Preparation is the key to success in any interview. In this post, we’ll explore crucial Knowledge of Die Maintenance and Repair Techniques interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Knowledge of Die Maintenance and Repair Techniques Interview

Q 1. Describe your experience with different types of dies (progressive, compound, etc.).

My experience encompasses a wide range of die types, each with its unique characteristics and applications. Progressive dies, for instance, are highly efficient for mass production, performing multiple operations in a single stroke. I’ve worked extensively with these, optimizing their setup for speed and precision in automotive part manufacturing. Compound dies, on the other hand, are more versatile but generally slower. They’re ideal for intricate parts requiring several operations within a single die set. I’ve used these effectively in the production of complex electronic components. I’m also familiar with single-stage dies (used for simpler operations), and transfer dies (often used for high-volume production with multiple stages). Understanding the strengths and limitations of each type is crucial for selecting the right die for a specific job. For example, a progressive die might be perfect for a high-volume, simple part like a washer, but a compound die would be more appropriate for a part requiring multiple, more complex operations, such as a stamped gear with a formed tooth profile.

Q 2. Explain the process of die troubleshooting and identifying common problems.

Die troubleshooting is a systematic process. It starts with a thorough examination of the produced parts, identifying defects like cracks, burrs, or dimensional inaccuracies. Then, I move to inspect the die itself, checking for wear and tear on punches, dies, and strippers. Common problems include punch breakage (often due to material hardness or misalignment), die wear (leading to dimensional inconsistencies), and stripper plate issues (causing part marking or sticking). I use a methodical approach, starting with the simplest possible causes and systematically eliminating them. For example, if parts are consistently undersized, I’d first check for die wear, then punch alignment, and finally, material properties. If parts are bent or cracked, I’d scrutinize stripper plate function and blank holding issues. Documentation and careful analysis are vital in identifying recurring problems and improving the preventative maintenance process.

Q 3. How do you maintain and repair die components such as punches, dies, and strippers?

Maintaining and repairing die components requires precision and care. Punch sharpening and repair might involve grinding, honing, or even replacing worn sections. I use specialized equipment to ensure the correct angles and tolerances are maintained. Die maintenance often includes cleaning and polishing to remove burrs and debris. Stripper plates need regular inspection for wear and alignment; replacement or adjustment is sometimes necessary. This process also includes lubrication – the correct lubricant, applied appropriately, extends the life of the die and improves the quality of the produced parts. For instance, I’ve used wire EDM (Electrical Discharge Machining) to repair minor cracks in hardened steel dies, minimizing downtime and material loss. Regular cleaning and lubrication of all components, as well as meticulous inspection for wear, prevent unexpected failures and enhance the lifespan of the die set.

Q 4. What are the safety precautions you take when maintaining and repairing dies?

Safety is paramount during die maintenance and repair. I always use appropriate personal protective equipment (PPE), including safety glasses, gloves, hearing protection, and steel-toed boots. Before starting any work, I lock out and tag out the power source to prevent accidental activation. Compressed air should be used cautiously to avoid injury from high-pressure blasts. I always ensure the die is properly secured and supported during maintenance to prevent it from falling or shifting. Sharp tools are handled with extreme care, and regular tool maintenance helps prevent accidents. Furthermore, I follow strict protocols for handling and disposing of potentially hazardous materials like cutting fluids and lubricants. Working with heavy equipment, I adhere to all company-specified safety guidelines.

Q 5. How do you ensure the accuracy and precision of die components during repair?

Ensuring accuracy and precision during repair involves using precise measuring tools and techniques. This might include using micrometers, calipers, and optical comparators to verify dimensions and tolerances. Precise grinding and polishing techniques, performed on specialized equipment, maintain the required accuracy. In cases of significant wear, replacement of the components is necessary, selecting parts with the correct specifications. Furthermore, careful alignment of punches and dies is critical, achieved using precise alignment pins and jigs. Regular calibration of measuring instruments and adherence to strict quality control procedures are crucial to maintain the overall precision of the die components. For example, I might use a coordinate measuring machine (CMM) to ensure that a repaired die conforms exactly to the original specifications.

Q 6. What methods do you use to measure and inspect die components?

