Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Knowledge of ISO 9001:2015 interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Knowledge of ISO 9001:2015 Interview

Q 1. Explain the key principles of ISO 9001:2015.

ISO 9001:2015 is built on several key principles that guide organizations in establishing and maintaining a robust Quality Management System (QMS). These principles aren’t just suggestions; they’re the foundation for achieving consistent quality and customer satisfaction. Think of them as the guiding stars for your quality journey.

- Customer Focus: Understanding and meeting customer needs and expectations is paramount. This involves actively seeking customer feedback and adapting your processes to deliver what they value. Imagine a bakery constantly asking customers about their preferences for cakes – that’s customer focus in action!

- Leadership: Top management must demonstrate commitment to the QMS. This involves setting clear quality objectives, providing necessary resources, and fostering a culture of continuous improvement. A strong captain steers the ship towards its destination, and similarly, strong leadership guides the QMS.

- Engagement of People: Empowering employees at all levels to contribute to the QMS is vital. This means providing training, recognizing achievements, and encouraging participation in improvement initiatives. A team of skilled rowers works better than a lone person trying to paddle a boat.

- Process Approach: Managing processes effectively ensures consistency and efficiency. Defining, monitoring, and improving processes is key. This is like having a well-defined recipe for baking a cake – following it consistently results in a consistent outcome.

- Improvement: Continuously seeking improvement in the QMS is critical. This includes using data to identify areas for improvement and implementing corrective actions. Think of it like a gardener tending to their plants, regularly checking and improving their growth.

- Evidence-based Decision Making: Decisions should be based on data analysis rather than assumptions. This ensures objective and effective improvements. Imagine a doctor making a diagnosis based on test results, not just intuition – that’s evidence-based decision-making.

- Relationship Management: Building strong relationships with suppliers and other stakeholders is vital for consistent quality. It’s like having reliable suppliers for your bakery, ensuring you have quality ingredients to work with.

Q 2. Describe the Plan-Do-Check-Act (PDCA) cycle and its application in a QMS.

The Plan-Do-Check-Act (PDCA) cycle is a cornerstone of ISO 9001:2015 and continuous improvement. It’s a cyclical process, meaning you repeat it continuously to refine your processes. Think of it as a never-ending loop of improvement.

- Plan: Identify an opportunity for improvement, set objectives, and develop a plan to achieve them. This involves researching what needs improvement, creating goals, and outlining how to reach them. For example, planning to reduce the number of customer complaints by improving a specific process.

- Do: Implement the plan, collect data, and monitor progress. This is where you put your plan into action and start gathering data to evaluate whether it’s working.

- Check: Analyze the results and compare them to the objectives. This might involve analyzing data, conducting reviews, and checking against initial goals. Perhaps you see a reduction in complaints, but not to the expected level.

- Act: Take action based on the results. If the plan is successful, standardize it. If not, revise the plan and repeat the cycle. This stage involves adjusting the plan based on the data to improve it, and continuing the cycle.

The PDCA cycle is applied throughout a QMS, from improving individual processes to enhancing the entire system. It’s not a one-time event but a continuous process of improvement.

Q 3. What are the core elements of a Quality Management System (QMS)?

A Quality Management System (QMS) is a set of interconnected elements that work together to ensure consistent quality in an organization’s products or services. It’s like a well-oiled machine, with each part contributing to the overall function. Core elements include:

- Scope: Defining what parts of the organization the QMS covers. This determines the boundaries of your QMS, which processes and activities are included.

- Leadership and Commitment: Demonstrating top management’s commitment to quality. This is essential for setting the tone and ensuring the QMS is prioritized.

- Resource Management: Providing the necessary resources (personnel, finance, equipment) to effectively implement and maintain the QMS. This ensures you have what you need to function effectively.

- Competency: Ensuring employees have the skills and knowledge to perform their jobs effectively. This involves training, education, and skill development.

- Process Management: Planning, implementing, monitoring, and improving key processes. This is the heart of the system and focuses on consistency and efficiency.

- Internal Audit: Regularly assessing the effectiveness of the QMS. This provides valuable feedback for continuous improvement.

- Management Review: Regularly reviewing the effectiveness of the QMS at the top management level. This ensures continued alignment with organizational goals.

- Continuous Improvement: Constantly seeking ways to enhance the QMS. This uses data, feedback, and the PDCA cycle.

- Customer Satisfaction: Meeting customer needs and expectations. This should always be at the forefront.

Q 4. How does risk-based thinking influence the implementation of ISO 9001:2015?

Risk-based thinking is integral to ISO 9001:2015. It’s about proactively identifying, assessing, and addressing potential risks and opportunities that could affect the QMS’s ability to consistently meet customer requirements. Think of it as being prepared for any challenge you might face in your QMS.

