Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Jewelry Manufacturing Processes interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Jewelry Manufacturing Processes Interview

Q 1. Describe your experience with different jewelry casting methods (investment casting, centrifugal casting, etc.)

My experience encompasses a wide range of jewelry casting methods, with a particular focus on investment casting and centrifugal casting. Investment casting, also known as lost-wax casting, is a highly precise method ideal for intricate designs. It involves creating a wax model of the piece, building an investment mold around it, melting out the wax, and then casting molten metal into the resulting cavity. I’ve used this extensively for creating detailed pendants and rings with filigree work. Centrifugal casting, on the other hand, is better suited for larger, simpler pieces where speed and efficiency are prioritized. Molten metal is spun at high speed within a mold, forcing it against the mold walls for even distribution. I’ve found this method particularly useful for producing hollow items like bangles and cuffs with uniform thickness.

Beyond these two, I have familiarity with other techniques like pressure casting, which offers finer detail than centrifugal casting but requires more specialized equipment, and sand casting, a more traditional but less precise approach often used for larger, less intricate pieces. The choice of method depends entirely on the design complexity, desired finish, production volume, and budget constraints of the project.

Q 2. Explain the process of stone setting, including different techniques and their applications.

Stone setting is a crucial stage in jewelry making, demanding both skill and precision. Various techniques exist, each best suited to different stone types and designs.

- Prong Setting: This classic method secures the stone with several metal prongs, offering excellent visibility and security. It’s ideal for showcasing brilliant-cut diamonds or gemstones requiring significant light exposure. I often use this for solitaire rings or earrings.

- Bezel Setting: The stone is encompassed by a metal rim, protecting it and providing a smooth, polished surface. This technique is versatile and works well with various shapes and sizes, and is particularly robust for everyday wear.

- Channel Setting: Stones are placed in grooves along a metal band, creating a continuous line of sparkle. This is commonly used in wedding bands or eternity rings, offering a secure and elegant setting.

- Pavé Setting: Tiny stones are set closely together, creating a sparkling, textured surface. This requires meticulous attention to detail and is a hallmark of high-end jewelry.

- Invisible Setting: Stones are skillfully hidden within the metal, creating a seamless look. This is exceptionally challenging but yields stunning results for sophisticated designs.

Choosing the right setting depends on factors such as the stone’s shape, size, and hardness, as well as the desired aesthetic and level of security. For example, softer stones might benefit from a bezel setting, while a diamond’s brilliance is often maximized with a prong setting.

Q 3. What are the common quality control checks performed during jewelry manufacturing?

Quality control is paramount in jewelry manufacturing. My process involves several checks at each stage:

- Initial Design Review: Checking CAD models for proportions, structural integrity and manufacturability.

- Wax Inspection (Investment Casting): Examining wax models for accuracy, detail, and surface flaws before investment.

- Casting Inspection: Checking for porosity, voids, or inclusions in the cast metal pieces.

- Stone Setting Inspection: Verifying the security of stones, checking for any loose prongs or settings, and ensuring alignment and symmetry.

- Metal Finishing Inspection: Checking for scratches, pits, tarnish, or other imperfections after polishing and plating.

- Dimension Check: Precise measurements are taken to ensure the final piece adheres to the design specifications. This is crucial for proper sizing and fit.

- Hallmarking and Quality Certification: Ensuring the piece meets the required standards and is properly marked with the appropriate hallmarks and certifications.

These checks, coupled with regular equipment maintenance and skilled craftsmanship, guarantee the highest quality product.

Q 4. How do you identify and resolve common issues in metal finishing (e.g., tarnishing, pitting)?

Tarnishing, pitting, and other finishing defects can be identified visually and sometimes through specialized testing. Tarnishing, the dulling of the metal’s surface due to oxidation, is typically addressed through polishing and/or plating. Pitting, small holes or indentations on the surface, usually requires more involved solutions like re-polishing, potentially buffing, or in severe cases, recasting.

Problem-solving steps for common issues:

- Identify the issue: Carefully examine the piece to determine the exact nature of the defect (e.g., type of tarnish, depth of pitting).

- Choose appropriate solution: Select the suitable polishing compound or treatment (e.g., ultrasonic cleaning, chemical etching).

- Implement the solution: Execute the chosen solution following best practices to avoid causing further damage.

- Inspect the results: Examine the piece carefully after the treatment to assess the effectiveness and plan for any further action.

For instance, if mild tarnish is present, I may start with a gentle polishing using a soft cloth and polishing compound. For deeper pitting, I might opt for a more abrasive compound and a polishing wheel, followed by a protective plating.

