Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Intergraph SmartPlant 3D interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Intergraph SmartPlant 3D Interview

Q 1. Explain the difference between a pipe spec and a pipe class.

In SmartPlant 3D, a pipe spec and a pipe class are distinct but related concepts that govern the properties of piping systems. Think of the pipe spec as a detailed recipe, specifying every ingredient and their exact quantities, while the pipe class is a more general category, grouping similar recipes together for easier management.

A pipe spec defines the precise material, diameter, schedule (wall thickness), coating, and other specific attributes of a pipe. For example, a pipe spec might detail a 6-inch diameter, Schedule 40, carbon steel pipe with a specific epoxy coating. This level of detail ensures consistency and accuracy in material procurement and construction.

A pipe class, on the other hand, groups together pipes with similar characteristics. It simplifies the design process by allowing engineers to assign a class to a pipe run instead of specifying every attribute individually. A class might be defined as ‘Main Process Line’ and automatically assign specific material, diameter, and other properties based on predefined specifications. This promotes standardization and reduces errors. Multiple pipe specs can fall under one pipe class, offering flexibility in design.

For example, you might have a pipe class called ‘Process Water’ that encompasses several pipe specs with different diameters (say, 2”, 4”, and 6”) but all using the same material and coating.

Q 2. Describe your experience with SmartPlant 3D’s clash detection tools.

My experience with SmartPlant 3D’s clash detection tools is extensive. I’ve used them across numerous projects to identify and resolve interferences between different disciplines’ models, such as piping, structural steel, and equipment. The process usually involves running automated clash reports, which highlight potential conflicts, then investigating the specifics within the 3D environment. The software is fantastic at visualizing these conflicts—allowing for quick identification and resolution.

I’m proficient in using different clash detection filters to prioritize critical conflicts. For example, I’d focus on resolving clashes involving critical process piping before addressing less critical ones. I’m also adept at using the tools to understand the context of the clash, which greatly helps in devising solutions. A typical workflow involves:

- Running automated clash detection reports.

- Filtering results by severity and discipline.

- Analyzing the clash details to identify the root cause.

- Collaborating with other disciplines to implement solutions.

- Documenting the resolution process.

I’ve found that proactively running clash detection throughout the project lifecycle, rather than just at the end, significantly reduces rework and delays. It’s a core part of efficient and successful project delivery.

Q 3. How do you manage revisions and version control within SmartPlant 3D?

SmartPlant 3D’s revision control relies heavily on its integration with data management systems like PVCS, Teamcenter, or other PLM (Product Lifecycle Management) platforms. Within these systems, each revision of the 3D model is carefully tracked, ensuring that every change is documented and accessible. This is crucial for maintaining model integrity and traceability.

My approach typically involves creating new revisions within the data management system, which automatically links them to changes in the SmartPlant 3D model. This includes utilizing the system’s workflows to manage the approval process for each revision. This isn’t just about tracking changes; it’s about controlling access to the model. Only authorized users can modify specific revisions, preventing accidental overwrites or conflicts. This is particularly vital in collaborative projects with multiple engineers and disciplines.

Imagine a scenario where a design error is discovered in Revision 5. With a robust revision control system, we can easily revert to Revision 4, implement the correction, and create Revision 6. This history ensures the model’s transparency and accountability for all modifications. This is a critical aspect of successful project management.

Q 4. What are the different types of reports you can generate in SmartPlant 3D?

SmartPlant 3D offers a comprehensive suite of reporting capabilities, allowing users to extract valuable information about the project’s progress and overall design. The types of reports are quite diverse, catering to different needs. Some of the most common include:

- Material Takeoffs: Provides a detailed list of materials required for construction, including quantities and specifications. This is essential for accurate budgeting and procurement.

- Isometric Drawings: Generates detailed 2D drawings of piping systems, crucial for fabrication and installation.

- Clash Reports: Highlights potential conflicts between different disciplines’ models, as discussed earlier.

- Equipment Lists: Provides a comprehensive list of all equipment included in the model, along with their specifications.

- Piping and Instrumentation Diagrams (P&IDs): These schematic diagrams show the flow of fluids, instruments, and equipment.

- Reports based on custom specifications: The software’s flexibility also allows generation of custom reports tailored to project-specific requirements.

The ability to customize reports is particularly beneficial for adapting to the unique needs of each project. For example, I once created a custom report to track the use of specific materials based on their environmental impact—helping meet sustainability goals.

Q 5. How do you handle model discrepancies between different disciplines?

Handling model discrepancies between disciplines requires a collaborative approach and meticulous attention to detail. I typically employ a combination of strategies to resolve these issues:

- Regular Model Coordination Meetings: These meetings are crucial for identifying and addressing discrepancies early on. This fosters communication and collaboration amongst disciplines.

- Clash Detection: As previously mentioned, clash detection plays a vital role in uncovering discrepancies in the models.

- Model Review Processes: Formal reviews involving team members from different disciplines are critical to catch errors.

- Clear Communication Protocols: Establishing clear and open communication channels among team members is vital in resolving differences of opinion.

- Version Control: Utilizing a robust version control system ensures that every change is tracked, allowing easy rollback if needed.

