Preparation is the key to success in any interview. In this post, we’ll explore crucial Hospitality Laundry Operations interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Hospitality Laundry Operations Interview

Q 1. What laundry equipment maintenance procedures are you familiar with?

Regular and preventative maintenance is crucial for extending the lifespan of laundry equipment and preventing costly breakdowns. My experience encompasses a wide range of procedures, including:

- Daily Checks: Inspecting washers and dryers for lint build-up (a common cause of fire hazards!), checking water levels, and ensuring proper soap and chemical dispensing. I also verify that all safety features, like emergency stops, are functioning correctly. Think of it like a daily car check – you catch small issues before they become major problems.

- Weekly Maintenance: This includes cleaning lint traps thoroughly, checking and cleaning water filters, and inspecting belts and pulleys for wear and tear. A good weekly clean can prevent significant future issues and improve energy efficiency.

- Monthly Maintenance: More in-depth cleaning is required here. This might involve descaling the washing machines to remove mineral deposits that can impede performance. Also, lubrication of moving parts is essential for smooth operation.

- Quarterly/Annual Maintenance: This often requires professional service. It includes more comprehensive inspections of electrical components, motors, and other critical parts. This preventative work is like a major car service – it’s an investment that keeps things running smoothly.

- Record Keeping: Meticulous record-keeping of all maintenance activities is essential for tracking performance, identifying trends, and planning for future maintenance needs. This data provides insight into the overall health of the equipment and can inform proactive replacement decisions.

Q 2. Describe your experience with different fabric types and their specific washing requirements.

Understanding different fabric types and their washing requirements is fundamental in hospitality laundry. My experience spans a wide range of materials, and I tailor my approach based on several factors:

- Fiber Content: Natural fibers like cotton, linen, and wool have different sensitivities than synthetics like polyester or nylon. Cotton and linen can typically withstand higher temperatures and stronger detergents, while wool and silk require gentler cycles and specialized detergents to avoid shrinkage or damage. For example, a delicate wool blanket requires a cool, gentle wash cycle and a mild detergent, whereas cotton sheets can handle hot water and a stronger detergent.

- Fabric Weight: Heavier fabrics, like towels, require more agitation and potentially longer wash cycles than lighter fabrics like pillowcases. Think of washing a heavy bath towel compared to a delicate lace doily – the treatment must be different.

- Colorfastness: Some fabrics may bleed color, especially during the initial wash. Sorting by color is critical to prevent color transfer. Dark-colored items should always be washed separately to avoid staining lighter-colored items.

- Stain Removal: Pre-treating stains with appropriate stain removers before washing is crucial for effective stain removal and extending the life of linens. Different stains (blood, grease, wine) require different approaches.

I use my knowledge to create efficient sorting systems and washing protocols that maintain fabric quality and extend the life of linens, contributing directly to cost savings.

Q 3. How do you manage linen inventory to minimize waste and ensure sufficient supply?

Efficient linen inventory management is critical for optimal hospitality operations. My approach involves:

- Par Stock System: Establishing a defined par stock level for each linen type ensures sufficient supply while minimizing excess inventory. This is the minimum quantity needed to satisfy daily demand while ensuring a reserve for unexpected circumstances. The par stock number will vary based on demand – a busy hotel will need a larger par stock for sheets than a less busy one.

- RFID or Barcoding: Utilizing RFID tags or barcodes for linen tracking allows for real-time inventory monitoring, facilitating accurate forecasting and minimizing loss. This gives immediate insight into usage, losses, and needed restocking.

- Regular Audits: Periodic inventory audits are conducted to reconcile physical inventory with system records, identifying discrepancies and adjusting par stock levels accordingly.

- Linen Loss Analysis: Identifying and addressing causes of linen loss (damage, theft, shrinkage) is essential for optimizing resource utilization. Understanding why linens are lost allows for implementation of strategies to minimize such loss. For example, proper training can help minimize accidental damage.

- Replenishment Strategies: Implementing a well-defined replenishment system ensures timely ordering and delivery of new linen to maintain sufficient stock levels.

Q 4. Explain your experience with implementing or improving laundry processes to increase efficiency.

Improving laundry processes is a continuous pursuit. In my previous role, I implemented several key improvements:

- Workflow Optimization: By analyzing the existing workflow, I identified bottlenecks and implemented changes to streamline the sorting, washing, drying, and folding processes, significantly reducing turnaround time. We moved from a linear workflow to a more efficient parallel workflow, increasing productivity.

