The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Hot Work Permit Issuance interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Hot Work Permit Issuance Interview

Q 1. What are the key elements of a valid Hot Work Permit?

A valid Hot Work Permit is a legally binding document authorizing specific hot work activities within a defined area. It’s your safety insurance policy before starting any potentially fiery operation. Key elements include:

- Job Description: A clear and concise description of the work to be performed, including the location, type of equipment, and materials involved. For example, ‘Welding steel pipe joint at location X using an oxy-acetylene torch.’

- Permit Issuer: The name and signature of the authorized person approving the hot work. This signifies responsibility and accountability.

- Permit Holder: The name and signature of the person responsible for conducting the hot work and ensuring safety precautions are followed.

- Location: The precise location where the hot work will take place, often including a site map or sketch.

- Date and Time: The start and expected completion times for the hot work. This creates a defined timeframe for the permit’s validity.

- Fire Prevention Measures: A detailed outline of the fire prevention and control measures that will be implemented, including the type and quantity of fire extinguishing equipment available.

- Emergency Procedures: Clear steps to take in case of a fire or emergency.

- Inspection and Clearance: Space for inspection before, during, and after the hot work to verify safety. This involves confirmation of the area being safe before the start, proper cleanup during, and final clearance once the risk has subsided.

- Signatures for each stage: Signatures are required at each stage to ensure accountability for safety checks and measures taken.

Think of it like a driver’s license for using fire – it ensures you’re qualified and have the necessary safety provisions in place.

Q 2. Describe the process for issuing a Hot Work Permit.

The Hot Work Permit issuance process is a structured system designed to minimize fire risks. It typically involves these steps:

- Application: The person requesting the permit fills out the application form, providing all the necessary details about the intended hot work.

- Risk Assessment: A thorough risk assessment is carried out to identify all potential hazards associated with the work. This involves inspecting the area for flammables, accessibility of firefighting equipment and evaluating the potential impact of the job.

- Permit Review and Approval: The completed application and risk assessment are reviewed by the authorized person who has the authority to approve or reject the permit based on safety criteria. This often involves a trained fire safety officer.

- Permit Issuance: If approved, the permit is issued to the permit holder who will be responsible for carrying out the hot work.

- Pre-Job Inspection: Before starting the work, a pre-job inspection is conducted to ensure that all fire prevention measures are in place and that the work area is prepared. This can involve ensuring no combustible materials are present in the vicinity.

- Hot Work Execution: The hot work is carried out according to the permit conditions and safety procedures. A fire watch is usually present during the duration of the activity to ensure adherence to measures and to react to incidents quickly.

- Post-Job Inspection: After the completion of the hot work, a post-job inspection is conducted to ensure that the area is safe and that any remaining fire hazards are eliminated. This includes confirming the area is clear of sparks, embers, and hot materials.

- Permit Closure: The permit is then closed once it has been confirmed that the job has been completed safely, and the work area is clear of any fire hazards.

Each step is crucial to ensure a safe working environment. Imagine it like preparing for a surgical procedure – meticulous planning and checks are paramount.

Q 3. What are the fire prevention measures required during hot work?

Fire prevention during hot work requires a multi-layered approach. Key measures include:

- Area Clearance: Removing all combustible materials (wood, paper, solvents, etc.) from a minimum radius around the work area. This creates a safety buffer zone.

- Fire-Resistant Barriers: Using fire-resistant barriers (sheets, blankets, etc.) to protect surrounding areas from sparks and heat. This would act as a protective shield against fire spread.

- Fire Extinguishers: Having appropriate fire extinguishers readily available and ensuring personnel are trained to use them effectively. Different types of extinguishers are used for different types of fire.

- Fire Watch: Maintaining a vigilant fire watch during and after the hot work to detect and extinguish any potential fires immediately. The fire watch acts as the first responder to any incident.

- Spark Arrestors: Using spark arrestors on equipment such as grinders or cutting tools to prevent the emission of flying sparks.

- Proper Ventilation: Ensuring adequate ventilation to prevent the buildup of flammable gases.

- Water Supply: Having a readily accessible water source (hose, bucket of water) for quick fire suppression.

These measures work together; one isn’t sufficient to guarantee safety.

Q 4. How do you identify and control hazards associated with hot work?

Identifying and controlling hazards associated with hot work involves a systematic approach:

- Hazard Identification: This includes identifying potential ignition sources (welding torches, grinders), flammable materials present nearby, and any other factors that could contribute to a fire. This involves examining the jobsite for any potential dangers.

