The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Identifying and removing cracked or broken eggs interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Identifying and removing cracked or broken eggs Interview

Q 1. Describe the visual cues you use to identify a cracked egg.

Identifying a cracked egg relies heavily on visual inspection. Cracks can range from barely visible hairline fractures to large, gaping holes. I look for several key indicators:

- Visible Cracks: This is the most obvious sign. Even tiny cracks can be a problem. I often hold the egg up to a bright light to detect subtle fractures.

- Shell Discoloration: Cracked eggs often show discoloration around the crack, indicating possible contamination from bacteria or other microorganisms.

- Shell Texture Changes: A cracked egg might feel slightly different to the touch around the damaged area, sometimes rougher or softer.

- Leakage: If the crack is significant, you might see a slight leakage of egg white or yolk.

Think of it like examining a precious vase – you’d carefully inspect it for any imperfections before placing it on display. Similarly, thorough visual inspection is crucial when handling eggs.

Q 2. What methods do you employ to efficiently remove cracked eggs from a batch?

Efficiently removing cracked eggs from a batch requires a systematic approach. My process typically involves:

- Candling: Using a candling light, I can quickly and effectively scan each egg to identify internal or external cracks that might be missed with a quick visual inspection. This method is particularly useful in identifying hairline fractures.

- Visual Inspection: After candling, I conduct a thorough visual inspection of the eggs, paying close attention to the details mentioned earlier (visible cracks, discoloration, texture changes).

- Manual Separation: Once identified, cracked eggs are gently removed from the batch using a clean utensil, such as a slotted spoon. This prevents contamination of the uncracked eggs.

- Automated Systems (Large-Scale): For larger-scale operations, automated egg grading and sorting machines incorporate cameras and sensors that can detect cracks with high accuracy, making the process faster and more efficient.

Imagine sorting through a basket of apples – you’d visually inspect each apple, removing any bruised or damaged ones. The same principle applies to egg selection, ensuring only high-quality eggs proceed further.

Q 3. Explain the importance of promptly removing cracked eggs in maintaining food safety.

Prompt removal of cracked eggs is paramount for food safety due to the increased risk of bacterial contamination. The shell provides a natural barrier against microorganisms. When compromised, bacteria like Salmonella can easily penetrate the egg and contaminate the contents. Consuming contaminated eggs can lead to foodborne illnesses, including salmonellosis, characterized by symptoms such as diarrhea, fever, and abdominal cramps.

Timely removal minimizes the risk of cross-contamination. Cracked eggs should be immediately discarded, preventing the spread of bacteria to other eggs or food surfaces. This is a crucial aspect of maintaining a hygienic food preparation environment.

Q 4. How would you handle a situation where a significant portion of eggs in a batch are cracked?

If a significant portion of a batch is cracked, I would first assess the cause. Was there a problem with handling or transportation? Understanding the root cause helps prevent future issues. Next, I’d separate the cracked eggs immediately, as described earlier. Depending on the context (e.g., a commercial setting vs. home cooking), I might consider:

- Replenishing the Stock: If commercially viable, I’d replace the damaged eggs with fresh, intact ones.

- Adjusting Recipes: Depending on the severity of cracking, and the recipes intended to use these eggs (e.g., egg-white omelets versus cakes), I might adapt recipes to use only the liquid egg whites and yolks, discarding the shells.

- Discarding the Batch: If the extent of damage is significant, and the quality and safety of the remaining eggs is in doubt, discarding the entire batch would be the safest course of action.

Imagine a baker finding a large quantity of cracked eggs – they might need to adjust their production schedule or find alternative ingredients to avoid disruption.

Q 5. What are the potential health risks associated with consuming cracked eggs?

Consuming cracked eggs poses significant health risks, primarily due to the potential for bacterial contamination. Salmonella is a common concern. Even if the egg looks and smells fine, bacteria might have already entered and multiplied. Symptoms of salmonellosis can range from mild discomfort to severe illness, especially for vulnerable populations like children, the elderly, and people with compromised immune systems. Other bacteria and pathogens might also contaminate cracked eggs, leading to various foodborne illnesses.

Think of a cracked egg like an open wound – it’s vulnerable to infection. The risk of consuming such eggs outweighs any potential benefit.