For example, if a piping model clashes with a structural model, I will not simply modify the piping model to make the clash disappear. Instead, I would carefully examine the clash, discussing with the structural engineers the implications of relocating either part, the feasibility of such changes, and their impact on the project. A resolution would be chosen collaboratively, ensuring the integrity of both the structural and the piping systems.

Q 6. Describe your experience with creating and managing P&IDs in SmartPlant 3D.

My experience with creating and managing P&IDs in SmartPlant 3D is substantial. I’ve worked on numerous projects where the software’s capabilities have enabled efficient creation, revision, and management of P&IDs. I find the tool’s integration with the 3D model exceptionally valuable, allowing for easy synchronization between the schematic and the 3D representation.

The process typically starts with creating the P&ID based on process requirements and specifications. SmartPlant 3D’s features help ensure the accuracy and consistency of the P&ID, such as automatic line numbering and tagging. Once the P&ID is created, we can link it to the 3D model. This helps to prevent discrepancies and ensure that changes made in one model are reflected in the other.

In a recent project, this bi-directional link was crucial in tracking down an error. A change in the P&ID wasn’t properly reflected in the 3D model, and the integrated capabilities saved us considerable time by instantly highlighting the discrepancy, avoiding downstream issues during construction.

Furthermore, SmartPlant 3D’s capabilities allow for easy management of revisions and the creation of multiple versions of the P&ID as the project evolves. This is essential for tracking changes and managing approvals.

Q 7. Explain your understanding of SmartPlant 3D’s data management capabilities.

SmartPlant 3D’s data management capabilities are central to its effectiveness. It’s not just about creating a 3D model; it’s about managing all associated data throughout the project’s lifecycle. The software facilitates this through its integration with various data management systems, providing a centralized repository for all project information.

This integration ensures data consistency across disciplines. Changes made in one area are automatically reflected in related areas, minimizing errors and inconsistencies. The system also includes robust search and retrieval functions, allowing easy access to specific data points whenever needed. This is invaluable for efficient design reviews and problem-solving.

Moreover, the software’s ability to handle large datasets efficiently is crucial for handling complex projects. Its database functionality allows for managing and tracking various information such as material specifications, equipment data, and project schedules, all linked to the 3D model. This integration allows for comprehensive reporting, as discussed earlier, streamlining processes for efficient project delivery.

In essence, SmartPlant 3D’s data management isn’t simply a supporting feature; it’s the backbone of effective collaboration and efficient project execution. It fosters data integrity, traceability, and accessibility, allowing for better decision-making and problem-solving.

Q 8. How do you ensure data integrity within a SmartPlant 3D project?

Data integrity in SmartPlant 3D is paramount for creating accurate and reliable plant designs. Think of it like building a house – you wouldn’t want mismatched bricks or incorrect measurements! We ensure integrity through several key strategies:

- Strict Data Management: Implementing a robust data management system is crucial. This involves defining clear naming conventions for components, using standardized specifications, and regularly auditing the model for inconsistencies. For example, we enforce a strict naming convention such as “EquipmentType_Location_ID” to prevent ambiguity.

- Version Control: Utilizing SmartPlant 3D’s version control features allows us to track changes, revert to previous versions if needed, and maintain a clear audit trail of modifications made by different engineers. This is like having a history of every edit in a document.

- Regular Data Validation: Employing regular data validation checks helps identify and resolve errors early in the design process. Built-in SmartPlant 3D checks, along with custom scripts, can be used to flag potential conflicts or discrepancies before they become major issues. Imagine this as a spell-checker for your 3D model.

- Collaboration and Communication: Effective communication among team members is crucial. This includes regular design reviews, utilizing collaborative annotation tools within SmartPlant 3D, and maintaining a central, accessible data repository.

- Automated Checks: SmartPlant 3D offers several built-in capabilities for automated checks such as clash detection which helps find and resolve interference between equipment, piping, and structures. This prevents costly rework during later stages of the project.

By combining these methods, we minimize errors, increase efficiency, and ultimately deliver a more reliable and accurate plant design.

Q 9. Describe your workflow for creating isometrics in SmartPlant 3D.

My isometric creation workflow in SmartPlant 3D is streamlined and efficient. It typically involves these steps:

- Preparation: I begin by selecting the piping systems or equipment I need to generate isometrics for. It’s important to ensure the 3D model is complete and accurate in this area. Any missing components or inconsistencies will impact the accuracy of the isometrics.

- Isometric Generation: Within SmartPlant 3D, I navigate to the isometric generation tools and define the output parameters, such as drawing scale, line styles, and annotation preferences. I also specify the sections I want included in the isometric and determine the necessary level of detail. The software then automatically generates the 2D isometric drawings.

- Review and Editing: After generation, I meticulously review the generated isometrics for accuracy and completeness. This might include verifying dimensions, checking for any clashes or inconsistencies that weren’t detected earlier, and ensuring compliance with relevant standards. SmartPlant 3D provides tools for annotating and editing the isometric drawings directly.

- Approval and Issuing: Once the isometrics are approved, I save them in the appropriate project directory and make them available to the relevant stakeholders (fabrication shops, contractors etc.).

Throughout the process, I adhere to company standards and best practices to ensure consistency and accuracy.

Q 10. How familiar are you with SmartPlant 3D’s customization options?