- Risk Assessment: Evaluating the likelihood and severity of each identified hazard to determine the level of risk. A higher risk might require more stringent safety measures.

- Control Measures: Implementing appropriate control measures to mitigate the identified hazards. This might include the use of fire-resistant barriers, fire watch personnel, and the availability of suitable fire extinguishers.

- Personal Protective Equipment (PPE): Providing and ensuring the correct use of appropriate PPE, such as fire-resistant clothing, gloves, and eye protection. This prevents the operator from injuries caused by the work.

- Training and Communication: Ensuring all personnel involved are adequately trained on the hazards and control measures. Clear communication is essential for team safety.

This approach is iterative – hazards might emerge during the work, requiring adjustments to the control measures.

Q 5. Explain the role of a fire watch during hot work activities.

A fire watch is a crucial safety role during hot work. Their responsibilities include:

- Constant Vigilance: Continuously monitoring the hot work area for any signs of fire, sparks, or smoldering materials. This would involve checking the equipment, the area, and the surroundings.

- Immediate Response: Quickly responding to any fire or potential fire hazard by using available fire extinguishers or raising the alarm. This would be the first line of defence in the event of an incident.

- Post-Job Inspection: After completion of the hot work, thoroughly inspecting the work area to ensure all embers and heat sources are extinguished. This would involve a physical check to make sure the area is secure and safe.

- Communication: Maintaining clear communication with the hot work personnel and others in the area.

The fire watch is the last line of defence against a fire starting, and their vigilance is paramount.

Q 6. What are the different types of fire extinguishers and their applications in hot work situations?

Several types of fire extinguishers are used for different classes of fires. In hot work, the most common are:

- Water (Class A): Effective for ordinary combustibles like wood and paper. Less effective for flammable liquids or electrical fires.

- Carbon Dioxide (CO2) (Class B, C): Suitable for flammable liquids (Class B) and electrical fires (Class C). Leaves no residue, but can cause frostbite if used improperly.

- Dry Chemical (Class A, B, C): A versatile extinguisher for Class A, B, and C fires. It’s a popular general-purpose extinguisher, however, it could leave a residue that could damage equipment.

- Foam (Class A, B): Effective for Class A and B fires. Forms a layer to smother the fire.

The choice of extinguisher depends on the potential fire hazards present in the hot work area. A risk assessment should dictate the appropriate type(s).

Important Note: Always ensure personnel are trained in the proper use and limitations of each type of extinguisher before starting any hot work. Improper use can be dangerous.

Q 7. How do you ensure the competency of personnel involved in hot work?

Ensuring competency in hot work involves several steps:

- Formal Training: Personnel involved in hot work must receive formal training on safe work practices, hazard identification, fire prevention, and the use of fire extinguishing equipment. This might involve formal certifications from accredited bodies.

- Experience and Skill Verification: Assessment of the individual’s prior experience and skill level. This can involve tests and checks to ensure competency.

- Regular Competency Assessments: Periodic competency assessments (e.g., practical demonstrations and written tests) are necessary to ensure ongoing skills and knowledge. This allows employers to check that standards are being upheld.

- Documentation: Maintaining accurate records of training, assessments, and qualifications of all personnel. This documentation will show legal compliance and accountability.

- Supervision: Providing adequate supervision by competent personnel during hot work activities. Supervisors can step in if any incidents happen or if there is a safety breach.

Competency isn’t just about ticking boxes; it’s about ensuring personnel have the skills and knowledge to perform the work safely and confidently.

Q 8. What are the legal requirements for hot work permits in your region?

Legal requirements for hot work permits vary by region, but generally align with overarching occupational safety and health regulations. In many jurisdictions, these regulations mandate a formal permit system for any activity involving a potential ignition source near flammable or combustible materials. This includes welding, cutting, brazing, soldering, and grinding. Specific requirements often include the identification of the work area, assessment of fire hazards, implementation of fire prevention measures, and the designation of a competent person to oversee the work. For instance, a specific regulation might dictate the minimum distance required from flammable materials, the type of fire extinguisher needed on-site, or the mandatory use of fire-resistant blankets. Failure to comply can result in significant fines and potential legal action.