Instead of waiting for problems to occur, risk-based thinking encourages a proactive approach. This is done through:

- Risk Identification: Identifying potential risks (like supplier failures, equipment malfunctions, or changing customer needs) that might negatively impact your QMS.

- Risk Analysis: Assessing the likelihood and potential impact of identified risks. This helps prioritize which risks to address first.

- Risk Response Planning: Developing plans to mitigate or eliminate identified risks. This might involve redundancy plans, robust supplier relationships, or employee training.

- Monitoring and Review: Continuously monitoring risks and reviewing the effectiveness of risk-reduction plans. The context and risks change, so you need to keep on top of this.

By integrating risk-based thinking, organizations can improve their QMS’s resilience and effectiveness, preventing issues before they arise and leading to better outcomes.

Q 5. What is the role of top management in establishing and maintaining a QMS?

Top management plays a crucial role in establishing and maintaining a successful QMS. Their commitment sets the tone and creates a culture of quality throughout the organization. Their responsibilities include:

- Defining the Quality Policy: Establishing a clear and concise quality policy that aligns with organizational goals and customer expectations.

- Providing Resources: Allocating the necessary resources (financial, human, technological) to support the implementation and maintenance of the QMS.

- Ensuring QMS Compliance: Overseeing the implementation and effectiveness of the QMS, guaranteeing compliance with ISO 9001:2015 requirements.

- Promoting a Culture of Quality: Fostering a culture where quality is valued and employees are empowered to contribute to continuous improvement.

- Leading Management Reviews: Actively participating in management reviews to assess the QMS’s performance, effectiveness, and areas for improvement.

- Communicating Quality Objectives: Ensuring clear communication of quality objectives throughout the organization, promoting understanding and alignment.

Without top management’s visible commitment and active participation, the QMS is unlikely to be effective or sustainable.

Q 6. Explain the importance of internal audits in a QMS.

Internal audits are a vital component of a robust QMS. They provide an objective assessment of the QMS’s effectiveness, identifying areas of strength and weakness. Think of them as a health check for your quality system.

Internal audits help to:

- Verify Conformity: Check that processes and activities conform to the requirements of the QMS and ISO 9001:2015.

- Identify Nonconformities: Detect any deviations from the established processes or standards.

- Promote Continuous Improvement: Provide valuable data and insights to drive continuous improvement initiatives.

- Enhance Credibility: Demonstrate a commitment to quality and improve credibility with customers and other stakeholders.

- Prepare for External Audits: Help prepare for external audits by identifying and addressing potential issues proactively.

Internal audits should be conducted regularly, by competent individuals who are independent from the audited areas. They should be planned meticulously, documented thoroughly, and their findings should be effectively addressed.

Q 7. Describe the process of corrective action and preventive action (CAPA).

Corrective Action (CA) and Preventive Action (PA), often referred to as CAPA, are crucial processes for addressing nonconformities and preventing their recurrence. They are about learning from mistakes and ensuring they don’t happen again.

- Corrective Action (CA): Addresses nonconformities that have already occurred. This involves identifying the root cause of the nonconformity, implementing corrective actions to eliminate the cause, and verifying the effectiveness of the corrective action. For instance, if a batch of products is defective, CA involves finding out why (e.g., faulty equipment), fixing the equipment, and retesting the products.

- Preventive Action (PA): Addresses potential nonconformities before they occur. This involves identifying potential problems, implementing preventative actions to prevent them, and verifying the effectiveness of the preventive action. For example, if a piece of equipment shows signs of wear and tear, preventative action might involve scheduled maintenance to avoid future failures.

Both CA and PA should be documented, reviewed, and monitored to ensure their effectiveness. A well-defined CAPA process is critical for continual improvement and preventing recurring problems within the QMS.

Q 8. What is a documented procedure and its importance under ISO 9001:2015?

A documented procedure, under ISO 9001:2015, is a standardized, written set of instructions detailing how to perform a specific task or process within a Quality Management System (QMS). Think of it as a recipe for consistent results. It outlines steps, responsibilities, and required resources to ensure uniformity and efficiency.

Its importance is paramount because it ensures consistency in performing critical activities. This consistency leads to:

- Predictable outcomes: Following a documented procedure reduces variability and increases the likelihood of achieving desired quality.

- Improved efficiency: Standardized processes streamline workflows and reduce waste.

- Enhanced compliance: Procedures help organizations meet regulatory requirements and internal standards.

- Reduced errors: Clear instructions minimize mistakes and rework.

- Easier training: New employees can quickly learn processes through well-defined procedures.

For example, a documented procedure might describe the steps for handling customer complaints, calibrating equipment, or managing nonconformities. Without such procedures, these activities would be left to individual interpretation, potentially leading to inconsistencies and quality issues.

Q 9. How do you ensure the effectiveness of a QMS?

