Cracking a skill-specific interview, like one for IEC 60617 (Electrical Installations in Buildings), requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in IEC 60617 (Electrical Installations in Buildings) Interview

Q 1. Explain the significance of earthing/grounding in IEC 60617.

Earthing, or grounding, in IEC 60617 is crucial for electrical safety. It provides a low-impedance path for fault currents to flow to the earth, preventing dangerous voltages from appearing on exposed conductive parts. Imagine a faulty appliance – if a live wire touches the metal casing, a significant voltage could shock anyone touching it. Earthing provides a safe route for that current to flow directly to the earth, tripping the protective device and preventing harm. This is achieved by connecting the metallic parts of the installation to a grounding electrode, typically a rod driven into the earth.

The significance lies in its role in protecting people and equipment. Without proper earthing, even small faults can lead to electrocution or equipment damage. IEC 60617 specifies requirements for earthing electrode resistance, connection methods, and testing procedures to ensure the effectiveness of the grounding system. For example, the earth electrode resistance should be kept low, typically below a specified value, to ensure that fault currents can flow effectively to ground.

Q 2. Describe the different types of protective devices used in electrical installations according to IEC 60617.

IEC 60617 outlines several protective devices designed to safeguard electrical installations. These devices automatically disconnect the power supply in the event of a fault, minimizing risks. Think of them as the safety net of your electrical system.

- Circuit Breakers (MCBs & RCCBs): Miniature Circuit Breakers (MCBs) protect against overcurrents caused by short circuits or overloads. Residual Current Circuit Breakers (RCCBs), also known as Ground Fault Circuit Interrupters (GFCIs), detect small current imbalances indicating a leakage current to earth, thus protecting against electric shock.

- Fuses: These are simpler protective devices that melt and break the circuit when excessive current flows. They’re often used in lower-current applications.

- Surge Protective Devices (SPDs): These protect equipment from voltage surges caused by lightning strikes or other transient events. They divert excess voltage to earth, preventing damage to sensitive appliances.

The choice of protective device depends on the specific application and the level of protection required. For example, RCCBs are mandatory in bathrooms and other high-risk areas, while MCBs are suitable for general-purpose circuits. SPDs are increasingly important with the growing reliance on sensitive electronics.

Q 3. What are the requirements for cable selection and installation as per IEC 60617?

Cable selection and installation are critical aspects addressed by IEC 60617. Incorrect choices can lead to fire hazards, electrical shocks, and system failures. Imagine using a cable with insufficient current-carrying capacity; it could overheat and cause a fire. The standard specifies requirements based on factors like:

- Current carrying capacity: The cable must be rated for the current it will carry to prevent overheating.

- Voltage rating: The cable’s insulation must withstand the voltage applied.

- Installation method: The cable’s rating changes depending on whether it’s installed in free air, conduit, or buried.

- Ambient temperature: Higher temperatures reduce the cable’s current carrying capacity.

- Mechanical protection: Cables need protection against physical damage during installation and operation.

IEC 60617 provides tables and formulas to assist in cable selection based on these factors. It also details requirements for proper cable installation, including correct termination techniques, mechanical protection, and avoidance of sharp bends. Compliance with these requirements is paramount for ensuring the safety and reliability of the electrical installation.

Q 4. Explain the importance of insulation resistance testing in electrical installations.

Insulation resistance testing is essential for verifying the integrity of the insulation on electrical equipment and cables. It measures the resistance to current flow between conductive parts and earth. A low insulation resistance indicates a weakening of the insulation, potentially leading to electric shock or a short circuit. Think of it as a health check for your electrical system’s insulation.

The test involves applying a DC voltage to the insulation and measuring the leakage current. A high resistance value indicates good insulation, while a low value suggests damage or deterioration. IEC 60617 specifies the testing procedures and acceptable resistance values for different types of installations and equipment. Regular insulation resistance testing is crucial for preventative maintenance, especially in older installations, to identify and address potential problems before they become safety hazards.

Q 5. How does IEC 60617 address electrical safety in hazardous locations?

IEC 60617 addresses electrical safety in hazardous locations by specifying additional requirements for equipment and installation methods. Hazardous locations are areas where flammable gases, vapors, or dusts are present, increasing the risk of fire or explosion. Think of areas like petrol stations, chemical plants, or grain silos.

