The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Jewelry Design and Fabrication interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Jewelry Design and Fabrication Interview

Q 1. Describe your experience with different jewelry-making techniques (e.g., casting, forging, soldering).

My experience in jewelry fabrication spans a wide range of techniques, each contributing to the unique characteristics of a finished piece. Casting, for example, allows for intricate designs and mass production. I’m proficient in both lost-wax casting, where a wax model is meticulously created and then encased in investment material before melting out the wax to leave a mold for molten metal, and centrifugal casting, a faster method ideal for simpler designs. Forging, on the other hand, is a more hands-on approach, where metal is shaped using hammers and other tools. It’s perfect for creating unique textures and strengthening the metal. I often use forging to create textured surfaces or unique forms for pendants. Soldering is crucial for joining different metal components. I’m skilled in various soldering techniques, including torch soldering and using different types of solder for various metals, ensuring clean, strong joins that are invisible to the naked eye. For instance, I recently used a combination of forging and soldering to craft a hammered silver cuff bracelet with intricate soldered details.

Q 2. Explain your proficiency in CAD software for jewelry design (e.g., Rhino, Matrix, Jewelcad).

CAD software is integral to my design process. I’m highly proficient in Rhino, a powerful 3D modeling software, which I use to create precise, detailed models before fabrication. I leverage its capabilities to design complex geometries, render photorealistic images, and generate detailed technical drawings. While I haven’t extensively used Matrix or JewelCAD, I’m familiar with their functionalities and understand the industry standards for CAD-based jewelry design. My workflow typically involves sketching initial concepts, then refining them digitally in Rhino. The software allows me to experiment with different design variations quickly and precisely, and to analyze the structural integrity of the piece before committing to fabrication. For example, I recently used Rhino’s rendering capabilities to present a client with photorealistic images of their custom engagement ring design in different lighting conditions before production.

Q 3. What are the common types of metals used in jewelry making, and their properties?

The choice of metal significantly impacts a piece’s aesthetics, durability, and cost. Some common metals include:

- Gold (various karats): Known for its malleability, luxurious appearance, and resistance to tarnish. 18k and 24k gold are popular choices, with 18k being a good balance of durability and purity. The higher the karat, the softer the gold.

- Silver (sterling silver): A more affordable option than gold, sterling silver (92.5% pure silver) is durable, readily available, and has a beautiful luster. It requires periodic polishing to maintain its shine.

- Platinum: Highly durable, hypoallergenic, and resistant to scratches and tarnish. It’s denser and more expensive than gold.

- Palladium: A white metal similar to platinum, but slightly less expensive and durable. It’s increasingly popular as a platinum alternative.

- Titanium: A lightweight, strong, and biocompatible metal. Its durability and modern aesthetic make it a favorite for contemporary designs. Its main drawbacks are its difficulty in working with and the resulting high costs

The properties of each metal, including its hardness, malleability, and color, influence design choices and fabrication methods.

Q 4. How do you select appropriate gemstones for a specific design?

Selecting gemstones is a crucial step that involves considering several factors:

- Design aesthetic: The gemstone’s color, cut, and clarity must complement the overall design concept. For instance, a vibrant emerald might be perfect for a statement ring, while a delicate diamond would suit a minimalist pendant.

- Client preferences: Client preferences regarding color, size, and type of gemstone are paramount. I always engage clients in discussions about their desires and style, ensuring the final choice reflects their personality.

- Budget: Gemstone prices vary widely depending on their type, size, quality, and treatment. We carefully discuss budget constraints and find gemstones that meet both the aesthetic and financial needs.

- Durability: The gemstone’s hardness (measured on the Mohs scale) and durability are vital, especially for everyday wear. Harder stones like sapphires and diamonds are preferred for rings, while softer stones like opals may be better suited to less-worn pieces.

For a recent project, a client wanted a necklace with a deep blue gemstone. After discussing their budget and preferences, we chose a vibrant blue sapphire that balanced beauty, durability, and cost-effectiveness.

Q 5. Describe your process for creating a wax model for casting.

Creating a wax model for casting is a meticulous process crucial for the final piece’s accuracy and detail. My process involves:

- Design refinement: The initial CAD design is further refined, ensuring all proportions and details are perfect.

- Wax carving (or 3D printing): I may use either traditional wax carving techniques, building the wax model layer by layer with specialized tools, or 3D printing technology for highly complex designs. 3D printing provides precise replication of the digital model.

- Detailing and sprues: Once the basic shape is formed, I meticulously add fine details using specialized tools. Sprue channels are created to allow for molten metal to flow into the mold during casting.

- Inspection and cleanup: The wax model is carefully inspected for any imperfections, and any necessary adjustments are made before moving to the investment casting phase. This stage eliminates any errors in the final product.

For example, in a recent project involving a detailed dragonfly pendant, I used a combination of 3D printing for the body and hand carving for the delicate wings to achieve the desired level of detail.

Q 6. Explain your experience with stone setting techniques (e.g., prong, bezel, channel).

Stone setting is a specialized skill requiring precision and care. I’m proficient in various techniques, including:

- Prong setting: Metal prongs are carefully shaped and secured around the gemstone, offering good visibility and security. It’s a popular choice for diamonds and other gemstones.

- Bezel setting: A metal rim completely encircles the gemstone, protecting it from damage and providing a smooth, secure setting. Ideal for stones with delicate edges.

- Channel setting: Gemstones are set in a channel created in the metal, resulting in a sleek, continuous line of stones. Often used in wedding bands.

The choice of setting depends on factors like the gemstone’s shape, size, and the overall design. I always select the technique that best complements the design and ensures the stone’s security and brilliance. For instance, I recently used a prong setting for a client’s diamond ring, emphasizing the stone’s brilliance, and a bezel setting for a cabochon opal pendant for protection and a smooth finish.

Q 7. How do you ensure the quality and durability of your finished jewelry?

Ensuring quality and durability is paramount. My approach involves:

- Material selection: Choosing high-quality metals and gemstones that are appropriate for the intended use. The karat of the gold, the purity of the silver, and the hardness of the gemstones are all critical considerations.

- Precision fabrication: Careful attention to detail during every stage of the process, from wax modeling to finishing, minimizing imperfections and ensuring structural integrity. For example, I always inspect for potential stress points during soldering to avoid future breakage.

- Quality control: Thorough inspection of the finished piece for any flaws, checking for proper stone settings, secure soldering, and a smooth surface finish. I regularly use magnification tools for this process.

- Finishing and polishing: Careful finishing and polishing techniques to enhance the piece’s beauty and protect it from wear and tear. This ensures that the piece’s shine and beauty will last for years to come.

My commitment to quality control means that I always carefully check every piece before it leaves my workshop. I aim for each piece to be not only aesthetically pleasing but also resilient enough to withstand daily wear.

Q 8. What are your preferred finishing techniques for metals?

My preferred finishing techniques for metals depend heavily on the design and desired aesthetic. However, I prioritize techniques that enhance the piece’s beauty and durability. I frequently utilize a combination of methods to achieve the perfect finish.

- High Polish: This creates a mirror-like shine, ideal for showcasing the brilliance of gemstones or the intricate details of a design. I achieve this using progressively finer grades of polishing compounds and mops.

- Satin Finish: This provides a soft, subtle sheen, which is excellent for minimizing scratches and creating a more understated elegance. I use various brushes, depending on the metal’s hardness and the desired texture.

- Brushed Finish: Offers a directional texture, often used to add visual interest and mask minor imperfections. Different brush types create varied textures, from fine lines to coarser strokes.