I employ a variety of methods for measuring and inspecting die components. Micrometers and calipers are used for precise dimensional measurements, verifying tolerances and detecting wear. Optical comparators help to examine the surface finish and detect minute imperfections. Surface roughness testers evaluate the surface texture, which is critical for some applications. Coordinate Measuring Machines (CMMs) provide highly accurate 3D measurements, especially useful for complex geometries. Hardness testing determines the material’s resistance to deformation, crucial for predicting component life. In addition, visual inspection is used extensively to identify wear, damage, or contamination. I also utilise specialized software to analyze and manage inspection data, ensuring traceability and facilitating preventative maintenance scheduling.

Q 7. Explain your experience with different die materials and their properties.

My experience covers a range of die materials, each with unique properties influencing their suitability for different applications. High-speed tool steels like M2 and D2 are common choices due to their hardness and wear resistance, suitable for high-volume production. Powder metallurgy steels offer superior toughness and fatigue resistance, often used in demanding applications. Carbide dies are exceptionally hard and wear-resistant but can be brittle; I’ve used these successfully in applications requiring exceptional durability. The choice of material is influenced by factors like the material being stamped, the production volume, and the desired part quality. For instance, when stamping very hard materials, a carbide die might be necessary, while a high-speed steel die may be sufficient for softer materials, offering a better balance of cost and performance. Understanding these material properties allows for informed decisions in selecting and maintaining optimal dies for specific needs.

Q 8. Describe your experience with various die maintenance tools and equipment.

My experience with die maintenance tools and equipment spans a wide range, encompassing both traditional and advanced technologies. I’m proficient in using precision measuring instruments like micrometers, calipers, and dial indicators to assess die dimensions and wear. I’m also experienced with various hand tools, including punches, chisels, files, and hammers, crucial for minor repairs and adjustments. Furthermore, I’m familiar with power tools such as surface grinders, lapping machines, and EDM (Electrical Discharge Machining) equipment for more complex repairs and refurbishment. For example, I’ve used a surface grinder to precisely remove material from a worn punch to restore its dimensions and ensure accurate stamping. My experience extends to using specialized equipment such as die setters, which allow for precise alignment and mounting of dies, and presses themselves which I regularly inspect and maintain to ensure optimal performance.

- Precision Measuring Instruments: Micrometers, calipers, dial indicators

- Hand Tools: Punches, chisels, files, hammers

- Power Tools: Surface grinders, lapping machines, EDM equipment

- Specialized Equipment: Die setters, presses

Q 9. How do you handle emergency die repairs during production?

Emergency die repairs during production require a calm, systematic approach. The first step is always safety – securing the press and ensuring no one is at risk. Then, a thorough assessment of the damage is necessary to determine the severity and cause. Minor issues, such as a broken screw or a slight misalignment, can often be quickly addressed with hand tools and adjustments. For more significant damage, like a cracked component, temporary fixes might involve welding or using shims to restore functionality until a proper repair can be performed. Accurate documentation of the issue, temporary fix, and downtime is crucial. For example, I once had to repair a broken stripper plate during a high-volume production run. I quickly fabricated a temporary replacement using readily available materials, minimizing downtime to a mere 30 minutes. Detailed documentation of the process allowed for a more efficient permanent repair later.

Q 10. What is your experience with preventative maintenance schedules for dies?

Preventative maintenance schedules are critical for maximizing die lifespan and minimizing downtime. These schedules vary depending on the type of die, material being processed, and production volume. However, a common approach involves regular inspections, cleaning, and lubrication. This includes checking for wear, damage, and misalignment. More involved preventative measures might include die sharpening, honing, or component replacement on a predetermined cycle. I usually develop these schedules in consultation with production managers, considering factors such as production targets and historical failure rates. For instance, a progressive die used in high-volume production would require more frequent inspections and lubrication compared to a less frequently used blanking die. Proper scheduling minimizes unplanned downtime due to die failure.

Q 11. How do you document die maintenance and repair activities?

Documentation of die maintenance and repair is crucial for tracking performance, identifying trends, and ensuring quality control. I use a combination of methods, including physical logs and digital records. Physical logs, often bound notebooks, are used to record immediate observations, repairs made, and the time spent. Digital systems, such as CMMS (Computerized Maintenance Management Systems) software, provide a centralized repository for this information, making it easily accessible and allowing for data analysis. Each entry includes the die identification number, date, time, description of the maintenance or repair, parts used, and the technician’s initials. Furthermore, photographs and/or videos can be used to document the extent of damage before and after the repair. This meticulous record-keeping ensures accountability and aids in preventative maintenance planning.

