Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Knowledge of embroidery hardware and machinery interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Knowledge of embroidery hardware and machinery Interview

Q 1. Explain the difference between single-head and multi-head embroidery machines.

The core difference between single-head and multi-head embroidery machines lies in their production capacity. A single-head machine has one needle and embroideries one design at a time. Think of it like a single artist meticulously crafting a piece. It’s ideal for smaller projects, intricate designs, or when high precision is crucial. On the other hand, a multi-head machine features multiple needles (anywhere from 2 to 16 or more), allowing it to embroider multiple designs simultaneously. This is akin to a team of artists working on different canvases, greatly increasing production speed. Multi-head machines are perfect for mass production and large orders where efficiency is paramount.

For example, a small custom embroidery business might rely on a single-head machine for personalized items, while a large apparel manufacturer would utilize a multi-head machine for logo embroidery on thousands of shirts.

Q 2. Describe your experience with various embroidery machine brands (e.g., Tajima, Barudan, Melco).

My experience spans a wide range of embroidery machine brands, including Tajima, Barudan, and Melco. I’ve worked extensively with Tajima machines, particularly their TME series, known for their robust build and reliable performance in high-volume production. I appreciate their user-friendly interface and advanced features like automatic thread trimming and pattern sequencing. I’ve also had considerable experience with Barudan’s machines, particularly their high-speed models which are excellent for large-scale projects needing quick turnaround times. Their precision is remarkable, especially in intricate designs requiring sharp details. Finally, I’ve worked with Melco machines, known for their intuitive software and exceptional stitching quality, making them perfect for high-end, detailed embroidery. Each brand has its strengths and weaknesses; the best choice often depends on the specific needs of the project and production volume.

For instance, if a project requires precise placement and intricate detailing, a Melco machine might be preferred, while a large order requiring fast production would be better suited for a Barudan high-speed model.

Q 3. How do you troubleshoot common embroidery machine errors, such as needle breakage or thread jams?

Troubleshooting embroidery machine errors requires a systematic approach. Let’s take needle breakage and thread jams as examples. Needle breakage often stems from blunt needles, incorrect needle type for the fabric, improper tension, or hitting the embroidery hoop or design elements. The solution involves inspecting the needle for damage, using the correct needle type for the thread and fabric (refer to manufacturer’s recommendations), adjusting thread tension (both upper and lower), and meticulously checking the design for areas that might cause needle strikes. Thread jams can be caused by incorrect threading, tangled thread, low thread tension, or lint and debris build-up. Troubleshooting involves checking the entire threading path for any obstructions, ensuring correct thread tension, cleaning lint and debris from the bobbin case and hook area, and verifying the thread path is correctly followed.

For instance, if you’re consistently experiencing needle breakage, you’ll systematically check the needle, tension, and then your design’s digitized file for potential problems. Similarly, a thread jam is resolved by systematically examining the thread path from the spool to the needle, checking tension and cleaning the machine.

Q 4. What are the different types of embroidery stitches and when would you use each?

Embroidery stitches are incredibly diverse, each serving a unique purpose. Common types include:

- Running Stitch: Simple, fast stitch, ideal for outlining or filling large areas quickly.

- Satin Stitch: Dense, smooth fill stitch used for solid color areas and creating sharp, clean designs.

- Fill Stitch: Various patterns (e.g., zigzag, cross-hatch) to fill areas with texture and shading.

- Chain Stitch: Creates a looped effect, used in decorative designs or as a base for other stitches.

- Appliqué Stitch: Securely attaches fabric pieces, often combined with other stitches for a finished look.

Choosing the right stitch depends on the design’s complexity, the desired effect, and the fabric type. For example, satin stitch is great for logos, while fill stitches add texture to floral designs. Appliqué stitches are necessary when adding fabric details to an embroidered piece.

Q 5. Explain the process of setting up an embroidery machine for a new design.

Setting up an embroidery machine for a new design involves several steps:

- Design Import: Load the embroidery design file (typically DST, EXP, or other formats) into the machine’s software.

- Fabric Preparation: Hoop the fabric securely, ensuring it’s taut but not stretched. The hoop’s size should match or be larger than the design.

- Needle and Thread Selection: Choose the appropriate needle size and type for the fabric and thread. Ensure the thread is properly wound onto the bobbin and spools.

- Thread Tension Adjustment: Adjust the upper and lower thread tensions according to the fabric and thread type. Incorrect tension can lead to poor stitching quality.

