Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Knowledge of electrical codes and standards interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Knowledge of electrical codes and standards Interview

Q 1. What is the National Electrical Code (NEC) and its purpose?

The National Electrical Code (NEC) is a nationally recognized standard for the safe installation of electrical wiring and equipment in the United States. It’s not a law itself, but it’s adopted by most states and local jurisdictions as the basis for their electrical codes. Its purpose is to safeguard people and property from electrical hazards. Think of it as a comprehensive instruction manual for safe electrical work, ensuring consistent practices across the country and minimizing the risk of fires, shocks, and other electrical-related incidents. It covers everything from wiring methods to equipment installation and maintenance, ensuring a consistent level of safety regardless of location.

Q 2. Explain the difference between grounding and bonding.

Grounding and bonding are often confused, but they serve distinct purposes in electrical safety. Grounding connects non-current-carrying metal parts of an electrical system to the earth. This provides a path for fault currents to flow safely to the ground, preventing dangerous voltage buildup on metal enclosures. Imagine it as a safety valve. Bonding, on the other hand, connects non-current-carrying metal parts within an electrical system to each other. This equalizes the voltage potential between these parts, preventing voltage differences that could cause dangerous shocks. Think of it as ensuring everything is at the same electrical ‘level’. For example, the metal conduit enclosing wiring is bonded to the electrical panel, and the panel is grounded.

Q 3. Describe the requirements for grounding electrical systems.

Grounding electrical systems is crucial for safety. The NEC outlines detailed requirements, varying based on the type of system (e.g., residential, commercial, industrial). Generally, it involves connecting the system’s grounding electrode conductor (GEC) to a grounding electrode, such as a metal water pipe, grounding rod, or a concrete-encased electrode. The GEC then connects to the electrical service panel, providing a low-impedance path to earth for fault currents. Proper grounding minimizes the risk of electrical shock and prevents dangerous voltage buildup on metal enclosures. Regular inspection and testing of the grounding system is essential to ensure its continued effectiveness. For example, a properly grounded system will ensure that if a fault occurs in an appliance, the current will flow to ground, tripping the circuit breaker and preventing a shock hazard. Improper grounding can lead to a significant risk of electrocution.

Q 4. What are the different types of electrical conduit and their applications?

Several types of electrical conduit are used to protect wiring. The choice depends on the application and environmental conditions:

- Rigid Metal Conduit (RMC): Strong and durable, suitable for harsh environments and places requiring high mechanical protection.

- Intermediate Metal Conduit (IMC): Lighter and easier to install than RMC, but still provides good protection.

- Electrical Metallic Tubing (EMT): Lightweight and flexible, commonly used in residential and commercial settings.

- Flexible Metal Conduit (FMC): Very flexible, used for short runs and connections where flexibility is needed.

- Plastic Conduit (PVC): Inexpensive and corrosion-resistant, widely used in dry locations.

For instance, RMC might be used in an industrial setting with heavy machinery, while PVC might be suitable for residential wiring in a dry basement. Choosing the right conduit ensures the protection of the wiring from physical damage and environmental factors.

Q 5. Explain the purpose and calculation of ampacity.

Ampacity is the maximum current, in amperes, that a conductor can carry continuously under the conditions of use without exceeding its temperature rating. It’s crucial for preventing overheating, which can lead to fire hazards. Ampacity is affected by factors like conductor size, insulation type, ambient temperature, and installation method. The NEC provides tables listing ampacity ratings for various conductors under different conditions. Calculating ampacity involves considering these factors and selecting a conductor with an ampacity rating greater than or equal to the expected current draw. For example, a circuit breaker rated for 20 amps should be used with wiring that has an ampacity of at least 20 amps to prevent the wiring from overheating.

Q 6. What are the requirements for installing electrical outlets in bathrooms?

Bathrooms pose unique safety challenges due to the presence of water. The NEC mandates specific requirements for electrical outlets in bathrooms to minimize the risk of electric shock. These include:

- Ground Fault Circuit Interrupter (GFCI) protection: All 120-volt, single-phase, 15- and 20-ampere receptacles in bathrooms must be GFCI-protected. GFCIs quickly detect and interrupt ground faults, preventing potentially lethal shocks.

- Location restrictions: Receptacles must be installed a specific distance from the shower or bathtub to minimize the risk of shock.

- Enclosure types: Receptacles must be installed in weatherproof or waterproof enclosures if located near water sources.

Failure to follow these regulations can lead to serious safety hazards. Always consult the NEC for precise distances and installation requirements.