Q 6. Describe your experience with different egg sorting and grading systems.

My experience encompasses various egg sorting and grading systems, from manual inspection to sophisticated automated technologies. Manual inspection is labor-intensive but allows for detailed visual assessment. I’ve worked with optical grading systems that use cameras and light sensors to detect cracks, shell imperfections, and internal quality. These systems are much faster and more objective than manual methods. I’ve also worked with weight-based sorters that classify eggs according to size.

In larger facilities, I’ve seen conveyor belt systems with automated cracking detectors and rejection mechanisms; the cracked eggs are automatically diverted to a separate container. These automated systems, while expensive, offer significant improvements in efficiency and consistency of egg quality control.

Q 7. How do you ensure the proper disposal of cracked eggs?

Proper disposal of cracked eggs is crucial to prevent contamination and maintain hygiene. In commercial settings, cracked eggs are typically disposed of in sealed containers to prevent leakage and odors. These containers are then sent to a commercial rendering plant or designated waste facility for proper treatment and disposal. In home settings, cracked eggs should be immediately sealed in a plastic bag and placed in a trash receptacle. Avoid leaving cracked eggs out in the open where they could attract pests.

Think of it like handling medical waste – safety and hygiene protocols are critical. The same care should be applied when dealing with cracked eggs.

Q 8. What are the industry standards for acceptable egg breakage rates?

Acceptable egg breakage rates are industry-specific and depend on factors like transportation methods, egg size, and the fragility of the eggs themselves. Generally, a well-managed operation aims for breakage rates below 1%. This means that for every 1000 eggs handled, less than 10 should be broken. However, some specialized operations, such as those dealing with free-range eggs or extra-large eggs, may have slightly higher tolerances. The key is consistent monitoring and improvement through process optimization. Exceeding 1% often signals a need to investigate and address weaknesses in the handling process.

Q 9. How do you maintain hygiene and sanitation while handling eggs?

Maintaining hygiene and sanitation during egg handling is paramount to prevent contamination and ensure food safety. This involves several key steps: Firstly, all personnel should wear clean, protective clothing, including gloves and hairnets. Secondly, work surfaces must be regularly sanitized with food-grade disinfectants. Thirdly, any spillage must be cleaned immediately. Fourthly, eggs should be handled gently to avoid cracking, which can introduce bacteria. Finally, regular handwashing is crucial, especially after handling cracked or broken eggs. Think of it like this: you’re handling a delicate product that is extremely susceptible to bacterial growth. Even a small crack compromises the shell’s protective barrier.

Q 10. Explain the difference between a hairline crack and a significant crack in an egg.

The difference between a hairline crack and a significant crack is primarily one of severity and visibility. A hairline crack is a very fine fracture in the eggshell, often barely visible to the naked eye. It might be felt as a slight imperfection when gently rolling the egg across your fingers. A significant crack, on the other hand, is a more pronounced break in the shell, often easily seen and potentially allowing some egg white or yolk to leak out. While both represent a compromise in the shell’s integrity, a significant crack poses a much higher risk of contamination and should immediately disqualify the egg from further use.

Q 11. How would you assess the overall quality of eggs based on their appearance and feel?

Assessing egg quality through appearance and feel involves a combination of visual and tactile inspection. Visually, we look for things like shell cleanliness, shape and uniformity, and the absence of cracks. A clean, symmetrical egg with a smooth shell is generally a good indicator. Tactile assessment involves gently rolling the egg in the palm. A strong, sturdy egg will feel solid and resistant to slight pressure. Eggs that feel weak or fragile, even without visible cracks, are likely of lower quality. Moreover, the weight of the egg relative to its size is a reliable indicator of internal quality. Heavy eggs generally suggest a larger, healthier yolk.

Q 12. What are the potential causes of cracked eggs during transportation or storage?

Cracked eggs during transportation or storage can result from several factors. Rough handling is a major culprit; vibrations, impacts, and careless stacking can easily cause fractures. Temperature fluctuations can also contribute, as expansion and contraction of the egg’s contents can create internal pressure, leading to cracks. Poorly designed packaging that doesn’t provide adequate cushioning or protection also plays a significant role. In short, it’s a matter of managing physical stress and environmental factors effectively.

