Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Inside Plant Cabling interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Inside Plant Cabling Interview

Q 1. What are the different types of cabling used in inside plant environments?

Inside plant cabling utilizes a variety of cable types, each suited for different applications and bandwidth requirements. The most common include:

- Copper Cabling: This is the workhorse of many networks, offering various categories (Cat5e, Cat6, Cat6a, Cat7, Cat8) with increasing bandwidth and performance capabilities. These are used for carrying data and voice signals.

- Fiber Optic Cabling: Utilizing light pulses instead of electrical signals, fiber offers significantly higher bandwidth and longer distances without signal degradation. This is crucial for high-speed data centers and long-haul network connections. Single-mode and multi-mode fibers are common types.

- Coaxial Cabling: While less prevalent in modern data networks, coaxial cable is still used in some applications, particularly for video distribution and legacy systems. It’s known for its ability to handle high frequencies.

- Power over Ethernet (PoE) Cabling: This specialized cabling transmits both data and power over a single cable, eliminating the need for separate power lines. It’s commonly used for IP phones, security cameras, and wireless access points.

The choice of cabling depends heavily on factors like budget, bandwidth needs, distance requirements, and the overall network architecture.

Q 2. Explain the importance of proper cable termination.

Proper cable termination is absolutely critical for reliable network performance. A poorly terminated cable can lead to signal loss, attenuation, crosstalk, and ultimately, network outages. Think of it like plugging a frayed power cord into an appliance – you wouldn’t expect it to work correctly, and the same principle applies to network cables.

Proper termination involves carefully preparing the cable ends and connecting them to the appropriate jacks or connectors. This includes stripping the outer sheath and insulation to the correct length, arranging the wires in the proper order according to the cabling standard (TIA/EIA standards are common), and crimping the connector securely. A poorly crimped connector can lead to intermittent connection problems or even short circuits.

Imagine a building’s network failing because of a poorly terminated cable in a critical server room – the consequences can be significant, including downtime, lost productivity, and financial losses. Careful and consistent termination ensures signal integrity and a robust network.

Q 3. Describe the process of installing fiber optic cable.

Installing fiber optic cable requires precision and care due to its delicate nature. The process typically involves these steps:

- Planning and Routing: Careful planning of the cable route is essential to minimize bends and stress on the fiber. This includes identifying potential obstacles and determining the optimal path.

- Cable Preparation: The fiber optic cable’s outer jacket is carefully removed, exposing the individual fiber strands. Protective coatings and buffers are often cleaned and prepared.

- Splicing or Connecting: For long runs, splicing is necessary to join fiber segments. This involves carefully aligning the fiber ends using fusion splicing (melting the fibers together) or mechanical splicing (using precise connectors). For shorter distances, termination with connectors such as SC, LC, or ST is used.

- Testing and Certification: After installation, optical time-domain reflectometry (OTDR) testing verifies the cable’s integrity, detecting any breaks or losses in the signal. This is crucial for ensuring the quality of the fiber optic link.

- Cable Management: Fiber cables are typically organized and secured using cable trays, racks, and other management systems to protect the cables and prevent damage.

Improper installation can lead to signal attenuation, fiber breakage, and ultimately network failure. Therefore, it is crucial to adhere to strict guidelines and utilize the appropriate tools and techniques.

Q 4. What are the key differences between Cat5e, Cat6, and Cat6a cabling?

Cat5e, Cat6, and Cat6a cables are all twisted-pair copper cables used for Ethernet networking, but they differ significantly in their performance characteristics:

| Feature | Cat5e | Cat6 | Cat6a |

|---|---|---|---|

| Bandwidth | 100 MHz | 250 MHz | 500 MHz |

| Maximum Recommended Length | 100 meters | 100 meters | 100 meters |

| Data Rates Supported | Up to 1 Gbps | Up to 10 Gbps | Up to 10 Gbps (over longer distances) |

| Alien Crosstalk | Higher | Lower | Significantly Lower |

The key difference lies in their bandwidth and alien crosstalk performance. Cat6a significantly reduces alien crosstalk (interference from adjacent cables), allowing for higher data rates and longer distances at 10 Gbps. Cat6 is an improvement over Cat5e but Cat6a offers a superior performance level, particularly important for high-speed network applications. Choosing the correct cable category is crucial to support current and future network speeds.

Q 5. How do you troubleshoot cabling problems?