Q 7. What are the safety precautions for working with high-voltage systems?

Working with high-voltage systems presents significant risks of electrical shock, burns, and even death. Safety precautions are paramount and require strict adherence to procedures and regulations:

- Lockout/Tagout procedures: Always de-energize the system and apply lockout/tagout devices before performing any work. This ensures that the system cannot be accidentally re-energized.

- Personal Protective Equipment (PPE): Use appropriate PPE, including insulated tools, rubber gloves, safety glasses, and arc flash protective clothing.

- Trained personnel: Only qualified and trained personnel should work on high-voltage systems.

- Proper testing and inspection: Thoroughly test the system before and after work to ensure its safety.

- Awareness of potential hazards: Understand the specific hazards associated with the system, such as arc flash, shock, and electrocution.

High-voltage work necessitates a thorough understanding of safety protocols and a cautious approach. Ignoring these precautions can have severe consequences.

Q 8. How do you identify and mitigate electrical hazards on a job site?

Identifying and mitigating electrical hazards on a job site is paramount for worker safety. It requires a proactive approach combining pre-planning, on-site inspections, and adherence to safety protocols.

Identification: This begins with a thorough pre-job site survey to identify potential hazards like exposed wiring, damaged insulation, overloaded circuits, improper grounding, and lack of lockout/tagout procedures. During the work itself, regular inspections are crucial. Look for things like frayed cords, damaged outlets, water near electrical equipment, and workers engaging in risky behavior (e.g., working on energized circuits). Using appropriate testing equipment, such as voltage detectors and circuit testers, is essential to confirm the absence of voltage before working on any circuit.

Mitigation: Mitigation strategies depend on the specific hazard identified. Exposed wiring should be immediately repaired or covered using proper conduit and protective equipment. Damaged equipment should be immediately tagged out of service and repaired by a qualified electrician. Overloaded circuits need to be addressed by adding capacity or redistributing loads. Improper grounding requires immediate correction to prevent shocks. Lockout/tagout procedures must be rigorously followed before any work begins on electrical equipment. Furthermore, providing adequate lighting, ensuring clear walkways, and using appropriate personal protective equipment (PPE) like insulated gloves and safety glasses are vital for mitigating risks.

Example: Imagine a construction site where exposed wiring is found near a wet area. Immediate mitigation would involve de-energizing the circuit (using lockout/tagout procedures), rerouting the wires through conduit, and installing GFCI protection to mitigate the risk of electrocution.

Q 9. What are the requirements for arc flash hazard analysis and mitigation?

Arc flash hazard analysis and mitigation are critical for protecting workers from the devastating effects of arc flash incidents – powerful electrical explosions that can cause severe burns, blindness, and even death. The requirements are governed by industry standards like NFPA 70E.

Analysis: A qualified electrical engineer performs an arc flash hazard analysis to determine the potential severity of arc flash events at various points in an electrical system. This involves calculating the incident energy (the amount of energy released in an arc flash) and determining the required PPE. Several factors are considered, including voltage, fault current, available short-circuit current, and equipment configuration.

Mitigation: After the analysis, appropriate mitigation strategies are implemented to reduce the risk. These may include:

- Engineering Controls: These are the most effective controls and focus on reducing the arc flash hazard at its source. This might involve upgrading equipment to reduce fault current, installing arc flash relays, or using equipment designed for reduced arc flash energy.

- Administrative Controls: These include safety procedures, training programs, and lockout/tagout procedures. Regular training on arc flash hazards and the proper use of PPE is mandatory.

- Personal Protective Equipment (PPE): Workers must wear appropriate PPE, such as arc flash suits, face shields, and insulated gloves, as determined by the arc flash analysis. The PPE rating must match or exceed the calculated incident energy.

Example: A panelboard analysis reveals a high incident energy level. Mitigation might involve installing arc flash relays to quickly interrupt the fault current, and ensuring all workers in the vicinity wear arc flash suits with a high arc rating.

Q 10. Explain the concept of overcurrent protection and its importance.

Overcurrent protection is a crucial safety measure in electrical systems. It’s designed to automatically disconnect a circuit when the current exceeds a safe level. Think of it as a circuit breaker for your home’s electrical system, but on a much larger scale.

Importance: Overcurrent protection prevents several dangerous conditions:

- Fire Hazards: Excessive current causes overheating in wires and equipment, potentially leading to fires. The protective devices prevent overheating by shutting down the circuit.

- Equipment Damage: Overcurrents can damage electrical equipment due to overheating or excessive stresses on components.