Q 13. How do you prevent cross-contamination when handling cracked and intact eggs?

Preventing cross-contamination when handling cracked and intact eggs necessitates strict procedures. Cracked eggs should always be separated from intact eggs to avoid spreading any potential contaminants. Dedicated tools and surfaces should be used for handling cracked eggs, and these should be thoroughly sanitized afterwards. Gloves should be changed frequently, and handwashing is essential. Imagine it like handling raw meat – you wouldn’t want any juices from a compromised piece to touch your uncontaminated products.

Q 14. Describe your experience with using egg candling techniques to detect cracks.

Egg candling is a time-tested technique for detecting cracks and other internal imperfections. I’ve used this extensively throughout my career. It involves holding an egg up to a bright light source (a candling lamp is ideal) and rotating it. A cracked egg will often reveal a visible break in the shell or small light leaks, showing the air pocket inside. Air cells increase in size as eggs age. The light will show the size and shape of the air cell, which can also hint at egg freshness. Candling is an efficient and effective way to quickly identify eggs unsuitable for consumption or further processing.

Q 15. What safety measures do you take when handling a large quantity of eggs?

Handling large quantities of eggs safely requires a methodical approach. Think of it like handling delicate glassware – care and attention are paramount. My safety measures begin with proper personal protective equipment (PPE), including cut-resistant gloves to prevent injuries from broken shells. I always work on clean, sanitized surfaces to minimize contamination risks. I avoid rushing and maintain a steady pace to reduce the chances of accidental drops or breakage. Furthermore, I ensure the area is well-lit to improve visibility and reduce the risk of overlooking cracked eggs. Regular breaks are essential to prevent fatigue, a major contributor to accidents.

For very large quantities, I implement a system of designated work zones – a receiving area, inspection zone, and processing/storage areas – to maintain order and reduce congestion, thereby minimizing the risk of accidental damage or spillage.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain accurate records of egg breakage and waste?

Maintaining accurate records of egg breakage and waste is critical for inventory management and loss prevention. I use a combination of digital and manual methods. A digital spreadsheet tracks daily egg counts, the number of cracked eggs identified, and the reasons for breakage (e.g., handling, transportation damage). This data is regularly updated throughout the day. A corresponding manual log provides backup and detailed notes on unusual occurrences, including any potential contributing factors or observations about the quality of the egg deliveries. For example, if a specific supplier consistently provides a high percentage of cracked eggs, this is noted in the manual log for further investigation.

These records are essential for identifying trends, calculating waste percentages, and making data-driven decisions on improvements in handling techniques or supplier choices. This data is vital for cost analysis and reporting to management.

Q 17. Describe a time you had to make a quick decision regarding the disposal of compromised eggs.

During a busy morning rush, we received a delivery of eggs with a significantly higher than usual number of cracked shells. A quick assessment revealed widespread contamination risk due to shell fragments and potential bacterial exposure. My immediate priority was to prevent the contaminated eggs from entering the production line. I had to make a quick decision about disposal. I immediately segregated the compromised eggs, clearly labeled them as ‘rejected,’ and contacted our waste management team for immediate removal and disposal in accordance with our facility’s biohazard protocols. I also alerted my supervisor about the situation and the actions taken to ensure transparency and prevent potential future occurrences by communicating the potential source of the problem.

This swift action prevented a potential food safety issue and maintained the integrity of our product.

Q 18. What are the regulations regarding the handling and disposal of cracked eggs in your area?

Regulations regarding the handling and disposal of cracked eggs vary by location, but they generally prioritize food safety and environmental protection. In our area, cracked eggs are considered a biohazard and require immediate disposal in accordance with local health and safety regulations. They are typically disposed of separately from other waste, often in sealed containers designated for biohazardous material, to minimize contamination risks. Detailed record-keeping is mandated, and regular inspections by health authorities are commonplace. Specific regulations cover proper cleaning and sanitation procedures in areas where eggs are handled, along with employee training in proper handling and safety protocols.

Regular updates on these regulations are crucial to maintaining compliance.

Q 19. How do you communicate effectively about egg quality issues with your supervisor or team?

