The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Ink Mixing and Color Matching interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Ink Mixing and Color Matching Interview

Q 1. Explain the difference between subtractive and additive color mixing.

Subtractive and additive color mixing are two fundamentally different approaches to creating colors. Think of it like this: additive color mixing is like shining lights together, while subtractive color mixing is like layering colored filters.

Additive Color Mixing: This method is used in displays like computer screens and TVs. It involves combining different colored lights to create new colors. The primary colors are red, green, and blue (RGB). When you combine all three at maximum intensity, you get white light. As you subtract light (reduce the intensity of one or more colors), you get darker colors. For example, combining red and green light creates yellow.

Subtractive Color Mixing: This is the process used in printing and painting. It involves mixing pigments or dyes, which absorb certain wavelengths of light while reflecting others. The primary colors are cyan, magenta, and yellow (CMY), often with black (K) added to improve the dark tones, forming the CMYK color model. Mixing all three primary subtractive colors ideally results in black, but in practice, it often yields a muddy dark brown. The more pigments you add, the more light is absorbed, resulting in darker colors. For instance, mixing cyan and magenta creates blue.

Q 2. Describe the process of creating a custom ink color match.

Creating a custom ink color match is a precise process requiring specialized equipment and expertise. Let’s say a client needs a specific shade of purple for their branding. Here’s how we’d approach it:

- Color Measurement: We begin by measuring the target color using a spectrophotometer. This device precisely quantifies the color’s spectral reflectance, providing numerical data (like L*a*b* values) representing its precise hue, saturation, and lightness.

- Ink Formulation: Using color matching software, we input the target color’s data. The software then suggests ink formulations – essentially recipes – combining base inks (cyan, magenta, yellow, black) and potentially specialty inks to achieve the desired shade. This is an iterative process. The software might initially suggest a combination, and we might adjust it based on our expertise.

- Test Prints: We create test prints using the proposed ink formulation. We meticulously compare these prints to the original color sample using a light booth to minimize the impact of varying lighting conditions.

- Refinement: The spectrophotometer measures the test print’s color, providing data we use to further refine the ink formulation. We repeat steps 2 and 3 until we reach an acceptable color match within a specified tolerance (Delta E).

- Quality Control: After finalizing the ink formulation, we conduct extensive quality control tests, printing several samples to check consistency across different substrates and printing conditions.

Q 3. What are the common methods used for measuring color accuracy?

Several methods ensure color accuracy in ink mixing and color matching:

- Spectrophotometry: This is the gold standard, using spectrophotometers to measure the spectral reflectance of a color. This provides objective numerical data (like L*a*b* values) representing the color’s precise characteristics. Different instruments use different illumination conditions, so matching instruments is crucial.

- Densitometry: This technique measures the density of ink on a printed surface. It’s less precise than spectrophotometry but provides a quicker and simpler assessment, particularly useful for evaluating consistency across prints.

- Visual Assessment: While subjective, visual comparison under controlled lighting conditions (e.g., a light booth) remains an important part of the process, especially for final approval. It lets us catch subtleties not always captured numerically.

The choice of method depends on the application’s needs. High-precision printing might demand spectrophotometry, whereas quality control checks might utilize densitometry for efficiency.

Q 4. How do you troubleshoot inconsistencies in color reproduction?

Troubleshooting inconsistencies in color reproduction requires systematic investigation. Here’s a common approach:

- Identify the inconsistency: Pinpoint the specific problem – is it a consistent shift in hue across multiple prints, a variation between different printing runs, or differences between the proof and the final product?

- Check the variables: Systematically review potential sources of error:

- Ink: Are the inks fresh and properly mixed? Is the viscosity correct?

- Substrate: Does the printing paper or material absorb ink consistently?

- Press Conditions: Are the printing press settings (ink keys, pressure, speed) consistent?

- Profile: Are the correct color profiles being used for the software, RIP, and press?

- Environment: Are temperature and humidity within the acceptable range for printing?

- Measure and Quantify: Use a spectrophotometer to objectively measure the color differences. This helps pinpoint the magnitude and nature of the problem.

- Isolate the Problem: Conduct controlled tests – for example, print with different ink batches, on different substrates, or with adjusted press settings – to determine which variable is responsible.

- Implement Corrections: Based on the analysis, adjust the ink formulation, printing parameters, or other variables to resolve the inconsistency.

Remember, careful record-keeping is vital for effective troubleshooting – documenting each step and its outcome aids in future problem-solving.

Q 5. Explain the role of spectrophotometers in color matching.

Spectrophotometers are essential tools in color matching. They measure the spectral reflectance of a color – essentially how much light is reflected at different wavelengths. This allows for precise numerical representation of a color, often in the L*a*b* color space. This data is crucial for:

- Objective Color Measurement: Provides an objective, measurable way to compare a target color to a printed sample, eliminating subjectivity inherent in visual comparison.

- Color Formulation: Used in conjunction with color matching software, the spectrophotometer’s data enables accurate ink formulation, ensuring the final printed color closely matches the desired shade.

