parameters according to the hide type and thickness. The risk of accidental cuts and inconsistencies is higher with machine trimming, which emphasizes the importance of worker training and regular equipment maintenance.

Often, I combine both techniques. I might use a machine to quickly trim large areas, followed by hand trimming for precision work around complex defects or to refine the edges.

Q 8. How do you handle damaged or irregular hides during trimming?

Handling damaged or irregular hides requires a careful and adaptable approach. My strategy focuses on assessing the damage first – is it a small hole, a large tear, or a significant area of scarring? For minor imperfections, like small holes, I might strategically trim around them, minimizing waste and preserving as much usable hide as possible. Think of it like sculpting – you’re working with a material that has its own unique challenges and possibilities. For larger tears or damaged sections, I’ll carefully assess if the damage compromises the structural integrity or quality of the hide to the point of making it unusable. If the damaged portion can be removed without significantly impacting the usable area, I’ll proceed with a clean, precise cut around the damaged area. If the damage renders it unusable, I’ll separate it and flag it accordingly, for further inspection and determination of whether it can be salvaged for other purposes. The goal is always to maximize yield while maintaining the quality standards of the finished product.

Q 9. What is your process for identifying and removing imperfections without damaging the hide?

Identifying and removing imperfections is a crucial step, demanding a keen eye and steady hand. I begin by carefully inspecting the entire hide, looking for anything from small blemishes and scratches to larger flaws such as holes, cuts, or insect damage. I use good lighting, often supplemented with a magnifying glass for close inspection, particularly in areas with complex markings or color variations. My method involves using a combination of visual inspection and touch. Feeling the hide helps me to understand its thickness and any subtle changes in texture which may indicate underlying problems. When removing imperfections, I use sharp, specialized trimming tools to make precise cuts, being very careful not to create more damage or alter the natural shape of the hide unnecessarily. I always start with a small cut, checking and readjusting as I go, rather than attempting to cut away the imperfection in one stroke. This minimizes risk and allows for greater control. Imagine you’re removing a stain from delicate fabric – you wouldn’t just scrub aggressively; you would be gentle and precise.

Q 10. How do you maintain the sharpness and efficiency of your trimming tools?

Maintaining the sharpness and efficiency of my trimming tools is paramount. Dull tools lead to imprecise cuts, increased risk of damage to the hide, and ultimately, a lower-quality final product. My process involves regular sharpening and cleaning of my knives and shears after each use. I use high-quality sharpening stones, following a systematic process to achieve the perfect edge. This involves multiple passes at different angles, ensuring a consistent sharpness across the blade. After sharpening, I carefully clean the tools to remove any remaining hide particles or residue, preventing corrosion and maintaining hygiene. I also store my tools properly – in a protective case or sheath, away from moisture and extreme temperatures. Regular maintenance of my tools is just as important as the skill I use to wield them. It is a matter of efficiency and prevents the need for expensive tool replacements.

Q 11. Describe your experience working with various types of knives or shears.

My experience spans a wide range of knives and shears, each suited to specific tasks in hide trimming. I’m proficient with various types of trimming knives, including those with curved blades for following contours and straight blades for precise cuts. I also use specialized shears for trimming delicate areas or larger sections, depending on the hide’s thickness and the specific trimming requirements. The choice of tool depends on the hide’s characteristics, the type of imperfection, and the desired outcome. For example, a curved knife works well for trimming around irregular shapes, while straight shears are ideal for making clean, straight cuts on thick, flat areas. Experience has taught me the nuances of each type of tool, helping me select the right instrument for the job at hand.

Q 12. What are the key quality control checkpoints in your hide trimming process?

Quality control is an ongoing process, not just a final check. My key checkpoints include:

- Initial Inspection: A thorough assessment of the hide before trimming to identify any major flaws or areas needing special attention.

- Trimming Process: Maintaining consistency in cuts, avoiding ragged edges and ensuring precise removal of imperfections.