Effective communication regarding egg quality issues is paramount. I employ a proactive approach, using a combination of verbal and written reports. If I notice a significant increase in breakage or a quality concern, I immediately inform my supervisor, using a clear and concise verbal report, describing the extent of the problem, potential causes, and recommended corrective actions. This initial verbal communication is then followed up with a detailed written report. For example, a detailed email might include photos of the damaged eggs, the quantity affected, potential source(s), and proposed solutions to prevent recurrence. Working as a team, we openly discuss solutions and prevention measures. This approach ensures that everyone is aware of the situation and actively involved in problem-solving.

Q 20. How do you prioritize tasks when dealing with a large volume of eggs with varying levels of damage?

Prioritizing tasks when handling a large volume of eggs with varying levels of damage involves a systematic approach. I use a tiered system. First, I prioritize the immediate removal and disposal of severely cracked or contaminated eggs to minimize biohazard risks. Next, I focus on processing eggs with minor cracks that can still be used, but often require careful sorting and hand-inspection. Finally, I address the undamaged eggs, preparing them for processing or storage. This prioritization ensures that potentially hazardous materials are addressed first, minimizing the risk of contamination and food safety issues. This approach, which combines risk assessment and efficient workflow, ensures timely handling and minimizes waste.

Q 21. What is your experience with using automated egg sorting machines?

I have extensive experience using automated egg sorting machines. These machines significantly enhance efficiency and accuracy in identifying and separating cracked or damaged eggs from intact ones. They employ various technologies, such as optical scanners and weight sensors, to quickly assess egg quality. The machines not only identify cracked eggs but also can sort eggs based on size and weight, optimizing the use of eggs for various applications. While the machines greatly increase efficiency, they still require human oversight for quality control and to handle exceptions or unusual cases. My role often includes regular maintenance checks on these machines, quality control of the sorted eggs, and troubleshooting any malfunctions to ensure continuous operation.

The implementation of these machines has dramatically reduced our error rates and improved productivity.

Q 22. Describe your understanding of the different types of egg cracks (e.g., surface cracks, check cracks).

Egg cracks aren’t all created equal. Understanding the different types is crucial for effective removal and preventing contamination. We primarily categorize cracks into two main groups: surface cracks and check cracks.

Surface cracks: These are visible fractures on the eggshell’s surface. They can range from tiny hairline fissures to larger breaks, often easily detectable by visual inspection under good lighting. Think of a small scratch or a slightly chipped edge – these are surface cracks. They often don’t compromise the egg’s integrity immediately, but they greatly increase the risk of bacterial contamination.

Check cracks: These are more insidious. They’re hairline fractures within the shell itself, invisible to the naked eye. You can’t see them, but they weaken the shell structure, making the egg more vulnerable to breakage and contamination during handling and processing. Imagine a tiny spiderweb crack hidden under the surface—that’s a check crack. These are harder to detect and require a more thorough examination, sometimes involving candling.

Identifying these different types is key to implementing appropriate safety measures. Surface cracks often lead to immediate rejection, while check cracks may require more sophisticated detection methods and potentially a stricter quality control process.

Q 23. How would you train a new employee on the procedures for identifying and removing cracked eggs?

Training new employees on egg crack identification and removal is a multi-step process focusing on both theory and practice. I start with a classroom session covering the different crack types (as discussed previously), followed by hands-on training.

Classroom Training: We use visual aids like pictures and real examples of cracked eggs to show the differences between surface and check cracks. I explain the importance of hygiene and the potential health risks associated with cracked eggs.

Practical Demonstration: I demonstrate the proper techniques for inspecting eggs under good lighting, using candling (passing a light through the egg to check for internal cracks), and safely removing cracked eggs. This includes proper disposal procedures to prevent cross-contamination.

Hands-on Practice: New employees practice inspecting and removing cracked eggs from a sample batch. I provide immediate feedback and guidance, correcting any improper techniques or missed cracks. We repeat this until they consistently demonstrate proficiency.

Ongoing Monitoring: I conduct regular spot checks on their work to ensure they maintain the skills and follow safety protocols. Regular retraining sessions are implemented to refresh knowledge and address any emerging concerns.

The goal is to instill a keen eye for detail, an understanding of food safety risks, and efficient, safe working practices. It’s not just about speed; it’s about consistent accuracy to prevent contamination.