- Quality Control: Allows for rigorous quality control checks by measuring color consistency across multiple prints, batches, and print runs.

- Color Management: Spectrophotometer measurements are crucial for creating accurate color profiles, which are necessary for consistent color reproduction across various printing devices and substrates.

Without spectrophotometers, color matching would rely heavily on subjective visual assessment, making consistent and accurate color reproduction highly challenging.

Q 6. What are the different types of inks used in printing?

The printing industry utilizes various ink types, each with specific properties impacting color and print quality:

- Solvent Inks: Used for durable prints on a wide range of materials, but often have strong odors and require specialized ventilation.

- UV-Curable Inks: These inks cure instantly upon exposure to UV light, enabling fast printing and excellent durability. They are common in high-quality commercial printing.

- Water-Based Inks: Environmentally friendly and low-odor, these inks are suitable for many applications, but often offer less durability than solvent or UV inks.

- Pigment Inks: These inks contain finely ground pigments suspended in a liquid carrier. They are more opaque and vivid than dye-based inks, making them ideal for achieving deep, rich colors.

- Dye-Based Inks: These inks consist of color dissolved in a liquid carrier. They offer bright, translucent colors but generally lack the opacity and durability of pigment inks.

The choice of ink depends heavily on the printing method, the substrate being printed on, and the desired print durability and color characteristics.

Q 7. How do ink viscosity and temperature affect color matching?

Ink viscosity and temperature significantly impact color matching. Viscosity, or the thickness of the ink, influences how much ink is deposited onto the substrate. Changes in viscosity can lead to variations in color density and hue. Higher viscosity can result in less ink being transferred, creating lighter colors. Conversely, lower viscosity can lead to excessive ink deposition and darker, potentially muddy, colors. Temperature also plays a significant role. Increased temperature can reduce ink viscosity, while lower temperatures can increase it. This temperature-viscosity relationship can dramatically influence color consistency, especially during long print runs. Therefore, maintaining consistent temperature and viscosity throughout the printing process is crucial for accurate color matching.

For example, a slight increase in temperature during a print run might cause the ink to become less viscous, leading to lighter colors in the later prints compared to the initial ones. Careful monitoring and control of ink temperature and viscosity through various techniques like temperature-controlled ink systems and rheological additives are essential for achieving accurate color reproduction.

Q 8. Describe your experience with Pantone Matching System (PMS).

The Pantone Matching System (PMS) is an essential tool in my workflow. It’s a standardized color reproduction system using a library of pre-mixed inks, each identified by a unique PMS number. My experience spans over [Number] years, encompassing various applications from print design to packaging. I’m proficient in using the PMS books and digital versions to specify and achieve accurate color matches across different projects and print methods. For example, if a client provides a design specifying PMS 186C, I can readily find that specific Pantone color in the PMS book, ensuring consistent color reproduction across various prints. I’ve also dealt with situations where a client’s desired PMS color wasn’t readily achievable on a specific substrate; in those cases, I would conduct thorough testing to find the closest possible match or suggest alternative colors to achieve a visually comparable result.

Q 9. How do you handle color variations between different printing substrates?

Color variations between printing substrates are a common challenge. Different substrates, such as coated and uncoated paper, absorb and reflect light differently, influencing the final color appearance. To handle these variations, I employ a multi-step approach. Firstly, I select the substrate before choosing the ink color. Then, I create test prints on the selected substrate using the target Pantone or CMYK values. This allows me to calibrate the ink formulations to account for substrate absorption and other variables. I might need to adjust the ink concentrations or use specific substrate-optimized color profiles for accurate color matching. This iterative process ensures that the final print accurately matches the design intent, regardless of the substrate used. For instance, a vibrant Pantone color might appear duller on an uncoated paper; adjusting the ink formulation with a slight increase in density can often compensate for this.

Q 10. What are the common challenges faced in color matching?

Color matching presents several consistent challenges. Metamerism, where colors appear identical under one light source but different under another, is a significant issue. Also, variations in ink manufacturing batches and the inherent limitations of the printing process can cause slight color shifts. Maintaining color consistency across different printing presses and even within a single press run is another obstacle. Lastly, subjective interpretation of color—what one person sees as ‘true blue’ might differ slightly from another’s perception—can add complexity to the color matching process. Addressing these issues often involves meticulous color measurements using spectrophotometers, precise ink formulation adjustments, and robust color management workflows.

Q 11. Explain your experience with color management software.

I’m highly proficient in several color management software packages, including [List Software Names, e.g., X-Rite i1Profiler, GMG ColorProof]. These tools are crucial for accurate color reproduction. My expertise includes creating and utilizing ICC profiles for different printers, substrates, and inks. I’m comfortable with color transformations between different color spaces (CMYK, RGB, Lab), ensuring consistency throughout the design and printing process. For example, I’ve used these software packages to create custom profiles for our high-end presses, resulting in a significant reduction in color discrepancies and improved overall print quality. I also employ these tools to simulate color appearance on different substrates before printing, thereby saving time and materials.

