Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Knot Tying and Break Detection interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Knot Tying and Break Detection Interview

Q 1. Explain the differences between a bowline and a clove hitch.

Both the bowline and the clove hitch are essential knots, but they serve different purposes. The bowline is a fundamental knot renowned for its strength and ease of untying, forming a fixed loop at the end of a rope. Think of it as a strong, reliable loop that won’t slip. It’s perfect for creating a secure loop for attaching a leash to a dog’s collar or making a climbing loop. The clove hitch, on the other hand, is a temporary knot, used for securing a rope to a post, ring, or other object. It’s easy to tie and untie, but it’s not as strong as a bowline and is prone to slipping under load if not tied correctly and with sufficient wraps. Imagine using a clove hitch to temporarily secure a tarp to a tree. The key difference is that the bowline creates a fixed loop, while the clove hitch creates a binding around an object.

- Bowline: Forms a fixed loop at the end of a rope. Strong, reliable, and easy to untie.

- Clove Hitch: Attaches a rope to an object. Temporary, easy to tie and untie, but can slip.

Q 2. Describe the process for tying a figure-eight knot and its applications.

The figure-eight knot is a stopper knot, meaning its primary function is to prevent a rope from running through a system. It’s relatively simple to tie, yet provides a secure and reliable stopper. To tie it, form a loop, pass the end through the loop, and then make a figure-eight shape with the end around the standing part, passing it through the final loop. The applications are diverse: You might use it to secure the end of a climbing rope to your harness, to stop a rope from slipping through a pulley system, or to prevent accidental slippage in sailing. Its reliability makes it a crucial element in various safety systems.

Here’s a step-by-step guide (imagine you’re holding the rope in your right hand):

- Make a loop with the rope.

- Pass the working end of the rope through the loop.

- Wrap the working end around the standing part, forming a figure-eight shape.

- Pass the working end through the loop you made in step 1.

Q 3. What are the safety considerations when working with ropes under tension?

Working with ropes under tension demands meticulous attention to safety. The primary concerns involve potential injury from sudden rope failure or uncontrolled movement. Here’s a breakdown:

- Proper Knot Selection: Use knots specifically designed for the load and application, ensuring they are correctly tied and secured.

- Inspecting the Rope: Thoroughly check for wear, damage, or weakening before each use. Any doubt warrants discarding the rope.

- Personal Protective Equipment (PPE): Always use appropriate PPE, including gloves to protect hands and eye protection to prevent injury from flying debris.

- Controlled Environment: Ensure a clear work area, free of obstructions that could cause the rope to snag or become entangled.

- Load Management: Gradually apply load, avoid sudden jerks, and stay clear of the load path during tensioning.

- Safety Communication: When working with a team, maintain clear communication, ensuring everyone understands their role and responsibilities.

Q 4. How do you identify a weakened or damaged section of rope?

Identifying weakened or damaged rope sections requires a keen eye and systematic approach. Look for the following:

- Cuts and Abrasions: Even minor cuts can significantly weaken the rope. Inspect the rope’s surface for any nicks, cuts, or abrasions.

- Kinks and Bends: Sharp bends can create stress points, leading to fiber breakage. Look for areas where the rope is severely kinked or bent.

- Fiber Breakage: Examine the rope closely for any broken fibers, particularly near the surface. This is a clear indication of internal damage.

- Discoloration: Significant discoloration can indicate chemical degradation or sun damage, weakening the rope’s structure.

- Stiffness or Brittleness: A rope that feels unusually stiff or brittle is likely degraded and should be replaced.

- Swelling or Flattening: These can indicate internal damage or the presence of moisture which can weaken the rope.

Remember, when in doubt, throw it out! Replacing a damaged rope is far cheaper than suffering the consequences of a failure.

Q 5. What are the common causes of rope breakage?

Rope breakage can stem from a variety of factors, often involving a combination of circumstances. Here are the most common causes:

- Overloading: Exceeding the rope’s rated load capacity is the most frequent cause of failure. Always use a rope with a safety factor appropriate for the application.