Q 24. What are the key factors to consider when setting up a safe and efficient egg-handling workspace?

A safe and efficient egg-handling workspace requires careful consideration of several key factors.

Cleanliness: The workspace must be meticulously clean and sanitized regularly. This includes surfaces, equipment, and even the air. We use food-grade sanitizers and maintain a strict cleaning schedule to minimize bacterial growth.

Lighting: Adequate lighting is crucial for effective crack detection. We use bright, even lighting to illuminate all areas of the workspace, reducing the risk of overlooking cracks.

Organization: A well-organized workspace minimizes clutter and potential hazards. Designated areas for cracked eggs, clean eggs, and equipment help maintain workflow and reduce contamination risks.

Temperature Control: Maintaining the correct temperature (generally refrigeration) is vital for preserving egg quality and minimizing bacterial growth. Temperature monitoring is essential.

Personal Protective Equipment (PPE): Gloves should be worn to maintain hygiene and prevent contamination. Aprons can offer additional protection.

Proper Waste Disposal: Designated containers for the disposal of cracked eggs are crucial. These containers must be clearly labeled and disposed of according to food safety guidelines.

Creating a safe and efficient workspace is an investment in food safety and employee well-being. It’s a continuous process of maintaining cleanliness, implementing efficient procedures, and staying updated on best practices.

Q 25. How do you stay updated on food safety regulations regarding egg handling?

Staying updated on food safety regulations is paramount. I achieve this through several avenues:

Government Agencies: I regularly check websites and publications from the FDA (Food and Drug Administration) and other relevant government bodies for updates on egg handling, processing, and sanitation guidelines.

Industry Associations: Membership in professional organizations related to food safety and egg production provides access to the latest regulations, best practices, and industry insights.

Training Courses: I regularly participate in food safety training courses and workshops to refresh my knowledge and learn about emerging issues.

Professional Journals and Publications: I stay informed by reading peer-reviewed articles and industry publications on food safety and egg handling.

Continual learning ensures that our egg-handling procedures comply with all current regulations, minimizing risks and maintaining the highest quality standards.

Q 26. How do you balance speed and accuracy when identifying and removing cracked eggs?

Balancing speed and accuracy is a crucial skill in egg handling. It’s not a matter of rushing; rather, it’s about developing an efficient and methodical approach.

Think of it like this: a surgeon doesn’t sacrifice precision for speed. Similarly, I focus on consistent accuracy to avoid contamination. This involves:

Efficient Workflow: Optimizing the egg-handling process, ensuring a smooth workflow, minimizes delays and allows for thorough inspection without rushing.

Good Lighting and Organization: As mentioned, adequate lighting and an organized workspace eliminate wasted time searching for eggs or equipment.

Practice and Training: Consistent practice and training enhance both speed and accuracy. With experience, visual inspection becomes faster and more reliable.

Quality Control Checks: Implementing regular quality control checks ensures consistent accuracy and identifies potential issues before they become widespread problems.

The focus should always be on safe handling and preventing contamination, even if it means a slightly slower process initially. Speed comes with practice and refined techniques; accuracy must never be compromised.

Q 27. Describe your experience with different types of egg packaging and their impact on crack prevention.

Different egg packaging significantly impacts crack prevention. I’ve worked with various types, each with its pros and cons:

Cartons: Paper cartons offer good protection but are susceptible to damage during transit and handling if not carefully managed. Proper stacking and handling are crucial.

Plastic Trays: Plastic trays provide better protection against impacts compared to cartons, but they can still be damaged if dropped or mishandled. The quality of the plastic and tray design also impact protection.

Bulk Packaging: Bulk packaging (e.g., crates of eggs without individual protection) is highly susceptible to cracks if not handled with extreme care. This method requires exceptionally gentle handling and ideally a controlled environment.

My experience shows that the choice of packaging significantly influences the rate of cracked eggs. For instance, switching from bulk packaging to individual cartons resulted in a considerable reduction of cracked eggs in our processing facility.

Q 28. How do you adapt your techniques for handling different sizes and types of eggs?