The standard classifies hazardous locations based on the type and likelihood of the hazard. It then specifies the type of equipment suitable for each class, including explosion-proof enclosures and intrinsically safe circuits. Installation methods are also tailored to minimize ignition risks, such as the use of special wiring techniques and bonding. For instance, special explosion-proof fittings and intrinsically safe circuits are used to eliminate any potential ignition sources. These measures ensure that electrical installations in hazardous locations are safe and do not pose a risk of fire or explosion.

Q 6. What are the requirements for electrical installations in bathrooms according to IEC 60617?

IEC 60617 imposes stringent requirements for electrical installations in bathrooms due to the increased risk of electric shock. The presence of water significantly increases the risk of electrocution. The standard mandates the use of specific protection measures to minimize this risk.

These measures typically include the use of:

- RCCBs (Residual Current Circuit Breakers): These are mandatory to protect against electric shock from leakage currents.

- Increased levels of protection against water ingress: This may involve the use of special waterproof enclosures and fittings, and specific zones are defined based on the likelihood of water ingress.

- Low-voltage systems (e.g., 12V): In zones where the risk of water ingress is particularly high, low-voltage systems are often preferred.

Compliance with these requirements is essential for ensuring the safety of individuals using bathrooms. Failure to comply could have severe consequences, including fatal electric shocks.

Q 7. Describe the different types of circuit breakers and their applications.

Circuit breakers are essential protective devices that interrupt the flow of electricity in the event of a fault. There are several types, each designed for different applications.

- Miniature Circuit Breakers (MCBs): These are the most common type, used in domestic and commercial installations. They protect against overcurrents caused by short circuits and overloads. They have thermal and magnetic tripping mechanisms to provide protection against both slow overloads and fast short circuits. Think of them as the everyday protectors of your home circuits.

- Residual Current Circuit Breakers (RCCBs): These protect against earth leakage currents, which are often caused by insulation faults. They detect even small current imbalances, quickly tripping to prevent electric shock. Essential for safety in bathrooms and other high-risk locations.

- Motor Circuit Breakers (MCBs with overload protection): These are specifically designed for motor circuits, providing protection against overloads, short circuits and phase loss.

- Earth Leakage Circuit Breakers (ELCBs): These are similar to RCCBs but often less sensitive and may not be considered as robust for modern applications. Mostly superseded by RCCBs.

The selection of the appropriate circuit breaker depends on the application’s specific requirements. For example, an MCB might be sufficient for general lighting circuits, but an RCCB is mandatory in bathrooms and areas where there’s a risk of water ingress. MCBs with overload protection are selected for motor circuits.

Q 8. Explain the concept of fault current and its impact on electrical installations.

Fault current is the excessive flow of electrical current in an unintended path, often caused by a short circuit or ground fault. Imagine a river overflowing its banks – that’s a fault current overwhelming the intended electrical path. This has severe consequences for electrical installations, including:

- Equipment Damage: High fault currents can instantly melt wires, damage appliances, and destroy electrical panels.

- Fire Hazards: The heat generated by a fault current can easily ignite flammable materials, leading to devastating fires.

- Electric Shock: Unprotected contact with a faulty circuit carrying a large fault current can be fatal.

- System Instability: Fault currents can cause voltage dips or complete power outages, disrupting operations and causing data loss in sensitive systems.

The magnitude of the fault current depends on the system’s impedance (resistance to current flow) and the available short-circuit power from the supply source. Protection devices like circuit breakers and fuses are designed to interrupt these fault currents before they cause significant damage.

Q 9. What are the requirements for lightning protection in buildings as per IEC 60617?

IEC 60617 doesn’t directly address lightning protection; that’s typically covered by standards like IEC 61024. However, a building’s electrical installation must be protected against the indirect effects of lightning strikes. This involves:

- Surge Protection Devices (SPDs): These devices, installed at the building’s incoming supply and at sensitive equipment, divert surge currents to earth, preventing damage to the electrical system. Think of them as dams diverting floodwaters away from a city.

- Earthing System: A robust earthing system is crucial to provide a low-impedance path for lightning currents, minimizing the voltage surge within the electrical installation. This is the main drainage system for electrical surges.

- Equipment Protection: Equipment vulnerable to surges, such as computers and electronic controls, should be protected by appropriate SPDs. This is like providing extra protection for valuable belongings in a flood-prone area.

