Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Knowledge of Die Materials and Heat Treatment Processes interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Knowledge of Die Materials and Heat Treatment Processes Interview

Q 1. Explain the difference between annealing and quenching.

Annealing and quenching are both heat treatment processes used to alter the microstructure and properties of metals, particularly steel, but they achieve opposite effects. Think of it like this: annealing is like giving the metal a relaxing spa day, while quenching is like plunging it into an ice bath.

Annealing involves heating the metal to a specific temperature, holding it there for a period of time, and then slowly cooling it. This process relieves internal stresses, softens the metal, and improves its ductility (ability to deform without breaking). It’s often used to make the metal easier to machine or form. For example, after forging a die, annealing might be used to reduce the hardness and make it easier to finish machining.

Quenching, conversely, involves heating the metal to a specific temperature, then rapidly cooling it, usually in water, oil, or a polymer solution. This rapid cooling traps the atoms in a high-energy state, resulting in a harder, stronger, but more brittle material. Quenching is crucial for achieving the high hardness needed in a die to withstand the forces of forming. Imagine the difference between a soft, malleable piece of clay versus a hardened ceramic tile – quenching is akin to transforming the clay into the tile.

Q 2. Describe the various types of steel used in die manufacturing and their properties.

Several types of steel are used in die manufacturing, each chosen based on the specific application and required properties. The selection depends heavily on the material being formed, the forming process (e.g., forging, stamping), and the expected die life.

- High Carbon Tool Steels (e.g., O1, A2, D2): These steels contain a high percentage of carbon (typically above 0.7%), providing exceptional hardness and wear resistance. O1 is a classic, versatile choice. A2 offers better toughness and resistance to softening at high temperatures. D2 is renowned for its excellent wear resistance and toughness, making it suitable for demanding applications. However, they can be brittle and require careful heat treatment.

- Hot Work Tool Steels (e.g., H13, P20): Designed for high-temperature applications like forging, these steels exhibit good hot hardness, resistance to softening at elevated temperatures, and moderate wear resistance. H13 is particularly popular due to its combination of properties. P20 is a less expensive alternative with good performance for certain applications.

- Cold Work Tool Steels (e.g., AISI D2, O1): Used in cold forming processes, these steels emphasize high hardness and wear resistance at room temperature. We’ve mentioned AISI D2 and O1 already – their versatility extends to cold work applications as well.

- Powder Metallurgy Tool Steels (e.g., CPM 10V, M4): These steels are made by powder metallurgy, leading to finer grain structures, improved uniformity, and enhanced properties like wear resistance and toughness. They often require specialized heat treatment procedures.

The choice of steel is a critical design consideration. Incorrect selection can lead to premature die failure or poor product quality.

Q 3. What are the common causes of die failure and how can they be prevented?

Die failure can be a costly issue, resulting in downtime, scrap, and potentially safety hazards. Common causes include:

- Wear and Erosion: Friction between the die and the workpiece leads to gradual wear, especially in high-volume production. This is exacerbated by abrasive materials or inadequate lubrication.

- Fracture: Excessive forces or impact during forming can cause cracking or fracture. This often stems from design flaws, improper heat treatment, or exceeding the die’s capacity.

- Plastic Deformation: Repeated stress cycles can cause the die to deform plastically, leading to dimensional inaccuracies and eventual failure. Poor material selection or inappropriate heat treatment contributes significantly to this.

- Thermal Fatigue: Repeated heating and cooling cycles, especially during hot forming, cause thermal stresses that can lead to cracking or degradation of the die material.

- Corrosion: Exposure to aggressive environments can corrode the die surface, reducing its lifespan and performance.

Prevention Strategies: Proper material selection, optimized die design, accurate heat treatment, effective lubrication, regular inspection and maintenance, and careful process control are crucial for preventing die failure. For instance, using a tougher steel grade or incorporating features to distribute stress more evenly can help extend die life significantly.

Q 4. Explain the process of case hardening and its applications in die manufacturing.

Case hardening is a process that selectively hardens the surface of a metal while keeping the core relatively soft and tough. This is achieved by increasing the carbon content of the surface layer. In die manufacturing, it’s a valuable technique because it provides the best of both worlds: a hard, wear-resistant surface for extended life and a tough core to resist fracture.

Common methods include:

- Carburizing: The workpiece is heated in a carbon-rich atmosphere (like methane gas), causing carbon to diffuse into the surface. This creates a carburized layer that can be hardened by subsequent heat treatment.