Q 5. What experience do you have with CAD/CAM software in jewelry design and manufacturing?

I possess extensive experience with CAD/CAM software in jewelry design and manufacturing. I’m proficient in various programs, including Rhino, Matrix, and JewelCad. I use these tools throughout the design and manufacturing process, from the initial conceptualization and 3D modeling to the generation of CNC machining paths for wax model creation and/or direct metal printing. CAD allows for creating intricate designs, experimenting with variations, and fine-tuning details before committing to physical production, which significantly reduces material waste and streamlines the manufacturing process. I routinely use the CAM capabilities to generate efficient toolpaths for automated milling and ensuring precision and consistency in the creation of wax models for investment casting. This integration of CAD/CAM is essential for producing high-quality pieces efficiently.

For example, I recently used Rhino to design a complex, organic-shaped pendant. The software allowed for intuitive manipulation of 3D forms, while the CAM functionality enabled seamless transition to creating the wax model using a CNC milling machine with the utmost accuracy.

Q 6. Describe your knowledge of different soldering techniques and their suitability for various metals.

Soldering is a fundamental skill in jewelry making, joining different metal components together. The choice of soldering technique and flux depends greatly on the metal type and design complexity.

- Hard Soldering (Brazing): Uses higher temperatures and stronger alloys, ideal for joining thicker metals or creating strong, durable connections. I typically use this for heavier pieces or situations needing significant strength.

- Soft Soldering: Lower temperature process, suitable for thinner metals and more delicate work. This is ideal for detailed work where high heat might damage adjacent components.

- Laser Soldering: A highly precise, localized heating method using a laser beam. This is exceptionally useful for intricate work and delicate repairs.

Different metals require specific fluxes and soldering alloys to ensure proper adhesion and prevent damage. For example, silver requires a different flux and solder than gold or platinum. Choosing the correct materials is critical to creating strong, reliable, and aesthetically pleasing joints.

Q 7. How do you ensure the accuracy and precision of measurements in jewelry manufacturing?

Accuracy and precision in measurements are critical to creating well-fitting and aesthetically pleasing jewelry. I employ several strategies to ensure this:

- Precision Measuring Tools: I use calibrated digital calipers, micrometers, and rulers to take highly accurate measurements at all stages, from initial design to final inspection. For example, I use calipers to measure the dimensions of a gemstone precisely before setting.

- CAD/CAM Software: The digital nature of CAD/CAM provides an intrinsic level of precision, allowing for minute adjustments and precise replication of designs.

- Templates and Jigs: To ensure consistency and repeatability, I often use templates and jigs during the manufacturing process, especially for repetitive tasks such as setting multiple stones in a channel setting.

- Regular Calibration: My measuring tools are regularly calibrated to ensure accuracy, preventing potential errors over time.

- Multiple Measurements: I frequently take multiple measurements to cross-check and minimize the risk of human error.

Consistent application of these methods ensures that the final product matches the design specifications and meets the highest standards of quality.

Q 8. Explain the process of creating wax models for investment casting.

Creating wax models for investment casting is a crucial step in jewelry manufacturing, allowing for intricate designs and complex shapes. The process typically begins with a design, often created using CAD (Computer-Aided Design) software. This digital design is then used to create a wax model using one of several methods:

- CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing): This is the most common method for mass production. The digital design is sent to a 3D printer, which builds the wax model layer by layer using a wax-like material. This provides excellent precision and repeatability.

- Hand-Carving: For unique pieces or smaller production runs, skilled artisans hand-carve the wax model using various tools. This method allows for unparalleled artistic expression and intricate detailing, but it is more time-consuming and labor-intensive.

- Lost-Wax Casting from Existing Models: In some cases, a master model might be created from a different method (e.g., carving). From this master model, a mold can be made from silicone or other rubbery material that can then be used to create multiple wax copies.

Regardless of the method used, the resulting wax model is carefully inspected for any imperfections before proceeding to the investment casting process. Think of the wax model as a detailed blueprint – its accuracy directly affects the quality of the final metal piece.

For example, I once worked on a project involving a highly intricate pendant featuring interwoven Celtic knots. Using CAD/CAM, we were able to create a wax model with the precise detail required, impossible to achieve through hand carving alone within the timeframe of the project. The end result was a stunning piece that met the client’s expectations perfectly.

Q 9. What are the different types of plating used in jewelry manufacturing and their properties?