The specific requirements for lightning protection depend on the building’s location, height, and the level of risk associated with lightning strikes. A risk assessment is typically performed to determine the necessary level of protection.

Q 10. How do you ensure compliance with IEC 60617 during the design and installation phases?

Compliance with IEC 60617 is achieved through careful planning and execution during both the design and installation phases:

- Design Phase: This involves selecting appropriate equipment and protection devices based on the load requirements and fault current calculations. Detailed drawings and specifications are prepared, ensuring all components meet the standard’s requirements. Careful consideration is given to cable sizing, earthing, and bonding arrangements.

- Installation Phase: Installation must strictly adhere to the approved design. Qualified electricians should perform all work, following safe practices and using proper tools and techniques. Regular inspections and tests are conducted to ensure the installation’s integrity and compliance. All work must be documented comprehensively.

Regular audits and inspections by certified professionals are vital to guarantee continuous compliance. Any deviations from the approved design must be properly documented and justified.

Q 11. Explain the process of performing an electrical inspection according to IEC 60617.

An electrical inspection according to IEC 60617 involves a systematic examination of the entire installation, verifying that it conforms to the standard and is safe to operate. This involves:

- Visual Inspection: Examining wiring, connections, equipment, and protective devices for any signs of damage, wear, or improper installation.

- Testing: Performing various tests, including insulation resistance tests, earth continuity tests, and loop impedance tests, to verify the installation’s electrical integrity.

- Documentation Review: Checking the installation’s documentation, including drawings, specifications, and test results, to ensure consistency and compliance.

- Compliance Verification: Confirming that the installation meets all relevant regulations and standards.

The inspection should be carried out by a competent person who is familiar with IEC 60617 and has the necessary testing equipment. A detailed report documenting the findings, including any non-compliances, must be generated.

Q 12. What are the common causes of electrical faults and how can they be prevented?

Common causes of electrical faults include:

- Overloading: Connecting too many appliances to a single circuit, exceeding its current-carrying capacity.

- Short Circuits: Accidental contact between live conductors, creating a low-impedance path for current.

- Ground Faults: A fault current flowing to earth through a person or object, potentially causing electric shock.

- Loose Connections: Poorly connected wires can create excessive heat, leading to fires or malfunctions.

- Damaged Insulation: Worn or damaged insulation can expose live conductors, creating a shock hazard or short circuit.

Prevention involves using appropriately sized cables and protection devices, regular maintenance checks, and proper installation practices. Adequate training for electricians is essential to prevent mistakes during installation and maintenance.

Q 13. What are the safety precautions to be taken while working on electrical installations?

Safety precautions while working on electrical installations are paramount. Always:

- Isolating the Circuit: Before starting any work, ensure the power supply is completely isolated and locked out using appropriate safety devices.

- Verifying Isolation: Use a voltage tester to confirm that the circuit is indeed de-energized before touching any components.

- Using Appropriate PPE: Wear safety glasses, insulated gloves, and other personal protective equipment to minimize the risk of electric shock or injury.

- Following Safe Work Practices: Adhere to established safety procedures and use proper tools and techniques.

- Working with a Partner: Whenever possible, work with a colleague who can provide assistance and ensure your safety.

Never assume a circuit is safe; always verify its de-energized state. If unsure about any procedure, seek guidance from a qualified electrician.

Q 14. Explain the importance of proper documentation in electrical installations.

Proper documentation is crucial for the safety and maintainability of electrical installations. It provides:

- Traceability: Detailed records enable tracking the installation’s history, identifying components, and simplifying future maintenance or repairs. Imagine trying to fix a complex system without a manual – it’s near impossible.

- Compliance Demonstration: Comprehensive documentation facilitates compliance verification and audits, ensuring the installation adheres to the relevant standards and regulations.

- Safety Enhancement: Accurate records help identify potential hazards and aid in risk assessment, improving overall safety.

- Facilitated Maintenance: Well-maintained documentation simplifies troubleshooting and maintenance tasks, leading to reduced downtime and cost savings.

Documentation should include installation drawings, specifications, test results, maintenance records, and any modifications made to the original design. This information is essential for the safe and efficient operation of the electrical system throughout its lifespan.

Q 15. Describe the role of protective earthing in preventing electric shock.

