The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to IEC 61082 interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in IEC 61082 Interview

Q 1. Explain the key differences between conducted and radiated emissions.

Conducted and radiated emissions are two primary ways electronic devices generate electromagnetic interference (EMI). Think of it like this: conducted emissions are like whispering secrets through a wire, while radiated emissions are shouting across a room.

- Conducted Emissions: These are unwanted electrical signals that travel along the power supply lines (mains) or signal cables connected to a device. They’re measured at the points where the device connects to the power grid or other equipment. These emissions can disrupt the operation of other devices connected to the same power supply or data network. An example would be a faulty power supply injecting noise onto the AC mains.

- Radiated Emissions: These are electromagnetic waves that propagate through the air from a device. Think of your phone’s signal – that’s a form of radiated emission. High-frequency radiated emissions, especially, can interfere with radio and television reception and other sensitive electronic equipment. A poorly shielded switching power supply could radiate strong interference across a wide frequency range.

The key difference lies in the *propagation path*: conducted emissions travel along physical conductors, while radiated emissions travel through free space.

Q 2. Describe the immunity test procedures outlined in IEC 61082.

IEC 61082 outlines various immunity test procedures to evaluate a device’s ability to withstand electromagnetic disturbances. These tests simulate real-world EMI conditions to assess the device’s robustness. The tests are categorized into various types, focusing on different interference sources and frequency ranges:

- EFT/Burst: This simulates fast transient bursts of energy, often from lightning strikes or switching transients. The test involves applying short, high-amplitude pulses to the device’s input and output lines.

- Surge: This simulates high-voltage surges, also often stemming from lightning strikes or power grid faults. A much slower waveform compared to EFT.

- Conducted Immunity (Power Line): This test assesses the device’s resistance to conducted disturbances injected onto its power supply lines. This test uses a noise generator to inject a specific disturbance onto the power line, often in a specific frequency range.

- Radiated Immunity: This evaluates the device’s resistance to electromagnetic fields radiated from external sources. This test uses a radiated field generator like a TEM cell or an open area test site.

- CS Immunity: Conducted Susceptibility applies specific disturbances to signal lines (e.g., data, control lines). The specifics are defined per application.

The specific test procedures, levels, and waveforms are defined based on the equipment under test (EUT) and its intended application, as referenced in the applicable product standard.

Q 3. What are the common methods for mitigating electromagnetic interference?

Mitigating electromagnetic interference requires a multi-faceted approach. It’s often about careful design and implementation, rather than a single solution. Common methods include:

- Shielding: Enclosing components or the entire device in a conductive enclosure helps to attenuate both radiated and conducted emissions. Think of a Faraday cage.

- Filtering: Using filters on power lines and signal lines attenuates unwanted frequencies. These are commonly used to suppress high-frequency noise.

- Grounding: Proper grounding techniques are crucial to reduce conducted emissions and improve immunity. A single-point ground is usually preferred.

- Cable management: Routing cables carefully and using shielded cables minimizes radiation and pickup of interference.

- Component selection: Choosing components with low EMI characteristics is crucial for the design phase. For example, selecting power supplies with lower conducted noise.

- PCB layout: Careful design of printed circuit boards (PCBs) can significantly reduce EMI. This includes considerations of component placement, trace routing, and ground plane design.

Often, a combination of these techniques is needed for effective EMI mitigation.

Q 4. How do you determine the appropriate test level for a specific product based on IEC 61082?

Determining the appropriate test level for a specific product requires careful consideration of several factors, aligning with the specifications and the intended application. IEC 61082 doesn’t directly specify the test levels – instead it provides the test methods. The specific test levels are determined by the particular product standard relevant to the product’s category and intended use. For instance, medical equipment will have different and often stricter requirements compared to a simple consumer appliance.

The process typically involves:

- Identifying the applicable product standard: This document specifies the required immunity and emission levels.

- Consulting the product standard’s tables: These tables list the appropriate test levels for various parameters, such as frequency range and test type.

- Considering the product’s intended use and environment: More demanding environments might require higher test levels.

It’s crucial to work closely with a testing laboratory experienced in EMC testing and the relevant standards to ensure compliance.

Q 5. Explain the significance of the limits specified in IEC 61082.

