Are you ready to stand out in your next interview? Understanding and preparing for ISO 9001/AS9100 interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in ISO 9001/AS9100 Interview

Q 1. Explain the core principles of ISO 9001.

ISO 9001’s core principles are the foundation of a robust Quality Management System (QMS). They guide organizations towards continuous improvement and customer satisfaction. Think of them as the guiding stars navigating your quality journey.

- Customer Focus: Understanding and meeting customer needs and expectations is paramount. This means actively soliciting feedback and ensuring your products and services consistently deliver value.

- Leadership: Leaders at all levels must be committed to the QMS, fostering a culture of quality and providing the necessary resources. It’s not just a top-down mandate; it requires engagement from everyone.

- Engagement of People: Empowering employees at all levels is crucial. Their expertise and input are vital for continuous improvement. A well-trained and motivated workforce is a key ingredient for success.

- Process Approach: Managing processes effectively is essential. This involves mapping processes, identifying potential risks, and establishing controls to ensure consistent output. Think of a well-oiled machine – each part has its role, and their interactions are carefully managed.

- Improvement: Continuous improvement is a core tenet. Regularly reviewing your QMS to identify areas for improvement and implementing corrective actions is vital for long-term success. Think of it as constantly refining your processes to enhance performance.

- Evidence-based Decision Making: Relying on data and analysis rather than assumptions. This means using metrics to track performance, identify trends, and make informed decisions. Data drives improvement; intuition can lead to guesswork.

- Relationship Management: Building strong relationships with suppliers and other stakeholders is essential for a robust supply chain and overall success. Collaboration is key.

Q 2. Describe the differences between ISO 9001 and AS9100.

While both ISO 9001 and AS9100 are quality management system standards, AS9100 is specifically tailored for the aerospace industry. Think of ISO 9001 as the general framework and AS9100 as its specialized aerospace version.

- Scope: ISO 9001 applies to a broad range of industries, while AS9100 is specifically designed for the aerospace industry, encompassing stringent requirements relevant to the high safety and reliability demands of aviation.

- Requirements: AS9100 includes additional requirements beyond those in ISO 9001, such as specific clauses on configuration management, risk management in the context of aviation safety, and counterfeit parts prevention.

- Industry-Specific Practices: AS9100 incorporates industry-specific best practices and terminology unique to aerospace manufacturing, design, and maintenance. This includes requirements for specialized processes and controls within the aerospace supply chain.

- Auditing and Certification: Audits for AS9100 are more rigorous and often involve specialized auditors with experience in the aerospace field. The certification process is more demanding due to the critical nature of aerospace operations.

For example, an organization manufacturing car parts might only need ISO 9001 certification. However, a company producing aircraft parts would require AS9100 certification to demonstrate compliance with aerospace industry regulations and customer requirements.

Q 3. What is a Quality Management System (QMS)?

A Quality Management System (QMS) is a structured set of processes and procedures that an organization uses to ensure its products, services, and operations consistently meet customer requirements and applicable regulations. It’s the roadmap to quality, ensuring consistent output and customer satisfaction.

Imagine a recipe for baking a cake. The QMS is like the detailed recipe, outlining each step, ingredient, and measurement. Following this recipe consistently will produce a consistently good cake. Without a well-defined recipe (QMS), the result will be inconsistent.

A QMS typically includes elements such as:

- Documented procedures: Detailed instructions for each process.

- Internal audits: Regular assessments to verify compliance.

- Management review: Periodic reviews to ensure the QMS remains effective.

- Corrective actions: Processes to address nonconformities.

- Continuous improvement initiatives:

Q 4. How do you conduct an internal audit according to ISO 9001?

Conducting an internal audit according to ISO 9001 involves a systematic and objective evaluation of the QMS’s effectiveness. It’s a self-assessment designed to identify gaps and areas for improvement. Think of it as a health checkup for your QMS.

- Planning: Define the scope, objectives, and resources required for the audit. Who will audit what? When and how?

- Audit Execution: Collect evidence through interviews, document review, observations, and testing. Are procedures being followed? Are records maintained correctly?

- Reporting: Document the audit findings, including any nonconformities, observations, and recommendations for improvement. Be objective and factual, including supporting evidence.

- Follow-up: Verify that corrective actions are implemented and effective. This ensures that identified issues are addressed and prevent recurrence.

For instance, during an internal audit of the purchasing process, you might review purchase orders, supplier agreements, and inspection reports to verify that purchased materials meet specified requirements. If inconsistencies are identified, nonconformities are recorded, and corrective actions are planned and implemented.

Q 5. What are the key clauses in ISO 9001:2015?

ISO 9001:2015 is structured around a high-level structure, making it easier to integrate with other management system standards. Key clauses include:

- Clause 4: Context of the organization: Understanding the internal and external issues that affect the QMS.

- Clause 5: Leadership: Demonstrating commitment to the QMS from top management.

- Clause 6: Planning: Setting objectives, determining the resources needed, and defining the processes necessary for achieving the objectives.

- Clause 7: Support: Providing resources, such as skilled personnel, infrastructure, and work environment.

- Clause 8: Operation: Executing the defined processes to deliver products and services.

- Clause 9: Performance evaluation: Monitoring, measuring, analyzing, and evaluating the effectiveness of the QMS.

- Clause 10: Improvement: Continuously improving the QMS through nonconformity handling and corrective actions.