- Design Placement: Position the hoop with the design in the desired location on the fabric.

- Stitch Out: Begin the stitching process. Monitor for any issues, like thread breaks or skipped stitches.

Proper setup is crucial for a successful embroidery process. For example, incorrect hooping can lead to distortion and fabric puckering. Using the wrong needle can cause breakage and poor stitching quality. Careful attention to detail ensures an accurate, beautiful result.

Q 6. How do you maintain and clean embroidery machines to ensure optimal performance?

Regular maintenance is key to prolonging the life and optimal performance of embroidery machines. This includes:

- Daily Cleaning: Remove lint and thread trimmings from the bobbin case, hook area, and needle plate after each use.

- Weekly Cleaning: Use a brush and compressed air to clean the machine’s interior, removing accumulated dust and debris.

- Lubrication: Apply appropriate lubricant to moving parts according to the manufacturer’s recommendations.

- Bobbin Case Inspection: Regularly inspect the bobbin case for wear and tear. Replace as needed.

- Needle Inspection: Examine needles for damage before each use. Replace bent or damaged needles promptly.

Preventive maintenance helps avoid costly repairs and downtime. Think of it as regular car maintenance – a little care goes a long way in preventing major problems.

Q 7. What safety precautions do you take when operating embroidery machinery?

Safety is paramount when operating embroidery machinery. Precautions include:

- Proper Training: Thoroughly understand the machine’s operation and safety features before use.

- Loose Clothing and Jewelry: Avoid wearing loose clothing or jewelry that could get caught in moving parts.

- Hair Restraint: Tie back long hair to prevent entanglement.

- Machine Guards: Ensure all safety guards are in place and functioning correctly.

- Emergency Stop: Know the location and operation of the emergency stop button.

- Regular Maintenance: Keep the machine clean and properly lubricated to prevent malfunctions.

Ignoring these safety precautions can lead to serious injuries. Always prioritize safety to protect yourself and others.

Q 8. Describe your experience with embroidery digitizing software.

My experience with embroidery digitizing software spans over 10 years, encompassing various software like Wilcom, Pulse, and Tajima. I’m proficient in converting artwork into stitch files, optimizing stitch density for different fabrics, and manipulating stitch attributes to achieve specific design effects. I’m particularly skilled in creating complex designs with intricate details, ensuring smooth transitions between color changes and avoiding thread breakage. For example, I once digitized a highly detailed floral design for a wedding dress, requiring precise control over underlay stitches to prevent puckering. The final result was a flawlessly embroidered piece that met the client’s exacting standards.

My workflow typically involves analyzing the artwork, selecting the appropriate stitch types (e.g., satin, fill, outline), optimizing stitch density and underlay, and meticulously cleaning up the digitized file to eliminate jump stitches and unnecessary movements. I also use software features to simulate the embroidery process, allowing me to identify and correct potential problems before production. This preventative approach saves time and materials, ensuring efficient and high-quality results.

Q 9. How familiar are you with different types of embroidery hoops and their applications?

I’m very familiar with a wide range of embroidery hoops, understanding their applications and limitations. The choice of hoop depends heavily on the size and shape of the design, the fabric type, and the embroidery machine itself. For example, smaller hoops (like 4×4 inches) are suitable for smaller designs or intricate details, while larger hoops (up to 15×15 inches or even larger) accommodate larger designs and garments. Different hoop materials (e.g., plastic, metal) also impact suitability; some materials are more suitable for delicate fabrics to prevent slippage or damage.

Specifically, I’ve worked extensively with:

- Standard circular hoops: Versatile for various projects.

- Rectangular hoops: Ideal for designs that are not circular.

- Magnetic hoops: Easy to use, particularly beneficial for smaller designs.

- Specialty hoops: Designed for specific items like caps or towels.

I understand the importance of correctly tensioning the fabric within the hoop to prevent puckering and distortion during the embroidery process. Incorrect hooping is a frequent source of errors, and experience allows me to rapidly identify and correct tension issues.

Q 10. What are the key factors to consider when choosing the right embroidery thread?

Selecting the right embroidery thread is crucial for achieving high-quality embroidery. Several key factors come into play:

- Fiber content: Polyester threads are the most common due to their durability, shine, and wide color range. Rayon threads offer a softer, more luxurious look, while cotton threads provide a natural look but are less durable. The choice depends on the desired aesthetic and the intended use of the embroidered item.