Troubleshooting cabling problems often involves a systematic approach:

- Visual Inspection: Begin by carefully inspecting the cables for any physical damage, such as cuts, kinks, or loose connectors. Check both ends and any intermediate connections.

- Cable Testing: Use a cable tester to verify cable continuity, shorts, and opens. This helps pinpoint faulty segments or connections.

- Network Diagnostics: Employ network monitoring tools to identify network segments with connectivity issues. Tools like ping, tracert, and network scanners can help isolate the problem.

- Connector Testing: Examine the connectors themselves, ensuring they are properly seated and making good contact. Sometimes, simply reseating the connector can resolve the issue.

- Signal Level Testing: Use a signal level meter to measure the signal strength at various points in the cable. Low signal levels can indicate attenuation or other issues in the cabling.

Remember that documenting your findings and systematically eliminating potential causes is crucial for efficient troubleshooting. Many network technicians have developed their own unique and efficient troubleshooting methods, but the key is to be methodical.

Q 6. What are the common grounding techniques used in inside plant cabling?

Grounding in inside plant cabling is essential for protecting equipment from surges, preventing electrical noise, and ensuring data integrity. Common grounding techniques include:

- Building Grounding System: This involves connecting the cabling system to the building’s main grounding system, typically through a grounding bus bar or grounding electrode. This provides a common reference point for electrical potential.

- Grounding Rods: Driven into the earth, grounding rods provide a direct path to the earth for excess electrical current, protecting equipment from surges.

- Grounding Strips and Connectors: These specialized components are used to connect cabling to the grounding system within the rack or cabinet, ensuring that all cabling is properly grounded.

- Equipment Grounding: Each piece of network equipment (switches, routers, servers) should have its own grounding connection, typically a third prong on the power cord.

Proper grounding prevents electrical noise that can interfere with data signals and protect expensive equipment from damage due to electrical surges. In some scenarios, failure to ground correctly could lead to significant data loss or equipment failure.

Q 7. Explain the importance of cable management.

Effective cable management is crucial for a variety of reasons:

- Improved Network Performance: Well-organized cabling minimizes crosstalk and signal interference, leading to better network performance and data transmission.

- Reduced Downtime: Proper cable management makes it easier to identify and troubleshoot cabling problems, minimizing downtime and the cost associated with it.

- Enhanced Safety: Organized cabling reduces the risk of tripping hazards, fire hazards (due to tangled cables), and accidental cable damage.

- Easier Maintenance and Expansion: Organized cables allow for easier maintenance and future expansion of the network without having to untangle a rat’s nest of wires.

- Improved Aesthetics: A well-organized cable infrastructure presents a professional image, especially critical in areas accessible to clients or visitors.

Think of it like a well-organized toolbox – finding the right tool is quick and easy. The same principle applies to network cabling. A disorganized cable infrastructure slows down troubleshooting, increases the risk of errors, and negatively impacts the overall efficiency of the network.

Q 8. What are the safety precautions you take while working with cabling?

Safety is paramount in inside plant cabling. Before starting any work, I always conduct a thorough site survey to identify potential hazards like power lines, exposed wiring, and uneven flooring. I utilize appropriate personal protective equipment (PPE) consistently, including safety glasses, gloves, and steel-toed boots. When working at heights or in confined spaces, I follow all relevant safety procedures and may use harnesses or other specialized equipment. Powering down equipment before working on it is critical, and I always use lockout/tagout procedures to prevent accidental energization. I also ensure proper grounding to prevent static electricity damage to sensitive equipment. For example, I use anti-static wrist straps when handling delicate fiber optic cables. Communication with coworkers and supervisors is crucial; I clearly communicate my location and work status to prevent accidents.

Q 9. What are the different types of connectors used in inside plant cabling?

Inside plant cabling uses a variety of connectors, depending on the cable type. For copper cabling (like twisted-pair Cat5e, Cat6, Cat6a), the most common connector is the RJ45, a modular connector that uses 8 pins to establish connections. For fiber optic cabling, connectors such as SC, LC, ST, and FC are widely used. These connectors are designed for precise alignment of the fiber cores to minimize signal loss. Each connector type has its own advantages; for example, LC connectors are smaller and more space-efficient, while SC connectors are known for their simplicity and reliability. We also use BNC connectors for coaxial cables, primarily in legacy systems or specialized applications requiring high bandwidth.

Q 10. How do you identify different types of cables?