- Regular checks for tool sharpness: Dull tools lead to uneven cuts and damage.

- Intermediate inspection: Checking the hide’s progress during trimming to correct any mistakes or inconsistencies immediately.

- Final Inspection: A complete evaluation of the trimmed hide to ensure it meets quality standards, including checking for evenness, consistency, and absence of any remaining imperfections.

Q 13. Explain how you identify and address inconsistencies in hide thickness or texture.

Inconsistencies in hide thickness or texture are addressed through careful trimming and selection. I use my knowledge and experience to identify areas of varying thickness or texture. If the variation is minimal and doesn’t compromise the hide’s usability, I might simply adjust my trimming technique to compensate. However, in cases of significant inconsistencies, I will often prioritize preserving the areas of better quality while carefully removing or reducing those sections that don’t meet the desired specifications. This could involve trimming away thin or excessively thick sections to achieve a more even final product. In cases of severe inconsistencies, the hide might be graded differently to reflect its varying quality. The goal is to maximize the usable portion while meeting specific quality standards. Think of it like tailoring a garment – you wouldn’t use a piece of uneven fabric for a critical part of the design.

Q 14. How do you manage your workload to meet production deadlines?

Managing workload effectively involves careful planning and prioritization. I start by assessing the number and type of hides that need processing, and then create a schedule that accounts for the complexity of each hide. I prioritize tasks based on deadlines and the level of expertise required. This means that I may tackle the most challenging hides earlier in the day when my energy levels are high and my concentration is optimal. I also use time management techniques, like breaking down large tasks into smaller, manageable steps, to avoid feeling overwhelmed. This allows for regular breaks and prevents burnout. Moreover, I maintain clear communication with my colleagues to ensure efficient workflow and collaboration, and I regularly monitor progress against deadlines, making adjustments as needed to stay on track. Consistent, efficient work habits are essential to meeting production targets without sacrificing quality.

Q 15. How do you ensure accurate and efficient material handling during trimming?

Accurate and efficient material handling in hide trimming is crucial for maximizing yield and minimizing damage. It starts with proper hide receiving – ensuring hides are inspected for defects and correctly identified before processing. We use specialized racking systems to store hides safely, preventing damage and facilitating easy access during trimming. Efficient handling involves employing ergonomic techniques to avoid repetitive strain injuries. For instance, we utilize conveyors and specialized lifting equipment for heavier hides. This minimizes physical strain on workers and ensures consistent processing speed. Finally, meticulous organization and clear labeling prevent mix-ups, ensuring the right hides are processed for the intended product. Think of it like a well-oiled machine: each step is carefully planned and executed to maximize throughput and minimize waste.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe a time you had to troubleshoot a problem during hide trimming.

During a large order of calfskin hides, we encountered an unusually high rate of knife blade dulling. This significantly slowed down the trimming process and increased the risk of inconsistent cuts. Initially, we suspected the hide quality, but after carefully inspecting the hides, we ruled that out. My troubleshooting involved systematically investigating the potential causes: blade sharpness, cutting pressure, and hide preparation methods. We tested different blade sharpening techniques and found that our standard procedure wasn’t removing enough burrs. Implementing a revised sharpening protocol – including more frequent honing and stropping – dramatically improved blade life and consistency. This highlights the importance of systematically investigating potential causes, from the obvious to the less apparent, when troubleshooting in a production environment.

Q 17. How do you work effectively as part of a team in a fast-paced production environment?

In a fast-paced hide trimming environment, teamwork is paramount. We utilize a system of cross-training and shared responsibility. Every team member is proficient in multiple trimming tasks, allowing for seamless coverage during absences or peak production periods. Clear communication is key; we use visual cues and standardized procedures to minimize miscommunication. Regular team meetings allow us to address challenges, share best practices, and ensure everyone feels involved in the process. A collaborative spirit is encouraged, fostering an environment where everyone feels comfortable sharing ideas and providing support to their colleagues. This collaborative approach ensures smoother workflows and a higher quality product. It’s like a sports team – each member plays a crucial role and depends on the others to achieve a common goal.

