Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Knowledge of HACCP Standards interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Knowledge of HACCP Standards Interview

Q 1. Describe the seven HACCP principles.

The seven HACCP principles are a systematic, preventative approach to food safety. They provide a framework for identifying and controlling hazards that can cause foodborne illness. Think of them as seven building blocks forming a strong foundation for food safety.

- Conduct a Hazard Analysis: Identify potential biological, chemical, and physical hazards that could occur at each step of the food production process. For example, in a bakery, a hazard analysis might consider flour contamination with E. coli, or the presence of metal fragments from equipment.

- Determine Critical Control Points (CCPs): Identify steps in the process where control is essential to prevent or eliminate a hazard or reduce it to an acceptable level. In the bakery example, baking to a specific temperature could be a CCP to eliminate E. coli.

- Establish Critical Limits: Set specific measurable criteria for each CCP that must be met to ensure the hazard is controlled. For our bakery, the critical limit for the CCP (baking temperature) might be 165°F (74°C) for a specific duration.

- Establish Monitoring Procedures: Implement a system to regularly monitor each CCP and record the results. This could involve using temperature probes to monitor oven temperature throughout the baking process and logging the data.

- Establish Corrective Actions: Define actions to take when monitoring shows that a CCP is not under control. If the oven temperature drops below 165°F (74°C), corrective actions might include adjusting the oven settings and discarding any affected products.

- Establish Verification Procedures: Implement procedures to verify that the HACCP system is working as intended. This might include regular audits of the HACCP plan, equipment calibration checks, and employee training reviews.

- Establish Record-Keeping and Documentation Procedures: Maintain detailed records of all HACCP activities. These records provide evidence that the system is functioning effectively and can be crucial for traceability in case of a food safety incident.

Q 2. Explain the difference between a critical control point (CCP) and a critical limit.

While both CCPs and critical limits are essential components of a HACCP plan, they represent different aspects of hazard control. Think of it like this: a CCP is the location where a control measure is applied, and the critical limit is the specific target that needs to be met at that location to control the hazard.

A Critical Control Point (CCP) is a step in the food production process where a control can be applied and is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level. For instance, cooking temperature during meat processing is a CCP.

A Critical Limit is a specific value that must be met at a CCP to prevent, eliminate, or reduce a food safety hazard to an acceptable level. For the meat cooking CCP, the critical limit might be an internal temperature of 165°F (74°C).

In short: The CCP is the where, and the critical limit is the what (specific value) needed at that where to control the hazard.

Q 3. How do you conduct a HACCP hazard analysis?

Conducting a HACCP hazard analysis involves systematically identifying potential biological, chemical, and physical hazards throughout the food production process. This is a team effort, often involving food scientists, production personnel, and quality control experts. It’s a crucial first step that sets the stage for the entire HACCP plan.

- Describe the product: Detail the product’s characteristics, intended use, and target consumer group.

- Identify intended use and consumers: Understanding who will consume the product and how helps define potential hazards. For example, a baby food product requires more stringent controls than a product for adult consumption.

- Develop a flow diagram: Map out every step of the food production process, from raw material acquisition to final product distribution. This visual representation helps identify all potential points of hazard introduction.

- Conduct a hazard analysis for each step: For each step in the process, identify potential biological, chemical, and physical hazards. Use your expertise and reference available data on hazards, prevalence, and potential severity (e.g., databases of foodborne illnesses).

- Categorize hazards based on severity and likelihood: Assess the severity and likelihood of each hazard occurring. This prioritizes control efforts on the most significant risks. This might involve a risk matrix.

- Document the findings: Maintain comprehensive records of the hazard analysis, including the identified hazards, their potential sources, severity assessments, and any supporting evidence.

A thorough hazard analysis ensures that the subsequent steps of the HACCP plan effectively address the most significant risks to food safety.

Q 4. What are the key elements of a HACCP plan?

A comprehensive HACCP plan includes detailed documentation of all the aspects necessary for effective food safety management. It’s not just a document; it’s a living system that requires regular review and updates.

- Product Description: A clear description of the product, including its intended use and target consumer group.

- Hazard Analysis: A detailed listing of potential hazards, their severity, and the likelihood of occurrence.

- CCP Identification: A clear identification of all critical control points in the food production process.

- Critical Limits: Specific measurable values for each CCP that must be met to control hazards.

- Monitoring Procedures: Details of how each CCP will be monitored, including the frequency, methods, and responsible personnel.

- Corrective Actions: Steps to take if a critical limit is not met, ensuring a prompt response to deviations.

- Verification Procedures: Methods to ensure the HACCP plan is functioning effectively (e.g., audits, calibration checks).

- Record-Keeping: Documentation procedures for all HACCP activities, including monitoring data, corrective actions, and verification results.

A well-structured HACCP plan ensures that all critical control points are effectively managed, significantly reducing the risk of foodborne illness.

Q 5. How do you validate a HACCP plan?

Validating a HACCP plan involves demonstrating that the plan effectively controls identified hazards. It’s more than just creating a document; it’s about proving its effectiveness in real-world conditions. Think of validation as the ‘proof of concept’ for your HACCP system.