Cable identification is crucial for efficient troubleshooting and maintenance. Cables are typically identified by their color-coding, markings printed directly on the jacket, and sometimes by accompanying labels. For instance, color-coding schemes such as T568A and T568B are used to identify the wiring configuration within twisted-pair cables. Manufacturers often print information on the cable jacket, including the cable type (e.g., Cat6A), gauge, and sometimes even the manufacturing date and batch number. Fiber optic cables might have additional markings indicating the core count, fiber type (single-mode or multi-mode), and its attenuation properties. In larger deployments, a well-documented cable management system is vital for easy identification, often relying on comprehensive labeling practices.

Q 11. Describe your experience with cable testing equipment.

I have extensive experience using various cable testing equipment. This includes cable certifiers that measure parameters like insertion loss, return loss, and near-end crosstalk to verify cable performance. I’m proficient with OTDRs (Optical Time-Domain Reflectometers) for testing fiber optic cables to detect faults and measure fiber length. My experience also includes using tone generators and probes to trace cables and identify specific wires within a bundle. Understanding the nuances of these tools and interpreting their results is crucial; for instance, high return loss on a copper cable indicates impedance mismatch that needs addressing. Regular calibration of this equipment is critical for accurate and reliable results.

Q 12. What is a patch panel and how is it used?

A patch panel is a centralized termination point for multiple cables, typically located in a wiring closet or server room. It allows for organized termination and management of cables, simplifying connections between network devices and other equipment. Imagine it as a highly organized telephone switchboard, but for data cables. It simplifies the task of connecting workstations to network switches, for example. Each port on the patch panel is clearly labelled, and cables are neatly terminated and connected, making troubleshooting and maintenance much easier. Patch panels enhance cable organization and reduce cable clutter, thereby improving the overall aesthetics and maintainability of the network infrastructure.

Q 13. What is the purpose of a cable label?

A cable label provides crucial information about the cable, acting like a digital ID for a physical cable. It typically contains information about the cable’s origin, destination, and purpose. For example, a label might indicate that a cable connects from ‘Server Room Rack 3, Port 10’ to ‘Workstation 42A, Port 2’. This information is essential for quick identification and troubleshooting. Labels also help to prevent accidental disconnections or modifications, reducing downtime and improving overall network management. Clear, concise, and consistent labeling practices are crucial for larger deployments with numerous cables.

Q 14. Explain your understanding of TIA/EIA standards.

TIA/EIA standards, primarily TIA-568 and its various revisions (e.g., TIA-568-C), are crucial for the design and implementation of structured cabling systems. These standards define cabling requirements for commercial buildings, data centers, and other facilities. They specify cable types, performance parameters, connector types, testing procedures, and overall infrastructure design. Adherence to these standards ensures interoperability, consistency, and performance reliability of the cabling infrastructure. For instance, TIA-568-C dictates the precise wiring schemes for Cat5e, Cat6, and Cat6A cables, ensuring compatibility across different vendors’ equipment. Following these standards is essential for creating a robust and future-proof network infrastructure that meets industry best practices.

Q 15. What is the difference between single-mode and multi-mode fiber optic cables?

The core difference between single-mode and multi-mode fiber optic cables lies in the size of the core and how light propagates through it. Think of it like this: single-mode is like a single-lane highway, allowing only one precise beam of light to travel down a very small core, while multi-mode is a multi-lane highway, allowing multiple light beams to travel down a larger core, each taking slightly different paths.

- Single-mode fiber: Uses a very small core (around 8-10 microns) and a single wavelength of light. This results in much lower signal attenuation (loss of signal strength) over long distances, making it ideal for long-haul telecommunications and high-bandwidth applications. The light travels in a straight line, minimizing modal dispersion (light spreading).

- Multi-mode fiber: Employs a larger core (50/125 or 62.5/125 microns), allowing multiple light paths. This is suitable for shorter distances and applications where cost is a primary concern. Because multiple paths are taken, multi-mode experiences more signal attenuation and modal dispersion over longer distances.

In practical terms, you’d choose single-mode for long-distance backbone networks or high-speed data centers, while multi-mode is suitable for shorter runs within a building or campus.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you splice fiber optic cables?

Splicing fiber optic cables requires precision and specialized equipment. The goal is to create a seamless connection that minimizes signal loss and maintains the integrity of the optical signal. The process typically involves these steps:

- Prepare the fibers: Carefully cleave (cut) the fiber ends to create a perfectly perpendicular surface. This is crucial for optimal light transmission. A fiber cleaver is used for this.