I’m highly familiar with SmartPlant 3D’s customization options. These options are crucial for tailoring the software to specific project needs and company standards. My experience includes:

- Customizing Spec Sheets: I’ve created and modified spec sheets to reflect our company’s unique specifications and standards, ensuring consistent data entry and reporting.

- Developing Custom Reports: I’ve developed custom reports to extract specific data from the SmartPlant 3D model, such as material take-offs or equipment lists, streamlining the information gathering process.

- Creating Custom Symbols and Catalogs: I have a solid understanding of creating and managing custom symbols and catalogs, which allows us to include project-specific components and equipment not included in the standard library.

- Utilizing API and Scripting: I’ve utilized the API and scripting capabilities of SmartPlant 3D to automate repetitive tasks, such as data migration or report generation. This boosts efficiency significantly.

- Workflow Customization: I am experienced with customizing the SmartPlant 3D workflow to optimize the design process for our team’s specific needs and project requirements. For example, this may involve creating custom check routines or developing custom commands.

This level of customization ensures that we leverage SmartPlant 3D’s full potential to improve project efficiency and data integrity.

Q 11. How do you troubleshoot and resolve issues within SmartPlant 3D?

Troubleshooting in SmartPlant 3D often involves a systematic approach. I typically begin by:

- Identifying the Issue: Clearly defining the problem is the first step. What exactly is happening? When did it start? What actions preceded the issue?

- Checking Logs and Messages: SmartPlant 3D provides detailed logs and error messages. Examining these messages frequently reveals clues to the root cause of the problem. This is like looking for clues in a detective story.

- Reviewing Recent Changes: If the issue appeared after a specific change, reverting to a previous version can help isolate the cause. This is akin to using undo in a word processor.

- Utilizing Online Resources and Support: Intergraph provides extensive online documentation, forums, and support resources. Leveraging these resources can offer quick solutions to common problems.

- Seeking Help from Colleagues: Consulting with colleagues with more experience or specialized knowledge is a valuable way to solve complex problems. Often, a fresh perspective can identify overlooked solutions.

For example, a common issue is model corruption. The first step is to review the logs for error messages and then attempt a repair using built-in tools before considering other steps like re-importing critical data. The key is a systematic, logical approach to finding the root cause.

Q 12. Describe your experience with working with large and complex SmartPlant 3D models.

I have extensive experience working with large and complex SmartPlant 3D models, often involving hundreds of thousands of components. These projects demand efficient data management and optimized workflows. My approach involves:

- Model Decomposition: Breaking down the large model into smaller, manageable sections streamlines the design process and allows for parallel work by different teams. This is like dividing a large construction project into separate phases.

- Efficient Data Management: Using robust data management strategies, including version control and clearly defined naming conventions, is essential to prevent confusion and data loss. This helps to manage the sheer volume of information involved.

- Optimized Workstations: Utilizing high-performance workstations with ample memory and processing power is necessary to handle the computational demands of large models. Without this, the software will become sluggish.

- Performance Tuning: Regularly reviewing and optimizing the model for performance helps prevent slowdowns or crashes, especially during regeneration or review sessions. This includes simplifying geometry where appropriate and optimizing database settings.

In one project, we handled a model exceeding 500,000 components by using a hierarchical model structure and employing a phased approach to design and review, which ensured project success despite the model’s complexity.

Q 13. How do you handle model updates and changes from different engineers?

Handling model updates and changes from different engineers requires a coordinated and structured approach. We implement the following:

- Centralized Data Repository: Utilizing a centralized data repository, accessible by all team members, ensures everyone is working with the latest version of the model. This eliminates version conflicts and ensures everyone is ‘on the same page.’

- Version Control: SmartPlant 3D’s version control system allows us to track changes, revert to previous versions if needed, and identify who made what changes. Think of this like a detailed log of all edits.

- Regular Model Reviews: Conducting regular design reviews helps identify potential conflicts or inconsistencies early. This is a proactive step to prevent issues from escalating.

- Communication Protocols: Clearly defined communication protocols ensure that all engineers are aware of ongoing changes and planned updates. This minimizes surprises and helps maintain a consistent workflow.

- Change Management Process: Establishing a formal change management process ensures that all modifications are properly documented, reviewed, and approved before being implemented. This adds an important layer of control and accountability.

This integrated approach ensures seamless collaboration and prevents conflicts within the project model.

Q 14. What is your experience with SmartPlant 3D’s integration with other software?

My experience with SmartPlant 3D’s integration with other software is extensive. I’ve worked with various integrations, including:

- SmartPlant Instrumentation: Seamless integration for creating and managing instrument specifications and drawings. This ensures consistency between the 3D model and instrumentation details.

- SmartPlant Electrical: Integration with SmartPlant Electrical allows for coordinated design between piping and electrical systems, preventing potential conflicts. This integration is important for minimizing conflicts and delays.

- SmartPlant P&ID: Direct integration with P&IDs enables a more accurate and streamlined design process by ensuring consistency between design drawings and the 3D model.

- Other Engineering Software: Integration with other software, such as AutoCAD and other CAE/CAD systems, enables data exchange and interoperability. This is important when working with multiple disciplines and vendors.

- Data Management Systems: Integration with various data management systems allows for efficient data storage, access, and control within a broader enterprise environment. This is crucial for large, multi-site projects.