- Electrical Shock Hazards: Overcurrents can create unsafe voltage levels and increased risk of electric shock.

In essence: Overcurrent protection safeguards life, property, and equipment from the harmful effects of excessive current flow.

Q 11. What are the different types of overcurrent protection devices?

Several types of overcurrent protection devices are available, each suited for different applications and current levels:

- Fuses: One-time use devices that melt and break the circuit when current exceeds their rating. They provide simple and inexpensive protection.

- Circuit Breakers: Reusable devices that can automatically interrupt current flow when an overcurrent is detected. They come in various types, including thermal-magnetic breakers (responding to both heat and magnetic field changes), and electronic circuit breakers (offering more sophisticated protection).

- Ground Fault Circuit Interrupters (GFCIs): Designed to protect against ground faults, where current leaks to ground, often causing electric shocks. They are commonly used in bathrooms, kitchens, and outdoor areas.

- Arc Fault Circuit Interrupters (AFCIs): Designed to detect and interrupt arc faults, which are often the cause of electrical fires. They are commonly used in bedrooms and other areas with potential ignition sources.

Q 12. How do you select the appropriate overcurrent protection device for a given circuit?

Selecting the appropriate overcurrent protection device involves careful consideration of several factors:

- Ampacity of the circuit: The device’s rating must be equal to or greater than the ampacity of the conductors and the load it protects. This ensures it can handle normal operating current without tripping.

- Type of load: Motor loads require different protection considerations than resistive loads (like lighting). Motors require devices that can handle higher inrush currents.

- Fault current available: The device must be able to interrupt the available fault current without damage to itself.

- Environmental conditions: Certain devices are suitable for hazardous locations or special environments (e.g., high temperatures or corrosive atmospheres).

- Coordination with other protective devices: The protective devices should be coordinated to ensure that the smallest one trips first in the event of a fault, minimizing the impact of the fault.

Example: A 20-ampere circuit powering lighting fixtures would require a 20-ampere circuit breaker. However, a circuit powering a motor might require a higher-rated breaker (e.g., 30-ampere) to accommodate the motor’s inrush current.

Q 13. What are the requirements for installing electrical equipment in hazardous locations?

Installing electrical equipment in hazardous locations (classified by OSHA and NEC as Class I, II, and III, Divisions 1 and 2 based on the type and presence of flammable gases, dusts, or fibers) requires adherence to strict regulations. The goal is to prevent ignition of the hazardous materials.

Key Requirements:

- Equipment Type: Only equipment specifically approved for the classified location (e.g., explosion-proof or intrinsically safe) can be used. This is usually indicated by markings on the equipment itself.

- Wiring Methods: Wiring methods must be designed to prevent the ignition of the hazardous atmosphere. This may involve using special conduit, sealing methods, and cable types.

- Installation Practices: Installation must follow specific procedures to maintain the integrity of the equipment’s explosion-proof or intrinsically safe features.

- Inspection and Maintenance: Regular inspection and maintenance are crucial to ensure the ongoing safety of the equipment and the integrity of its protective features.

Example: In a Class I, Division 1 location (flammable gases present), you would use explosion-proof enclosures for all electrical equipment, and all wiring would need to be installed in explosion-proof conduit and fittings with proper seals.

Q 14. Explain the requirements for grounding and bonding in hazardous locations.

Grounding and bonding in hazardous locations are critical for safety. Grounding ensures a low-impedance path to earth for fault currents, while bonding connects metallic parts to equalize their potential, preventing voltage differences that could cause sparks and ignite flammable materials.

Requirements:

- Grounding: Equipment must be effectively grounded to a suitable grounding electrode system to provide a low-impedance path for fault currents. This minimizes the risk of electrical shock and prevents voltage build-up.

- Bonding: Metallic parts of equipment and enclosures must be effectively bonded to equalize their potentials. This minimizes the risk of voltage differences that could create sparks.

- Grounding Conductors: Grounding conductors must be sized and installed appropriately according to the NEC for the specific hazardous location.

- Inspection and Testing: Regular inspection and testing of grounding and bonding systems are required to ensure their integrity.

Importance in Hazardous Locations: In hazardous locations, grounding and bonding are even more critical to prevent the possibility of a spark igniting flammable materials. Any voltage difference, however small, can be sufficient to trigger an explosion or fire.

Q 15. What are the requirements for installing lighting fixtures in various locations?

