Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Inspection Tracking interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Inspection Tracking Interview

Q 1. Explain your experience with different inspection tracking software and tools.

Throughout my career, I’ve worked with a variety of inspection tracking software and tools, ranging from simple spreadsheet-based systems to sophisticated, cloud-based platforms. Early in my career, I relied heavily on spreadsheets for smaller projects, manually tracking inspection data, which was time-consuming and prone to errors. This experience taught me the importance of robust systems. Later, I transitioned to using dedicated software like [Software Name A], a comprehensive solution offering features like automated reporting, real-time data updates, and customizable dashboards. I’ve also used [Software Name B], which excels in integrating with other systems within our quality management infrastructure. Finally, I’ve had experience with mobile-first applications designed for on-site inspections, allowing for immediate data entry and reducing manual data transfer. Each tool presents its own strengths and weaknesses; the best choice depends heavily on the scale and complexity of the inspection process and the overall organizational needs.

For example, in one project involving large-scale construction, [Software Name A] allowed us to track thousands of inspection points across multiple sites efficiently. The automated reporting features saved considerable time and resources compared to the manual methods used in previous projects.

Q 2. Describe your process for ensuring data accuracy in inspection tracking systems.

Data accuracy is paramount in inspection tracking. My process centers around several key strategies. First, I ensure that all inspection protocols are clearly defined and readily accessible to all inspectors, reducing ambiguity and minimizing human error. Second, we utilize a system of checks and balances, often involving multiple inspectors for critical inspections, and cross-referencing data across different inspection points. Third, the software we use often includes built-in validation rules, which prevent the entry of illogical or impossible data (e.g., a negative measurement). Fourth, regular audits are conducted to identify any inconsistencies or potential errors in the data, followed by a thorough investigation and corrective actions. Finally, we also leverage data visualization tools to readily identify outliers or patterns that might indicate inaccuracies in our datasets.

Think of it like building a house: Each step needs to be accurate, from the foundation (the initial inspection protocol) to the roof (the final report). Neglecting accuracy at any stage compromises the integrity of the entire structure.

Q 3. How do you handle discrepancies or inconsistencies in inspection data?

Discrepancies in inspection data are addressed systematically. The first step is to identify the source of the inconsistency. This might involve reviewing the original inspection reports, verifying the calibration of inspection equipment, or re-inspecting the item in question. Once the source is identified, corrective actions are taken, which may range from correcting the erroneous data entry, to retraining inspectors on proper inspection procedures, or even recalibrating equipment. Documentation of the discrepancy, investigation, and corrective actions is meticulously maintained for auditing purposes. In some cases, a root cause analysis might be necessary to prevent similar discrepancies from recurring in the future. For example, repeated discrepancies related to a specific inspector might indicate the need for additional training or supervision.

Q 4. What methods do you use to track and report inspection results effectively?

Effective tracking and reporting of inspection results relies on a combination of automated tools and clear communication. The software I use typically generates reports automatically, tailored to specific needs, ranging from simple summaries to detailed analyses. These reports are often customizable, allowing us to focus on key metrics and trends. Data visualization techniques, such as charts and graphs, are used to present the data clearly and concisely, making it easy for stakeholders to understand the results. We also use dashboards to provide real-time monitoring of inspection progress and key performance indicators (KPIs).

For instance, a simple bar chart might illustrate the number of defects found across different product lines, while a trend line could show the improvement in defect rates over time. This approach enables proactive identification of areas needing improvement and informed decision-making.

Q 5. Explain your understanding of quality control and its relationship to inspection tracking.

Quality control (QC) and inspection tracking are intrinsically linked. Inspection tracking is a crucial component of the QC process, providing the data needed to assess product quality, identify defects, and ensure compliance with standards. Without effective tracking, QC efforts would be significantly hampered, leading to inconsistent product quality and potential safety hazards. QC sets the standards and defines what needs to be inspected, while inspection tracking provides the mechanism to record the results and monitor adherence to these standards. The data gathered through inspection tracking informs the continuous improvement efforts within the QC process, highlighting areas requiring attention and demonstrating the effectiveness of implemented changes.

Q 6. Describe your experience with various inspection methodologies (e.g., visual, dimensional, etc.).