Plating is a crucial finishing process that enhances the aesthetics and durability of jewelry. Several types of plating are commonly used, each with its own properties:

- Rhodium Plating: Known for its brilliant white shine, exceptional hardness, and tarnish resistance, rhodium plating is often applied to white gold and platinum jewelry to enhance their luster and durability. It is highly resistant to scratches and wear.

- Gold Plating: Available in various karats (e.g., 18k, 24k), gold plating provides a rich, luxurious look. The thickness of the plating determines its longevity. Thicker plating is more durable and long-lasting.

- Silver Plating: A cost-effective option that offers a bright, reflective surface. Silver plating is more prone to tarnishing than rhodium or gold plating, requiring more frequent polishing and cleaning.

- Ruthenium Plating: Similar to rhodium in hardness and tarnish resistance, ruthenium offers a darker, gunmetal-gray finish, often used in more contemporary designs.

The choice of plating depends on factors like the base metal, desired finish, budget, and the expected lifespan of the jewelry. For instance, a high-end white gold ring might be rhodium plated for its superior durability and shine, while a less expensive piece might receive only gold or silver plating.

Q 10. How do you manage inventory and materials in a jewelry manufacturing setting?

Efficient inventory and materials management is essential for smooth operations and profitability in jewelry manufacturing. This involves a multi-faceted approach:

- Precise Inventory Tracking: Using a software system (or even a well-organized spreadsheet) to meticulously track all materials – metals (by karat and weight), gemstones (by type, cut, and carat), findings (clasps, jump rings, etc.), and consumables (polishing compounds, chemicals).

- Regular Stock Audits: Conducting regular physical audits to reconcile the inventory records with the actual stock on hand. This helps identify discrepancies and prevent stockouts or overstocking.

- Strategic Procurement: Establishing strong relationships with reliable suppliers to ensure a consistent supply of high-quality materials at competitive prices. Negotiating favorable payment terms and minimum order quantities can also significantly reduce costs.

- Demand Forecasting: Analyzing sales data and market trends to predict future demand for materials, which helps optimize purchasing decisions and minimize waste.

- Proper Storage: Implementing a well-organized storage system to protect materials from damage, theft, and environmental factors (like humidity and light). This includes secure storage of precious metals and gemstones.

In my previous role, we implemented an inventory management system that reduced material waste by 15% within a year by optimizing our purchasing and production scheduling. This demonstrates the significant impact of effective inventory management.

Q 11. Describe your experience with different types of polishing techniques and equipment.

Polishing is a crucial step in jewelry manufacturing, enhancing the shine and smoothness of the finished piece. I have experience with various techniques and equipment:

- Hand Polishing: Using polishing cloths, buffs, and various compounds (like rouge, tripoli, and white diamond) to achieve a high luster. This is often used for intricate details or smaller pieces where machine polishing might be too aggressive.

- Machine Polishing: Utilizing rotating wheels and belts, often with diamond compounds or polishing pastes, for achieving a high-volume and consistent finish. This is more efficient for larger-scale production.

- Vibratory Finishing (Tumbling): A mass finishing process using a rotating container filled with abrasive media (like ceramic pellets or steel shot) to polish many pieces simultaneously. This is ideal for removing burrs and achieving a uniform finish but less precise for intricate details.

- Electrolytic Polishing: A specialized process where an electrochemical reaction removes a microscopic layer of metal, yielding a very smooth and bright surface, often preferred for high-quality pieces.

The equipment used includes various types of polishing lathes, vibratory tumblers, and specialized polishing wheels. Selecting the appropriate technique and equipment depends on the metal, the desired finish, and the scale of production. For example, I used vibratory finishing to create a consistently smooth finish on a large batch of sterling silver earrings, and followed up with hand polishing to achieve a high-gloss on the intricate details.

Q 12. What safety precautions are necessary when working with different jewelry manufacturing tools and materials?

Safety is paramount in jewelry manufacturing. Several precautions are essential when working with different tools and materials:

- Eye Protection: Always wear safety glasses or goggles to protect against flying debris or chemical splashes.

- Hearing Protection: Machine polishing and other processes can be noisy. Ear plugs or muffs are crucial to prevent hearing damage.

- Respiratory Protection: When working with certain chemicals (e.g., polishing compounds, fluxes) or handling fine metal dust, a respirator is necessary to protect the lungs.

- Hand Protection: Gloves should be worn when handling chemicals or abrasive materials to prevent skin irritation or cuts.

- Proper Ventilation: Adequate ventilation is crucial to prevent the buildup of harmful fumes or dust particles.

- Safe Tool Usage: All machinery and tools must be used according to manufacturer’s instructions, and regular maintenance is vital.

