Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Induction Machine Troubleshooting interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Induction Machine Troubleshooting Interview

Q 1. Explain the principle of operation of a three-phase induction motor.

A three-phase induction motor operates on the principle of electromagnetic induction. It uses a rotating magnetic field created by three-phase AC power supplied to its stator windings. This rotating field induces currents in the rotor windings (either squirrel-cage or wound-rotor type), creating a magnetic field in the rotor. The interaction between the rotating stator field and the rotor field produces torque, causing the rotor to rotate.

Imagine it like this: the stator’s magnetic field is like a spinning magnet. This spinning magnet pulls the rotor’s magnetic field along with it, causing the rotor to turn. The speed of the rotor is slightly less than the speed of the rotating magnetic field, a difference known as slip, which is essential for torque production. The higher the slip, the higher the torque (up to a point).

Q 2. Describe the different types of induction motors (squirrel cage, wound rotor).

Induction motors primarily come in two types: squirrel-cage and wound-rotor.

- Squirrel-Cage Motors: These are the most common type. Their rotor consists of solid bars of copper or aluminum embedded in slots and shorted at both ends, forming a cage-like structure. They are simple, rugged, inexpensive, and require less maintenance. However, they have a less flexible speed control compared to wound-rotor motors.

- Wound-Rotor Motors: These have a rotor with windings similar to the stator, which are connected to slip rings. External resistance can be connected to these slip rings, allowing for speed control and higher starting torque. They’re more complex, expensive, and require more maintenance, but offer superior control capabilities for applications needing variable speed or high starting torque (like cranes or hoists).

Q 3. What are the common causes of induction motor overheating?

Overheating in induction motors can stem from several issues:

- High Ambient Temperature: Operating in excessively hot environments can lead to overheating if proper ventilation isn’t ensured.

- Overloading: Demanding more power than the motor is rated for generates excessive heat due to increased current flow.

- Mechanical Problems: Imbalance, misalignment, or bearing wear can create friction and heat.

- Electrical Faults: Winding faults (shorts, opens), incorrect voltage, or unbalanced power supply increase losses and lead to higher temperatures.

- Blocked Ventilation: Obstructions that impede airflow around the motor can trap heat.

Think of it like this: each problem acts like an extra layer of clothing on the motor; it makes it harder to dissipate heat.

Q 4. How do you troubleshoot a motor that is not starting?

Troubleshooting a motor that won’t start is a systematic process:

- Check Power Supply: Verify the presence of power at the motor terminals using a multimeter. Check for correct voltage and phase sequence.

- Inspect for Obstructions: Ensure the motor’s shaft isn’t seized or obstructed.

- Examine the Motor Leads: Look for loose connections, broken wires, or damaged insulation.

- Check the Starting Mechanism (if applicable): For motors with starters (star-delta, autotransformer, etc.), check the operation of the starter.

- Measure Winding Resistance: Use a multimeter to measure the resistance of each motor winding. High or unequal resistance suggests a winding fault.

- Test the Capacitor (if applicable): If the motor is capacitor-start, test the capacitor for capacitance and ESR (Equivalent Series Resistance). A faulty capacitor can prevent starting.

Remember, safety first! Always disconnect power before performing any checks.

Q 5. How do you diagnose a motor with high vibration?

High vibration in an induction motor points towards mechanical issues. The diagnostic process involves:

- Visual Inspection: Look for any obvious signs like loose bolts, bent shafts, or damaged components.

- Check Alignment: Misalignment between the motor and the driven equipment is a common cause of vibration. Use alignment tools for precise measurement.

- Bearing Inspection: Worn or damaged bearings are significant contributors to vibration. Listen for unusual noises and check for play in the bearings.

- Balance Check: An unbalanced rotor will cause significant vibration. Dynamic balancing is crucial for high-speed motors.

- Vibration Measurement: Use a vibration meter to measure the amplitude and frequency of the vibrations. This helps identify the source and severity of the problem.

High vibration not only reduces motor life but can also cause damage to the connected equipment. Early detection and resolution are crucial.

Q 6. Explain the significance of motor nameplate data.

The motor nameplate provides crucial information for operation, maintenance, and troubleshooting. Key data includes:

- Voltage and Frequency: Specifies the required power supply.

- Power (kW or HP): Indicates the motor’s output power.