- Nitriding: Similar to carburizing, but nitrogen is used instead of carbon. Nitriding offers advantages like lower distortion and improved corrosion resistance.

After the case hardening process, the workpiece is typically quenched and tempered to achieve the desired hardness and toughness. The depth of the hardened case is controlled by the process parameters. In die manufacturing, case hardening enhances the wear resistance of die components, such as punches and inserts, extending their service life significantly without compromising the core’s toughness.

Q 5. What are the advantages and disadvantages of different die materials (e.g., steel, tungsten carbide)?

Choosing the right die material is a critical decision. Let’s compare steel and tungsten carbide:

Steel:

- Advantages: Relatively inexpensive, good toughness, readily machinable, and available in various grades with differing properties.

- Disadvantages: Lower wear resistance than tungsten carbide, prone to chipping and cracking under severe conditions, and requires heat treatment.

Tungsten Carbide:

- Advantages: Exceptional wear resistance, high hardness, and excellent resistance to abrasion and impact. It holds up exceptionally well in severe forming operations.

- Disadvantages: Very expensive, brittle and prone to fracture under shock loading, difficult to machine, and requires specialized tooling and expertise for processing.

The choice depends on the application. For example, high-volume production of less-abrasive materials might favor steel to reduce costs, while highly abrasive materials or extremely high-pressure applications would require the superior wear resistance of tungsten carbide, despite its higher price tag. Other materials like ceramics might also be considered for niche applications demanding even greater hardness or resistance to specific chemical environments.

Q 6. How does grain size affect the properties of die materials?

Grain size significantly impacts the mechanical properties of die materials. Think of grains as individual crystals within the metal structure. Smaller grains lead to higher strength and hardness due to increased grain boundary area, which hinders dislocation movement (dislocations are crystal imperfections that cause plastic deformation). However, smaller grain sizes often result in reduced ductility and increased brittleness. Conversely, larger grains lead to increased ductility and toughness but decreased strength and hardness. It’s a delicate balance.

Controlling grain size through heat treatment (e.g., annealing, normalizing) is a key technique in die manufacturing. Fine-grained structures are generally preferred for wear resistance, while coarser grain structures might be acceptable where toughness and fracture resistance are prioritized. The optimal grain size is determined by considering the desired balance of properties and the specific application requirements.

Q 7. Describe the different types of heat treatment processes and their effects on material properties.

Various heat treatment processes are used in die manufacturing to tailor the material properties. The choice depends on the material and desired outcome.

- Annealing: As previously discussed, reduces internal stresses, softens the metal, and improves ductility. Useful for stress relief after machining or for improving machinability.

- Quenching: Rapid cooling from a high temperature, increases hardness and strength but reduces ductility. Crucial for achieving high wear resistance in dies.

- Tempering: Heating the quenched metal to a lower temperature, reduces brittleness and increases toughness. A necessary step after quenching to balance hardness and toughness.

- Normalizing: Heating to a higher temperature followed by air cooling, refines grain size and improves mechanical properties. Often used to homogenize the microstructure after various processes like forging.

- Stress Relieving: Low-temperature heating to reduce residual stresses without significant changes in hardness. This is beneficial in preventing distortion and cracking.

The specific temperatures and times involved are critical and depend on the type of steel and the desired final properties. Improper heat treatment can severely compromise the die’s performance and life. Detailed knowledge of phase diagrams and transformation kinetics is essential for optimal heat treatment.

Q 8. Explain the concept of hardenability and its importance in die selection.

Hardenability refers to the ability of a steel to form a hard martensitic layer during quenching. It’s not just about achieving hardness, but also about the *depth* of hardness penetration. A high hardenability steel will form a deep hard layer, while a low hardenability steel will only have a shallow hard case. In die selection, this is crucial because dies often experience high stress and impact during operation. A die with sufficient hardenability will resist wear and cracking in the critical areas where it experiences the most pressure, extending its service life considerably. For example, a die used for forging high-strength steel would require a much higher hardenability than one used for softer aluminum alloys. Choosing a steel with inadequate hardenability could lead to premature failure and costly downtime.

Q 9. How do you determine the optimal heat treatment cycle for a specific die material?

Determining the optimal heat treatment cycle is a complex process that depends heavily on the die material’s composition, the desired hardness and toughness, the die’s geometry, and the intended application. It often involves a combination of laboratory testing and practical experience.