- Clean the fibers: Remove any dust or debris from the cleaved ends using alcohol wipes or specialized cleaning tools. Contamination can significantly impact signal quality.

- Align the fibers: Use a fusion splicer to precisely align the cleaved ends of the two fibers. The fusion splicer uses microscopic cameras and sophisticated alignment mechanisms to ensure perfect alignment.

- Fuse the fibers: The fusion splicer then generates an electric arc that melts and fuses the fiber ends together, creating a strong and continuous connection.

- Test the splice: An optical power meter is used to measure the optical loss at the splice. Acceptable loss is typically below 0.35dB.

Alternative splicing methods include mechanical splicing, which utilizes connectors and sleeves to join the fiber ends, although fusion splicing offers superior performance.

Q 17. What is the importance of proper cable routing?

Proper cable routing is critical for several reasons. It’s like planning a well-organized city – if you don’t plan the roads well, you get traffic jams. Similarly, poor cable routing leads to signal degradation, maintenance nightmares, and potential safety hazards. Here’s why it’s important:

- Signal Integrity: Excessive bends, kinks, or sharp turns in cables can cause signal attenuation and distortion, especially in fiber optics.

- Cable Management: Organized routing prevents tangles and makes it easier to identify and access specific cables, simplifying maintenance and troubleshooting.

- Safety: Proper routing keeps cables away from hazards like sharp objects, heat sources, and areas of high traffic flow. It also prevents tripping hazards.

- Future Expansion: Well-planned routing makes it easier to add or modify cables in the future without disrupting existing installations.

Following standards and best practices, including using appropriate cable trays and conduits, are essential for successful cable routing.

Q 18. Describe your experience with different types of cable trays and conduits.

My experience encompasses various cable tray and conduit types. The choice depends on the environment, cable type, and required capacity. Here are some I’ve worked with:

- Ladder Trays: Commonly used for large numbers of cables. They offer good ventilation and accessibility.

- Cable Trays: These are enclosed trays, providing better protection from the environment and damage, suitable for sensitive equipment.

- Wire Mesh Trays: Offer good ventilation and flexibility but less protection than enclosed trays.

- Conduit (PVC, Steel, Aluminum): Excellent for protecting individual cables or small bundles from environmental damage and physical stress. PVC is common for indoor use, while metal conduits are used in more demanding environments.

In one project, we used a combination of ladder trays for the main cable runs and conduit for sensitive fiber optic cables running through areas with potential physical impact.

Q 19. What are the challenges you’ve faced in inside plant cabling projects?

Inside plant cabling projects often present unique challenges. Some I’ve encountered include:

- Space Constraints: Working in existing buildings with limited space can make cable routing and installation challenging.

- Existing Infrastructure: Navigating around existing electrical, plumbing, and HVAC systems requires careful planning and coordination.

- Access Restrictions: Limited access to certain areas can delay the project and increase installation costs.

- Unforeseen Obstacles: Discovering unexpected obstacles during installation (like hidden pipes or structural elements) can necessitate design changes on the fly.

- Meeting Tight Deadlines: Balancing the need for high-quality installation with project deadlines can be stressful.

For example, in one project, we had to reroute a significant portion of the cabling due to the discovery of an unexpected conduit that was not documented in the blueprints.

Q 20. How do you ensure the integrity of cabling installations?

Ensuring the integrity of cabling installations involves a multi-faceted approach:

- Thorough Planning and Design: Creating detailed plans that consider all aspects, including cable routing, tray selection, and termination points.

- Quality Materials: Using high-quality cables, connectors, and other components.

- Proper Installation Techniques: Following best practices and industry standards during installation to minimize stress on cables and connections.

- Testing and Documentation: Conducting thorough testing after installation to verify signal quality and document the entire cabling infrastructure. This includes generating accurate as-built drawings.

- Ongoing Maintenance: Regular inspections and preventive maintenance to identify and address potential issues early.

We use OTDR (Optical Time-Domain Reflectometer) testing for fiber optic cables to identify any breaks or attenuation along the cable path.

Q 21. What experience do you have with different types of cable pulling equipment?

My experience includes various cable pulling equipment, each suited for different situations:

- Cable Pulling Grip: Used for smaller cable runs and easily manageable cables.