Q 12. How do you interpret engineering drawings and specifications related to dies?

Interpreting engineering drawings and specifications is fundamental to my work. I am proficient in reading blueprints and technical specifications, understanding symbols, dimensions, tolerances, and material specifications. This allows me to identify critical components, understand the die’s functionality, and properly perform maintenance and repairs. For example, the tolerances on a precision die might require the use of specialized measuring equipment and more delicate repair techniques. A strong understanding of the drawings ensures that repairs restore the die to its original specifications, maintaining the quality of the stamped parts. I am comfortable using various CAD software packages, helping me to visualize the die’s 3D structure and aiding in trouble-shooting.

Q 13. Explain your understanding of different die lubrication techniques.

Die lubrication is critical for extending die life and ensuring smooth operation. Different lubrication techniques are employed depending on the application and die materials. Common methods include applying oil or grease directly to the critical contact surfaces such as punch and die interfaces or using a centralized lubrication system. The choice of lubricant is crucial, and factors such as the material being stamped, the temperature, and the pressure exerted should be considered. For instance, a high-pressure stamping operation might require a specialized high-temperature grease capable of withstanding the extreme conditions. The goal is to minimize friction and wear while ensuring that the lubricant doesn’t interfere with the stamping process. Insufficient lubrication can result in galling or seizing, while excessive lubrication can cause contamination of the final product.

Q 14. Describe your experience with die sharpening and honing.

Die sharpening and honing are specialized processes used to restore the sharpness and precision of punches and dies. Die sharpening typically involves using grinders, while honing involves using abrasive stones or lapping compounds for finer adjustments. These procedures require a high degree of skill and precision to avoid damaging the die. The process is often iterative, with regular measurements to ensure the desired dimensions and surface finish are achieved. I use specialized fixtures to hold the die components securely during sharpening and honing, minimizing the risk of damage. The success of these processes depends on understanding the geometry of the die components and the proper selection of abrasives. Incorrect sharpening can lead to premature failure or defects in the final product.

Q 15. How do you manage and maintain a die inventory?

Managing a die inventory effectively requires a robust system that ensures traceability, accessibility, and efficient utilization. Think of it like a well-organized library for your tooling. I typically employ a combination of physical and digital methods. Physically, dies are stored in clearly labeled, climate-controlled areas to prevent damage from rust or warping. Each die has a unique identification number linked to a detailed record in a database. This database includes information such as the die’s specifications, material, intended use, maintenance history (including repair dates, parts replaced, and any notes from technicians), and its current status (in use, in storage, requiring repair, etc.). Regular audits are conducted to ensure accuracy and identify any discrepancies. The digital aspect allows for quick searching, tracking, and reporting, streamlining the entire process. For instance, if we need a specific die for a production run, we can quickly locate its storage location and its maintenance history to ensure it’s in optimal condition. This minimizes downtime and maximizes productivity.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your troubleshooting skills for common die failures?

Troubleshooting die failures requires a systematic approach. I usually start by visually inspecting the die for obvious signs of damage like cracks, fractures, or excessive wear. Then, I analyze the nature of the defect in the produced part—is it a dimensional issue, a surface imperfection, or a complete part failure? This helps pinpoint the potential source of the problem within the die. For example, if the parts are consistently undersized, it might indicate wear on the punch or die cavity. If there are surface imperfections, the problem may lie with the die’s surface finish or lubrication. I use a combination of measuring instruments (more on that later) and specialized software to analyze the data and confirm my diagnosis. Finally, based on my findings, I develop a repair plan, sourcing any necessary replacement parts or coordinating with specialized technicians if the damage is beyond simple repair.

Q 17. How do you identify and address die wear and tear?

Identifying and addressing die wear and tear is crucial for maintaining production quality and efficiency. It’s like regularly servicing a car to prevent major breakdowns. Regular inspections are key, checking for things like:

- Erosion: Gradual loss of material due to friction.

- Fractures: Cracks or breaks in the die material.

- Scoring: Surface scratches or gouges.

- Chipping: Small pieces breaking off the die.

- Polishing: Restoring the surface finish of the die.

- Grinding: Removing worn material to restore dimensions.

- Re-coating: Applying a protective coating to extend die life.

- Replacing worn components: Swapping out damaged punches, dies, or other parts.