- Material Analysis: First, the exact chemical composition of the die steel needs to be known. This will guide the selection of appropriate heat treatment parameters.

- Hardness Testing: Multiple small test samples should undergo various heat treatment cycles (different temperatures and times for austenitizing, quenching, and tempering). Hardness tests (e.g., Rockwell C) are then performed on these samples to determine the optimal cycle producing the desired properties.

- Microstructural Analysis: Microscopic examination (metallography) of the test samples helps assess the microstructure resulting from each heat treatment. This ensures that the desired microstructure (e.g., fine martensite for high hardness) is achieved.

- Practical Considerations: The die’s size and shape will affect the cooling rate during quenching. Larger dies cool slower, requiring adjustments to the heat treatment cycle to ensure consistent hardness throughout the die.

Think of it like baking a cake: You need the right ingredients (material), the right temperature (austenitizing), and the right baking time (soaking) to achieve the desired outcome (hardness and toughness). Getting the timing wrong might lead to a burnt or undercooked cake – similarly, incorrect heat treatment can lead to a brittle or soft die.

Q 10. What are the different methods for surface treatment of dies and their purpose?

Surface treatments enhance die performance by improving wear resistance, corrosion resistance, or fatigue life. Common methods include:

- Nitriding: Introduces nitrogen into the surface, forming hard nitrides. (Detailed explanation in question 5)

- Chromizing: Diffuses chromium into the surface, improving corrosion and wear resistance.

- Carburizing: Introduces carbon into the surface, increasing hardness after subsequent heat treatment.

- Plasma Nitriding: A more controlled and precise nitriding process offering improved surface properties.

- Hard Chrome Plating: Applies a layer of hard chromium, increasing wear resistance significantly. This is especially useful for dies with complex geometries where diffusion treatments might be less effective.

- Electroplating: Provides a protective layer, but not necessarily a hardness increase. This is mainly for corrosion protection.

The choice of method depends on the application and the desired properties. For example, a die for high-temperature applications might benefit from chromizing, while a die experiencing significant abrasive wear might benefit from hard chrome plating or plasma nitriding.

Q 11. What is the importance of proper cooling during heat treatment?

Proper cooling is absolutely vital during heat treatment, especially quenching, as it directly influences the final microstructure and thus the mechanical properties of the die. The cooling rate dictates the transformation of austenite (high-temperature phase) into different phases, like martensite (hard and brittle) or bainite (tougher but less hard).

Too slow cooling can result in a softer, less wear-resistant die, potentially leading to premature failure. Too rapid cooling, on the other hand, might create internal stresses and cracking, again shortening the die’s life. The selection of the quenching medium (e.g., oil, water, polymer quenchants) and the control of the cooling rate are critical to avoid these issues. Imagine rapidly cooling a glass bottle in cold water – it’ll likely shatter. Controlled cooling is essential to avoid this in heat treatment. Quenching is often followed by a tempering step, which reduces internal stress and enhances toughness without sacrificing much hardness.

Q 12. Describe the process of nitriding and its applications in die manufacturing.

Nitriding is a thermochemical surface treatment that introduces nitrogen into the surface of a steel component, typically at temperatures between 480-570°C (900-1060°F). This process forms hard, wear-resistant nitrides (like iron nitrides) within the surface layer, increasing hardness, wear resistance, and fatigue strength. The nitrogen diffuses into the surface, creating a case-hardened layer. This case is significantly harder than the core material, providing superior wear resistance.

Applications in die manufacturing are numerous, particularly where wear resistance is crucial. This could include dies for cold forging, extrusion dies, plastic injection molds, and drawing dies. The nitrided surface offers extended tool life compared to untreated dies, leading to cost savings and improved product quality.

Q 13. How do you inspect a die for defects after heat treatment?

Inspecting a die for defects after heat treatment is essential to ensure its quality and functionality. This involves a multi-step approach:

- Visual Inspection: Check for cracks, warping, or other visible surface imperfections using magnifying glasses or other optical aids.

- Dimensional Measurement: Using measuring instruments like calipers or coordinate measuring machines (CMMs), verify that the die’s dimensions are within the specified tolerances.

- Hardness Testing: Perform hardness tests at various locations on the die’s surface to ensure uniform hardening and to identify any areas with insufficient hardness.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing (UT) or magnetic particle inspection (MPI) can detect internal flaws such as cracks or voids that are not visible on the surface.

- Leak Testing (for molds): For dies used in casting or molding, leak tests are crucial to ensure the integrity of the mold cavity.

