Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Hydraulic and Electrical Systems Maintenance interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Hydraulic and Electrical Systems Maintenance Interview

Q 1. Explain the difference between a hydraulic pump and a hydraulic motor.

Hydraulic pumps and motors are the heart of any hydraulic system, but they perform opposite functions. Think of it like this: a pump is like your heart, pumping blood (hydraulic fluid) throughout your body (the system), while a motor is like a muscle, converting that blood (fluid pressure) into movement.

A hydraulic pump converts mechanical energy (typically from an electric motor or internal combustion engine) into hydraulic energy (fluid flow under pressure). It increases the pressure and flow rate of the hydraulic fluid. There are various types, including gear pumps, vane pumps, and piston pumps, each with its own advantages and disadvantages depending on the application. For example, gear pumps are simple and reliable for low-pressure applications, while piston pumps provide higher pressure and flow rates for heavy-duty machinery.

A hydraulic motor, conversely, converts hydraulic energy (pressure and flow) into mechanical energy (rotational or linear motion). It receives pressurized fluid and utilizes that pressure to drive a rotating shaft (like in a hydraulic rotary actuator) or to create linear movement (like in a hydraulic cylinder). Similar to pumps, different types of motors exist, offering variations in speed, torque, and efficiency.

Q 2. Describe the function of a hydraulic accumulator.

A hydraulic accumulator acts as a temporary energy storage device within a hydraulic system. Imagine it as a shock absorber or a reservoir for extra power. Its primary function is to smooth out pressure fluctuations, provide surge protection, and supply hydraulic power during brief periods of peak demand. It does this by storing pressurized hydraulic fluid and releasing it when needed.

Accumulators are crucial in several applications. For instance, they can help reduce the load on the hydraulic pump, extending its lifespan. They also provide backup power in case of pump failure, allowing for a controlled shutdown rather than a sudden stop. Furthermore, they minimize pressure surges caused by sudden changes in demand, protecting system components from damage.

Different types of accumulators exist, including bladder accumulators (using a flexible bladder to separate the fluid from the gas), diaphragm accumulators, and piston accumulators. The selection depends on the system’s specific requirements in terms of pressure, volume, and the type of fluid used.

Q 3. What are the common types of hydraulic fluids and their applications?

The choice of hydraulic fluid is critical to a system’s performance and longevity. Several types are available, each with specific properties and applications.

- Mineral Oils: These are the most common and cost-effective, suitable for many general-purpose applications. However, they have limitations in terms of temperature range and biodegradability.

- Synthetic Fluids: Offer enhanced performance in extreme temperature conditions, improved oxidation resistance, and better lubricity compared to mineral oils. They are often used in high-performance systems or where environmental concerns are significant.

- Water-Glycol Fluids: These are fire-resistant and environmentally friendly, ideal for applications where fire safety is paramount, such as in mining equipment or aircraft.

- Phosphate Esters: Another fire-resistant option offering excellent lubricity and compatibility with many seal materials. They are frequently used in aviation and other specialized applications.

Selecting the appropriate fluid depends on factors like operating temperature range, the type of seals and components in the system, and environmental considerations. Incorrect fluid choice can lead to premature component failure, leaks, and system malfunction.

Q 4. How do you troubleshoot a hydraulic leak?

Troubleshooting a hydraulic leak requires a systematic approach. Safety first! Always ensure the system is depressurized before starting any inspection.

- Visual Inspection: Carefully examine all hoses, fittings, seals, and components for visible leaks. Look for signs of wetness, dripping fluid, or fluid trails.

- Pressure Testing: Isolate sections of the system and pressurize them individually to pinpoint the leak’s location. Use pressure gauges to monitor pressure drops.

- Dye Penetrant Inspection: Apply a dye penetrant to suspect areas to make even small leaks easier to detect.

- Listening for Leaks: A hissing sound can indicate a leak, especially in pressurized components.

- Component Replacement: Once the source is identified, replace the faulty component, such as a hose, seal, or fitting. Always use the correct replacement parts.

Accurate identification of the leak source is crucial. Ignoring a leak can lead to significant fluid loss, system failure, and potential damage to surrounding equipment or the environment.

Q 5. Explain Pascal’s Law and its relevance to hydraulic systems.

Pascal’s Law is fundamental to hydraulic systems. It states that pressure applied to a confined fluid is transmitted equally and undiminished to every point in the fluid and to the walls of the container.