Each clause is crucial, forming a chain of actions that ultimately ensure a consistently effective QMS. For example, if Clause 7 (Support) doesn’t provide adequate resources (e.g., training), Clause 8 (Operation) might fail, leading to issues identified in Clause 9 (Performance Evaluation).

Q 6. Explain the concept of risk-based thinking in a QMS.

Risk-based thinking is a proactive approach to identifying and managing potential threats and opportunities that could impact the QMS’s ability to meet its objectives. It’s about anticipating challenges and planning for them.

Imagine you’re building a house. Risk-based thinking would involve identifying potential problems like bad weather, material shortages, or skilled labor availability. You then plan how to mitigate those risks (e.g., having a backup plan for materials, using weather-resistant materials, scheduling work carefully).

In a QMS, risk-based thinking involves:

- Risk identification: Identifying potential hazards or opportunities within the organization’s processes.

- Risk analysis: Assessing the likelihood and potential impact of each identified risk.

- Risk response planning: Developing strategies to mitigate or prevent identified risks, or exploit opportunities.

- Risk monitoring: Regularly tracking and evaluating the effectiveness of risk response plans. Are the mitigation strategies working? Do we need to adjust our plans?

This proactive approach ensures that the QMS is robust and resilient to unforeseen circumstances, minimizing disruption and maximizing success.

Q 7. How do you handle nonconformities and corrective actions?

Handling nonconformities and corrective actions is crucial for continuous improvement and maintaining customer satisfaction. Nonconformities are deviations from specified requirements. Corrective actions address the root causes to prevent recurrence.

- Identify the Nonconformity: Clearly define the deviation from the specified requirements. What went wrong? Where did it occur?

- Investigate the Root Cause: Determine the underlying reasons for the nonconformity. Why did it happen? This often requires a thorough analysis, involving various stakeholders.

- Implement Corrective Actions: Develop and implement actions to eliminate the root cause and prevent recurrence. This could involve process changes, employee training, or equipment upgrades.

- Verify Effectiveness: Monitor the effectiveness of the implemented corrective actions. Did it solve the problem? Is the issue resolved permanently?

- Document Everything: Maintain records of all nonconformities, root cause analyses, corrective actions, and verification results.

For example, if a batch of products fails a quality inspection, the nonconformity is investigated. The root cause might be identified as a faulty machine setting. The corrective action would be to recalibrate the machine and retrain the operator. The effectiveness is then verified by checking subsequent batches.

Q 8. Describe your experience with root cause analysis.

Root cause analysis (RCA) is a systematic process for identifying the underlying cause of a problem, not just its symptoms. It’s crucial in ISO 9001/AS9100 for continuous improvement and preventing recurrence. My experience involves employing various RCA techniques, depending on the complexity of the issue. For instance, I’ve used the 5 Whys method for simpler problems – repeatedly asking ‘why’ to drill down to the root cause. For more complex situations, I’ve utilized Fishbone diagrams (Ishikawa diagrams), which help visualize potential causes categorized by categories like manpower, machinery, materials, methods, measurement, and environment. In a recent project involving non-conforming parts, we used a Failure Mode and Effects Analysis (FMEA) to proactively identify potential failure modes and their root causes, allowing us to implement preventative measures before any issues arose. I also have experience with Fault Tree Analysis (FTA) to systematically investigate potential causes and their relationships leading to a specific failure.

For example, in a situation where a batch of manufactured components failed a quality inspection, the 5 Whys might reveal a sequence like: 1. Why did the parts fail inspection? (Dimensional inaccuracy) 2. Why were the dimensions inaccurate? (Incorrect machine settings) 3. Why were the machine settings incorrect? (Operator error) 4. Why did the operator make the error? (Lack of adequate training) 5. Why was the training inadequate? (Outdated training materials). This leads to corrective actions focused on updating training materials and providing refresher training.

Q 9. What is a corrective action preventative action (CAPA) system?

A Corrective Action Preventative Action (CAPA) system is a structured process for identifying, investigating, correcting, and preventing the recurrence of nonconformities (problems that don’t meet requirements). It’s a cornerstone of ISO 9001/AS9100. A robust CAPA system ensures that problems are not merely addressed reactively but proactively prevented in the future. The system typically involves several key steps: 1. Identifying the nonconformity. 2. Conducting a root cause analysis (RCA). 3. Developing and implementing corrective actions to address the immediate problem. 4. Developing and implementing preventative actions to prevent recurrence. 5. Verifying the effectiveness of the actions taken. 6. Documenting the entire process. I have extensive experience developing and implementing CAPA systems, including designing forms, establishing workflows, and training personnel on the process. I’ve also worked with various software solutions for managing CAPA reports and tracking progress. The effectiveness is regularly monitored through internal audits and management reviews.

Imagine a scenario where a customer reported a defective product. Our CAPA process would involve identifying the nonconformity, investigating the cause using RCA (perhaps revealing a faulty component from a specific supplier), implementing corrective actions (replacing the defective components and notifying affected customers), and preventative actions (implementing a stricter inspection process for that component and potentially switching suppliers). The entire process is meticulously documented to aid continuous improvement and ensure traceability.

Q 10. How do you ensure the effectiveness of your QMS?