A comprehensive inspection ensures that the die is free of defects and suitable for its intended application. Failing to conduct proper inspection could lead to unexpected die failure during production, causing significant losses.

Q 14. What are the common types of die wear and how can they be mitigated?

Die wear is inevitable, but understanding the mechanisms and implementing mitigation strategies can significantly extend die life. Common types of die wear include:

- Abrasive Wear: Caused by the friction of the workpiece against the die surface, leading to material removal. This is prevalent in processes like forging and extrusion. Mitigation involves using harder die materials, optimizing lubrication, and implementing surface treatments (like hard chrome plating).

- Adhesive Wear: Occurs when material from the workpiece adheres to the die surface and is subsequently removed. This is common in hot forging. Mitigation strategies include employing better lubricants and utilizing die materials with lower adhesion properties.

- Fatigue Wear: Repeated stress cycles can cause cracks and eventually failure in the die. This is often accelerated by high temperatures or cyclic loading. Mitigation strategies involve proper design of the die to reduce stress concentrations, employing surface treatments to enhance fatigue strength, and optimizing the process parameters to reduce cyclic loading.

- Erosion Wear: Caused by the impact of high-velocity particles or fluids on the die surface. This is common in casting processes. Mitigation strategies include using erosion-resistant materials and optimizing process parameters to reduce erosion.

Understanding the dominant wear mechanism for a given application allows for the selection of appropriate materials, surface treatments, and process parameters to effectively mitigate die wear and extend its service life. Regular maintenance, including cleaning and lubrication, also plays a crucial role.

Q 15. Explain the concept of residual stress and its influence on die life.

Residual stress refers to internal stresses within a material that remain after the manufacturing process, such as casting, forging, or machining, is complete. These stresses can be either compressive or tensile. Think of it like a tightly wound spring; it’s under internal pressure even when it’s not actively being compressed or stretched. In die materials, high tensile residual stresses are particularly detrimental. They act as microscopic cracks waiting to propagate under the high pressures and temperatures experienced during die casting or forging. These stresses can initiate cracks, leading to premature die failure. Conversely, compressive residual stresses are generally beneficial, as they can enhance fatigue resistance and extend die life by counteracting the tensile stresses induced during operation. The goal of optimized heat treatments is often to induce beneficial compressive residual stresses on the die surface.

For example, a poorly designed heat treatment might leave a die with high tensile residual stresses in its critical regions, resulting in cracking after only a few hundred cycles. Conversely, a carefully designed treatment might introduce compressive stresses, making the die last thousands of cycles longer. Proper shot peening, a surface treatment, is an example of a technique used to introduce beneficial compressive stresses.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How does the selection of die material influence the manufacturing process?

Die material selection significantly impacts the entire manufacturing process. The choice hinges on the specific application, considering factors such as the material being processed (e.g., aluminum, steel, magnesium), the required die life, the production volume, and cost considerations. For instance, using a harder, more wear-resistant material like H13 tool steel will allow for longer production runs with less frequent die changes, minimizing downtime and increasing efficiency. However, this comes at a higher initial cost. Conversely, a softer material might be more easily machinable, reducing tooling costs, but it will likely need replacing more frequently. The selection also dictates the type of heat treatment required to achieve optimal performance. A material like H13 needs a specific heat treatment process to achieve its full hardness and toughness, while a different material like beryllium copper may require a completely different approach.

For example, high-volume production of aluminum parts often utilizes dies made of H13 tool steel, which is known for its excellent wear resistance and high hardenability. In contrast, a lower-volume production of a complex shape in a softer material might use a different, more easily machinable steel, accepting a shorter die life.

Q 17. What are the safety precautions associated with heat treatment processes?

Heat treatment processes involve high temperatures and often hazardous materials, demanding strict safety precautions. These include:

- Proper Personal Protective Equipment (PPE): This includes heat-resistant gloves, safety glasses, closed-toe shoes, and potentially a face shield or respirator, depending on the process and materials involved.

- Ventilation: Adequate ventilation is crucial to remove harmful fumes and gases generated during certain heat treatments, particularly those involving quenching oils.

- Fire Safety: Quenching oils are flammable; therefore, the area must be free of ignition sources, and fire extinguishers must be readily available and regularly inspected.

- Temperature Control and Monitoring: Precise temperature control is essential. Malfunctions in temperature control systems could lead to unsafe conditions.