- Full Load Current (FLA): The current drawn when the motor is operating at its rated power. This is vital for overload protection.

- Speed (RPM): The motor’s rotational speed at rated load.

- Frame Size: Helps identify the motor’s physical dimensions and mounting type.

- Insulation Class: Indicates the motor’s ability to withstand high temperatures.

- Service Factor: Specifies the overload capacity beyond the rated power.

Understanding the nameplate data is essential for selecting the appropriate motor, preventing overloads, and performing proper maintenance.

Q 7. How do you test the insulation resistance of an induction motor winding?

Insulation resistance testing is crucial for evaluating the condition of motor windings. A megohmmeter (or insulation tester) is used to apply a high DC voltage to the windings and measure the resistance between the windings and ground, and between windings.

The procedure generally involves:

- Power Off and Discharge: Ensure the motor is completely disconnected from the power supply and discharged.

- Connect Megohmmeter: Connect the megohmmeter leads to the motor windings, making sure to properly ground the motor.

- Apply Voltage and Measure: Apply the appropriate test voltage (usually 500V or 1000V DC) and read the insulation resistance in megohms (MΩ).

- Record and Interpret Results: Record the readings for each winding and compare them to the manufacturer’s specifications or accepted industry standards. Lower than expected insulation resistance indicates insulation degradation.

Low insulation resistance poses a significant safety risk and can lead to motor failure. Regular insulation resistance tests are part of preventative maintenance.

Q 8. Describe the procedure for testing motor bearings.

Testing motor bearings involves assessing their condition for wear, damage, or lubrication issues, which significantly impact motor performance and lifespan. A faulty bearing can lead to noise, vibration, and eventual motor failure. There are several methods:

- Listen for Noise: Carefully listen to the motor while it’s running. Unusual noises like growling, rumbling, or squealing often indicate bearing problems. A stethoscope can help pinpoint the source.

- Check for Play: With the motor stopped and disconnected from power, try to move the shaft axially (along its length) and radially (side to side). Excessive play indicates wear. This is best done with a bearing puller to help stabilize the motor.

- Vibration Analysis: Using a vibration meter, measure the vibration levels at the bearing housings. High vibration levels can indicate bearing wear or imbalance. This method requires specialized equipment and expertise.

- Temperature Measurement: High bearing temperatures (measured with a thermal gun) can indicate friction due to wear or insufficient lubrication.

- Visual Inspection: If possible, visually inspect the bearings for signs of damage, such as pitting, corrosion, or excessive grease leakage. This usually requires disassembly.

Example: Imagine you’re troubleshooting a noisy pump motor. After isolating the noise to a bearing, a radial play check confirms significant looseness, indicating the need for bearing replacement.

Q 9. What are the common causes of motor noise?

Motor noise can stem from various sources, and diagnosing the cause is crucial for effective troubleshooting. Common culprits include:

- Bearing Wear: As mentioned earlier, worn bearings produce characteristic growling, rumbling, or squealing noises.

- Loose Parts: Loose mounting bolts, internal components, or even debris within the motor casing can cause rattling or knocking sounds.

- Winding Faults: Damaged or shorted windings may create humming or buzzing sounds, often accompanied by reduced performance.

- Rotor Imbalance: An unbalanced rotor will vibrate and generate a whirling noise, particularly at higher speeds. This can be caused by manufacturing defects, or damage to the rotor.

- Air Gap Problems: An uneven air gap between the rotor and stator will cause unusual vibrations and noises.

- Mechanical Issues: Problems with the driven equipment (like a pump or fan) can transmit noise to the motor.

Example: A high-pitched squeal from a motor, localized to one end, is a strong indicator of a worn bearing. A rhythmic thumping noise could be related to a loose component. Careful listening and observation are essential for accurate diagnosis.

Q 10. How do you troubleshoot a motor with reduced torque?

Reduced torque in an induction motor indicates a problem hindering its ability to deliver the required mechanical power. Troubleshooting steps include:

- Check the Load: Is the motor overloaded? Excessive load will result in reduced torque. Measure the current and compare it to the motor’s nameplate rating.

- Inspect for Mechanical Issues: Are the belts, couplings, or driven equipment functioning correctly? A slipping belt or a seized component will reduce the torque transmitted to the load.