- Technology Integration: I introduced new software for linen tracking and management, providing real-time visibility into inventory levels and reducing manual data entry errors. The software also helps in predictive maintenance scheduling.

- Staff Training: Providing staff with proper training on efficient laundry techniques and equipment operation led to improved productivity and reduced linen damage.

- Lean Principles: Applying Lean principles to eliminate waste and improve efficiency in the laundry process. This included a focus on reducing linen handling, optimizing equipment utilization, and implementing a 5S methodology to improve workplace organization.

These changes resulted in a 15% increase in throughput and a 10% reduction in linen loss within six months.

Q 5. What are the common causes of laundry equipment malfunctions and how do you troubleshoot them?

Laundry equipment malfunctions can stem from various sources. Common issues include:

- Lint Buildup: Clogged lint traps in dryers reduce efficiency and can cause overheating. Regular cleaning is vital.

- Water Supply Problems: Low water pressure or insufficient water supply can affect washing machine performance. Checking water valves and pressure is key.

- Mechanical Issues: Worn-out belts, broken pulleys, or malfunctioning motors often require professional repair.

- Electrical Problems: Faulty wiring, blown fuses, or malfunctioning heating elements can cause equipment failure. Electrical safety should be a top priority.

- Chemical Imbalances: Incorrect use or dosage of detergents or other chemicals can damage equipment or cause poor washing results.

My troubleshooting approach follows a systematic process: First, I identify the symptom (e.g., machine not starting, poor washing quality). Then, I check the obvious things (power supply, water supply, lint traps) before moving to more complex issues (checking wiring, contacting a technician). Detailed documentation of problems and solutions is crucial for preventative maintenance.

Q 6. How do you ensure the highest standards of hygiene and sanitation in laundry operations?

Maintaining the highest standards of hygiene and sanitation is paramount. My approach incorporates:

- Regular Cleaning and Sanitizing: All laundry equipment is thoroughly cleaned and sanitized at regular intervals using approved chemicals. This includes washing machines, dryers, and all surfaces in the laundry area.

- Water Temperature Control: Using appropriate water temperatures during the washing cycle ensures effective sanitation and eliminates many bacteria and viruses.

- Chemical Management: Proper handling, storage, and usage of detergents, disinfectants, and other chemicals is vital to prevent cross-contamination and maintain workplace safety. Strict adherence to safety protocols is essential.

- Pest Control: Implementing a preventative pest control program safeguards the laundry area and prevents infestation. Regular inspections are crucial.

- Personal Hygiene: Staff training emphasizes the importance of proper handwashing, wearing appropriate protective clothing, and maintaining cleanliness to prevent the spread of contamination.

Regular inspections by health authorities are also encouraged to ensure continuous compliance with all health and safety regulations.

Q 7. What are your strategies for managing staff in a fast-paced laundry environment?

Managing staff in a fast-paced laundry environment requires effective communication, clear expectations, and a supportive work environment. My strategies include:

- Clear Roles and Responsibilities: Clearly defined roles and responsibilities minimize confusion and ensure smooth workflow.

- Effective Communication: Regular staff meetings, shift briefings, and open communication channels ensure everyone is informed and updated. This helps to resolve issues quickly and maintain team morale.

- Training and Development: Providing regular training and development opportunities not only enhances skills but also boosts morale and promotes a culture of continuous improvement. Training on safety protocols is crucial.

- Performance Management: Implementing fair and consistent performance management systems that acknowledge accomplishments, address shortcomings constructively, and reward high performance. This can include regular feedback and performance reviews.

- Team Building: Promoting teamwork and collaboration through team-building activities can foster a positive and supportive environment. This can be as simple as recognizing good work or having a team lunch.

A well-trained, motivated, and effectively managed team is crucial for achieving high productivity, maintaining quality standards, and ensuring a safe and positive work environment.

Q 8. How do you handle customer complaints related to laundry services?

Handling customer complaints about laundry services requires a calm, empathetic approach focused on resolution. My first step is to actively listen to the guest’s concerns, acknowledging their frustration and validating their experience. I avoid interrupting and instead ensure I fully understand the issue – was an item damaged? Was it not cleaned properly? Was there a delay in service?

Once the problem is clearly understood, I offer a sincere apology, regardless of fault. This sets a positive tone. Then, I work to find a practical solution. This could involve re-washing the item, offering a discount on their next stay, or providing a replacement item, depending on the severity of the issue. Finally, I follow up with the guest to ensure they are satisfied with the resolution and to prevent future similar occurrences. For example, if a stain wasn’t removed, I’d investigate if there’s a need for staff training on stain removal techniques or a change in laundry chemicals. Good record-keeping of complaints helps identify trends and improve service consistently.