- Sharp Objects: Abrasion from sharp objects weakens the fibers and creates stress points, leading to eventual breakage.

- Age and Degradation: Ropes degrade over time due to ultraviolet (UV) radiation, exposure to moisture, and chemical weathering. Older ropes lose strength and become more susceptible to failure.

- Improper Knots: Incorrectly tied knots concentrate stress on specific points, causing premature failure.

- Impact Loads: Sudden, forceful impacts can exceed the rope’s dynamic strength, resulting in breakage.

- Manufacturing Defects: Although rare, manufacturing defects can cause inherent weaknesses within the rope.

Q 6. Explain different methods for inspecting ropes for damage.

Rope inspection is a critical aspect of safety. Different methods are employed depending on the context and type of rope. Here’s a breakdown:

- Visual Inspection: This is the most basic method, involving a thorough visual examination of the entire rope length for cuts, abrasions, kinks, broken fibers, and signs of wear.

- Touch Inspection: Running your hands along the rope can help detect subtle irregularities, such as stiffness or unusual softness, which might indicate internal damage.

- Load Testing (with caution): For critical applications, controlled load testing can verify the rope’s strength, although this should only be done by trained professionals with specialized equipment.

- Ultrasonic Testing: Advanced techniques, such as ultrasonic testing, provide a more thorough assessment of the rope’s internal structure, detecting hidden damage.

Remember, regular inspections, conducted before every use, are crucial to identify potential problems before they lead to accidents.

Q 7. Describe the proper procedure for inspecting a climbing harness.

Inspecting a climbing harness is a crucial safety measure, and should be done before every climb. The inspection must be thorough and meticulous. Here’s a step-by-step process:

- Visual Inspection: Examine all straps, buckles, and stitching for any signs of wear, cuts, abrasions, or fraying. Pay close attention to high-stress areas, such as leg loops and waist belt.

- Buckle Check: Carefully inspect all buckles, ensuring they function smoothly and lock securely. Check for any damage or distortion.

- Stitching: Examine the stitching throughout the harness, looking for any loose or broken threads. Weak stitching is a significant safety concern.

- Webbing: Inspect the webbing carefully for any signs of cuts, wear, or unusual stiffness. Look for any discoloration that might suggest degradation from UV exposure.

- Padding: Check the padding for any tears, wear or detachment. Significant wear may compromise comfort and protection.

- Function Test: After the visual inspection, perform a function test by putting on the harness and adjusting the straps, ensuring everything fits securely and correctly.

If you find any signs of damage or wear, the harness should be immediately removed from service and replaced. Don’t take chances with your safety!

Q 8. What are the limitations of various knot types under different loads?

Different knots have varying strengths and weaknesses depending on the load type and direction. For instance, a Bowline, while excellent for forming a loop that won’t slip, might not be ideal under heavy, sustained loads compared to a stronger knot like a Figure Eight. A clove hitch is quick to tie and useful for temporary attachments but is not suitable for heavy loads or critical situations. The same knot tied with different ropes will have different strengths; a larger diameter rope can bear more weight. Tensile loads (pulling straight) are generally better handled than side loads (forces perpendicular to the rope). A poorly tied knot, regardless of type, will significantly reduce its strength. Consider these limitations:

- Slippage: Some knots, like the overhand knot, are prone to slippage under load, rendering them unsuitable for critical applications.

- Creep: Certain knots can gradually loosen under sustained tension.

- Binding: Knots can bind or damage the rope, weakening it and creating a potential failure point.

- Load Type: A knot strong under tension might fail under side loading or shock loads.

- Rope Material: The material properties of the rope (strength, elasticity) interact significantly with knot performance.

For example, a bowline is suitable for a climbing rope used for attaching a harness, but for lifting heavy equipment, a more robust knot like a bowline on a bight would be better as it distributes stress. In contrast, an unreliable knot like a granny knot should be avoided for situations with weight considerations because of its poor ability to hold tension.