Protective earthing, also known as grounding, is a crucial safety mechanism in electrical installations. Its primary role is to provide a low-impedance path for fault currents to flow back to the source, preventing dangerous voltages from appearing on exposed conductive parts of equipment. Imagine a scenario where the live wire of an appliance touches its metal casing. Without earthing, the casing becomes live, posing a serious shock risk to anyone who touches it. However, with a properly installed earth connection, the fault current will flow through the earth wire, tripping the protective device (like a circuit breaker or RCD) and isolating the faulty appliance from the supply. This rapid disconnection prevents a potentially lethal electric shock.

Essentially, earthing creates a safe route for fault currents, prioritizing safety over continuing operation. The earth wire acts like a safety valve, preventing dangerous voltages from building up on exposed metal parts. The low resistance of the earth path ensures a high fault current, quickly activating the protective device.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is the difference between TN-S, TT, and IT earthing systems?

The TN-S, TT, and IT systems are different earthing arrangements classified by how the neutral and earth conductors are connected. They differ in terms of safety and fault protection.

- TN-S (Terra-Neutral-Separated): This system has separate neutral and protective earth conductors throughout the installation. The neutral is earthed at the transformer’s secondary winding, providing a low impedance path for fault currents. This is generally considered the safest system for its ability to rapidly clear faults.

- TT (Terra-Terra): This system has the neutral earthed at the transformer, and the exposed conductive parts are also earthed locally, independently from the transformer neutral. The local earthing electrode is often a rod driven into the ground. A high fault current requires a more sensitive protection device like an RCD.

- IT (Insulated-Terra): In this system, the neutral point is not directly earthed but may be connected to earth via a high impedance path. This system offers a high level of insulation and minimizes the risk of earth fault current. However, it necessitates more complex fault detection systems, as the first earth fault does not necessarily trip the circuit.

Choosing the right system depends on factors such as the risk assessment of the specific installation and the available resources. In general, TN-S is preferred for its enhanced safety in residential and light commercial settings. Industrial settings sometimes utilise TT or IT depending on the requirements.

Q 17. Explain the concept of impedance bonding.

Impedance bonding connects the protective earth conductor to the metal parts of electrical equipment and installations. It is crucial in equalizing the electrical potentials in the system to minimize potential differences that could lead to electric shock. This method is particularly important where multiple earth connections exist, and it prevents voltage build-up from fault currents and ensures a safer environment.

Imagine a scenario in a bathroom where the metal piping has a slight voltage due to stray currents. Impedance bonding reduces this voltage difference by connecting the metal piping to the protective earth conductor. This way, if a fault occurs, the current flows safely and prevents a dangerous electric shock.

The impedance of the bond is critical. A low impedance will cause high current flow when a fault occurs, thus tripping the circuit breaker promptly. A high impedance may not allow sufficient current flow to activate the protective device, leaving exposed conductive parts energized.

Q 18. What are the requirements for electrical installations in industrial settings?

Electrical installations in industrial settings face unique challenges due to the presence of heavy machinery, hazardous materials, and potentially explosive atmospheres. The requirements are significantly more stringent than those for residential or commercial buildings.

- Increased Fault Current Protection: Industrial settings often need more robust protection against high fault currents using circuit breakers with higher breaking capacities and sophisticated protection schemes.

- Specialized Wiring Methods: Wiring systems must withstand harsh environmental conditions, often utilizing conduit, armored cable, or other methods to ensure mechanical protection and fire safety.

- Hazardous Area Classification: Areas with flammable materials must comply with specific regulations regarding the use of explosion-proof equipment and intrinsically safe circuits.

- Regular Inspections and Maintenance: Regular inspection and testing schedules are essential to guarantee continued safety and compliance with relevant standards.

- Emergency Shutdown Systems: Redundant safety systems, including emergency stops and interlocking mechanisms, are implemented to prevent accidents.

Specific regulations and standards, such as those from relevant national or international standards bodies, govern the design and implementation of industrial electrical installations. A qualified electrician with relevant industrial experience should always carry out these installations.

Q 19. How do you calculate the size of a conductor for a given load?

Calculating conductor size involves several factors. The primary ones are the current carrying capacity (CCC) of the conductor and the voltage drop.

Step 1: Determine the Load Current: Calculate the total current drawn by the connected loads (e.g., using power (W) = voltage (V) x current (A)).

Step 2: Apply Correction Factors: Account for ambient temperature, grouping of conductors, installation method (e.g., buried, in conduit), and other factors that affect the CCC. These correction factors are found in relevant tables within IEC 60364-5-52.