Q 9. Describe your experience with laundry chemicals and their safe handling procedures.

My experience with laundry chemicals spans over ten years, encompassing safe handling and usage within a variety of settings. I’m proficient in using various detergents, bleaches, softeners, and stain removers. Safety is paramount; I strictly adhere to the manufacturer’s instructions for handling, storage, and disposal of all chemicals. This includes wearing appropriate personal protective equipment (PPE) such as gloves, eye protection, and aprons. Chemicals are stored in designated areas, properly labeled, and kept away from food and drink. I’m also well-versed in the proper dilution ratios for different chemicals to ensure effectiveness and minimize environmental impact. For instance, using too much bleach can damage fabrics and harm the environment; using too little renders the cleaning ineffective. Regular safety training sessions are crucial to maintain high standards of safe chemical handling.

Q 10. How do you calculate laundry costs per room or guest?

Calculating laundry costs per room or guest involves a detailed breakdown of expenses. The first step is to identify all direct costs. These include the cost of water, electricity, detergents, and other chemicals used. Next, we consider labor costs—the wages paid to laundry personnel. Then, we factor in indirect costs such as equipment maintenance, repairs, and replacement of worn-out items.

Once all costs are compiled, they are divided by the total number of rooms or guests serviced within a given period. For example, if the total laundry cost for a month is $5000 and the hotel serviced 1000 guests, the cost per guest is $5. However, this is a simplified calculation. A more sophisticated approach might involve assigning different costs based on room type (e.g., a suite generates more laundry than a standard room). We also need to consider the occupancy rate to get a more precise cost per occupied room. Regular review and adjustments of these cost calculations are essential to maintain profitability and efficiency.

Q 11. What are your strategies for reducing water and energy consumption in laundry operations?

Reducing water and energy consumption in laundry operations is crucial for both environmental sustainability and cost savings. My strategies focus on several key areas. Firstly, we implement water-efficient washing machines and dryers that utilize advanced technology to optimize water usage. This includes choosing machines with high-efficiency extraction rates to reduce drying times and energy consumption. Secondly, we implement a pre-sorting system, separating heavily soiled items from lightly soiled ones. This reduces the need for excessive washing cycles. Thirdly, we optimize water temperature. Using cold water where possible significantly reduces energy usage. We also maintain the equipment regularly; efficient machinery consumes less water and energy. Finally, we invest in water reclamation systems to reuse treated water for non-potable purposes like toilet flushing, reducing reliance on fresh water sources.

Q 12. How familiar are you with different types of washing machines (e.g., tunnel washers, washer-extractors)?

I’m familiar with a range of washing machines commonly used in hospitality laundry operations. I have hands-on experience with tunnel washers, washer-extractors, and smaller capacity machines. Tunnel washers are highly efficient for high-volume operations, processing large quantities of laundry continuously. They excel in large hotels or commercial settings. Washer-extractors are more commonly found in smaller facilities; they combine washing and extraction in a single unit and are versatile for different laundry types. I’m familiar with their operational parameters, including load sizes, water levels, and spin speeds. My experience includes understanding the strengths and limitations of each type of machine and selecting the appropriate model for a given operational need. The choice depends on factors like volume of laundry, space constraints, budget, and the types of textiles being processed.

Q 13. What safety measures do you implement to protect staff from workplace hazards in the laundry?

Safety is a top priority in our laundry operations. We implement several measures to protect staff from workplace hazards. This begins with comprehensive safety training for all employees, covering topics like proper lifting techniques to prevent back injuries, the safe handling of chemicals as discussed earlier, and the correct use of machinery. We also provide and enforce the use of PPE such as gloves, eye protection, and hearing protection (where necessary) to minimize risks. Regular maintenance checks are performed on all equipment to prevent malfunctions and accidents. The laundry area is well-lit and designed to minimize tripping hazards; clear signage and color-coded systems are used for easy identification of chemical storage and emergency exits. Finally, we have clear emergency procedures in place and conduct regular safety drills to prepare the team for any unforeseen circumstances.

Q 14. How do you ensure compliance with all relevant health and safety regulations?