- Chemical Handling: Follow proper storage and handling procedures for all chemicals, and ensure the workspace is properly labeled and ventilated.

Regular safety training and adherence to safety protocols are crucial to maintain a safe working environment. A safety-first approach isn’t just important; it is essential for preventing accidents and protecting workers’ health and well-being.

Q 13. How do you handle and troubleshoot problems related to metal alloys and their properties?

Troubleshooting issues related to metal alloys and their properties requires a thorough understanding of metallurgy and material science. Here’s how I approach such problems:

- Identifying the Issue: Precisely identify the problem; is it discoloration, brittleness, poor casting, or something else? Careful examination of the affected metal is crucial.

- Analyzing the Alloy Composition: Determining the exact composition of the alloy is vital. Spectroscopic analysis can be used to identify the elements and their proportions. Any deviations from the intended composition can be the root cause of many issues.

- Considering Processing Variables: Evaluate the different stages of the manufacturing process. Incorrect temperatures during casting, annealing, or soldering can lead to undesirable properties. Improper cleaning or finishing can also contribute to problems.

- Testing and Experimentation: If the problem is not immediately apparent, I’d conduct controlled experiments to isolate the cause. This may involve varying parameters such as temperature, time, or cleaning agents.

- Consultations: When necessary, I consult with material science experts or metallurgical engineers to obtain expert advice.

For example, I once encountered a batch of castings that were unusually brittle. After thorough investigation, we discovered that the alloy composition deviated slightly from the standard, resulting in a lower ductility. Adjusting the alloy composition in the next batch resolved the issue.

Q 14. Explain your experience with different types of gemstones and their setting requirements.

My experience encompasses a wide range of gemstones and their setting requirements. Each gemstone presents unique challenges and opportunities related to its physical properties and durability:

- Diamonds: Their exceptional hardness requires robust settings, often using strong prongs or bezel settings. The cut and clarity of the diamond will also influence the setting style.

- Sapphires and Rubies: These corundum gemstones are highly durable and can withstand a variety of settings. Channel settings, pave settings, and prong settings are all suitable.

- Emeralds: More susceptible to chipping than sapphires or rubies, emeralds often benefit from protective settings like bezel settings or closed-back settings.

- Opals: Comparatively softer gemstones, opals require settings that minimize impact and protect the stone’s surface. Bezel settings or protective channel settings are usually preferred.

- Other Gemstones: The setting chosen depends on hardness, fragility, and desired aesthetic effect. Some stones, like pearls, might require careful glueing or wire wrapping to prevent damage.

Understanding a gemstone’s properties and selecting the appropriate setting is crucial to protect it from damage and showcase its beauty. For instance, the elaborate prong setting on a delicate opal would not be appropriate, a bezel would protect it better. Choosing the correct setting is critical for the durability and longevity of the finished jewelry.

Q 15. How do you maintain quality standards throughout the jewelry manufacturing process?

Maintaining quality standards in jewelry manufacturing is a holistic process that begins with design and extends through every stage of production. It’s like baking a cake – if one ingredient is off, the whole thing suffers. We employ a multi-pronged approach:

- Strict Material Sourcing: We meticulously source high-quality materials, ensuring certifications and rigorous testing for purity and durability. For example, we only use ethically sourced gold with proper documentation.

- Detailed Design Specifications: Detailed CAD designs and specifications are crucial. These serve as blueprints, minimizing ambiguity and ensuring consistency across production runs. We meticulously define dimensions, tolerances, and finishes.

- Quality Control at Each Stage: We integrate quality checks at every step – from wax carving to polishing and finishing. This includes visual inspections, using measuring tools (calipers, micrometers), and even employing specialized equipment like spectrometers for metal analysis. Regular calibration of these tools is paramount.

- Skilled Craftsmanship: Investing in training and development of our artisans is critical. Experienced jewelers possess the keen eye and dexterity to identify even subtle flaws.

- Continuous Improvement: Regularly reviewing our processes, tracking defects, and implementing corrective actions is key to reducing errors and enhancing quality consistently. This might involve adjusting techniques, updating equipment, or even refining our training programs.

This systematic approach ensures we deliver consistently high-quality jewelry that meets or exceeds customer expectations.