- Antiqued Finish: This involves chemical or mechanical treatments to create a darkened, aged look, emphasizing the piece’s depth and character. This technique is particularly popular with silver and sterling silver jewelry.

The choice of finish isn’t arbitrary; it’s an integral part of the design process, influencing the overall feel and impact of the piece.

Q 9. Describe your experience with different types of finishes (e.g., polishing, brushing, satin).

My experience spans a wide range of metal finishes. I’ve worked extensively with:

- Polishing: From initial rough polishing with coarse compounds to the final mirror-like shine with fine rouge, I’ve mastered the process for various metals like gold, silver, and platinum. I understand the importance of using appropriate compounds and techniques to avoid damaging delicate details or leaving swirl marks.

- Brushing: I’m proficient in using different types of brushes – wire wheels, bristle brushes, and even specialized abrasive pads – to create various brushed finishes. This allows me to adapt the texture to the design, ranging from a fine hairline brush to a more pronounced, coarse texture.

- Satin Finishing: This is a more nuanced technique requiring precision and control. I utilize specialized brushes and compounds to achieve an even, smooth satin finish without compromising the metal’s integrity. This technique is great for modern minimalist designs.

- Other finishes: My skillset also includes techniques like sandblasting, bead blasting, and chemical patinas for creating unique textures and colors. For example, I once created a stunning necklace by combining a high polish on the central pendant with a brushed finish on the chain for a sophisticated contrast.

Each finish requires a different approach and understanding of the metal’s properties. My experience ensures I can select and execute the best finish for any design, enhancing its beauty and longevity.

Q 10. How do you troubleshoot common problems encountered during jewelry fabrication?

Troubleshooting is a crucial aspect of jewelry fabrication. Encountering problems is inevitable, and my approach is systematic and methodical. I approach troubleshooting by using a combination of observation, testing, and experience.

- Identify the problem: Carefully examine the piece, noting the exact nature of the issue. Is it a dimensional problem? A finish issue? A structural weakness?

- Analyze the cause: Consider the steps involved in creating the piece. Did the problem arise during design, fabrication, or finishing? What specific actions or materials may have contributed to the issue?

- Develop solutions: Based on the analysis, I devise appropriate solutions. This might involve adjusting the design, modifying fabrication techniques, selecting different materials or finishes, or even employing alternative tools.

- Test and refine: I test my solutions on a small scale or a similar piece before implementing them on the original. This allows for iterative refinements and minimizes potential for further damage.

For instance, if a soldering joint is weak, I would assess the solder type, the temperature of the flame, and the cleanliness of the metal surfaces before attempting a repair. Experience helps in quickly identifying the root cause, allowing for efficient and effective solutions.

Q 11. Describe your experience with different soldering techniques.

I’m proficient in various soldering techniques, selecting the method based on the metals involved, the design’s intricacy, and the desired outcome.

- Torch Soldering: This is a common technique using a propane/oxygen torch. I’m adept at controlling the flame’s temperature and size for precise soldering of delicate pieces.

- Induction Soldering: This technique utilizes electromagnetic induction to heat the metal, allowing for quicker and more controlled soldering, especially beneficial for larger or thicker pieces.

- Laser Soldering: For extremely delicate work, I use laser soldering, which offers pinpoint accuracy and minimal heat spread, preserving the integrity of the surrounding metal.

- Different solders: I understand the properties of various solders—hard, medium, and easy—and use the appropriate solder for the job, ensuring a strong and aesthetically pleasing joint. For example, hard solder might be used for structural elements, while easy solder is preferred for delicate components.

Proper flux application is crucial in all soldering techniques to ensure a clean and strong bond. I meticulously clean the metal surfaces before soldering to remove oxides and contaminants which can hinder a successful joint.

Q 12. Explain your understanding of metal alloys and their implications for jewelry design.

Understanding metal alloys is fundamental to jewelry design. The properties of an alloy—its hardness, color, workability, and durability—significantly influence the design possibilities and the longevity of the final piece.

- Gold Alloys: The karat (K) rating indicates the percentage of pure gold. 18K gold is 75% pure gold, while 14K is approximately 58.3%. Higher karat gold is softer, more malleable, and holds its shape less easily but exhibits a brighter color. Lower karat gold alloys are harder and more durable, suitable for high-wear pieces.

- Silver Alloys: Sterling silver (92.5% silver) is the most common alloy for silver jewelry. The addition of other metals increases its hardness and durability compared to pure silver, which is very soft.

- Platinum Alloys: Platinum is naturally strong and durable, often alloyed with iridium or other metals to enhance its hardness and other properties.

- Other Alloys: Other alloys, such as nickel silver or brass, are used for base metals, offering cost-effectiveness and specific material properties.

The choice of alloy is a critical design decision, balancing aesthetics, durability, and cost. A designer must carefully consider the metal’s properties to ensure the final piece meets the intended function and aesthetic.

Q 13. How do you determine the karat weight of gold?

The karat weight of gold is determined by assaying, a process that measures the proportion of pure gold in an alloy. There are several methods:

- Assaying by fire: This traditional method involves melting a sample of the gold alloy with specific fluxes and lead to separate the gold from other metals. The remaining gold is weighed to determine its percentage and thus, the karat weight.

- X-ray fluorescence (XRF) spectroscopy: This non-destructive method uses X-rays to analyze the sample and determine the elemental composition, providing the karat weight quickly and accurately.

- Acid testing: This is a less precise method, used for quick estimations. Different acids react differently with various gold karats, allowing for a rough approximation.

Assay offices or reputable jewelers usually perform the assaying. The result is stamped on the piece (e.g., ’18K’ or ‘750’), verifying its gold content.

Q 14. What safety precautions do you take while working with jewelry-making tools and materials?

Safety is paramount in jewelry making. I strictly adhere to the following precautions:

- Eye protection: I always wear safety glasses or a face shield to protect my eyes from flying debris, sparks, and chemical splashes.

- Respiratory protection: When working with chemicals or dust, I use a respirator to avoid inhaling harmful particles.

- Hearing protection: Loud machinery like polishing wheels necessitate the use of earplugs or earmuffs to prevent hearing damage.

- Hand protection: I always wear gloves when handling chemicals or abrasive materials to protect my skin from irritation or burns.

- Proper ventilation: I ensure adequate ventilation in my workspace to minimize the risk of inhaling toxic fumes from soldering or polishing compounds.

- Tool maintenance: I regularly inspect and maintain my tools to prevent accidents. Sharp tools are properly stored, and machinery is kept in good working condition.

- Proper disposal of waste: I dispose of chemicals and waste materials following all safety regulations and environmental guidelines.

Safety is not just about preventing injuries; it’s about respecting the materials, tools and myself to create high-quality jewelry without risk.

Q 15. Describe your experience with jewelry repair and restoration.

Jewelry repair and restoration is a crucial aspect of my work, requiring a blend of technical skill, artistic sensibility, and a deep understanding of materials. It’s more than just fixing a broken clasp; it’s about preserving the history and sentimental value embedded in a piece.

My experience encompasses a wide range of repairs, from simple solder repairs on broken chains and prongs to intricate stone resetting and the complete restoration of antique pieces. For instance, I once restored a Victorian locket that had a severely damaged hinge and tarnished gold. This involved carefully cleaning the locket, crafting a new hinge using historically accurate techniques, and then applying a patina to match the existing gold. I often work with clients to understand the emotional significance of their pieces, ensuring the repair not only restores the functionality but also respects the piece’s original craftsmanship.