- Cable Pulling Equipment (winches): For heavier cables or longer runs, winches provide the necessary pulling force, and various types exist, including hydraulic and electric winches.

- Cable Lubricants: Reducing friction is crucial for successful pulling. We use specialized cable lubricants to minimize the risk of cable damage.

- Pulling Sockets and Eyes: These connect to the cables and enable them to be properly pulled through conduits and trays.

On larger projects, I have coordinated the use of specialized cable pulling equipment, ensuring safe and efficient installation while carefully monitoring tension to prevent cable damage.

Q 22. Describe your experience with documentation of cabling systems.

Comprehensive documentation is the backbone of any successful cabling project. It ensures efficient maintenance, troubleshooting, and future expansion. My experience encompasses creating and maintaining various documentation types, from simple cable diagrams to complex as-built drawings. This includes detailed records of cable pathways, termination points, patch panel configurations, and equipment connections. I utilize both manual and software-based methods to create and manage these documents, ensuring accuracy and ease of access for all stakeholders.

For instance, during a recent project involving a large data center, I meticulously documented every cable run, labeling each cable with its function and destination. This included detailed floor plans with overlaid cable routes, annotated patch panel diagrams showing cable terminations, and a comprehensive database linking each cable to its associated equipment. This documentation proved invaluable during a subsequent server relocation, allowing for a smooth and efficient process.

Q 23. How familiar are you with different cable labeling methods?

I’m proficient in several cable labeling methods, each tailored to specific needs and industry standards. Common methods include using heat-shrink sleeves, adhesive labels, and even laser marking directly onto the cable jacket. The choice depends on factors like environmental conditions (e.g., temperature, humidity), cable type, and the desired level of permanence.

Heat-shrink labels offer excellent durability and resistance to abrasion, making them ideal for harsh environments. Adhesive labels are more cost-effective and readily available but can be susceptible to damage. Laser marking provides a highly permanent solution but requires specialized equipment. Beyond the label itself, consistent labeling systems that clearly identify cable type, location, and function are critical for maintainability. I often use a structured numbering system, such as Building-Room-Rack-Port, to enhance readability and traceability.

Q 24. What software or tools do you use for cable management and design?

My toolset for cable management and design includes both specialized software and general-purpose applications. I regularly use AutoCAD for creating detailed floor plans and cable pathway diagrams. This allows for precise visualization and planning, minimizing installation errors. For more sophisticated cable management, I utilize specialized software like [Software Name - replace with an actual software name, e.g., Commscope's iPatch], which aids in creating accurate patch panel layouts, managing cable inventories, and generating reports. Furthermore, I leverage spreadsheets and databases for tracking cable information, materials, and project progress. This integrated approach ensures accuracy and simplifies documentation.

Q 25. Explain your experience with testing and certification of cabling systems.

Testing and certification of cabling systems are crucial for ensuring performance and compliance with industry standards like TIA-568. My experience involves using industry-standard testing equipment, such as cable certifiers, to verify the performance of installed cabling. This includes testing for various parameters like attenuation, return loss, and near-end crosstalk. I create detailed test reports that document the results, including any identified faults or deviations from standards. The process starts with a thorough pre-installation planning phase to avoid issues like excessive bend radius, which could lead to signal degradation.

For example, during a recent project, testing revealed an unexpected attenuation issue in a specific cable run. Using the test results and my understanding of the cabling system’s layout, I was able to pinpoint the problem to a poorly terminated connection. After rectifying the termination, subsequent testing confirmed the problem was resolved, and the system met all the required standards.

Q 26. How do you handle unexpected problems or delays during a cabling installation?

Unexpected problems and delays are inevitable in cabling installations. My approach focuses on proactive problem-solving and effective communication. When faced with an unexpected issue, I first assess its impact on the project timeline and budget. This involves clearly defining the problem and identifying potential solutions. I then communicate the issue and proposed solutions to the project manager and stakeholders. Open and transparent communication helps in gaining consensus and adjusting the project plan accordingly.

For example, if a shipment delay occurs, I may explore alternative sourcing options or adjust the installation schedule to minimize disruption. If an unforeseen obstacle is encountered during installation (e.g., structural interference), I’ll assess the situation, create alternative routes, and document the changes made. The key is to remain flexible, utilize available resources effectively, and ensure that all parties involved are informed and updated.

Q 27. Describe a time you had to troubleshoot a complex cabling issue.