Ensuring the effectiveness of a Quality Management System (QMS) is an ongoing process. It relies on several key strategies. Regular internal audits are essential to assess compliance with standards and identify areas for improvement. These audits should be conducted by trained personnel and cover all aspects of the QMS. Management reviews provide a high-level overview of the QMS performance, focusing on key performance indicators (KPIs) and addressing any systemic issues. Data analysis, including metrics related to customer satisfaction, nonconformities, and process efficiency, provides valuable insights into QMS performance. Corrective and preventative actions are implemented based on audit findings and data analysis. Finally, regular calibration of measuring equipment and validation of processes ensure that the QMS operates accurately and reliably. We employ a closed-loop system where observations are turned into recommendations for improvements and the improvements are then verified to ensure the effectiveness. The ongoing monitoring and improvement approach is a hallmark of a robust QMS.

Q 11. Explain your experience with document control.

Document control is a fundamental aspect of ISO 9001/AS9100. It ensures that all documents relevant to the QMS are identified, reviewed, approved, and controlled to prevent the use of obsolete or incorrect information. My experience includes developing and implementing document control procedures, including creating document numbering systems, establishing version control practices, and managing document change requests. I’ve worked with both paper-based and electronic document management systems, ensuring procedures are followed diligently. We utilize a system where all documents are reviewed and approved by designated personnel before release. Changes are tracked through version control, ensuring only the latest approved versions are used. Obsolete documents are removed from circulation and archived appropriately. A robust document control system is vital for maintaining a consistent and reliable QMS.

For example, if a manufacturing process is updated, the corresponding work instructions must be revised, reviewed, approved, and distributed to the relevant personnel. The older version is clearly marked as obsolete and archived to maintain a historical record.

Q 12. Describe your experience with record management.

Record management is the systematic process of controlling and maintaining records that provide evidence of QMS activities. It’s crucial for demonstrating compliance with ISO 9001/AS9100. My experience includes developing and maintaining a comprehensive record management system, including establishing retention policies, implementing storage procedures (both physical and digital), ensuring data security and integrity, and managing record retrieval requests. This includes ensuring records are readily available for audits and other needs. We use a combination of physical filing systems for critical documents and a digital system for easy access and backup. A secure, organized record-keeping system is vital for traceability and demonstrating compliance to auditors.

For instance, records of calibration certificates, inspection reports, training records, and corrective actions are all carefully stored and retained for the duration defined by our retention policy.

Q 13. How do you manage internal and external audits?

Managing internal and external audits is a critical component of maintaining a compliant QMS. Internal audits assess the effectiveness of the QMS, identify areas for improvement, and ensure conformity to the ISO 9001/AS9100 standards. I have extensive experience in planning, conducting, and following up on internal audits. This includes developing audit plans, selecting auditors, performing audits based on defined criteria and checklists, reporting findings, and tracking corrective actions. External audits, conducted by independent certification bodies, verify the organization’s compliance with the standards. My role includes preparing for external audits, gathering necessary documentation, responding to auditor queries, and implementing any corrective actions arising from the audit findings. Successful management of both types of audits ensures continuous improvement and enhances customer confidence.

For example, I coordinate the scheduling of internal audits, ensuring appropriate coverage across all departments and processes. After an audit, I work with the audited departments to implement corrective actions and verify their effectiveness. For external audits, I help gather and organize all required documentation, ensuring its readiness for the auditors.

Q 14. What are the key elements of a management review?

A management review is a formal process for evaluating the performance of the QMS. It involves a senior management team analyzing key performance indicators (KPIs), identifying trends and areas for improvement, and making strategic decisions to enhance the QMS. Key elements include: 1. Review of the QMS performance. This includes analyzing data on customer satisfaction, nonconformities, process performance, and other relevant metrics. 2. Review of the effectiveness of corrective and preventative actions. This involves verifying whether actions taken to address identified problems have been successful. 3. Review of opportunities for improvement. This includes considering ways to improve the QMS’s effectiveness and efficiency. 4. Consideration of resource allocation. Management reviews assess the resources available to the QMS and determine whether additional resources are needed. 5. Communication of the management review findings. This ensures that all relevant personnel are informed about the review’s results and any subsequent actions. The review should result in actionable decisions and clear assignments of responsibility. The findings are documented and provide a valuable record of ongoing QMS improvement. It fosters a culture of continuous improvement and enhances the overall effectiveness of the system.

Q 15. How do you ensure customer satisfaction?

Ensuring customer satisfaction is paramount in any ISO 9001/AS9100 compliant organization. It’s not just about meeting requirements; it’s about exceeding expectations. This involves a multi-faceted approach focusing on understanding customer needs, consistently meeting those needs, and actively seeking feedback for continuous improvement.

- Understanding Customer Needs: This starts with thorough requirement gathering – analyzing contracts, specifications, and engaging in open communication with the customer. For instance, in a project involving aerospace components, we’d conduct thorough design reviews with the customer to ensure we fully grasp their performance, reliability, and safety expectations.

- Meeting Requirements Consistently: This relies on robust processes, well-defined procedures, and effective monitoring. Using process control charts (a key aspect of SPC – see my answer to question 3) allows for early detection of deviations from specifications, preventing non-conforming products from reaching the customer. In a recent project involving the manufacturing of precision bearings, our SPC charts identified a slight shift in a critical dimension, which we addressed immediately through a corrective action.

- Seeking Feedback: Implementing mechanisms for gathering customer feedback – surveys, feedback forms, regular meetings – provides invaluable insight into areas for improvement. For example, we regularly solicit feedback on our delivery performance and product quality from our key clients. This feedback is directly fed into our continuous improvement activities.