Ensuring compliance with health and safety regulations is an ongoing process that requires vigilance. We maintain detailed records of all safety training sessions, equipment maintenance, and chemical handling procedures. We regularly review and update our safety policies to ensure they align with the latest regulations. This includes compliance with OSHA (Occupational Safety and Health Administration) standards and any other relevant local, state, or national regulations concerning laundry operations, chemical handling, and employee safety. We also conduct regular internal audits to identify any potential safety risks and address them promptly. External audits by regulatory bodies are welcomed as an opportunity to demonstrate our commitment to safe and compliant operations and to identify areas for further improvement. Our commitment to safety is not just a formality but a fundamental part of our operational philosophy.

Q 15. Describe your experience with using laundry management software.

My experience with laundry management software spans several years and various systems. I’ve worked with both cloud-based solutions and on-premise systems, gaining expertise in features like inventory tracking, work order management, and reporting. For instance, at my previous role, we implemented a system that integrated with our property management system, automating linen tracking and reducing manual data entry significantly. This improved our accuracy in forecasting linen needs and managing inventory effectively. Another system I utilized allowed us to track individual items, streamlining the process of identifying and addressing linen loss or damage. Key features I value in such software include real-time reporting, robust data analysis capabilities, and user-friendly interfaces that empower staff to utilize the system efficiently.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you train new laundry staff members on proper procedures and safety protocols?

Training new staff involves a multi-stage process focusing on both procedural knowledge and safety. We begin with a comprehensive overview of laundry operations, including the various types of equipment, their safe operation, and routine maintenance procedures. I emphasize the importance of following safety protocols, such as proper lifting techniques to prevent injuries, and the correct use of Personal Protective Equipment (PPE), including gloves and eye protection, when handling chemicals. Hands-on training is crucial, guiding new employees through each step of the process, from sorting and pre-treating linens to operating washing machines, dryers, and finishing equipment. We incorporate role-playing scenarios to address potential hazards and build their confidence in handling unexpected situations. Ongoing mentorship and regular feedback sessions ensure they’re comfortable and proficient in their tasks. For instance, we simulate a machine malfunction and work through troubleshooting steps together.

Q 17. How do you track and report key performance indicators (KPIs) for the laundry department?

Tracking and reporting KPIs is essential for optimizing laundry operations. We monitor key metrics including linen yield (pounds of clean linen produced per hour), linen usage rates per guest room, labor costs per pound of laundry, and linen loss/damage rates. These KPIs are tracked daily using our laundry management software. Regular reports are generated, highlighting trends and areas for improvement. For instance, if our linen yield decreases, we investigate potential causes such as machine efficiency or staffing levels. This data-driven approach ensures that we can identify areas needing attention and make informed decisions to improve efficiency and reduce costs. We present these reports to management using clear visualizations, making it easier for them to understand the overall performance of the laundry department.

Q 18. What are your strategies for improving the efficiency of laundry processes?

Improving laundry efficiency requires a holistic approach. We focus on optimizing equipment utilization, streamlining workflow processes, and implementing preventative maintenance programs. For example, we’ve implemented a system for optimizing washing machine loads, maximizing the capacity of each cycle without compromising cleaning efficacy. We also analyze workflow bottlenecks and redesign processes to minimize unnecessary movement or handling of linens. Regular staff training on efficient sorting techniques and equipment operation is essential. Moreover, preventative maintenance programs reduce downtime by addressing potential issues before they escalate into major problems. This includes scheduled cleaning and inspection of equipment, resulting in longer equipment lifespan and reduced repair costs.

Q 19. How do you handle linen loss or damage?

Linen loss and damage are addressed through a combination of prevention and recovery strategies. Preventing losses involves implementing a robust linen tracking system, using barcodes or RFID tags to track individual items throughout the entire laundry process. Regular inventory checks and staff training on proper handling techniques also play a crucial role. When damage occurs, we categorize it (e.g., minor stains, tears, significant damage). Minor damage is addressed through repairs whenever possible. Items beyond repair are properly disposed of and replaced, and we use the data collected to identify trends and potential areas of improvement, for example, adjusting handling procedures to reduce tears in sheets. We also maintain a detailed inventory of losses and damages to support our linen purchasing decisions.

Q 20. Describe your experience with different types of stain removal techniques.

My experience with stain removal encompasses a wide range of techniques, depending on the type of stain and fabric. We use a combination of pre-treatment solutions tailored to specific stains (e.g., enzyme-based solutions for organic stains, oxygen bleach for discoloration). For instance, blood stains require immediate cold water rinsing before any other treatment. Grease stains are often pre-treated with a solvent-based product, while ink stains might necessitate specialized stain removers. Understanding fabric types is crucial, as aggressive treatments can damage delicate materials. We train staff to correctly identify stains and select appropriate pre-treatment methods, and we maintain a detailed chart that guides our staff through stain-removal procedures, ensuring the right approach for each situation.