- Test the Power Supply: Verify the motor is receiving the correct voltage and frequency. A low voltage supply will directly impact torque output.

- Assess Winding Condition: Perform a winding resistance test to check for shorted or open windings. These faults significantly reduce motor torque.

- Inspect the Rotor: Examine the rotor for any damage or wear. Problems like broken rotor bars or rotor eccentricity can cause reduced torque.

- Verify Air Gap: Measure the air gap between the stator and rotor. An uneven or too-large air gap reduces motor efficiency and torque.

- Check for Overheating: Excessive temperature rise indicates excessive load or internal problems, both affecting torque.

Example: A conveyor belt motor struggles to move heavier loads. Initial checks reveal the motor’s current draw is at its maximum, suggesting the motor is overloaded and needs replacement or the need for a larger motor.

Q 11. Explain the role of motor starters and their types.

Motor starters control the starting current and voltage to an induction motor, protecting the motor and the power supply from damage during the high-inrush current of starting. Different types of starters cater to varying motor sizes and applications:

- Direct-On-Line (DOL) Starters: The simplest type, connecting the motor directly to the power supply. Suitable for smaller motors where inrush current is manageable.

- Star-Delta Starters: Reduce starting current by initially connecting the motor windings in a star configuration during start-up, then switching to a delta configuration for normal operation.

- Autotransformer Starters: Use an autotransformer to reduce the voltage applied to the motor during starting, further reducing the inrush current. More sophisticated than star-delta starters.

- Soft Starters: Utilize power electronics to gradually increase the voltage applied to the motor, limiting the starting current and torque. Provide smooth starting and reduce mechanical stress.

- Variable Frequency Drives (VFDs): Offer precise control over motor speed and torque by varying the frequency and voltage supplied. Provide energy savings and improved motor control compared to other starters.

Example: A large industrial fan might use a soft starter to prevent excessive stress on the motor and power system, whereas a small pump motor might only need a simple DOL starter.

Q 12. How do you identify a shorted winding in an induction motor?

Identifying a shorted winding requires careful testing and analysis because a short circuit can drastically impact motor operation. Methods include:

- Insulation Resistance Test (Megger Test): Use a megger (an insulation resistance tester) to measure the resistance between each winding and the motor frame. Low resistance readings indicate a short circuit.

- Winding Resistance Test: Measure the resistance of each winding individually using an ohmmeter. Unexpectedly low resistance compared to other windings or the motor’s nameplate data suggests a shorted coil.

- Visual Inspection: In some cases, a visual inspection might reveal signs of damage such as burned insulation or discoloration, potentially indicating a shorted winding.

Important Note: Always disconnect the motor from the power supply before performing any electrical tests. If a short circuit is detected, replace the affected winding or the entire motor, as it compromises safety and performance.

Example: A megger test reveals low insulation resistance between one winding and the motor casing, indicating a short circuit. The shorted winding needs to be repaired or the motor needs to be replaced.

Q 13. What are the safety precautions when working on induction motors?

Safety is paramount when working on induction motors. Always follow these precautions:

- Lockout/Tagout: Always lock out and tag out the power supply to the motor before starting any maintenance or repair work. This prevents accidental energization.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, gloves, and potentially hearing protection.

- Grounding: Ensure the motor is properly grounded to prevent electrical shock.

- High Voltage Awareness: Be aware of high voltage components within the motor, especially in larger motors. Consult the motor’s documentation and take appropriate precautions.

- Lifting Safely: Use appropriate lifting equipment to handle the motor, preventing injury from heavy loads.

- Proper Ventilation: Provide adequate ventilation to prevent exposure to hazardous fumes or gases that might be released during motor work.

Example: Before testing the insulation resistance of a motor, a worker must ensure that it is properly de-energized, and locked out to prevent accidental power up during maintenance.

Q 14. Explain the difference between VFD and DOL starters.

Both VFDs and DOL starters control the operation of induction motors, but they differ significantly in their functionality and capabilities:

- DOL Starters: Provide simple on/off control, applying full voltage to the motor immediately. This causes high inrush currents and may produce mechanical stress during starting. They are inexpensive and easy to implement but lack the sophistication of a VFD.

- VFDs (Variable Frequency Drives): Offer precise control of motor speed and torque by adjusting the frequency and voltage supplied to the motor. They provide smooth starting, reduce inrush current, and allow for optimized motor performance across various operating conditions. VFDs are more expensive but provide enhanced control, energy savings, and extended motor lifespan.