Ensuring the effectiveness of a QMS involves a multi-faceted approach that focuses on continuous monitoring, measurement, analysis, and improvement. It’s not a one-time effort but an ongoing cycle. Key elements include:

- Regular internal audits: These systematic, independent assessments verify the QMS’s conformity to the ISO 9001:2015 standard and the organization’s own documented procedures. Think of them as internal health checks.

- Management review: This high-level review assesses the QMS’s performance, identifies areas for improvement, and ensures its continued suitability, adequacy, and effectiveness.

- Monitoring and measurement: This involves tracking key performance indicators (KPIs) related to quality, customer satisfaction, and process efficiency. Examples could include defect rates, customer feedback scores, and on-time delivery rates.

- Corrective and preventive actions (CAPA): This system ensures that nonconformities are identified, addressed, and prevented from recurring. It’s about learning from mistakes and avoiding them in the future.

- Continual improvement: The QMS should be constantly evaluated and improved based on data analysis, customer feedback, and best practices. This is a proactive, ongoing process.

For instance, if customer satisfaction scores decline, the organization can analyze the root cause using data and implement corrective actions, potentially revising procedures or training staff. This iterative process ensures that the QMS remains dynamic and relevant.

Q 10. Explain the concept of continual improvement in the context of ISO 9001:2015.

Continual improvement, a cornerstone of ISO 9001:2015, is the ongoing commitment to enhancing the QMS’s effectiveness and efficiency. It’s not just about fixing problems; it’s about proactively seeking opportunities for growth. It’s a journey, not a destination.

The Plan-Do-Check-Act (PDCA) cycle is a widely used framework for continual improvement.

- Plan: Identify areas for improvement, set objectives, and develop strategies.

- Do: Implement the planned changes.

- Check: Monitor the results and evaluate the effectiveness of the changes.

- Act: Take action based on the results, either standardizing successful changes or making further adjustments.

Imagine a manufacturing company consistently experiencing delays in the production process. Through data analysis, they discover a bottleneck in the assembly line. They plan to re-engineer the workflow (Do), monitor the results (Check), and then standardize the improved process (Act) if successful. This exemplifies continual improvement in action.

Q 11. Describe the difference between quality control and quality assurance.

While both quality control and quality assurance contribute to overall quality, they differ in their approach and focus:

- Quality Control (QC): Focuses on inspecting the output of processes to identify defects and ensure that they meet specifications. It’s reactive, addressing problems after they occur. Think of QC as a final check before shipment.

- Quality Assurance (QA): Focuses on preventing defects by ensuring that processes are designed and controlled effectively. It’s proactive, aiming to improve processes to minimize the possibility of errors. Think of QA as designing a robust system to prevent errors from happening in the first place.

Analogy: Imagine baking a cake. QC would involve tasting the final product to check for sweetness and texture. QA would involve ensuring the oven is calibrated, the ingredients are measured accurately, and the recipe is followed meticulously.

Q 12. What is a Management Review and its purpose?

A Management Review is a formal, periodic meeting of top management to assess the QMS’s performance and suitability. It’s a crucial mechanism for ensuring the system remains effective and aligned with organizational goals. Think of it as a high-level performance review for the entire QMS.

Its purpose is multifaceted:

- Evaluate the QMS’s effectiveness: Management reviews analyze data from internal audits, customer feedback, and KPI monitoring to determine the system’s strengths and weaknesses.

- Address improvement opportunities: The review identifies areas needing improvement and establishes corrective actions to address them.

- Ensure resource allocation: Management reviews allocate resources effectively to support QMS improvements and ensure the system is properly supported.

- Review objectives and strategy: The review aligns the QMS with organizational goals and strategic objectives.

- Communicate with stakeholders: Management reviews provide an opportunity to share relevant information with key stakeholders.

A management review might uncover that customer complaints related to a specific product are increasing. This could trigger a deeper investigation into the production process, leading to improvements and preventative measures.

Q 13. Explain the concept of ‘interested parties’ in the context of ISO 9001:2015.

Interested parties, according to ISO 9001:2015, are individuals or groups that can affect or be affected by the organization’s decisions and activities. It’s a broader concept than just customers.

Examples of interested parties include:

- Customers: Their needs and expectations directly influence the QMS.

- Suppliers: Their performance affects the organization’s ability to deliver quality products or services.

- Employees: Their skills and engagement are critical to quality.

- Owners/Shareholders: They have a stake in the organization’s financial success and reputation.

- Regulators: They enforce compliance with legal and regulatory requirements.

- Local communities: Their concerns regarding the organization’s environmental impact or social responsibility must be considered.

Understanding and addressing the needs and expectations of all interested parties is vital for maintaining a robust and sustainable QMS. A company ignoring local environmental concerns, for example, might face negative publicity and regulatory issues, ultimately affecting its quality management capabilities.

Q 14. How do you handle nonconformities within a QMS?