Q 18. What are your strategies for minimizing waste during hide trimming?

Minimizing waste in hide trimming involves several strategies. Firstly, precise cutting techniques, achieved through training and the use of precision tools, minimize material loss. Secondly, we optimize hide layout to maximize the yield from each piece. This involves strategically planning cuts to prioritize larger, high-value pieces. Thirdly, we meticulously inspect hides for defects and sort them accordingly to utilize even imperfect sections for lower-grade products. Finally, we implement a rigorous quality control system that monitors waste and identifies areas for improvement. For instance, we regularly track waste-to-yield ratios for different hide types and trimming methods to continually refine our processes. It’s all about being resourceful and maximizing the usable portion of each hide.

Q 19. How do you stay up-to-date on industry best practices for hide trimming?

Staying current with industry best practices is crucial in hide trimming. I regularly attend industry conferences and workshops to learn about new techniques and technologies. I subscribe to relevant trade publications and online journals to stay informed about advancements in equipment, cutting methods, and quality control. I also participate in professional organizations that foster collaboration and knowledge sharing within the leather industry. Additionally, I actively seek out opportunities for continuing education, such as online courses and training programs, to enhance my skills and keep abreast of emerging trends. Staying updated allows us to optimize our processes, enhance product quality, and maintain competitiveness.

Q 20. Describe your experience with different types of hide finishing techniques.

My experience encompasses various hide finishing techniques, from traditional hand-trimming to automated systems. I’m proficient in different trimming styles based on the specific requirements of the final product, like wet-blue trimming, crust trimming, and finished leather trimming. I’m also familiar with various finishing techniques like splitting, shaving, buffing, and embossing. Each technique requires a different approach and skill set, and I’ve honed my expertise in adapting my methods depending on the hide type, desired thickness, and final application. For example, handling delicate calfskin requires a lighter touch and sharper tools than trimming a robust cowhide. Understanding these nuances is critical for producing high-quality, consistent results.

Q 21. How do you understand and interpret hide grading standards?

Understanding and interpreting hide grading standards is fundamental to ensuring consistent quality and fair pricing. Hide grading systems assess various factors like hide size, thickness, defects (scars, brands, etc.), and overall quality. This involves understanding different grading scales and their criteria, such as the USDA hide grading system or other industry-specific standards. I can accurately assess hides according to these standards, identifying their quality level and categorizing them accordingly for optimal use in different applications. This knowledge is vital for accurate costing, material selection, and meeting customer specifications. It’s like assessing the quality of a gemstone; understanding its characteristics and grades allows for appropriate pricing and application.

Q 22. What are the common challenges encountered in hide trimming, and how do you address them?

Hide trimming presents several challenges. One major hurdle is irregular hide shapes and sizes. Animals aren’t perfectly uniform, leading to inconsistencies that require skilled manual adjustments. Another is dealing with varying hide thicknesses and textures; thicker areas might require more aggressive trimming, while delicate parts need careful handling to avoid damage. Contamination, such as dirt, blood, or insect damage, can also complicate the process. Finally, meeting precise specifications for different end-products can be demanding. We address these challenges using a multi-pronged approach: precise, high-quality cutting tools; careful visual inspection and hand-trimming for irregular areas; specialized techniques for handling different hide types; and consistent adherence to quality control measures throughout the process. For example, we use different blade angles and pressures when trimming a thick cowhide versus a delicate lambskin. For contamination, pre-trimming cleaning is crucial.

Q 23. Describe your understanding of the importance of hygiene and sanitation in hide trimming.

Hygiene and sanitation are paramount in hide trimming. Poor hygiene can lead to bacterial contamination, spoilage, and ultimately, a lower-quality final product. This also poses a health risk to workers. Our procedures always begin with thoroughly cleaning the workspace and equipment. We use sanitized tools and surfaces. Regular handwashing with appropriate disinfectants is mandatory. Waste is disposed of properly to prevent attracting pests or contaminating the environment. Think of it like preparing a surgical field—every step is meticulously clean to ensure the integrity and safety of the process. We also regularly inspect our equipment to ensure no bacteria can build up.