I regularly handle repairs involving various metals, including gold, silver, platinum, and even less common alloys. My expertise extends to understanding the different properties of these metals and how to best approach each repair based on the metal’s characteristics. I also have experience in repairing damage to gemstones, which requires meticulous care and often specialized tools to minimize further damage.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How familiar are you with industry standards and regulations related to jewelry making?

I am intimately familiar with industry standards and regulations related to jewelry making, including hallmarking, karat marking, and ethical sourcing of gemstones. My knowledge spans international standards as well as local regulations. For example, I understand the importance of adhering to hallmarking regulations which help ensure the purity of the metal used in the jewelry. This guarantees consumer trust and protects against fraud. I am also deeply committed to ethical sourcing of gemstones, ensuring I only work with suppliers that prioritize responsible mining practices and respect human rights.

Furthermore, I am up-to-date on safety regulations regarding the handling of chemicals and tools used in jewelry making, ensuring a safe working environment for myself and my colleagues. This includes proper ventilation, the use of personal protective equipment, and safe disposal of hazardous materials. Staying informed about these regulations is an ongoing process, and I consistently participate in professional development to remain compliant and up-to-date with best practices.

Q 17. What is your experience working with different types of gemstones (e.g., diamonds, sapphires, emeralds)?

My experience working with different types of gemstones is extensive. I have worked with a broad spectrum of gemstones, from the ‘big four’ – diamonds, sapphires, rubies, and emeralds – to a multitude of other precious and semi-precious stones. Each stone presents unique challenges and opportunities in terms of cutting, setting, and care.

For example, working with diamonds requires a detailed understanding of their grading system (the 4Cs: cut, clarity, color, and carat weight) and how these factors influence the stone’s brilliance and value. Sapphires and emeralds, on the other hand, require careful handling due to their potential for fracturing. I am adept at choosing the appropriate setting style for each stone, ensuring its security and maximizing its beauty. I’m also trained in identifying treated versus untreated stones and am committed to transparency and honesty in my dealings with clients.

Beyond the common gemstones, I have worked with many other varieties, including opals, topazes, garnets, and many more, developing a keen eye for color, clarity, and the unique characteristics of each.

Q 18. How do you handle customer feedback and incorporate it into your design process?

Customer feedback is invaluable to my design process. I actively solicit feedback throughout the design process, from initial concept sketches to the final product. I believe in open communication and encourage clients to share their thoughts and preferences at every stage. I find that incorporating feedback early on prevents costly revisions later and ensures a higher client satisfaction rate.

For example, if a client expresses concern about the size of a particular element in a design, I will revise the sketch accordingly. If a client prefers a different gemstone setting, I will explore different options and present them with various alternatives. This collaborative approach ensures that the final piece reflects the client’s vision and expectations.

I also actively seek feedback even after the piece is delivered. This helps me understand my strengths and weaknesses, leading to continuous improvement in my design and customer service.

Q 19. Describe your experience with creating custom designs based on client specifications.

Creating custom designs based on client specifications is a cornerstone of my work. I thrive on the challenge of translating a client’s vision into a tangible piece of jewelry. The process begins with an in-depth consultation to understand the client’s needs, preferences, and budget.

I start by gathering information about their desired style, gemstones, metals, and any other specific requirements. Then, I create sketches and renderings to visualize the design, incorporating feedback from the client at each stage. This iterative process ensures that the final design meets the client’s expectations. Once the design is finalized, I proceed to the fabrication stage, carefully selecting materials and employing precise techniques to bring the design to life.

A recent example involved designing a bespoke engagement ring. The client provided inspiration images and described her preferred style, incorporating family heirlooms. We worked together to select the perfect diamond, and I designed a custom setting that both complemented the stone and incorporated elements from her heirloom pieces. The result was a unique and meaningful ring that exceeded her expectations.

Q 20. How do you manage deadlines and prioritize tasks in a fast-paced environment?

Managing deadlines and prioritizing tasks in a fast-paced environment is crucial in jewelry design and fabrication. I use a project management system to track all my projects, deadlines, and tasks. This system helps me visualize my workload and prioritize tasks based on urgency and importance. I break down large projects into smaller, manageable tasks, making them less daunting and easier to track.

For instance, I might allocate specific days for tasks such as design, material sourcing, fabrication, and quality control. This structured approach ensures that all aspects of the project are given due attention and completed within the allocated timeframe. I also proactively communicate with clients regarding potential delays and maintain open lines of communication to manage expectations effectively. This helps to mitigate stress and build trust.

Furthermore, I am adept at adapting to unexpected changes or challenges. I’m not afraid to adjust my schedule or seek assistance from colleagues when necessary, ensuring projects are delivered on time and to a high standard.

Q 21. Explain your understanding of design principles relevant to jewelry (e.g., proportion, balance, harmony).

Design principles are fundamental to creating aesthetically pleasing and functional jewelry. Understanding and applying these principles is essential for crafting pieces that are both beautiful and well-balanced.

- Proportion: This refers to the relative size and scale of different elements in a design. A well-proportioned piece feels harmonious and visually appealing. For instance, the size of the central gemstone should be in proportion to the surrounding elements, creating a balanced aesthetic.

- Balance: Balance refers to the visual equilibrium of a design. It can be symmetrical (mirror image) or asymmetrical (visually balanced but not identical). A well-balanced piece feels stable and visually satisfying.

- Harmony: Harmony refers to the overall unity and coherence of a design. This is achieved by using consistent colors, textures, and shapes that complement each other. A harmonious piece feels cohesive and visually pleasing.

- Emphasis: This involves highlighting a specific element in the design to draw the viewer’s eye. This might involve using a larger gemstone, a different metal, or a unique texture.

- Rhythm: Rhythm is created by the repetition of elements, such as shapes, textures, or colors. This can create a sense of movement and visual interest.

By understanding and skillfully applying these principles, I create jewelry that is not only beautiful but also expresses a sense of visual order and harmony.

Q 22. How do you stay updated with the latest trends and techniques in jewelry design and fabrication?

Staying ahead in the dynamic world of jewelry design requires a multi-pronged approach. I actively engage with several key resources to ensure I’m always up-to-date on the latest trends and techniques.

Industry Publications and Trade Shows: I religiously follow leading jewelry magazines like JCK and National Jeweler, and attend major trade shows like JCK Las Vegas and Couture. These events offer invaluable insights into emerging trends, new materials, and innovative techniques.

Online Communities and Platforms: I’m actively involved in online forums, social media groups (like Instagram and Pinterest), and professional networking sites (like LinkedIn) dedicated to jewelry design and fabrication. These platforms provide a constant stream of inspiration, new ideas, and opportunities to learn from other designers and artisans.

Workshops and Courses: Continuous learning is paramount. I regularly participate in workshops and online courses focusing on specific techniques, software proficiency, or emerging materials, like 3D printing in jewelry or new gemstone cutting methods. This ensures I stay at the forefront of innovation.

Competitor Analysis: I also pay close attention to the work of other established and up-and-coming jewelry designers, studying their aesthetics, techniques, and marketing strategies. This helps me identify potential opportunities and avoid replicating existing designs.

This holistic approach allows me to maintain a comprehensive understanding of the ever-evolving landscape of jewelry design and fabrication, and creatively apply these advancements to my own work.

Q 23. What software and tools are you proficient in?

My proficiency spans a range of software and tools crucial for efficient and high-quality jewelry design and fabrication. This includes:

CAD Software: Rhino, Matrix, and JewelCAD are my primary tools for 3D modeling, design refinement, and rendering photorealistic images.

2D Design Software: Adobe Photoshop and Illustrator are invaluable for creating initial sketches, developing design concepts, and preparing marketing materials.

CAM Software: I’m experienced with software that translates 3D models into instructions for CNC machines, enabling precise and efficient fabrication.

