Cracking a skill-specific interview, like one for Knowledge of Moving Equipment and Techniques, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Knowledge of Moving Equipment and Techniques Interview

Q 1. Describe your experience operating a forklift.

My forklift operating experience spans over eight years, encompassing various warehouse and construction environments. I’m proficient in operating both sit-down and stand-up forklifts, handling diverse loads ranging from pallets of materials to individual heavy items. I’ve consistently maintained a perfect safety record, prioritizing safe operating procedures above all else. For instance, I recall a situation where a pallet was precariously stacked; instead of attempting a risky lift, I carefully rearranged the load to ensure stability before proceeding, preventing a potential accident. My experience includes working with different forklift types, including electric and propane-powered models, and I’m familiar with their unique operational characteristics and maintenance requirements.

Beyond basic operation, I’m adept at maneuvering forklifts in tight spaces, navigating uneven terrain, and loading/unloading trucks efficiently. I’m also well-versed in load-handling techniques, ensuring proper weight distribution and stability to prevent tipping or damage to goods.

Q 2. Explain the pre-operational checks you perform on a crane before lifting.

Pre-operational crane checks are paramount for safety. My checklist is thorough and includes:

- Visual Inspection: A comprehensive examination of the crane’s structure, cables, hooks, and all moving parts for any signs of damage, wear, or corrosion. This includes checking for loose bolts, frayed wires, or hydraulic leaks.

- Mechanical Checks: Testing the functionality of all controls, brakes, and safety mechanisms, including the emergency stop. I’ll verify the smooth operation of the hoisting, slewing, and traversing mechanisms.

- Load Capacity Verification: Confirming the crane’s load capacity chart is displayed and easily accessible, and that the load being lifted is within the crane’s rated capacity. This also includes checking for appropriate load-handling equipment.

- Documentation Review: Verifying that all required certifications and permits are current and in order.

- Ground Conditions: Assessing the stability of the ground where the crane is positioned, ensuring that it’s level and capable of supporting the crane and its load.

One time, during a pre-operational check, I discovered a hairline crack in a supporting strut. This was immediately reported, preventing a potentially catastrophic failure during operation.

Q 3. What safety procedures do you follow when operating heavy machinery?

Safety is my top priority. My procedures include:

- Personal Protective Equipment (PPE): Always wearing appropriate PPE, including safety helmets, high-visibility clothing, safety shoes, and hearing protection.

- Area Awareness: Maintaining constant awareness of my surroundings, including other workers, obstacles, and overhead obstructions.

- Safe Operating Procedures: Strictly adhering to all established operating procedures and safety regulations.

- Load Securement: Ensuring loads are properly secured and balanced before lifting, using appropriate rigging techniques and equipment.

- Communication: Maintaining clear and consistent communication with other workers using hand signals, radios, or other designated methods.

- Emergency Procedures: Familiarizing myself with emergency procedures and knowing how to react appropriately in case of an emergency.

- Regular Maintenance: Reporting any defects or malfunctions to the supervisor immediately.

For example, I’ll always use spotters when operating in areas with limited visibility or when working near other personnel. This prevents accidents due to blind spots or miscommunication.

Q 4. How do you handle a malfunctioning piece of equipment?

If equipment malfunctions, my immediate response is to:

- Shut Down: Immediately shut down the equipment and secure it in a safe position.

- Assess the Situation: Determine the nature and extent of the malfunction, avoiding any further interaction with the faulty component.

- Report the Issue: Immediately report the malfunction to my supervisor and follow their instructions.

- Isolate the Area: Isolate the area to prevent unauthorized access and potential accidents.

- Await Assistance: Wait for qualified personnel to assess and repair the equipment before resuming operations.

I once experienced a sudden hydraulic leak on a forklift. I immediately shut down the machine, secured it, and reported the issue, preventing any potential injuries or further damage. The prompt reporting ensured a swift repair, minimizing downtime.

Q 5. Explain the different types of rigging techniques.

Rigging techniques are crucial for safe load handling. Common types include:

- Vertical Lift: The most straightforward method, using a single vertical line to lift the load.

- Choker Hitch: A simple knot that uses a loop of rope around the load, suitable for smaller, round objects.

- Basket Hitch: Using two legs of a sling to cradle the load, evenly distributing the weight.

- Bridle Sling: Two or more legs of a sling converging to a single point, providing stability and better load distribution for heavier objects or those with uneven weight distribution.

The choice of rigging technique depends heavily on the load’s shape, weight, and handling requirements. Incorrect rigging can lead to load slippage, damage, or even catastrophic failure.