Lighting fixture installation requirements vary significantly depending on location. Think of it like choosing the right shoes for different terrains – you wouldn’t wear hiking boots to a formal event. Key factors include the fixture type, location’s environment (damp, wet, or hazardous), and the building’s occupancy.

- Bathrooms and Kitchens: These areas often require GFCI (Ground Fault Circuit Interrupter) protection to prevent electric shock. Fixtures must be rated for damp or wet locations, depending on proximity to water sources. Imagine a recessed light in a shower – it needs a waterproof enclosure.

- Outdoor Locations: Fixtures need to be weatherproof (rated for outdoor use) and often require a higher level of protection against moisture and dust. Think about a porch light enduring rain and snow; it needs a robust design.

- Garages and Workshops: These locations may necessitate fixtures that are impact-resistant and protected from dust and debris. A garage light should withstand accidental bumps and airborne particles.

- Specific Occupancy Types: Commercial buildings, industrial facilities, and healthcare settings have stricter codes and require fixtures that meet specific safety and performance standards. A hospital operating room will have very different lighting needs (and codes) compared to a retail store.

Always consult the relevant electrical code (like the NEC in the US) and the fixture’s manufacturer’s instructions before installation. Ignoring these can lead to electrical hazards, fines, and even injury.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the difference between a GFCI and an AFCI.

Both GFCIs (Ground Fault Circuit Interrupters) and AFCIs (Arc Fault Circuit Interrupters) are safety devices that protect against electrical hazards, but they target different types of faults. Imagine a GFCI as a lifeguard watching for someone falling into the water (ground fault), while an AFCI is watching for a hidden fire starting (arc fault).

- GFCI: These devices detect imbalances in current flow, indicating a possible ground fault. This is crucial in wet locations because if someone touches a live wire while grounded, the GFCI will immediately cut off power, preventing electrocution. Think of it like a sensitive tripwire that detects an imbalance and quickly shuts down the system.

- AFCI: AFCIs detect abnormal current flow patterns that may indicate an arc fault – a dangerous condition that can create sparks and lead to fires. These faults are often subtle, hidden within walls or behind appliances, making rapid detection critical. Think of it as a smoke detector for electrical systems.

While both enhance safety, GFCIs are more commonly found in wet locations, while AFCIs are often required in bedrooms and other areas where fire risks are higher. Many modern circuit breakers combine both GFCI and AFCI protections for broader safety.

Q 17. What are the requirements for installing and using extension cords?

Extension cords provide temporary power, but their use requires careful consideration of safety and code compliance. Improper usage can cause overheating, fire hazards, and electrical shocks. It’s like using a temporary bridge – you wouldn’t overload it or use it indefinitely.

- Appropriate Gauge: The cord’s gauge (thickness) must match the load. A heavier load (like a power tool) requires a thicker gauge cord. Using a too-thin cord can lead to overheating and potentially fire. It’s critical to know the amperage draw of your device and select an extension cord capable of safely handling that current.

- Outdoor Use: Outdoor extension cords must be specifically rated for outdoor use and have appropriate weatherproofing. Regular indoor cords will not withstand prolonged exposure to water and might fail, resulting in electric shock or fire.

- Avoid Overloading: Never plug too many devices into a single extension cord. Overloading can cause the cord to overheat and potentially start a fire.

- Proper Condition: Inspect cords for damage before each use. Cracked insulation, exposed wires, or damaged plugs are safety hazards and should be replaced immediately. A damaged cord is like a cracked dam – it’s only a matter of time before something breaks.

Always use extension cords as temporary solutions. If you need permanent power to a location, install a dedicated circuit instead of relying on extension cords long-term. This avoids the long-term risks associated with their usage.

Q 18. What are the requirements for electrical work in commercial buildings?

Commercial electrical work is significantly more complex than residential work and requires strict adherence to codes like the NEC (National Electrical Code) and local ordinances. It involves specialized design considerations, power distribution, and safety regulations to ensure the well-being of employees and customers. Think of a commercial building like a sophisticated machine – every component must function correctly and safely.

- Increased Power Demands: Commercial buildings often have higher power demands compared to homes, requiring larger service panels, heavier wiring, and dedicated circuits for equipment like HVAC systems, lighting, and specialized machinery.

- Specialized Systems: These may include fire alarm systems, security systems, and communication networks, all with specific electrical requirements.

- Accessibility and Maintenance: All wiring and components should be easily accessible for future maintenance and repairs. Clear labeling and organized wiring are crucial for quick and safe troubleshooting.