The limits specified in IEC 61082 (and related standards) are crucial for ensuring electromagnetic compatibility (EMC). These limits define the maximum acceptable levels of emissions a device can generate and the minimum levels of immunity it must possess. They’re based on protecting other devices from interference and ensuring reliable operation of the device itself.

The significance lies in:

- Preventing interference: The emission limits prevent devices from creating interference that could disrupt the operation of other equipment.

- Ensuring functionality: The immunity limits ensure that a device can withstand typical electromagnetic disturbances without malfunctioning. This is critical to maintain reliable operation in the presence of inevitable noise sources.

- Safety and regulatory compliance: Compliance with these limits is essential for obtaining regulatory approvals to sell and use devices, often legally mandated.

The limits are set based on extensive research, considering typical interference sources and sensitivity levels of common electronic devices.

Q 6. What are the different types of EMC test equipment used in compliance testing?

Various EMC test equipment is used in compliance testing. This equipment is often highly specialized and calibrated to precise standards. Key equipment includes:

- EMI receivers/spectrum analyzers: Used to measure the amplitude and frequency of radiated and conducted emissions.

- LISN (Line Impedance Stabilization Network): Used to provide a controlled impedance for measuring conducted emissions on the power supply lines.

- EFT/Burst generators: Used to generate fast transient/burst pulses for immunity tests.

- Surge generators: Generate high-voltage surges to assess immunity to such disturbances.

- Conducted immunity injection equipment: Used to inject noise signals onto power and signal lines.

- Radiated immunity test chambers (e.g., GTEM, TEM cells, anechoic chambers): Used to generate controlled radiated electromagnetic fields for immunity tests.

- Antennas (e.g., broadband, horn): Used to transmit and receive electromagnetic radiation in radiated emission and immunity tests.

The choice of equipment depends on the specific test being performed and the frequency range of interest.

Q 7. Describe your experience in using EMC measurement equipment.

Throughout my career, I’ve extensively utilized various EMC measurement equipment for product development and testing. My experience includes setting up and operating EMI receivers, LISNs, conducted and radiated immunity injection equipment, and GTEM cells. I’m proficient in using specialized software for data acquisition, analysis, and report generation. I’ve worked extensively with equipment from [mention specific brands if comfortable, e.g., Rohde & Schwarz, Keysight], and have experience in troubleshooting equipment malfunctions and ensuring proper calibration.

For example, during a project involving a medical device, I used a GTEM cell to perform radiated immunity testing to ensure the device remained functional under various high-intensity electromagnetic fields. I meticulously documented all procedures, calibration checks, and test results to ensure compliance with relevant standards. I’ve also trained junior engineers on the proper use and maintenance of this equipment, emphasizing best practices in safety and data accuracy.

Q 8. How do you interpret EMC test reports?

Interpreting EMC test reports requires a thorough understanding of the standards used (like IEC 61000 series) and the specific test procedures followed. A report typically includes limit values, measured values, and a pass/fail indication for each test. I begin by checking the report’s conformity to the relevant standard and verifying the test setup matches the product’s intended use. Then, I carefully examine the measured results, comparing them against the limits specified in the standard. Any values exceeding the limits signify potential EMC problems. The report should also include detailed information on the measurement methods, equipment used, and environmental conditions, all crucial for evaluating the validity and accuracy of the results. I look for trends or patterns in the data – for example, consistently high emissions at a specific frequency could point to a design flaw. Finally, I consider the uncertainty of measurement and the overall context to draw a comprehensive conclusion about the product’s EMC performance.

For instance, if a conducted emissions test shows that a device’s emissions are exceeding the limits at certain frequencies, it indicates poor filtering or grounding within the device’s power supply. A radiated emissions test showing high levels at a specific frequency might point to issues with the device’s PCB layout or insufficient shielding.

Q 9. Explain the role of shielding in reducing electromagnetic interference.

Shielding is a fundamental technique in EMC design to reduce electromagnetic interference (EMI) by creating a barrier between the source of EMI and the susceptible equipment. It works by reflecting, absorbing, or attenuating the electromagnetic fields. Effective shielding depends on factors such as the material’s conductivity, permeability, and thickness, as well as the frequency of the EMI. Materials commonly used for shielding include copper, aluminum, and steel. The design of the shield is equally important; it needs to be continuous and well-grounded to be effective. Gaps, holes, or poor grounding can significantly compromise its performance. Think of it like a Faraday cage – a conductive enclosure that blocks external electromagnetic fields.