Q 12. How do you maintain accurate ink records and inventory?

Maintaining accurate ink records and inventory is vital for efficient operation and consistent color reproduction. We utilize a combination of digital inventory management systems and physical stock checks. All ink purchases and usages are meticulously documented. We track batch numbers to identify potential variations in ink color between batches. Our digital system automatically triggers reorder alerts when ink levels drop below a predefined threshold. Regular physical checks help verify the digital records and identify any discrepancies. This system enables us to avoid ink shortages and to quickly trace the source of any color inconsistencies, optimizing our workflows and ensuring timely project completion.

Q 13. Describe your process for resolving color discrepancies between proofs and final prints.

Resolving color discrepancies between proofs and final prints requires a systematic approach. I start by comparing the proof and the print using a spectrophotometer to quantify the color difference. Then, I analyze potential causes such as variations in printing press settings, ink density, or substrate. I review the ICC profiles used and check for any inconsistencies. Corrective actions might involve adjusting press settings, modifying ink formulations, or even re-creating the print using a calibrated profile. Open communication with the client is key; I explain the reasons for discrepancies and offer solutions. Sometimes, subtle color shifts are unavoidable; in those instances, I’d work with the client to determine if the discrepancy is acceptable or requires further adjustment.

Q 14. What safety precautions do you take when handling inks and solvents?

Safety is paramount. We adhere strictly to all relevant safety regulations and guidelines when handling inks and solvents. This includes using proper personal protective equipment (PPE) such as gloves, eye protection, and respirators. Our workspace is well-ventilated to minimize exposure to fumes. Inks and solvents are stored in designated areas, away from ignition sources. Spill kits are readily available for quick response to accidents. Regular training sessions remind our team of the safety protocols and potential hazards. Proper disposal of waste inks and solvents follows environmental regulations. We maintain detailed safety logs and conduct periodic safety inspections to ensure our processes are safe and compliant.

Q 15. Explain your understanding of color space (e.g., CMYK, RGB, LAB).

Color spaces are mathematical models that describe the range of colors that can be represented. Think of them as different languages for describing color. Each has its strengths and weaknesses depending on the application.

- RGB (Red, Green, Blue): This is an additive color model used for screens, like your computer monitor or phone. It mixes light, so combining all three at maximum intensity produces white. Black is the absence of light. Each color is represented by values from 0 to 255 (or 0 to 1).

- CMYK (Cyan, Magenta, Yellow, Key [Black]): This is a subtractive color model used for printing. It involves subtracting light from white to create color. Combining all four inks at full strength ideally produces black, although in reality, a rich black often requires extra black ink. Values typically range from 0 to 100%.

- LAB (L*a*b*): This is a device-independent color space, meaning it attempts to represent color perception more accurately than RGB or CMYK. ‘L’ represents lightness, ‘a’ represents the green-red axis, and ‘b’ represents the blue-yellow axis. It’s often used as a reference point for color matching across different devices and printing processes because it better correlates to human vision.

For example, a bright red might be represented as (255, 0, 0) in RGB, (0, 100, 100, 0) in CMYK, and (L, a, b) values in LAB, depending on the specific shade of red.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you calculate the correct amount of each ink component for a specific color?

Calculating the correct ink amounts is the core of color matching and involves a combination of art and science. It’s rarely a simple formula, and usually requires specialized software and instruments. Here’s a simplified outline:

- Color Measurement: Use a spectrophotometer to measure the desired color’s precise LAB values. This gives us a numerical target.

- Ink Characterization: We need to know how each ink behaves individually and in combination. This involves creating and measuring color patches with different ink percentages. This data is used to create an ink profile, a database crucial for accurate predictions.

- Color Matching Software: This software uses the ink profile, the target LAB values, and algorithms (often based on linear or non-linear transformations) to predict the optimal ink percentages for achieving the desired color. This often involves iterative adjustments.

- Proofing and Adjustments: A test print (proof) is made using the calculated ink amounts. This print is re-measured, and the results are used to fine-tune the ink percentages for even better accuracy. This process may repeat multiple times.

The exact calculations are complex and depend heavily on the specific software and printing process. However, the fundamental principle involves finding the combination of cyan, magenta, yellow, and black inks that best approximates the desired color’s LAB values.

Q 17. Describe your experience with different ink mixing equipment.

My experience encompasses a wide range of ink mixing equipment, from basic hand-mixing systems to sophisticated automated systems. I’ve worked with:

- Hand-mixing systems: These involve manually adding inks to a container and stirring to achieve the desired color. This is suitable for small-scale applications, but it’s time-consuming and prone to inconsistencies. I’ve used this for smaller projects and proofing.

- Automated ink mixing systems: These use precise metering pumps and sophisticated software to automatically mix inks based on pre-defined recipes or color specifications. These systems are far more accurate, efficient, and repeatable than manual systems. I’ve extensively used these in high-volume printing operations.

- Ink dispensing systems: These systems are designed to accurately dispense small amounts of ink for proofing or special color applications, ensuring consistency across multiple prints.