Ultimately, customer satisfaction is measured through metrics such as on-time delivery, defect rates, and customer satisfaction surveys. Continuous monitoring and improvement of these metrics are key to achieving and maintaining high levels of customer satisfaction.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with continuous improvement methodologies (e.g., Kaizen, Lean)?

Continuous improvement is the backbone of any effective quality management system. I have extensive experience with methodologies such as Kaizen and Lean, applying them in various projects across different sectors.

- Kaizen (Continuous Improvement): I’ve used Kaizen extensively to foster a culture of small, incremental improvements within teams. This involves identifying areas for improvement, brainstorming solutions, implementing them, and then monitoring the results. For example, we implemented Kaizen in our assembly line, identifying and eliminating bottlenecks through small workflow adjustments, resulting in a significant reduction in cycle time.

- Lean Manufacturing: Lean principles have been instrumental in streamlining our processes, minimizing waste (time, materials, effort), and improving efficiency. We’ve successfully applied Lean techniques such as value stream mapping to identify and eliminate non-value-added activities in our production process. This resulted in a significant reduction in lead times and inventory costs.

My experience encompasses not just the implementation of these methodologies but also the crucial aspect of training and fostering a culture of continuous improvement among all team members. A successful continuous improvement program requires buy-in and participation from everyone involved.

Q 17. Explain your experience with statistical process control (SPC).

Statistical Process Control (SPC) is a crucial tool for monitoring and controlling processes to ensure consistent product quality and reduce variation. My experience involves implementing and interpreting various SPC charts to identify trends, detect anomalies, and prevent defects.

- Control Charts: I’m proficient in using various control charts, including X-bar and R charts, p-charts, and c-charts, depending on the nature of the data (variables or attributes). These charts help visualize process variation over time and identify points where the process is going out of control. For example, in a recent project, we utilized X-bar and R charts to monitor the critical dimensions of manufactured parts, which allowed us to detect and promptly address a subtle shift in the machining process before it resulted in widespread non-conformance.

- Process Capability Analysis: I’ve conducted process capability studies (e.g., Cp, Cpk) to assess the ability of a process to meet specified requirements. This analysis provides valuable data for process improvement initiatives. For example, low Cp and Cpk values indicated that a particular process was not capable of meeting customer specifications. Using this data, we implemented process improvements, like upgrading equipment, ultimately resulting in a significant increase in the process capability.

SPC is not just about using statistical tools; it’s about understanding the data, drawing meaningful conclusions, and taking appropriate actions. It requires a blend of statistical knowledge, process understanding, and problem-solving skills.

Q 18. How do you ensure compliance with regulatory requirements?

Ensuring regulatory compliance is non-negotiable, especially in industries like aerospace, where safety is paramount. My approach involves a proactive and systematic approach to identifying, understanding, and adhering to all applicable regulations.

- Regulatory Identification: We start by conducting a thorough analysis of all relevant regulations, standards, and legal requirements applicable to our products and processes. This includes reviewing industry-specific regulations, such as FAA regulations for aerospace components, and international standards like ISO 9001 and AS9100.

- Implementation and Documentation: Once the regulations are identified, we implement procedures and controls to ensure compliance. This includes detailed documentation of our processes, training personnel on compliance requirements, and maintaining up-to-date records.

- Monitoring and Auditing: Regular internal audits and management reviews are crucial for evaluating our compliance status. This helps identify any gaps in our compliance system and allows for corrective actions to be taken promptly. External audits by certification bodies are also essential for independent verification of compliance.

Non-compliance can have serious consequences, including legal penalties, reputational damage, and even safety hazards. A robust compliance program is not just a regulatory necessity; it’s a fundamental element of good business practice.

Q 19. Describe your experience with supplier management.

Effective supplier management is vital for ensuring the consistent quality of inputs and maintaining a robust supply chain. My experience encompasses all aspects of supplier management, from selection to performance monitoring.

- Supplier Selection: We employ a rigorous supplier selection process that involves evaluating potential suppliers based on various criteria, including quality certifications (e.g., ISO 9001, AS9100), capabilities, capacity, and financial stability. We often conduct supplier audits to verify their quality management systems.

- Performance Monitoring: Ongoing monitoring of supplier performance is essential. This involves reviewing incoming inspection data, tracking defect rates, and regularly communicating with suppliers to address any issues. We use key performance indicators (KPIs) to track supplier performance and identify areas for improvement. For example, we track on-time delivery and quality metrics for all key suppliers.

- Continuous Improvement: We work collaboratively with our suppliers to identify and implement continuous improvement initiatives. This may involve sharing best practices, providing technical assistance, and jointly working on projects to improve product quality and efficiency.

Maintaining strong supplier relationships and fostering a collaborative environment are crucial for a successful supplier management program. It’s not just about compliance; it’s about building strategic partnerships to ensure a reliable and high-quality supply chain.

Q 20. Explain your understanding of process mapping.

Process mapping is a fundamental tool for understanding and improving processes. It provides a visual representation of how work flows through an organization, identifying steps, decision points, and potential areas for improvement.

I’m experienced in creating various types of process maps, including flowcharts, swim lane diagrams, and value stream maps. For example, a flowchart would show the sequence of steps in a manufacturing process, while a swim lane diagram would highlight the responsibilities of different teams or departments involved. Value stream maps, particularly useful in lean implementations, focus on identifying and eliminating waste in a process.