Key Differences Summarized:

| Feature | DOL Starter | VFD |

|---|---|---|

| Cost | Low | High |

| Starting Current | High | Low |

| Speed Control | None | Precise |

| Energy Efficiency | Lower | Higher |

| Complexity | Simple | Complex |

Example: A conveyor system requiring variable speed control for precise material handling would benefit greatly from a VFD, while a simple pump with a constant speed requirement might effectively use a DOL starter.

Q 15. How do you interpret motor current readings?

Motor current readings are a vital indicator of the motor’s health and load. A stable, relatively constant current within the motor’s nameplate rating indicates normal operation. However, deviations from this norm can point to various problems. For instance, a consistently high current suggests an overload, while fluctuating current might signal intermittent faults.

Interpreting these readings involves understanding the context. Consider the motor’s load, the ambient temperature, and the voltage supply. You’ll typically use an ammeter, either clamp-on or directly connected, to take these measurements. Comparing the measured current to the motor’s nameplate rating is the first crucial step. If the current exceeds the rated value, it’s a strong indication of a problem. Analyzing current waveforms can also reveal issues like unbalanced phases or short circuits. For example, a significantly higher current in one phase compared to others immediately points to a phase imbalance.

Career Expert Tips:

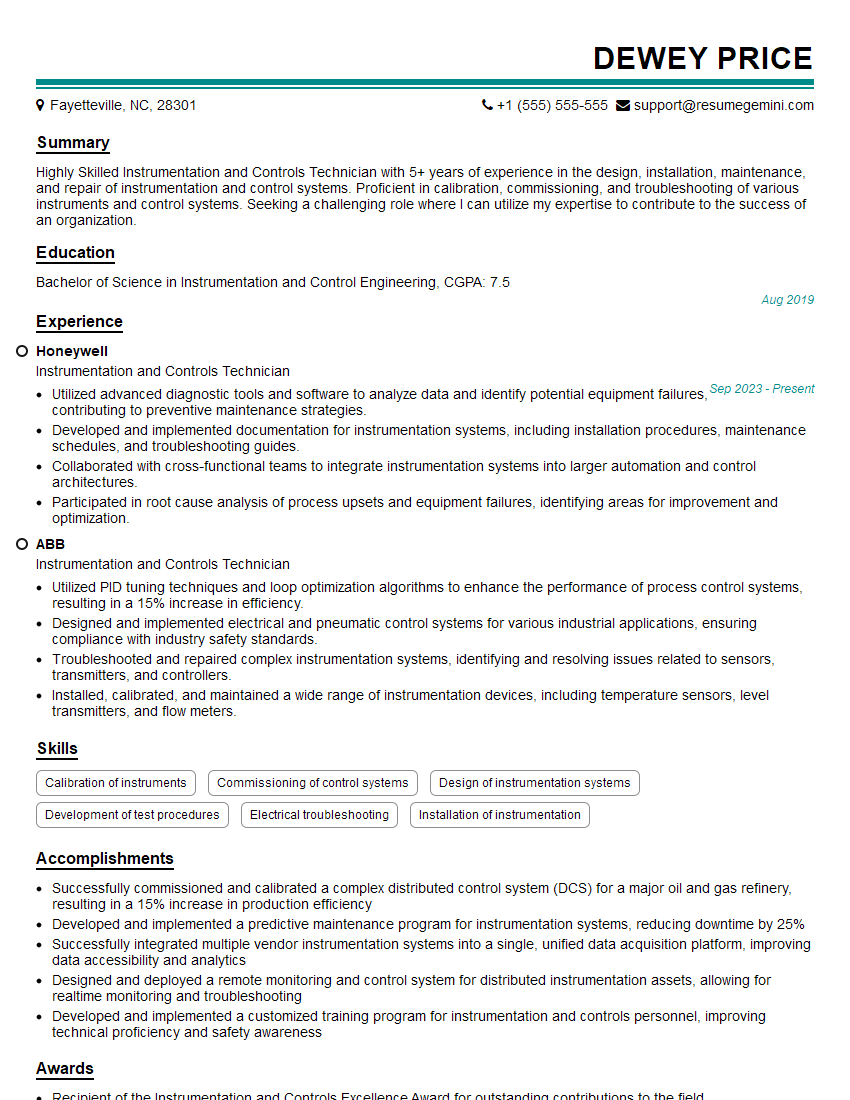

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you troubleshoot a motor that is drawing excessive current?