- Thread weight/thickness: Different weights (e.g., 40 wt, 60 wt) are suitable for different fabric weights and stitch densities. Thicker threads are better suited for heavier fabrics and larger stitches.

- Colorfastness: Choosing colorfast threads is essential to prevent fading and color bleeding, particularly when washing the embroidered item. I always consult the thread manufacturer’s specifications for washing instructions.

- Luster/Shine: The level of shine can significantly impact the final look. Some designs benefit from high-luster threads, while others might require a more matte finish.

For example, when embroidering on delicate silk, I would choose a finer-weight rayon thread to avoid damaging the fabric. Conversely, heavier-weight polyester thread is ideal for heavier denim or canvas materials.

Q 11. Explain your experience with different fabric types and their suitability for embroidery.

My experience includes working with a diverse range of fabrics, from delicate silks and linens to sturdy denim and canvas. Understanding fabric properties is critical for choosing the appropriate stitch density, needle type, and stabilizer. For instance, lightweight fabrics like chiffon might require a water-soluble stabilizer to prevent puckering and provide support during embroidery, whereas a heavier-weight fabric like denim might need only tear-away stabilizer.

Some fabrics are more challenging to embroider than others. Stretchy fabrics, for instance, require careful hooping and might need special stabilizers to prevent distortion. I’ve developed techniques for handling various fabric types, including pre-treatments (like pre-washing or sizing) to prepare fabrics for embroidery and prevent issues with shrinkage or color bleeding.

I always test my stitch settings and stabilizer choices on a fabric scrap before embroidering the final piece. This prevents costly mistakes and ensures the best possible outcome.

Q 12. How do you handle complex embroidery designs requiring multiple color changes?

Managing complex designs with multiple color changes requires careful planning and execution. The digitizing software plays a crucial role, allowing me to optimize the stitch order to minimize color changes and thread trims. Techniques like color blocks and efficient jump stitches reduce production time and improve the overall aesthetic. Additionally, I use the software’s functions to preview the color changes and to identify potential issues before starting the embroidery process.

In practice, I always ensure the machine is properly threaded with the correct color before starting a new section. I also make sure to use appropriate thread management techniques to avoid tangles or thread breakage. For very complex designs, I might use a multi-needle machine to reduce the number of color changes. Careful organization and a thorough understanding of the stitching sequence are critical to successful execution.

Q 13. How do you manage production deadlines and prioritize tasks in a busy embroidery environment?

Managing production deadlines and tasks in a busy embroidery environment requires efficient organization and prioritization. I utilize project management software to track deadlines and allocate time for each project. I break down complex tasks into smaller, manageable steps and use a prioritized task list to ensure that the most urgent tasks are completed first. This approach allows me to manage my workload effectively and consistently meet deadlines, even under pressure.

For example, I use Kanban boards to visualize the workflow and quickly identify potential bottlenecks. I also maintain open communication with clients and colleagues to ensure everyone is informed about project status and potential delays.

Furthermore, proactive planning is crucial. Anticipating potential issues (such as thread stock availability or machine maintenance) and planning accordingly helps in preventing delays.

Q 14. What is your experience with embroidery machine programming and editing stitch data?

I have extensive experience with embroidery machine programming and editing stitch data, focusing on machines from Tajima, Barudan, and Melco. My skills encompass loading designs, adjusting stitch parameters (like speed and density), and troubleshooting errors directly on the machine. I am comfortable editing stitch data to correct errors, optimize stitch paths, and improve the overall quality of the embroidery. This includes working with the machine’s control panel and using specialized software to interact with the machine’s controller.

For example, I have successfully resolved issues with thread breakage by adjusting the machine’s tension settings or by modifying the stitch density in problem areas. I also know how to edit stitch data to correct stitch jump issues, resulting in cleaner and more efficient embroidery.

Understanding the intricacies of stitch data allows me to diagnose and resolve technical problems quickly, contributing to high efficiency and minimal downtime.

Q 15. Describe your experience with troubleshooting and repairing embroidery machine hardware.