The benefits of process mapping include:

- Improved Process Understanding: Visualizing the process makes it easier to identify bottlenecks, redundancies, and areas for improvement.

- Enhanced Communication: Process maps serve as a common language for everyone involved, fostering better understanding and collaboration.

- Facilitated Process Improvement: Identifying process weaknesses through mapping enables targeted improvement initiatives.

Process mapping is an iterative process. The map itself is a living document that evolves as the process changes and improves. This dynamic nature allows for continuous improvement and ensures the map stays relevant and useful.

Q 21. How do you measure the effectiveness of your QMS?

Measuring the effectiveness of a Quality Management System (QMS) requires a balanced approach, combining quantitative and qualitative data. It’s not enough to simply have a QMS in place; you need to demonstrate its effectiveness in achieving organizational objectives.

- Key Performance Indicators (KPIs): We track various KPIs to measure the effectiveness of our QMS. These include metrics such as defect rates, customer satisfaction scores, on-time delivery performance, and the effectiveness of corrective and preventive actions. These KPIs are reviewed regularly in management review meetings.

- Internal Audits: Internal audits provide an independent assessment of the QMS’s effectiveness and compliance with the standard. Findings from internal audits are used to drive improvement initiatives.

- Management Review: The management review is a critical process for assessing the overall performance of the QMS. It involves reviewing KPI data, audit findings, customer feedback, and other relevant information to identify areas for improvement and adjust the QMS as needed.

- Customer Feedback: Direct feedback from customers provides valuable insights into the effectiveness of the QMS in meeting customer requirements and expectations.

By using a combination of these approaches, we get a comprehensive view of the QMS’s effectiveness, allowing us to continuously improve and adapt the system to meet evolving business needs and customer expectations. Regular monitoring and review are vital to ensure that our QMS remains a valuable tool for achieving organizational success.

Q 22. What are your strengths and weaknesses in quality management?

My strengths in quality management lie in my deep understanding of ISO 9001 and AS9100 standards, coupled with practical experience in implementing and auditing these systems. I excel at identifying potential risks, developing preventative measures, and leading teams to achieve consistent quality. I’m adept at root cause analysis, using tools like the 5 Whys and Fishbone diagrams to address quality issues effectively. My experience spans various manufacturing environments, allowing me to adapt my approach to different contexts.

One area I’m actively working to improve is my delegation skills. While I’m confident in my abilities, I recognize that effectively delegating tasks and empowering team members leads to greater efficiency and develops individual capabilities. I’m currently implementing strategies like creating clear task assignments and providing regular feedback to improve in this area.

Q 23. Describe a time you had to deal with a major quality issue.

In a previous role, we experienced a significant quality issue with a batch of manufactured components. An unexpectedly high failure rate was detected during final testing. This immediately triggered our corrective action process. First, we isolated the affected batch and prevented further shipment. We then conducted a thorough root cause analysis, engaging cross-functional teams from engineering, production, and quality control. Through detailed investigation, we identified a flaw in the calibration of a crucial piece of testing equipment. This miscalibration led to incorrect readings, allowing faulty components to pass inspection. We corrected the calibration, implemented a verification process to prevent recurrence, and performed a full re-inspection of the affected batch. We also implemented preventative measures, improving our calibration procedures and adding automated checks to ensure future accuracy.

Q 24. How do you prioritize your tasks in a busy environment?

In a busy environment, I prioritize tasks using a combination of methods. I start by identifying urgent and important tasks using an Eisenhower Matrix (Urgent/Important). I then break down larger tasks into smaller, manageable steps. I use project management tools to track progress, deadlines, and dependencies. This allows for better visualization of workload and prioritization. Finally, I regularly review my task list and adjust priorities as needed. For example, if an unexpected customer issue arises, I’ll adjust my schedule to address it promptly, understanding that customer satisfaction is paramount.

Q 25. What is your experience with AS9100 specific requirements?

My experience with AS9100 encompasses several years of working with companies in the aerospace industry. I understand the nuances of the standard, including its focus on the aerospace safety and reliability requirements. I’m familiar with requirements related to counterfeit parts prevention, configuration management, and process control within this highly regulated sector. I have practical experience auditing AS9100 compliant organizations and assisting in the implementation of corrective and preventive actions (CAPA). Specifically, I’ve been involved in the development and maintenance of quality management systems that meet the stringent requirements of AS9100, including documentation control and process audits.

Q 26. Explain the concept of First Article Inspection (FAI).

First Article Inspection (FAI) is a critical process, particularly in manufacturing, where it verifies the conformance of the first production articles to the design specifications. It’s a pre-production check, ensuring that the manufacturing process is producing parts that meet the requirements before full-scale production begins. A thorough FAI involves a detailed examination of the initial production parts, comparing them against drawings, specifications, and other relevant documentation. It might involve dimensional checks, material testing, and functional testing. A successful FAI provides confidence that the manufacturing process is correctly set up and producing parts as intended, minimizing defects and rework later on. An FAI report documents the findings and is essential for production approval. Think of it as a quality ‘gate’ before mass production.

Q 27. Describe your understanding of traceability in a manufacturing environment.