My experience encompasses a wide range of inspection methodologies. Visual inspection is the most common, involving a detailed visual examination of the item to detect defects like scratches, cracks, or discoloration. Dimensional inspection utilizes precise measuring tools such as calipers, micrometers, and coordinate measuring machines (CMMs) to verify that dimensions conform to specifications. Other methodologies include functional testing (verifying functionality as intended), destructive testing (testing to failure to determine material properties), and non-destructive testing (NDT) techniques like ultrasonic testing and radiography, which reveal internal flaws without damaging the item. The choice of methodology depends entirely on the nature of the item being inspected and the specific requirements for quality assurance. For example, visual inspection might suffice for assessing the cosmetic quality of a consumer product, while dimensional inspection and NDT would be critical in evaluating the structural integrity of an aircraft component.

Q 7. How do you prioritize and manage multiple inspection tasks simultaneously?

Managing multiple inspection tasks simultaneously requires a structured approach. I utilize project management techniques such as prioritization matrices, assigning tasks based on urgency and importance. Critical inspections with tight deadlines are prioritized over less urgent ones. I also leverage task management tools and software, which allow for efficient scheduling, delegation, and tracking of progress. Clear communication with inspectors and stakeholders is crucial for coordinating efforts and ensuring that tasks are completed efficiently and accurately. Regular status updates help to monitor progress, identify potential roadblocks, and make necessary adjustments to the schedule.

Think of it like conducting an orchestra: each instrument (inspection task) needs to be played at the right time and with the right intensity to create a harmonious whole. Effective management ensures that all instruments play their part effectively, resulting in a flawless performance (successful project completion).

Q 8. How familiar are you with regulatory compliance standards related to inspections?

Regulatory compliance in inspection tracking is paramount. My familiarity encompasses a wide range of standards, including but not limited to ISO 9001 (Quality Management Systems), ISO 14001 (Environmental Management Systems), FDA regulations (for industries like food and pharmaceuticals), and OSHA guidelines (for workplace safety). I understand the specific documentation requirements, audit trails, and reporting procedures mandated by these standards. For instance, in a food manufacturing setting, I’d ensure that all sanitation inspections are meticulously documented, following FDA’s Hazard Analysis and Critical Control Points (HACCP) guidelines, to maintain traceability and demonstrate adherence to food safety regulations. This ensures consistent quality and minimizes the risk of non-compliance penalties.

Q 9. How do you ensure the security and integrity of inspection data?

Data security and integrity are critical. We employ a multi-layered approach: First, access control restricts data viewing and modification to authorized personnel only, utilizing role-based access control (RBAC) systems. Second, data encryption, both in transit and at rest, protects sensitive information from unauthorized access. Third, regular data backups and version control provide redundancy and recovery mechanisms. Finally, we conduct regular security audits and penetration testing to identify and address vulnerabilities. Think of it like a bank vault – multiple layers of security to protect the valuable assets within. For example, inspection reports may be encrypted using AES-256 encryption before being stored in a secure cloud database with access logs meticulously maintained for auditability.

Q 10. Describe your experience with data analysis and reporting related to inspection results.

My experience with data analysis and reporting revolves around extracting meaningful insights from inspection data. I utilize various tools and techniques, including data visualization (using tools like Tableau or Power BI) to create charts and dashboards that illustrate trends and patterns. This allows us to pinpoint areas needing improvement and make data-driven decisions. For example, I might analyze inspection data to identify recurring issues in a particular production line, indicating a potential equipment malfunction or training deficiency. This analysis would then be presented in a concise report, using clear visuals, highlighting key findings and recommendations for corrective actions. Statistical analysis methods like regression or trend analysis are applied to predict potential issues and prevent them proactively.

Q 11. What metrics do you use to evaluate the effectiveness of your inspection tracking processes?

Evaluating the effectiveness of inspection tracking processes relies on key metrics. These include:

- Inspection Completion Rate: The percentage of planned inspections completed on time.

- Defect Detection Rate: The percentage of defects identified through inspections.

- Time to Resolution: The time taken to address identified defects.

- Compliance Rate: The percentage of inspections meeting regulatory requirements.

- Inspection Cycle Time: The time taken to complete an entire inspection cycle.

Q 12. How do you identify and address areas for improvement in inspection tracking procedures?