Handling different sizes and types of eggs requires adaptable techniques. While the core principles of careful handling and thorough inspection remain consistent, minor adjustments are necessary:

Size Variations: Larger eggs may require a slightly gentler touch to prevent breakage. Smaller eggs require careful attention to avoid overlooking cracks due to their size.

Shell Thickness: Some egg breeds have thicker shells than others. While thicker shells offer better protection, care must still be taken to avoid chipping or cracking during handling. Thinner shelled eggs, however, necessitate even more gentle handling.

Shape Variations: Variations in egg shape may require slight adjustments in handling techniques to ensure a secure grip and prevent slippage during inspection and movement. A firm yet gentle grasp is always best practice, regardless of egg shape.

Adaptability is key. Understanding the unique characteristics of each egg type allows for the implementation of optimized handling procedures that minimize the risk of damage and maintain high-quality standards.

Key Topics to Learn for Identifying and Removing Cracked or Broken Eggs Interview

- Visual Inspection Techniques: Mastering the art of quickly and accurately identifying cracks, fissures, or shell imperfections through careful observation under various lighting conditions.

- Candling Techniques: Understanding how to use a candling light to detect internal defects like blood spots or cracks not visible to the naked eye. Practical application includes mastering the correct candling technique and interpreting the results.

- Handling and Processing: Developing efficient and safe methods for removing cracked or broken eggs from a production line or storage area, minimizing waste and preventing contamination.

- Quality Control Procedures: Understanding the importance of adhering to quality control standards and regulations related to egg handling and identifying defects. This includes knowledge of relevant safety and hygiene protocols.

- Waste Management: Developing strategies for properly disposing of cracked or broken eggs in accordance with health and safety regulations. This includes understanding appropriate sanitation and waste disposal methods.

- Problem-Solving Scenarios: Preparing for scenarios where you might encounter unexpected challenges, such as a high volume of damaged eggs or equipment malfunctions. Consider how you would adapt your techniques and maintain efficiency.