To illustrate, imagine a construction site. Before any hot work commences, a detailed permit application needs to be submitted and approved by the site safety officer, outlining the work to be performed, the location, and the safety precautions to be taken. This permit must be prominently displayed throughout the duration of the hot work. The specific legal requirements will be defined in the relevant national or regional safety regulations, such as OSHA in the US or similar legislation elsewhere.

Q 9. How do you handle a non-compliance incident related to a hot work permit?

Handling a non-compliance incident related to a hot work permit involves a structured process focusing on immediate action to mitigate any immediate danger and a thorough investigation to prevent future occurrences. The first step is to immediately stop the hot work activity and ensure the safety of personnel. Then, a thorough investigation is undertaken to determine the root cause of the non-compliance. This involves reviewing the permit itself, interviewing the personnel involved, and inspecting the work area. Depending on the severity of the non-compliance, corrective actions may include retraining personnel, improving safety procedures, disciplinary measures for those responsible, and potentially reporting the incident to regulatory authorities.

For example, if a welder begins work without a valid permit, the immediate action is to stop the welding. The investigation might uncover a lack of awareness of permit requirements, a failure in the permit issuance process, or insufficient supervision. Corrective actions might involve retraining the welder on permit procedures and reinforcing supervisory oversight of hot work activities. Documentation of the entire process, from the initial incident to the implemented corrective actions, is crucial for demonstrating compliance and preventing future similar incidents.

Q 10. Describe the pre-work inspection process for hot work.

The pre-work inspection for hot work is a critical step in ensuring safety. It’s a systematic examination of the work area to identify and mitigate potential fire hazards before the commencement of any hot work. This inspection usually involves checking for the presence of flammable materials, assessing the adequacy of fire prevention measures, and verifying the availability of appropriate fire suppression equipment. The inspector needs to identify and isolate any potentially combustible materials, ensuring they are removed or adequately protected. This might involve covering nearby materials with fire-resistant blankets, using fire-retardant barriers, or removing flammable liquids.

Let’s say we’re preparing for welding near a storage area. The pre-work inspection would involve: 1) checking for flammables in the vicinity (e.g., solvents, wood, paper) and either removing or protecting them; 2) verifying the presence and operability of fire extinguishers; 3) ensuring that a fire watch is established and properly trained; 4) confirming the area has appropriate ventilation. A checklist is typically used to ensure a thorough and consistent inspection, documenting findings and any necessary corrective actions before the hot work begins.

Q 11. What are the post-work procedures for hot work?

Post-work procedures for hot work focus on ensuring the complete extinguishment of any embers and confirming the area is safe. This includes allowing sufficient time for the area to cool down before declaring it safe for other activities. A visual inspection is usually carried out to check for any lingering sparks or smoldering materials. The work area is then thoroughly cleaned to remove any debris or potentially hazardous materials. Documentation of the post-work inspection and confirmation of the area’s safety is essential, closing out the hot work permit. This usually involves the permit holder or supervisor signing off on a completion report.

Following welding, for example, the post-work procedure involves checking for glowing embers, dousing the area with water (if appropriate for the materials involved), and ensuring the surrounding area has cooled down. Any slag or other debris will be cleaned up, and the completed hot work permit is signed off, indicating completion and safety confirmation. This detailed process is documented and retained as part of site safety records.

Q 12. How do you manage hot work permits in a confined space?

Managing hot work permits in a confined space adds a layer of complexity due to the inherent risks associated with limited ventilation and potential for oxygen depletion or hazardous gas accumulation. Before any hot work is allowed, a thorough risk assessment specifically addressing confined space hazards is necessary. This includes evaluating the atmospheric conditions inside the confined space, ensuring adequate ventilation, and implementing appropriate respiratory protection measures. The permit must clearly specify entry and exit procedures and the use of appropriate personal protective equipment (PPE), including respiratory protection and eye protection. A qualified person must supervise the hot work activity to monitor atmospheric conditions and ensure the safety of personnel working inside the confined space.

In a scenario such as welding inside a tank, a pre-entry atmospheric test must be conducted to ensure the air is safe to breathe. Adequate ventilation must be provided, and respiratory protection might be required. A permit-required confined space entry procedure must be followed, with continuous monitoring of atmospheric conditions during the hot work. The permit will have specific requirements for atmospheric monitoring and emergency procedures. The permit might even specify the use of a gas detection system and procedures for evacuation in case of any gas leaks or oxygen depletion.

Q 13. Explain the importance of risk assessment in hot work permit issuance.