These integrations significantly streamline workflows, reduce errors, and improve the overall quality of the plant design process.

Q 15. Explain your process for creating and managing materials in SmartPlant 3D.

Managing materials in SmartPlant 3D is crucial for accurate costing, procurement, and fabrication. My process begins with meticulously defining material specifications within the SmartPlant Material database. This involves specifying properties like grade, size, weight, and cost. I leverage the system’s built-in capabilities to categorize materials using a hierarchical structure, allowing for easy searching and retrieval. For instance, I might create categories for steel pipes, fittings, valves, and insulation, further sub-dividing them based on standards and grades. This structured approach facilitates efficient material selection during design and helps manage potential conflicts. I routinely review and update the material database, ensuring it remains accurate and aligned with the project’s requirements and any changes in industry standards or supplier offerings. Regular audits, comparing the database with actual material takeoffs from the model, are essential to maintaining data integrity. Finally, I generate reports summarizing material quantities and costs, providing critical input for project budget control and procurement planning.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How familiar are you with SmartPlant 3D’s drawing management features?

I’m highly proficient in SmartPlant 3D’s drawing management capabilities. I routinely create and manage various drawing types, including isometrics, orthographics, and general arrangements. I leverage SmartPlant’s automation features to generate drawings from the 3D model, ensuring consistency and accuracy. My process includes defining drawing templates with customized title blocks, scales, and annotation standards to maintain a consistent project look and feel. Furthermore, I implement rigorous version control procedures, utilizing the built-in revision capabilities to track design changes and ensure that all stakeholders are working from the most up-to-date versions. Managing drawing revisions effectively is critical to avoid confusion and ensure that construction is performed based on the latest approved design. I also utilize SmartPlant’s drawing review and approval workflows to streamline the review process and ensure that drawings meet quality standards before release.

Q 17. What is your experience with SmartPlant 3D’s automation capabilities?

SmartPlant 3D’s automation capabilities are essential for improving efficiency and accuracy. I extensively use automation features to generate reports, drawings, and even parts of the 3D model itself. For example, I’ve utilized automation to generate piping isometrics directly from the 3D model, eliminating the need for manual drafting and reducing the potential for errors. I’ve also used scripting (e.g., using the provided API) to automate tasks like creating custom reports detailing material takeoffs or generating equipment lists based on specific criteria. This improves the speed and accuracy of data processing and allows for efficient analysis of large datasets. One particular project involved automating the creation of cable tray layouts based on equipment locations, substantially reducing engineering hours. The key is to carefully plan automation tasks to ensure that the results are accurate and consistent with the overall project design. Thorough testing and validation of automated processes are crucial before widespread deployment.

Q 18. Describe your approach to quality control within SmartPlant 3D projects.

My approach to quality control in SmartPlant 3D projects is multifaceted and proactive. It starts with establishing clear quality standards and procedures at the beginning of the project. This involves defining tolerance levels, naming conventions, and checking procedures that the whole team adheres to. I routinely perform model checks using SmartPlant’s built-in tools to identify clashes, inconsistencies, and errors early on. This includes checking for pipe stress issues, ensuring compliance with design standards, and verifying that equipment specifications are correctly applied. Beyond model checking, I engage in regular peer reviews with other engineers, utilizing markups and feedback within the software to identify and resolve issues collaboratively. We create a comprehensive checklist for various phases of the project to ensure no aspect of the design is overlooked. Finally, I generate comprehensive quality control reports documenting the identified issues, the corrective actions taken, and the overall project quality status. This rigorous approach minimizes errors and ensures the final design is accurate, efficient, and meets all project requirements.

Q 19. How do you handle conflicting design changes from different disciplines?

Handling conflicting design changes from different disciplines requires a systematic and collaborative approach. We start by establishing a clear communication protocol, utilizing integrated project delivery methods and regular interdisciplinary meetings. In SmartPlant 3D, we leverage the version control system to track changes made by each discipline. When conflicts arise (e.g., clash detection between piping and structural steel), we use the model’s clash detection tools to pinpoint the problem areas. We then hold a collaborative review session involving representatives from the relevant disciplines to discuss the conflict and develop a resolution. This involves considering factors like cost, schedule, and constructability. The resolution is then documented, communicated to the team, and implemented in the model. Utilizing a centralized data management system is essential for this process, ensuring that all team members work from the same, updated information. The iterative nature of these meetings ensures we address conflicts proactively and maintain a cohesive and functional design.

Q 20. Explain your understanding of the different coordinate systems used in SmartPlant 3D.

SmartPlant 3D utilizes several coordinate systems, understanding which is crucial for accurate modeling and data exchange. The primary systems include the Project Coordinate System (PCS), which serves as the overall reference for the entire project, the Local Coordinate System (LCS), frequently used for individual equipment or structures, and the User Coordinate System (UCS), used for temporary positioning during modeling. Understanding the relationship between these systems is vital to avoid misalignments and ensure that all components are accurately positioned within the overall model. Incorrect coordinate system usage can lead to significant errors during design and construction, so establishing a clear coordinate system strategy early in the project is critical. This involves carefully defining the PCS, establishing consistent conventions for LCS usage, and training team members on their proper implementation. I regularly verify the coordinate systems used in the model to prevent inconsistencies and integration issues with other project data.