In simpler terms, if you apply pressure to one part of a sealed container filled with liquid, that pressure will be felt equally throughout the entire container. This principle is the foundation of hydraulic power multiplication. By using different sized pistons or cylinders, a small force applied to a smaller piston can generate a much larger force on a larger piston. This is why hydraulic systems are capable of lifting heavy loads or producing powerful movements.

Example: A hydraulic jack uses Pascal’s Law to lift heavy vehicles. A small force applied to the smaller piston is amplified proportionally to the area ratio between the two pistons, resulting in a much larger force capable of lifting the vehicle.

Q 6. What are the different types of hydraulic valves and their functions?

Hydraulic valves are essential control elements that regulate the flow of hydraulic fluid. They can direct, control, and stop fluid flow, making them crucial for managing the operation of hydraulic systems.

- Directional Control Valves: These valves switch the flow direction of hydraulic fluid, controlling the movement of actuators. They can be simple two-way valves (on/off) or more complex multi-way valves allowing for various movement sequences.

- Pressure Control Valves: These regulate the pressure within the system. Examples include pressure relief valves (to protect against overpressure), pressure reducing valves, and pressure sequence valves.

- Flow Control Valves: These control the rate of fluid flow, regulating the speed of hydraulic actuators. They include needle valves, flow control valves, and proportional flow control valves.

- Check Valves: These allow fluid flow in one direction only, preventing backflow. They are essential for maintaining system pressure and preventing unwanted movement.

The choice of valves depends on the specific requirements of the application, the complexity of the system, and the desired level of control.

Q 7. How do you diagnose a faulty hydraulic cylinder?

Diagnosing a faulty hydraulic cylinder involves a series of checks, again starting with safety precautions – ensure the system is depressurized.

- Visual Inspection: Check for external leaks, damage to the cylinder rod, or signs of bending or misalignment.

- Check for Free Movement: Manually check if the rod extends and retracts freely without binding or resistance. Sticking or rough movement indicates internal problems.

- Check for Rod Straightness: A bent or damaged rod will impact the cylinder’s performance and could damage other system components.

- Pressure Testing: Measure the pressure required for the cylinder to extend and retract. Any significant deviation from the specifications indicates internal issues such as seal damage or internal leakage.

- Internal Inspection (If Possible): If possible, carefully disassemble the cylinder to inspect seals, piston rings, and other internal components. Wear or damage to these components can be identified and addressed.

Remember that specialized tools and expertise are often required for proper cylinder diagnosis and repair, particularly for internal issues. Attempting complex repairs without proper training can lead to further damage and injury.

Q 8. Describe the process of bleeding a hydraulic system.

Bleeding a hydraulic system involves removing trapped air from the lines and components. Air in a hydraulic system reduces efficiency, causes erratic operation, and can damage components. The process varies slightly depending on the system’s design, but the general principles remain the same.

The process typically involves these steps:

- Lowering the reservoir: This allows air to rise to the top.

- Loosening bleed screws or valves: These are usually located at high points in the system or on individual actuators.

- Operating the hydraulic system: This helps to push the air out through the bleed points. This may involve cycling actuators or running the pump.

- Tightening the bleed screws or valves: Once a steady stream of clean hydraulic fluid, free of air bubbles, emerges, the screws or valves are tightened.

- Checking for leaks: After bleeding, inspect all connections for any leaks.

- Topping off the reservoir: Add hydraulic fluid to the reservoir to the correct level.

Example: Imagine bleeding the brakes on a car. You open the bleeder valve on each caliper, and an assistant pumps the brake pedal. Air bubbles will come out, replaced by brake fluid, until only fluid comes out. This same principle applies to larger hydraulic systems, although the methods of actuating the system can be more complex (e.g., using a pump or external power source).

Q 9. What safety precautions should be taken when working with hydraulic systems?

Working with hydraulic systems demands strict adherence to safety precautions due to the high pressures and potential for hazardous energy release.

- Eye protection: Always wear safety glasses or goggles to protect against potential fluid sprays or ejected debris.

- Hand protection: Heavy-duty gloves are necessary to protect against cuts, abrasions, and exposure to hydraulic fluid.

- Proper clothing: Avoid loose clothing that could get caught in moving parts.

- Lockout/Tagout procedures: Before working on any hydraulic system, implement a lockout/tagout procedure to prevent accidental activation. This ensures the system is completely de-energized and safe to work on.