Validation often involves:

- Scientific validation of CCPs and critical limits: Using scientific data and testing to confirm the effectiveness of chosen CCPs and critical limits in preventing or eliminating hazards. This often involves microbiological testing and other scientific methods.

- On-site verification: Conducting regular on-site monitoring and observation to check that the CCPs are operating within the established critical limits and that corrective actions are effective.

- Review and update of the HACCP plan: Regularly reviewing and updating the HACCP plan based on the validation results, monitoring data, and changes in the production process or scientific understanding.

- Internal audits: Regularly conducting internal audits to assess the effectiveness of the HACCP system and identify areas for improvement.

- External audits: Subjecting the HACCP plan to external audits by regulatory agencies or independent certification bodies.

Successful validation provides assurance that the HACCP plan is functioning as intended and is effectively controlling food safety hazards.

Q 6. Explain the importance of record-keeping in a HACCP system.

Record-keeping is the backbone of a functioning HACCP system. It provides crucial evidence that the system is working effectively and allows for traceability in case of a food safety incident. These records act as a historical record and can be essential for investigations and regulatory compliance.

Essential records include:

- Hazard analysis records: Documentation of the identified hazards, their assessment, and the rationale for CCP selection.

- CCP monitoring records: Daily records of CCP monitoring, including measurements, dates, times, and the names of personnel involved.

- Corrective action records: Documentation of any deviations from critical limits, the corrective actions taken, and the effectiveness of these actions.

- Verification records: Records of regular audits, calibration checks, and other verification activities.

- Training records: Documentation of employee training on HACCP principles and procedures.

Maintaining accurate and complete records is critical for demonstrating compliance with food safety regulations and protecting consumer health. Poor record-keeping can lead to regulatory non-compliance and significant liabilities.

Q 7. How do you identify potential hazards in a food processing environment?

Identifying potential hazards in a food processing environment requires a systematic and thorough approach. It’s not just about looking for obvious dangers; it’s about anticipating potential problems before they occur. Think of it like a detective investigating a crime scene—you need to examine all possible angles.

Methods for identifying hazards include:

- Hazard analysis workshops: Bringing together personnel from all aspects of the food production process to brainstorm potential hazards.

- Review of previous incidents: Examining past food safety incidents (internal or industry-wide) to identify potential hazards in your own process.

- Supplier information: Reviewing information provided by suppliers about potential hazards associated with raw materials.

- Process flow diagrams: Using flowcharts to visually identify all steps in the food production process, making it easier to spot potential weak points.

- Scientific literature: Consulting scientific literature and databases on foodborne illnesses to understand common hazards and their control measures.

- Equipment maintenance logs: Reviewing equipment maintenance logs to identify any potential hazards related to malfunctioning equipment.

- Environmental monitoring: Regularly monitoring the processing environment for potential contamination sources (e.g., pests, temperature variations).

A proactive approach to hazard identification is vital for developing a robust and effective HACCP plan.

Q 8. What are some common food safety hazards?

Common food safety hazards can be broadly categorized into biological, chemical, and physical contaminants. Biological hazards include bacteria like Salmonella and E. coli, viruses such as Norovirus, and parasites like Toxoplasma gondii. These microorganisms can contaminate food at various stages, from production to consumption, causing illnesses ranging from mild discomfort to severe, life-threatening conditions. Chemical hazards encompass things like pesticides, cleaning chemicals, and toxins that can leach into food during processing or storage. Improper use of sanitizers, cross-contamination with cleaning agents, or inadequate storage practices are common culprits. Finally, physical hazards are foreign objects that accidentally end up in food, such as glass shards, metal fragments, or pieces of plastic. These can cause injuries and are unacceptable from a safety perspective.

- Example: Undercooked chicken harboring Salmonella is a biological hazard leading to salmonellosis.

- Example: Improperly stored cleaning chemicals leaking into food is a chemical hazard.

- Example: A piece of metal found in a can of soup is a physical hazard.

Q 9. Describe your experience with HACCP implementation.

I have extensive experience implementing HACCP plans across various food processing environments, from small-scale bakeries to large-scale meat processing plants. My approach always begins with a thorough hazard analysis, identifying potential hazards at every stage of the production process. This involves a collaborative effort with the production team to understand the flow of materials, equipment used, and the inherent risks at each step. For instance, in a bakery, we’d focus on potential bacterial contamination during dough preparation, while in a meat processing plant, the emphasis might be on temperature control to prevent bacterial growth. Once hazards are identified, we determine critical control points (CCPs) – points where control can be applied to prevent or eliminate the hazard. For each CCP, we establish critical limits, monitoring procedures, corrective actions, and verification methods. This entire process is meticulously documented, forming the basis of the HACCP plan. I’ve also been involved in the ongoing monitoring and updating of these plans, ensuring they remain relevant and effective in light of changes in production processes, regulations, or emerging threats.

For example, in a recent project at a seafood processing facility, we identified the cooking temperature as a CCP for preventing Listeria contamination. We established a critical limit of 165°F (74°C), implemented a monitoring system using calibrated thermometers, and defined corrective actions like discarding batches that didn’t reach the required temperature. The plan also included regular equipment calibration checks and staff training to ensure compliance.

Q 10. How do you manage CCP deviations?