Excessive current draw in a motor is a serious issue that requires systematic troubleshooting. Think of it like a car engine overheating – it’s a symptom, not the problem itself. The goal is to identify the root cause.

Check the Load: Is the motor driving a load that exceeds its rated capacity? This is often the simplest explanation. Imagine a motor designed to lift 100 kg trying to lift 200 kg; it will draw excessive current. Measuring the actual load is crucial here.

Inspect the Motor for Mechanical Problems: Look for things like bearing wear, misalignment (shaft misalignment is a common cause of high current draw), or rotor rubbing. A faulty bearing can create significant friction and increase current. A simple visual inspection and checking for abnormal sounds are often helpful.

Examine the Winding Insulation: Deteriorated insulation can lead to short circuits within the motor windings, resulting in excessive current. An insulation resistance test using a megohmmeter is a standard diagnostic test.

Assess the Power Supply: Check the voltage supply for imbalances between phases. Even slight voltage unbalances can lead to substantial current increases in some phases and increased overall current. Similarly, low voltage can force the motor to draw more current to deliver the same power.

Verify the Controller: Faulty motor starters, variable frequency drives (VFDs), or other control devices can lead to excessive current draw. Inspect these components for any signs of damage or malfunction.

Remember to always prioritize safety and follow lockout/tagout procedures before performing any motor inspection or repair work.

Q 17. Explain the concept of motor slip.

Motor slip is the difference between the synchronous speed of the motor’s rotating magnetic field and the actual rotational speed of the motor shaft. It’s expressed as a percentage. Imagine a perfectly synchronized motor; the rotor would spin at exactly the same speed as the rotating magnetic field – zero slip. However, in real-world induction motors, the rotor always lags slightly behind the magnetic field, allowing torque to develop. The slip is necessary for the motor to produce torque.

For example, a four-pole motor operating at 60 Hz has a synchronous speed of 1800 RPM (120f/p, where f is the frequency and p is the number of poles). If the actual rotor speed is 1750 RPM, the slip is (1800-1750)/1800 *100% = 2.78%. High slip indicates increased load or potential motor problems. Low slip may be a sign of a lightly loaded motor or an issue with the motor itself.

Q 18. What are the common causes of motor tripping?

Motor tripping, or the sudden shutdown of the motor by a protective device, is usually a safety mechanism to prevent damage. The common causes include:

Overcurrent: This is by far the most frequent cause, triggered by excessive current draw due to overload, short circuits, or other motor faults.

Overtemperature: Internal motor temperature exceeding safe limits, often due to prolonged overload, blocked ventilation, or bearing problems. Thermal overload relays protect against this.

Ground Faults: A fault where the motor’s windings become grounded, leading to a leakage current that can trip the protection system.

Phase Unbalance: Unequal voltage in the three phases of a three-phase motor can lead to increased current in one phase and overload the motor.

Low Voltage: Extended periods of low voltage can cause motors to draw excessive current and trip the protective device.

Loss of Phase: If one phase of the power supply is lost, the motor will not run properly and can draw excessive current in the remaining phases, causing it to trip.

Identifying the specific cause of the trip requires investigating the protective device (circuit breaker or overload relay) status and reviewing the motor’s operating conditions before the trip.

Q 19. How do you troubleshoot a motor with intermittent operation?

Intermittent motor operation can be tricky to troubleshoot because the fault is not consistently present. It’s like a flickering light – you need to track down the intermittent connection or component.

Loose Connections: Check all electrical connections, including those at the motor terminals, control panel, and power source. Loose connections can intermittently interrupt the power supply.

Faulty Wiring: Inspect wiring for damage, wear, or corrosion. A wire that’s partially damaged may work sometimes and fail at other times.

Contactors and Relays: These electromechanical switches are prone to wear and can exhibit intermittent behavior. Check for sticking contacts, burnt contacts, or weak springs.

Temperature-Sensitive Issues: Some faults manifest only at certain temperatures. Observe the motor’s behavior at various operating temperatures.

Overheating Issues: The intermittent operation might be a safety mechanism triggered by overheating. Examine the motor windings, bearings, and ventilation.