Q 9. How do you choose the appropriate knot for a specific task?

Choosing the right knot involves considering several factors:

- The task: What is the purpose of the knot? Is it for temporary attachment, a permanent connection, or to create a loop?

- The load: What kind of load will the knot be subjected to? Is it a static load, dynamic load (sudden impact), or a combination of both?

- The rope: What material is the rope made of? What is its diameter and strength?

- The environment: Are there any environmental factors that could affect the knot’s performance (e.g., temperature, moisture)?

For example, if I need to secure a heavy object for transport, I might choose a strong knot like a Figure Eight, a taut-line hitch, or a bowline, depending on the specific configuration required. For a lighter load, a simple overhand knot might suffice, but again, I need to consider what kind of load the knot will be experiencing (static or dynamic) and the overall setting.

A systematic approach is essential. I always start with a thorough risk assessment, considering all the possible load cases. I’d then research various knot options, comparing their strengths and weaknesses in light of my findings.

Q 10. Explain the concept of working load limit (WLL).

The Working Load Limit (WLL) is the maximum load that a piece of equipment, such as a rope, can safely withstand under normal working conditions. It’s crucial to stay well below the WLL to ensure safety and prevent equipment failure. The WLL is typically a fraction of the rope’s breaking strength, accounting for factors such as wear, tear, and unforeseen circumstances. Think of it as the safety margin built in.

Exceeding the WLL significantly increases the risk of rope failure, which can have serious consequences depending on the application. Imagine using a rope with a WLL of 100 kg to lift a 150kg load – the risk of a catastrophic failure would be unacceptably high.

Q 11. How do you determine the WLL of a rope?

Determining the WLL of a rope isn’t a simple calculation; it’s based on several factors including the manufacturer’s specifications, the rope’s material, diameter, construction, and age. The manufacturer typically provides the breaking strength (the force required to break the rope) but it is not a measure of safety.

The WLL is usually a fraction of the breaking strength – a common safety factor is 5:1 or 6:1, meaning the WLL is 1/5th or 1/6th of the breaking strength. However, this can vary based on industry standards and specific applications. Furthermore, the WLL can be affected by environmental factors like UV degradation and chemical exposure. Regular rope inspections are paramount. Always refer to the manufacturer’s documentation. Using a damaged or aged rope should always be avoided; if unsure, replace the rope.

For example, if a rope has a breaking strength of 600kg, a safety factor of 5 would give a WLL of 120kg. If it’s not clearly indicated on the equipment, consulting the manufacturer’s specifications is crucial.

Q 12. What are the safety regulations related to rope usage in your field?

Safety regulations regarding rope usage vary based on location and the specific application (e.g., climbing, rigging, marine). However, common threads include:

- Regular Inspections: Ropes must be inspected regularly for signs of wear, damage, or deterioration.

- WLL Compliance: Loads must always remain below the WLL.

- Proper Knot Selection: Appropriate knots should be used for the task, considering factors mentioned earlier.

- Training and Certification: Personnel using ropes in critical operations must be adequately trained and certified.

- Safe Work Practices: Following established safety protocols and procedures is essential.

- Record Keeping: Maintaining records of inspections, training, and rope usage is vital for accountability and tracking.

Ignoring safety regulations can lead to accidents and fatalities; therefore, adhering to them is of utmost importance.

Q 13. Describe your experience with different types of rope materials.

My experience encompasses various rope materials, each with unique characteristics:

- Nylon: Strong, lightweight, and stretches under load, making it suitable for shock absorption. It’s commonly used in climbing and rescue applications. However, it is susceptible to UV degradation.

- Polyester: Strong, durable, and less stretchy than nylon. It’s often used in heavy lifting or applications where minimal stretch is desired. It is also more resistant to UV degradation than nylon.

- Polypropylene: Lightweight, inexpensive, and floats on water. It’s often used in marine or general-purpose applications. It possesses low strength compared to nylon or polyester.