Risk assessment is paramount in hot work permit issuance. It’s a systematic process of identifying and evaluating the potential hazards associated with hot work activities. The assessment identifies the potential for fire, burns, explosions, and other injuries. The severity and likelihood of each hazard are evaluated, and appropriate control measures are implemented to mitigate the identified risks. The outcome of the risk assessment directly influences the conditions stipulated on the hot work permit, ensuring sufficient safety precautions are taken. This might involve specifying the type of fire extinguishers needed, the distance from flammable materials, the need for a fire watch, and the necessary personal protective equipment.

For instance, welding near a large quantity of flammable liquids carries a high risk of fire. The risk assessment would identify this, and the permit would likely specify the use of a specific type and quantity of fire extinguishers, the need for a fire watch, and the mandatory use of fire-resistant blankets. Without a thorough risk assessment, the permit might be insufficient, leading to inadequate safety precautions and an increased risk of accidents.

Q 14. What are the communication protocols during hot work activities?

Effective communication protocols during hot work activities are critical for safety. This involves clear communication between the permit holder, the fire watch, other workers in the vicinity, and emergency responders. Before starting the hot work, a pre-work briefing should take place to communicate the hazards, control measures, and emergency procedures. During the hot work, clear communication channels must be maintained to report any incidents or unexpected events immediately. This could involve the use of radios, visual signals, or a designated communication system. Post-work communication confirms the safe completion of the hot work and ensures all personnel are aware of the status of the work area.

Imagine a situation where a fire breaks out during welding. Clear and immediate communication between the fire watch and emergency services is vital to ensure a swift and effective response. This might involve using a designated emergency phone line or radio communication to inform emergency responders of the location, the nature of the emergency, and the number of people involved. Effective communication protocols are crucial to minimize the impact of any incident and ensure the safety of personnel.

Q 15. How do you handle emergency situations during hot work?

Emergency situations during hot work require immediate and decisive action. The primary goal is to ensure the safety of personnel and prevent further escalation. Our protocol dictates that all hot work immediately ceases. The fire watch, if present, will take primary action, using available fire suppression equipment (e.g., fire extinguishers, fire blankets). We have a well-rehearsed emergency response plan, including pre-determined evacuation routes and assembly points, which is communicated to all workers before any hot work commences. Depending on the severity, we may need to call emergency services (fire department, paramedics) and follow their instructions. A post-incident investigation is always carried out to identify root causes and prevent future occurrences. Imagine a scenario where welding sparks ignite nearby combustible materials – the fire watch would immediately act, and depending on the situation, initiate a full site evacuation. Following the emergency, a comprehensive report would be prepared detailing the incident, actions taken, and recommendations for future improvements.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the proper use of personal protective equipment (PPE) during hot work?

Proper PPE (Personal Protective Equipment) use is paramount in hot work. This isn’t just about compliance; it’s about protecting lives. Before any hot work begins, we conduct a thorough PPE check, ensuring each worker has and understands how to use appropriate equipment based on the specific task. This includes, but is not limited to: flame-resistant clothing (FR clothing), welding helmets with appropriate shades, gloves, safety footwear, and respiratory protection (if necessary). Regular inspections of PPE are carried out to ensure it’s in good working order. Training on correct PPE usage and its importance is mandatory for all personnel authorized for hot work. For instance, failure to use the appropriate welding helmet shade can lead to serious eye damage. We reinforce the importance of PPE not as a mere requirement but as a crucial element of personal safety.

Q 17. What are the responsibilities of a fire watch?

The fire watch is the first line of defense against fire hazards during hot work. Their responsibilities are critical and include: continuously observing the hot work area for fire hazards (sparks, embers, smoking materials); having readily accessible fire suppression equipment (extinguishers, fire blankets); knowing how to use this equipment; reporting any unusual occurrences or potential hazards to the hot work supervisor immediately; remaining at the hot work location until the permit is closed out; and being properly trained on fire safety procedures. They are the eyes and ears in the hot work zone, and their vigilance is a key element to safety.

Q 18. Describe the process for reviewing and closing out a hot work permit.

Reviewing and closing out a hot work permit is a systematic process. First, the area is inspected for any signs of fire or damage. The fire watch confirms the area is safe and all hot work is complete. The hot work permit itself is then reviewed to ensure all activities listed on the permit were actually performed. Any deviations need to be documented. Once the supervisor confirms all tasks are complete and the area is safe, they sign off the permit, indicating its closure. The completed permit is then filed for record-keeping purposes – this serves as a critical audit trail for safety compliance and for potential incident investigations. Think of it as closing a file on a project; only after a thorough check can we ensure it’s truly concluded.