In one project, we were experiencing intermittent network connectivity issues in a specific part of the building. Initial troubleshooting pointed towards a potential problem within the cabling infrastructure. After thorough testing, it turned out to be a faulty patch panel that was causing signal degradation in several cable connections. Standard testing only highlighted a general problem, however, deeper analysis of the cable connections and detailed examination of the patch panel components finally identified the root cause. Simply replacing the faulty patch panel resolved the network connectivity problems. This experience highlighted the importance of systematic troubleshooting and thorough testing for isolating the exact location of the fault.

Key Topics to Learn for Your Inside Plant Cabling Interview

- Network Topologies: Understand and be able to discuss common topologies like star, bus, ring, and mesh, including their advantages and disadvantages in an inside plant environment. Be prepared to explain how these relate to cabling infrastructure.

- Cabling Standards and Codes: Familiarity with TIA/EIA standards (e.g., T568A/B) is crucial. Discuss your experience with adhering to these standards during installation and troubleshooting. Be ready to explain the importance of proper grounding and bonding.

- Fiber Optics: Demonstrate knowledge of fiber optic cable types (single-mode, multi-mode), connectors (SC, LC, ST), and testing methods (OTDR). Be prepared to discuss practical applications and troubleshooting scenarios involving fiber optic cables.

- Copper Cabling: Understand the different types of copper cabling (CAT5e, CAT6, CAT6A), their bandwidth capabilities, and applications. Discuss termination techniques, testing procedures, and troubleshooting common issues.

- Cable Management and Organization: Explain the importance of proper cable management for efficient operation, maintainability, and safety. Discuss techniques for labeling, routing, and securing cables within a structured cabling system.

- Troubleshooting and Problem Solving: Prepare examples demonstrating your ability to diagnose and resolve cabling-related issues. This includes using testing equipment and interpreting results effectively.

- Safety Regulations and Practices: Showcase your understanding of safety procedures related to working with cabling, including proper lockout/tagout procedures and working at heights.

- Documentation and Design: Discuss your experience with creating and interpreting cabling schematics and documentation. Be prepared to explain how these documents support efficient installation, maintenance, and troubleshooting.