Traceability in a manufacturing environment refers to the ability to track a product or component through all stages of its lifecycle, from raw material acquisition to final delivery and beyond. This involves maintaining detailed records that allow for identification of the origin, processing, handling, and location of each item. Good traceability is crucial for several reasons: It allows for quick identification and isolation of faulty products (recall situations), enables effective analysis of defects and root causes, ensures compliance with regulations, and supports product warranty claims. Methods for maintaining traceability include using unique identification numbers (serial numbers, barcodes), maintaining detailed manufacturing records, and employing robust tracking systems. Think of it as creating a complete ‘history’ for every item produced. This is essential for regulatory compliance (think aerospace or medical device industries).

Q 28. How do you handle customer complaints effectively?

Handling customer complaints effectively involves a structured approach. First, I acknowledge the complaint promptly and empathize with the customer’s situation. Then, I gather all necessary information about the complaint, including details of the product, the nature of the issue, and the customer’s expectations. I document the complaint thoroughly. Next, I investigate the root cause of the problem, often using the tools and techniques mentioned previously (5 Whys, Fishbone diagrams). Based on the investigation, I develop a solution and communicate it to the customer, keeping them informed every step of the way. It’s important to resolve the issue fairly and efficiently. Finally, I implement corrective actions to prevent similar issues from occurring in the future. It’s crucial to maintain open communication throughout the entire process, focusing on customer satisfaction as the primary goal. A well-handled complaint can turn a negative experience into an opportunity to improve processes and strengthen customer relationships.

Key Topics to Learn for ISO 9001/AS9100 Interview

- Understanding the ISO 9001 Quality Management System: Focus on the core principles, the Plan-Do-Check-Act (PDCA) cycle, and its application in various contexts.

- AS9100 Specific Requirements: Explore the additions and modifications AS9100 brings to the ISO 9001 framework, particularly concerning aviation, space, and defense industries.

- Internal Audits and Corrective Actions: Understand the process of conducting internal audits, identifying nonconformities, and implementing effective corrective and preventive actions (CAPA).

- Document Control and Record Management: Learn the importance of maintaining a controlled document system and how to manage records effectively to meet regulatory requirements.

- Risk-Based Thinking: Grasp the concept of proactively identifying and mitigating risks to prevent nonconformities and improve the effectiveness of the quality management system.

- Process Approach: Understand how to apply a process approach to identify and manage key processes within an organization to ensure efficiency and effectiveness.

- Continuous Improvement: Familiarize yourself with various continuous improvement methodologies (e.g., Kaizen, Lean) and their practical application within an ISO 9001/AS9100 framework.

- Management Review: Understand the role and purpose of management reviews in driving continuous improvement and ensuring the effectiveness of the quality management system.

- Practical Application of Quality Tools: Demonstrate familiarity with common quality tools such as Pareto charts, fishbone diagrams, and control charts.

- Problem-Solving Methodologies: Be prepared to discuss your approach to problem-solving, including root cause analysis techniques, and demonstrate how you’ve applied them in a quality management context.