For example, shielding an electronic device within a metallic enclosure reduces radiated emissions by preventing electromagnetic waves from escaping. Similarly, shielding cables with conductive braided or foil shielding reduces conducted emissions by preventing electromagnetic interference from traveling along the cables.

Q 10. What are the common grounding techniques used in EMC design?

Several grounding techniques are employed in EMC design to minimize EMI and ensure safety. The primary goal is to establish a low-impedance path to earth for unwanted currents. Common methods include:

- Single-point grounding: Connecting all grounds to a single point, minimizing ground loops and reducing noise. This is often the preferred approach for minimizing current loops, but careful planning is needed to avoid excessive voltage drops.

- Star grounding: A variation of single-point grounding, where multiple ground connections radiate from a central point, resembling a star. This helps to maintain a consistent ground potential.

- Multiple grounding: Employing multiple ground points for safety or functional reasons, but requires careful consideration to prevent ground loops. This approach is used cautiously because of the increased risk of ground loops.

- Ground plane: Creating a large conductive surface (often a copper layer on a printed circuit board) to act as a common ground reference. This is crucial for minimizing noise and improving signal integrity.

Choosing the right technique depends on the specific application and design constraints. For instance, in high-frequency applications, a carefully designed ground plane is crucial for signal integrity and reducing EMI.

Q 11. How do you troubleshoot EMC issues in a product design?

Troubleshooting EMC issues involves a systematic approach. I typically start by carefully reviewing the design specifications and EMC test reports to pinpoint the areas of non-compliance. This includes analyzing the failed test cases and understanding the magnitude of the exceedances.

Next, I employ various diagnostic techniques, such as:

- Near-field probing: Identifying the sources of emissions using near-field probes to locate the precise area generating excessive EMI.

- Spectrum analysis: Using a spectrum analyzer to analyze the frequency spectrum of the emissions and identify the dominant frequencies and their intensity. This will highlight which components are contributing the most to the problem.

- Current probes: Measuring the current flowing in different parts of the circuit to detect any unexpected current spikes or high-frequency noise.

- Impedance analysis: Determining the impedance of various parts of the circuit to identify any potential impedances that might be causing unwanted current flows or high frequency ringing.

Based on the diagnostic results, I’ll implement corrective actions, such as adding filters, shielding components, improving grounding, or modifying the PCB layout. Each modification is then verified through repeated testing until compliance is achieved. It’s iterative process of testing, analysis, and refinement.

For example, if a conducted emissions test fails, I might start by adding a common-mode choke filter to the power input line. If radiated emissions are excessive, I might shield the device, modify its PCB layout, or add absorbing materials.

Q 12. Describe your experience with different EMC test standards and their applicability.

My experience encompasses a wide range of EMC test standards, including the IEC 61000 series (which is the most widely recognized standard), CISPR standards, and military standards such as MIL-STD-461. I understand the differences between conducted and radiated emissions, immunity tests, and specific requirements based on the application and geographical region. For example, IEC 61000-4-2 covers electrostatic discharge (ESD) immunity testing, while IEC 61000-4-3 addresses radiated radio-frequency electromagnetic field (RF-EMF) immunity. Understanding the nuances of each standard is crucial to ensure product compliance and to select the correct test procedures. I have hands-on experience with various testing equipment, including spectrum analyzers, network analyzers, and EMC test chambers.

For example, when designing a medical device, I’d focus on standards relevant to medical equipment, which would likely have stricter limits than standards for consumer electronics. The same product might need to comply with different standards for different geographical markets, emphasizing the importance of keeping up to date with international regulations.

Q 13. What are the key considerations for designing a product for EMC compliance?

Designing a product for EMC compliance requires careful consideration at every stage of the design process, from initial concept to final testing. Key considerations include:

- PCB Layout: Careful PCB layout is essential for minimizing EMI. Techniques such as proper grounding, signal routing, and placement of components can significantly reduce emissions and improve immunity.

- Component Selection: Choosing components with low EMI characteristics is important. This includes using shielded components and considering the EMC performance of integrated circuits and other active components.

- Shielding: Employing appropriate shielding techniques, as discussed earlier, is crucial to reducing radiated emissions and improving immunity to external interference.

- Filtering: Implementing appropriate filters (such as common-mode chokes and EMI filters) to attenuate unwanted frequencies in both power and signal lines.