Handling nonconformities (instances where requirements aren’t met) is crucial for maintaining the integrity of the QMS. It’s a systematic process that involves several steps:

- Identification and documentation: Nonconformities are identified, documented, and analyzed to determine their root cause. This often involves investigation and data gathering.

- Corrective action: Actions are taken to correct the immediate nonconformity, addressing the specific issue. This might involve rework, repair, or replacement.

- Preventive action: Measures are implemented to prevent similar nonconformities from occurring in the future. This might involve changes to processes, training, or equipment.

- Verification of effectiveness: The effectiveness of corrective and preventive actions is verified to ensure the issue is resolved and won’t recur. This often involves monitoring and follow-up.

- Record keeping: All aspects of the nonconformity handling process are meticulously documented and maintained.

For example, if a batch of products fails a quality inspection, the root cause might be traced to faulty raw materials. Corrective action would involve replacing the affected products. Preventive action would involve tightening quality control checks on incoming raw materials and potentially changing suppliers. The entire process is then documented to ensure future prevention.

Q 15. Describe your experience with implementing or maintaining an ISO 9001:2015 certified QMS.

I’ve been directly involved in implementing and maintaining ISO 9001:2015 certified Quality Management Systems (QMS) for over eight years across diverse industries, including manufacturing and software development. In my previous role at Acme Manufacturing, I led the initial certification process, which involved a thorough gap analysis against the standard, development of documented procedures, training of personnel, and conducting internal audits. This culminated in successful certification with minimal non-conformities. Following certification, I played a key role in maintaining the system through ongoing monitoring, management reviews, and continuous improvement initiatives. For instance, we implemented a new corrective action process that reduced the time to resolve customer complaints by 30%. In my current role, I’m supporting the ongoing maintenance of our QMS, focusing on proactively identifying potential areas of risk and implementing preventative measures.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the key performance indicators (KPIs) used to measure the effectiveness of a QMS?

Key Performance Indicators (KPIs) for a QMS are crucial for measuring its effectiveness. These should be aligned with the organization’s strategic goals and regularly monitored. Some vital KPIs include:

- Customer Satisfaction: Measured through surveys, feedback forms, and complaint analysis. A high customer satisfaction score reflects a well-functioning QMS.

- Defect Rate: Tracks the number of defects produced relative to total output. A decreasing defect rate signifies improvements in processes and quality control.

- On-Time Delivery Rate: Measures the percentage of orders delivered on schedule. This reflects the efficiency and reliability of processes.

- Lead Time Reduction: Monitors the time taken to complete processes from start to finish. Shorter lead times show streamlined processes and increased efficiency.

- Internal Audit Effectiveness: Tracks the number of non-conformities identified during internal audits and their timely resolution. A low number indicates a robust and well-functioning QMS.

- Corrective Action Effectiveness: Measures the success rate of corrective actions in preventing recurrence of non-conformities. High success rates show effective problem-solving and improvement strategies.

These KPIs, along with others specific to the organization and its industry, are essential for demonstrating the effectiveness of the QMS and identifying areas for improvement.

Q 17. How do you ensure customer satisfaction within the framework of ISO 9001:2015?

Ensuring customer satisfaction is paramount within the ISO 9001:2015 framework. It’s not just a matter of meeting requirements; it’s about exceeding expectations. This is achieved through several interconnected strategies:

- Understanding Customer Needs: Proactively seeking customer feedback through surveys, focus groups, and regular communication is critical. This helps identify needs and expectations.

- Meeting Requirements: Consistently meeting specified requirements as outlined in contracts, purchase orders, and other agreements is fundamental. Processes must be designed and controlled to achieve this.

- Proactive Communication: Keeping customers informed throughout the process, particularly regarding potential delays or issues, builds trust and confidence.

- Complaint Handling: Establishing a robust process for handling and resolving customer complaints effectively and promptly is crucial. Root cause analysis should be conducted to prevent recurrence.

- Continuous Improvement: Regularly reviewing customer feedback and utilizing data from KPIs to identify areas for improvement in products, services, and processes demonstrates commitment to customer satisfaction.

By focusing on these aspects, organizations can cultivate strong customer relationships and demonstrate a commitment to quality that drives satisfaction and loyalty.

Q 18. Explain your understanding of document and record control.

Document and record control is the backbone of a functioning QMS. It ensures that information is accurate, readily available, and controlled to prevent misinterpretations and ensure traceability. This involves:

- Document Control: This encompasses creating, reviewing, approving, distributing, updating, and archiving documents such as procedures, instructions, and forms. A version control system is usually employed to manage revisions and ensure everyone is using the most current version. For example, we use a document management system with workflow approvals and version tracking.

- Record Control: This focuses on creating, handling, storing, retrieving, and disposing of records – evidence of activities and results. Records provide audit trails and demonstrate compliance. This includes maintaining records of calibrations, inspections, and corrective actions. Secure storage and retention policies are crucial aspects of record control.