Managing CCP deviations requires a structured and documented approach. When a deviation occurs, immediate action is crucial. This begins with identifying the deviation—was the temperature outside the critical limit? Was there a failure in the sanitation process? The next step is to isolate the affected product to prevent further contamination or distribution. A thorough investigation is then undertaken to determine the root cause of the deviation. This could involve reviewing production records, interviewing staff, and inspecting equipment. Based on the root cause analysis, corrective actions are implemented. This might include cleaning and sanitizing equipment, retraining staff, or adjusting processes to prevent future occurrences. All deviations, investigations, and corrective actions are meticulously documented, providing valuable data for continuous improvement. Finally, the effectiveness of the corrective action is verified, ensuring that the problem is truly resolved and not just temporarily masked.

Example: If a batch of meat fails to reach the required cooking temperature (a CCP deviation), it’s immediately quarantined, a full investigation determines if the equipment malfunctioned or if there was a procedural error, the affected batch is discarded, and the equipment is thoroughly inspected and repaired/calibrated.

Q 11. How do you verify the effectiveness of your HACCP plan?

Verifying the effectiveness of a HACCP plan is an ongoing process, not a one-time event. It involves regularly reviewing the plan’s effectiveness and making adjustments as needed. This includes monitoring CCPs, checking the accuracy of monitoring equipment, reviewing records of deviations and corrective actions, and conducting regular audits. Audits can be internal, performed by trained personnel within the company, or external, conducted by independent auditors. These audits evaluate the effectiveness of the entire HACCP system, identifying areas for improvement. Sampling and testing of finished products can further verify the plan’s efficacy, ensuring that hazards are being controlled effectively. By continuously reviewing and improving the HACCP plan, we can be confident that the food safety program remains effective and robust.

Example: Regularly checking the calibration of temperature probes used to monitor CCPs, reviewing monthly deviation reports to assess trends and improve corrective actions, and conducting annual internal HACCP audits are all key verification activities.

Q 12. What is the role of a HACCP team?

A HACCP team plays a vital role in developing, implementing, and maintaining a successful HACCP plan. The team should comprise individuals with diverse expertise relevant to the food production process. This typically includes personnel from production, quality control, sanitation, management, and potentially even external consultants. Each member brings a unique perspective and contributes to a holistic risk assessment. The team’s responsibilities extend to conducting hazard analysis, identifying CCPs, establishing critical limits and monitoring procedures, developing corrective actions, and verifying the plan’s effectiveness. Regular meetings are essential to review monitoring data, discuss deviations, and make necessary adjustments to the plan. The team’s composition and expertise should reflect the complexities of the food production process.

Example: A HACCP team for a dairy processing plant might consist of a production supervisor, a quality control manager, a sanitation specialist, a plant manager, and a food safety consultant.

Q 13. How do you communicate HACCP information to employees?

Communicating HACCP information to employees is critical for its success. It’s not enough to simply have a HACCP plan; employees need to understand their roles and responsibilities within the system. Training is key, and it should be tailored to different roles and levels of understanding. This could involve interactive workshops, hands-on training, visual aids like posters and diagrams, and readily available written materials. Regular refresher training keeps the knowledge fresh and addresses potential changes in the HACCP plan. Open communication channels, such as regular meetings and feedback sessions, allow employees to ask questions and express concerns. By fostering a culture of food safety awareness, we can ensure that employees are actively involved in preventing food safety hazards. Clear, concise, and consistent communication is paramount.

Example: Training modules for production workers might focus on proper handwashing techniques and temperature monitoring procedures, while management training could cover reviewing and interpreting monitoring data and performing internal audits.

Q 14. How do you handle a food safety crisis?

Handling a food safety crisis requires a swift, decisive, and well-coordinated response. The first step is to immediately contain the situation, preventing further contamination or distribution of the affected product. This often involves isolating the suspected product, notifying relevant authorities (e.g., local health departments), and initiating a full-scale investigation to determine the root cause of the crisis. The investigation will involve analyzing product samples, interviewing staff, and reviewing production records. Transparent communication is paramount, both internally with employees and externally with customers, regulatory bodies, and the media. Open communication helps manage public perception and minimizes potential damage. Once the root cause is identified, corrective actions are taken, and measures are implemented to prevent similar incidents from happening again. Thorough documentation of the entire crisis, including the investigation, corrective actions, and lessons learned, is essential for continuous improvement and future preparedness.

Example: A recall of a product due to contamination requires immediate notification to regulatory agencies and customers, a thorough investigation into the source of the contamination, and implementation of preventative measures (like improved sanitation procedures or new supplier selection criteria) to avoid recurrence.

Q 15. Explain the role of preventive controls in a HACCP system.

Preventive controls are the cornerstone of a HACCP (Hazard Analysis and Critical Control Point) system. Instead of simply reacting to contamination, HACCP focuses on proactively preventing hazards from occurring in the first place. This is achieved by identifying potential biological, chemical, and physical hazards in the food production process and implementing measures to control them at critical control points (CCPs).

For example, imagine a bakery. A potential hazard is bacterial contamination in the dough. A CCP might be the baking process, where the high temperature effectively eliminates most bacteria. The preventive control would be maintaining a precise baking temperature and time, monitored and recorded to ensure its effectiveness. Another hazard might be cross-contamination from raw to cooked ingredients. A preventive control could be a strict separation of areas, dedicated equipment, and color-coded cutting boards to eliminate the possibility of cross-contamination.