- Pressure relief: Before disconnecting any lines or components, relieve system pressure using the designated pressure relief valve. Never assume the pressure is gone; always verify.

- Awareness of high-pressure jets: Be aware that even a small leak can result in a high-velocity jet of hydraulic fluid, which can cause serious injury.

- Proper disposal of fluids: Hydraulic fluids are often hazardous; follow proper procedures for collection and disposal of used fluid and contaminated materials.

Ignoring these precautions can lead to serious injuries, including high-pressure fluid injection injuries, which can be incredibly dangerous.

Q 10. What are the common causes of hydraulic system failure?

Hydraulic system failures stem from a variety of causes, often interlinked. Common culprits include:

- Contamination: Dirt, debris, and moisture entering the system can cause valve sticking, pump wear, and seal failure. This is often the biggest culprit.

- Component wear: Pumps, valves, and seals wear out over time due to normal operation, leading to leaks and reduced efficiency.

- Leaks: Leaks can lead to pressure loss, reduced system performance and eventual failure.

- Improper maintenance: Lack of regular maintenance, including fluid changes and inspections, can accelerate component wear and increase the risk of failure.

- Overheating: Excessive heat can degrade hydraulic fluid and damage components, particularly seals and hoses.

- Incorrect fluid level: Low fluid levels lead to cavitation, which is a phenomenon that damages pumps.

- Improper installation: Incorrect assembly or installation of components can cause premature failure.

Example: A hydraulic excavator experiencing sluggish movement may be due to contaminated fluid causing valve sticking or a worn pump. Regular fluid analysis and preventative maintenance can greatly reduce the likelihood of these issues.

Q 11. Explain the difference between AC and DC electricity.

The primary difference between AC (Alternating Current) and DC (Direct Current) electricity lies in the direction of electron flow.

- DC electricity: Electrons flow in one direction consistently. Think of a battery; its positive and negative terminals maintain a constant voltage polarity, resulting in a unidirectional current flow.

- AC electricity: Electrons change direction periodically, usually 50 or 60 times per second (Hertz). Imagine a water pump pushing water back and forth through a pipe instead of just in one direction. This cyclical change in direction is what distinguishes AC from DC.

Applications: DC is commonly used in low-voltage applications like batteries and electronics, while AC is primarily used for power transmission over long distances because of its efficient transformation to higher voltages for transmission and then stepping down to lower voltages for safer use in homes and industry.

Q 12. Describe the function of a circuit breaker.

A circuit breaker is an automatic electrical switch designed to protect an electrical circuit from damage caused by overcurrent/overload or short circuits. It acts as a safety device, interrupting the flow of electricity when a fault occurs.

Function: When the current flowing through a circuit exceeds a predetermined threshold (due to overload or short circuit), the circuit breaker’s internal mechanism trips, opening the circuit and stopping the flow of current. This prevents overheating, fires, and damage to equipment.

Types: There are various types including thermal, magnetic, and thermo-magnetic circuit breakers, each employing different mechanisms to detect and respond to overcurrent situations.

Example: Imagine a house circuit overloaded by too many appliances. The circuit breaker would trip, cutting off the power to prevent a fire hazard. Resetting it involves simply switching the breaker back on, provided the overload condition has been corrected.

Q 13. What are the common types of electrical motors and their applications?

Several types of electrical motors exist, each suited to specific applications.

- AC Induction Motors: These are the most common type, robust, relatively inexpensive, and require minimal maintenance. They are used widely in industrial settings like fans, pumps, and conveyors.

- DC Motors: Offer precise speed control and high torque at low speeds. Commonly used in applications requiring precise speed control, like robotics and electric vehicles.

- Stepper Motors: Provide precise rotational control in discrete steps, making them ideal for positioning systems in printers, CNC machines, and 3D printers.

- Servo Motors: Combine a motor with an integrated feedback mechanism (like an encoder), allowing for very precise control and positioning. Used in robotics, automation, and precision machinery.

- Synchronous Motors: Run at a constant speed synchronized with the AC power frequency; often used in applications requiring constant speed like clocks and timers.

The choice of motor depends on factors like required speed, torque, precision, cost, and operating environment.

Q 14. How do you troubleshoot a motor control circuit?

Troubleshooting a motor control circuit requires a systematic approach.

Steps:

- Visual Inspection: Begin by carefully inspecting all wiring, connections, and components for any visible damage, loose connections, or burn marks. Look for anything out of the ordinary.