- Manila (Natural Fiber): Strong, relatively inexpensive, and biodegradable. However, it’s susceptible to moisture and rot, and its strength is affected by environmental conditions. This type of rope is less common in professional settings today.

- Kevlar: Extremely strong, heat-resistant, and used in specialized applications such as high-strength rescue and industrial settings.

The choice of material is critical to match the needs of the job. I would choose a nylon rope for a situation requiring shock absorption, but polyester for heavy lifting where strength and low stretch are priorities.

Q 14. How do you handle a broken rope during a critical operation?

Handling a broken rope during a critical operation requires immediate and decisive action, prioritizing safety above all else.

Steps I’d take:

- Immediate Stop: Stop the operation immediately. Do not attempt to continue with a compromised rope.

- Secure the Load: If possible, secure the load to prevent it from falling or causing damage. This might involve using alternative equipment or securing the load to a stable structure.

- Assess the Situation: Carefully assess the situation to determine the cause of the break and identify any potential hazards.

- Alert Others: Inform any relevant personnel about the situation, including emergency responders if necessary.

- Evacuate if Necessary: If there is any risk to personnel, evacuate the area immediately.

- Damage Control: Once the immediate danger has passed, thoroughly inspect the remaining equipment. Determine the extent of the damage and take steps to prevent future incidents.

- Investigation: After the situation has been resolved, conduct a thorough investigation to determine the root cause of the rope failure. This might involve examining the broken rope, reviewing safety procedures, and interviewing personnel.

Remember, safety is paramount. Improvised solutions should only be considered if they do not introduce additional risks, and only after a thorough risk assessment.

Q 15. What are the signs of impending rope failure?

Recognizing impending rope failure is crucial for safety. Several signs indicate weakening: abrasions (surface wear), which can significantly reduce strength; cuts or nicks, which create stress concentration points; fraying, where individual fibers are separating; unusual stiffness or softness compared to its normal feel; and a musty or unusual odor, suggesting internal degradation. Additionally, if the rope shows signs of UV degradation (fading, brittleness) from prolonged sun exposure, it’s time for replacement. Think of it like a worn-out tire – cracks and bulging are clear signs of impending failure. Regular inspection is key to identifying these issues before they lead to accidents.

- Abrasions: Look for areas where the rope’s outer sheath is worn away, exposing the core fibers.

- Cuts/Nicks: Even small cuts can dramatically reduce strength.

- Fraying: Individual fibers separating indicate internal damage.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with knot tying in challenging environments.

My experience with knot tying in challenging environments includes working on high-angle rescue operations in mountainous terrain and maritime environments during storms. In these situations, speed, precision, and choosing the right knot for the conditions are paramount. I’ve worked extensively with both static and dynamic ropes, employing different knots depending on the load, environment, and the task at hand. For instance, a bowline is reliable for a static load and quick to tie, but a figure-eight follow-through provides more security for climbing applications. In high winds, securing knots firmly and using extra precautions to avoid slippage becomes critical. I always prioritize using redundant knots and systems wherever possible to mitigate risk. The ability to adapt knot choice and tying techniques to the specific conditions is a skill honed over many years of practical experience.

Q 17. How do you ensure the security of knots under dynamic loads?

Ensuring knot security under dynamic loads requires a multi-pronged approach. First, choose the correct knot – a poorly chosen knot can easily fail under stress. The bowline, while versatile, isn’t ideal for dynamic loads; instead, a figure-eight or a clove hitch, properly backed up, would be better choices. Second, proper technique is crucial. Each knot needs to be tied tightly, with no slack, and cinched securely. Third, it is essential to always have multiple redundancies built into your system. This means using multiple knots, or incorporating additional safety features such as carabiners or other locking mechanisms. Think of it like a backup parachute—you hope you’ll never need it, but having it is crucial. Finally, regular inspection and testing are crucial. Regularly check the integrity of knots and related equipment to ensure they are securely fastened and free from damage.

Q 18. Explain your experience with different types of break detection techniques.