Step 3: Select the Conductor Size: Choose a conductor size with a CCC that is greater than or equal to the calculated load current after applying correction factors. Remember that the chosen cable must also comply with the voltage drop limits specified in IEC 60364.

Step 4: Check Voltage Drop: Calculate the voltage drop using the following formula:

Voltage Drop = (2 x L x I x R) / 1000where:

- L = length of the cable (meters)

- I = current (amperes)

- R = resistance of the conductor per 1000 meters (ohms/1000m)

The voltage drop should be within the permissible limits specified in IEC 60364. If the voltage drop is excessive, a larger conductor size must be selected.

Example: A 10kW load at 230V needs a current of approximately 43.5A (10000W / 230V). After applying correction factors, let’s assume the required CCC is 50A. You would then select a cable with a CCC of at least 50A and then verify that the voltage drop is within acceptable limits.

Q 20. What are the different types of wiring systems used in electrical installations?

Several wiring systems are used in electrical installations, each with its own advantages and disadvantages:

- Conduit Wiring: Conductors are run inside metal or plastic pipes (conduits), offering excellent mechanical protection and fire resistance. Common in industrial settings and areas with high risk of mechanical damage.

- Trunking Wiring: Conductors are installed in large enclosures (trunking) that can accommodate many cables. Often used for large-scale installations, providing easy access for maintenance.

- Cable Tray Wiring: Cables are laid on metal or plastic trays, providing support and organization. Suitable for large numbers of cables and easy accessibility.

- Surface Mounting: Cables are fixed directly to the surface of walls or ceilings using clips or other fastening methods. Simple and cost-effective for certain applications.

- Concealed Wiring: Cables are run inside walls or ceilings during construction. Offers a neat and aesthetically pleasing finish but requires careful planning and can be more difficult to access for maintenance.

The choice of wiring system depends on factors such as the type of building, the complexity of the installation, the environmental conditions, and cost considerations. Compliance with relevant standards is always crucial.

Q 21. Explain the concept of voltage drop and its implications.

Voltage drop refers to the reduction in voltage between the supply point and the load. It occurs due to the resistance of the conductors carrying the current. A significant voltage drop can lead to inefficient operation of equipment, reduced performance, and potential safety hazards.

Think of it like water flowing through a pipe. The pipe’s resistance causes a pressure drop along its length. Similarly, a conductor’s resistance causes a voltage drop along its length. Excessive voltage drop can cause motors to overheat, lights to dim, and even cause malfunction of sensitive electronic equipment.

The implications of excessive voltage drop include:

- Reduced Equipment Efficiency: Motors may not operate at their rated power, leading to reduced efficiency and increased energy consumption.

- Overheating: Excessive current flow due to voltage drop can lead to overheating of conductors and equipment, posing a fire risk.

- Malfunctioning Equipment: Some equipment is sensitive to voltage variations and may malfunction or fail due to excessive voltage drop.

- Safety Concerns: In extreme cases, low voltage can affect the effectiveness of safety devices.

Therefore, it’s crucial to keep voltage drop within acceptable limits, as specified in IEC 60364, through proper conductor sizing and careful design of the electrical system.

Q 22. What are the requirements for emergency lighting systems according to IEC 60617?

IEC 60617 doesn’t directly address emergency lighting in detail; that’s typically covered by supplementary standards and national regulations. However, the overarching principles of safety and reliability within IEC 60617 are crucial for emergency lighting systems. These systems must be designed to provide illumination in case of a power failure, ensuring safe evacuation and preventing accidents. Requirements generally include:

- Autonomy: The emergency lighting needs to operate for a specific duration (typically 1 hour minimum, but this varies by jurisdiction) after the main power supply fails.

- Reliability: Regular testing and maintenance are essential to ensure the system functions when needed. This often involves battery checks and load tests.

- Illumination Levels: Specific illumination levels must be maintained in escape routes and critical areas, according to local building codes which often reference IEC standards for lighting design.

- Signaling: Emergency lighting often incorporates exit signs and directional indicators to guide people to safety.

- Protection: The emergency lighting system itself needs protection from damage and environmental factors.

Think of it like this: Imagine a hospital during a blackout. The emergency lighting is crucial for doctors and nurses to continue providing care, and for patients and staff to safely evacuate. The design and implementation are critical for ensuring safe and reliable operation during such events.