Sensor Problems: If the motor uses sensors (e.g., proximity sensors, temperature sensors), check their integrity and functionality.

Troubleshooting intermittent faults requires careful observation and often involves systematic checks of all the potential points of failure.

Q 20. Describe the procedure for performing a motor thermal scan.

A motor thermal scan uses an infrared (IR) camera to measure the surface temperature of the motor’s components. This non-invasive technique helps identify localized overheating, which is a strong indicator of underlying problems. Think of it as a thermal image revealing ‘hot spots’ that might otherwise go unnoticed.

The procedure generally involves:

Preparation: Ensure the motor is operating under normal load conditions. Safety precautions are crucial. The area should be well-lit to allow for better contrast in the thermal images.

Scanning: Use the IR camera to scan the motor’s surface, paying close attention to areas like windings, bearings, and connections. Record thermal images for later analysis.

Interpretation: Compare the temperature readings to the motor’s manufacturer’s specifications and look for significant temperature differences between components or regions. An unusually hot spot is a sign of a problem. For instance, a hot winding might indicate a shorted turn or increased load.

Documentation: Record the thermal images and temperature data for future reference. This is especially important for tracking down intermittent problems.

The thermal scan provides a visual representation of the motor’s thermal profile, allowing technicians to pinpoint problem areas before they cause significant damage.

Q 21. How do you diagnose a motor with unbalanced voltage?

Unbalanced voltage in a three-phase motor means that the voltage levels across the three phases (A, B, and C) are not equal. This creates unequal magnetic fields and leads to a variety of problems. It’s like trying to run a three-legged race with legs of unequal length – it won’t be smooth or efficient.

Diagnosis involves measuring the voltage across each phase using a multimeter. Significant voltage differences (typically more than 2-3%) between phases indicate an unbalanced condition. This imbalance can result in:

Increased Motor Current: The motor will draw more current to compensate, potentially leading to overheating and premature failure.

Reduced Efficiency: The motor won’t operate at its rated power and efficiency, wasting energy.

Excessive Vibration and Noise: The uneven magnetic fields can cause the motor to vibrate excessively.

Premature Bearing Wear: Increased vibration can damage the bearings and lead to their premature failure.

Troubleshooting involves identifying the source of the voltage imbalance, which could be problems in the power supply wiring, distribution system, or even a faulty transformer. The solution may involve correcting wiring issues, replacing faulty components, or adding voltage balancing equipment.

Q 22. What are the different types of motor protection relays?

Motor protection relays are crucial for safeguarding induction motors from various damaging conditions. They continuously monitor the motor’s electrical parameters and initiate a trip signal if pre-defined thresholds are exceeded. Different types cater to specific protection needs:

- Overcurrent Relays: These are fundamental and protect against excessive current draw due to overload, short circuits, or stalled rotors. Think of them as the motor’s ‘circuit breaker’ on steroids, providing more sophisticated protection than a simple breaker.

- Thermal Relays: These relays detect excessive motor temperature, often caused by prolonged overload or insufficient ventilation. They act as the motor’s ‘fever detector,’ preventing overheating damage.

- Ground Fault Relays: These detect ground faults, a potentially dangerous condition where current flows to ground. They ensure the safety of personnel and equipment by quickly isolating the faulted motor.

- Phase Unbalance Relays: These monitor the balance of current in each phase of the motor. An imbalance indicates a problem like a faulty winding or wiring issue, which can lead to motor damage. Imagine it like monitoring the balance of a three-legged stool – if one leg is shorter, the whole thing is unstable.

- Locked Rotor Relays: These detect a stalled motor, a situation that can lead to overheating and winding damage. They’re like the motor’s ’emergency stop’ button, tripping when the motor can’t turn.

The specific relays used depend on the motor’s application, size, and the level of protection required. For critical applications, a combination of relays provides comprehensive protection.

Q 23. Explain the importance of preventive maintenance on induction motors.

Preventive maintenance on induction motors is paramount to ensure operational reliability, extend lifespan, and minimize downtime. Neglecting this can lead to catastrophic failures, costly repairs, and potential safety hazards. Think of it like regular servicing for your car – preventative maintenance prevents larger, more expensive problems later on.