My experience with break detection spans various methods. For ropes, visual inspection is the first step, looking for signs of wear and tear as mentioned earlier. Beyond visual inspection, specialized equipment like rope testers can measure residual strength. For fiber optic cables, optical time-domain reflectometry (OTDR) is invaluable. OTDR sends pulses of light down the cable and measures the reflections to pinpoint breaks or other impairments. This provides a precise location of the break, making repairs more efficient. In addition, I’ve used techniques like visual fault locators (VFLs), which use a visible laser light source to help trace the cable and visually locate breaks. Each method has its strengths and limitations, and selecting the appropriate technique depends on the specific application and available resources.

Q 19. How do you troubleshoot a break in a fiber optic cable?

Troubleshooting a fiber optic cable break begins with identifying the precise location of the break. As mentioned, OTDR testing is the gold standard. Once the location is pinpointed, access to the cable is needed. The damaged section is then carefully removed and replaced with a new fiber optic splice or connector. The splice or connector is then carefully tested using an OTDR to ensure the repair is successful and that there are no further signal impairments. Proper cleaning and preparation of the fiber ends are absolutely crucial for a successful splice, preventing signal loss or further breaks. Finally, the entire repaired section is then retested to ensure the repair has restored the integrity of the cable and its optical performance.

Q 20. Describe a time you had to solve a knot-related problem.

During a high-angle rescue training exercise, a trainee accidentally tied a knot that was not suitable for the load and conditions. This was a type of slippery knot that would loosen under tension. Recognizing the potential danger, I immediately intervened, explaining the inadequacy of the knot and demonstrating the proper technique for securing a safety line. The knot was carefully untied and replaced with a secure figure-eight on a bight, which distributes the load more effectively. It is crucial to ensure that all involved understand the significance of using the correct knot for the specific situation. This incident highlighted the importance of proper knot selection and the need for constant vigilance to prevent accidents.

Q 21. What are the common types of rope damage and how do you address them?

Common rope damage includes abrasion (surface wear), cuts, crushing, UV degradation (sunlight damage), chemical damage, and internal damage. Abrasion can be addressed by careful handling and using protective sleeves where necessary; cuts usually require cutting the damaged section and re-tying (or replacing the rope). Crushing can weaken the rope significantly, and damaged sections should be removed. UV degradation necessitates replacing the rope as this weakens the fiber structure. Chemical damage might require specialized cleaning or, again, replacement. Internal damage is often invisible and may require destructive testing to assess the extent of the damage. Always inspect rope thoroughly before each use. Regular maintenance and prompt attention to any damage will minimize risk of failure.

Q 22. How do environmental factors influence rope strength and lifespan?

Environmental factors significantly impact rope strength and lifespan. Think of it like this: just as prolonged sun exposure fades a shirt, harsh elements weaken ropes. UV radiation from sunlight degrades the rope’s fibers, making it brittle and prone to breakage. Similarly, moisture, especially saltwater, can weaken fibers and promote the growth of mildew, reducing strength and creating weak points. Extreme temperatures, both high and low, can also affect a rope’s flexibility and durability. For example, prolonged exposure to freezing temperatures can make synthetic ropes brittle, increasing the risk of snapping under load. Conversely, prolonged exposure to high temperatures can cause the fibers to weaken and melt. Regular inspection is crucial to identify such damage. I always recommend storing ropes in a cool, dry place, away from direct sunlight and moisture, to prolong their life.

Q 23. Describe your proficiency in different knot tying techniques.

My knot-tying proficiency spans a wide range of techniques, from basic knots like the bowline and clove hitch, essential for everyday tasks, to more complex knots used in specialized applications, such as the figure eight follow-through for climbing and the taut-line hitch for camping. I’m adept at choosing the appropriate knot for a given task, considering factors such as rope material, load requirements, and the environment. I also understand the importance of proper knot execution, ensuring that there’s no slippage or potential for failure. I’ve had extensive experience with knots used in sailing, arboriculture, and rescue operations, each requiring a nuanced understanding of knot behavior under different load and stress conditions.