Think of it like building a house: documents are the blueprints, and records are the inspection reports and permits that show the house was built according to plan. Both are essential for a successful and verifiable outcome.

Q 19. How do you ensure the competency of personnel involved in the QMS?

Ensuring personnel competency is crucial for a successful QMS. It involves identifying the necessary skills and knowledge, then providing training and evaluating performance to verify competence. This typically includes:

- Skills Gap Analysis: Identifying the skills required for each role within the QMS. This might involve reviewing job descriptions and identifying training needs.

- Training Programs: Developing and delivering relevant training programs to address identified skill gaps. Training records are carefully maintained as evidence of competence.

- Performance Evaluation: Regularly evaluating personnel performance to ensure they possess the necessary skills and knowledge to perform their duties effectively. This might include both on-the-job observation and formal assessments.

- Certification & Qualification: Where necessary, supporting personnel in achieving relevant certifications or qualifications that demonstrate their competency.

Think of it as equipping a team with the right tools and training to succeed. Investing in your people is investing in the success of your QMS.

Q 20. Describe your experience with internal audits and corrective actions.

I have extensive experience in conducting internal audits and managing corrective actions. Internal audits are planned, documented, and executed to evaluate the effectiveness of the QMS. They identify non-conformities and areas for improvement. Following an audit, a formal report is produced detailing findings. Corrective actions are then planned and implemented to address these non-conformities, preventing recurrence. I usually follow a structured approach, including:

- Root Cause Analysis: Thoroughly investigating the root cause of each non-conformity to ensure a lasting solution. Tools like 5 Whys or fishbone diagrams can be helpful.

- Corrective Action Implementation: Developing and implementing effective corrective actions, documenting the steps taken and verifying their effectiveness.

- Preventive Action Implementation: Identifying potential problems that could lead to similar non-conformities in the future and implementing measures to prevent them.

- Verification of Effectiveness: Following implementation, verifying that the corrective/preventive actions have been successful in resolving the identified issue and preventing recurrence.

The effectiveness of corrective actions is regularly monitored and reviewed as a KPI, ensuring continuous improvement and a strong QMS.

Q 21. What are the common challenges in implementing ISO 9001:2015 and how would you address them?

Implementing ISO 9001:2015 presents several common challenges:

- Resistance to Change: Employees may resist changes to processes or procedures. Addressing this requires clear communication, training, and demonstrating the benefits of the new system.

- Lack of Management Commitment: Without strong management support and commitment, the implementation effort will likely fail. Top-down support is essential.

- Inadequate Resources: Sufficient resources (time, personnel, and budget) are necessary for successful implementation. Proper planning and resource allocation are key.

- Poor Documentation: Incomplete or poorly written procedures can lead to confusion and non-compliance. Clear, concise, and accessible documentation is crucial.

- Lack of Training: Inadequate training can result in employees not understanding the QMS or their roles within it. Comprehensive training programs are essential.

To address these, I employ a proactive approach that includes:

- Executive Sponsorship: Securing buy-in from top management to ensure the necessary resources and support are available.

- Comprehensive Training: Developing and delivering robust training programs to educate all personnel on the QMS.

- Phased Implementation: Implementing the QMS in phases to manage complexity and ensure a smooth transition.

- Communication: Regularly communicating progress, updates, and challenges to all stakeholders.

- Continuous Improvement: Regularly reviewing and improving the QMS based on audit findings and feedback.

By addressing these challenges strategically, organizations can successfully implement and maintain an effective ISO 9001:2015 compliant QMS.

Q 22. How would you handle a situation where a process does not conform to ISO 9001:2015 requirements?

Discovering a non-conforming process under ISO 9001:2015 necessitates a structured response focusing on containment, corrective action, and preventive action. Think of it like a doctor diagnosing and treating an illness. First, we must contain the problem – prevent further defects from occurring. This might involve isolating affected products, halting the process, or implementing temporary controls.

Next, we conduct a thorough root cause analysis (RCA). Several tools can aid this, such as the 5 Whys, fishbone diagrams (Ishikawa diagrams), or fault tree analysis. The goal is to identify the underlying cause of the non-conformity, not just the symptom. For instance, if we find consistently flawed welds, a simple RCA might reveal insufficient welder training as the root cause.

Once the root cause is identified, we implement corrective actions to address the immediate problem. This could involve retraining welders, adjusting equipment settings, or revising the welding procedure. Crucially, we must verify the effectiveness of these corrective actions – did they truly solve the problem? This often involves monitoring the process and checking for recurring defects.

Finally, and this is often overlooked, we implement preventive actions to stop the same problem from happening again. This might involve changes to the process, improved monitoring procedures, or additional training programs. For example, introducing a more rigorous weld inspection process or implementing a system for regular equipment calibration could prevent future weld failures.