Career Expert Tips:

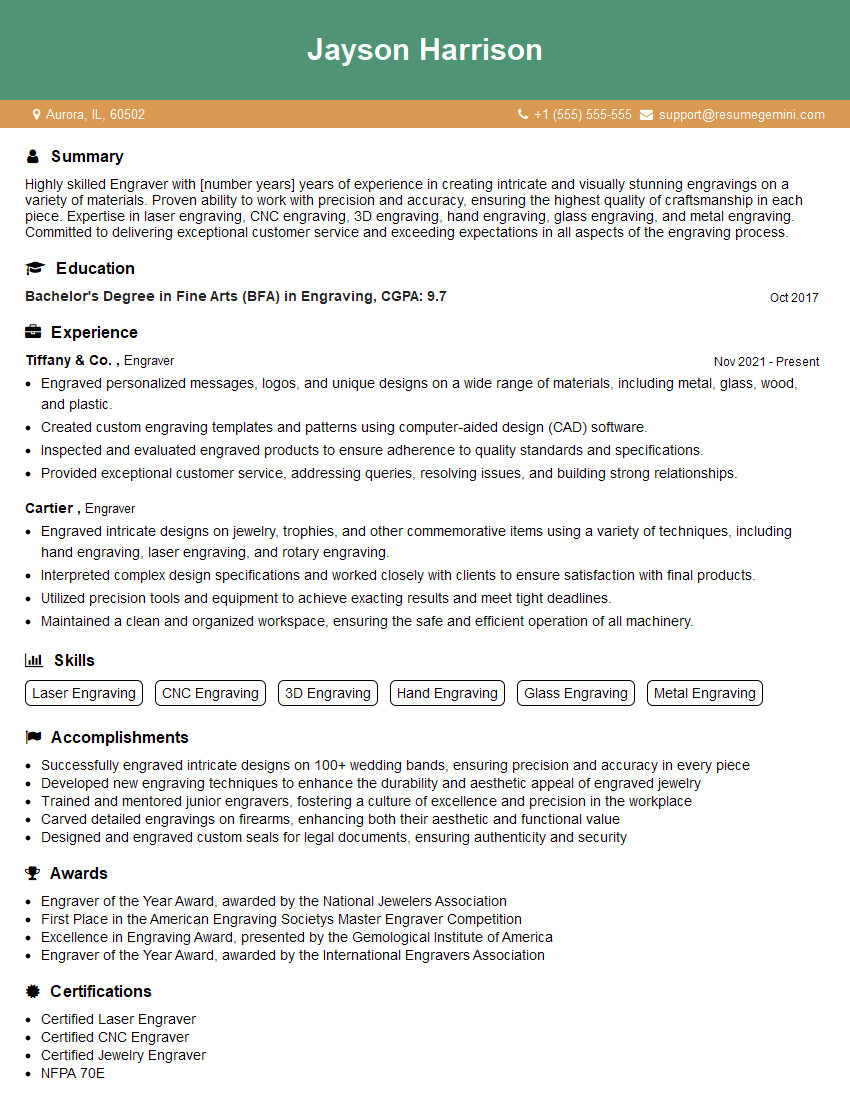

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with CNC machining or 3D printing in jewelry manufacturing.

I have extensive experience with both CNC machining and 3D printing in jewelry manufacturing. They represent significant advancements in precision and efficiency.

- CNC Machining: We use CNC milling machines to create intricate wax models for casting, as well as directly machining metal components for certain designs. This allows for high precision, repeatability, and faster production compared to traditional hand-carving for complex pieces. For example, we utilize CNC to produce highly detailed filigree work that would be impractical by hand.

- 3D Printing (Additive Manufacturing): This technology has revolutionized rapid prototyping and short-run production. We use 3D printing to create wax models, investment casting molds, and even directly print metal components using techniques like selective laser melting (SLM). This is particularly useful for complex geometries and highly customized designs that would be difficult or expensive to produce using traditional methods. For instance, we’ve used 3D printing to create bespoke, anatomical jewelry based on customer-provided scans.

The selection between CNC machining and 3D printing depends on factors like design complexity, required quantity, material, and budget. We often use a combination of both for optimal results.

Q 17. What are the common challenges in managing a jewelry manufacturing team?

Managing a jewelry manufacturing team presents unique challenges. The work requires specialized skills, and maintaining morale and productivity demands a thoughtful approach.

- Skill Gaps and Training: Jewelry making requires both artistic skill and technical proficiency. Bridging skill gaps through ongoing training and mentorship programs is essential.

- Maintaining Precision and Consistency: Ensuring consistent quality across all team members is a major challenge. Clear communication, thorough training, and standardized processes are vital.

- Managing Creative Differences: Balancing artistic expression with production requirements can be tricky. Open communication and collaborative design processes can help resolve conflicts.

- Safety and Ergonomics: Jewelry manufacturing involves working with sharp tools and potentially hazardous materials. Prioritizing workplace safety through training and providing appropriate safety equipment is crucial.