Q 18. Describe your experience with automated die maintenance systems.

My experience with automated die maintenance systems involves working with computerized monitoring systems that track die performance parameters in real time. These systems often incorporate sensors that detect vibrations, temperature changes, and other indicators of potential problems. Data collected by these systems can provide early warnings of impending failures, allowing for proactive maintenance and reducing downtime. I’m also familiar with robotic systems used for tasks like die cleaning, polishing, and even the automated replacement of worn components. While automation offers significant advantages in terms of efficiency and consistency, it’s important to remember that human expertise remains essential for diagnosing complex issues and implementing nuanced repair strategies. The human element is indispensable in interpreting the data generated by these systems and applying effective problem-solving techniques.

Q 19. What are your skills in using measuring instruments like calipers and micrometers?

I possess extensive experience with various precision measuring instruments, including calipers and micrometers. Calipers are useful for quick measurements, such as checking the overall dimensions of a die or a produced part. Micrometers, on the other hand, offer higher precision, allowing for extremely accurate measurements down to fractions of a millimeter—crucial for detecting subtle wear patterns. I’m proficient in using both digital and vernier models, understanding the nuances of each instrument’s operation and maintaining calibration to ensure accuracy. For instance, when inspecting a die for wear, I might first use calipers to check the overall dimensions and then employ micrometers to measure critical features with greater precision, ensuring all measurements are within the specified tolerance. This skill is fundamental to my ability to accurately assess the condition of dies and determine the appropriate maintenance strategies.

Q 20. How familiar are you with different types of die coatings and their applications?

My familiarity with die coatings extends to various types and their specific applications. Different coatings offer different benefits, such as enhanced wear resistance, improved lubricity, or corrosion protection. For instance:

- Titanium nitride (TiN): Offers excellent wear resistance and hardness, ideal for high-speed, high-pressure applications.

- Chromium nitride (CrN): Provides good wear resistance and corrosion protection.

- Diamond-like carbon (DLC): Offers exceptional wear resistance, low friction, and chemical inertness.

Q 21. How do you assess the overall condition of a die to determine necessary maintenance?

Assessing a die’s condition involves a multifaceted approach. It’s like a thorough medical checkup for the die. I start with a visual inspection, looking for cracks, chipping, or excessive wear. I then use precision measuring instruments like calipers and micrometers to check for dimensional accuracy and measure wear patterns. I might also employ non-destructive testing methods such as ultrasonic testing or magnetic particle inspection to detect internal flaws. The assessment includes checking the die’s surface finish and assessing the condition of any coatings. I analyze the die’s maintenance history, noting any previous repairs or replacements. Finally, I consider the production history of the die, identifying any trends in part quality or production issues that might indicate die-related problems. This holistic approach helps me create a maintenance plan that addresses both immediate needs and potential future problems. My goal is not only to fix immediate issues but also to optimize die lifespan and maximize its operational efficiency.

Q 22. Explain your experience with working on different types of presses.

Throughout my career, I’ve had extensive experience working with various types of presses, including progressive dies, transfer presses, and single-stage presses. My experience spans across different tonnage capacities, from smaller presses used for intricate components to larger presses for high-volume production. This experience encompasses all aspects of press operation, from setup and troubleshooting to maintenance and repair.

For example, in my previous role at Acme Manufacturing, I regularly maintained and repaired a 500-ton progressive die press used for stamping complex automotive parts. I was responsible for troubleshooting mechanical issues, such as die misalignment, broken punches and dies, and lubrication problems. I also have experience with hydraulic presses, where I addressed issues related to hydraulic leaks and pressure regulation. This diversity of experience allows me to quickly adapt to new press types and diagnose problems effectively.

- Progressive Dies: Expertise in troubleshooting complex die sets and optimizing production.

- Transfer Presses: Experience in maintaining the intricate transfer mechanisms and addressing alignment issues.

- Single-Stage Presses: Proficiency in repairing and maintaining simpler die sets, often used for smaller-scale production.

Q 23. Describe your experience with using Computer Numerical Control (CNC) machines for die maintenance or repair.

I possess significant experience utilizing CNC machines for die maintenance and repair. This includes using CNC milling machines, CNC lathes, and wire EDM (Electrical Discharge Machining) machines for precision machining of die components. My skills encompass programming CNC machines, setting up tooling, and performing complex machining operations to repair or replace damaged die sections. I am proficient in various CAM (Computer-Aided Manufacturing) software packages, ensuring accurate and efficient programming for complex geometries.