Identifying areas for improvement involves continuous monitoring and evaluation of the inspection tracking system. We utilize data analysis techniques as described earlier to highlight bottlenecks or inefficiencies. We regularly solicit feedback from inspectors, maintenance personnel, and management to understand challenges and uncover hidden problems. A structured approach like a process mapping exercise can visually highlight areas for improvement. For instance, if the ‘time to resolution’ metric is consistently high, it indicates a problem in the corrective action process, which would then be investigated. Root cause analysis techniques, like the ‘5 Whys,’ would be employed to find the underlying cause of the issue and implement effective solutions.

Q 13. Explain your experience with using inspection tracking software to generate reports.

I have extensive experience generating reports using various inspection tracking software packages. This typically involves configuring the software to extract the required data, applying filters and sorting criteria, and selecting appropriate visualization methods. The software I have worked with commonly allows for customizable report templates, enabling the generation of reports tailored to specific audiences and needs. For example, a summary report for management would highlight key performance indicators, while a detailed report for the maintenance team would provide specifics on identified defects and their locations. Example report generation code (pseudocode): generateReport(reportType, filterCriteria, visualizationType);

Q 14. How do you collaborate with other teams or departments to ensure effective inspection tracking?

Effective inspection tracking necessitates strong collaboration. I consistently engage with maintenance teams to ensure timely repair of identified issues. I work closely with quality control departments to analyze inspection data and implement corrective actions. Communication with management provides updates on inspection progress and highlights areas needing attention. Regular meetings and collaborative tools (e.g., shared databases, project management software) facilitate transparent and efficient information sharing. In essence, a collaborative approach ensures that everyone is on the same page, fostering a proactive approach to preventing future issues.

Q 15. Describe your experience with troubleshooting technical issues related to inspection tracking systems.

Troubleshooting technical issues in inspection tracking systems requires a systematic approach. My experience involves diagnosing problems ranging from software glitches and database errors to connectivity issues and hardware malfunctions. I typically start by identifying the source of the problem – is it a user error, a software bug, a network problem, or a hardware failure?

For example, I once encountered a situation where inspection data wasn’t updating correctly in our system. After systematically checking user permissions, data entry procedures, and the database integrity, I discovered a corrupted database index. The solution involved restoring the database from a backup and implementing preventative measures to regularly check and maintain database health. In another instance, slow response times were traced to a network bottleneck. This required collaborating with the IT department to optimize network bandwidth. My approach prioritizes identifying the root cause before implementing a solution, ensuring the problem is permanently resolved and not just temporarily masked.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain up-to-date knowledge of industry best practices for inspection tracking?

Staying current in the field of inspection tracking requires a multifaceted approach. I actively participate in industry conferences and webinars, which often feature cutting-edge technology and best practices. I regularly subscribe to and read relevant industry publications and journals to keep abreast of emerging trends. Moreover, I actively engage with online professional communities and forums, where experts discuss challenges and share successful strategies. Finally, I ensure I am well-versed with relevant industry standards and regulatory requirements which often drive best practices. This multi-pronged approach helps me maintain a deep and up-to-date understanding of best practices.

Q 17. Describe your experience with developing and implementing new inspection tracking procedures.

I have extensive experience in developing and implementing new inspection tracking procedures, focusing on efficiency, accuracy, and compliance. This typically involves a thorough needs analysis, which starts by understanding the current processes, pain points, and requirements. For instance, a previous project involved streamlining a complex multi-step inspection process for a manufacturing facility. This involved designing a new digital workflow that integrated with existing systems, including a custom-built mobile application for inspectors to input data directly in the field. The new process reduced paperwork significantly, improved data accuracy, and cut down reporting times by 50%. This involved close collaboration with stakeholders, clear documentation of the new procedures, thorough testing, and robust training for the inspectors. Successfully implemented changes are followed by monitoring and evaluation to continuously refine them.

Q 18. How familiar are you with different data formats used in inspection tracking (e.g., CSV, XML, JSON)?

I am proficient in handling various data formats commonly used in inspection tracking, including CSV, XML, and JSON. Understanding these formats is crucial for data exchange and integration with different systems. CSV (Comma Separated Values) is simple and widely used for its ease of import/export to spreadsheets. XML (Extensible Markup Language) provides a more structured format suitable for complex data structures. JSON (JavaScript Object Notation) is a lightweight format popular for web applications and APIs. My experience includes importing and exporting inspection data in all three formats, transforming data between them as needed for compatibility with different systems. For instance, I might receive inspection data in XML format from a legacy system and transform it into JSON for integration with a newer, web-based reporting dashboard.