- Hazard Analysis: Identifying potential hazards.

- CCP Identification: Determining points where hazards can be controlled.

- Establishing Critical Limits: Setting measurable parameters (e.g., temperature, time) for each CCP.

- Monitoring: Regularly checking CCPs to ensure parameters are met.

- Corrective Actions: Implementing steps to address deviations from critical limits.

- Verification: Confirming the effectiveness of the HACCP plan.

- Record Keeping: Documenting all aspects of the HACCP plan.

Career Expert Tips:

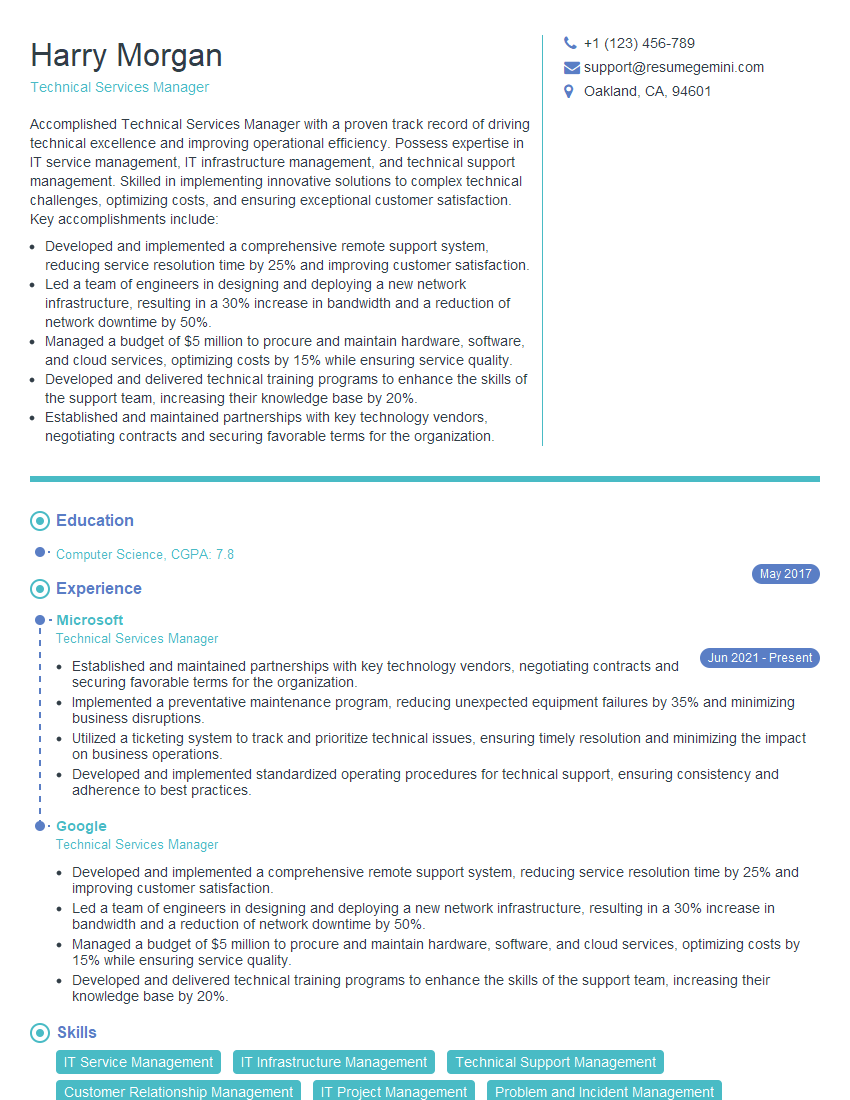

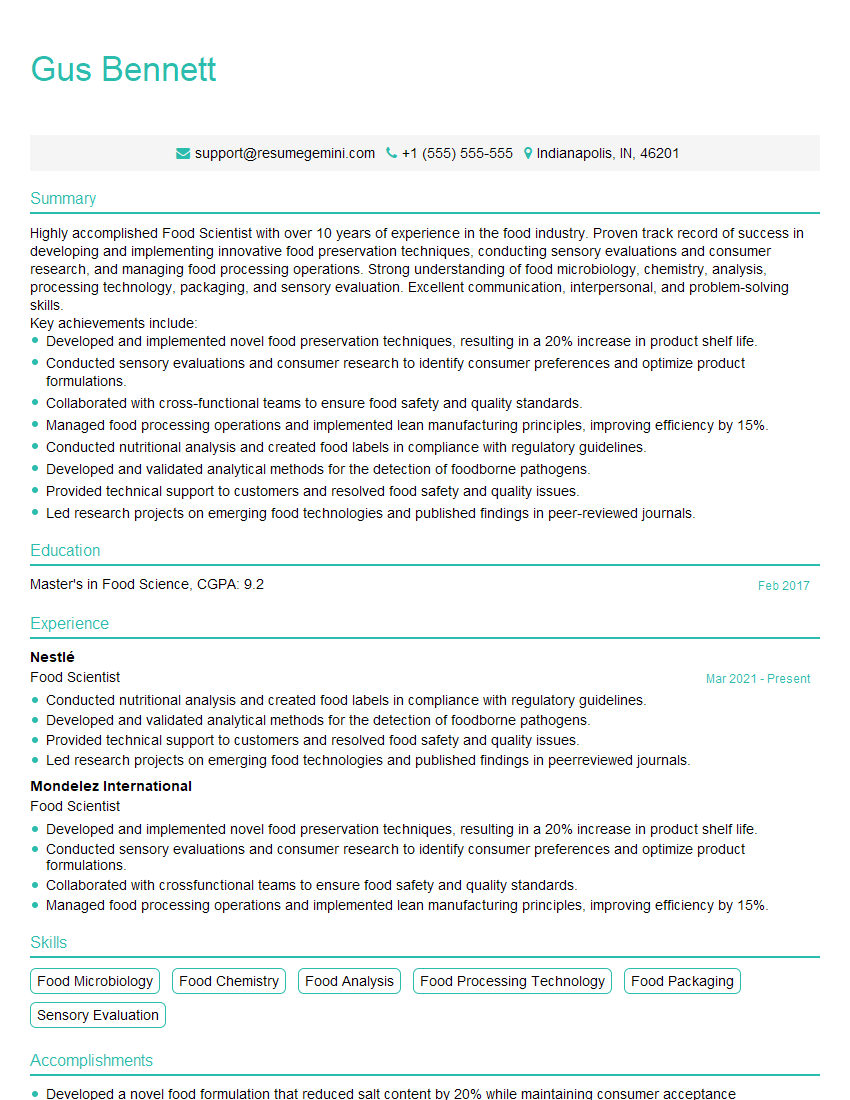

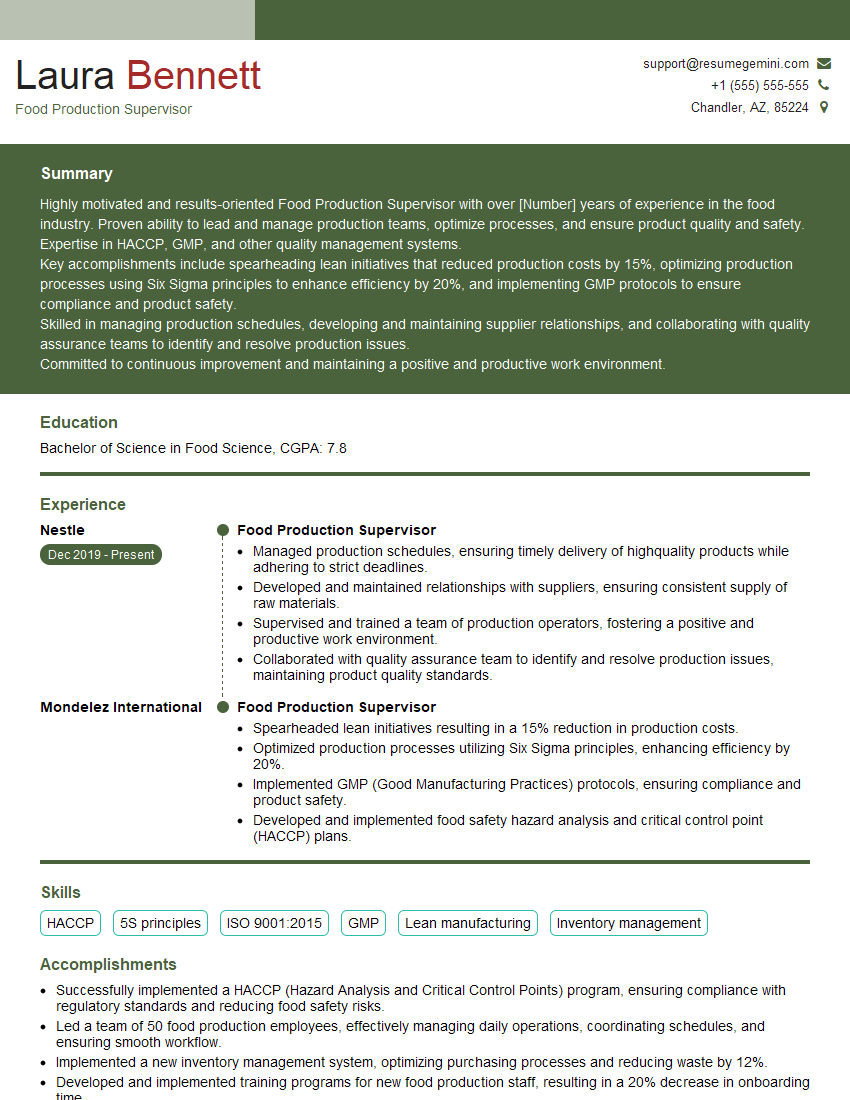

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is the difference between HACCP and GMP?

While both HACCP and GMP (Good Manufacturing Practices) are crucial for food safety, they differ significantly in their scope and approach. GMPs are a broader set of general guidelines that cover sanitation, hygiene, facility maintenance, and personnel practices. Think of GMPs as the foundation upon which HACCP is built. They establish the basic conditions necessary for safe food production. HACCP, on the other hand, is a science-based, preventative system that focuses specifically on identifying and controlling hazards that can cause foodborne illnesses.