For instance, at Beta Industries, I used a CNC milling machine to precisely recreate a broken punch for a progressive die. The original punch was intricate and required highly accurate machining to ensure proper functionality. Using CAD/CAM software, I designed the replacement punch, programmed the CNC machine, and executed the machining process, resulting in a perfectly functional replacement part. This ensured minimal downtime and saved the company significant costs compared to sourcing a replacement from an external vendor.

Example G-code (simplified):G01 X10.0 Y20.0 Z-5.0 F100; Linear interpolationQ 24. How do you stay updated with the latest advancements in die maintenance and repair techniques?

Staying current with advancements in die maintenance and repair is crucial for maintaining peak efficiency and competitiveness. I actively engage in several methods to ensure my knowledge remains up-to-date. These include attending industry conferences and workshops, subscribing to relevant trade publications, and actively participating in online forums and professional networking groups dedicated to die-making and manufacturing.

Furthermore, I regularly participate in training courses focused on new technologies and techniques, such as advanced machining processes, predictive maintenance strategies, and new materials for die construction. I also actively seek out and review case studies and best-practice examples from industry leaders. This multifaceted approach helps me incorporate the latest advancements into my work, optimizing processes and improving overall productivity.

Q 25. Explain a situation where you had to make a critical repair decision under pressure.

During a critical production run at Gamma Manufacturing, a major fracture developed in the main shear of a high-volume progressive die. This caused a complete production shutdown. Under immense pressure to resume production as quickly as possible, I assessed the situation, considering the safety implications and the potential production losses.

Instead of a complete die replacement, which would have taken several days, I opted for an on-site repair. This involved carefully welding the fracture, followed by precision machining using a portable CNC milling machine to restore the shear’s original geometry and integrity. This approach required careful planning and precise execution, but it allowed us to resume production within 12 hours, significantly reducing financial losses and preventing schedule disruptions. The temporary repair held until a permanent replacement could be made, showcasing my ability to make critical decisions under pressure and optimize solutions in a time-sensitive context.

Q 26. Describe your understanding of the relationship between die maintenance and overall production efficiency.

The relationship between die maintenance and overall production efficiency is paramount. Proper die maintenance directly impacts production output, quality, and cost. Neglecting maintenance leads to increased downtime due to breakdowns, rejects due to inconsistent stamping quality, and ultimately, higher production costs.

Regular preventative maintenance, such as lubrication, inspection for wear and tear, and timely repairs, minimizes downtime and maintains product quality. A well-maintained die produces consistent, high-quality parts, reducing waste and the need for rework. This, in turn, translates to increased productivity and reduced manufacturing costs. A proactive approach to die maintenance is an investment that yields significant returns in overall production efficiency.

Q 27. How do you handle and resolve conflicts regarding die maintenance priorities?

Conflicts regarding die maintenance priorities often arise due to competing demands and resource constraints. My approach involves a collaborative and data-driven solution. I start by clearly understanding the production schedule and the impact of potential delays on different production lines.

I then assess the criticality of each die, considering factors such as production volume, potential downtime costs, and the impact on downstream processes. This assessment helps prioritize repairs based on urgency and potential impact. Open communication with production management and other stakeholders is crucial to ensure everyone understands the rationale behind the prioritization decisions. This transparent and collaborative approach fosters trust and minimizes potential conflicts.

Q 28. What are your salary expectations for this role?

My salary expectations for this role are in the range of [Insert Salary Range] annually. This is based on my extensive experience, proven track record of success, and the specific requirements and responsibilities of this position. I am flexible and open to discussing this further based on the full compensation and benefits package offered.

Key Topics to Learn for Knowledge of Die Maintenance and Repair Techniques Interview

- Die Design and Construction: Understanding various die types, materials, and their functionalities. This includes knowledge of critical dimensions and tolerances.

- Preventive Maintenance Procedures: Developing and implementing routine inspection and cleaning protocols to maximize die lifespan and minimize downtime. This also encompasses understanding lubrication techniques and schedules.

- Troubleshooting and Diagnostics: Identifying common die failures (e.g., cracking, wear, breakage) through visual inspection and performance analysis. This involves understanding the root causes of these failures.