Throughout this entire process, thorough documentation is key. All findings, corrective actions, and preventive actions must be recorded and reviewed as part of the management review process. This documentation provides a critical audit trail and evidence of continuous improvement within the QMS.

Q 23. Explain the importance of data analysis in a QMS.

Data analysis is the backbone of a robust and effective Quality Management System (QMS). It’s not enough to just collect data; we need to analyze it to understand trends, identify areas for improvement, and demonstrate the effectiveness of the QMS. Think of it like a car’s dashboard – it provides vital information about the car’s performance. Without it, you’d be driving blind.

Data analysis within a QMS helps us:

- Identify recurring problems: By analyzing defect data, we can pinpoint areas where improvements are needed. For instance, consistently high defect rates in a specific manufacturing stage suggest the need for process optimization or retraining.

- Measure process effectiveness: Analyzing key performance indicators (KPIs) – like cycle times, defect rates, or customer satisfaction – provides insights into the overall efficiency and effectiveness of our processes. This data helps to track progress toward improvement goals.

- Support decision-making: Data analysis provides factual evidence to support strategic decisions, rather than relying on gut feelings. This leads to more effective allocation of resources and prioritization of improvements.

- Demonstrate compliance: Analysis of audit findings and internal inspection data helps us to demonstrate compliance with ISO 9001 requirements and regulatory standards.

Tools and techniques for data analysis within a QMS include statistical process control (SPC), control charts, Pareto charts, and data visualization software. The choice of tools depends on the specific data and the questions we are trying to answer. The key is to leverage data to make our QMS more efficient and effective.

Q 24. What is the role of process mapping in improving a QMS?

Process mapping is a crucial tool for improving a QMS. It’s essentially creating a visual representation of a process, showing all the steps, inputs, outputs, and responsibilities involved. Think of it as a roadmap for your processes, allowing you to identify bottlenecks, redundancies, and areas for improvement.

The benefits of process mapping include:

- Improved understanding: Mapping helps everyone involved in a process to clearly understand its steps and interdependencies.

- Identification of bottlenecks: By visualizing the process flow, bottlenecks and inefficiencies become readily apparent, allowing for targeted improvements.

- Reduced waste: Identifying unnecessary steps or redundancies allows for the elimination of waste, improving efficiency and reducing costs.

- Enhanced communication: Process maps serve as a visual communication tool, promoting better understanding and collaboration across teams.

- Improved process control: Clear process maps provide a framework for better process control and monitoring, leading to higher quality output.

Different mapping techniques exist, such as flowcharts, swim lane diagrams, and value stream maps, each suited for different purposes. For example, a flowchart would be appropriate for a simple process, while a value stream map would be more effective for analyzing a complex process involving multiple departments.

Q 25. Describe your understanding of the relationship between ISO 9001 and other management system standards (e.g., ISO 14001, ISO 45001).

ISO 9001 is a quality management system standard, focusing on customer satisfaction and continuous improvement. However, its principles align well with other management system standards like ISO 14001 (environmental management) and ISO 45001 (occupational health and safety). They share a common structure based on the Annex SL framework, making integration easier.

The relationship is one of synergy and integration. Implementing multiple standards, like ISO 9001, ISO 14001, and ISO 45001, can lead to:

- Efficiency gains: Integrated management systems (IMS) streamline processes, avoiding duplication of effort and reducing administrative burden.

- Improved resource allocation: A combined approach allows for more efficient resource allocation, focusing on holistic improvement rather than isolated initiatives.

- Enhanced organizational performance: An integrated approach encourages a culture of continuous improvement across various aspects of the organization.

- Reduced risk: A holistic approach helps identify and manage risks across environmental, safety, and quality dimensions.

For example, a company implementing ISO 9001 might find that many of the environmental aspects outlined in ISO 14001 are already addressed within their quality processes. Integrating these systems can simplify audits and improve overall performance.

Q 26. How do you measure the effectiveness of implemented corrective and preventive actions?

Measuring the effectiveness of corrective and preventive actions (CAPA) is critical for demonstrating continuous improvement within a QMS. Simply implementing a CAPA isn’t enough; we must verify that it actually resolved the problem and prevented recurrence.

We can measure the effectiveness of CAPAs through:

- Monitoring and Measurement: After implementing a CAPA, we need to monitor the relevant processes and measure key performance indicators (KPIs) to assess if the problem has been resolved and is not recurring. This might involve tracking defect rates, customer complaints, or process cycle times.

- Audits and Inspections: Internal audits and inspections should verify the implementation and effectiveness of CAPAs. Are the corrective measures being consistently applied? Are the preventive measures preventing future occurrences?

- Management Review: The management review process should evaluate the effectiveness of CAPAs, ensuring that they are producing the desired outcomes. If a CAPA is not effective, further actions must be taken.