- Grounding: A well-designed grounding scheme is vital for reducing ground loops and maintaining a consistent ground potential.

- Cable Management: Properly managing cables and connections to minimize unwanted coupling and signal radiation.

- EMC testing and verification: Thorough testing throughout the design process is crucial to ensure compliance with the relevant EMC standards.

It’s a holistic approach; neglecting any one of these aspects could lead to non-compliance.

Q 14. Explain the concept of electromagnetic susceptibility.

Electromagnetic susceptibility (EMS) refers to a device’s vulnerability to electromagnetic interference (EMI). It’s essentially the opposite of electromagnetic emission; instead of a device producing EMI, it’s the device’s reaction to external electromagnetic fields. High EMS means a device is easily affected by external electromagnetic fields, potentially leading to malfunction, data corruption, or even damage. Various factors influence a device’s EMS, including its design, operating frequency, and the strength and nature of the interfering electromagnetic fields.

For example, a poorly shielded electronic device might be susceptible to interference from nearby radio transmitters or industrial equipment. This could manifest as erratic behavior, data loss, or even complete failure. EMS testing aims to determine a device’s tolerance levels to various forms of electromagnetic interference, helping ensure it can function reliably in its intended environment.

Q 15. How do you manage the risks associated with EMC non-compliance?

Managing risks associated with EMC non-compliance involves a proactive, multi-stage approach. It starts even before the design phase, incorporating EMC considerations into the product’s architecture. This includes selecting components with good EMC characteristics and employing appropriate layout techniques to minimize interference. During the design process, we use simulation tools to predict potential EMC issues and address them early on. This is significantly more cost-effective than trying to fix problems after the product is built.

Next, we conduct thorough pre-compliance testing to identify and mitigate potential problems before formal testing. This allows us to fine-tune the design and save time and money in the long run. Then comes formal EMC testing according to IEC 61082 standards and relevant product-specific standards. If failures occur, we implement corrective actions – this might involve adding filters, shielding, or redesigning parts of the circuitry. A crucial aspect is maintaining comprehensive documentation throughout the entire process, ensuring traceability and providing evidence of compliance.

Finally, we establish a robust quality control system to maintain compliance throughout the product’s lifecycle. This includes regular checks and audits to ensure that manufacturing processes don’t inadvertently introduce EMC issues. Think of it like building a house: It’s far cheaper to address foundation problems early than to demolish and rebuild later. EMC compliance is similar; addressing potential issues early saves significant resources and prevents costly delays.

Career Expert Tips:

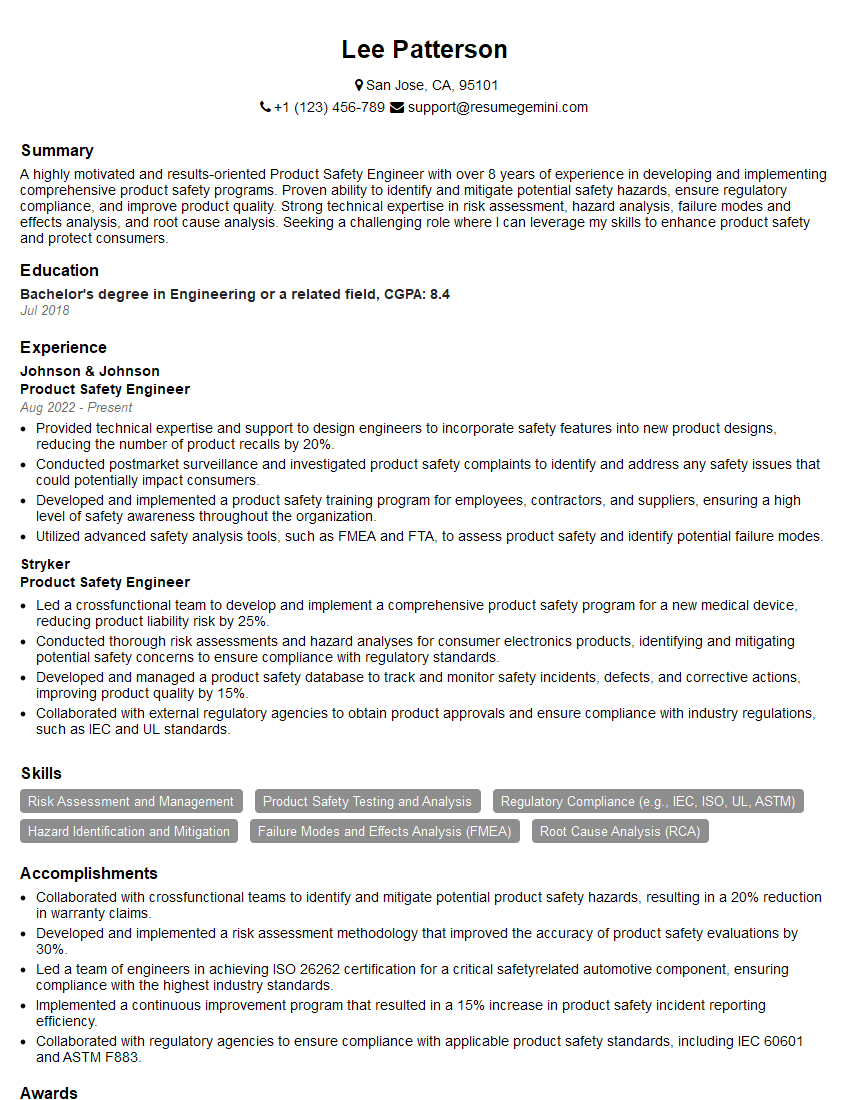

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of proper documentation in EMC testing.

Proper documentation in EMC testing is paramount for several reasons. It provides irrefutable evidence of compliance with regulatory standards, facilitating successful product certification and market access. Think of it as a legal record, showing a clear and verifiable path to demonstrating your product meets the required standards.

Detailed documentation aids in troubleshooting and debugging. If problems arise later, having a complete record of tests, measurements, and configurations helps identify the root cause quickly and efficiently. Without it, you’re essentially working blind.

- Test Procedures: Clearly outlined procedures ensure consistency and repeatability across multiple tests. This is crucial for maintaining accurate and reliable results.

- Calibration Records: All testing equipment needs to be regularly calibrated. Records of these calibrations are essential to demonstrate the accuracy and reliability of the test data.

- Test Results: Detailed test results with clear diagrams, graphs, and supporting data are mandatory. This allows for easy comparison against specifications and assists in identifying areas for improvement.

- Corrective Actions: Any corrective actions taken during the testing process should be precisely documented, along with the associated test results that demonstrate their effectiveness.

In essence, comprehensive documentation serves as a historical record of the entire EMC testing process, establishing transparency, ensuring accountability, and supporting compliance claims.

Q 17. How do you ensure traceability in EMC testing?

Traceability in EMC testing is achieved through a meticulous and well-organized documentation system. Each step of the testing process should be linked to the preceding and subsequent steps, forming a clear chain of evidence. This ensures that any result can be traced back to its origin and the methods used to obtain it.

We achieve traceability by:

- Unique Identifiers: Assigning unique identifiers (e.g., serial numbers) to all test equipment, samples, and test reports.

- Version Control: Maintaining version control for all documents and software used during the testing process. This ensures that the correct versions are used and avoids confusion.

- Cross-referencing: Cross-referencing different documents and reports. For example, a test report should reference the test plan, calibration certificates, and equipment used.

- Database Management: Implementing a database system to manage and track all the testing data and documents. This allows for efficient retrieval and analysis of information.

A well-defined traceability system assures the integrity of the testing process and simplifies audits, enabling us to quickly and confidently respond to any inquiries about the testing procedures or results. It’s like a detailed breadcrumb trail, letting us easily follow every step from beginning to end.

Q 18. What is your experience with EMC pre-compliance testing?

My experience with EMC pre-compliance testing is extensive. I’ve conducted numerous pre-compliance tests on a wide range of products, from small consumer electronics to large industrial machinery. Pre-compliance testing is crucial because it identifies potential issues early in the design cycle, saving significant time and cost later on. It essentially acts as a trial run before the official certification testing.

I’m proficient in using various test equipment such as spectrum analyzers, LISNs (Line Impedance Stabilization Networks), and EMI receivers. I’m experienced with different test standards and methodologies, allowing me to tailor the testing approach based on the specific needs of the product and its intended market. During pre-compliance testing, I’ve encountered and solved numerous common EMC issues like conducted emissions from switching power supplies and radiated emissions from poorly shielded cables. I typically create detailed reports summarizing the findings, including recommendations for design modifications to address any non-compliance issues detected. This proactive approach has significantly reduced the time and cost involved in obtaining final certification.