- Check Power Supply: Verify the correct voltage and phase sequence are being supplied to the motor control circuit. Use a multimeter to test the voltage at the input terminals.

- Check Control Signals: Examine the control signals (start, stop, direction) using a multimeter or logic probe to ensure they are reaching the motor starter correctly and the correct sequence is being observed.

- Test the Motor Starter: If the control signals are correct, test the motor starter itself. This often involves checking the overload relays and other internal components to determine if the starter is functioning properly.

- Check the Motor: If the starter checks out, test the motor itself using a multimeter or a dedicated motor testing equipment. Check for winding resistance, insulation resistance, and any signs of damage.

- Check the Wiring: If everything else checks out, carefully inspect and retest all wiring connections in the control circuit. Look for loose connections or wiring that could be shorted or grounded.

Example: A motor fails to start. The troubleshooting process might reveal a blown fuse in the power supply, a faulty start button, a problem within the motor starter itself, or a short circuit in the motor windings.

Effective troubleshooting often requires a combination of methodical checks, understanding of motor control circuits, and the use of appropriate testing equipment. Always prioritize safety and follow the manufacturer’s recommendations.

Q 15. Explain Ohm’s Law and its application in electrical circuits.

Ohm’s Law is a fundamental principle in electrical circuits that describes the relationship between voltage (V), current (I), and resistance (R). It states that the current flowing through a conductor is directly proportional to the voltage across it and inversely proportional to its resistance. This relationship is expressed mathematically as: V = I * R

In simpler terms, imagine water flowing through a pipe. Voltage is like the water pressure, current is the flow rate of the water, and resistance is how narrow the pipe is. Higher pressure (voltage) leads to a faster flow (current), while a narrower pipe (higher resistance) reduces the flow.

Applications: Ohm’s Law is crucial for calculating any one of the three variables (V, I, or R) if the other two are known. This is vital in circuit design, troubleshooting, and ensuring components operate within their safe limits. For example, if you know the voltage of your power supply and the resistance of a resistor, you can calculate the current flowing through it to avoid overheating or damage.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of electrical wiring and their applications?

Electrical wiring comes in various types, each suited for specific applications based on factors like voltage, current carrying capacity, and environmental conditions. Some common types include:

- Solid Wire: A single strand of copper or aluminum, typically used for permanent wiring in buildings or appliances where flexibility is less critical. It’s often more cost-effective than stranded wire.

- Stranded Wire: Composed of multiple smaller strands of copper or aluminum twisted together, offering greater flexibility. It’s preferred in applications where the wire needs to bend frequently, like appliance cords or automotive wiring.

- Coaxial Cable: Used for transmitting high-frequency signals with minimal signal loss. It has a central conductor surrounded by insulation, a shield, and an outer jacket, commonly used for cable television and internet connections.

- Fiber Optic Cable: Transmits data as light pulses, offering high bandwidth and long transmission distances with minimal signal degradation. Used extensively in telecommunications and high-speed internet networks.

The choice of wiring depends heavily on the application. High-current applications require thicker gauge wire to handle the current without overheating. Environments with high moisture require wire with better insulation. For example, a house’s main power supply uses heavier-gauge solid wire, while a lamp cord uses flexible stranded wire.

Q 17. How do you test for continuity and voltage in a circuit?

Testing for continuity and voltage involves using a multimeter, a versatile instrument for measuring electrical quantities.

Continuity Test: This checks if there’s a complete, unbroken path for current to flow between two points in a circuit. You set the multimeter to the continuity setting (often symbolized by a diode or a buzzing sound). Touching the probes to the two points should result in a continuous tone or an indication of continuity if the circuit is closed. A lack of continuity indicates a break in the circuit, like a broken wire or a faulty component.

Voltage Test: This measures the electrical potential difference between two points in a circuit. Set the multimeter to the appropriate voltage range (AC or DC, and an appropriate voltage level). Touching the probes to the points will show the voltage reading. A reading of zero volts usually indicates a lack of power or a short circuit. Always select a voltage range higher than what you expect to measure to prevent damaging the multimeter.

Example: To test a switch, you’d check continuity when the switch is closed (continuity should be present) and then open (continuity should be absent). You’d then check the voltage across the switch terminals to verify power is present when the switch is closed.

Q 18. What safety precautions should be taken when working with electrical systems?