Q 24. Explain your knowledge of different hide types and their specific trimming requirements.

Different hides have unique characteristics affecting trimming requirements. Cattle hides are typically thick and strong, requiring more robust trimming techniques. Sheepskins, on the other hand, are often thinner and more delicate, necessitating a gentler approach to avoid tearing. Goat hides are similarly delicate but can vary in thickness. Pigskins have a unique texture and require specific tools and techniques to trim effectively. The trimming process must be adjusted for each type. For example, we might use a sharper, narrower blade for sheepskin and a sturdier blade for cattle hide. The pressure applied, and the angle of the blade also needs to be modified accordingly. Understanding these differences is crucial for producing high-quality, consistent results.

Q 25. How do you adapt your trimming techniques based on the intended use of the finished hide?

The intended use of the finished hide significantly influences trimming techniques. A hide destined for leather goods requires precise trimming to maintain uniformity and optimal surface area. Imprecise trimming can lead to defects in the finished product. Hides for upholstery might require less precision but still need to be free of major defects. A hide intended for rugs might require more liberal trimming, focusing on removing imperfections rather than striving for perfect uniformity. We meticulously adapt our techniques based on the client’s specifications and the final application, ensuring the trimmed hide perfectly meets the requirements of its purpose. For instance, for high-end leather jackets, we are extremely precise. For heavier work gloves, less precision is needed.

Q 26. How do you measure and evaluate the efficiency of your trimming process?

We evaluate trimming efficiency through several key metrics. Yield—the percentage of usable hide after trimming—is a primary indicator. Higher yield signifies less waste and greater efficiency. We also track processing time per hide, striving for consistent and fast trimming without compromising quality. Defect rates are closely monitored; fewer defects mean better efficiency and less rework. Regularly analyzing these metrics allows us to identify areas for improvement, optimize our processes, and ultimately enhance overall efficiency. For example, a high defect rate might suggest needing improved tool maintenance or retraining for team members. Data is collected and analyzed daily to improve operational efficiency.

Q 27. Describe your experience with using automated or semi-automated trimming equipment.

I have extensive experience with both automated and semi-automated trimming equipment. Automated systems, such as robotic trimming machines, offer increased speed and consistency, especially for high-volume processing. However, they might lack the flexibility and precision needed for complex hides or intricate trimming patterns. Semi-automated systems, incorporating features like automated knives with manual adjustments, provide a balance between speed and precision. For instance, semi-automated machines help with initial trimming of large hides, and manual trimming is used to fine-tune the edges. The choice depends on the scale of operations, the complexity of the tasks, and the desired level of precision. My expertise allows me to effectively utilize both types of equipment.

Q 28. What are your strategies for maintaining a clean and organized workspace during hide trimming?

Maintaining a clean and organized workspace is vital for safety and efficiency. We employ a 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to organize our workspace. Tools are stored in designated locations, waste is immediately disposed of, and surfaces are regularly cleaned. Clear pathways are maintained to prevent accidents. Proper ventilation systems are utilized to minimize dust and unpleasant odors. This systematic approach ensures a safe, efficient, and productive working environment. We also conduct regular spot checks throughout the day to maintain the high standards needed. It’s a constant process, not a one-time event.

Key Topics to Learn for Hide Trimming Interview

- Hide Structure and Anatomy: Understanding the different layers of the hide, including grain, flesh, and corium, and their impact on trimming techniques.

- Trimming Tools and Equipment: Familiarity with various knives, shears, and automated trimming machines; understanding their appropriate uses and maintenance.

- Trimming Techniques: Mastering different trimming methods for various hide types and end-products (e.g., leather, fur). This includes understanding the importance of precision and minimizing waste.