The choice of equipment always depends on the scale of operation, required accuracy, budget, and the specific printing process. For instance, while an automated system may be ideal for commercial offset printing, hand-mixing might suffice for small-scale screen printing.

Q 18. How do you calibrate and maintain color measuring instruments?

Calibrating and maintaining color measuring instruments, such as spectrophotometers, is critical for accurate color reproduction. It involves regular checks and adjustments to ensure that the instrument’s readings are consistent and reliable.

- Regular Calibration: This usually involves using certified color standards (calibration tiles) that are measured against known values. Any discrepancies are adjusted using the instrument’s internal calibration routines. The frequency of calibration depends on the instrument’s specifications and usage, but it’s often daily or weekly.

- Cleaning and Maintenance: Regular cleaning of the instrument’s measuring head is vital to prevent dust, ink, or other contaminants from affecting measurements. This typically involves using a lint-free cloth and appropriate cleaning solutions. Proper handling also prevents damage.

- Environmental Factors: Temperature and humidity can affect instrument performance. Maintain a stable environment according to the manufacturer’s specifications.

- Verification: Periodically, a more comprehensive verification may be required by a qualified technician to ensure that the instrument continues to meet performance standards. This may be annually or at longer intervals.

Neglecting calibration and maintenance can lead to inaccurate color measurements, resulting in costly reprints and dissatisfied clients. It’s an essential part of maintaining a consistent and reliable workflow.

Q 19. What are the effects of dot gain on color reproduction?

Dot gain refers to the increase in the size of ink dots during the printing process. Think of it like the ink bleeding slightly and making the printed dots larger than intended. This has significant consequences for color reproduction:

- Increased Darkness: Dot gain leads to darker colors than intended, especially in mid-tones and shadows. A color that appears vibrant on screen might be significantly darker in print due to dot gain.

- Color Shift: Since different colors have varying degrees of dot gain, it can lead to unintended color shifts. Accurate color matching requires accounting for this effect.

- Loss of Detail: Excessive dot gain can blur fine details and reduce image sharpness.

To mitigate the effects of dot gain, we use specialized software that compensates for it during the pre-press stage. This involves adjusting the image’s dot sizes (in a process called dot gain compensation) to counteract the spreading that will occur during printing. This requires precise measurements and knowledge of the specific printing press’s characteristics.

Q 20. Explain your experience with different printing processes (offset, flexo, screen).

My experience spans various printing processes, each with its unique challenges and considerations regarding ink mixing and color management:

- Offset Printing: This is a high-volume process using plates to transfer ink onto a blanket cylinder and then to the substrate (paper). Offset printing requires precise ink control and careful color balancing to maintain consistency across large print runs. The viscosity and properties of offset inks are crucial for proper transfer.

- Flexographic Printing (Flexo): This process uses flexible relief plates to print on a variety of substrates, often at high speeds. Flexo inks tend to be more viscous than offset inks, requiring careful adjustments to achieve accurate color reproduction. The substrate plays a big role in how the ink lays down.

- Screen Printing: This is a stencil-based process that allows for printing on a vast array of materials. Screen printing inks have higher viscosity and a wider range of textures and finishes. Color matching can be more challenging due to the nature of the process and the unique characteristics of each ink.

In each process, ink selection, mixing techniques, and press settings need to be optimized for best results. For example, the same color recipe will not necessarily yield the same color across offset and flexo printing due to the differences in ink behavior and printing mechanisms.

Q 21. How do you ensure consistency in color across multiple print runs?

Ensuring color consistency across multiple print runs requires a meticulous approach at every stage:

- Standardized Ink System: Using a consistent set of inks and color management system is crucial. This includes specifying ink brands, batches, and mixing ratios.

- Accurate Color Measurement: Use calibrated spectrophotometers to measure and document colors at every stage, from the initial color recipe to the final print. This provides valuable data for tracking and making adjustments.

- Controlled Environment: Maintaining a consistent temperature and humidity in the printing environment helps prevent variations in ink behavior.

- Regular Press Calibration: Periodic checks and adjustments to the printing press ensure that the ink is applied consistently and evenly across the substrate.

- Ink Management System: Use a database or software to track ink usage, mixing ratios, and color measurements. This system aids in identifying and resolving inconsistencies.

- Color Standards: Use color standards (e.g., Pantone swatches) as references for critical colors to ensure consistency throughout the runs.

Consistent record-keeping and monitoring allow for identifying deviations and making necessary adjustments promptly. This proactive approach is fundamental to delivering high-quality, consistent prints across multiple runs.

Q 22. What are the different types of colorimetric standards?

Colorimetric standards are the foundation of accurate color communication and reproduction in ink mixing and color matching. They provide a standardized way to define, measure, and communicate colors, ensuring consistency across different devices, processes, and locations. Several key types exist:

- Pantone Matching System (PMS): This is a proprietary color system widely used in printing and design. Each PMS color has a unique formula and number, facilitating consistent color reproduction across different printers and print methods. Think of it like a universal color dictionary.