Safety is paramount when working with electrical systems. Never compromise on safety practices, as electrical hazards can be fatal. Key precautions include:

- Lockout/Tagout Procedures: Always de-energize the circuit completely before working on it. Lock and tag the circuit breaker or disconnect switch to prevent accidental re-energization.

- Personal Protective Equipment (PPE): Wear insulated gloves, safety glasses, and appropriate footwear. Consider using a safety harness when working at heights.

- Proper Tools: Use insulated tools specifically designed for electrical work. Never use damaged or makeshift tools.

- Awareness of Surroundings: Be mindful of potential hazards like wet conditions, flammable materials, and other workers.

- Training and Knowledge: Only work on electrical systems if you are properly trained and understand the risks involved. If unsure, seek professional help.

Always remember: When in doubt, don’t do it. If you’re uncomfortable or unsure about any aspect of the work, consult a qualified electrician.

Q 19. What are the common causes of electrical system failure?

Electrical system failures can stem from various causes, including:

- Overloading: Drawing more current than the system is designed for can lead to overheating, wire melting, and component failure.

- Short Circuits: An unintended path for current to flow, often caused by damaged insulation or loose connections, leading to excessive current and potential fire hazards.

- Loose Connections: Poorly connected wires or terminals can increase resistance, leading to overheating and potential fire hazards.

- Component Failure: Components like capacitors, resistors, and switches can fail due to age, wear, or overheating.

- Environmental Factors: Moisture, corrosion, extreme temperatures, and rodents can damage electrical components and wiring.

- Faulty Wiring: Improper installation or damaged wiring can lead to a multitude of problems.

Regular inspection and maintenance are crucial to prevent these issues and prolong the lifespan of the electrical system.

Q 20. Explain the purpose of grounding and bonding in electrical systems.

Grounding and bonding are essential safety measures in electrical systems that protect against electrical shocks and fire hazards.

Grounding: This involves connecting non-current-carrying metallic parts of an electrical system to the earth. If a fault occurs, it provides a low-resistance path for fault current to flow to the earth, tripping the circuit breaker and preventing dangerous voltage buildup on the equipment’s metallic casing.

Bonding: This involves connecting multiple metallic parts of a system together to ensure they are at the same electrical potential. This prevents voltage differences between these parts, reducing the risk of electric shock if a fault occurs. For instance, metal pipes and equipment casings are bonded together to create a safe equipotential zone.

Analogy: Imagine a lightning strike. Grounding provides a safe path for the lightning current to flow into the earth, preventing damage to your house. Bonding ensures that all the metal parts of your house are at the same electrical potential, preventing dangerous voltage differences.

Q 21. How do you interpret electrical schematics?

Interpreting electrical schematics requires understanding the symbols used and how they represent the components and their connections. Schematics are simplified diagrams that show the functional relationships between different parts of an electrical system.

Steps to Interpret a Schematic:

- Familiarize yourself with common symbols: Learn the symbols for components like resistors, capacitors, inductors, switches, and power sources.

- Trace the signal flow: Start at the power source and trace the path of the current or signal flow through the various components.

- Identify circuit paths: Look for series and parallel connections between components.

- Understand the logic: Consider how different components interact and what the overall function of the circuit is.

- Use reference materials: If you encounter unfamiliar symbols, consult an electrical engineering handbook or online resource.

Practice is key. The more you work with schematics, the more comfortable you will become in understanding them. Start with simple circuits and gradually progress to more complex ones. It’s also helpful to compare a schematic with a physical circuit to build your understanding.

Q 22. Describe your experience with PLC programming and troubleshooting.

My PLC programming experience spans over eight years, encompassing various platforms like Allen-Bradley (Logix5000, RSLogix 500), Siemens (TIA Portal), and Schneider Electric (Unity Pro). I’m proficient in ladder logic, structured text, and function block diagrams. Troubleshooting involves a systematic approach: I begin by reviewing alarm logs and historical data to identify patterns. Then, I use diagnostic tools like online monitoring and forced outputs to isolate the faulty component. For example, I once resolved a production line stoppage by identifying a faulty proximity sensor using the PLC’s diagnostic capabilities, leading to a quick replacement and minimal downtime. I’m also experienced in using simulation software to test PLC programs before deployment, minimizing potential issues in the field.

A recent project involved migrating an older PLC system to a more modern platform. This required not only re-programming the logic but also thoroughly testing it to ensure compatibility with existing hardware and processes. This involved extensive testing and verification.