- Proper Handling of Hot Parts: Using appropriate tools and techniques to handle hot parts is critical to prevent burns.

- Emergency Procedures: Clear emergency procedures, including contact information for emergency services, must be readily accessible.

Failure to adhere to these precautions can lead to serious injury, including burns, inhalation of toxic fumes, or fire hazards.

Q 18. Explain the difference between austempering and martempering.

Both austempering and martempering are heat treatment processes used to improve the toughness and strength of steel, specifically by creating bainite, a microstructure that offers a better balance of strength and ductility than martensite. The key difference lies in the cooling process:

- Austempering: Involves isothermal transformation. After austenitizing (heating to a high temperature), the steel is immediately quenched into a molten salt bath held at a temperature just above the martensite start temperature (Ms). The steel is held isothermally at this temperature to allow the formation of bainite, which is a softer, more ductile microstructure compared to martensite. This process minimizes distortion and cracking.

- Martempering: Involves an interrupted quench. The steel is first austenitized, then quenched in a molten salt bath to rapidly reduce the temperature to just above Ms. This process equalizes the temperature throughout the part, preventing the internal stresses that can lead to cracking or warping during the final cooling stage. The part is then air cooled. This results in a martensitic microstructure but reduces internal stresses, allowing for more dimensional stability than a direct quench.

In essence, austempering produces a bainitic microstructure, resulting in higher toughness, whereas martempering produces martensite with reduced internal stresses, resulting in higher hardness and better dimensional accuracy.

Q 19. What is the role of alloying elements in die materials?

Alloying elements are crucial in die materials because they significantly influence their mechanical properties, such as hardness, strength, wear resistance, and toughness. Different elements provide different effects:

- Chromium (Cr): Increases hardness, wear resistance, and corrosion resistance.

- Molybdenum (Mo): Enhances hardenability (the ability to form martensite during quenching), enabling deeper hardening in larger sections. It also improves high-temperature strength and creep resistance.

- Vanadium (V): Refines the grain size, improving toughness and strength. It also enhances wear resistance and high-temperature properties.

- Tungsten (W): Increases hardness, wear resistance, and high-temperature strength. It’s often used in applications requiring very high wear resistance.

- Nickel (Ni): Improves toughness and ductility, helping to reduce cracking during heat treatment.

The specific combination and concentration of these alloying elements determine the final properties of the die material and its suitability for a given application. For example, H13 tool steel (a common die material) contains chromium, molybdenum, vanadium, and tungsten, providing an excellent balance of hardness, toughness, and wear resistance.

Q 20. Describe the process of induction hardening.

Induction hardening is a surface hardening technique that uses electromagnetic induction to heat a specific area of a workpiece to its austenitizing temperature, followed by rapid quenching. A high-frequency alternating current flows through an induction coil surrounding the workpiece. This induces eddy currents within the workpiece, generating heat through resistance. The depth of heating is controlled by the frequency of the current and the workpiece’s material properties. The heated surface region then undergoes a rapid quench, typically using water or oil, to transform the austenite into martensite, resulting in a hardened surface while the core remains relatively soft and tough.

The process is advantageous because it precisely hardens only the surface, improving wear resistance and fatigue strength while maintaining the core’s toughness and reducing distortion. This is particularly useful for dies, where a hard surface is needed to resist wear and abrasion, while a tough core helps prevent cracking under stress.

For example, a die for forging might have its critical wear areas hardened by induction hardening, significantly extending its service life.

Q 21. How do you interpret a hardness test result?

Hardness testing provides a measure of a material’s resistance to indentation or scratching. The results are typically reported as a specific hardness number, based on the chosen testing method (e.g., Rockwell, Brinell, Vickers). The interpretation depends on the testing method and the specific application. A higher hardness number generally indicates greater resistance to wear and deformation.

For example, a Rockwell C hardness test might yield a value of 60 HRC (Rockwell C scale, 60 units). This indicates a relatively high hardness, suitable for a die application. Different materials will have different hardness ranges deemed acceptable; for example, the acceptable hardness range for H13 tool steel after heat treatment might be between 58-62 HRC. Deviation from this range could signal problems in the heat treatment process or material defects. Hardness testing is crucial in quality control during die manufacturing to ensure the material meets the required specifications.

It’s important to always consider the specific hardness scale used and to consult relevant standards to interpret the results correctly. The hardness value alone does not fully characterize the material, but it is a vital parameter when assessing die quality and performance.

Q 22. What are the limitations of different heat treatment processes?