Q 19. What is the duration validity of a hot work permit?

The duration validity of a hot work permit is highly dependent on the nature of the work and the risks involved. It’s not a fixed timeframe. Generally, a permit is valid only for the duration specified by the permit issuer, which may range from a few hours to a full work shift. The duration is based on a risk assessment of the specific job, taking into account factors like the type of hot work, materials involved, location, and the presence of combustible materials nearby. The permit can be extended only if a formal review confirms continued safety and risk mitigation measures are in place. However, the permit will automatically expire at the end of the scheduled shift, necessitating a new permit for any continuation of the work.

Q 20. How do you manage multiple concurrent hot work permits?

Managing multiple concurrent hot work permits requires careful coordination and communication. A central register of all active permits is maintained, allowing for a clear overview of all ongoing hot work. This also prevents potential conflicts in the work area. Each hot work area is clearly identified and demarcated, with appropriate signage and safety barriers to avoid interaction between different work groups. A dedicated safety officer or supervisor oversees all ongoing hot work to ensure compliance and prevent any potential overlap or interference. This prevents chaos and maintains a safe and controlled environment, effectively managing the simultaneous execution of multiple hot work projects.

Q 21. How do you handle permit modifications or extensions?

Permit modifications or extensions are handled through a formal request process. Any changes to the original hot work plan, such as altering the location, extending the duration, or adding new tasks, require a re-evaluation of the risks involved. The request needs to be submitted in writing and reviewed by the permit issuer. The supervisor assesses the situation and either approves the modification/extension with any necessary updates to the safety precautions, or rejects the request if the modified plan poses unacceptable risks. This ensures that safety considerations are always prioritised, even in the face of changes to the original plan. For example, if a welder needs more time to complete the work, they would formally request an extension; this triggers a re-evaluation to ensure that the fire watch remains in place and other safety measures remain effective.

Q 22. What are the potential consequences of failing to follow hot work permit procedures?

Failing to follow hot work permit procedures can lead to severe consequences, ranging from minor incidents to catastrophic events. The most immediate risk is fire. A single spark in the presence of flammable materials can quickly escalate into a major fire, causing property damage, equipment destruction, and potentially serious injuries or fatalities. Beyond fire, there’s the risk of explosions if flammable gases or vapors are ignited. Further, even if a fire doesn’t occur, improper procedures can lead to damage to equipment or structures due to heat exposure. Finally, non-compliance can result in significant legal and financial repercussions, including hefty fines and potential lawsuits from injured workers or damaged property owners. Imagine, for instance, a welder working without a proper permit in a facility storing highly flammable solvents – the potential for disaster is immense.

- Property damage: Significant costs in repairing or replacing damaged structures and equipment.

- Injuries and fatalities: Burns, smoke inhalation, and potential death to workers and others nearby.

- Legal repercussions: Fines, lawsuits, and potential criminal charges.

- Reputational damage: Negative impact on company image and future business opportunities.

Q 23. What are the differences between hot work and cold work?

The distinction between hot work and cold work lies primarily in the potential for ignition. Hot work involves processes that produce a significant heat source, like welding, cutting, brazing, soldering, or grinding, all of which carry a risk of igniting flammable materials. Cold work, on the other hand, involves operations that don’t generate significant heat and pose minimal ignition risk. Examples include routine maintenance, repairs that don’t involve heat sources, or tasks like painting or cleaning.

Think of it this way: hot work is like cooking on a stove – the potential for starting a fire is high if precautions aren’t taken. Cold work is more like assembling furniture – it’s unlikely to start a fire, even without specific precautions.

Q 24. How do you prevent accidental ignition during hot work?

Preventing accidental ignition during hot work requires a multi-layered approach. First, a thorough pre-work inspection is crucial to identify and remove any flammable materials from the work area. This includes cleaning up debris, removing combustible substances, and ensuring proper ventilation. Second, appropriate fire prevention measures must be implemented. This involves using fire-resistant blankets to protect surrounding areas, having fire extinguishers readily available, and designating a fire watch to monitor the work area for any signs of ignition. Third, workers should use appropriate personal protective equipment (PPE), including flame-resistant clothing and eye protection. Lastly, ensuring that the equipment used is in good working order and properly maintained is critical.