- Bowline: A strong loop that won’t slip.

- Clove Hitch: Quick and easy for attaching a rope to a post.

- Figure Eight Follow-Through: Secure and reliable for climbing.

- Taut-line Hitch: Adjustable tension knot for tarps and lines.

My practical experience involves consistently achieving secure and reliable knots across diverse applications, often under pressure.

Q 24. What safety precautions do you take when inspecting or working with ropes?

Safety is paramount when handling ropes. Before inspecting or working with any rope, I always conduct a thorough risk assessment. This includes identifying potential hazards, such as sharp objects, overhead obstructions, and unstable surfaces. I wear appropriate personal protective equipment (PPE), such as gloves to protect my hands from abrasion and eye protection to prevent injury from flying debris. I always ensure that the area is clear of obstructions and that I have sufficient space to work safely. When inspecting a rope under load, I never put myself in a position where I could be injured if the rope were to fail. I utilize proper lifting techniques and ensure that any heavy ropes are handled safely, with the assistance of colleagues when needed. I frequently inspect my equipment and maintain high standards of cleanliness. The prevention of falls is always at the forefront of my safety procedures.

Q 25. How do you document your inspection and findings?

My inspection documentation is meticulous and thorough. I use a standardized inspection checklist to ensure consistency and avoid overlooking critical details. The checklist includes information such as the rope’s type, diameter, length, manufacturer, date of manufacture, and previous use history. I meticulously document any visible damage, including fraying, cuts, abrasion, discoloration, or unusual stiffness. I take photographs of any significant damage found. The date and time of the inspection are recorded along with my signature and any recommendations for repair or replacement. This detailed record-keeping is crucial for maintaining safety standards, tracking rope lifespan, and complying with regulatory requirements. All findings are entered into a digital database for easy access and retrieval.

Q 26. Explain the importance of regular rope inspection and maintenance.

Regular rope inspection and maintenance are vital for ensuring safety and preventing accidents. Think of it like regular car maintenance; neglecting it can lead to serious consequences. Regular inspection allows early detection of wear and tear, preventing catastrophic failures. This can include minor damage like abrasions that, if ignored, could lead to complete rope breakage under load. Furthermore, regular maintenance ensures optimal rope performance. Proper storage, cleaning, and occasional treatment with UV protectant extend the lifespan of ropes and prevent premature degradation. This proactive approach not only safeguards life and property but also reduces the overall cost of ownership by extending the life of equipment.

Q 27. Describe your experience with different types of splicing techniques.

My experience with splicing techniques encompasses various methods, tailored to different rope types and applications. I’m proficient in techniques such as the eye splice, used to create a strong loop at the end of a rope, perfect for creating anchor points or attaching to equipment. I am also skilled in the long splice, which creates a seamless join between two ropes, ideal for creating longer lengths without sacrificing strength. These splicing techniques involve careful manipulation of individual fibers within the rope, requiring precision and skill. My experience includes splicing both natural fiber ropes (like manila) and synthetic ropes (like nylon and polypropylene), each requiring specific techniques to achieve optimal strength and longevity. The selection of the appropriate splice depends on the material, load capacity, and application. Incorrect splicing can lead to significant strength reduction and ultimately rope failure.

Q 28. How do you identify and address potential hazards related to knot failure?

Identifying and addressing potential hazards related to knot failure requires a multifaceted approach. Firstly, I always conduct a thorough visual inspection of the knot, checking for any signs of slippage, deformation, or damage to the rope fibers. Secondly, I assess the load on the rope and its compatibility with the knot’s capacity. Using an incorrect knot for the load is a common cause of failure. Thirdly, I consider the environmental conditions that may impact the knot’s performance; factors like moisture, extreme temperature, and UV radiation can significantly affect knot strength. If I identify any potential hazards, I immediately take corrective action, which may include replacing the knot with a more appropriate one, replacing the damaged rope section, or even stopping the operation entirely until the hazard is mitigated. Prevention is key: regular inspection and using the correct knots for the situation are crucial for avoiding this type of failure.