Q 19. Describe your understanding of the different EMC test environments (e.g., open area test site).

Understanding different EMC test environments is crucial for accurate and reliable testing. Different environments are designed to simulate real-world conditions and ensure that the product will perform as intended in various electromagnetic fields. Choosing the appropriate environment is critical for reliable test results.

Open Area Test Site (OATS): This is a large, open space designed to minimize reflections and other environmental influences, ideal for radiated emission and immunity testing. The ground plane needs to be extremely flat and the surrounding environment free from significant RF sources. Measurements are taken far from any reflecting surfaces and far enough away from other emissions sources to minimize interference. The size of the OATS dictates the minimum measurement distance and its suitability for the product under test. It provides an accurate measure of a product’s radiated emissions in a controlled, open space, which helps ensure reliable results.

Shielded Anechoic Chamber (SAC): SACs are anechoic chambers designed to reduce reflections from the environment. Materials designed to absorb RF signals cover the walls, ceilings and floors, making it useful for both radiated emission and immunity testing in a controlled environment that helps eliminate reflections from altering the measurements.

Semi-Anechoic Chamber (Semi-SAC): These chambers are only partially anechoic—typically the walls and ceiling are anechoic, while the floor is a reflective metal ground plane. They’re used for radiated emission testing, offering a balance between absorption and reflections, making them less expensive than fully anechoic chambers but still offering a significant reduction in reflection compared to other environments.

The selection of the appropriate testing environment depends significantly on the nature of the product being tested and the required regulatory standards. It’s essential to choose the correct environment to obtain reliable and meaningful results.

Q 20. How do you handle discrepancies between test results and specifications?

Discrepancies between test results and specifications require a thorough and systematic investigation. Simply dismissing the results isn’t an option; it’s important to understand the root cause of the discrepancy and take appropriate corrective action. The first step is to meticulously review the test setup, procedures, and equipment to rule out any errors in the measurement process.

Here’s a step-by-step approach:

- Verify Test Setup: Double-check all aspects of the test setup, ensuring that it complies with the relevant standard and that all equipment is properly calibrated and functioning correctly. Look for loose connections, incorrect cabling, or other issues that could affect the results.

- Repeat the Test: Repeat the test multiple times to confirm the results. If the discrepancy persists, move to the next step.

- Analyze the Results: Carefully analyze the test results, looking for patterns or trends that might indicate the source of the discrepancy. Compare the results to the expected behavior based on the product’s design and specifications.

- Investigate the Product: Inspect the product for any physical defects or design flaws that might be causing the non-compliance.

- Implement Corrective Action: Based on the findings of the investigation, implement appropriate corrective actions, such as design modifications or improved manufacturing processes. Re-test the product after implementing the corrections.

- Document Everything: Thoroughly document all steps of the investigation, including the initial discrepancy, the investigation process, the corrective actions taken, and the results of the retesting.

This systematic approach ensures that the issue is addressed effectively and prevents it from recurring. It’s like a detective solving a case: you need to follow the clues to identify the root cause.

Q 21. What are the common causes of conducted emissions?

Conducted emissions, meaning electromagnetic interference (EMI) that travels along power lines or signal cables, are a common problem. They stem from various sources within an electronic device.

Common causes include:

- Switching Power Supplies: Switching power supplies, ubiquitous in modern electronics, are a major source of conducted emissions. The rapid switching of transistors generates high-frequency noise that can couple into the power line.

- Digital Logic Circuits: Fast digital logic circuits generate sharp transitions that radiate noise. These transitions create high-frequency energy that can couple into power lines or signal cables.

- Improper Grounding: Poor grounding or ground loops can amplify conducted emissions by creating unintended current paths. Noise can circulate and be picked up by measurement equipment.

- Insufficient Filtering: Inadequate filtering on power lines or signal cables allows noise to pass through. Filtering components such as common-mode chokes and capacitors can significantly reduce conducted emissions.

- Poor Component Selection: Using components that are not designed for EMC can contribute to conducted emissions. For example, components that are not properly shielded can easily radiate noise.

Addressing conducted emissions requires careful design considerations such as proper grounding techniques, the use of appropriate filtering components, and careful PCB layout. It’s about managing the flow of current and minimizing unintended radiation paths.

Q 22. What are the common causes of radiated emissions?