- Occupancy Considerations: Electrical systems must be designed to accommodate the specific needs and occupancy levels of the building. Different types of commercial buildings have very distinct electrical requirements and safety considerations.

- Compliance and Permits: Thorough documentation and obtaining all necessary permits are vital to ensure compliance and to protect against potential issues down the line. This is an essential part of project management in any commercial electrical project.

It’s essential to work with licensed electricians who are experienced in commercial building codes to ensure a safe and code-compliant installation.

Q 19. What are the requirements for electrical work in industrial settings?

Industrial electrical work presents unique challenges due to the presence of heavy machinery, hazardous materials, and potentially explosive environments. Safety is paramount, and stringent codes are in place to mitigate risks. Imagine working in a refinery – even a small mistake can have devastating consequences.

- Hazardous Locations: Industrial settings may include areas classified as hazardous locations due to the presence of flammable gases, dust, or fibers. Special wiring methods, explosion-proof equipment, and specific safety measures are mandatory in such areas.

- High-Voltage Systems: Industrial facilities frequently use high-voltage systems to power large motors and other equipment. Specialized training and safety precautions are vital when dealing with such voltages.

- Grounding and Bonding: Proper grounding and bonding are crucial to prevent electric shock and fire hazards. This is especially important in industrial environments with conductive materials and moving machinery.

- Maintenance and Inspections: Regular inspections and maintenance are essential for ensuring the safety and reliability of industrial electrical systems. Preventative maintenance is critical for reducing potential downtime and avoiding costly repairs.

- Lockout/Tagout Procedures: Strict lockout/tagout procedures are essential before any work is performed on electrical equipment to prevent accidental energization and injuries. This is vital for ensuring worker safety.

Working in industrial settings requires extensive experience, specialized knowledge, and adherence to strict safety protocols and codes. Only highly trained and qualified electricians should perform electrical work in such environments.

Q 20. Explain the process of obtaining electrical permits and inspections.

Obtaining electrical permits and inspections is crucial for ensuring that electrical work is done safely and according to code. It’s like getting a building permit before constructing a house – it ensures the project meets safety standards and local regulations.

- Application: Submit an application to the local authority having jurisdiction (AHJ), usually the building department. The application typically requires details about the proposed work, including drawings, specifications, and the contractor’s license information.

- Review and Approval: The AHJ reviews the application to ensure it complies with relevant codes and regulations. They may request modifications or clarifications before granting a permit.

- Permit Issuance: Once the application is approved, the AHJ issues a permit allowing the work to begin.

- Work Execution: The electrical work is performed according to the approved plans and specifications.

- Inspections: Inspections are conducted at various stages of the project, such as rough-in, and final inspections to verify compliance with codes and safety standards. The inspector verifies that the work meets the required specifications and safety standards outlined in the electrical code.

- Permit Closure: After all inspections are passed, the permit is closed, officially signifying that the electrical work meets the applicable codes and regulations. This completes the process.

Failing to obtain permits or ignoring inspections can lead to serious consequences, including fines, delays, and potential legal issues. It’s vital to follow the process correctly.

Q 21. What are the consequences of non-compliance with electrical codes?

Non-compliance with electrical codes can have severe consequences, ranging from minor inconveniences to life-threatening hazards. It’s like ignoring traffic laws – the consequences can range from a small fine to a serious accident.

- Fines and Penalties: The AHJ can impose significant fines for violations, and repeated violations can lead to more severe penalties.

- Insurance Issues: Insurance companies may refuse coverage or void policies if electrical work is not up to code, leaving you liable for damages.

- Legal Liability: If someone is injured due to non-compliant electrical work, you may face legal action and significant financial liability.

- Fire Hazards: Non-compliant electrical work is a major fire hazard and can lead to property damage and loss of life.

- Electrocution Risks: Improper wiring and grounding can cause electrocution, leading to serious injury or death.

- Building Code Violations: Failure to meet electrical codes could result in the building failing inspection, preventing occupancy or sale of the property.

Adhering to electrical codes is not just a legal requirement but also a crucial aspect of ensuring safety and protecting lives and property.

Q 22. How do you interpret electrical drawings and schematics?

Interpreting electrical drawings and schematics requires a systematic approach. Think of it like reading a map for electricity. First, you identify the key elements: power sources, loads (lights, motors, appliances), protective devices (circuit breakers, fuses), and wiring pathways. Each symbol represents a specific component, and the lines connecting them show the electrical flow. For example, a circle might represent a light fixture, while a zigzag line might indicate a ground connection.