Troubleshooting and repairing embroidery machine hardware requires a methodical approach combining technical knowledge with practical skills. My experience spans various machine types, from single-head domestic machines to multi-head industrial models. I start by identifying the problem – is it a mechanical issue, an electrical fault, or a software glitch? This often involves careful observation, listening for unusual noises, and checking error codes displayed on the machine’s control panel. For instance, if a machine is skipping stitches, I’d systematically check the bobbin tension, needle condition, thread path, and the timing of the hook mechanism. Electrical problems might involve checking wiring connections, fuses, or even replacing faulty components. I always prioritize safety, ensuring the machine is properly disconnected from the power supply before undertaking any repairs. I document all repairs thoroughly, including the problem, the steps taken, and the parts replaced, to facilitate future troubleshooting and maintenance.

For example, I once diagnosed a machine consistently breaking needles as a problem with the needle clamp screw. A simple tightening resolved the issue, preventing costly needle replacements and production downtime. Another time, I traced a power failure to a faulty capacitor in the main control board, requiring its replacement – a repair that saved the cost of a complete board replacement.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure consistent quality and accuracy in embroidery production?

Consistent quality and accuracy in embroidery production hinges on attention to detail at every stage, from design preparation to final inspection. This starts with ensuring the embroidery design is digitized correctly, optimizing stitch density and avoiding sharp transitions that can lead to thread breakage. Proper machine setup is critical: correct needle type, thread tension, bobbin winding, and hooping technique are essential. Regular maintenance, including cleaning and lubrication, prevents mechanical wear and ensures smooth operation. Using high-quality threads and materials significantly contributes to a consistent outcome. Finally, a robust quality control process, including regular checks during production, helps identify and correct inconsistencies early on, minimizing waste and maximizing efficiency.

Think of it like baking a cake. You wouldn’t use different amounts of flour every time; you’d follow a recipe to the letter. In embroidery, that recipe is your machine setup, design parameters, and quality control checks. Any deviation can lead to inconsistencies in the final product.

Q 17. What is your understanding of different types of embroidery needles and their uses?

Embroidery needles are highly specialized, each designed for specific fabric types and thread weights. Choosing the right needle is crucial for achieving quality and preventing damage to both the fabric and the machine.

- Embroidery Needles (Standard): These are used for most embroidery types and fabrics, coming in varying sizes to suit thread thickness and fabric weight. A smaller needle is used for finer fabrics and threads, while a larger needle is used for heavier fabrics and threads.

- Sharp Needles: Designed for woven fabrics, these needles have a sharp point that easily penetrates the fabric.

- Ballpoint Needles: Used for knits and other stretchy fabrics, the rounded point glides between the fabric loops, preventing snags and damage.

- Metallic Needles: Their reinforced construction prevents bending or breakage when embroidering with metallic threads.

- Embroidery Needles for Jeans: These durable needles have thicker shafts and points for heavy fabrics like denim.

Selecting the wrong needle can lead to broken needles, thread breakage, skipped stitches, or damaged fabric. For example, using a sharp needle on a knit fabric will likely cause runs, whereas a ballpoint needle on woven fabric might create uneven stitches.

Q 18. How do you calculate the cost of an embroidery job, considering materials and labor?

Calculating the cost of an embroidery job requires considering several factors. The most important are materials and labor.

- Materials: This includes the cost of the fabric, threads, stabilizers (like tear-away or wash-away), needles, bobbins, and any embellishments. You need to calculate the quantity of materials used based on the design’s complexity and the fabric’s size.

- Labor: This involves the hourly rate for the embroiderer, plus any design digitization costs, setup time, and machine operation time. The complexity of the design significantly affects labor costs, as more intricate designs will take longer to execute.

- Overhead: Don’t forget about overhead costs, including rent, utilities, and machine maintenance. These are often calculated as a percentage markup on the materials and labor cost.

A thorough cost breakdown allows for accurate pricing, ensuring profitability while remaining competitive. I usually create a spreadsheet to track material costs for each job and calculate labor based on the hourly rate and estimated completion time. This ensures transparency and accuracy in my pricing.

Q 19. Describe your experience with quality control processes in embroidery production.

Quality control in embroidery production is a multi-step process that begins with the design’s approval and continues throughout the production. At each stage, we meticulously inspect the work for any imperfections.

- Pre-Production Checks: This involves checking the design digitization for errors, verifying the correct materials and thread colors are selected, and ensuring proper machine setup.

- In-Process Checks: During production, regular checks are conducted to ensure consistent stitch quality, thread tension, and fabric alignment. Any defects are immediately addressed.

- Post-Production Checks: After completion, each piece is thoroughly inspected for any stitch irregularities, thread breaks, or fabric damage. This might include examining under a bright light to detect subtle flaws.