For example, a basket hitch is ideal for lifting a drum, while a bridle sling is essential for lifting a large, heavy, irregularly shaped component.

Q 6. What are the load capacity limitations of a typical forklift?

Load capacity limitations for forklifts vary widely depending on the model, make, and configuration. However, a typical forklift might have a load capacity ranging from 2,000 to 10,000 pounds (900 to 4500 kg). The load center—the distance from the load’s center of gravity to the forklift’s mast—is also a crucial factor. Exceeding the rated capacity or exceeding the load center can lead to instability and tipping.

Always consult the forklift’s data plate for its specific load capacity and load center limitations before operating. Ignoring these limits can result in accidents and damage.

Q 7. Describe your experience with different types of cranes (e.g., tower, mobile).

My experience encompasses various crane types, including:

- Tower Cranes: Extensive experience operating tower cranes in large-scale construction projects. This includes understanding their assembly, dismantling, and precise control mechanisms for placing loads at significant heights.

- Mobile Cranes: Proficient in operating various mobile cranes, including rough-terrain and all-terrain cranes, used for both construction and industrial applications. This includes navigating challenging terrains and handling varied load requirements.

- Overhead Cranes: Experience operating overhead cranes in industrial settings for moving heavy components within factories and warehouses.

Each crane type requires unique skills and knowledge. For example, operating a tower crane demands a strong understanding of wind conditions and potential sway, while mobile cranes necessitate excellent maneuvering skills in constrained spaces. Safety protocols are adapted to each crane type, to maintain the highest level of safety.

Q 8. How do you ensure the safety of personnel around moving equipment?

Ensuring personnel safety around moving equipment is paramount and requires a multi-layered approach. It starts with comprehensive risk assessments identifying potential hazards specific to the equipment and work environment. This includes analyzing the movement paths of the equipment, identifying blind spots, and assessing the potential for collisions or entanglement.

Next, we implement robust control measures. This involves establishing clear designated zones, using barriers and warning signs, implementing speed limits and traffic management systems, and ensuring that all personnel involved are properly trained and equipped with appropriate personal protective equipment (PPE), such as high-visibility clothing, safety helmets, and safety shoes.

Furthermore, effective communication is crucial. This means using designated signal persons, two-way radios, or other communication systems to coordinate movements and alert personnel of any potential dangers. Regular safety briefings and toolbox talks reinforce safe practices and address emerging risks. Finally, continuous monitoring and observation of both personnel and equipment during operation is vital for early detection and response to any unsafe conditions. For instance, during a crane operation, a dedicated signaler will be responsible for guiding the crane operator, ensuring that there are no obstructions in the crane’s path and that personnel are clear.

Q 9. What are the regulations and safety standards you adhere to?

My work adheres strictly to all relevant national and international safety regulations and standards. This includes, but isn’t limited to, OSHA (Occupational Safety and Health Administration) regulations in the US, or equivalent standards in other countries. Specific standards relevant to moving equipment encompass:

- Crane safety standards: These address aspects such as crane inspection, operator certification, load capacity, and safe operating procedures.

- Forklift safety standards: These cover operator training, pre-operational checks, load stability, and safe operating practices in various environments.

- Load securing standards: These dictate the proper techniques and equipment for securing loads to prevent shifting or falling during transport.

Regular audits and inspections are conducted to ensure compliance and identify potential areas for improvement. Staying updated on the latest regulations and best practices is an ongoing process, involving participation in relevant training and industry updates.

Q 10. Explain your experience with load securing techniques.

I have extensive experience in various load securing techniques, adapting my approach to the specific characteristics of the load and the mode of transport. This includes:

- Understanding Load Characteristics: Before securing any load, I carefully assess its weight, dimensions, center of gravity, and any inherent fragility.

- Choosing the Right Securing Equipment: Selecting appropriate lashing straps, chains, ropes, or nets depends on the load type and transport method. I always ensure that all equipment is in good working order and properly rated for the load’s weight.

- Securing Techniques: My techniques involve creating multiple secure points of contact, distributing the load evenly, and preventing shifting or swaying. I avoid over-tightening straps, which can damage the load or the securing equipment. Proper tension is key.

- Documenting the Process: Detailed records are kept of the load securing process, including type and quantity of securing equipment, tension levels, and any relevant observations.

For example, when securing a large, oddly shaped piece of machinery on a flatbed truck, I’d use a combination of chains and straps, ensuring multiple anchor points are distributed to prevent uneven weight distribution and possible tipping. Each step is documented to ensure accountability and to provide a record of the securement process.