Q 21. How do you manage the scheduling of laundry staff to ensure adequate coverage?

Staff scheduling requires careful consideration of peak demand periods and workload fluctuations. We use a combination of historical data and forecasting techniques to anticipate staffing needs. Our scheduling considers factors such as day of the week, occupancy levels, and special events. We use a digital scheduling system that allows for easy adjustments based on real-time needs. Shift patterns are designed to ensure adequate coverage throughout the day and night, accounting for breaks and meal periods. Cross-training staff on various tasks enhances flexibility and ensures coverage when staff are absent. Regular communication with the team ensures everyone understands the schedule and their responsibilities, aiming for optimal coverage and a balanced workload.

Q 22. What are your experience with different folding and sorting techniques?

Folding and sorting techniques are crucial for efficiency and maintaining a professional image in hospitality laundry. My experience encompasses a range of methods tailored to different linen types and client needs. For example, I’ve mastered the ‘waterfall fold’ for sheets, ensuring a crisp, neat presentation, and the ‘envelope fold’ for pillowcases, which maximizes space and minimizes wrinkles. I’m also proficient in various towel folding techniques, from simple squares to more elaborate designs, depending on the establishment’s branding and guest expectations. Sorting involves categorizing linens by type (sheets, towels, pillowcases), size (single, double, king), and condition (stained, damaged, etc.) to streamline the cleaning and distribution process. This often includes using color-coded bins or tags for efficient segregation and tracking. In one instance, implementing a new sorting system reduced our linen processing time by 15%.

- Waterfall Fold: A quick and efficient fold for sheets.

- Envelope Fold: Space-saving and wrinkle-resistant fold for pillowcases.

- Color-Coded Sorting: Utilizing different colored bins for different linen types ensures easy identification and prevents mixing.

Q 23. Explain your experience in managing the budget for laundry supplies and equipment.

Budget management in a hospitality laundry involves careful planning and monitoring of expenses related to supplies (detergents, bleach, fabric softeners) and equipment maintenance (washing machines, dryers, folding machines). My approach involves creating a detailed budget that incorporates projected costs based on historical data, linen volume, and anticipated price fluctuations. I then regularly monitor actual spending against the budget, identifying any variances and implementing corrective actions. For example, I successfully negotiated a lower price with a detergent supplier by leveraging our high volume of purchases, resulting in annual savings of approximately 10%. Equipment maintenance is planned proactively to prevent costly breakdowns. This includes scheduling routine servicing and repairs, tracking maintenance logs, and evaluating the cost-effectiveness of replacing aging equipment with more energy-efficient models.

I also explore opportunities for cost optimization by monitoring linen usage and minimizing waste. For example, through staff training and implementing stricter controls, we reduced linen loss by implementing a robust linen tracking system and investing in durable, high-quality linens which significantly reduced replacement costs.

Q 24. How do you ensure the proper storage and handling of clean and soiled linens?

Proper storage and handling of linens are paramount to maintaining hygiene and preserving their quality. Clean linens are stored in designated areas, away from soiled linens, in clean, dry, and well-ventilated spaces. Shelving units or linen carts are used to maintain organization and prevent contamination. We use clearly labeled containers to segregate different linen types and sizes. Soiled linens are collected in designated receptacles (laundry hampers or bags) and transported promptly to the laundry facility to prevent the spread of bacteria and odors. This involves following strict protocols to prevent cross-contamination—for example, using separate carts or containers for soiled linens from different areas.

Regular checks are performed to ensure that the storage areas are kept clean and free of pests. Proper handling practices include wearing clean gloves when handling soiled linens to protect staff from potential exposure to pathogens.

Q 25. How do you maintain a clean and organized laundry facility?

Maintaining a clean and organized laundry facility is essential for hygiene, safety, and efficiency. My approach involves establishing a daily cleaning schedule that covers all areas of the facility, including washing machines, dryers, sorting areas, and storage spaces. This includes regular cleaning of floors, walls, and equipment using appropriate disinfectants. I implement a system for managing chemical storage, ensuring proper labeling and safety precautions are followed. Organization involves clearly designated areas for different tasks, proper labeling of storage containers, and regular decluttering to prevent build-up of unnecessary items. For example, I implemented a 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) which helped streamline workflows and improve overall cleanliness. Regular inspections are carried out to identify and address any cleanliness or organizational issues promptly.

Q 26. What is your experience with different types of laundry detergents and their applications?