- Documentation: All quality control checks are documented with the use of checklists and records of any corrections or adjustments that were made.

By maintaining a strict quality control process, we minimize errors and ensure that all final products meet or exceed our clients’ expectations.

Q 20. How do you handle customer complaints or issues related to embroidery quality?

Handling customer complaints about embroidery quality requires a calm and professional approach. My strategy prioritizes understanding the customer’s concerns, empathizing with their situation, and finding a fair resolution. I begin by listening attentively to their description of the problem, asking clarifying questions to fully understand the issue. I then examine the embroidery piece to verify the complaint, looking for inconsistencies, defects, or damage. Once I’ve identified the cause, I explain the situation clearly to the customer, outlining the steps we will take to correct it, whether it’s a re-embroidery of the piece, a partial refund, or another appropriate solution. Transparency and clear communication are key to resolving the issue effectively and maintaining a positive relationship with the customer. In some cases, I might offer a discount on future orders as a goodwill gesture.

For instance, if a customer complained of uneven stitching, I’d first verify if it was a result of a machine malfunction, incorrect needle selection, or perhaps an inherent issue with the design itself. Once determined, I would propose an appropriate solution and communicate that clearly to the customer, keeping them informed at each step.

Q 21. Explain your experience with different types of embroidery designs (e.g., appliqué, 3D, free motion).

My experience encompasses a wide range of embroidery techniques and designs.

- Appliqué: This involves sewing fabric pieces onto a base material to create layered designs. I’m proficient in various appliqué methods, including raw-edge appliqué and satin-stitch appliqué, adapting techniques based on fabric types and desired aesthetic.

- 3D Embroidery: Creating dimensional effects through layering, foam padding, and specialized stitching techniques, I have extensive experience in crafting intricate 3D designs, from raised lettering to textured floral patterns.

- Free Motion Embroidery: This involves guiding the fabric freely under the needle to create free-flowing designs. I can create unique and customized embroidery patterns using this technique, often incorporating decorative stitches and details.

- Traditional Embroidery: I’m well-versed in creating traditional embroidery designs using various stitch patterns and techniques, ensuring the accuracy and quality of traditional stitches.

Each technique demands a unique skill set and understanding of design principles. For instance, successful 3D embroidery requires precise layering and the right type of stabilizer to support the form. Free-motion embroidery requires precise hand control and creative vision.

Q 22. How familiar are you with different types of stabilizers and their applications?

Stabilizers are crucial in embroidery; they provide support to the fabric, preventing puckering and ensuring clean stitches. Choosing the right stabilizer depends heavily on the fabric type, design complexity, and desired outcome.

- Cut-away stabilizer: This is a strong, tear-away stabilizer used for most embroidery projects. After stitching, the excess stabilizer is cut away from the finished design. I frequently use this for towels, sweatshirts, or denim projects where extra support is needed.

- Tear-away stabilizer: This type is easily removed by tearing after embroidery. It’s perfect for delicate fabrics like silk or lace where a completely clean finish is essential. Think of delicate blouses or bridal veils.

- Wash-away stabilizer: As the name suggests, this stabilizer dissolves in water after embroidery. Ideal for fabrics that can’t tolerate tearing or cutting, such as jerseys or lightweight knits. I’ve used this for children’s clothing items frequently.

- Sticky/Heat-n-Bond stabilizer: This stabilizer has an adhesive backing and is particularly useful for lightweight fabrics that need extra support in place. This is handy for smaller designs or when stabilizing just a section of the fabric.

- Fusible interfacing: Though not strictly an embroidery stabilizer, it often gets incorporated, especially for applications like appliqués. It provides structure and a firm backing, preventing the fabric from distorting under the needle.

Selecting the appropriate stabilizer is paramount. Using the wrong one can lead to puckering, poor stitch quality, or even damage to the fabric. My experience has taught me to always assess the project needs before selecting a stabilizer – it’s a crucial first step to successful embroidery.

Q 23. What is your experience working with different embroidery software packages?

My experience spans several leading embroidery software packages. I’m proficient in industry standards like Wilcom EmbroideryStudio, Pulse, and Tajima DG/ML. Each has its unique strengths: Wilcom, for example, is renowned for its advanced features and customization options, while Pulse is known for its user-friendly interface. My expertise extends beyond basic digitizing to advanced techniques like color separation, lettering creation, and intricate design manipulation. I understand the nuances of each software and can easily adapt between them. In one project involving a complex logo for a corporate client, the intricate design required using Wilcom’s advanced features for perfect stitch placement and density control. In contrast, a smaller project with a simple design, I used Pulse’s ease of use for efficient creation and quick turnaround.