Radiated emissions, as defined in IEC 61082, are electromagnetic disturbances that propagate through space. They’re essentially unwanted radio waves emanating from electronic equipment. Several factors contribute to their generation.

- High-speed switching circuits: Fast changes in current create sharp voltage transitions, radiating significant energy. Think of a poorly shielded power supply switching at high frequencies.

- Antenna-like structures: Components like long wires, PCB traces, and even improperly designed enclosures can act as antennas, radiating electromagnetic energy. Imagine a long unshielded cable acting as a dipole antenna.

- Insufficient shielding: Metallic enclosures are crucial for containing electromagnetic fields. Gaps or inadequate shielding allow radiation to escape.

- Poor grounding practices: Inadequate grounding provides a path for unwanted currents, increasing radiated emissions. A poorly grounded chassis can act as a radiating element.

- Harmonic generation: Non-linear components generate harmonics of the fundamental frequency, leading to emissions outside the intended frequency range. A rectifier generating multiple harmonics of the mains frequency is a common example.

Understanding the source and mechanism of these emissions is crucial for effective EMC design. The key is minimizing the current that is radiating and using proper shielding techniques.

Q 23. Explain your understanding of the CISPR standards and their relationship to IEC 61082.

CISPR (International Special Committee on Radio Interference) standards are a crucial part of the electromagnetic compatibility (EMC) landscape. They define limits for radiated and conducted emissions and immunity for various types of electronic equipment. IEC 61082, focusing on industrial-process measurement and control equipment, directly utilizes these CISPR standards to establish specific emission limits. In essence, CISPR sets the overall regulatory framework, while IEC 61082 applies this framework to a particular category of equipment.

For example, CISPR 11 defines limits for industrial equipment’s radiated emissions. IEC 61082 then incorporates these CISPR 11 limits into its requirements for the testing and compliance of industrial process measurement and control devices. If a device complies with IEC 61082, it’s implicitly compliant with the relevant CISPR standards for its category. This ensures a harmonized and internationally recognized approach to EMC compliance.

Q 24. Describe your experience with EMC simulations and modeling tools.

I have extensive experience with EMC simulations using various tools like ANSYS HFSS, CST Microwave Studio, and FEKO. These tools allow for accurate prediction of radiated and conducted emissions before physical prototyping. This significantly reduces development time and cost by identifying and mitigating potential issues early in the design cycle.

My work has involved 3D modeling of complex assemblies, including PCB layouts, enclosures, and cables, to precisely analyze electromagnetic field distributions. I’m proficient in defining boundary conditions, exciting the model with various signals and evaluating the results against CISPR and IEC 61082 limits. For instance, I’ve successfully used these tools to optimize enclosure design, identify problematic PCB traces, and design effective filters to meet compliance standards. The ability to visualize and quantify the impact of design changes is essential in ensuring EMC compliance.

Q 25. How do you balance EMC compliance with other product requirements (e.g., cost, performance)?

Balancing EMC compliance with cost and performance considerations is a crucial aspect of product development. It often requires a carefully planned iterative process.

- Prioritize EMC early: Integrating EMC considerations from the initial design phase minimizes costly rework later on. This involves selecting appropriate components and designing for EMC compliance from the start.

- Cost-effective solutions: Employing cost-effective shielding techniques, like using conductive coatings or strategically placing absorbing materials, can be more effective than excessively shielding the entire device.

- Trade-off analysis: A thorough risk assessment is essential to identify and prioritize the most critical EMC issues. This helps focus efforts on critical areas, rather than over-engineering solutions for minor issues.

- Component selection: Choosing components with inherently low emissions reduces the need for extensive filtering or shielding.

- Iterative design process: Simulations and initial testing help identify areas that need improvement. This iterative approach allows for continuous optimization between EMC performance, cost, and performance without starting from scratch.

The key is to find the optimal balance between stringent regulatory requirements and the practical realities of manufacturing and product performance.

Q 26. Explain your understanding of the different types of filters used in EMC design.

Several types of filters are employed in EMC design to attenuate unwanted signals. The choice depends on the frequency range and the type of interference.

- LC filters (Inductor-Capacitor): These are widely used for conducted emissions and can be designed for specific frequencies. They work by creating a high impedance at the unwanted frequencies while offering a low impedance path for the desired signals. A simple example is a common-mode choke used to suppress common-mode noise.