- Retention of Skilled Artisans: Experienced jewelers are highly sought after. Creating a positive work environment, offering competitive compensation and benefits, and providing opportunities for career advancement helps retain valuable team members.

Effective leadership, clear communication, and a commitment to employee well-being are crucial for managing a successful and productive jewelry manufacturing team.

Q 18. How do you ensure the timely completion of jewelry manufacturing projects?

Ensuring timely project completion requires careful planning, efficient execution, and proactive problem-solving. It’s a bit like orchestrating a symphony – all sections need to be in sync.

- Project Scheduling and Planning: We utilize project management software to create detailed schedules, breaking down complex projects into smaller, manageable tasks. This helps identify potential bottlenecks early on.

- Efficient Workflow Management: Streamlining workflows and optimizing production processes minimizes delays. This includes efficient material handling, minimizing waste, and maintaining a well-organized workspace.

- Resource Allocation: Matching available resources (personnel, equipment, materials) to project demands is crucial. Over-allocation or under-allocation can both lead to delays.

- Proactive Problem-Solving: Regularly monitoring progress, identifying potential roadblocks, and developing contingency plans is critical for keeping projects on track. For example, maintaining a buffer stock of commonly used materials prevents supply chain disruptions.

- Effective Communication: Maintaining open communication between team members, clients, and suppliers ensures everyone is informed and any issues are addressed promptly.

By employing these strategies, we effectively manage our time and resources, ensuring consistent and timely project completion.

Q 19. Describe your experience with different types of jewelry manufacturing equipment (e.g., lathes, rolling mills).

My experience encompasses a wide range of jewelry manufacturing equipment. Each machine plays a specific role in the process, much like different instruments in an orchestra.

- Lathes: Used for shaping metal rods and creating components with cylindrical symmetry, such as earring posts or bands. We use both manual and CNC lathes depending on the complexity and quantity of the pieces.

- Rolling Mills: These are essential for flattening and shaping metal sheets, creating consistent thicknesses for various components. They are indispensable for working with precious metals.

- Casting Equipment: This includes furnaces for melting metals, centrifugal casting machines for producing intricate designs, and investment casting equipment for creating highly detailed pieces.

- Soldering and Welding Equipment: Different types of torches and specialized soldering irons are used to join metal components together. The choice depends on the metals being joined and the desired joint strength.

- Polishing and Finishing Equipment: Rotary tools, buffing wheels, and various polishing compounds are used to achieve a desired surface finish. Different grits and compounds are used to remove scratches and achieve a high shine.

Proficiency with this equipment is vital for efficient and high-quality jewelry production. Regular maintenance and calibration of this equipment are crucial to ensuring its longevity and accuracy.

Q 20. How do you stay updated with the latest trends and technologies in jewelry manufacturing?

Staying current in jewelry manufacturing requires a multi-faceted approach. It’s like being a detective – you need to constantly investigate and gather information.

- Industry Publications and Trade Shows: I regularly read industry magazines, journals, and attend international trade shows such as JCK Las Vegas and Baselworld. This exposes me to the latest trends, technologies, and innovations.

- Online Resources and Forums: I actively participate in online forums and communities dedicated to jewelry manufacturing, exchanging ideas and learning from other professionals.

- Networking with Peers: I maintain strong relationships with colleagues and other professionals in the industry, sharing knowledge and staying abreast of the latest developments.

- Continuing Education Courses: I regularly participate in workshops and seminars offered by reputable institutions to improve my skills and knowledge.

- Research and Development: We dedicate resources to research and development, exploring new technologies and materials to enhance our manufacturing capabilities.

This ongoing pursuit of knowledge helps us maintain a competitive edge and adapt to the ever-evolving demands of the jewelry industry.

Q 21. Explain your understanding of lean manufacturing principles and their application in jewelry production.

Lean manufacturing principles, focused on eliminating waste and maximizing efficiency, are highly applicable to jewelry production. It’s about making the process smoother, like streamlining a river to improve its flow.

- Value Stream Mapping: We meticulously analyze the entire production process to identify and eliminate non-value-added steps. This involves mapping every step, from design to delivery, to pinpoint bottlenecks and areas for improvement.

- 5S Methodology (Sort, Set in Order, Shine, Standardize, Sustain): This organizational system helps create a cleaner, safer, and more efficient workspace, reducing errors and improving workflow. This is crucial in a craft-intensive industry like jewelry making.