Q 21. Describe your experience with creating and managing equipment specifications in SmartPlant 3D.

Managing equipment specifications in SmartPlant 3D is a key aspect of ensuring accurate design and procurement. I start by importing equipment data from vendor catalogs or creating custom specifications using SmartPlant’s tools. This involves defining parameters like dimensions, weight, material, and connection points. I then link these specifications to the 3D model, ensuring that the model accurately reflects the actual equipment to be installed. Accurate specifications are crucial for accurate clash detection, weight calculations, and piping design. I maintain a structured database of equipment specifications, categorized for easy retrieval. Version control is also critical here; tracking changes to equipment specifications and ensuring that the model reflects the latest approved versions prevents confusion and potential construction errors. Regularly reviewing and updating equipment specifications, especially as the project progresses, ensures accuracy and consistency throughout the lifecycle of the project.

Q 22. How do you utilize SmartPlant 3D to improve project efficiency?

SmartPlant 3D dramatically improves project efficiency through its integrated design environment. Instead of working with disparate tools, engineers, designers, and constructors collaborate within a single platform, eliminating data discrepancies and reducing rework. This unified approach streamlines workflows. For example, automatic clash detection prevents costly design errors early in the project lifecycle, saving time and resources that would otherwise be spent on revisions later. Furthermore, the automated generation of drawings, reports, and material lists reduces manual effort and minimizes human error. In one project, we reduced the design phase by 20% by implementing efficient workflows and leveraging SmartPlant 3D’s automation capabilities.

- Improved Collaboration: Real-time collaboration features reduce conflicts and expedite decision-making.

- Automated Processes: Automated tasks such as isometric generation and material takeoffs free up valuable time for engineers to focus on design optimization.

- Early Error Detection: Clash detection tools prevent costly design revisions during construction.

Q 23. What are your strategies for optimizing model performance in SmartPlant 3D?

Optimizing SmartPlant 3D model performance involves several key strategies. A well-structured model is crucial. This means organizing your model into logical areas, using appropriate levels of detail (LOD) and leveraging the power of the model hierarchy. This includes using named views and sub-assemblies effectively. It’s essential to regularly purge the model of unnecessary data, such as obsolete components or revisions. This will improve performance dramatically. Using efficient modeling techniques like parameterization and leveraging templates will significantly reduce overall modeling time and lead to cleaner models. For example, using families of parts instead of creating individual components saves significant storage and improves the model’s overall size. Regularly optimizing the model’s geometry, particularly reducing polygon count where possible in areas that aren’t critical for accurate visualization, also contributes to performance gains.

- Regular Purging: Removing obsolete data keeps the model lightweight.

- LOD Management: Using appropriate Levels of Detail (LOD) helps maintain performance without sacrificing accuracy where necessary.

- Model Organization: A well-structured model using sub-assemblies enhances efficiency and ease of use.

- Geometry Optimization: Reducing the number of polygons in non-critical areas improves performance.

Q 24. Explain your experience with SmartPlant 3D’s reporting and analysis tools.

SmartPlant 3D’s reporting and analysis tools are extensive and highly customizable. I’ve extensively used them to generate a wide variety of reports, including material takeoffs (MTOs), isometric drawings, and equipment lists. The ability to customize reports based on specific project requirements is particularly valuable. For instance, I’ve created custom reports showing the total length of piping for each material type to streamline material procurement. The software’s ability to export data in various formats (like Excel, PDF) allows for easy integration with other project management tools. I’ve found the built-in analysis tools, particularly the clash detection capabilities, invaluable in identifying and resolving potential conflicts early in the design process, before they become costly problems during construction.

- Material Takeoffs (MTOs): Accurate and automated generation of MTOs for efficient procurement.

- Isometric Drawings: Automated generation of detailed isometric drawings for fabrication.

- Custom Reports: Ability to create specialized reports based on project needs.

- Clash Detection: Effective identification and resolution of design conflicts.

Q 25. How do you ensure consistency in design standards within SmartPlant 3D projects?

Ensuring design consistency in SmartPlant 3D projects hinges on establishing and enforcing robust standards early on. This involves creating and implementing a detailed style guide that outlines standards for naming conventions, component specifications, and drawing formats. This guide is then enforced through the use of SmartPlant 3D’s built-in features, like catalogs, families, and templates. The project team is trained to follow these standards carefully, and regular reviews of the model are conducted to ensure compliance. For example, consistent piping specifications, valve designations, and equipment tags are crucial for avoiding confusion and ensuring accurate construction. We use SmartPlant Foundation to manage and control these standards.

- Style Guide: Defining clear standards for naming, components, and drawing formats.

- Catalogs and Families: Standardizing component specifications through pre-defined catalogs and families.

- Templates: Establishing standardized drawing templates for consistent output.

- Regular Model Reviews: Consistent checks to ensure adherence to established standards.

Q 26. Describe your experience with using SmartPlant 3D for construction support.

SmartPlant 3D provides crucial support throughout the construction phase. The 3D model serves as a primary reference for field engineers and construction crews. Detailed isometrics generated directly from the model aid in fabrication. Clash detection during construction is simplified using the model, minimizing costly delays. Moreover, the model can be used for site planning, identifying potential obstructions, and improving the coordination of different trades. In a recent project, the use of the model on-site reduced rework by 15% as any identified clashes or conflicts were already resolved at the design phase. The model also facilitated the use of reality capture (laser scanning) technology, leading to improved accuracy.