- Clear the area: Remove all flammable materials within a specified radius.

- Use fire-resistant materials: Protect surrounding areas with fire blankets or other fire-resistant barriers.

- Provide fire suppression equipment: Have readily available fire extinguishers and trained personnel.

- Maintain proper ventilation: Ensure adequate airflow to prevent the buildup of flammable gases.

- Use appropriate PPE: Workers should wear flame-resistant clothing, gloves, and eye protection.

Q 25. Describe the use of fire blankets and other fire suppression equipment.

Fire blankets are essential fire suppression equipment used during hot work. They’re made from fire-resistant materials and designed to smother flames by depriving them of oxygen. They’re crucial for containing small fires quickly, preventing them from spreading. Fire extinguishers are another key component; they are rated for various types of fires (Class A, B, C, D) and should be selected and positioned strategically based on the potential fire hazards in the work area. Other equipment might include fire suppression systems like sprinklers or foam systems in larger facilities, and these should be checked regularly to ensure functionality. Remember, the goal isn’t just to extinguish a fire but to prevent it from starting in the first place. Fire watch personnel provide that crucial extra layer of safety.

Imagine a fire blanket as a firefighter’s first response in a small kitchen fire; it swiftly covers the flames to smother them, preventing escalation. Fire extinguishers are like the next level of defense, for larger or more stubborn fires.

Q 26. What training is required for personnel performing hot work?

Personnel performing hot work require comprehensive training covering several key areas. This includes thorough instruction on hot work permit procedures, including understanding the permit’s purpose, how to complete it correctly, and the importance of adhering to its stipulations. They need hands-on training in the safe use and handling of equipment relevant to their specific tasks. Moreover, fire safety training is paramount, including the proper use of fire extinguishers and fire blankets, as well as emergency procedures in case of fire. Finally, training should cover hazard recognition and risk assessment, allowing them to proactively identify and mitigate potential fire hazards before starting work. Regular refresher courses help ensure ongoing competence and up-to-date knowledge of safety regulations.

Q 27. Explain the concept of ‘Permit to Work’ system and its importance.

A Permit-to-Work (PTW) system is a formal procedure used to control potentially hazardous work activities. It’s a crucial safety management tool that ensures all necessary precautions are in place before commencing high-risk tasks, including hot work. The system involves issuing a permit only after a thorough risk assessment and confirmation that all safety measures are implemented. The permit outlines the specific work to be done, the hazards involved, and the necessary precautions. It requires authorization from multiple parties to ensure accountability and oversight. This structured approach helps mitigate the risk of accidents and promotes a safety-conscious work environment. The PTW system’s importance lies in its ability to standardize procedures, ensure accountability, and systematically reduce risks associated with hazardous operations.

Think of it as a gatekeeper; it only allows the commencement of work after all the required safety measures have been taken and approved. This prevents accidental initiation of potentially hazardous processes.

Q 28. How would you address a situation where a worker refuses to follow hot work permit instructions?

If a worker refuses to follow hot work permit instructions, a firm and measured approach is necessary. First, engage the worker in a calm and professional conversation to understand their concerns or objections. It’s important to listen empathetically but firmly reiterate the importance of following safety procedures. If the refusal persists, their supervisor or manager should intervene, reiterating the safety regulations and the potential consequences of non-compliance. Depending on company policies and the severity of the refusal, disciplinary actions may be necessary, ranging from a written warning to suspension or termination. Never compromise safety for the sake of expediency or to appease a worker unwilling to comply with critical safety protocols. The safety of all personnel is paramount.

This requires a documented process; every step, from the initial conversation to any disciplinary action, should be carefully documented for accountability and transparency.

Key Topics to Learn for Hot Work Permit Issuance Interview

- Hot Work Permit Procedures: Understanding the complete lifecycle of a hot work permit, from application to completion and closure, including all necessary documentation and approvals.

- Hazard Identification and Risk Assessment: Mastering the techniques for identifying potential fire and explosion hazards associated with hot work activities and implementing appropriate control measures. This includes practical application of risk matrices and risk reduction strategies.

- Safety Precautions and Control Measures: Detailed knowledge of fire prevention and suppression methods, including the use of fire extinguishers, fire blankets, and other safety equipment. Practical application of safe work practices and emergency response procedures.