Next Steps

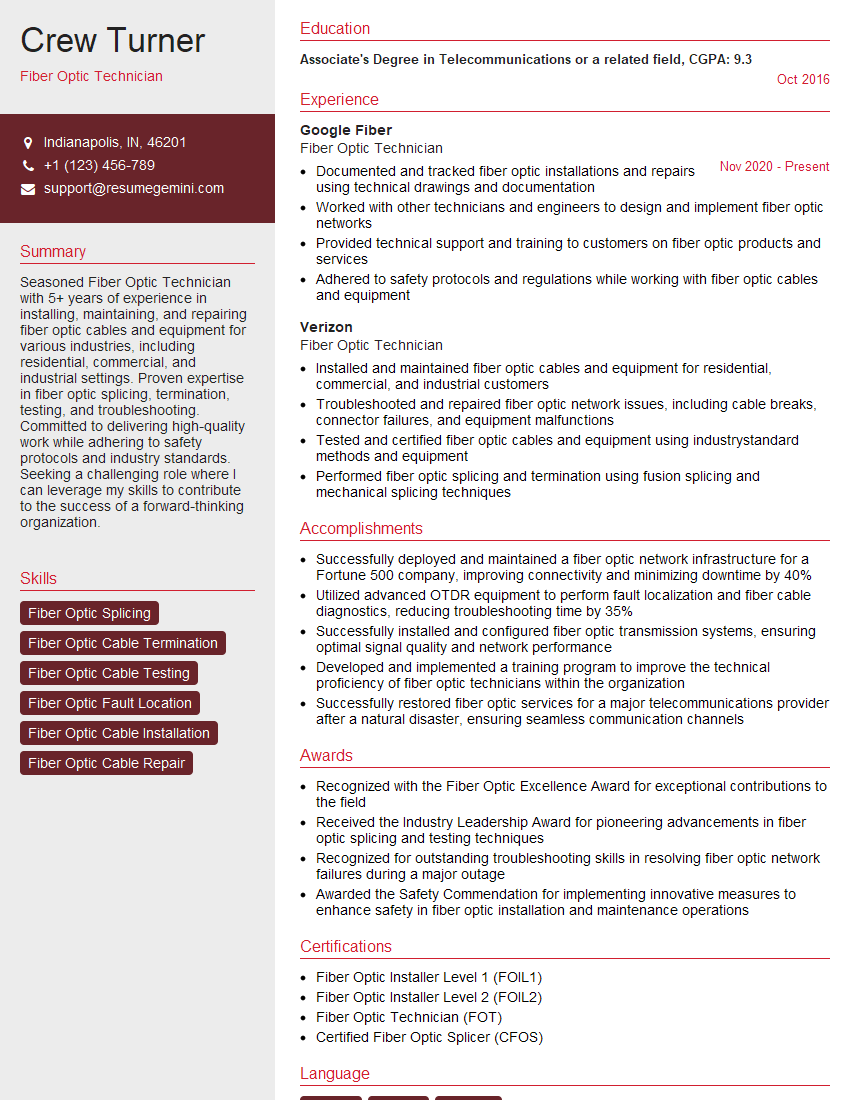

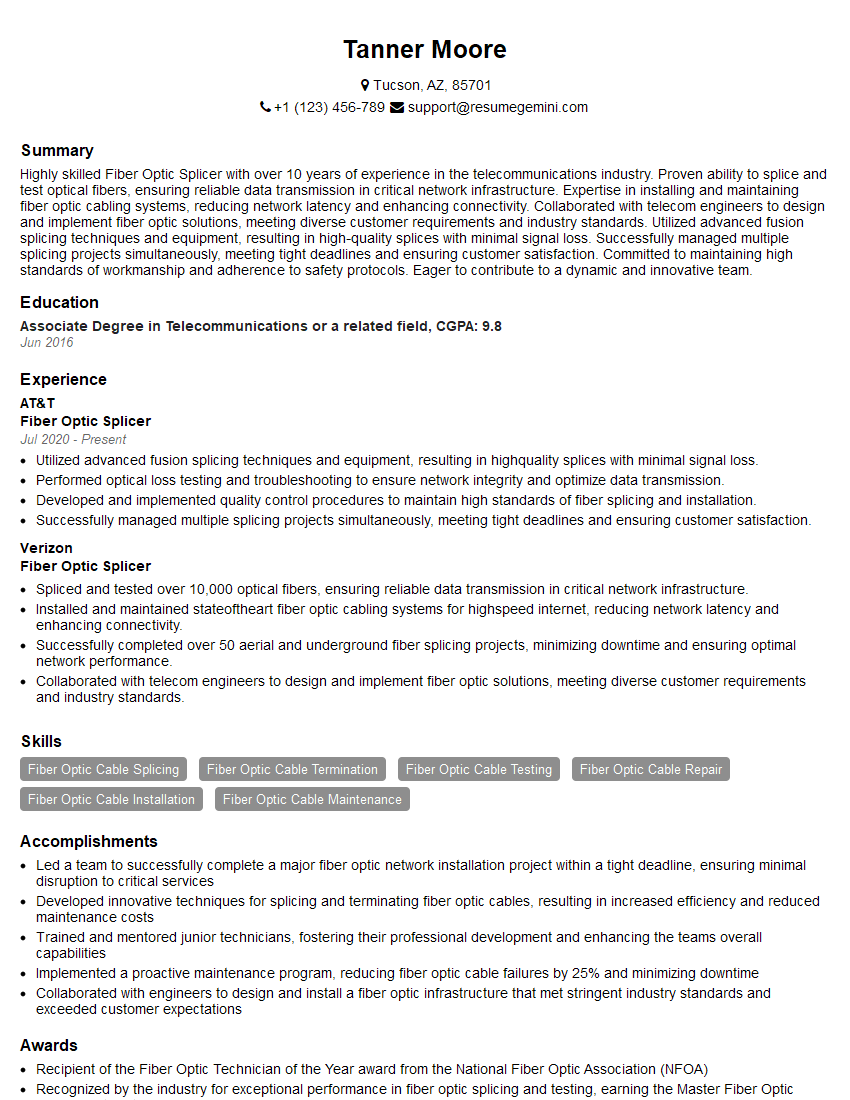

Mastering Inside Plant Cabling opens doors to exciting career opportunities in networking, telecommunications, and data center management. A strong understanding of these concepts will significantly enhance your interview performance and career prospects. To make a lasting impression, a well-crafted resume is key. Focus on building an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you create a professional and impactful resume. They provide examples of resumes tailored to Inside Plant Cabling to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good