Q 11. How do you calculate the center of gravity for a load?

Calculating the center of gravity (CG) of a load is crucial for safe lifting and transport. For simple, regularly shaped loads, this can be straightforward; however, for complex shapes, a more detailed calculation is required. There are several methods:

- Simple Shapes: For symmetrical objects, the CG is located at the geometric center. For instance, a cube’s CG is at its center.

- Multiple Objects: For a load composed of multiple parts, we calculate the CG of each part individually and then find the combined CG based on the individual weights and locations.

- Complex Shapes: For irregularly shaped loads, we may use software or employ techniques like suspending the load from multiple points, identifying the balance point to determine the CG.

In practice, if the load is complex, I use specialized software or consult with engineers. Understanding CG is essential for preventing tipping and ensuring safe lifting.

Q 12. Describe your experience with different types of lifting equipment.

My experience encompasses a wide range of lifting equipment, including:

- Overhead Cranes: Including gantry cranes, jib cranes, and tower cranes; I’m proficient in their operation, maintenance, and safety protocols.

- Forklifts: I’m experienced with various types of forklifts, from counterbalance to reach trucks, and am familiar with their operational limits and safety features.

- Hoists: Both electric and manual hoists, including chain hoists and wire rope hoists, are part of my operational expertise.

- Other Lifting Devices: This includes pallet jacks, scissor lifts, and specialized lifting equipment for particular tasks.

For each type, I’m knowledgeable about pre-operational checks, load capacity limits, and necessary safety precautions. This includes daily inspection routines to ensure equipment functionality and safety before commencing any operations.

Q 13. How do you handle unexpected situations or emergencies during operation?

Handling unexpected situations demands quick thinking, decisive action, and adherence to established emergency procedures. My approach involves:

- Immediate Assessment: First, I assess the nature of the emergency, identifying any immediate risks to personnel or equipment.

- Prioritization: Next, I prioritize actions based on risk level, ensuring the safety of personnel is always the top priority.

- Emergency Procedures: I follow the established emergency protocols, which could include initiating a site evacuation, contacting emergency services, or securing the equipment.

- Communication: I ensure clear and consistent communication with all involved parties, including supervisors, colleagues, and emergency responders, keeping everyone informed of the situation and actions being taken.

- Post-Incident Analysis: Following the emergency, a thorough investigation is conducted to determine the root cause and prevent similar incidents in the future.

For example, if a crane malfunctions, I would immediately shut down the crane, clear the area, and notify my supervisor while following company emergency procedures. Depending on the nature of the malfunction, external repair crews might be called in.

Q 14. What are the common causes of equipment malfunctions?

Equipment malfunctions can stem from several sources:

- Lack of Maintenance: Regular maintenance and inspections are crucial. Overlooking these can lead to component wear, fluid leaks, and other issues.

- Operator Error: Incorrect operation, overloading equipment, or disregarding safety procedures can cause damage and malfunctions.

- Environmental Factors: Exposure to harsh weather conditions, such as extreme temperatures or excessive moisture, can affect equipment performance and lifespan.

- Component Failure: Components such as engines, hydraulic systems, and electrical components can fail due to wear and tear or manufacturing defects.

Preventing malfunctions requires a combination of preventive maintenance, operator training, and adherence to safety regulations. Regular checks, fluid changes, and inspections can greatly reduce equipment failures. For example, a forklift malfunctioning might be caused by a worn hydraulic hose which would be revealed during a routine maintenance inspection.

Q 15. Explain the preventative maintenance procedures you follow.

Preventative maintenance is crucial for ensuring the safety and longevity of moving equipment. My approach is proactive and systematic, focusing on regular inspections and scheduled servicing. This involves a combination of visual checks, functional testing, and lubrication.

- Daily Inspections: Before each shift, I perform a thorough visual inspection of the equipment, checking for any signs of damage, leaks, loose bolts, or worn parts. This includes checking tire pressure, fluid levels (hydraulic fluid, engine oil), and the overall condition of the machine.

- Scheduled Maintenance: I adhere to a strict maintenance schedule provided by the manufacturer, which typically involves more in-depth checks and servicing at specific intervals (e.g., monthly, quarterly, annually). This might include filter changes, belt replacements, and more comprehensive system checks.

- Lubrication: Regular lubrication of moving parts is critical to reduce friction and wear. I follow the manufacturer’s recommendations for the type and frequency of lubrication.

- Record Keeping: Meticulous record-keeping is essential. I maintain a detailed log of all inspections and maintenance activities, including dates, observations, and actions taken. This helps in tracking equipment performance and identifying potential issues early on.