The limitations of different heat treatment processes are multifaceted and depend heavily on the specific process and the material being treated. For instance, annealing, while excellent for stress relief and softening, can lead to grain growth, reducing strength and hardness. Quenching, used to harden steel, can introduce internal stresses, potentially causing cracking or warping, especially in complex shapes. The severity of these issues depends on factors such as the cooling rate, the material’s composition, and the part geometry.

- Surface Hardening Techniques (e.g., Carburizing, Nitriding): These methods, while increasing surface hardness, can create a hardness gradient, leading to potential subsurface cracking under stress. The depth of the hardened layer is also limited and controlled by the process parameters.

- Tempering: This process relieves internal stresses introduced by quenching but can also reduce the hardness achieved. The exact balance between hardness and toughness needs to be carefully managed.

- Austempering and Martempering: These isothermal treatments offer better control over distortion and cracking compared to traditional quenching, but they require specialized equipment and precise control over the process parameters.

Imagine trying to bake a cake – if you don’t control the oven temperature and baking time correctly, you’ll either end up with a burnt cake or a raw one. Similarly, incorrect heat treatment parameters can result in a die that’s either too brittle or too soft for its intended application.

Q 23. How do you troubleshoot a problem with a heat-treated die?

Troubleshooting a problem with a heat-treated die requires a systematic approach. First, we need to understand the specific problem: Is it cracking, warping, insufficient hardness, or something else? Then, we need to trace the steps back to the heat treatment process.

- Examine the Die: Carefully inspect the die for any visible defects like cracks, warping, or discoloration. Document your observations with photos or sketches.

- Review the Heat Treatment Process Parameters: Check the temperature profile, heating and cooling rates, holding times, and atmosphere used during each step. Any deviations from the standard procedure should be investigated.

- Analyze the Material: If possible, perform material testing (e.g., hardness testing, microstructure analysis) to determine if the material properties are within the required specifications. A chemical analysis might also be useful to check for unexpected impurities.

- Consider the Die Design: Complex die designs with sharp corners or thin sections are more prone to cracking and warping. The design itself may need to be revised to minimize these risks.

- Evaluate the Furnace and Equipment: Ensure the furnace is properly calibrated and maintained. Any malfunctioning equipment (e.g., faulty thermocouples, inaccurate temperature controllers) can affect the heat treatment outcome.

For instance, if a die shows excessive warping, the problem might be due to uneven heating or too rapid cooling. If the hardness is too low, it might indicate an incorrect tempering temperature or time. Careful investigation is key to identify the root cause and implement corrective actions.

Q 24. Explain the concept of critical cooling rate.

The critical cooling rate is the minimum cooling rate required to transform austenite (a high-temperature phase of steel) into martensite (a very hard and brittle phase) during quenching. It’s crucial for achieving the desired hardness in steel dies. Different steels have different critical cooling rates; some require very rapid cooling, while others can be cooled more slowly. This rate is affected by the alloying elements in the steel. Higher alloy content typically increases the critical cooling rate, requiring faster quenching methods.

Imagine you’re trying to solidify a liquid quickly – some liquids solidify readily at room temperature (low critical cooling rate), whereas others need extremely low temperatures or special cooling techniques (high critical cooling rate) to solidify quickly. Similarly, different steels require different cooling speeds to transform into martensite, achieving the desired hardness.

Determining the critical cooling rate for a specific steel alloy often involves experimental methods, such as dilatometry or thermal analysis, and is crucial for selecting appropriate quenching media (oil, water, polymer solutions) and optimizing the quench cycle to achieve the desired microstructure and properties.

Q 25. What are the environmental considerations related to heat treatment?

Environmental considerations in heat treatment are significant. The primary concerns are air pollution from combustion processes (furnaces using fossil fuels) and the disposal of spent quenching oils or other treatment chemicals. Modern heat treatment processes often emphasize environmentally friendly practices.

- Air Pollution Control: Furnaces using gas or oil as fuel generate emissions that must be controlled through proper ventilation and potentially the use of emission control systems (scrubbers). Electric furnaces are a more environmentally friendly alternative.

- Waste Management: Spent quenching oils, salts, and other chemicals require proper disposal to prevent environmental contamination. Recycling or appropriate disposal methods should always be implemented.

- Energy Efficiency: The heat treatment industry consumes significant amounts of energy. Improved furnace designs and process optimization can reduce energy consumption and minimize the carbon footprint.