- CIELAB (L*a*b*): This is a device-independent color space that represents colors based on human perception. It’s used extensively in color management software and provides a mathematical description of color, making it ideal for precise color matching and calculations. It’s like a mathematical map of colors.

- CMYK (Cyan, Magenta, Yellow, Key/Black): This subtractive color model is used in many printing processes. It defines colors based on the amount of each ink used to create a final color. It’s like mixing paints – the more you add, the darker and more saturated the color becomes.

- RGB (Red, Green, Blue): This additive color model is used in digital displays. While not directly used in ink mixing, it’s crucial when translating digital designs for print, requiring careful color conversion.

Choosing the right standard depends on the application. For instance, PMS is preferred when absolute color consistency across different print runs is critical, while CIELAB is better for managing complex color workflows in digital and print environments.

Q 23. How do you handle customer requests for specific color matches?

Handling customer requests for specific color matches involves a systematic approach. First, I clarify the customer’s requirements, obtaining as much information as possible about the desired color. This might include a physical sample, a Pantone number, or a digital image.

Next, I use spectrophotometry to measure the color of the sample, obtaining its precise color coordinates in a device-independent color space like CIELAB. This ensures objective measurements regardless of the original sample’s source.

Then, I use color matching software to formulate an ink recipe based on the measured color. This software utilizes sophisticated algorithms to calculate the precise proportions of different inks needed to achieve the desired color. The process often involves iterative adjustments and fine-tuning to achieve the best possible match.

Finally, I create a test print and compare it to the original sample. If the match isn’t perfect, I adjust the ink recipe and repeat the process until customer approval is obtained. This might involve making slight adjustments to ink concentration or selecting alternative inks within the range to provide a better color match.

Q 24. Describe your approach to resolving a complex color matching problem.

Resolving a complex color matching problem requires a structured approach. I start by thoroughly analyzing the challenge – understanding the substrate (the material being printed on), the printing process, the available inks, and any limitations. Metamerism (where colors appear the same under one light source but different under another) is a frequent complicating factor, requiring careful attention to lighting conditions.

My approach uses a combination of techniques:

- Spectrophotometric Analysis: Precise measurement of the target color and the existing ink formulations is essential.

- Color Matching Software: Sophisticated software helps predict and refine ink formulations.

- Iterative Testing: Small adjustments to the ink recipe are made and tested until the desired color is achieved.

- Expert Consultation: For particularly challenging situations, consulting with colleagues and leveraging broader experience is helpful.

I’ve encountered several complex situations, like matching a color from a faded fabric sample or reproducing a metallic effect, which all require the creative application of these techniques. Documenting every step is crucial for troubleshooting and future reference.

Q 25. How do you stay up-to-date on the latest developments in ink technology?

Staying current in ink technology is vital. I actively participate in industry conferences and workshops, attending webinars, and reading trade publications like Ink World and Packaging World. This provides insights into new ink chemistries, printing techniques, and sustainability advancements.

I also regularly engage with ink suppliers, attending their workshops, and participating in beta testing programs for new products. This offers hands-on experience with the latest technologies and provides opportunities for feedback.

Additionally, I monitor research papers and patents related to ink technology. This helps me understand the fundamental science behind ink formulation and color development, allowing me to solve complex problems effectively.

Q 26. What is your experience with color proofing methods?

My experience with color proofing methods is extensive. I’m proficient with various techniques including:

- Soft Proofing: Utilizing color management software to simulate the final printed output on screen. This offers a quick and cost-effective initial assessment.

- Hard Proofing: Creating physical proofs using different proofing systems (e.g., inkjet, laser, or contract proofing services) to provide a highly accurate visual representation of the final product. This ensures visual accuracy under specified lighting conditions.

- Proofing Standards: I’m familiar with industry standards such as ISO 12647, which provides guidelines for achieving consistent color across different stages of the printing process.

The choice of proofing method depends on factors like budget, turnaround time, and the required level of accuracy. For critical applications, hard proofing with a validated proofing system is essential to minimize discrepancies.

Q 27. How do you manage the environmental impact of ink usage?

Managing the environmental impact of ink usage is a significant responsibility. I implement several strategies to minimize our environmental footprint:

- Using Eco-Friendly Inks: I prioritize the use of vegetable-based, low-VOC (volatile organic compound) inks, and water-based inks whenever possible. These alternatives reduce air pollution and offer lower toxicity.

- Waste Reduction: Proper ink management, minimizing waste during color mixing and cleaning procedures, and responsible disposal of spent inks are crucial.

- Supplier Collaboration: I work with suppliers who prioritize sustainable sourcing and manufacturing practices.

- Process Optimization: Efficiency improvements reduce ink consumption, minimizing waste and environmental impact.

I believe environmental responsibility is integral to our operation and I’m always exploring newer, more sustainable solutions.

Q 28. Explain your experience with ink quality control procedures.