- Legal and Regulatory Compliance: Familiarity with relevant codes, standards, and regulations governing hot work permits and fire safety in your industry or region. Understanding the consequences of non-compliance.

- Permit Review and Issuance Criteria: Knowing the criteria for approving or rejecting a hot work permit application, including assessment of risk assessments, control measures, and competence of personnel.

- Communication and Coordination: Understanding the importance of effective communication between all parties involved in hot work activities, including supervisors, workers, and emergency responders. Practical application of communication protocols and reporting procedures.

- Incident Investigation and Reporting: Knowledge of procedures for investigating incidents involving hot work and preparing accurate and detailed reports for analysis and prevention of future occurrences. This includes root cause analysis and corrective action planning.

- Hot Work Permit Software/Systems (if applicable): Understanding the use of any specific software or systems used for managing hot work permits within your target organization.

Next Steps

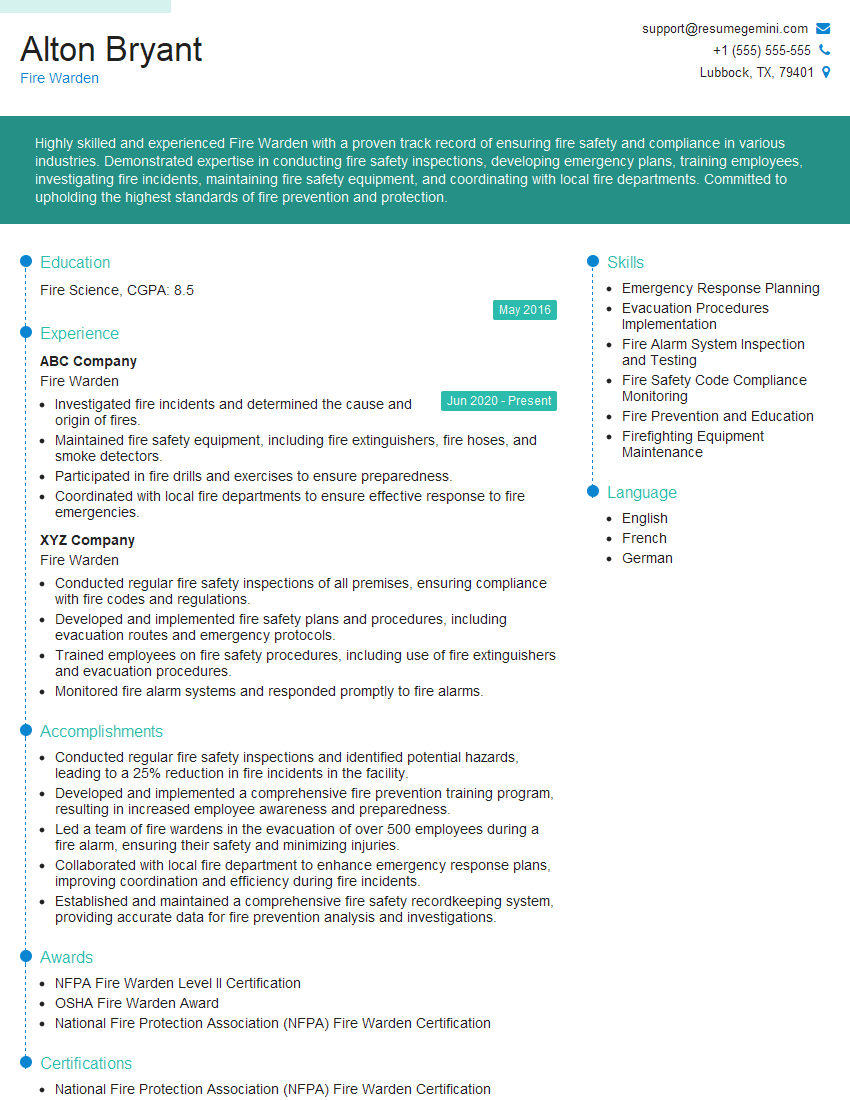

Mastering Hot Work Permit Issuance demonstrates a strong commitment to safety and regulatory compliance, significantly enhancing your career prospects in many industries. A well-crafted resume is crucial for showcasing these skills to potential employers. Building an ATS-friendly resume will maximize your chances of getting your application noticed. We recommend using ResumeGemini to create a professional and impactful resume. ResumeGemini offers examples of resumes tailored to Hot Work Permit Issuance to help guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good