My experience includes working with a variety of laundry detergents, each tailored to specific linen types and soil levels. I’m familiar with both liquid and powder detergents, as well as specialized formulations for delicate fabrics or heavily soiled items. For instance, I use high-efficiency (HE) detergents in our front-loading washers to optimize cleaning and reduce water usage. I also utilize bleach solutions for whitening and sanitizing white linens, carefully following manufacturer instructions to prevent damage. For delicate fabrics like silk or wool, I opt for mild detergents or specialized cleaning agents. The selection of detergents depends on factors such as the type of fabric, the level of soil, water hardness, and environmental considerations. I regularly evaluate the performance of different detergents, considering factors such as cleaning effectiveness, cost, and environmental impact, to ensure we are using the most suitable and cost-effective options.

Q 27. Describe your experience working with a laundry vendor or outsourcing laundry services.

I’ve worked extensively with laundry vendors, both managing existing contracts and negotiating new ones. This involved understanding their capabilities, comparing pricing structures, and ensuring adherence to quality standards. The process includes outlining specific requirements, such as turnaround time, linen handling protocols, and quality control measures. Effective communication and regular meetings with vendors are vital for addressing issues, monitoring performance, and maintaining a strong working relationship. During one project, I successfully negotiated a contract with a vendor who offered environmentally friendly cleaning practices, reducing our carbon footprint while maintaining a high quality of service. This experience has provided me with a valuable understanding of the logistics and challenges associated with outsourcing laundry services.

Q 28. How do you prioritize tasks effectively in a high-volume laundry environment?

Prioritizing tasks in a high-volume laundry environment requires a systematic approach. I use a combination of techniques including: First, I prioritize tasks based on urgency and importance, utilizing methods like the Eisenhower Matrix (Urgent/Important). Tasks requiring immediate attention, such as processing urgent orders or addressing equipment malfunctions, take precedence. Next, I organize tasks using a workflow system which breaks down the laundry process into logical steps and assigns responsibilities effectively. This might involve using a Kanban board or a similar visual management system for tracking progress. Finally, I leverage technology where appropriate, for example, using laundry management software to track linen inventory and automate scheduling. Regular communication and coordination with my team is critical in ensuring efficient task completion and minimizing bottlenecks.

Key Topics to Learn for Hospitality Laundry Operations Interview

- Laundry Process Flow: Understanding the entire cycle from collection to distribution, including sorting, washing, drying, ironing, and folding.

- Equipment Operation and Maintenance: Knowing how to operate and troubleshoot common laundry equipment like washers, dryers, and pressing machines; demonstrating practical knowledge of preventative maintenance.

- Chemical Handling and Safety: Safe and efficient use of detergents, bleaches, and other chemicals; adhering to safety regulations and procedures to prevent accidents and damage.

- Inventory Management: Tracking linen inventory, managing stock levels, and minimizing waste; understanding the importance of accurate stock counts and reporting.

- Quality Control and Standards: Maintaining high standards of cleanliness and hygiene; understanding and implementing quality control checks throughout the laundry process; identifying and addressing quality issues.

- Hygiene and Sanitation Practices: Implementing and adhering to strict hygiene and sanitation protocols to prevent the spread of infection; knowledge of relevant health and safety regulations.

- Teamwork and Communication: Effective collaboration with colleagues and supervisors; clear and concise communication regarding workload, challenges, and solutions.

- Efficiency and Productivity: Optimizing laundry processes to maximize efficiency and minimize operational costs; implementing strategies for improved workflow and turnaround times.

- Sustainability and Environmental Awareness: Understanding and applying eco-friendly laundry practices; minimizing water and energy consumption; knowledge of sustainable laundry detergents and techniques.

- Problem-Solving and Troubleshooting: Demonstrating the ability to identify and resolve issues related to equipment malfunctions, process inefficiencies, and quality control problems.