- Pi filters and T filters: Variations of LC filters providing improved attenuation. They can offer better attenuation than a basic LC filter by adding more components.

- EMI/RFI filters: Commercially available, pre-designed filters optimized for specific applications, such as line filtering to reduce mains interference.

- High-pass and low-pass filters: Used to selectively block frequencies above or below a certain cutoff frequency. These are used in conjunction with other filtering techniques.

- Shielded filters: Used for high-power signals. The filter is enclosed in a metal case to reduce magnetic fields.

The design of filters is frequency-dependent and requires careful consideration of component selection to achieve the desired attenuation while minimizing signal loss and insertion losses of desired signals.

Q 27. What is your experience with EMC certification bodies?

I’ve collaborated extensively with various nationally and internationally recognized EMC certification bodies, including (mention relevant certification bodies like UL, TÜV, Intertek, etc., avoiding specific company names to remain general). This involves understanding their specific testing procedures, documentation requirements, and reporting standards. My experience includes preparing test plans, managing testing schedules, reviewing test reports, and addressing any non-compliance issues effectively. Successful collaborations with certification bodies are critical for a smooth and timely certification process, ensuring the product meets all regulatory requirements.

Q 28. Describe a challenging EMC problem you solved and how you approached it.

One particularly challenging project involved a high-frequency industrial control system exhibiting unexpectedly high radiated emissions. Initial testing revealed emissions exceeding CISPR 11 limits by a significant margin. The system was incredibly complex, with numerous high-speed digital circuits and several sensitive analog components.

My approach involved a systematic troubleshooting process:

- Detailed Emission Mapping: We used a spectrum analyzer and a near-field probe to pinpoint the sources of the emissions.

- Targeted Simulations: We used simulations to model the identified sources and assess the effectiveness of different mitigation strategies.

- Shielding Modifications: Based on the simulations, we redesigned the system enclosure with improved shielding, paying special attention to any gaps or potential leakage points.

- PCB Trace Optimization: The simulations highlighted problematic high-speed traces on the PCB. We implemented appropriate grounding techniques, optimized trace lengths, and added decoupling capacitors.

- Filtering Adjustments: We added additional filtering elements to suppress specific frequencies identified as significant emission sources.

- Iterative Testing: Following each modification, we conducted thorough retesting until the device met all regulatory compliance standards.

This multi-faceted approach, leveraging both simulation and experimental testing, successfully reduced the radiated emissions to well below the required limits. The key was systematically identifying the problem areas and then using appropriate simulation tools and analysis before implementing specific mitigation methods.

Key Topics to Learn for IEC 61082 Interview

Acing your IEC 61082 interview requires a solid understanding of its core principles and practical applications. Focus your preparation on these key areas:

- Measurement Principles: Thoroughly grasp the fundamental measurement techniques defined in IEC 61082, including the underlying physics and potential sources of error.

- Electromagnetic Compatibility (EMC): Understand how EMC considerations impact the design and testing of equipment compliant with IEC 61082. Be prepared to discuss specific EMC tests and their significance.

- Safety Requirements: Familiarize yourself with the safety regulations and standards integrated into IEC 61082. This includes understanding potential hazards and mitigation strategies.

- Calibration and Traceability: Understand the importance of proper calibration procedures and the concept of traceability to national or international standards for ensuring accurate measurements.

- Data Acquisition and Analysis: Review methods for acquiring, processing, and analyzing measurement data according to IEC 61082 guidelines. This includes data interpretation and reporting.

- Specific Test Methods: Gain proficiency in the various test methods described within IEC 61082. Focus on understanding the purpose, procedure, and interpretation of results for each method.

- Practical Problem Solving: Practice applying your knowledge to real-world scenarios. Consider how you would troubleshoot issues related to measurement accuracy, EMC compliance, or safety concerns.

Next Steps

Mastering IEC 61082 is a significant step towards career advancement in your field. Demonstrating this expertise is crucial for securing your dream role. To maximize your chances, creating an ATS-friendly resume is essential. This ensures your application gets noticed by recruiters and hiring managers. We highly recommend using ResumeGemini to craft a professional and impactful resume. ResumeGemini provides tools and resources to create a compelling document that showcases your skills and experience effectively. Examples of resumes tailored to IEC 61082 are available within ResumeGemini to guide your process. Invest the time to create a strong resume – it’s an investment in your future.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good