- Fabrication Drawings: Isometric and other drawings are invaluable tools in the fabrication phase.

- Clash Detection: Minimizing construction conflicts through early identification of clashes.

- Site Planning: Supporting site layout and planning to optimize workflows.

- Integration with Reality Capture: Enhanced accuracy of the model by incorporating reality capture data.

Q 27. How familiar are you with SmartPlant 3D’s collaboration features?

I’m highly familiar with SmartPlant 3D’s collaboration features. These features are central to effective teamwork on large-scale projects. The software’s version control system prevents conflicts and ensures all team members work with the latest model revision. This system is integrated and highly efficient. Additionally, SmartPlant 3D’s ability to support simultaneous model access by multiple users, when implemented correctly using a properly configured server, allows for real-time collaboration and reduces the time spent on merging revisions. We also use the built-in communication tools for efficient communication and coordination within the team. For example, the ability to add comments and markups directly on the model speeds up the review process and facilitates better communication among designers and reviewers.

- Version Control: Preventing conflicts through robust version management.

- Simultaneous Access: Concurrent work on the model through a properly configured server environment.

- Integrated Communication Tools: Facilitating collaboration through built-in comment and markup features.

Key Topics to Learn for Intergraph SmartPlant 3D Interview

- 3D Modeling Fundamentals: Understanding the core principles of creating and manipulating 3D models within SmartPlant 3D, including object snapping, constraints, and model cleanup techniques.

- Piping and Instrumentation Diagrams (P&IDs): Deep familiarity with creating, modifying, and interpreting P&IDs, including understanding the symbology and the connection to the 3D model.

- Isometrics and Reports Generation: Mastering the creation and customization of isometric drawings and other crucial reports generated from the SmartPlant 3D model, understanding their importance in construction and fabrication.

- Material and Equipment Specification: Proficiency in assigning materials and equipment to the model, understanding the importance of accurate specifications for cost estimations and project management.

- Clash Detection and Resolution: Practical experience identifying and resolving clashes between different disciplines (piping, structural, electrical, etc.) within the 3D model, a critical skill for efficient project delivery.

- Data Management and Collaboration: Understanding SmartPlant 3D’s data management capabilities and how to effectively collaborate with team members on large projects using the platform.

- Project Setup and Configuration: Knowledge of setting up and configuring projects within SmartPlant 3D, including defining standards, units, and other project-specific parameters.

- Customization and Scripting (Optional): While not always essential, familiarity with customizing SmartPlant 3D through scripting or add-ins demonstrates advanced skills and can be a significant advantage.

- Practical Problem-Solving: Be prepared to discuss real-world scenarios where you used SmartPlant 3D to solve a design challenge or improve efficiency. Focus on your problem-solving process and the results achieved.