Fabrication Tools: My expertise extends to a wide range of traditional and advanced fabrication tools, including wax carving tools, casting equipment (lost-wax casting), laser welders, 3D printers, various metalworking hand tools (files, hammers, saws etc.), and polishing and finishing equipment.

My ability to seamlessly integrate these digital and physical tools allows for a fluid and efficient workflow, from initial concept to final product.

Q 24. Describe your experience with designing for different styles of jewelry (e.g., contemporary, vintage, ethnic).

My design experience encompasses a broad spectrum of styles, allowing me to adapt to diverse client preferences and project requirements.

Contemporary: I’m comfortable designing modern, minimalist pieces featuring clean lines, geometric shapes, and unconventional materials. For example, I recently designed a series of necklaces using recycled silver and ethically-sourced gemstones, showcasing a contemporary focus on sustainability.

Vintage: I’m adept at replicating and reimagining vintage designs, drawing inspiration from Art Deco, Victorian, and Edwardian eras. This involves meticulous research into historical techniques and aesthetics to faithfully recreate or subtly update classic styles. I once restored and redesigned a family heirloom brooch, blending vintage charm with modern functionality.

Ethnic: My work also incorporates influences from various ethnic styles, incorporating traditional motifs and techniques from around the world. For example, I have designed several pieces drawing inspiration from traditional Indian jewelry, using intricate filigree work and colorful gemstones.

This versatility ensures I can cater to a diverse clientele and tackle projects requiring unique stylistic approaches.

Q 25. How do you handle design challenges?

Design challenges are inevitable, but they are also opportunities for innovation and growth. My approach to handling them is systematic and creative.

Thorough Understanding: I begin by carefully analyzing the challenge, identifying its root causes, and understanding the constraints (budget, materials, time, etc.).

Brainstorming and Ideation: I employ brainstorming techniques, sketching numerous ideas, and exploring different approaches. This stage encourages creative problem-solving, thinking outside the box.

Research and Experimentation: If the challenge involves a new material or technique, I undertake thorough research and experimentation to determine its feasibility and optimize its use.

Iteration and Refinement: I create prototypes and iteratively refine my designs based on feedback and practical testing. This ensures the final product meets the design brief and functional requirements.

Collaboration: If the challenge requires specialized expertise, I readily collaborate with other artisans or professionals to overcome the obstacles.

By following this structured approach, I ensure that design challenges are not roadblocks, but stepping stones toward creating unique and successful pieces.

Q 26. Explain your process for creating a detailed jewelry design sketch or rendering.

My process for creating detailed jewelry design sketches and renderings is meticulous and ensures clarity and precision.

Initial Concept and Sketches: I start with rough sketches, exploring different design concepts, proportions, and arrangements of elements.

Detailed Sketches: Once a concept is selected, I create detailed technical sketches, including precise measurements, gemstone placements, and metalwork details. These sketches are critical for communicating the design to the fabricator and ensuring accuracy.

3D Modeling: I then translate the 2D sketches into 3D models using CAD software. This allows for a virtual manipulation of the design, enabling further refinement and exploration of different perspectives.

Rendering: I use advanced rendering techniques to create photorealistic images of the design, showing it from various angles and under different lighting conditions. This provides a clear and compelling visualization for clients.

Technical Drawings: I prepare detailed technical drawings showing dimensions, material specifications, and manufacturing instructions, which are essential for the fabrication process.

This comprehensive approach guarantees accurate communication and a smooth transition from concept to production.

Q 27. What are your strengths and weaknesses as a jewelry designer/fabricator?

As a jewelry designer and fabricator, I possess a unique blend of strengths and weaknesses.

Strengths: My strong points include my creative vision, meticulous attention to detail, proficiency in diverse design styles, technical expertise in both traditional and advanced fabrication methods, and effective communication with clients.

Weaknesses: While I’m adept at managing multiple projects, occasionally taking on too much can lead to slight delays. I’m continually working on improving my time management skills to mitigate this.

I actively seek feedback to identify areas for improvement and utilize my strengths to compensate for any weaknesses. This self-awareness and proactive approach to development are key to my continuous professional growth.

Q 28. Describe your experience with managing inventory and materials.

Managing inventory and materials is crucial for efficient workflow and cost control. My approach involves a combination of meticulous record-keeping and proactive strategies.

Inventory Tracking System: I maintain a detailed inventory management system, using spreadsheets or specialized software to track materials, quantities, costs, and suppliers. This helps avoid material shortages and minimizes waste.

Material Sourcing: I establish relationships with reputable suppliers to ensure a consistent supply of high-quality materials at competitive prices. I also prioritize ethically sourced materials whenever possible.

Waste Reduction: I implement strategies to minimize material waste, such as careful planning, precise cutting, and recycling of scrap materials. This is environmentally responsible and economically beneficial.

Storage and Organization: Materials are stored in a clean, organized manner, allowing for easy access and preventing damage. Proper storage is vital to maintain the quality and longevity of materials.

This system ensures that I have the necessary materials readily available while effectively managing costs and minimizing environmental impact.

Key Topics to Learn for Jewelry Design and Fabrication Interview

- Design Principles: Understanding the elements and principles of design (line, shape, form, color, texture, space) as applied to jewelry creation. Practical application includes sketching and rendering designs, considering proportion and balance.

- Material Properties and Selection: Knowledge of various metals (gold, silver, platinum), gemstones, and other materials used in jewelry making, including their properties (malleability, hardness, durability), and appropriate applications. Practical application involves selecting materials based on design requirements and budget considerations.

- Fabrication Techniques: Proficiency in various jewelry fabrication techniques such as soldering, casting, forging, stone setting (various methods), finishing, and polishing. Practical application involves demonstrating a clear understanding of the processes and potential challenges.

- CAD/CAM in Jewelry Design: Familiarity with Computer-Aided Design (CAD) software commonly used in the industry for 3D modeling and design visualization. Practical application includes showcasing proficiency in software such as Rhino, Matrix, or similar programs.

- Manufacturing Processes: Understanding the production pipeline from design to finished product, including aspects like prototyping, quality control, and cost estimation. Practical application involves discussing experience with different manufacturing methods and their limitations.

- Jewelry History and Trends: Knowledge of significant periods and styles in jewelry history, along with current market trends and aesthetics. Practical application involves demonstrating an understanding of design influences and adapting to evolving tastes.

- Problem-Solving and Troubleshooting: Ability to identify and solve common problems encountered during the design and fabrication process, demonstrating resourcefulness and technical skills. This includes adapting designs based on material limitations or technical challenges.