Q 23. How do you diagnose and repair faulty sensors and actuators?

Diagnosing faulty sensors and actuators involves a multi-step process. First, I’d visually inspect the component for obvious damage or loose connections. Then, I’d use appropriate testing equipment—multimeters for electrical signals, pressure gauges for hydraulic systems, and signal analyzers to check sensor outputs. For example, if a pressure sensor is suspect, I’d compare its readings to other pressure points in the system and possibly use a calibrated pressure gauge for verification. If it’s an actuator, I’d check its power supply, control signals, and mechanical operation. Sometimes, a simple calibration or cleaning resolves the issue. If not, I’d replace the faulty component after verifying the rest of the system is functioning correctly.

I often use process diagrams and schematics to trace signals and pinpoint the location of the failure. Imagine troubleshooting a robotic arm: if the arm isn’t moving, I’d systematically check each sensor (position, limit switches) and actuator (hydraulic cylinder, electric motor) using the diagrams to follow the signal path.

Q 24. What is your experience with preventive maintenance procedures?

Preventive maintenance is crucial for avoiding costly breakdowns. My experience includes developing and implementing preventive maintenance schedules based on manufacturer recommendations, operating hours, and historical failure data. This often involves creating checklists for regular inspections and lubrication of equipment. For instance, I’ve developed a detailed schedule for hydraulic systems that includes oil analysis, filter changes, and leak checks at specified intervals. Additionally, I’ve implemented predictive maintenance strategies utilizing vibration analysis and thermal imaging to detect potential problems before they become major issues. This allows for proactive repairs and extends the lifespan of equipment.

I’ve found that using CMMS (Computerized Maintenance Management System) software is essential for scheduling, tracking, and managing preventive maintenance activities effectively. This improves efficiency and provides a central database for all maintenance records.

Q 25. Describe your experience with different types of industrial control systems.

I’ve worked with a variety of industrial control systems, including Programmable Logic Controllers (PLCs), Distributed Control Systems (DCS), Supervisory Control and Data Acquisition (SCADA) systems, and Human-Machine Interfaces (HMIs). My experience extends to various communication protocols such as Modbus, Profibus, Ethernet/IP, and others. I understand the interplay between these different systems and how they integrate to control complex processes. For example, I’ve worked on projects where PLCs control individual machines while a DCS manages the overall process, with SCADA providing visualization and operator control. My understanding extends to both discrete and continuous control systems, as required by different applications.

In one project, I was responsible for integrating a new SCADA system with existing PLC and DCS systems in a chemical plant. This required a deep understanding of different communication protocols and data formats to ensure seamless data exchange.

Q 26. Explain your troubleshooting methodology for complex electro-mechanical systems.

My troubleshooting methodology for complex electro-mechanical systems follows a structured approach. It begins with a thorough understanding of the system’s functionality and schematic diagrams. I then systematically isolate the problem by checking power supply, control signals, and mechanical operation of each component. I utilize a ‘divide and conquer’ approach: if the system is modular, I test each module separately. This is similar to diagnosing a car problem – you check the battery, then the starter, then the ignition system and so on.

I rely heavily on diagnostic tools like oscilloscopes, multimeters, and specialized software to analyze signals and identify anomalies. Proper documentation and clear communication are essential throughout the process to avoid errors and ensure efficiency. I always prioritize safety and follow all relevant lockout/tagout procedures when working with potentially hazardous equipment.

Q 27. How do you prioritize maintenance tasks in a busy environment?

Prioritizing maintenance tasks in a busy environment involves a combination of factors. I use a risk-based approach, prioritizing tasks that pose the greatest risk to production or safety. This includes considering factors such as the criticality of the equipment, the potential consequences of failure, and the likelihood of failure. Urgency is also a key factor; tasks with immediate safety or production implications are given top priority. A CMMS is invaluable in this process; it allows for efficient scheduling based on all of these parameters.

For example, a leak in a high-pressure hydraulic line poses an immediate safety risk and would have top priority, whereas a preventative lubrication task on a less critical machine could be scheduled for a later time. The CMMS then assists with work order assignment and tracking of completed tasks.

Q 28. Describe a time you had to solve a challenging hydraulic or electrical problem.