Q 23. Describe the importance of regular maintenance of electrical installations.

Regular maintenance of electrical installations is paramount for safety, reliability, and longevity. Neglecting maintenance can lead to fire hazards, electrical shocks, equipment failure, and increased energy consumption. A comprehensive maintenance program should include:

- Visual Inspections: Regularly check for signs of damage to cables, insulation, and equipment.

- Testing: Perform regular testing of RCDs, circuit breakers, and insulation resistance to ensure they’re functioning correctly.

- Cleaning: Keep electrical equipment clean and free of dust and debris to prevent overheating and malfunction.

- Tightening Connections: Loose connections can lead to overheating and fire hazards. These should be checked and tightened regularly.

- Documentation: Maintain a detailed record of all maintenance activities, including dates, findings, and corrective actions.

Consider this: A poorly maintained electrical system in an old office building could lead to a fire, causing significant damage and potential loss of life. Regular maintenance is not just a cost; it’s a critical investment in safety and operational efficiency.

Q 24. What is the role of a Residual Current Device (RCD)?

A Residual Current Device (RCD), also known as a Ground Fault Circuit Interrupter (GFCI), is a safety device designed to protect against electric shock. It continuously monitors the current flowing in a circuit. If there’s a current imbalance (e.g., current leaking to ground), indicating a potential fault, the RCD rapidly disconnects the power supply, preventing potential injury or death. This is especially vital in areas with high risk, like bathrooms and kitchens.

Think of it as a lifeguard for your electrical system. While circuit breakers protect against overcurrent, the RCD protects against potentially deadly ground faults.

Q 25. Explain the difference between a fuse and a circuit breaker.

Both fuses and circuit breakers protect electrical circuits from overcurrent, but they operate differently:

- Fuse: A fuse is a one-time protection device. Once the current exceeds its rated value, the fuse melts, breaking the circuit. It needs to be replaced after it blows.

- Circuit Breaker: A circuit breaker is a reusable device. It contains a mechanism that trips when the current exceeds its rating. It can be reset after tripping, restoring power to the circuit.

Analogously, a fuse is like a disposable lighter, whereas a circuit breaker is like a switch that can be turned off and on again.

Q 26. How do you interpret electrical drawings and schematics?

Interpreting electrical drawings and schematics requires a strong understanding of electrical symbols and conventions. I typically start by understanding the purpose of the drawing (e.g., single-line diagram, wiring diagram, panel schedule). I then analyze the symbols representing various components (switches, outlets, circuit breakers, etc.) and trace the flow of current through the circuit. I use the legend or key provided to understand the meaning of each symbol. It’s crucial to be meticulous and verify all connections and components. Sometimes I use software to help visualize complex layouts in 3D.

For example, understanding the different line thicknesses can denote different voltage levels or wire sizes. A thorough knowledge of symbols, like those found in IEC 60617 annexes, is essential. Experience is crucial for rapidly and correctly interpreting these drawings.

Q 27. What are the relevant safety standards related to IEC 60617?

IEC 60617 itself is a foundational standard, but it often works in conjunction with other relevant safety standards. Some key related standards include:

- IEC 60364: This is the international standard for electrical installations in buildings, providing detailed requirements and guidance.

- National Standards: Many countries have their own national standards that incorporate and often extend IEC 60617, adding specific requirements relevant to their region.

- Standards for specific equipment: There are numerous standards addressing specific electrical equipment like transformers, motors, and lighting fixtures.

- Standards for fire safety: Standards related to fire prevention and protection are directly related to the safety of electrical installations.

These standards need to be considered collectively, as they provide a complete framework for safe and compliant electrical installations.

Q 28. Describe your experience with electrical testing and troubleshooting.

I have extensive experience in electrical testing and troubleshooting, using a variety of instruments, including multimeters, insulation resistance testers, and loop impedance testers. My experience encompasses various testing procedures, such as:

- Insulation Resistance Testing: This is crucial to identify insulation degradation and potential risks.

- Continuity Testing: Checking for complete electrical paths in circuits.

- Earth Grounding Testing: Ensuring proper grounding to protect against shocks.

- RCD Testing: Regularly testing RCDs to ensure they trip within the required timeframe.

- Loop Impedance Testing: Measuring the overall impedance of a circuit to determine its protective device capacity.