- Just-in-Time Inventory Management: We aim to minimize inventory by procuring materials only as needed, reducing storage costs and minimizing waste from obsolete materials. This reduces risk and enhances agility.

- Kaizen (Continuous Improvement): We foster a culture of continuous improvement, encouraging team members to suggest and implement small, incremental changes that enhance efficiency and quality. This might involve modifying a tool, streamlining a process, or improving workspace organization.

- Waste Reduction (Muda): We strive to eliminate seven types of waste: transportation, inventory, motion, waiting, overproduction, over-processing, and defects.

By embracing lean principles, we have significantly improved our efficiency, reduced production costs, and enhanced the overall quality of our jewelry.

Q 22. How do you ensure compliance with industry standards and regulations in jewelry manufacturing?

Ensuring compliance in jewelry manufacturing involves a multi-faceted approach, focusing on legal requirements and ethical sourcing. We adhere strictly to regulations regarding hallmarking, ensuring each piece meets the mandated standards for precious metal content. This often involves working with independent assay offices for testing and certification. Beyond legal compliance, we prioritize ethical sourcing of materials, verifying our suppliers’ commitment to fair labor practices and environmentally responsible mining. We maintain meticulous records of our supply chain, from raw material origin to finished product, to ensure traceability and transparency. For example, we might use a dedicated software system to track each batch of materials and its corresponding certifications, making it easy to audit our compliance at any time.

Furthermore, we regularly update our knowledge of evolving regulations through industry associations and legal consultations. This proactive approach minimizes risks and ensures we remain ahead of any changes. We conduct internal audits to identify potential compliance gaps and implement corrective actions promptly. Our commitment to compliance isn’t just a legal obligation; it’s an integral part of our brand reputation and customer trust.

Q 23. Describe your experience with process improvement initiatives in a jewelry manufacturing environment.

In my previous role, we implemented a Lean manufacturing approach to streamline our production process. This involved mapping out each step of jewelry creation, from design to finishing, to identify bottlenecks. We discovered a significant delay in the polishing stage, which was resolved by investing in more efficient polishing equipment and training our staff on optimized techniques. This resulted in a 15% increase in production efficiency and reduced lead times for orders.

Another initiative focused on reducing material waste. We implemented a system for precisely measuring and cutting precious metals, minimizing scraps. This not only saved costs but also contributed to our sustainability goals. We also introduced a quality control checkpoint at each production stage, catching defects early and preventing costly rework. These improvements were meticulously tracked using key performance indicators (KPIs), allowing us to measure our progress and identify areas for further optimization. Think of it like a finely tuned orchestra – each section (stage of production) needs to work in perfect harmony to create a beautiful final product (the finished jewelry).

Q 24. What is your experience with different types of jewelry findings and their applications?

My experience encompasses a wide range of jewelry findings, from simple jump rings and clasps to more intricate components like bezels, earring wires, and settings. I understand the nuances of each finding type and their optimal applications. For example, I know that a lobster clasp is suitable for necklaces and bracelets that require a secure closure, while a spring ring is more appropriate for delicate chains. Similarly, the choice of bezel setting depends on the gemstone’s shape and size, and the desired level of protection.

I’m familiar with various materials used in findings, including precious metals (gold, silver, platinum), base metals (brass, copper, nickel silver), and even non-metal options like silicone or plastic for certain applications. My expertise extends to understanding the durability and compatibility of different findings with various gemstones and metals, ensuring longevity and preventing reactions. For instance, choosing a nickel-free finding is crucial for customers with nickel allergies. The selection of findings is a critical aspect of jewelry construction, impacting both aesthetics and the structural integrity of the final piece.

Q 25. How do you handle customer complaints related to the quality or production of jewelry?

Handling customer complaints begins with empathetic listening. I strive to understand the customer’s perspective fully before offering a solution. We document each complaint thoroughly, noting the specific issue, the date of purchase, and the customer’s contact information. This ensures efficient tracking and resolution. We then investigate the cause of the complaint, examining the piece and our internal processes. This might involve inspecting the manufacturing records or contacting the relevant production team.

Depending on the nature of the complaint, we offer solutions such as repair, replacement, or a refund. Our goal is to resolve the issue swiftly and fairly, maintaining customer satisfaction. In cases where a manufacturing defect is identified, we use the feedback to improve our quality control processes and prevent similar issues in the future. For example, a recurring complaint about a specific clasp malfunction might prompt a review of our clasp supplier or a redesign of the clasp mechanism. Transparent communication with the customer throughout the process is key to maintaining their trust and loyalty.

Q 26. Explain your understanding of different metal alloys used in jewelry manufacturing and their properties.