- Water Usage: Quenching processes, especially water quenching, can consume large quantities of water. Efficient quenching techniques and water recycling can help minimize water consumption.

Industries are increasingly adopting cleaner technologies like vacuum heat treatment, which minimizes atmospheric contamination, and focusing on energy-efficient equipment to reduce environmental impact. Regulations and certifications are increasingly important in this space.

Q 26. Describe different types of die coatings and their applications.

Die coatings significantly enhance the lifespan and performance of dies by improving wear resistance, reducing friction, and enhancing corrosion resistance. The choice of coating depends on the specific application and the materials being processed.

- Chromium Carbide Coatings: Excellent wear resistance, particularly for applications involving abrasive materials. Commonly used in extrusion dies and forging dies.

- Titanium Nitride (TiN) Coatings: Good wear resistance and reduced friction. Often used in drawing dies and cold forming dies.

- Tungsten Carbide Coatings: High hardness and wear resistance, suited for applications with high impact loads or abrasive materials. Often used in die casting and hot forging dies.

- Diamond-Like Carbon (DLC) Coatings: Excellent wear resistance, low friction, and good corrosion resistance. Applied in various applications where high precision and smooth surfaces are critical.

- Nickel-Phosphorus Coatings: These coatings offer good corrosion resistance and lubricity, improving the life of the die under corrosive environments.

For example, a die used for extrusion of aluminum might benefit from a chromium carbide coating due to the abrasive nature of aluminum oxides. On the other hand, a die used for cold forming of steel might be better served by a TiN coating to reduce friction and increase tool life.

Q 27. How does the design of a die affect its heat treatment requirements?

The design of a die significantly impacts its heat treatment requirements. Complex geometries with sharp corners or thin sections are more susceptible to cracking and warping during quenching. These features create areas with concentrated stresses that are prone to failure. Therefore, the choice of heat treatment process and parameters needs to be carefully tailored to the die’s design.

For instance, a die with intricate internal channels may require slower cooling rates to minimize internal stresses and reduce the risk of cracking. Thicker sections may require longer holding times at the austenitizing temperature to ensure complete transformation. A simple, uniform shape is much easier to heat treat than a complex part with varying thicknesses and geometries. The design must consider the inherent challenges and limitations of the heat treatment process in order to produce a functional and durable die.

In some cases, the design might incorporate features that facilitate uniform heating and cooling, such as strategically placed vents or cooling channels, to mitigate the challenges posed by complex geometries.

Q 28. What are the latest advancements in die materials and heat treatment technologies?

Recent advancements in die materials and heat treatment technologies are focused on improving performance, extending die life, and enhancing sustainability. Some key developments include:

- Advanced Materials: Development of new alloys with improved high-temperature strength, wear resistance, and corrosion resistance. This includes powder metallurgy techniques which allow for the creation of more uniform and fine-grained materials.

- Optimized Heat Treatment Processes: Advancements in process control, such as using laser heating and quenching or induction heating for more precise and uniform heating and cooling, allowing for tailored microstructures and superior mechanical properties.

- Surface Modification Techniques: Advanced coating techniques like plasma spraying, physical vapor deposition (PVD), and chemical vapor deposition (CVD) are producing increasingly durable and wear-resistant coatings.

- Additive Manufacturing (3D Printing): Allows for the creation of complex die geometries with intricate internal cooling channels or optimized designs that minimize stress concentrations, leading to improved heat treatment outcomes and enhanced die performance.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML algorithms can be used to predict and optimize heat treatment parameters based on the specific die material and geometry, resulting in enhanced performance and efficiency.

These advancements are driving the creation of longer-lasting, more efficient, and environmentally friendlier die manufacturing processes. These allow for the production of higher quality parts while minimizing waste and energy consumption.

Key Topics to Learn for Knowledge of Die Materials and Heat Treatment Processes Interview

- Die Material Selection: Understanding the properties of various die materials (e.g., tool steels, carbide, ceramics) and their suitability for different applications based on factors like strength, hardness, wear resistance, and thermal shock resistance. Consider the trade-offs between cost and performance.

- Heat Treatment Techniques: Mastering the principles and practical applications of various heat treatment processes such as annealing, normalizing, hardening, tempering, and cryogenic treatment. Be prepared to discuss the effects of these processes on the microstructure and mechanical properties of die materials.

- Microstructural Analysis: Familiarize yourself with techniques used to analyze the microstructure of die materials (e.g., optical microscopy, SEM, TEM) and how these analyses relate to the material’s performance and potential failure mechanisms.