Q 19. Explain your experience with using inspection tracking data to identify trends and patterns.

Analyzing inspection data to identify trends and patterns is key to continuous improvement. I utilize data analysis techniques such as data visualization, statistical analysis, and trend forecasting. For example, I may use data visualization tools to create charts and graphs that show inspection results over time, highlighting areas where issues are consistently occurring. Statistical analysis helps identify correlations between different factors and pinpoint root causes. In one project, I used trend analysis to predict future equipment failures based on historical inspection data, allowing for proactive maintenance and minimizing downtime. This proactive approach improved operational efficiency significantly. I also use data mining techniques to identify outliers or anomalies that indicate potential problems that might otherwise be overlooked.

Q 20. How do you handle situations where inspections reveal critical safety or compliance issues?

When inspections reveal critical safety or compliance issues, immediate action is paramount. My approach involves a multi-step process. First, I verify the findings through a thorough review of the inspection data and, if necessary, conduct further investigations. Then, I immediately escalate the issue to the relevant authorities – this might involve reporting to management, regulatory bodies, or safety officers depending on the nature and severity of the issue. Next, I work with the responsible parties to implement corrective actions to mitigate the risks and prevent recurrence. Finally, I meticulously document all actions taken, including the corrective measures, follow-up inspections, and any necessary reports, creating a clear audit trail.

Q 21. How do you ensure timely completion of inspections and reporting of results?

Ensuring timely completion of inspections and reporting of results requires effective planning and execution. This starts with establishing clear timelines and assigning responsibilities. I use project management techniques to track progress, manage resources, and identify potential delays. Regular communication with inspectors is crucial to address any roadblocks promptly. I utilize automated reporting tools and systems to streamline the process and ensure consistency. In addition to routine progress monitoring, I conduct regular audits of the inspection process to identify areas for improvement. For example, if a particular type of inspection is consistently taking longer than expected, I’ll analyze the process to determine potential causes such as inefficient procedures or a lack of training.

Q 22. Describe your experience with the integration of inspection tracking systems with other business systems.

Integrating inspection tracking systems with other business systems is crucial for efficient data flow and streamlined operations. It allows for a holistic view of assets, processes, and performance. For instance, I’ve worked on projects where the inspection data was seamlessly integrated with CMMS (Computerized Maintenance Management System) software. This allowed maintenance teams to directly access inspection reports to schedule repairs, preventing equipment downtime. Another example involves integrating with ERP (Enterprise Resource Planning) systems, where inspection data could directly impact procurement decisions, for example, flagging the need for replacement parts based on inspection results. This integration often involves using APIs (Application Programming Interfaces) to exchange data between systems, ensuring data accuracy and consistency. A common challenge is ensuring data mapping is correct between different systems, requiring careful planning and testing.

Consider a scenario where an inspection reveals a critical flaw in a piece of equipment. If the inspection system is integrated with the ERP system, the purchasing department is automatically alerted and can initiate the procurement of a replacement part immediately. This proactive approach significantly reduces downtime and maintenance costs.

Q 23. What is your experience with using inspection tracking systems to manage preventative maintenance?

Inspection tracking systems are invaluable tools for managing preventative maintenance (PM). By scheduling inspections based on asset criticality and manufacturer recommendations, we can identify potential issues before they escalate into costly failures. For example, I used a system where inspections of critical equipment like HVAC systems were scheduled routinely, with reminders sent to technicians based on inspection due dates. The inspection results, including any identified defects, are then automatically linked to a PM work order within the CMMS, streamlining the maintenance process. This proactive approach significantly reduces unexpected downtime and maintenance expenses.

Think of it like regular check-ups for your car. Routine inspections identify potential problems – worn tires, low oil – before they cause a breakdown. Similarly, scheduled inspections on industrial equipment, using an integrated tracking system, prevent catastrophic failures.

Q 24. How do you communicate inspection results effectively to stakeholders?