An analogy would be building a house. GMPs are like the foundation, framing, and plumbing – the essential elements ensuring a structurally sound building. HACCP is like the electrical wiring and fire safety systems – ensuring the house is not only built correctly but also safe to inhabit. GMPs are necessary but not sufficient to guarantee food safety; HACCP adds the crucial layer of hazard analysis and preventative control.

Q 17. How do you ensure the accuracy of your HACCP records?

Accuracy of HACCP records is paramount. We maintain accuracy through a multi-pronged approach:

- Calibration of Equipment: Regularly calibrating thermometers, timers, and other measuring devices ensures accurate data collection. Calibration records are meticulously maintained.

- Trained Personnel: Our team undergoes thorough training on HACCP procedures, record-keeping protocols, and proper use of equipment. This training includes detailed instruction on data entry and record management.

- Data Integrity Procedures: We use standardized forms, electronic data logging systems wherever possible, and implement checks and balances to prevent errors. For instance, multiple staff members might review critical data points before finalizing records.

- Regular Audits: Internal and external audits systematically review our HACCP records for completeness, accuracy, and compliance with regulations.

- Secure Storage and Archiving: Records are stored securely, both physically and electronically, to prevent alteration or loss, often with a dedicated and secure server and paper records kept in a climate-controlled area.

In short, accuracy is not an accident; it is the result of a system designed to minimize errors and maximize accountability.

Q 18. How do you stay current with changes in food safety regulations?

Staying current with changes in food safety regulations is crucial. I utilize several strategies:

- Subscription to Regulatory Updates: I subscribe to newsletters and alerts from relevant agencies like the FDA and USDA. This provides immediate notification of any changes to regulations.

- Professional Development: I actively participate in conferences, workshops, and webinars focused on food safety and HACCP. This allows for direct engagement with experts and the opportunity to learn about the latest developments in the field.

- Membership in Professional Organizations: Affiliation with organizations such as the International Association for Food Protection provides access to resources, publications, and networking opportunities to stay informed about changes in regulations and best practices.

- Review of Industry Publications: I regularly review peer-reviewed articles and industry publications to keep abreast of emerging issues and research in food safety.

By combining these approaches, I ensure my knowledge base remains up-to-date, allowing me to adapt and implement changes necessary to ensure ongoing compliance.

Q 19. Explain your experience with food safety audits.

I have extensive experience with food safety audits, having participated in numerous internal and external audits throughout my career. I understand the audit process thoroughly, from pre-audit preparation to responding to findings. I have helped several facilities achieve and maintain their food safety certifications.

During audits, my role typically involves preparing documentation, facilitating the audit process, addressing auditor questions, and developing corrective action plans where needed. I’m adept at using audit findings to improve our HACCP plan and overall food safety practices. For example, during one audit, a minor discrepancy was identified in our temperature monitoring logs. This allowed us to refine our recording process by using electronic logging, leading to greater accuracy and traceability.

Q 20. What is a prerequisite program and how does it support HACCP?

A prerequisite program (PRP) encompasses the fundamental operational and environmental conditions necessary to produce safe food. It’s the foundation upon which a successful HACCP system is built. These programs address elements such as good hygiene practices, sanitation, pest control, staff training, and supplier verification. They ensure that the environment and processes are suitable for producing safe food before specific hazards are even considered in the HACCP plan.

For instance, a robust sanitation program (a PRP) is crucial to preventing bacterial contamination. Without effective cleaning and sanitizing procedures, the likelihood of bacterial contamination is significantly higher, regardless of the controls in place within the HACCP plan. Therefore, the PRP provides a baseline of safety, enabling the HACCP plan to focus on the specific, high-risk hazards and controls.

Q 21. How do you conduct a root cause analysis of a food safety incident?

Conducting a root cause analysis (RCA) of a food safety incident involves systematically investigating the underlying reasons for the event. A common methodology is the ‘5 Whys’ technique, where you repeatedly ask ‘why’ to delve deeper into the causes. However, a more structured approach like the Fishbone Diagram (Ishikawa Diagram) is often preferred for complex incidents.

For instance, let’s say a batch of product was contaminated with Salmonella. Using the Fishbone diagram:

- Central Problem: Salmonella contamination in Batch X.

- Causes: These could include inadequate cooking temperature (process control failure), contaminated ingredient (supplier issue), poor hand hygiene (employee issue), or a lapse in sanitation (facility issue).

Each of these causes then requires further investigation using the 5 Whys or other root-cause analysis techniques. The goal is to identify the root causes, not just the immediate symptoms. Only by identifying and addressing the root causes can you prevent similar incidents in the future. Once root causes are identified, corrective actions are developed and implemented, and monitoring systems are refined to prevent recurrence.

Q 22. Describe your experience with allergen control within a HACCP framework.

Allergen control is paramount in a HACCP (Hazard Analysis and Critical Control Point) system. It involves identifying and controlling allergens throughout the entire food production process, from raw material sourcing to finished product packaging. This is crucial to prevent cross-contamination and protect consumers with allergies.