Q 24. Describe your problem-solving approach when facing unexpected challenges during embroidery production.

My problem-solving approach is systematic and data-driven. When facing unexpected challenges, I follow these steps:

- Identify the Problem: First, I carefully analyze the issue. Is it a machine malfunction, a problem with the design, a stabilizer issue, or something else?

- Isolate the Cause: I systematically eliminate possible causes. For example, if there’s skipping, I’ll check the tension, needle, and bobbin. Is the fabric moving? Does the stabilizer have the correct support? One time a series of broken needles was tracked down to a tiny, almost invisible snag in the fabric.

- Consult Resources: I leverage my experience, consult manuals, online forums, and even reach out to colleagues when necessary. Often, a simple online search reveals a solution someone else has already found.

- Implement Solutions: Once the cause is identified, I implement the appropriate solution. This could involve adjusting machine settings, replacing parts, or redesigning a portion of the embroidery.

- Document Findings: Finally, I document my findings, including the problem, the cause, and the solution, so I can refer to them in the future and to help others learn from the experience.

This methodical approach ensures efficient troubleshooting and prevents similar issues from recurring. It is essential for maintaining high quality and minimizing production downtime.

Q 25. How do you stay up-to-date on the latest advancements in embroidery technology and techniques?

Staying current is essential in this dynamic field. I employ several strategies:

- Industry Publications and Websites: I regularly read trade magazines, online articles, and industry blogs to stay informed about new technologies, techniques, and trends.

- Trade Shows and Conferences: Attending industry trade shows and conferences allows me to see new equipment, software, and techniques firsthand. Networking with other professionals offers invaluable insights and connections.

- Online Courses and Workshops: I actively participate in online courses and workshops to expand my knowledge and learn new skills. This allows continuous professional development in advanced digitizing or specific machine maintenance techniques.

- Manufacturer Websites and Documentation: Regularly checking manufacturer websites and reviewing machine manuals helps keep me updated on software updates, troubleshooting guides, and machine maintenance procedures.

This multi-pronged approach ensures I remain at the forefront of embroidery technology and techniques.

Q 26. Explain your experience with automation and robotics in embroidery production.

My experience with automation and robotics in embroidery is growing. I’ve worked with multi-needle machines featuring automated hooping systems, improving efficiency and reducing manual labor. I understand the programming and operational aspects of these systems. I’ve also been involved in projects integrating robotic arms for material handling and pre-stitching tasks. These automated systems allow for high-volume production with increased precision and consistency. For example, we use a robotic arm to accurately place the fabric on the embroidery machine, eliminating inconsistencies and improving productivity.

However, it’s important to note that while automation improves efficiency, human expertise remains crucial for quality control, complex design implementation, and troubleshooting. My skillset balances the benefits of automation with the precision and creative input that only a human can provide.

Q 27. What is your understanding of the role of tension in embroidery?

Tension is the force applied to the top and bottom threads during embroidery. Proper tension is critical for achieving high-quality stitches. If the tension is too loose, the stitches will look uneven and may break. If it’s too tight, the fabric may pucker or the stitches will be distorted. Think of it like a tug-of-war between the top and bottom threads – a delicate balance is needed.

Factors influencing tension include the type of fabric, thread, needle size, stabilizer type, and even the design density. Troubleshooting tension problems involves checking all these factors. It might require adjusting the machine’s tension dials, changing the needle, using a different type of thread, or even switching stabilizers. Experience allows me to quickly identify the source of tension issues and implement the correct adjustments.

Q 28. How would you train a new employee on embroidery machine operation and maintenance?

Training a new employee involves a structured approach combining theoretical knowledge with hands-on experience:

- Safety First: I begin by emphasizing safety procedures – proper machine operation, use of safety guards, and handling of needles and sharp objects.

- Machine Overview: A comprehensive overview of the embroidery machine is given, covering its components, functions, and controls. We cover basic maintenance like lubrication and cleaning.

- Software Training: The employee learns the embroidery software, focusing on design manipulation, stitch types, color separation, and thread selection.

- Hands-on Practice: Practical sessions are crucial, starting with simple designs and gradually progressing to more complex projects. I provide continuous feedback and guidance throughout.