I begin by reviewing the title block for project information, then I look for the legend to understand the symbols used. Next, I trace the power flow from the source through the circuit, noting the components, wire sizes, and protection levels. I also check for details like voltage ratings, amperage ratings, and grounding methods. Complex schematics require careful attention to detail and a good understanding of electrical theory. For example, understanding the difference between a single-line diagram and a detailed wiring diagram is crucial for accurate interpretation. The single-line provides a simplified overview, while the detailed diagram provides the specific connection details needed for installation.

Q 23. Describe your experience with electrical code updates and revisions.

My experience with electrical code updates and revisions is extensive. I’ve worked with several editions of the National Electrical Code (NEC), witnessing changes in grounding techniques, arc flash mitigation requirements, and the increasing emphasis on renewable energy integration. For example, I’ve seen a significant shift in the approach to arc flash hazard analysis and the implementation of personal protective equipment (PPE) requirements. The updates regarding the use of GFCI and AFCI protection have also been crucial in preventing electrical hazards.

One significant experience involved migrating a system from an older code to the latest edition. This required a thorough assessment of existing systems and equipment to determine compliance with new standards. This involved significant modifications to the existing setup, which included upgrading the breaker panel and rerouting some circuits to meet the updated grounding requirements. Thorough documentation throughout the entire process was vital in ensuring both compliance and maintaining a detailed record of the work performed.

Q 24. How do you stay current with changes in electrical codes and standards?

Staying current with changes in electrical codes and standards is paramount. I accomplish this through a multi-pronged approach. First, I subscribe to relevant industry publications and newsletters, like those published by NFPA (National Fire Protection Association) which publishes the NEC. Second, I regularly attend seminars and workshops offered by professional organizations and code-training providers. These provide a deeper understanding of the practical implications of code changes. Third, I actively participate in professional networking groups to engage in discussions and share experiences with colleagues, learning from their practical experiences and insights into different interpretations or challenges related to code compliance. This approach ensures I’m always aware of the latest advancements and best practices within the electrical field.

Q 25. Explain your understanding of lockout/tagout procedures.

Lockout/Tagout (LOTO) procedures are critical for preventing accidental energization of electrical equipment during maintenance or repair. Imagine LOTO as a safety protocol, ensuring that no one gets shocked during work on an electrical panel. It’s a systematic process that involves de-energizing equipment, verifying its de-energized state, and applying a lockout device to prevent accidental re-energization. The ‘lock’ prevents anyone from turning the power back on, and the ‘tag’ identifies the worker responsible and the reason for the lockout.

The steps typically include: 1) Preparation (Planning and gathering necessary PPE). 2) Equipment shutdown (Following established procedures to safely turn off power to the equipment). 3) Lockout (Applying lockout devices to prevent re-energization). 4) Verification (Double-checking that the equipment is de-energized). 5) Tagging (Clearly labeling the equipment with a tag indicating who performed the lockout). 6) Work Performance (Safety procedure completed and personnel can start work). 7) Tag removal (After work is complete and verified, the tag is removed and the equipment is re-energized under controlled conditions). Failure to follow these steps can lead to serious injury or even death.

Q 26. Describe a time you had to troubleshoot an electrical problem.

During a recent project, a newly installed lighting system intermittently failed. Initially, I checked the obvious – bulbs and circuit breakers – but found no immediate issue. After using a multimeter to test the voltage across different points within the circuit, I identified a weak connection at a junction box. This was causing an intermittent disruption in power supply, leading to the flickering lights.

My troubleshooting involved systematically checking voltage, current, and continuity at various points in the circuit, using both visual inspection and testing equipment. Once the loose connection was identified, I tightened the wiring connections, and the issue was resolved. This experience highlights the importance of methodical troubleshooting, using appropriate tools, and not jumping to conclusions based on initial observations.

Q 27. How do you ensure electrical safety during a project?

Ensuring electrical safety is a top priority and starts with planning. Before beginning any electrical work, a thorough risk assessment is crucial to identify potential hazards and implement necessary precautions. This includes having a clear understanding of the electrical system’s architecture and characteristics. Next, utilizing appropriate safety measures like proper grounding, isolation techniques (LOTO), and the use of personal protective equipment (PPE) is paramount.

Regular inspections and maintenance of electrical equipment help prevent faults that could lead to accidents. Also, ensuring all work complies with relevant electrical codes and standards is fundamental to safeguarding safety. Effective communication between team members about safety procedures further minimizes risks during a project.

Q 28. Explain the importance of using proper PPE when working with electricity.