Ink quality control is paramount. My experience encompasses a range of procedures, beginning with rigorous incoming inspection of raw materials. This ensures that the inks we receive meet our quality standards before entering the mixing process.

During the mixing process, regular quality checks are performed using spectrophotometers to verify that the mixed inks match the specified colorimetric values. We also assess viscosity, rheology (flow behavior), and other physical properties to ensure consistency.

After mixing, we conduct stability tests to ensure that the inks remain consistent over time and don’t separate or degrade. Regular calibration and maintenance of our equipment, especially spectrophotometers and mixing machines, are crucial for accuracy.

Finally, we perform print tests on various substrates to verify color consistency and ink performance. This holistic quality control system ensures that our inks consistently meet the highest standards of quality and performance.

Key Topics to Learn for Ink Mixing and Color Matching Interview

- Color Theory Fundamentals: Understanding color models (RGB, CMYK), color spaces, and color relationships (complementary, analogous, etc.). This forms the bedrock of accurate mixing.

- Ink Properties and Behavior: Learn about different types of inks (solvent, water-based, UV), their viscosity, opacity, and how these properties affect mixing and final color output.

- Mixing Techniques and Ratios: Master the practical skills of accurately measuring and mixing inks to achieve specific color targets. Understanding percentage calculations and color formulation is crucial.

- Color Matching Processes: Familiarize yourself with various color matching methods, including visual matching, spectrophotometry, and densitometry. Understand the limitations and advantages of each.

- Troubleshooting and Problem Solving: Be prepared to discuss common issues encountered during ink mixing, such as metamerism, color drift, and achieving accurate color consistency across different batches.

- Equipment and Technology: Demonstrate understanding of the tools and technologies used in ink mixing and color matching, such as spectrophotometers, colorimeters, and mixing equipment.

- Quality Control and Standards: Explain how quality control measures are applied to maintain color accuracy and consistency, and your familiarity with relevant industry standards.

- Health and Safety: Show awareness of safety procedures and regulations related to handling inks and using mixing equipment.