- Troubleshooting: Troubleshooting is a key part of the training; we address common problems and develop effective problem-solving skills. Learning to identify and fix basic problems independently is essential.

- Quality Control: Understanding quality control is emphasized – including stitch quality evaluation, fabric handling, and stabilizer selection.

- Continuous Learning: Encouraging continuous learning through self-study, attending workshops, and staying informed about new technologies is emphasized.

My training methods ensure a thorough understanding of machine operation, maintenance, troubleshooting, and quality control. A structured, hands-on approach ensures they gain the necessary skills and confidence to work independently.

Key Topics to Learn for Knowledge of Embroidery Hardware and Machinery Interview

- Machine Types and Functionality: Understanding the differences between single-head, multi-head, and industrial embroidery machines; their capabilities and limitations; and appropriate applications for each.

- Needle Types and Selection: Knowing the various needle types (e.g., embroidery needles, topstitching needles), their purposes, and how to select the correct needle for different fabrics and threads.

- Thread Management and Tension: Mastering the principles of proper thread tension, troubleshooting tension issues, and understanding the impact of thread type and quality on embroidery results.

- Bobbin Winding and Insertion: Proficiency in winding bobbins correctly and efficiently, and understanding the importance of proper bobbin insertion for consistent stitching.

- Digitizing and Design Software: Familiarity with common embroidery digitizing software, understanding design elements, stitch types, and their application in creating embroidery designs.

- Maintenance and Troubleshooting: Knowledge of routine maintenance procedures, common machine malfunctions, and troubleshooting techniques to address minor issues independently.

- Safety Procedures and Regulations: Understanding and adhering to relevant safety guidelines and regulations related to the operation and maintenance of embroidery machinery.

- Fabric Selection and Preparation: Understanding how different fabric types affect embroidery results and how to prepare fabrics for optimal embroidery performance (e.g., hooping techniques).

- Embroidery Techniques: Familiarity with various embroidery techniques such as appliqué, free motion, and 3D embroidery, and their practical applications.

- Production Processes and Efficiency: Understanding workflow optimization, production planning, and strategies for maximizing efficiency in an embroidery environment.