Next Steps

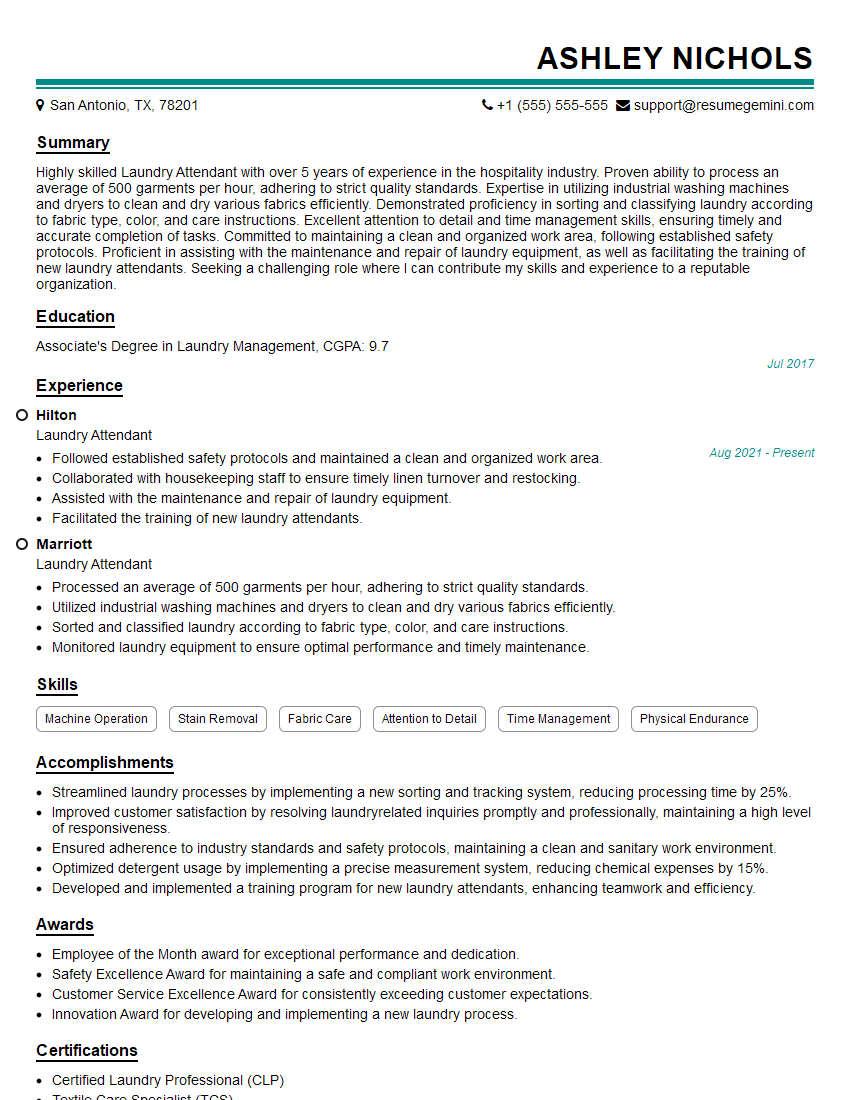

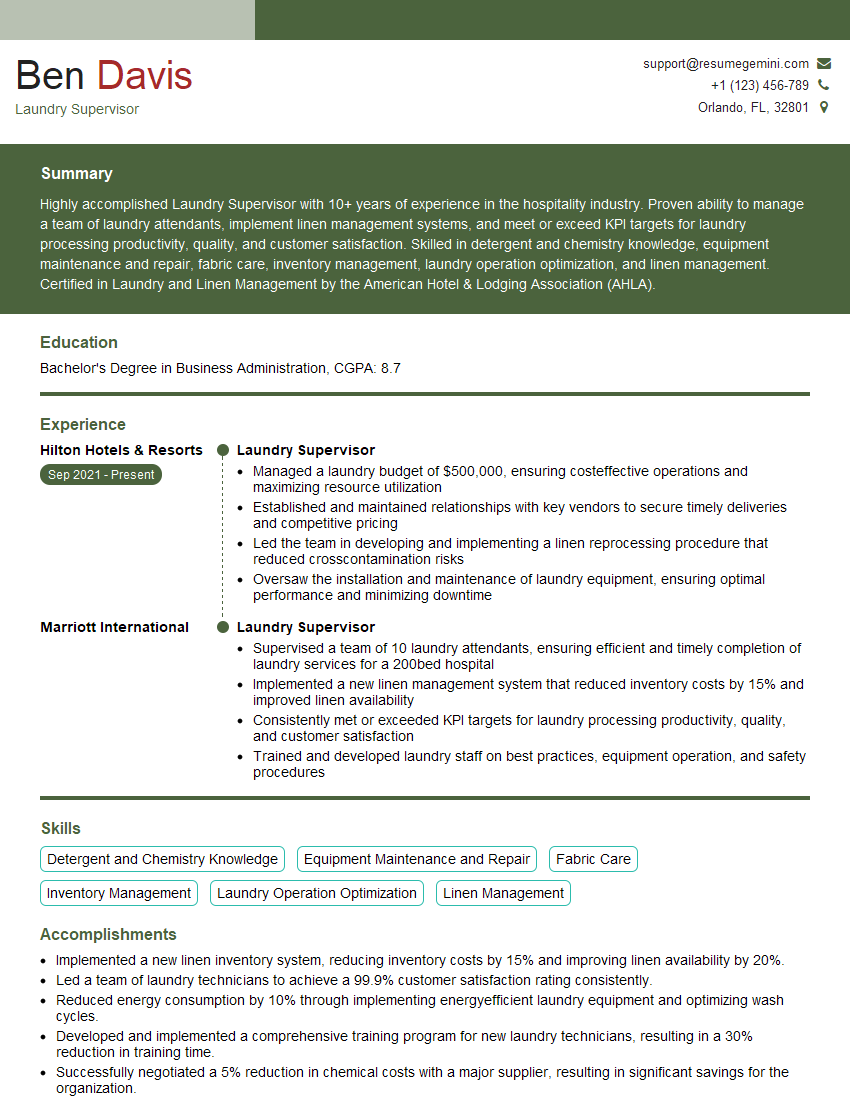

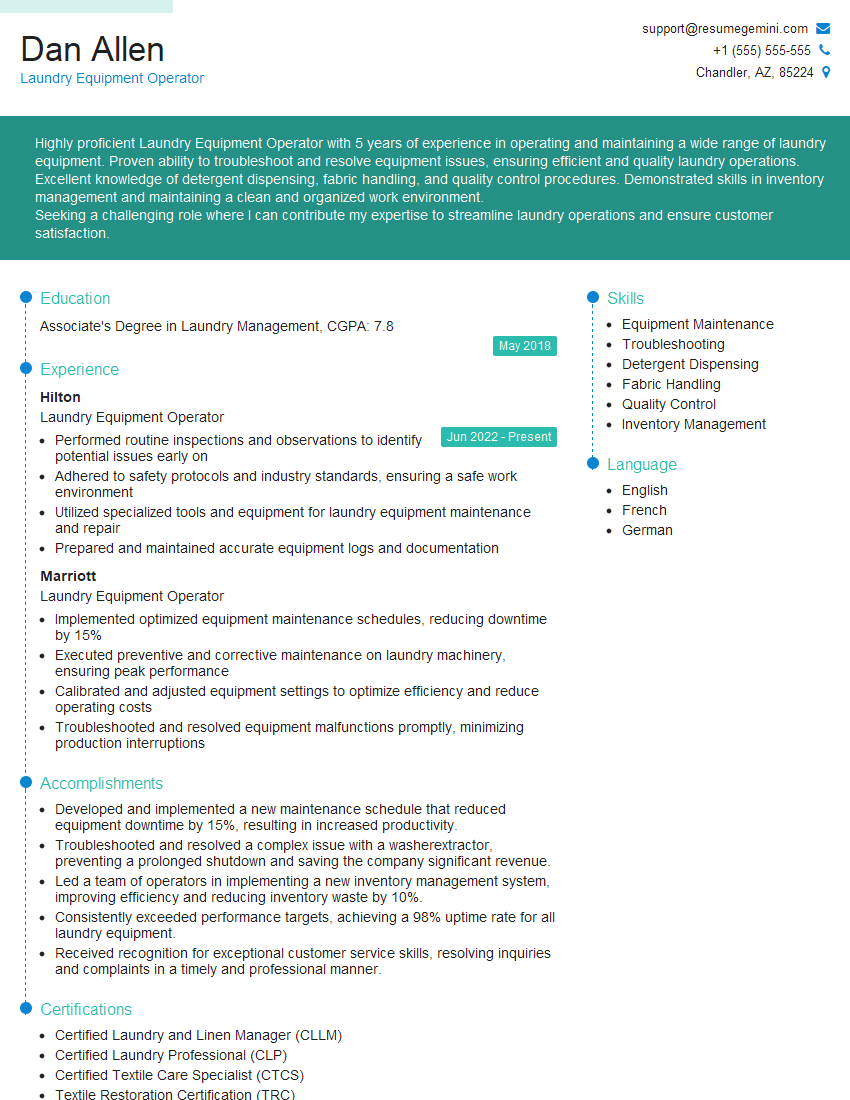

Mastering Hospitality Laundry Operations is crucial for career advancement, opening doors to supervisory roles and increased responsibility. A strong understanding of these operational aspects demonstrates competence and commitment, making you a highly desirable candidate. To maximize your job prospects, focus on crafting an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, ensuring your application stands out. Examples of resumes tailored to Hospitality Laundry Operations are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good