- Repair Techniques: Mastering various repair methods such as grinding, polishing, welding, and part replacement. This includes selecting the appropriate repair method based on the type and severity of damage.

- Safety Procedures: Prioritizing safe working practices, including the proper use of personal protective equipment (PPE) and adherence to safety regulations during maintenance and repair.

- Record Keeping and Documentation: Maintaining accurate and detailed records of die maintenance, repairs, and performance data for analysis and future reference.

- Material Science and Metallurgy: Understanding the properties of different die materials and how they impact performance and longevity. This includes knowledge of heat treating and surface treatments.

- Problem-Solving and Analytical Skills: Applying systematic approaches to identify, analyze, and resolve die-related issues effectively and efficiently. This involves using root cause analysis techniques.

Next Steps

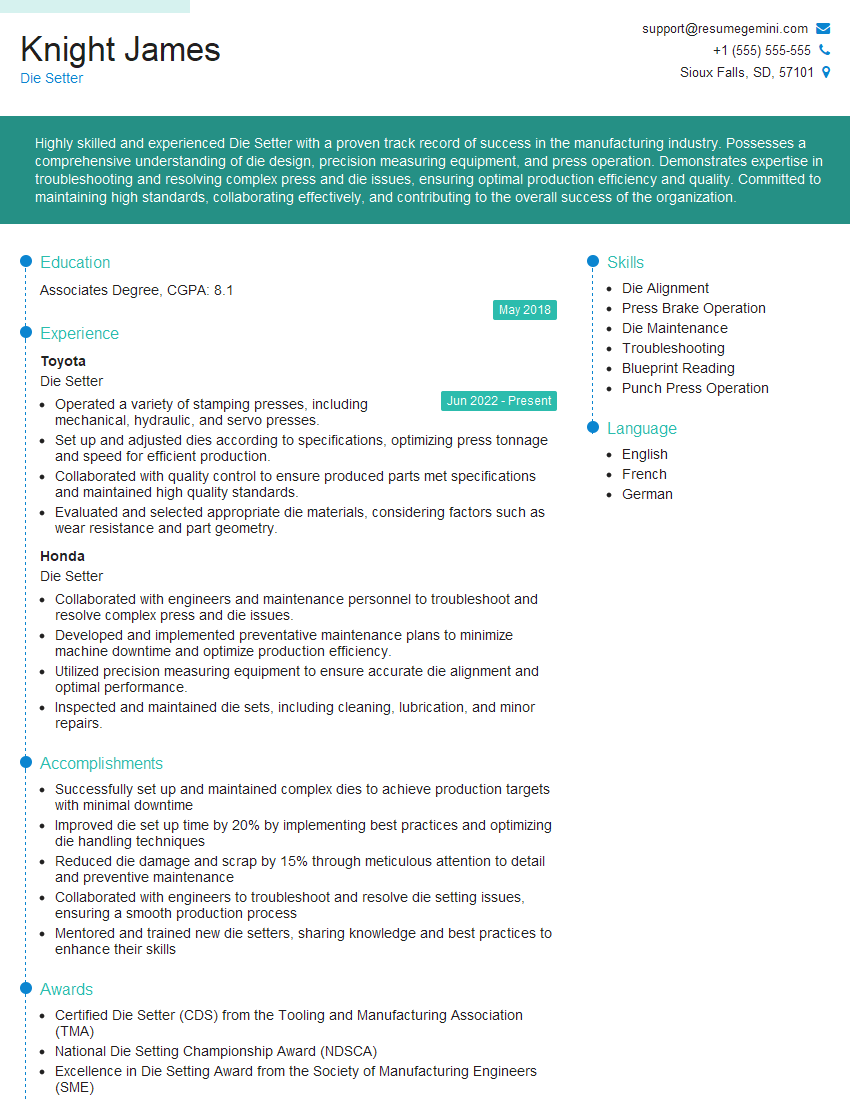

Mastering Knowledge of Die Maintenance and Repair Techniques is crucial for career advancement in manufacturing and related fields. A strong understanding of these techniques demonstrates valuable skills and expertise, leading to increased responsibility and higher earning potential. To showcase these skills effectively, create an ATS-friendly resume that highlights your accomplishments and technical proficiency. ResumeGemini is a trusted resource to help you build a professional and impactful resume that gets noticed. Examples of resumes tailored to Knowledge of Die Maintenance and Repair Techniques are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good