Recently, I worked on a project where a faulty RCD caused intermittent power outages in a large office building. Through systematic testing, I identified the faulty RCD and replaced it, resolving the issue and avoiding potential hazards.

I also have experience with various troubleshooting techniques, from using basic multimeter checks to more sophisticated diagnostic tools. Careful observation and a systematic approach are critical to quickly and safely identifying and resolving electrical issues.

Key Topics to Learn for IEC 60617 (Electrical Installations in Buildings) Interview

- Fundamental Principles: Understanding basic electrical theory, including Ohm’s Law, Kirchhoff’s Laws, and power calculations as applied to building installations.

- Wiring Systems and Protection: Familiarize yourself with different wiring methods (e.g., conduit, cable tray), protective devices (e.g., circuit breakers, fuses, RCDs), and earthing techniques. Be prepared to discuss practical applications and selection criteria based on building requirements.

- Electrical Safety: Master the safety regulations and procedures related to electrical installations, including risk assessment, safe working practices, and compliance with relevant standards.

- Lighting Systems: Understand the design principles of lighting systems, including illuminance calculations, energy efficiency considerations, and the selection of appropriate luminaires.

- Power Distribution Systems: Gain a solid understanding of low-voltage power distribution systems in buildings, including transformers, switchboards, and busbars. Be ready to discuss system sizing and protection coordination.

- Special Installations: Explore specific installations such as fire alarm systems, emergency lighting, and security systems within the context of IEC 60617.

- Regulations and Compliance: Demonstrate a thorough understanding of relevant building codes and regulations concerning electrical installations, emphasizing practical problem-solving approaches related to compliance.

- Testing and Inspection: Be prepared to discuss different testing methods (e.g., insulation resistance, earth continuity) and their significance in ensuring the safety and reliability of electrical installations.

- Troubleshooting and Fault Finding: Develop your ability to identify and diagnose common faults in electrical systems and explain your systematic troubleshooting methodology.