Key Topics to Learn for Knot Tying and Break Detection Interview

- Fundamental Knots: Mastering essential knots like the bowline, clove hitch, and figure eight, understanding their strengths, weaknesses, and appropriate applications.

- Knot Strength and Material Science: Analyzing the impact of rope material, diameter, and knot type on overall strength and reliability. Understanding factors that contribute to knot failure.

- Break Detection Techniques: Identifying visual indicators of rope damage (e.g., fraying, abrasion, discoloration) and developing effective inspection protocols.

- Practical Application in Various Fields: Exploring the applications of knot tying and break detection in relevant industries (e.g., maritime, climbing, construction, rescue). Consider scenarios and case studies.

- Safety Procedures and Regulations: Understanding relevant safety standards and best practices for working with ropes and related equipment. Knowing how to mitigate risks associated with knot failure.

- Troubleshooting and Problem-Solving: Developing the ability to diagnose and solve problems related to knotting and break detection, including identifying and addressing potential hazards.

- Advanced Knotting Techniques: Explore more complex knots and their applications relevant to your target role. Consider specialized knots used in your field.

- Non-Destructive Testing Methods: Familiarize yourself with any non-destructive testing methods used to assess rope integrity beyond visual inspection.

Next Steps

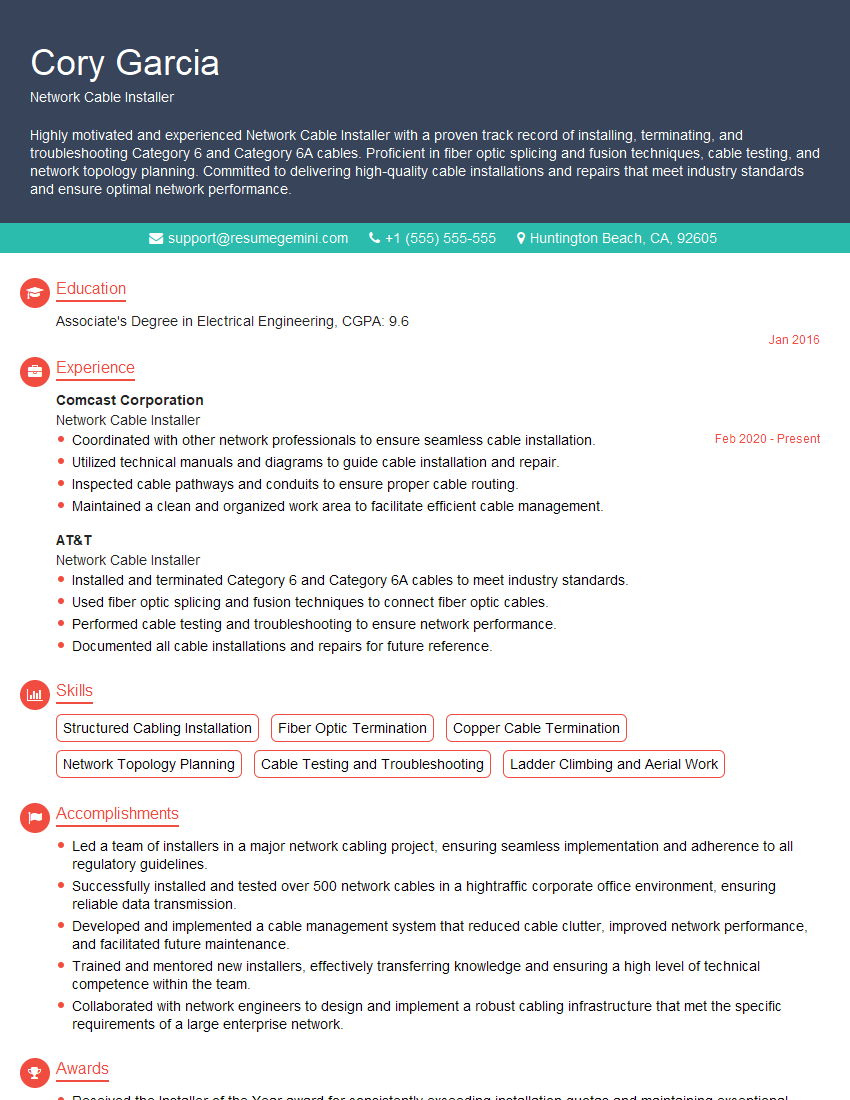

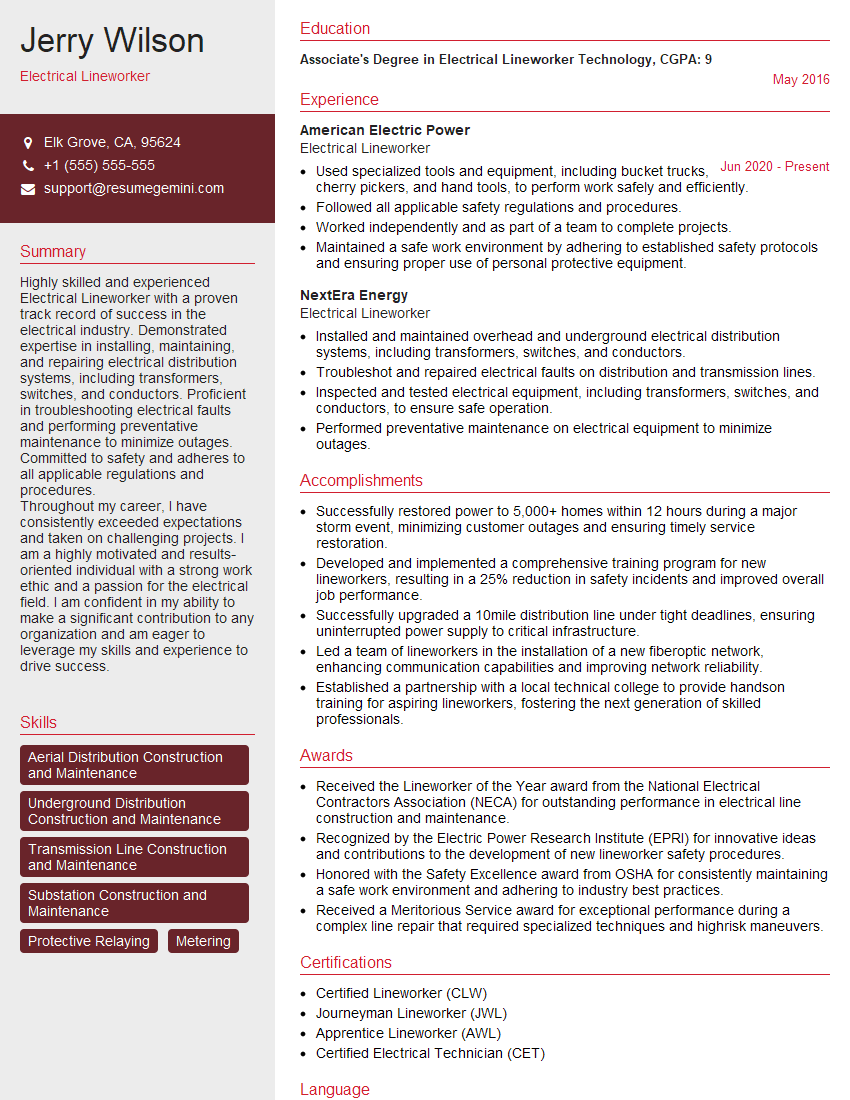

Mastering knot tying and break detection is crucial for career advancement in many high-skill fields, ensuring safety and efficiency. A strong resume is your first step towards landing your dream job. To make your application stand out, craft an ATS-friendly resume that highlights your expertise. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We offer examples of resumes tailored to the Knot Tying and Break Detection field to guide you in showcasing your skills and experience effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good