Next Steps

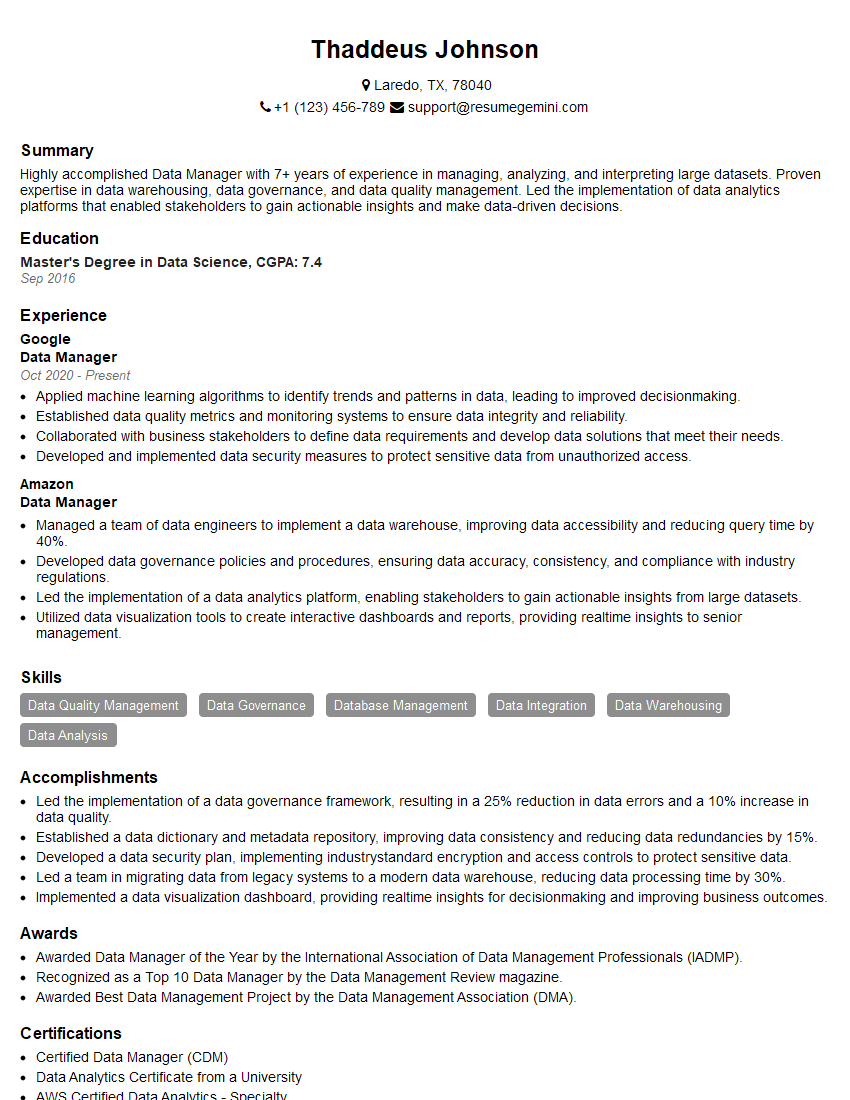

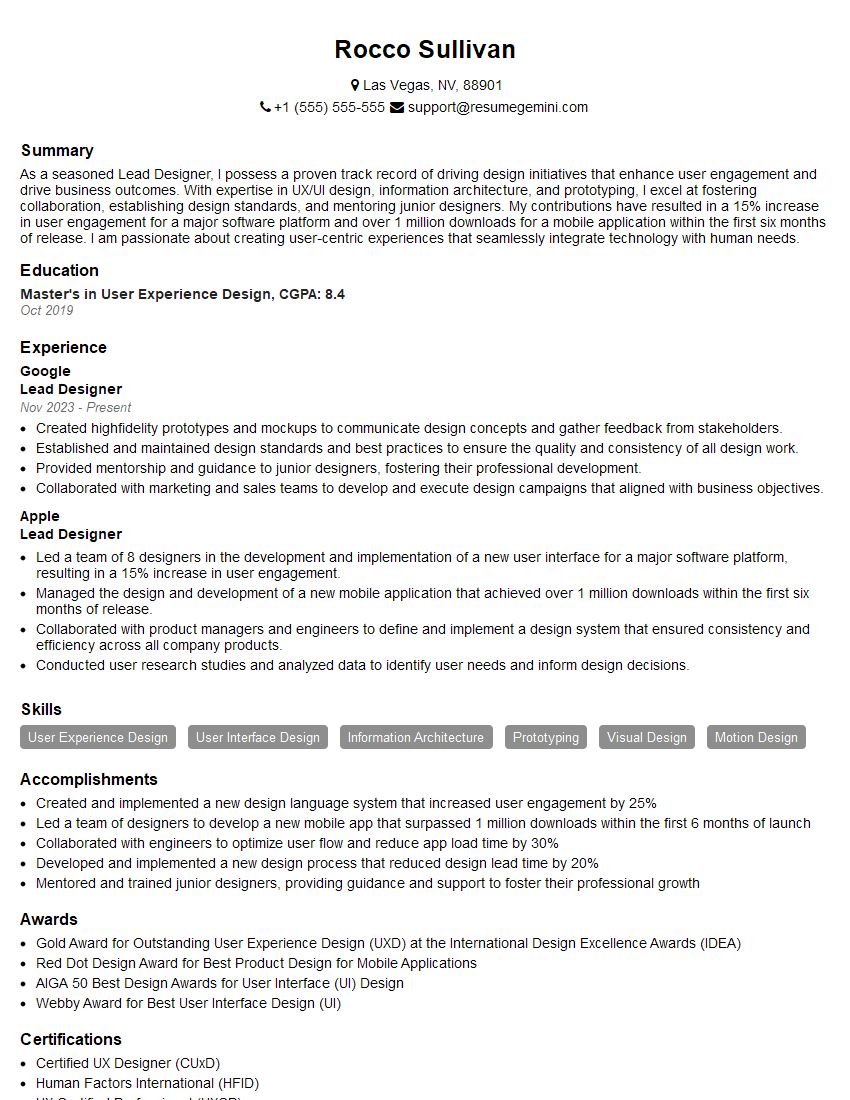

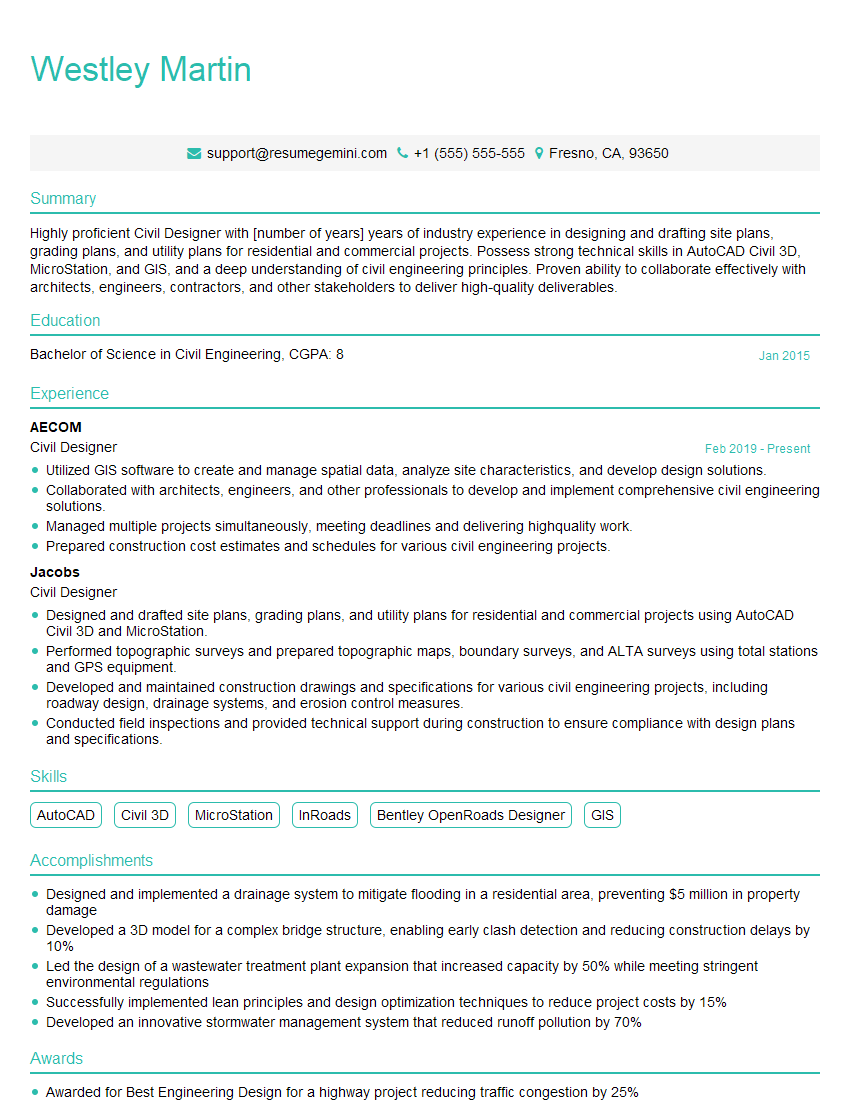

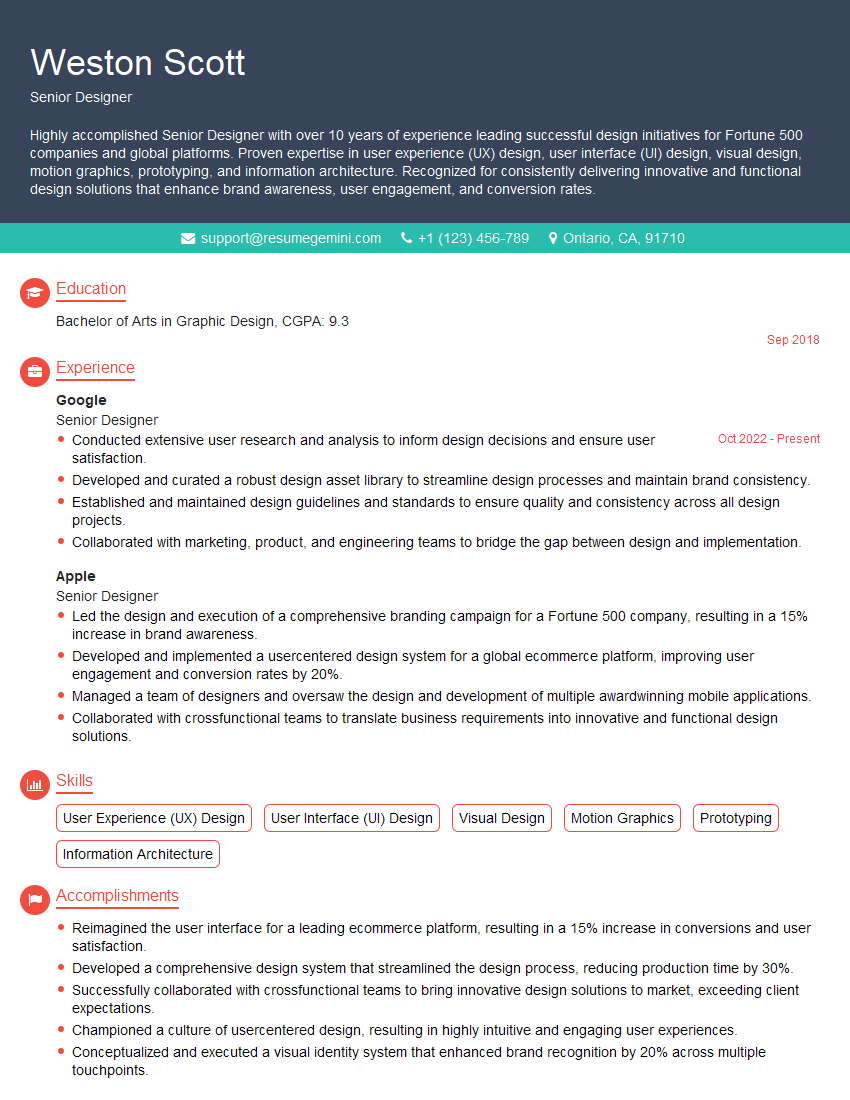

Mastering Intergraph SmartPlant 3D significantly enhances your career prospects in the engineering and construction industries, opening doors to exciting opportunities and higher earning potential. To maximize your chances of landing your dream job, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed. We highly recommend using ResumeGemini to build a professional and compelling resume that highlights your SmartPlant 3D expertise. ResumeGemini provides valuable resources and examples of resumes tailored to Intergraph SmartPlant 3D roles, ensuring your application stands out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good