Next Steps

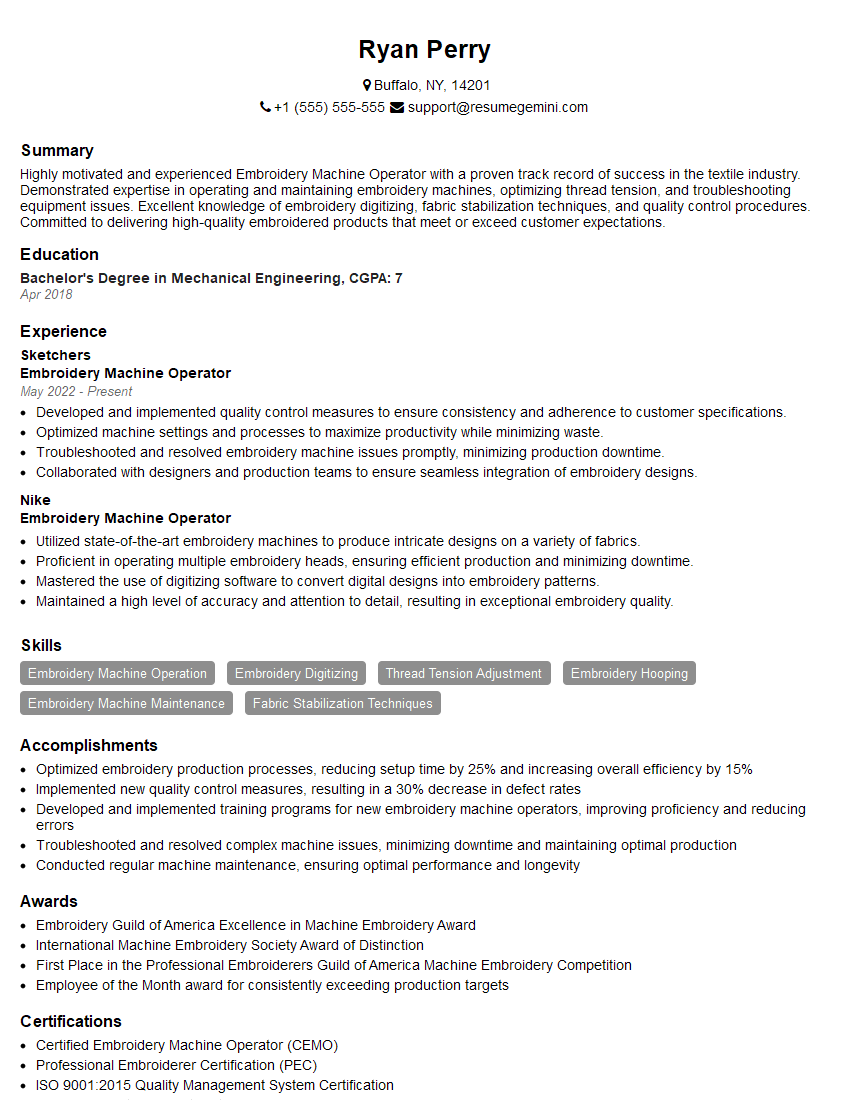

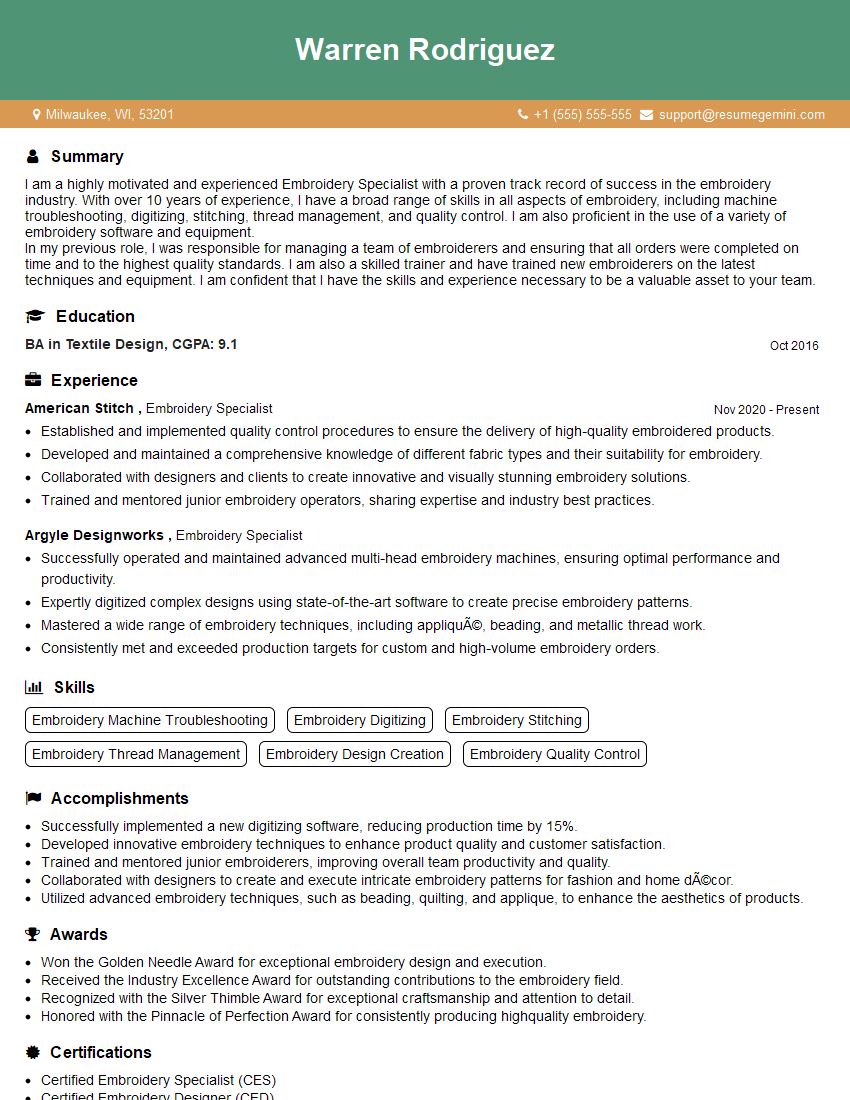

Mastering knowledge of embroidery hardware and machinery is crucial for career advancement in the textile and apparel industries. A strong understanding of these concepts demonstrates technical proficiency and problem-solving skills highly valued by employers. To significantly boost your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you craft a professional and impactful resume tailored to highlight your specific skills and experience. Examples of resumes tailored to showcasing expertise in Knowledge of embroidery hardware and machinery are available through ResumeGemini to help guide your resume creation.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good