Effective communication of inspection results is critical for accountability and informed decision-making. My approach involves tailoring the communication to the audience. For instance, I’d generate automated reports summarizing key findings for management, highlighting trends and critical issues. For on-site teams, I’d utilize mobile apps with real-time updates, allowing immediate feedback and corrective actions. Visual representations such as charts, graphs, and dashboards are very useful for conveying complex data succinctly. In cases requiring detailed explanations of complex findings, I would hold presentations and meetings to ensure a thorough understanding. The key is using the most efficient and appropriate method for the specific audience and context.

For example, I once used a color-coded system in a dashboard to show the status of inspections: green for completed without issues, yellow for minor issues requiring attention, and red for critical issues requiring immediate action. This instantly conveyed the overall health of the assets to management.

Q 25. Describe a time you had to troubleshoot a problem within an inspection tracking system.

In one instance, we encountered a problem where the inspection tracking system failed to automatically generate reports on scheduled inspections. This disrupted our maintenance scheduling and reporting. My troubleshooting involved a systematic approach:

- Identify the problem: Reports not generating, and the system log indicated database connectivity issues.

- Isolate the cause: Further investigation pinpointed the problem to a corrupted database connection string.

- Implement a solution: We restored the database connection string from a backup and verified the system’s connectivity.

- Test and verify: We successfully generated reports after restoring the connection.

- Preventative measures: We implemented regular database backups and developed a more robust error handling mechanism to prevent recurrence.

This experience highlighted the importance of regular system maintenance, thorough testing, and comprehensive data backup strategies.

Q 26. How familiar are you with using dashboards and visualisations to present inspection data?

I’m highly proficient in using dashboards and visualizations to represent inspection data. I find that visual representations are the most effective way to communicate complex information and identify trends. I routinely use tools like Power BI and Tableau to create dashboards that display key performance indicators (KPIs) such as the number of overdue inspections, percentage of critical defects, and the overall asset health score. These dashboards allow stakeholders to quickly assess the status of inspections and identify areas needing immediate attention. I also utilize various chart types (bar charts, pie charts, line graphs, etc.) to represent various aspects of the inspection data, depending on the type of information being conveyed.

For example, a line graph can effectively show trends in the number of defects over time, allowing us to identify periods of higher risk and potential systemic problems. A geographical map can show the distribution of assets needing attention, facilitating efficient resource allocation.

Q 27. Describe your experience with implementing or improving an inspection tracking system.

I’ve been involved in both implementing and improving inspection tracking systems. In one project, we implemented a new system to replace an outdated spreadsheet-based method. This involved selecting the right software, customizing it to meet specific needs, integrating it with existing business systems (as described earlier), training users, and developing comprehensive reporting strategies. A key improvement was streamlining the data entry process by using mobile devices and bar code scanners, reducing errors and improving efficiency. In another instance, I led the effort to improve an existing system by adding features like automated email alerts for overdue inspections, improved reporting capabilities, and a user-friendly interface. This involved working closely with stakeholders to understand their requirements and prioritizing features based on their impact and feasibility.

The successful implementation and improvement of inspection tracking systems require careful planning, stakeholder engagement, thorough testing, and a continuous improvement approach.

Q 28. How do you stay organized and manage your workload effectively when handling multiple inspections?

Managing multiple inspections effectively requires a structured approach. I use a combination of techniques to stay organized. First, I prioritize inspections based on asset criticality and urgency. I use project management software (like Jira or Asana) to track the progress of each inspection, setting deadlines, and assigning responsibilities. I leverage the system’s features for automated reminders and notifications. Regularly reviewing my schedule and updating the system keeps me on track. I also batch similar inspections to improve efficiency. For instance, I’ll group inspections within a specific geographical location to reduce travel time. Finally, maintaining detailed records and clear communication are crucial for maintaining order and accountability.

Think of it like a chef managing multiple dishes simultaneously. Prioritization, organization, and efficient workflow are key to delivering high-quality results on time.

Key Topics to Learn for Inspection Tracking Interview

- Inspection Planning & Scheduling: Understanding the process of planning and scheduling inspections, including resource allocation and prioritization. Practical application: Developing a schedule for a large-scale construction project’s inspections.

- Data Collection & Management: Mastering various data collection methods (e.g., checklists, software, mobile apps) and techniques for efficient data management and organization. Practical application: Implementing a system to track and analyze inspection data for quality control.

- Defect Tracking & Reporting: Proficiently identifying, documenting, and reporting defects found during inspections. Understanding different reporting methodologies and their applications. Practical application: Creating clear and concise defect reports that facilitate timely remediation.