- Defect Identification and Handling: Recognizing common hide defects (scars, holes, etc.) and applying appropriate trimming techniques to salvage usable material.

- Quality Control and Standards: Understanding industry standards and quality control measures related to hide trimming, ensuring consistent product quality.

- Safety Procedures and Regulations: Knowledge of workplace safety protocols, including proper handling of sharp tools and adherence to relevant industry regulations.

- Production Processes and Efficiency: Understanding the overall production workflow and optimizing trimming techniques for maximum efficiency and throughput.

- Waste Management and Sustainability: Exploring environmentally friendly practices related to hide trimming and minimizing waste generation.

Next Steps

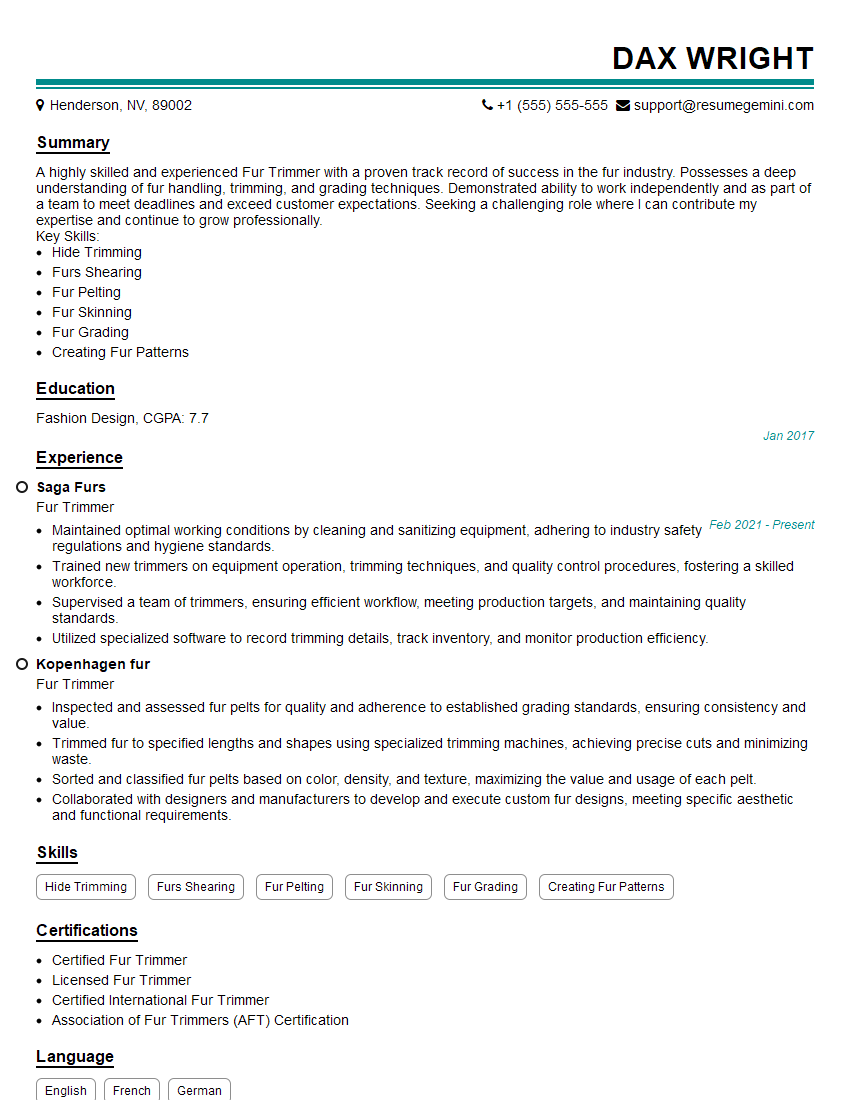

Mastering hide trimming opens doors to rewarding careers in the leather and related industries. It’s a highly skilled trade with consistent demand. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to the Hide Trimming field are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

good