In my experience, this starts with a thorough allergen risk assessment. We identify all potential allergens present in our ingredients and processes. This often involves reviewing ingredient labels, supplier specifications, and production flowcharts. For example, if we’re producing a peanut butter cookie, peanuts are an obvious allergen. But we also need to consider cross-contamination risks – could peanuts come into contact with other products on the same line? We document potential allergen sources in a matrix. This matrix guides the development of control measures, such as dedicated equipment, cleaning procedures, and clear labeling.

Next, we implement controls. This could involve physically separating allergen-containing ingredients and equipment from non-allergen products, employing rigorous cleaning and sanitizing protocols between production runs, and providing allergen-free production zones where possible. Regular employee training is also critical to ensure everyone understands the importance of allergen control and the procedures to follow.

Finally, verification is key. We implement monitoring procedures to ensure the effectiveness of our controls. This may include visual inspections, allergen testing of equipment and surfaces, and regular review of our allergen control program. Any deviations require immediate corrective action, documentation, and investigation to prevent recurrence.

Q 23. How do you monitor CCPs effectively?

Monitoring Critical Control Points (CCPs) effectively is essential for ensuring food safety. CCPs are steps in the food production process where control is essential to prevent or eliminate a food safety hazard. Effective monitoring involves establishing critical limits for each CCP and regularly checking if these limits are being met.

Imagine baking bread: a CCP might be the baking temperature. Our critical limit could be a minimum temperature of 190°F (90°C) to ensure that all pathogens are destroyed. To monitor this, we use calibrated thermometers placed in different parts of the oven. Readings are recorded at regular intervals (e.g., every 30 minutes) and compared to the critical limit. Any deviations trigger corrective action, such as adjusting the oven temperature.

Other effective monitoring strategies involve using data loggers that automatically record temperature and other relevant parameters over time. This provides a detailed audit trail and eliminates the possibility of human error in recording data. Regular calibration and maintenance of monitoring equipment is also vital for accuracy and reliability. Visual inspections and sensory evaluations are crucial for monitoring some CCPs. For example, visual checks for spoilage signs on raw materials are essential. A well-documented monitoring plan, tailored to each CCP, is fundamental for effective monitoring and traceabilty.

Q 24. What are the key challenges in implementing and maintaining a HACCP system?

Implementing and maintaining a HACCP system presents several challenges. One major hurdle is the initial cost and time investment required. Developing a comprehensive HACCP plan needs thorough hazard analysis, CCP identification, and establishing monitoring procedures. This requires dedicated resources and trained personnel.

Another challenge is maintaining employee compliance. Consistent training and reinforcement of HACCP principles are crucial for ensuring that all employees understand and follow the plan. Lack of buy-in and commitment from staff can lead to deviations from the plan, potentially compromising food safety.

Furthermore, keeping the HACCP plan updated and relevant is essential. Changes in ingredients, processing methods, or equipment may necessitate revisions to the plan. This requires ongoing vigilance and adaptation to ensure the system remains effective. Technological advancements also need to be integrated. Implementing new technology and data management systems can increase efficiency and facilitate compliance, but it can be challenging and costly.

Lastly, regulatory compliance and audits pose challenges. Different jurisdictions have varying requirements for HACCP implementation, and successfully navigating these requirements demands consistent effort. Regular internal audits are crucial for identifying weaknesses and ensuring the continued effectiveness of the HACCP plan. External audits by regulatory bodies can be stressful but valuable in ensuring compliance.

Q 25. How do you develop and implement corrective actions for HACCP non-conformances?

Corrective actions for HACCP non-conformances are crucial for preventing recurrence and ensuring food safety. My approach follows a structured process.

Step 1: Immediate Action: The first step is to immediately address the non-conformity. This might involve stopping the production line, removing affected products, and initiating appropriate cleaning and sanitizing procedures. For instance, if a thermometer reading shows a critical limit has been breached during cooking, the batch is discarded, and the oven’s temperature is corrected.

Step 2: Root Cause Analysis: The next stage is to thoroughly investigate the root cause of the non-conformance using a structured methodology like a fishbone diagram. This helps determine why the deviation occurred, enabling us to identify effective preventative measures. Perhaps the oven’s thermostat was malfunctioning, or an employee failed to follow a critical step.

Step 3: Corrective Action Plan: Based on the root cause analysis, a corrective action plan is developed. This outlines specific actions to prevent the issue from happening again. This might involve repairing or replacing faulty equipment, revising training procedures, or improving monitoring protocols. For the malfunctioning oven, the corrective action could involve oven repair, employee retraining on temperature monitoring, and routine oven maintenance.

Step 4: Verification: After implementing the corrective action, verification is key. This involves monitoring the effectiveness of the actions taken and ensuring the problem is resolved. Regular monitoring ensures the implemented corrections remain effective.

Step 5: Documentation: Every step of the corrective action process, from the initial non-conformity to verification, is meticulously documented. This provides a clear record of the event and the actions taken, which is essential for internal audits and regulatory compliance.

Q 26. Describe your experience with different types of food safety testing.

My experience encompasses various food safety testing methods, each serving a distinct purpose. These include microbiological testing, chemical testing, and physical testing.

Microbiological testing focuses on detecting the presence and levels of microorganisms, such as bacteria (Salmonella, E. coli, Listeria), yeasts, and molds. Methods include plate counts, rapid tests (e.g., ATP bioluminescence), and PCR techniques. These tests are crucial for assessing the microbial safety of raw materials, finished products, and environmental samples (e.g., equipment surfaces).