A comprehensive preventive maintenance program includes:

- Visual Inspection: Checking for loose connections, damaged insulation, signs of overheating, and foreign object intrusion.

- Vibration Analysis: Detecting abnormal vibrations that can indicate bearing wear, rotor imbalance, or misalignment.

- Insulation Resistance Testing: Measuring the insulation resistance of the motor windings to identify degradation and potential short circuits. A low resistance value is a warning sign of deterioration.

- Lubrication: Proper lubrication of bearings extends their lifespan and reduces friction and wear. Improper lubrication is a common cause of premature bearing failure.

- Cleaning: Removing dust, dirt, and debris that can obstruct ventilation and lead to overheating.

A well-defined maintenance schedule, based on the motor’s operating conditions and manufacturer’s recommendations, is crucial for effective preventive maintenance. Regular checks allow for early detection of issues, minimizing the risk of major failures and ensuring smooth operation.

Q 24. Describe the process of motor rewinding.

Motor rewinding is a complex process where the damaged windings of an induction motor are replaced with new ones. It’s a specialized task requiring expertise and the right equipment. Think of it as a major surgery for the motor.

The process generally involves these steps:

- Disassembly: Carefully dismantling the motor, removing the end bells, stator, and rotor.

- Winding Removal: Removing the old windings from the stator slots, taking careful note of the winding configuration.

- Stator Cleaning: Thoroughly cleaning the stator slots and core to remove any residual insulation or debris.

- Winding Preparation: Preparing the new winding wire according to the original motor specifications. This often involves carefully calculating and measuring the wire to ensure precise fit and function.

- Winding Insertion: Carefully placing the new windings into the stator slots, ensuring proper insulation and placement. This is a delicate step and requires skill and patience.

- Insulation Testing: Testing the new windings for insulation resistance and short circuits to ensure the quality of the rewinding.

- Assembly: Reassembling the motor, ensuring proper alignment of components.

- Testing: Testing the rewinded motor under load to verify performance and ensure it meets specifications.

Motor rewinding is usually a cost-effective solution compared to replacing the motor, especially for larger motors where the cost of replacement is significantly higher. However, it requires skilled technicians and specialized tools.

Q 25. How do you identify a faulty capacitor in a single-phase induction motor?

Identifying a faulty capacitor in a single-phase induction motor often involves a combination of visual inspection and testing. Single-phase motors use a capacitor to create a phase shift, enabling the motor to start and run. A bad capacitor significantly impacts motor performance.

Here’s how to identify a faulty capacitor:

- Visual Inspection: Look for physical damage like bulging, leaking electrolyte, or burnt markings on the capacitor. These are clear signs of a faulty component.

- Capacitance Measurement: Using a capacitance meter (a multimeter with capacitance measurement function), measure the capacitor’s capacitance. Compare the measured value to the rated value printed on the capacitor. A significant deviation indicates a problem. For example, a significantly lower capacitance than rated suggests degradation.

- ESR (Equivalent Series Resistance) Measurement: High ESR indicates internal resistance within the capacitor and is often a sign of aging or damage. Modern multimeters capable of ESR measurement will greatly help in this analysis.

- Motor Performance Test: A faulty capacitor can result in a motor that is difficult to start, runs poorly, or makes unusual noises. These symptoms, in conjunction with the visual and measurement tests, confirm the capacitor as the likely culprit.

Always remember safety precautions when working with electrical components. Disconnect power before any testing or inspection.

Q 26. Explain the use of a motor analyzer for diagnostics.

A motor analyzer is a sophisticated diagnostic tool that provides comprehensive information about the condition of an induction motor. It’s much more powerful than simply checking voltage or current; it allows for in-depth analysis of motor parameters and facilitates the precise pinpointing of faults. Think of it as a highly advanced ‘check-up’ for your motor.

A motor analyzer typically measures and analyzes various parameters such as:

- Winding resistance: Detects shorted or open windings.

- Insulation resistance: Reveals insulation degradation that could lead to a breakdown.

- Current waveforms: Identifies problems such as rotor imbalances or winding faults.

- Vibration analysis: Detects bearing wear, rotor imbalance, or shaft misalignment.

- Motor speed and torque: Determines the motor’s performance under load and can unveil power-related problems.

By analyzing these parameters, a motor analyzer helps to quickly diagnose the root cause of motor problems, enabling targeted maintenance and avoiding unnecessary repairs. Its data-driven approach helps in planning and optimizing maintenance, potentially saving both time and money in the long run.