My understanding of metal alloys used in jewelry making is comprehensive. I’m well-versed in the properties of various gold alloys, such as 14k, 18k, and 24k, understanding their differences in purity, color, hardness, and workability. Similarly, I’m familiar with different sterling silver alloys, and the implications of varying levels of silver content. Platinum alloys, known for their durability and hypoallergenic properties, are also within my area of expertise.

Beyond precious metals, I have knowledge of base metal alloys used in jewelry making, including brass, copper, and nickel silver. I understand their cost-effectiveness and how their properties impact the final product’s durability, finish, and suitability for various applications. I also recognize the importance of considering the hypoallergenic aspects of alloys, especially regarding nickel content. For example, I’d select a nickel-free silver alloy for individuals with nickel sensitivities. This knowledge helps me select the right alloy for a specific design, balancing aesthetic appeal with the required durability and cost-effectiveness.

Q 27. What are the key considerations when selecting materials for specific jewelry designs?

Selecting materials for jewelry design necessitates careful consideration of several factors. The design itself plays a crucial role; delicate designs might require softer, more malleable metals, while bolder designs might benefit from more durable and robust materials. The intended use of the jewelry is also key. A piece intended for daily wear requires a more resistant material than one for occasional use.

The gemstone’s properties significantly influence material selection. A softer gemstone might require a protective setting to prevent damage. The color and tone of the gemstones must harmonize with the metal’s color, creating a visually appealing combination. The client’s preferences, including budget and allergy concerns, are also paramount. For example, a client with a nickel allergy would necessitate the use of nickel-free metals. Ultimately, the choice of materials is a balance of aesthetics, functionality, budget, and ethical considerations, ensuring the final piece is both beautiful and durable.

Q 28. How do you maintain accurate records and documentation throughout the jewelry manufacturing process?

Maintaining accurate records is crucial for efficient production and traceability. We use a combination of digital and physical records. Each project begins with a detailed design specification, including material requirements and production steps. We maintain a comprehensive database tracking the raw materials used for each piece, including their origin, purity, and certifications. Production progress is monitored meticulously using a work-order system, indicating each stage of completion.

Quality control checkpoints are documented with detailed inspection reports, noting any defects or adjustments. Once completed, the finished jewelry is tagged with a unique identification number that links it to all previous documentation. We also keep meticulous records of inventory, ensuring we have sufficient materials on hand and track the movement of stock effectively. This comprehensive record-keeping ensures accountability, facilitates quality control, aids in inventory management, and simplifies compliance audits. It’s like building a detailed history for each piece, ensuring transparency and traceability throughout its entire lifecycle.

Key Topics to Learn for Jewelry Manufacturing Processes Interview

- Casting Techniques: Understand the various methods (lost-wax casting, investment casting, centrifugal casting), their applications, advantages, and limitations. Be prepared to discuss material selection and quality control within each process.

- Metalworking: Master the principles of rolling, drawing, forging, stamping, and spinning. Discuss the impact of these techniques on metal properties and the finished product’s aesthetic qualities. Consider the practical applications for different jewelry types.

- Soldering and Brazing: Know the different types of solder and brazing alloys, their melting points, and their suitability for various metals. Be ready to explain the importance of flux and proper technique to avoid damage.

- Stone Setting: Familiarize yourself with various stone setting methods (prong, bezel, channel, pave). Discuss the selection of appropriate settings based on stone type, size, and design. Highlight the importance of security and durability.

- Finishing and Polishing: Understand the sequence of operations involved in preparing a piece for finishing, including cleaning, polishing, and buffing techniques. Discuss the use of different abrasives and polishing compounds.

- Quality Control and Inspection: Describe the methods used to ensure the quality and integrity of the finished product, including dimensional accuracy, surface finish, and stone security. Discuss common quality issues and their causes.

- CAD/CAM in Jewelry Manufacturing: Understand the role of computer-aided design and manufacturing in modern jewelry production. Discuss the advantages and limitations of this technology and its impact on efficiency and design possibilities.

- Material Science: Demonstrate a foundational understanding of the properties of common jewelry metals (gold, silver, platinum, etc.) including their alloying characteristics, workability, and durability. Discuss the impact of different alloys on the final product.

Next Steps

Mastering Jewelry Manufacturing Processes is crucial for career advancement in this specialized field. A strong understanding of these processes demonstrates technical expertise and problem-solving skills highly valued by employers. To maximize your job prospects, create an ATS-friendly resume that clearly highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume that gets noticed. Examples of resumes tailored to Jewelry Manufacturing Processes are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good