Next Steps

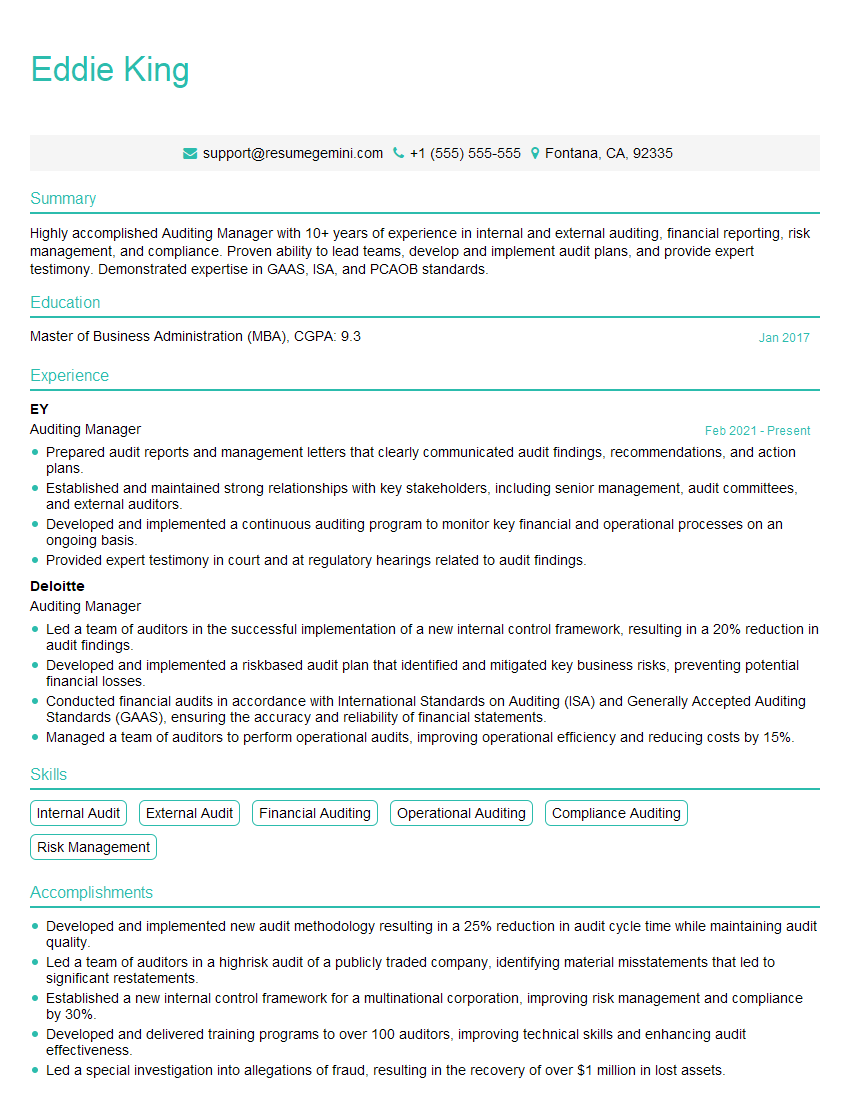

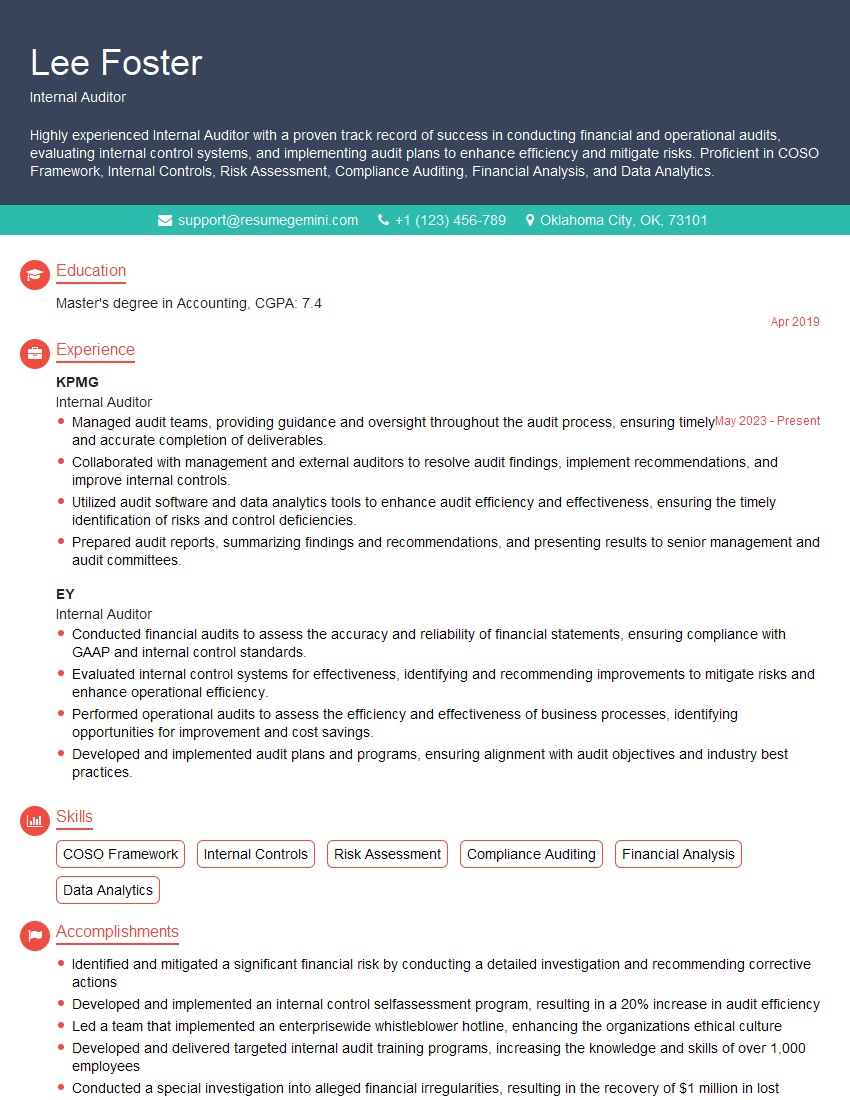

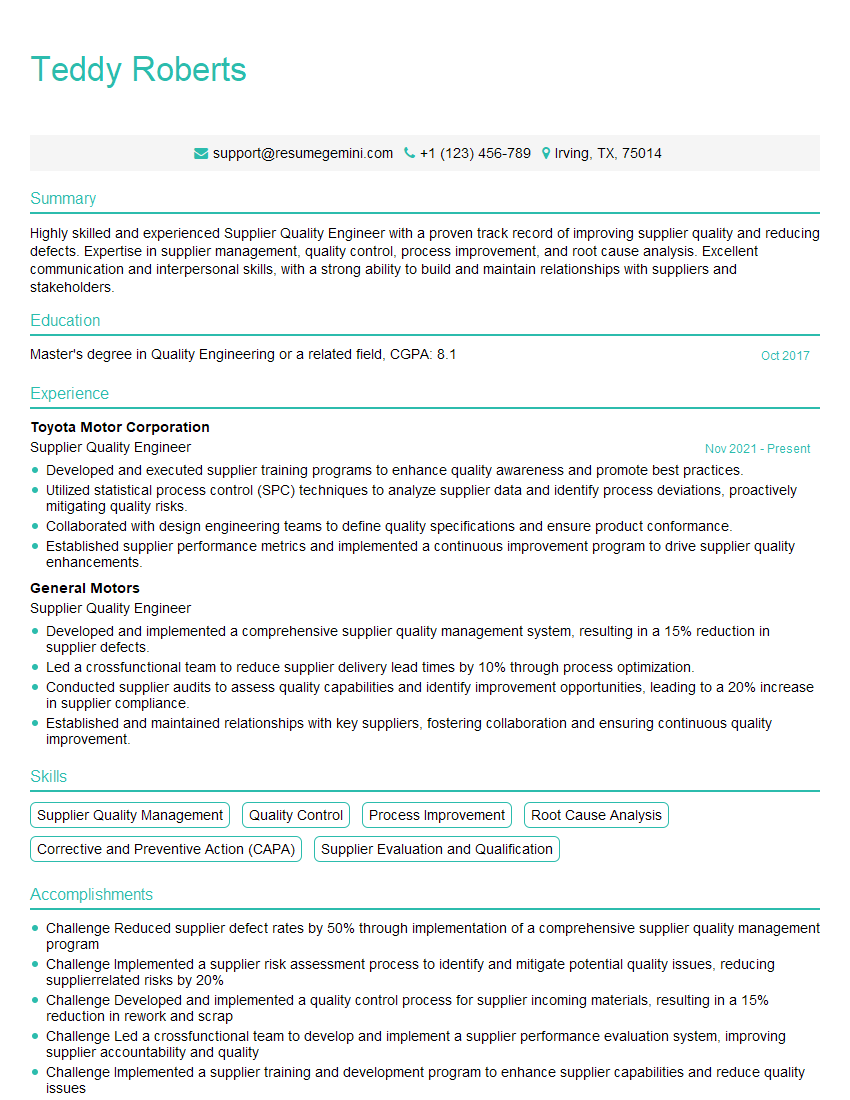

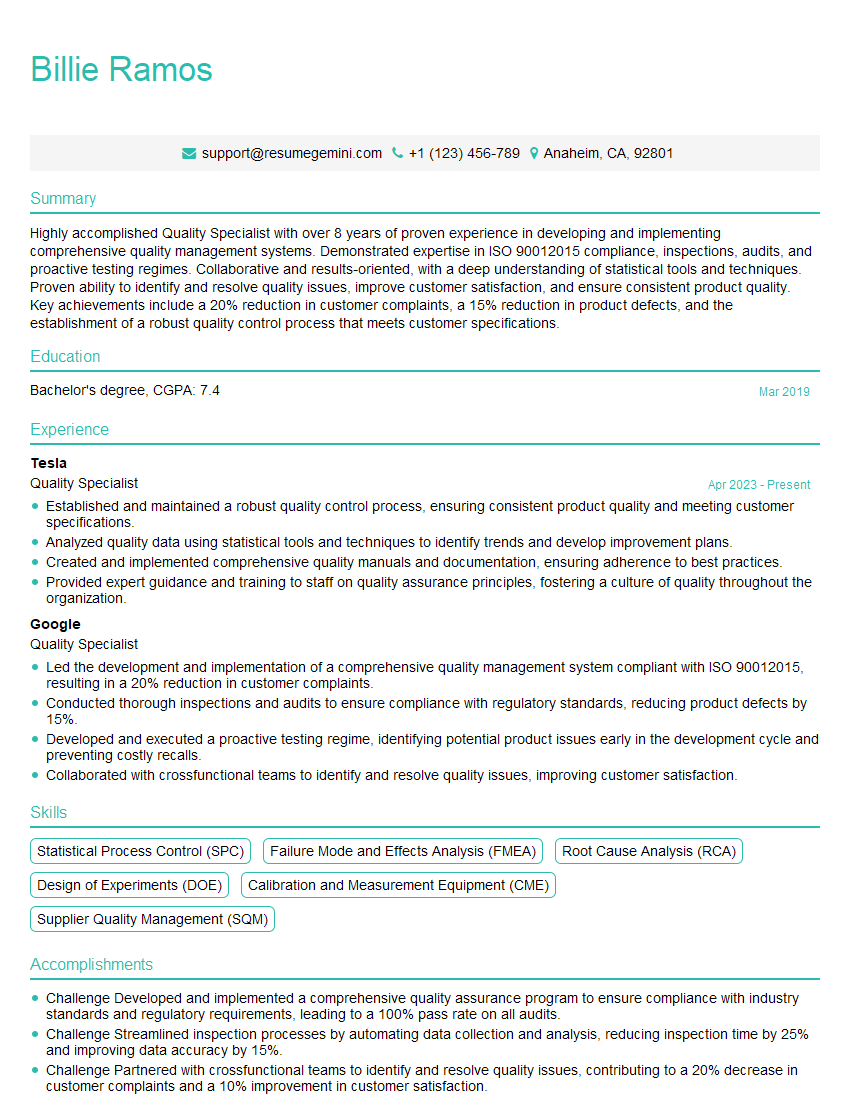

Mastering ISO 9001/AS9100 significantly enhances your career prospects in various industries, particularly those requiring stringent quality control and regulatory compliance. It demonstrates your commitment to quality and your understanding of best practices. To maximize your job search success, focus on creating an ATS-friendly resume that highlights your relevant skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. They provide examples of resumes tailored to ISO 9001/AS9100, helping you present your qualifications in the best possible light. Take advantage of these tools and resources to propel your career forward.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi I am a troller at The aquatic interview center and I suddenly went so fast in Roblox and it was gone when I reset.

Hi,

Business owners spend hours every week worrying about their website—or avoiding it because it feels overwhelming.

We’d like to take that off your plate:

$69/month. Everything handled.

Our team will:

Design a custom website—or completely overhaul your current one

Take care of hosting as an option

Handle edits and improvements—up to 60 minutes of work included every month

No setup fees, no annual commitments. Just a site that makes a strong first impression.

Find out if it’s right for you:

https://websolutionsgenius.com/awardwinningwebsites

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good