During a large-scale chemical processing plant shutdown, a critical pump failed, halting the entire process. The initial diagnosis pointed to a faulty motor, but after replacing it, the problem persisted. Using a combination of pressure gauges, flow meters, and temperature sensors, I discovered that the pump’s internal seals had worn down and were leaking hydraulic fluid, causing cavitation and preventing the pump from functioning correctly. The problem wasn’t simply electrical; it had a significant hydraulic component. Replacing the worn seals after confirming the electrical components were functioning correctly solved the issue.

This experience highlighted the importance of a holistic approach to troubleshooting and the need to consider all aspects of a system—electrical, mechanical, and hydraulic—when diagnosing complex problems.

Key Topics to Learn for Hydraulic and Electrical Systems Maintenance Interview

- Hydraulic System Fundamentals: Understanding fluid power principles, Pascal’s Law, and the operation of hydraulic pumps, valves, and actuators. Consider practical applications like troubleshooting hydraulic leaks or analyzing system pressure.

- Electrical System Fundamentals: Mastering basic electrical theory (Ohm’s Law, Kirchhoff’s Laws), understanding AC/DC circuits, and familiarizing yourself with various electrical components (motors, sensors, PLCs).

- Troubleshooting and Diagnostics: Develop strong skills in identifying malfunctions in both hydraulic and electrical systems. Practice using diagnostic tools and interpreting schematics and diagrams. Consider real-world scenarios involving system failures and their systematic resolution.

- Preventive Maintenance: Learn about scheduled maintenance procedures, including inspection, lubrication, and component replacement. Understand the importance of preventative maintenance in extending system lifespan and minimizing downtime.

- Safety Procedures: Demonstrate a thorough understanding of safety regulations and best practices related to working with high-pressure hydraulic systems and electrical equipment. This includes lockout/tagout procedures and personal protective equipment (PPE).

- PLC Programming (if applicable): If your target role involves Programmable Logic Controllers (PLCs), prepare to discuss your experience with PLC programming, troubleshooting, and ladder logic diagrams.

- Hydraulic and Electrical System Integration: Understand how hydraulic and electrical systems work together in complex machinery. Be prepared to discuss the interplay between the two systems and how problems in one can affect the other.