Q 27. How do you assess the condition of motor shaft alignment?

Assessing motor shaft alignment is crucial to prevent premature bearing failure, vibrations, and mechanical damage to the motor and coupled equipment. Misalignment can lead to inefficiencies and reduce motor lifespan. Imagine trying to connect two pipes that aren’t perfectly aligned – it’s going to cause problems.

Several methods exist for assessing shaft alignment:

- Dial Indicator Method: This is a widely used method where dial indicators are used to measure the radial and axial misalignment between the motor and the driven equipment shafts.

- Laser Alignment Tools: These advanced tools use laser beams to measure alignment, providing more accurate and efficient measurement compared to traditional methods. They drastically reduce the time required for alignment and are less prone to human error.

- Alignment Software: Some laser alignment systems use software to automatically analyze measurements and suggest corrections, making the alignment process even more efficient and precise.

Regardless of the method used, proper alignment involves adjusting the motor’s position relative to the driven equipment to minimize misalignment within acceptable tolerances. The chosen method depends on budget, precision needed, and the machinery’s complexity.

Q 28. What are the benefits of using predictive maintenance techniques for induction motors?

Predictive maintenance techniques for induction motors go beyond scheduled maintenance; they leverage data analysis to predict potential failures before they occur. This proactive approach minimizes downtime, optimizes maintenance schedules, and reduces overall maintenance costs. Think of it as preventative maintenance but with advanced warning.

Benefits of using predictive maintenance include:

- Reduced Downtime: By anticipating potential failures, maintenance can be planned proactively, minimizing unplanned outages and production disruptions.

- Optimized Maintenance Schedules: Maintenance is performed only when necessary, eliminating unnecessary interventions and maximizing the efficiency of maintenance resources.

- Extended Motor Lifespan: Early detection and correction of potential problems significantly extend the operational life of the motor.

- Lower Maintenance Costs: Proactive maintenance prevents major failures, leading to lower repair costs and fewer replacement parts.

- Improved Safety: Predictive maintenance can identify potential safety hazards, such as insulation degradation, before they pose a risk.

Predictive maintenance strategies often involve continuous monitoring of motor parameters (vibration, temperature, current) through sensors and data analysis using software to identify trends and potential anomalies. The predictive nature of these techniques provides invaluable information, allowing for strategic maintenance decisions.

Key Topics to Learn for Induction Machine Troubleshooting Interview

- Understanding Induction Motor Principles: Grasp the fundamental operating principles of three-phase induction motors, including rotating magnetic fields, torque production, and slip.

- Fault Diagnosis Techniques: Learn to effectively diagnose common faults like stator winding failures, rotor defects, bearing issues, and problems with the power supply. Practical experience with diagnostic tools like multimeters, insulation testers, and motor current analyzers is crucial.

- Safety Procedures: Understand and emphasize the importance of adhering to all relevant safety regulations and procedures when troubleshooting high-voltage electrical equipment. This demonstrates responsibility and professionalism.

- Practical Application: Be prepared to discuss real-world scenarios where you’ve applied your troubleshooting skills. Examples might include identifying a specific fault based on observed symptoms, explaining your diagnostic process step-by-step, and outlining the repair strategy.

- Preventive Maintenance: Demonstrate your knowledge of preventive maintenance techniques to minimize downtime and extend the lifespan of induction motors. This showcases a proactive approach to maintenance.

- Troubleshooting Specific Motor Types: Familiarize yourself with the nuances of different induction motor types (e.g., squirrel cage, wound rotor) and their respective troubleshooting challenges.

- Advanced Troubleshooting Methods: Explore advanced techniques like motor vibration analysis, thermal imaging, and motor performance testing. These demonstrate a higher level of expertise.

- Data Interpretation and Analysis: Be prepared to interpret data from motor performance monitoring systems and use it to identify potential problems before they escalate.

Next Steps

Mastering Induction Machine Troubleshooting is vital for career advancement in industrial maintenance, manufacturing, and power systems. Proficiency in this area significantly increases your value to potential employers. To maximize your job prospects, focus on crafting an ATS-friendly resume that clearly highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume that gets noticed. Examples of resumes tailored to Induction Machine Troubleshooting are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good