- Data Analysis: Analyzing data related to the specific problem before and after the implementation of the CAPA allows for a quantitative assessment of its effectiveness.

For example, if a CAPA addressed a high defect rate in a specific process, we would track the defect rate post-implementation to verify the CAPA’s effectiveness. A significant and sustained reduction in the defect rate would demonstrate the effectiveness of the implemented CAPA.

Q 27. Describe a time you had to make a difficult decision regarding quality.

In a previous role, we faced a situation where a major client reported a significant defect in a large batch of our product. The defect, if not addressed, would have resulted in substantial financial losses, damage to our reputation, and potential legal ramifications. Initial investigations pointed to a supplier’s faulty component, but the client was demanding a swift resolution from us.

The difficult decision was whether to accept the financial burden of replacing the entire batch ourselves, potentially incurring significant short-term losses, or to engage in a protracted dispute with our supplier, risking further delays and reputational damage. Both options had substantial risks. Accepting the loss was painful financially but maintained a positive customer relationship. Fighting the supplier risked damaging that relationship and the potential for a lengthy legal battle.

Ultimately, we chose to replace the entire batch, prioritizing customer satisfaction and our long-term relationship with the client. This decision, although costly in the short term, averted a significant reputational crisis and strengthened our client relationship. We then initiated a comprehensive root cause analysis with our supplier to prevent a similar situation from occurring again and implemented additional quality control measures to further mitigate future risks. This experience reinforced the importance of proactive risk management and the long-term value of strong customer relationships within our QMS.

Key Topics to Learn for Your ISO 9001:2015 Interview

Ace your interview by mastering these crucial areas of ISO 9001:2015. Understanding both the theory and practical application will set you apart.

- Understanding the Context of the Organization: Explore how the standard applies within different organizational structures and industry sectors. Consider the impact of organizational context on the Quality Management System (QMS).

- Leadership and Commitment: Delve into the role of leadership in establishing and maintaining a robust QMS. Be prepared to discuss practical examples of leadership commitment to quality.

- Risk-Based Thinking: This is central to ISO 9001:2015. Understand how to identify, analyze, and address risks and opportunities affecting the QMS. Prepare examples of proactive risk mitigation strategies.

- Planning and Objectives: Know how to set quality objectives, plan for their achievement, and demonstrate their alignment with the organization’s strategic goals.

- Support: Understand the resources, infrastructure, competence, and work environment required for the effective functioning of the QMS.

- Operation: This covers the core processes of your organization and how they are controlled to meet requirements. Be ready to discuss process mapping and control techniques.

- Performance Evaluation: Learn how to monitor, measure, analyze, and evaluate the QMS’s performance. Prepare examples of key performance indicators (KPIs) and their interpretation.

- Improvement: Understand the importance of continuous improvement, corrective actions, and preventative actions within the framework of ISO 9001:2015. Be ready to discuss examples of implementing corrective actions.