Next Steps

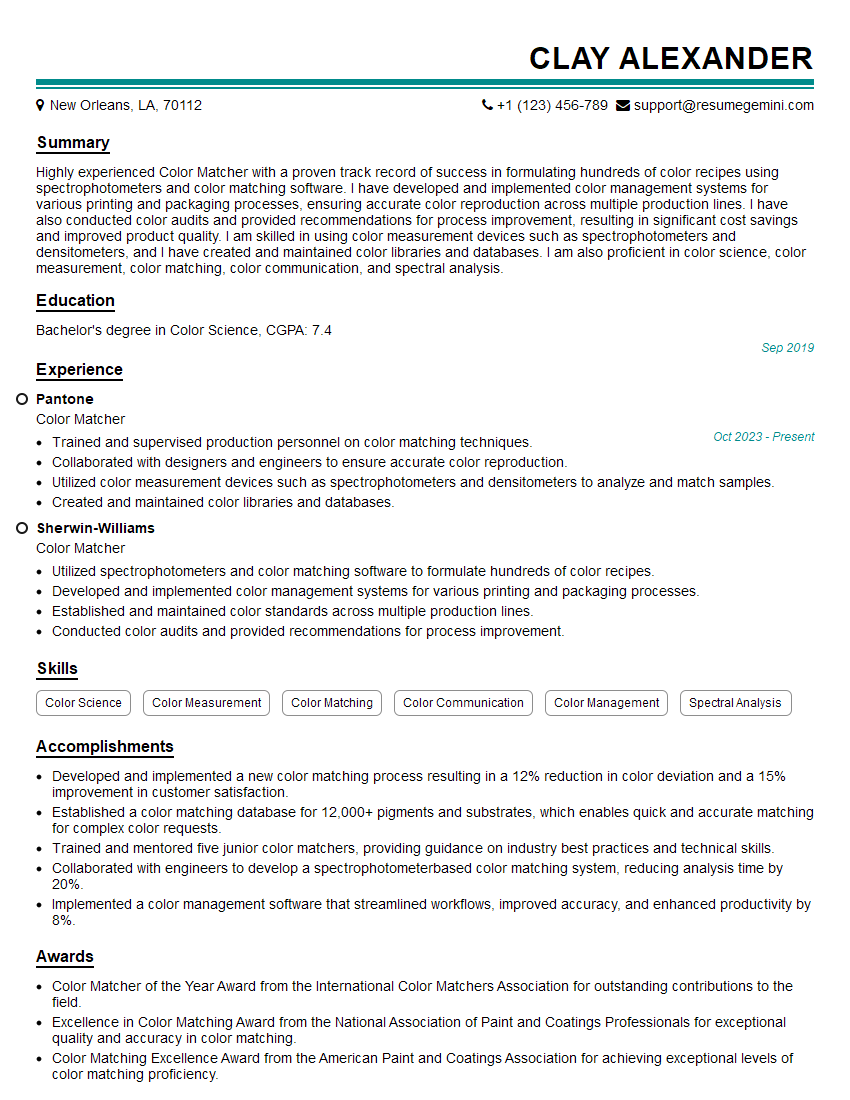

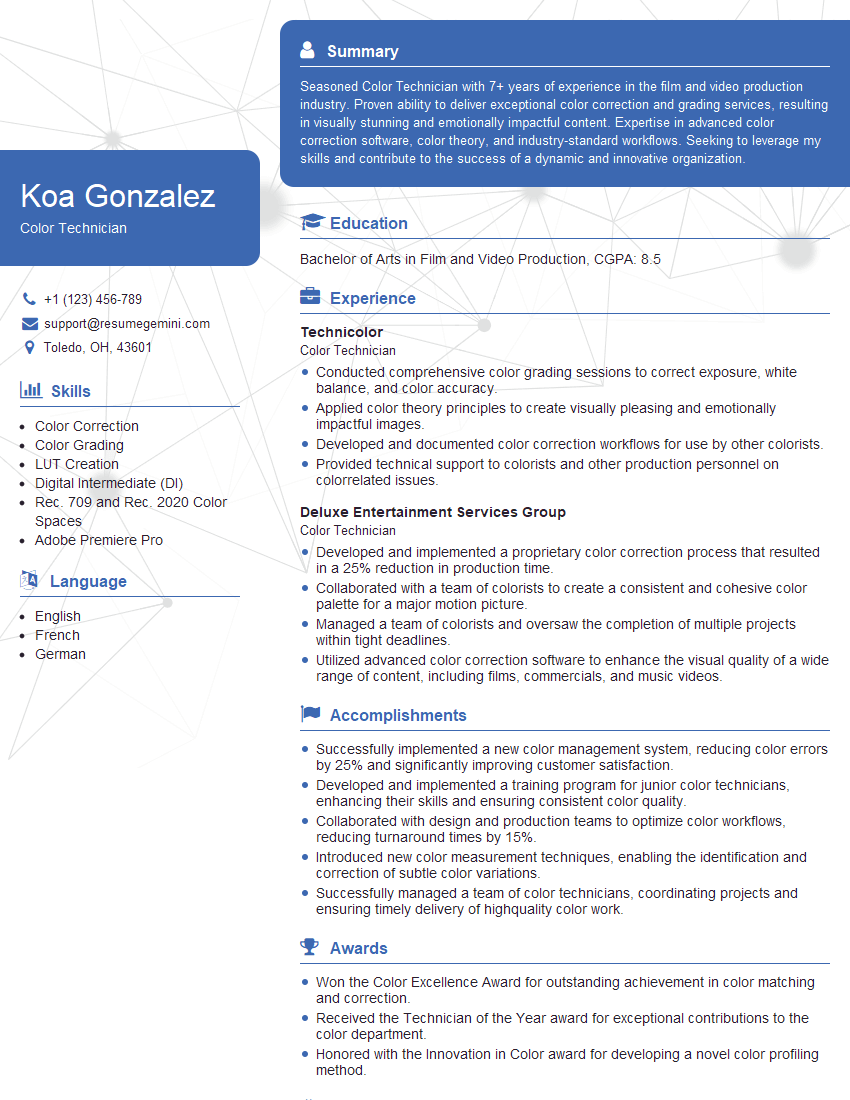

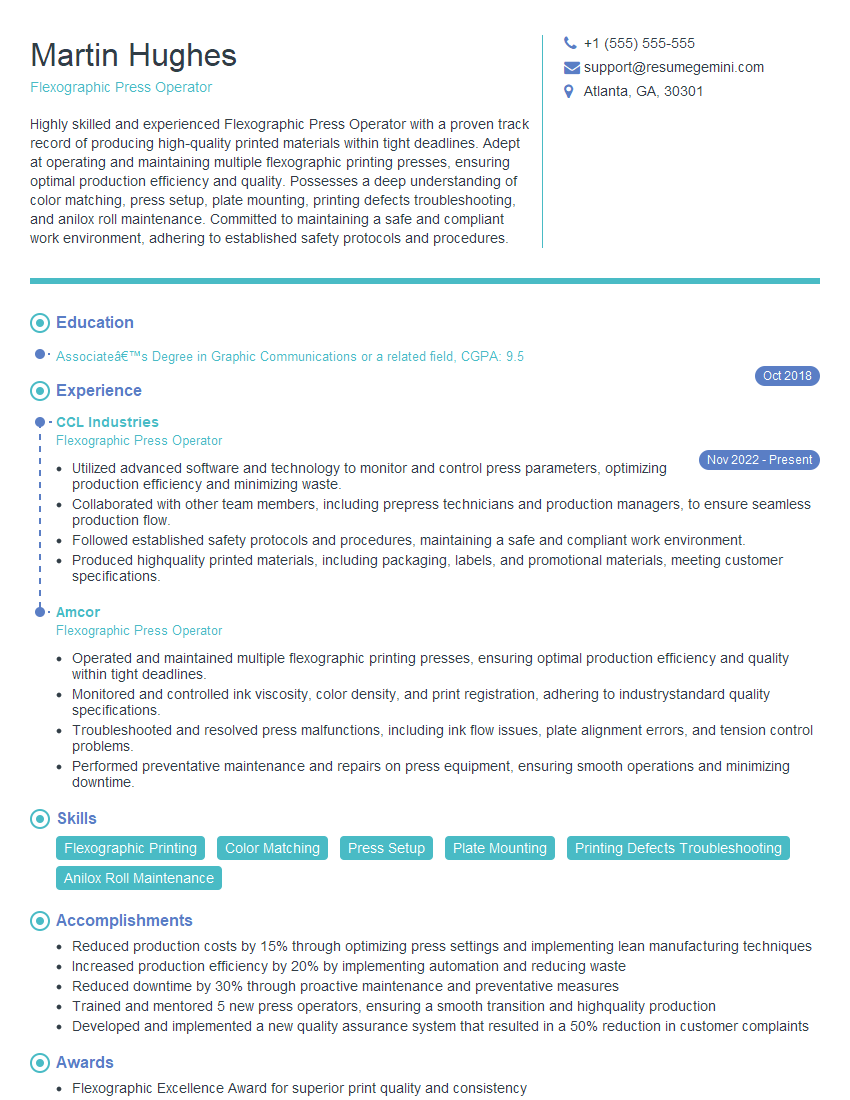

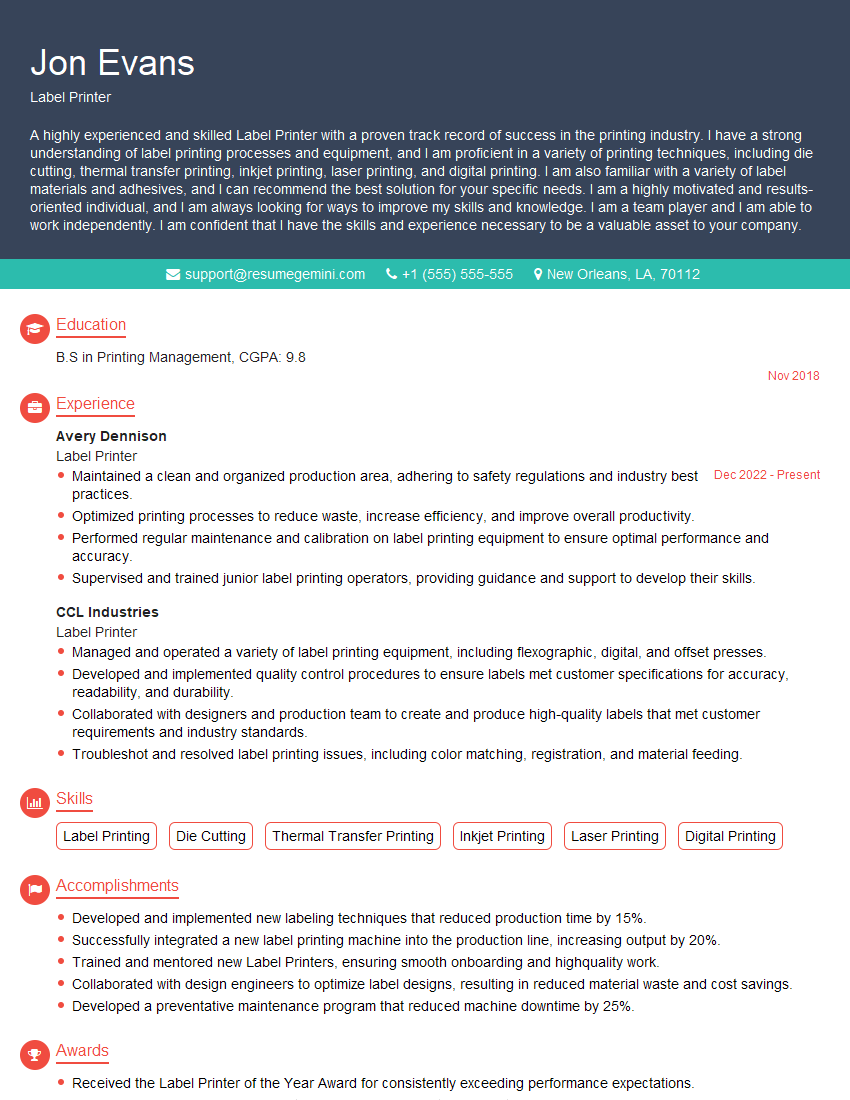

Mastering ink mixing and color matching opens doors to exciting career opportunities in printing, packaging, and various creative industries. A strong understanding of these skills is highly valued and will significantly boost your job prospects. To maximize your chances of landing your dream role, it’s essential to present yourself effectively. Creating an ATS-friendly resume is key to getting your application noticed by recruiters. We strongly recommend using ResumeGemini to build a professional and impactful resume that highlights your skills and experience in ink mixing and color matching. ResumeGemini provides valuable tools and resources, including examples of resumes tailored to this specific field, to help you create a winning application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good