Next Steps

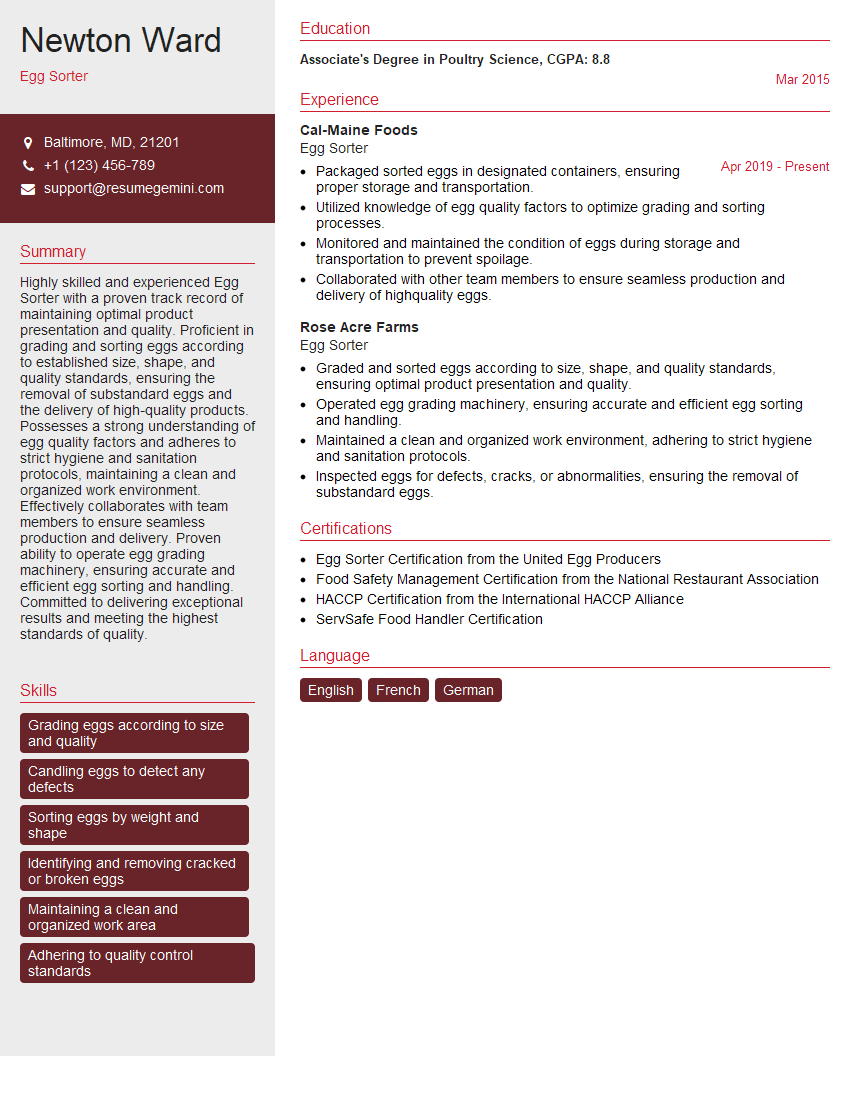

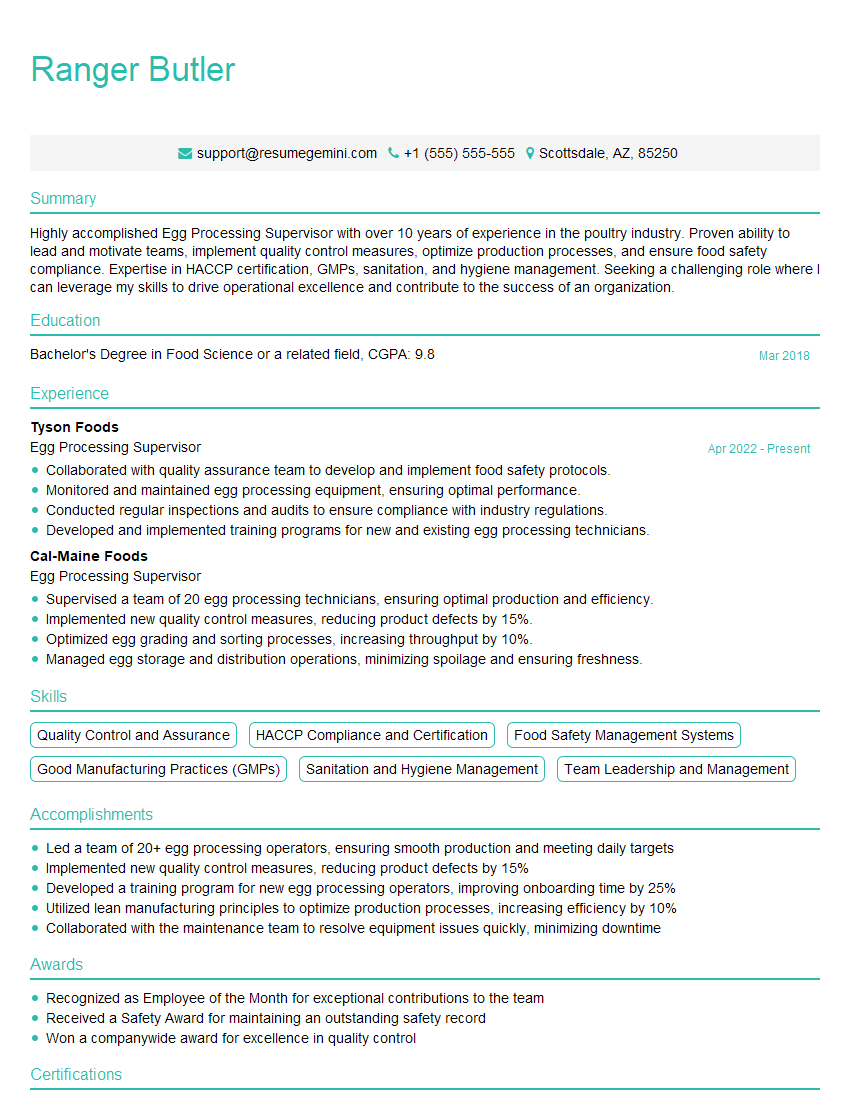

Mastering the skills of identifying and removing cracked or broken eggs is crucial for demonstrating attention to detail, adherence to safety protocols, and efficiency in a food production or handling environment. These skills are highly valuable and transferable across various roles within the food industry and beyond. To enhance your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to identifying and removing cracked or broken eggs are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good