Next Steps

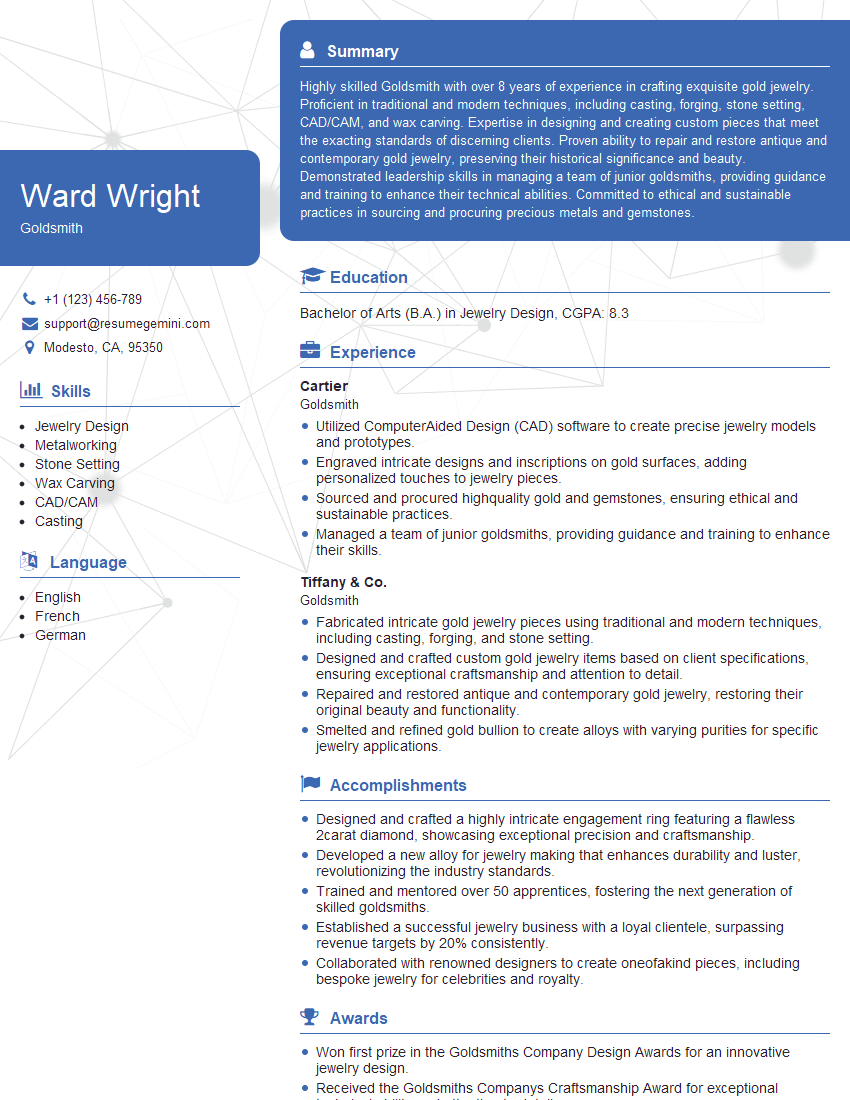

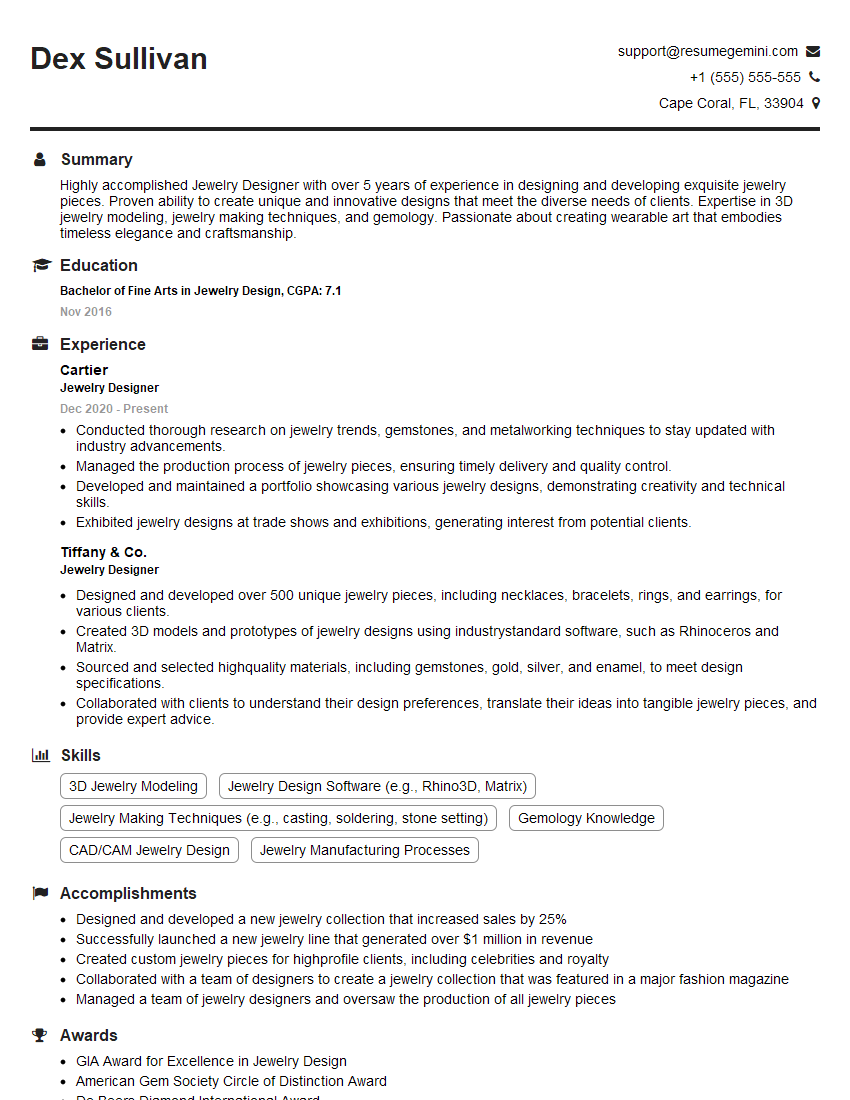

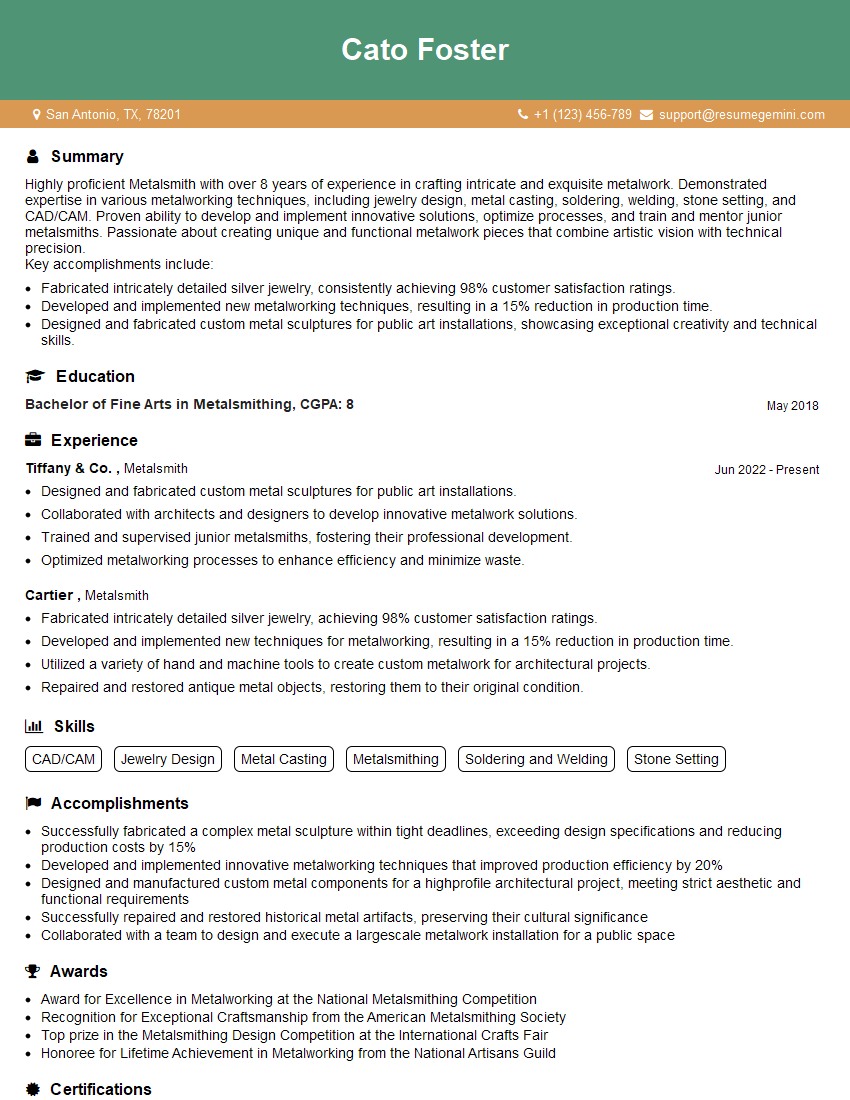

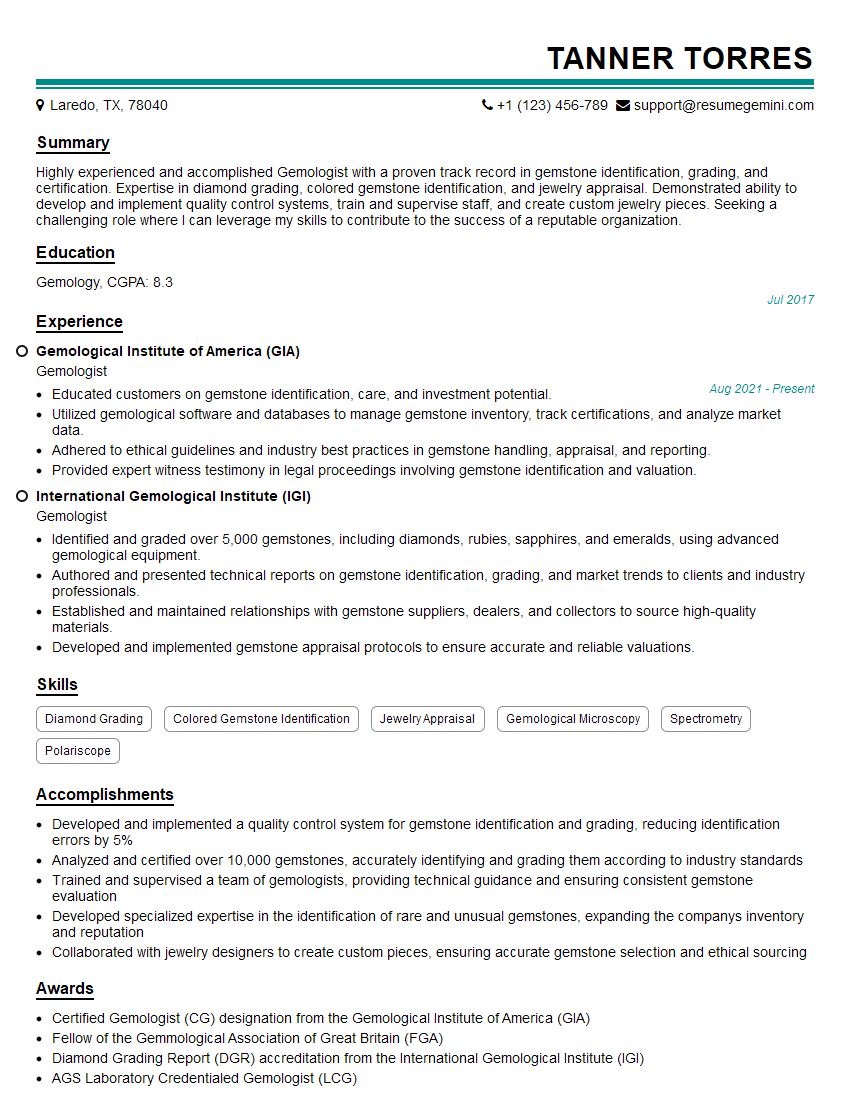

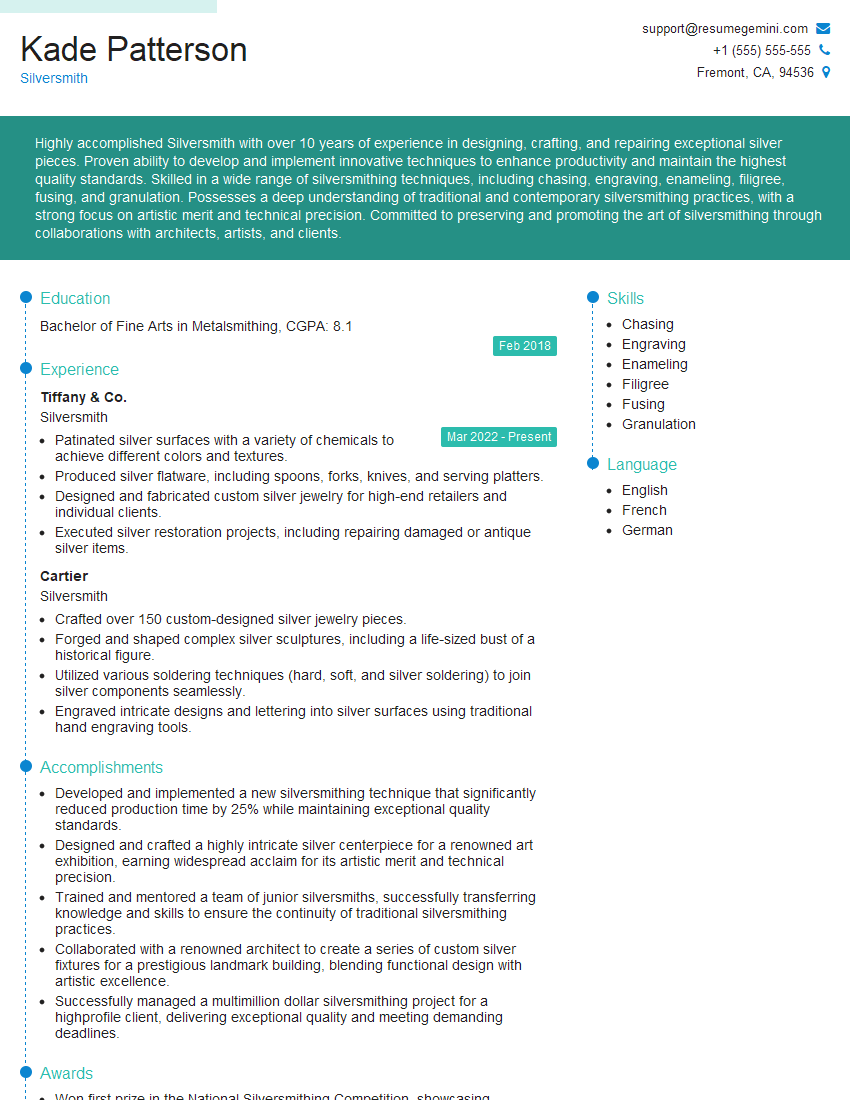

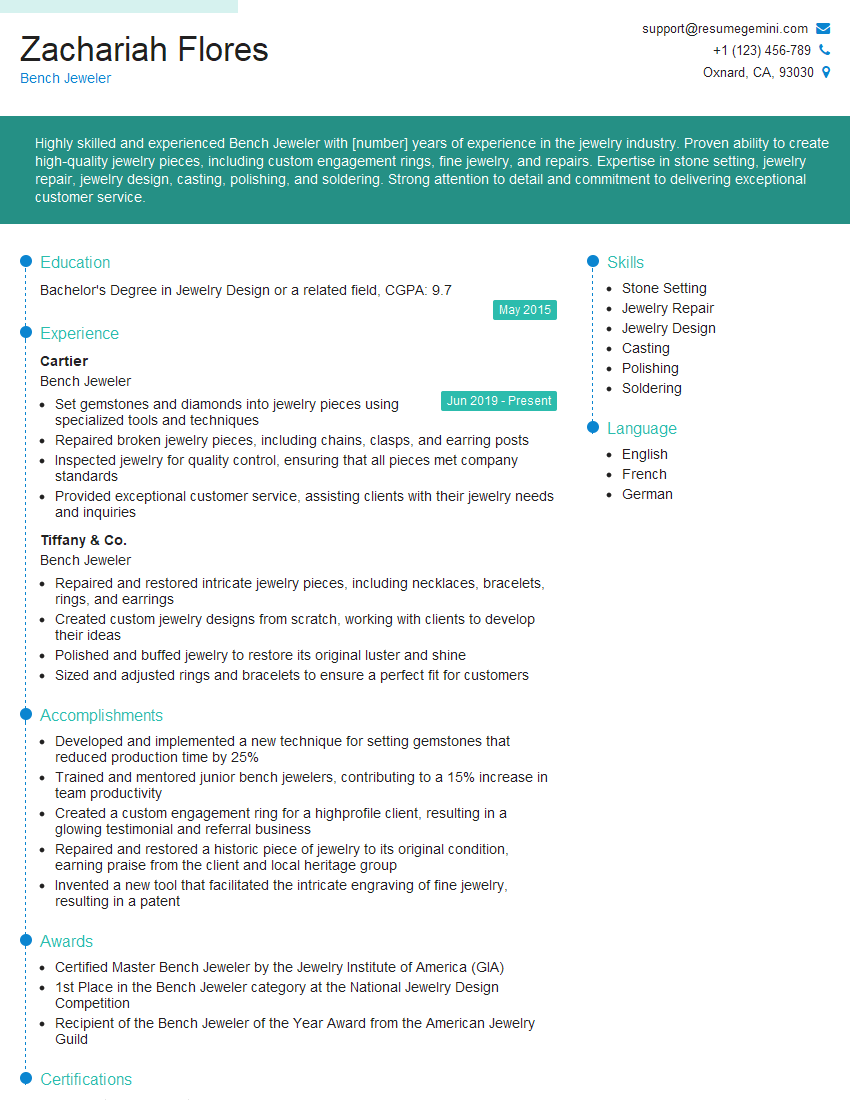