Chemical testing evaluates the presence of harmful chemicals, such as pesticides, heavy metals, or mycotoxins. Techniques include chromatography (HPLC, GC) and spectroscopy (AAS, UV-Vis). This ensures compliance with legal limits on chemical contaminants.

Physical testing identifies foreign materials, such as glass, metal, or plastic fragments in food. This is often done through visual inspection, metal detectors, and X-ray systems. This prevents the presence of physical hazards that could cause harm to consumers.

The choice of testing method depends on the specific hazard being assessed and the regulatory requirements. A comprehensive food safety program incorporates a combination of these testing methods to ensure the safety and quality of food products.

Q 27. How do you ensure traceability of ingredients within a HACCP system?

Ingredient traceability is vital in a HACCP system. It allows us to track the origin and movement of ingredients throughout the entire supply chain, enabling rapid identification and removal of contaminated products if needed. This enhances both food safety and consumer confidence.

We implement traceability through a robust system of documentation and record-keeping. This begins with clearly identifying each ingredient’s source through detailed supplier information, including lot numbers, batch codes, and dates of manufacture. We document all stages of the ingredient’s journey from the supplier to finished product, including storage conditions, production date and time, and any processing steps. This data is typically maintained in a computerized system that allows for seamless tracking.

Barcode and RFID technologies enhance traceability significantly. Barcodes on packaging enable rapid scanning and tracking of ingredients as they progress through production. RFID tags provide even greater detail, allowing real-time monitoring of product location and environmental conditions. These techniques minimize manual data entry, reducing errors and increasing efficiency.

Our system also integrates with our production records, linking specific ingredient batches to the finished products they went into. This ensures we can quickly identify and isolate all products made with a potentially contaminated ingredient. Regular audits ensure that our traceability system is consistently effective and reliable.

Q 28. Explain how technology can support HACCP implementation.

Technology significantly enhances HACCP implementation, improving efficiency, accuracy, and data management. Several technological tools play crucial roles.

Data loggers and sensors: These automatically monitor CCP parameters like temperature, humidity, and pressure, providing real-time data and eliminating manual recording errors. This enhances accuracy and allows for immediate responses to deviations.

Software solutions: Specialized HACCP software can facilitate plan development, record-keeping, and reporting. It streamlines data management, simplifies compliance, and provides comprehensive audit trails. This is especially important in larger facilities with complex operations.

MES (Manufacturing Execution Systems): These integrate production data, including ingredient tracking, process parameters, and quality control results, into a central system. This provides a holistic overview of the production process and supports proactive hazard management.

Blockchain technology: While still emerging in the food industry, blockchain offers enhanced traceability by providing a secure and transparent record of ingredient provenance and product movement. This enhances transparency and trust along the supply chain.

By adopting these technologies, companies can streamline their HACCP implementation, improve data integrity, facilitate compliance, and ultimately enhance food safety and consumer protection. However, investment in training and maintenance of these systems remains critical.

Key Topics to Learn for Your HACCP Standards Interview

Ace your interview by mastering these crucial aspects of HACCP. Remember, understanding the “why” behind the principles is as important as knowing the “what”.

- HACCP Principles: Deeply understand the seven principles – Hazard Analysis, Critical Control Points (CCP) identification, establishment of critical limits, monitoring procedures, corrective actions, verification procedures, and record-keeping. Be prepared to discuss each in detail and provide real-world examples.

- Hazard Identification & Risk Assessment: Practice identifying potential biological, chemical, and physical hazards in various food processing environments. Learn how to perform a thorough risk assessment to prioritize hazards and determine which require CCP control.

- Critical Control Point (CCP) Determination: Understand the decision tree approach to identifying CCPs. Be prepared to explain your methodology and justify your choices for CCPs in different scenarios. Consider various food processing examples.

- Critical Limits & Monitoring: Explain how to establish scientifically-based critical limits for each CCP. Discuss various monitoring methods and their effectiveness in ensuring control. Understand the importance of accurate and timely monitoring.

- Corrective Actions & Verification: Develop a strong understanding of implementing corrective actions when deviations from critical limits occur. Explain the importance of verification procedures to ensure the HACCP plan’s effectiveness. Be ready to discuss different verification methods.

- Record Keeping & Documentation: Explain the importance of maintaining accurate and comprehensive records. Understand the legal requirements and best practices for documentation related to HACCP implementation.

- Practical Applications: Be ready to discuss practical applications of HACCP in various food processing settings, including manufacturing, retail, and food service. Think about examples from your experience or research.

- Problem-Solving Scenarios: Prepare for hypothetical scenarios involving HACCP implementation and troubleshooting. Practice identifying and solving problems related to hazard control, monitoring, and corrective actions.

Next Steps: Unlock Your Career Potential

Mastering HACCP principles significantly enhances your career prospects in the food industry. A strong understanding demonstrates your commitment to food safety and opens doors to exciting opportunities. To make your application stand out, create an ATS-friendly resume that highlights your HACCP expertise. ResumeGemini is a trusted resource for building professional, impactful resumes. They even provide examples tailored to showcasing Knowledge of HACCP Standards – helping you present your skills effectively to potential employers. Take the next step towards your dream job today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good