Next Steps

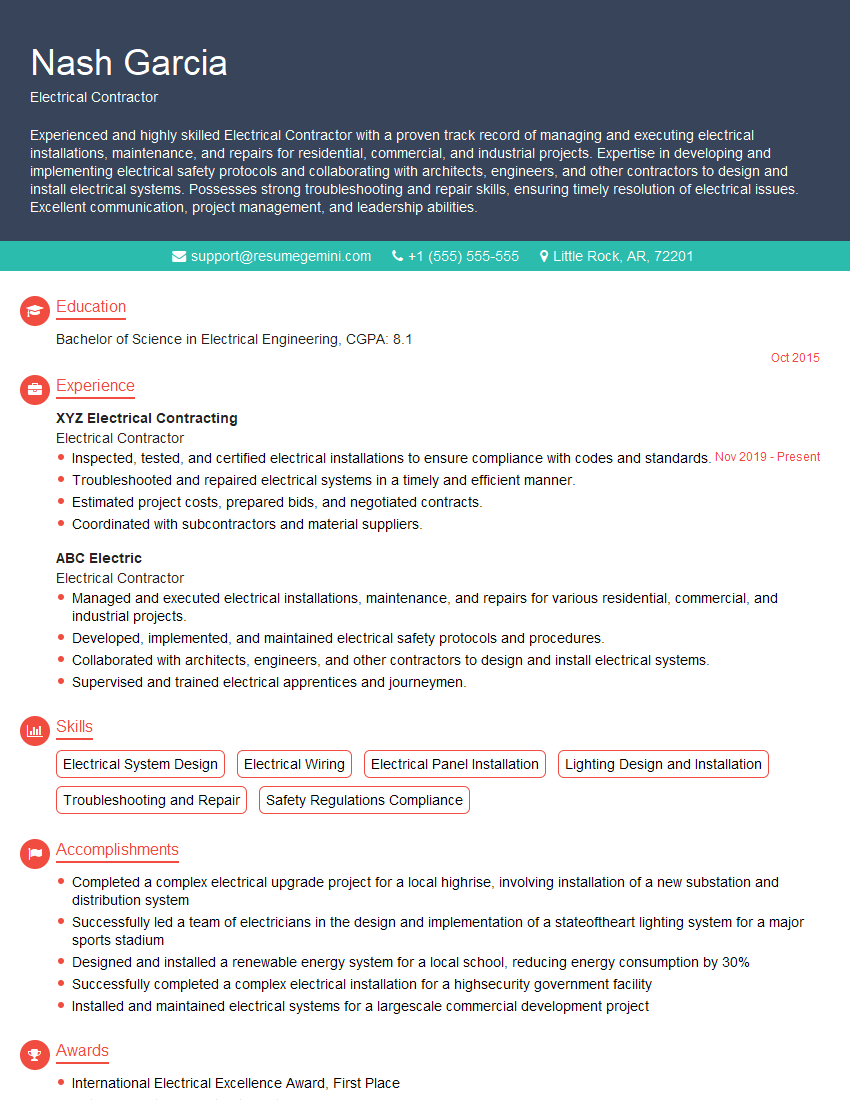

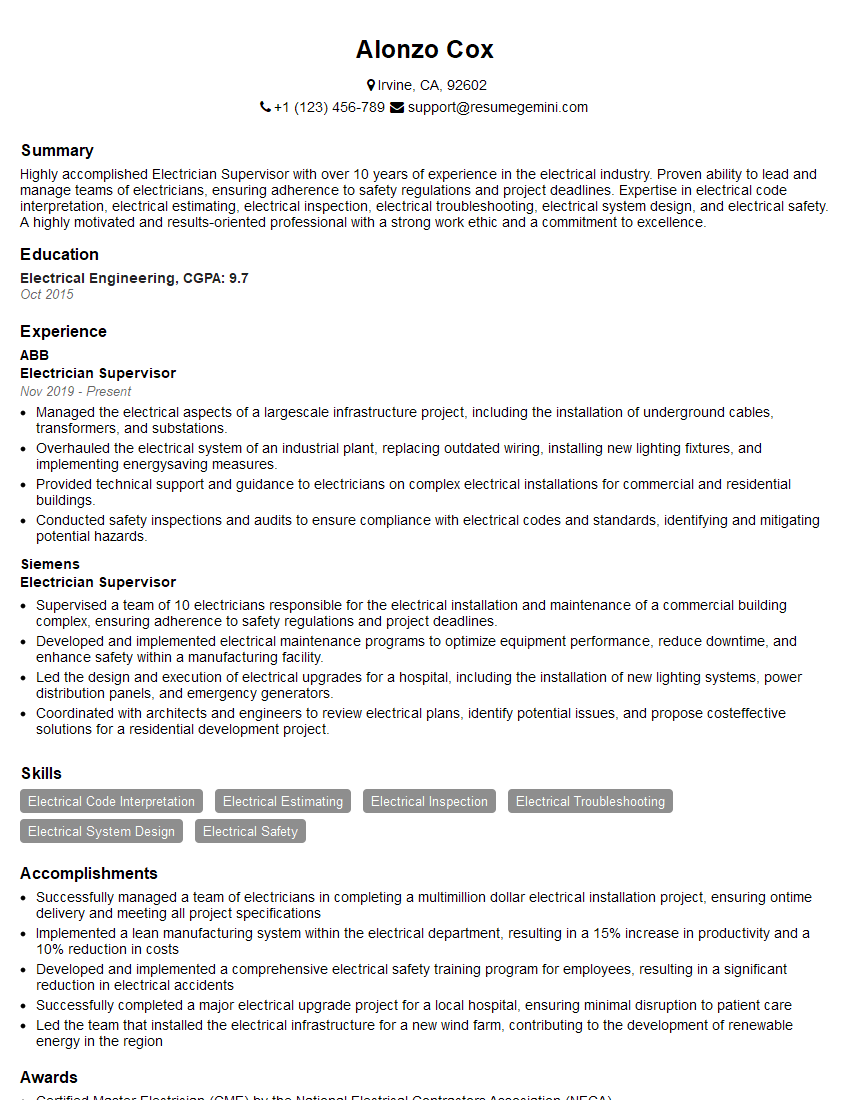

Mastering IEC 60617 significantly enhances your career prospects in the electrical engineering field, opening doors to exciting opportunities and higher earning potential. To maximize your chances of securing your dream role, it’s crucial to present your skills and experience effectively. Building an ATS-friendly resume is key to getting noticed by recruiters. We highly recommend using ResumeGemini, a trusted resource, to craft a professional and impactful resume that highlights your IEC 60617 expertise. Examples of resumes tailored to IEC 60617 (Electrical Installations in Buildings) are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good