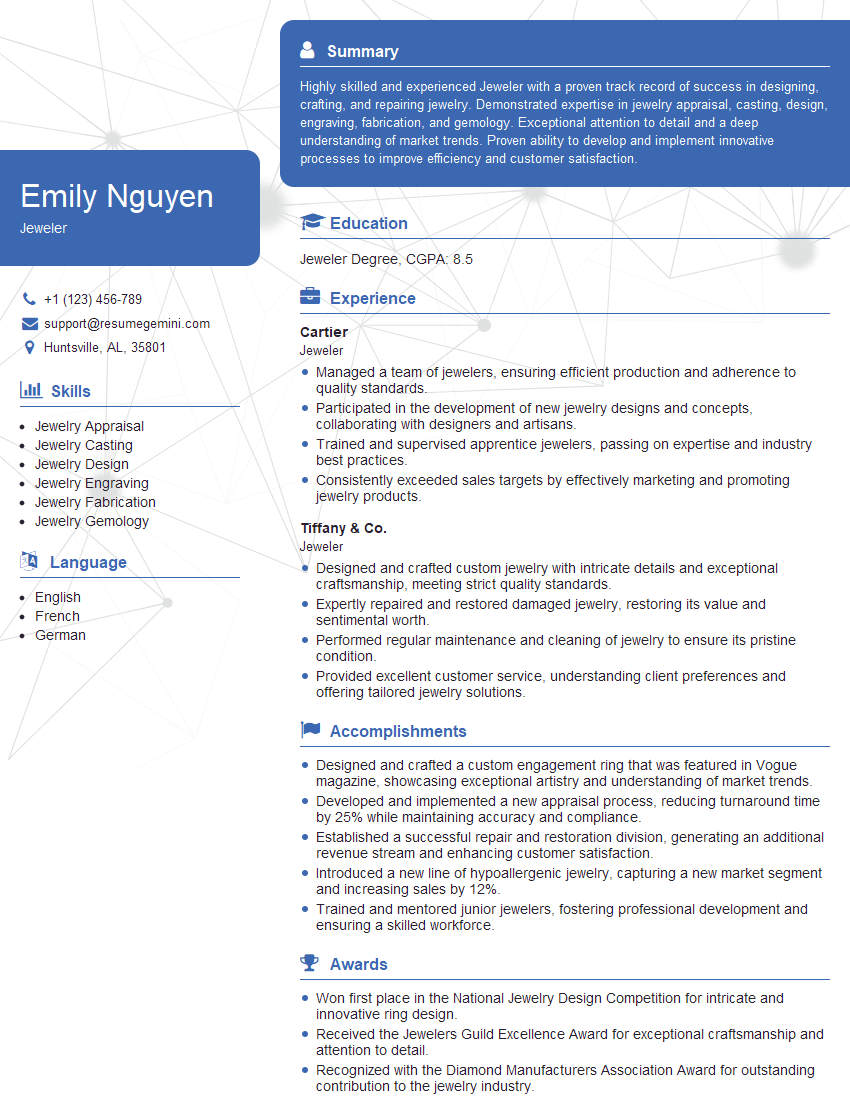

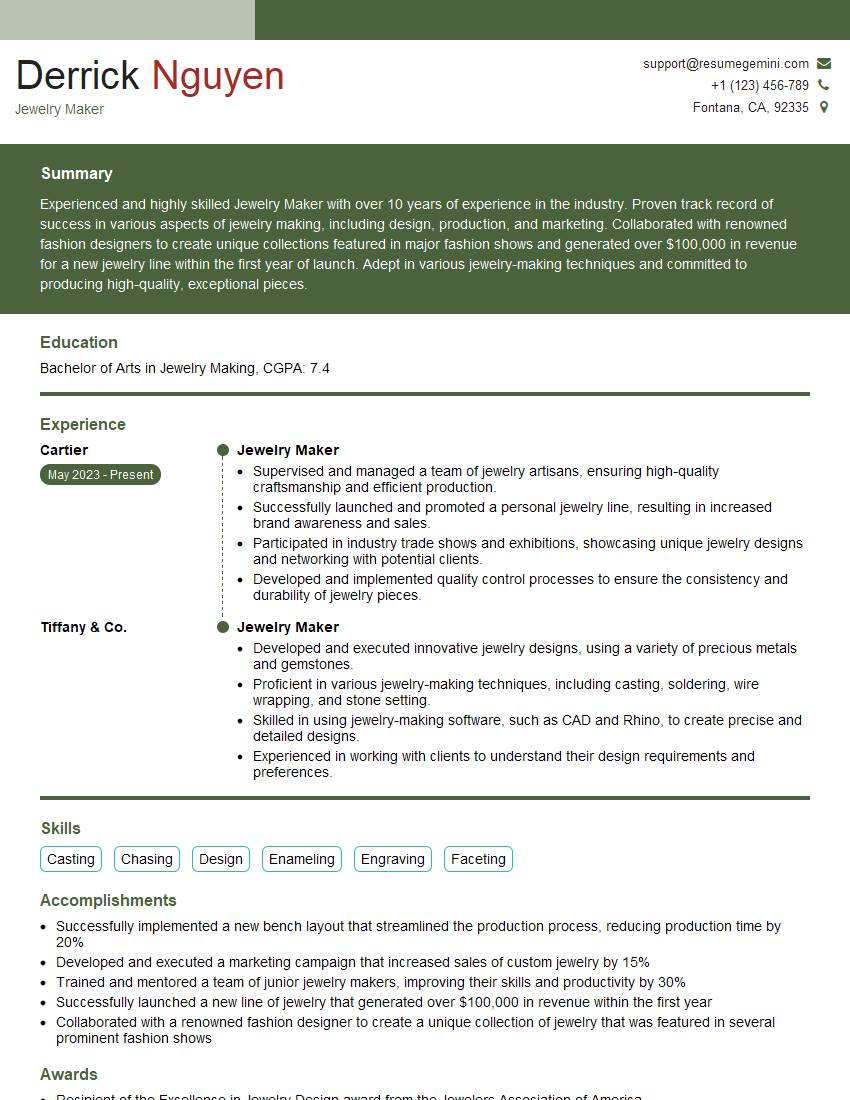

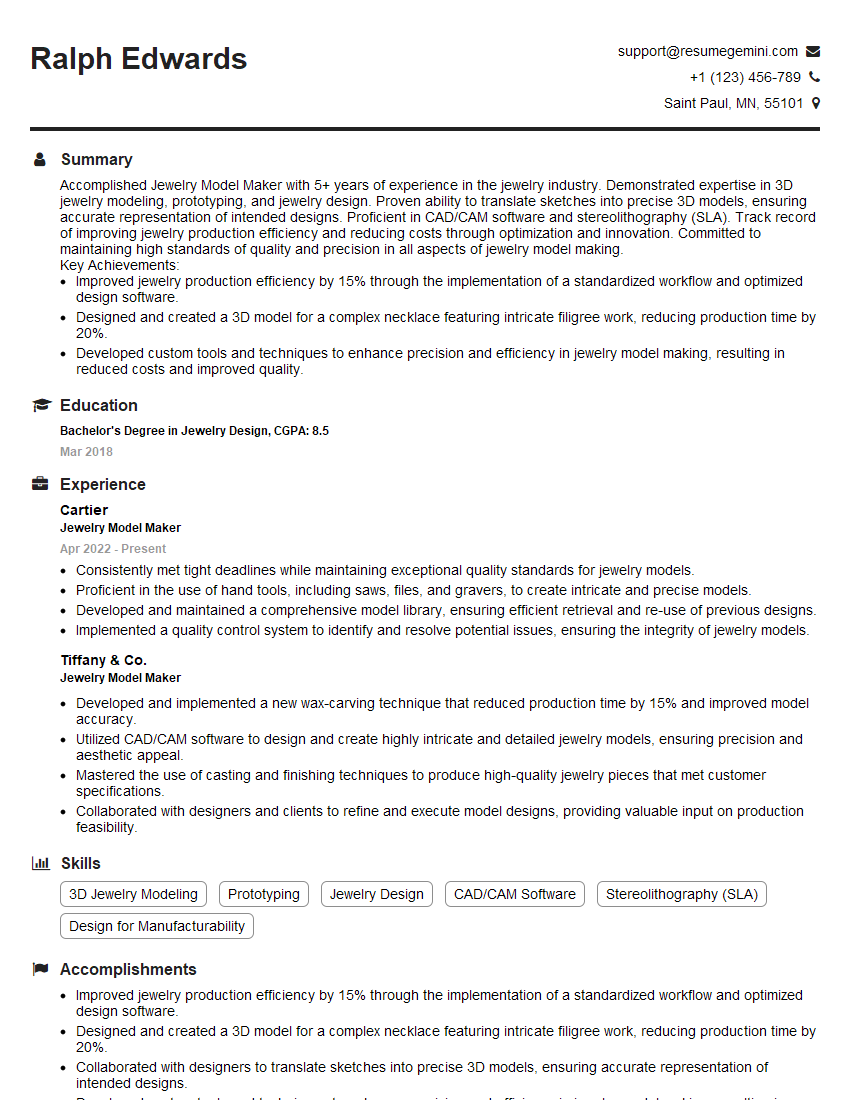

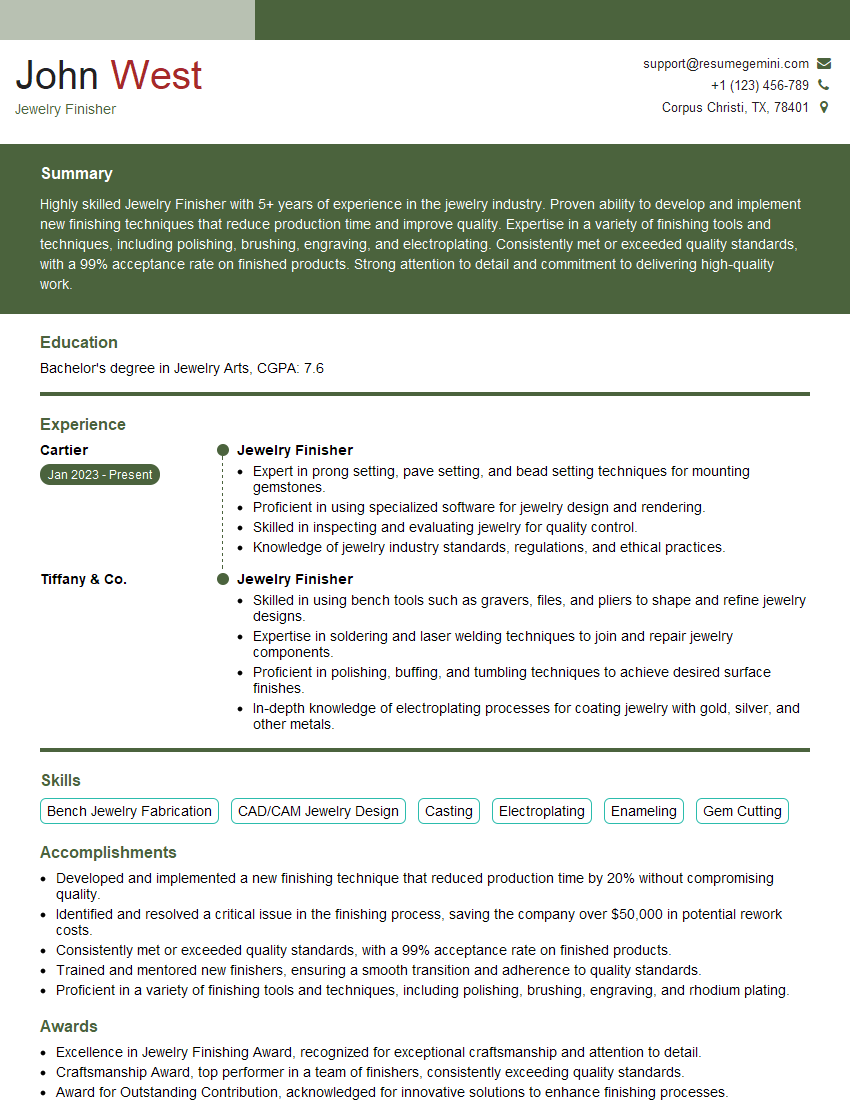

Mastering Jewelry Design and Fabrication opens doors to a rewarding career with diverse opportunities for creativity and innovation. To stand out, a strong and ATS-friendly resume is crucial. A well-crafted resume highlights your skills and experience effectively, increasing your chances of landing your dream job. We encourage you to leverage ResumeGemini, a trusted resource for building professional resumes. ResumeGemini provides valuable tools and resources to help you create a compelling document that showcases your unique talents. Examples of resumes tailored to Jewelry Design and Fabrication are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good