Next Steps: Unlock Your Career Potential

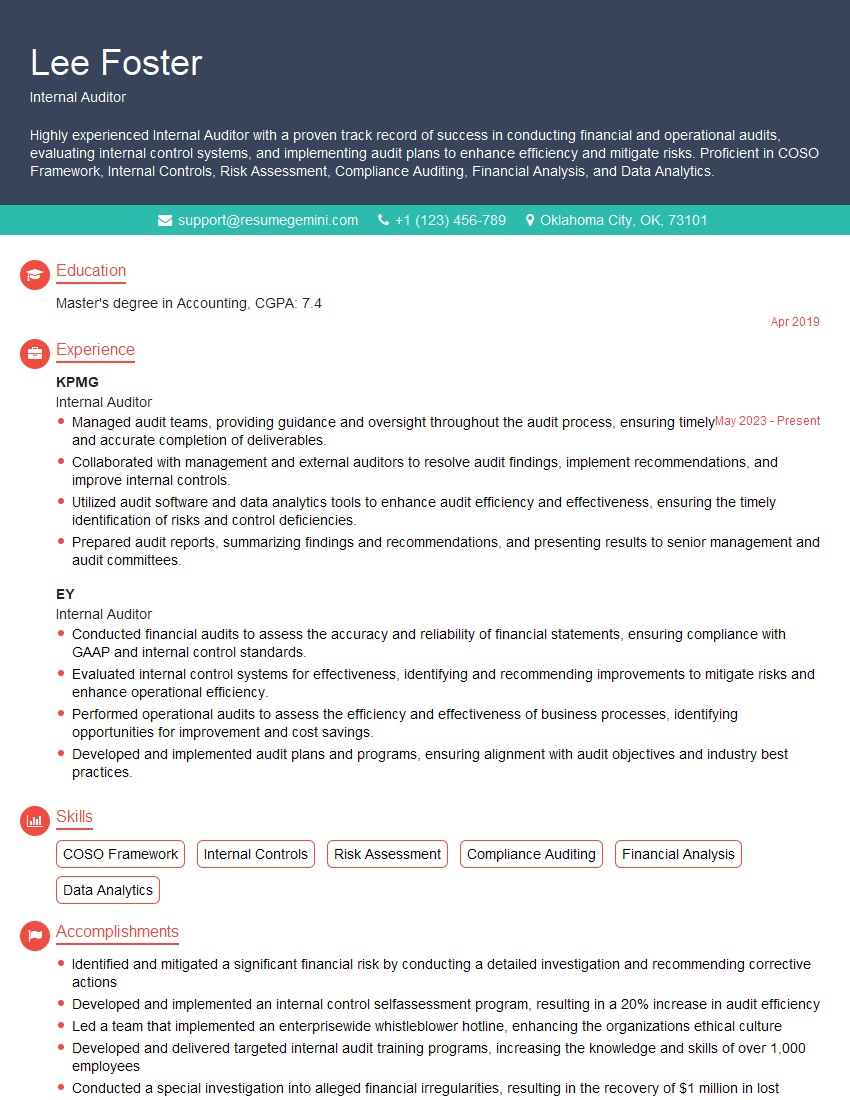

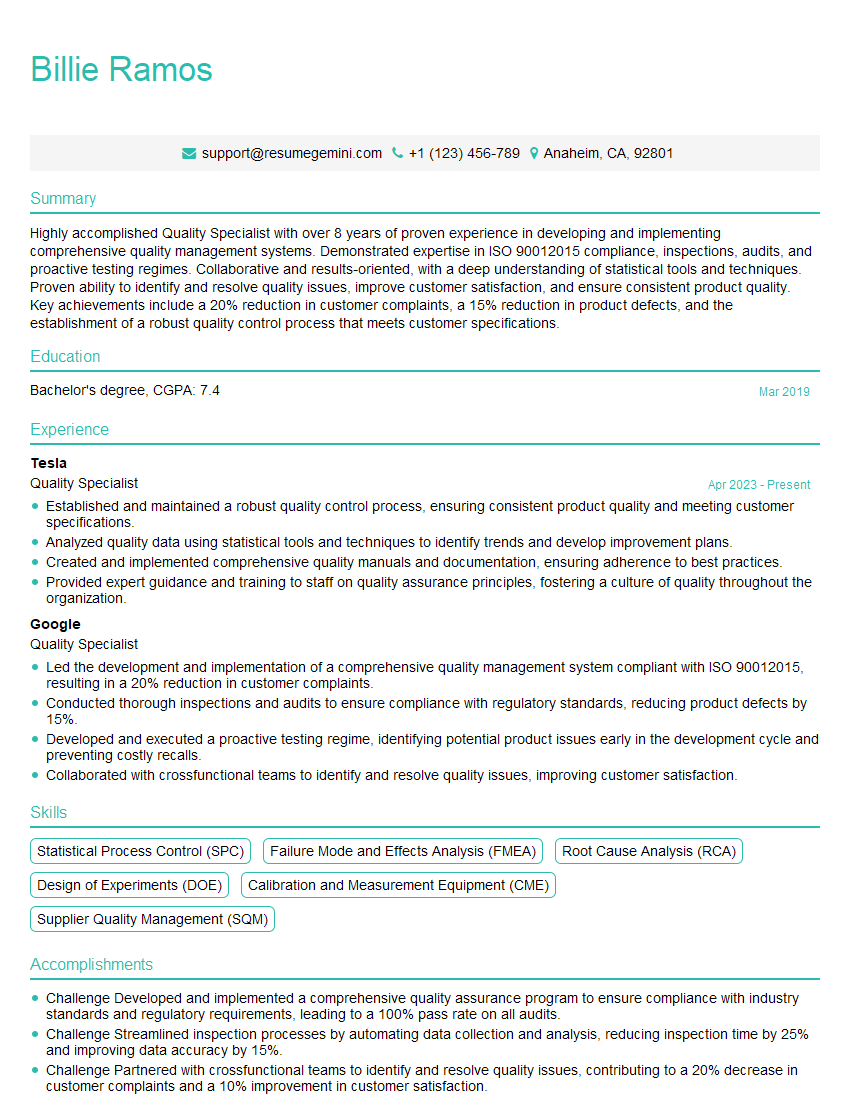

Mastering ISO 9001:2015 demonstrates a valuable skillset highly sought after in many industries. This knowledge significantly enhances your career prospects and positions you for leadership roles. To maximize your chances of landing your dream job, a strong resume is crucial.

Create an ATS-friendly resume that highlights your ISO 9001:2015 expertise. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to showcase expertise in ISO 9001:2015, helping you present your skills effectively to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good