Using proper PPE when working with electricity is non-negotiable. Electricity can be lethal; proper PPE acts as a barrier between you and potential hazards. Imagine PPE as your armor against electrical dangers. Essential PPE includes insulated gloves, safety glasses, and arc flash protective clothing in high-voltage situations. These protect against electrical shock, burns, and eye injuries. The specific PPE needed depends on the voltage level and the nature of the work being performed. For example, working with high voltage might necessitate specialized arc flash suits, while lower voltage work might only require insulated gloves and safety glasses.

Ignoring PPE can result in severe injuries, including burns, electrical shock, and even death. Always select and use PPE appropriate for the specific task and voltage level, adhering to manufacturer’s instructions and guidelines for use and maintenance. Regular inspection and proper storage of PPE is also crucial to ensure its effectiveness and longevity.

Key Topics to Learn for Knowledge of Electrical Codes and Standards Interview

- National Electrical Code (NEC) Understanding: Deep dive into the NEC’s structure, organization, and key articles relevant to your experience. Focus on practical application of these codes in various electrical systems.

- Wiring Methods and Techniques: Master different wiring methods (e.g., conduit, cable tray, raceway), their applications, and code compliance considerations. Be prepared to discuss best practices for safe and efficient installations.

- Overcurrent Protection: Understand the principles of fuses, circuit breakers, and their role in protecting electrical systems. Be ready to explain calculations and selection criteria based on code requirements.

- Grounding and Bonding: Thoroughly grasp grounding and bonding techniques, their importance in safety, and how they are implemented according to the NEC. Be able to explain different grounding systems and their applications.

- Electrical Calculations and Design: Demonstrate proficiency in performing basic electrical calculations (e.g., voltage drop, power calculations). Be ready to discuss your experience with electrical system design and code compliance within those designs.

- Safety Regulations and Practices: Showcase your knowledge of relevant safety regulations and practices in the electrical field. Highlight your commitment to safe work habits and adherence to safety protocols.

- Specific Code Interpretations: Prepare to discuss specific scenarios where code interpretation is crucial. Show your ability to analyze situations and apply the relevant codes correctly.

- Troubleshooting and Problem-solving: Practice explaining your approach to troubleshooting electrical problems. Focus on systematic methods, safety precautions, and code-compliant solutions.

- Emerging Technologies and Standards: Stay updated on new technologies and standards relevant to electrical codes. Demonstrating awareness of industry trends is valuable.