- Inspection Software & Technologies: Familiarity with common inspection software and technologies used to streamline the inspection process. Practical application: Utilizing software to automate reporting, data analysis, and communication.

- Regulatory Compliance & Standards: Understanding relevant industry regulations, standards, and best practices related to inspection tracking and reporting. Practical application: Ensuring compliance with building codes during a construction project’s inspection process.

- Problem-Solving & Troubleshooting: Developing effective strategies for identifying and resolving issues related to inspection discrepancies and reporting inconsistencies. Practical application: Analyzing inspection data to identify trends and predict potential problems.

- Communication & Collaboration: Effective communication with stakeholders (e.g., inspectors, contractors, clients) to ensure transparency and efficient resolution of identified issues. Practical application: Facilitating meetings and creating reports to communicate inspection findings.

Next Steps

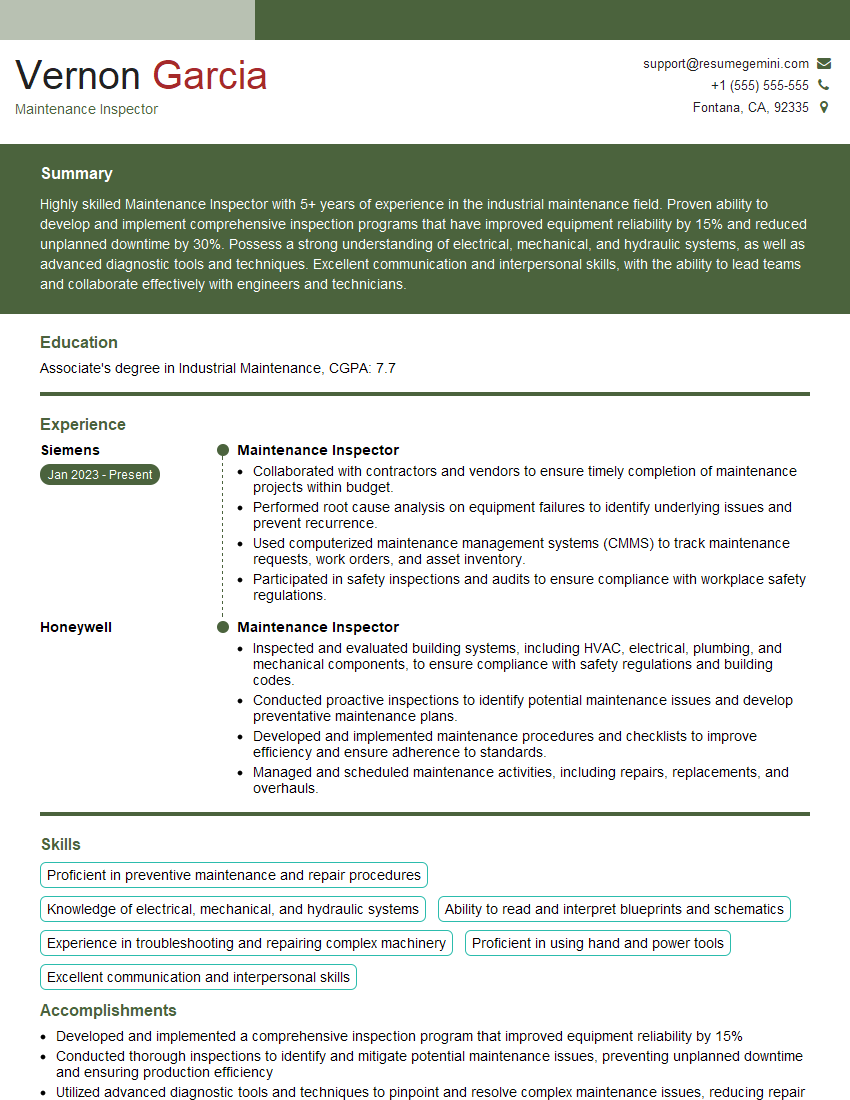

Mastering inspection tracking is crucial for career advancement in many industries, offering opportunities for growth and specialization. A strong understanding of these processes significantly enhances your value to potential employers. To increase your chances of landing your dream job, focus on creating an ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and effective resume. We provide examples of resumes tailored to the Inspection Tracking field to guide you through the process, ensuring your qualifications shine.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good