- Die Design and Manufacturing Considerations: Understand how material selection and heat treatment influence die design, manufacturing processes (e.g., machining, EDM), and overall die life. Be prepared to discuss the challenges and solutions related to optimizing die geometry for specific applications.

- Failure Analysis and Troubleshooting: Develop your ability to diagnose die failures (e.g., cracking, wear, deformation) and propose solutions based on your understanding of material properties and heat treatment effects. This includes identifying root causes and preventative measures.

- Process Optimization: Discuss strategies for optimizing the heat treatment process to achieve desired material properties while minimizing distortion and maximizing die life. Consider factors like heating rates, cooling rates, and holding times.

- Quality Control and Testing: Be prepared to discuss the importance of quality control measures throughout the die manufacturing and heat treatment process, including inspection techniques and material testing methods to ensure consistent performance.

Next Steps

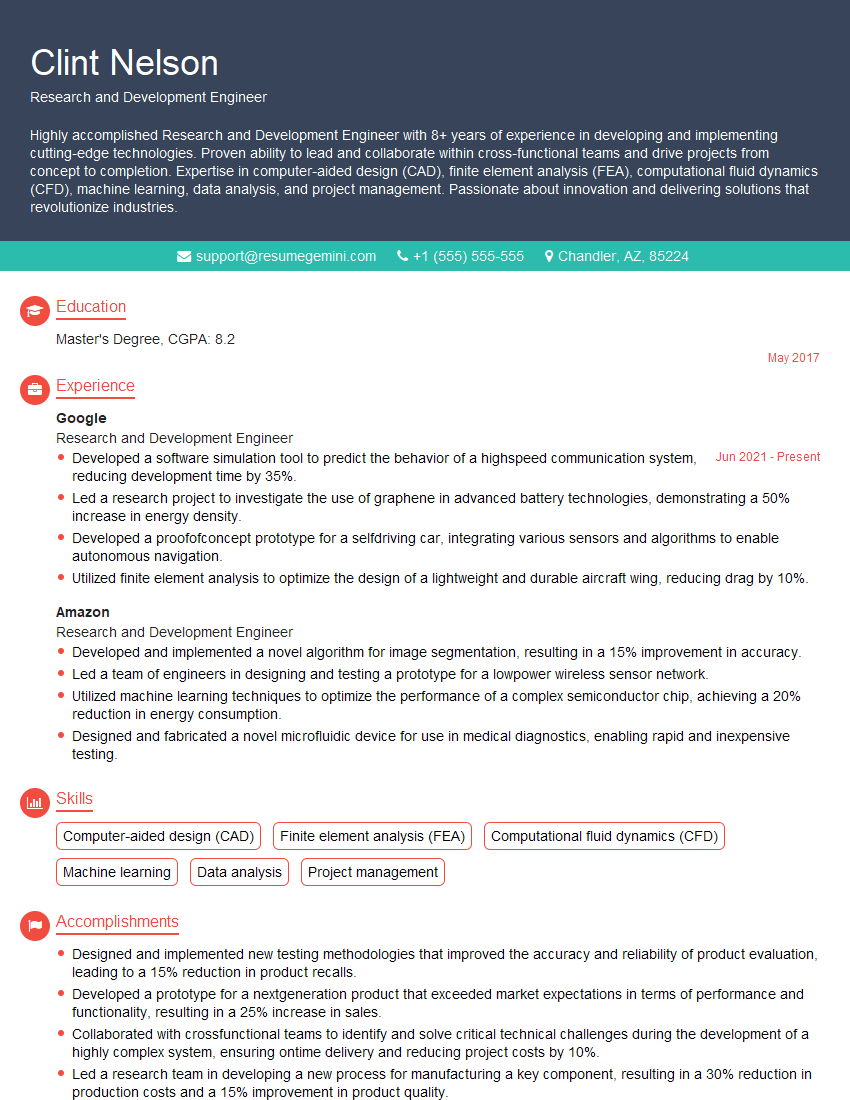

Mastering Knowledge of Die Materials and Heat Treatment Processes is crucial for career advancement in manufacturing and engineering roles. A deep understanding of these concepts demonstrates technical expertise and problem-solving abilities, making you a highly valuable asset to any team. To significantly boost your job prospects, focus on creating a strong, ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We offer examples of resumes tailored to showcase expertise in Knowledge of Die Materials and Heat Treatment Processes to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good