Next Steps

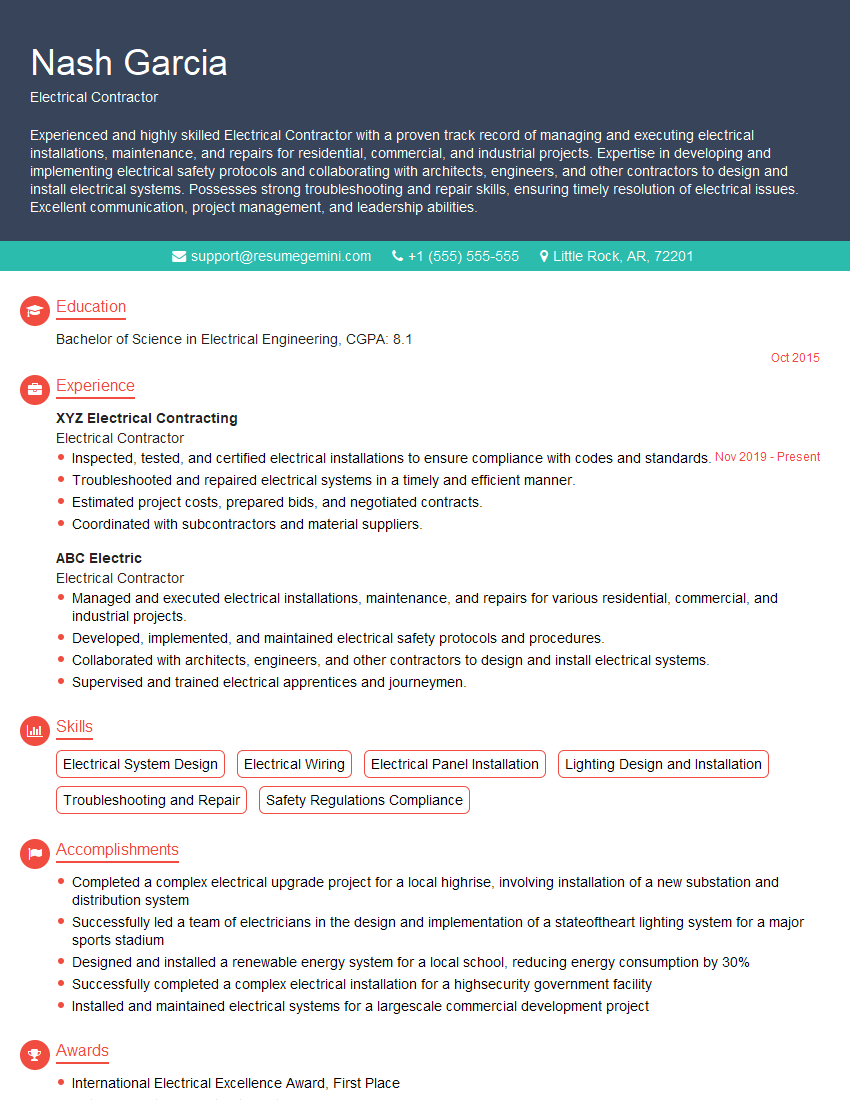

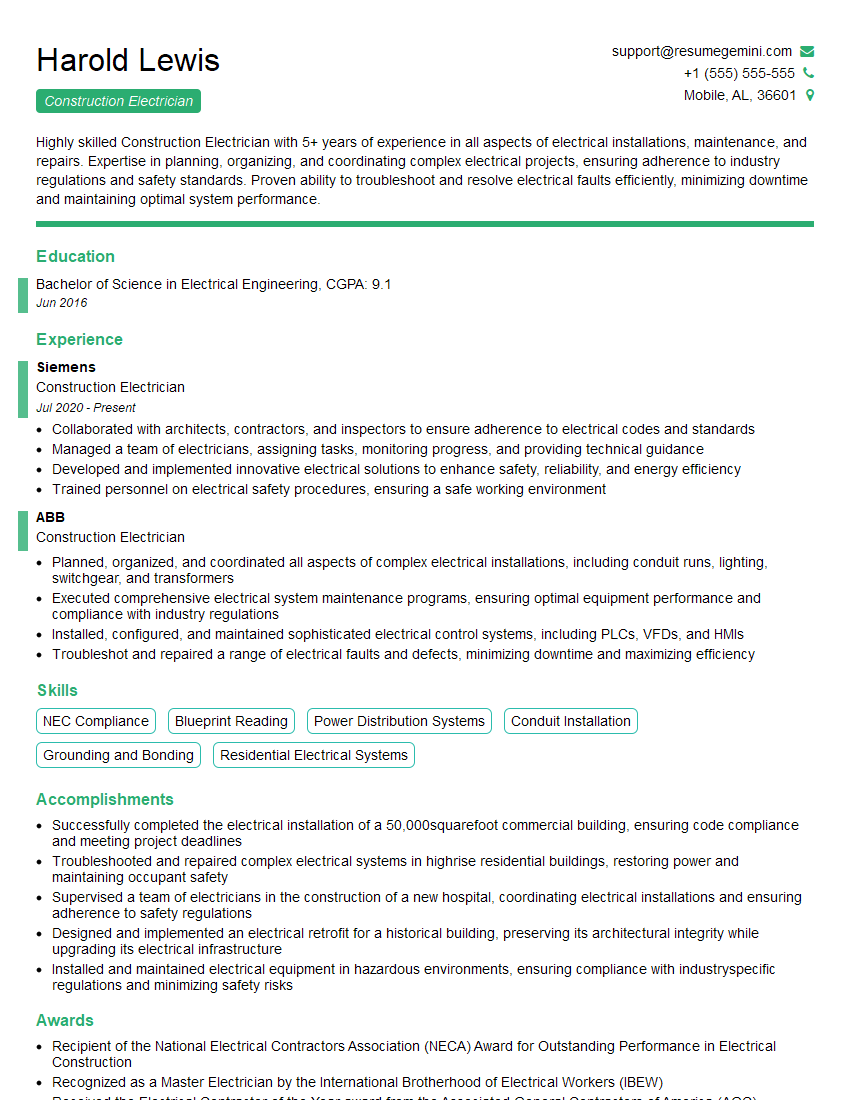

Mastering electrical codes and standards is paramount for career advancement in the electrical field, opening doors to more challenging and rewarding roles. A strong understanding of these codes demonstrates your competence, professionalism, and commitment to safety. To significantly boost your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We offer examples of resumes tailored to showcasing expertise in Knowledge of electrical codes and standards – explore these examples to inspire your own resume creation.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good