Next Steps

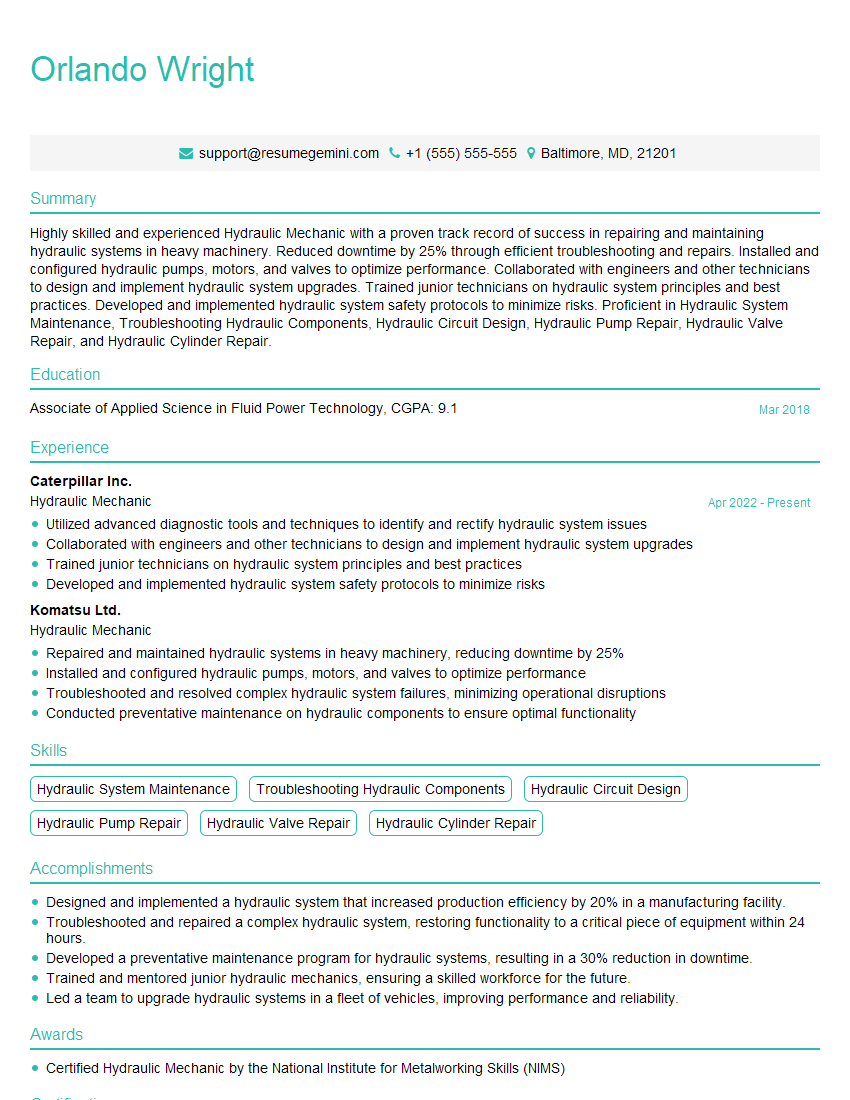

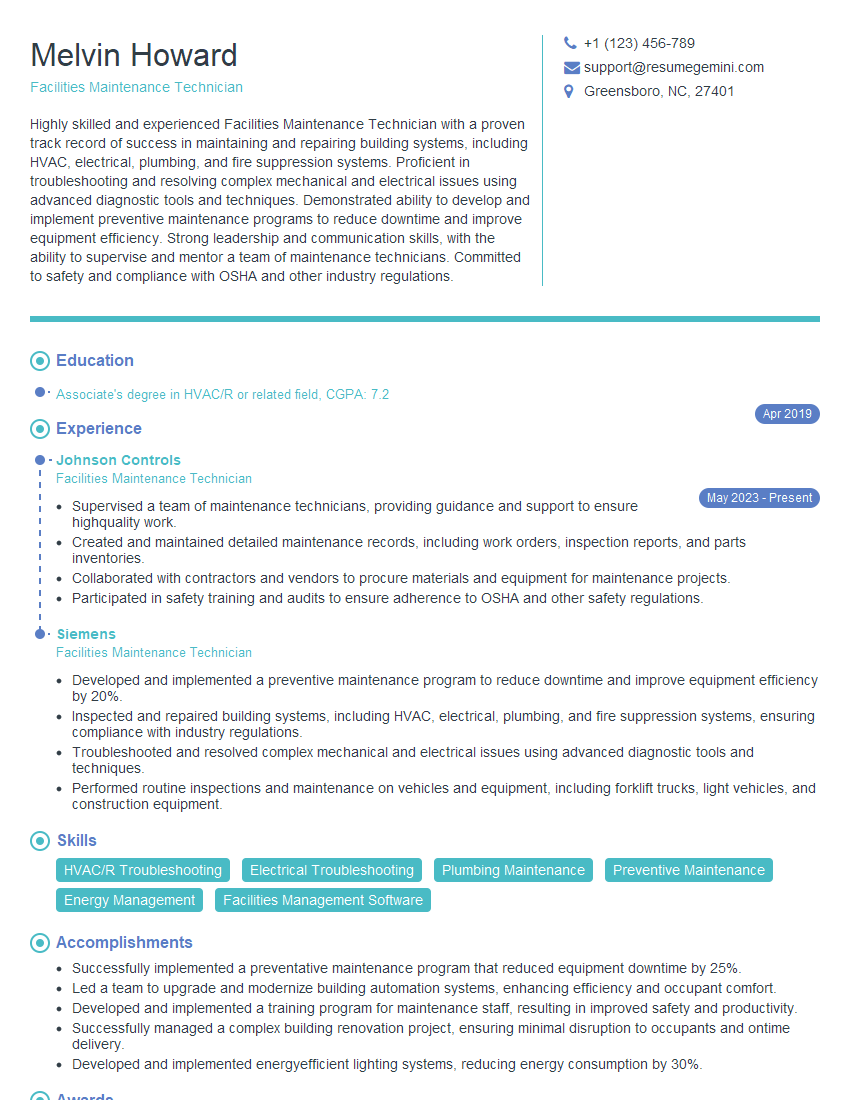

Mastering Hydraulic and Electrical Systems Maintenance opens doors to rewarding and stable careers in various industries. A strong understanding of these systems is highly valued, leading to greater job security and career advancement opportunities. To maximize your chances of landing your dream job, create an ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, ensuring your application stands out. We provide examples of resumes tailored to Hydraulic and Electrical Systems Maintenance to guide you through the process. Invest time in crafting a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good