For example, during a daily inspection of a forklift, I might notice a slight leak in the hydraulic system. I would immediately report this and prevent further use until it is repaired, preventing a potential breakdown and ensuring safety.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you communicate effectively with colleagues during equipment operation?

Effective communication during equipment operation is paramount for safety and efficiency. I utilize a combination of verbal, visual, and sometimes even written communication strategies depending on the context.

- Clear and Concise Verbal Communication: Before commencing any operation, I ensure I clearly communicate my intentions to colleagues in the vicinity. I use standardized hand signals where appropriate (especially in noisy environments), ensuring everyone understands my plan. Simple phrases like “Moving load – keep clear,” or “Backing up,” are effective.

- Visual Signals: Using flashing lights, horns, and backup alarms are crucial, especially when operating in confined spaces or areas with limited visibility.

- Written Communication: For complex movements or large-scale operations involving multiple pieces of equipment, I may utilize written checklists or pre-planned routes to coordinate activities effectively.

- Active Listening: Effective communication is a two-way street. I always listen actively to my colleagues’ instructions and concerns and address them promptly.

For instance, when moving a large pallet in a warehouse, I would verbally announce my intentions before starting, use the horn to alert others, and then move slowly and deliberately, observing my surroundings for obstacles or personnel.

Q 17. Describe your experience with different types of material handling equipment.

My experience encompasses a broad range of material handling equipment, including:

- Forklifts: I am proficient in operating various forklift types (sit-down, stand-up, reach trucks) and am certified in their safe operation.

- Overhead Cranes: I have extensive experience operating overhead cranes, including both bridge and gantry cranes, for moving heavy loads.

- Conveyors: I am familiar with various conveyor systems, including belt conveyors, roller conveyors, and specialized conveyors for specific materials.

- Pallet Jacks: Proficient in manual handling equipment such as pallet jacks and hand trucks for smaller loads.

- Other equipment: I have also worked with specialized equipment such as side loaders, order pickers, and aerial lift platforms, depending on the specific job requirements.

This diverse experience allows me to adapt quickly to different operational needs and select the most appropriate equipment for any given task, optimizing efficiency and safety.

Q 18. How do you manage the logistics of moving large or heavy items?

Managing the logistics of moving large or heavy items requires meticulous planning and execution. My approach involves several key steps:

- Assessment: First, a thorough assessment of the item’s dimensions, weight, and center of gravity is crucial. This information informs the selection of appropriate equipment and techniques.

- Route Planning: The route must be carefully planned to avoid obstacles, ensure sufficient clearance, and minimize risk. This might involve consulting blueprints, conducting site surveys, and coordinating with other personnel.

- Equipment Selection: Selecting the right equipment is vital. Factors such as weight capacity, maneuverability, and specialized attachments are considered.

- Teamwork and Communication: Moving large items usually requires teamwork. Clear communication among the team is crucial throughout the entire process to ensure everyone is aware of their roles and responsibilities.

- Safety Precautions: Safety must be prioritized. This includes using appropriate safety gear, implementing traffic control measures, and establishing clear communication protocols.

For example, when moving a large industrial machine, I would assess its weight and dimensions, plan a route that avoids narrow corridors and low ceilings, select a suitable crane and rigging equipment, assemble a team, and clearly communicate the lifting procedure before commencing the move.

Q 19. Explain your understanding of load charts and weight limits.

Load charts and weight limits are fundamental to safe equipment operation. Load charts provide critical information on the maximum weight an item of equipment can safely lift at various distances from its center of gravity. Weight limits specify the maximum load capacity for the specific equipment, often expressed in pounds or kilograms.

Understanding load charts involves recognizing that the lifting capacity decreases as the load’s center of gravity moves further from the equipment’s pivot point. Exceeding weight limits or improper load distribution can result in equipment failure, serious injury, or death. I always consult the load chart before lifting any load and ensure that the load weight and its position are within the safe operating limits. Ignoring these limits is unacceptable and may lead to significant safety hazards.

For example, a forklift might have a maximum lifting capacity of 5000 lbs when the load’s center of gravity is directly over the forks, but this capacity might reduce to 3000 lbs if the load is significantly offset. Understanding this difference is crucial for maintaining safety.

Q 20. How do you ensure the stability of a load during transport?

Ensuring load stability during transport is critical for preventing accidents. Several techniques are used:

- Proper Securing: Loads must be properly secured using appropriate tie-down straps, chains, or other restraining devices. These should be correctly positioned and tightened to prevent shifting or movement during transport. The number and placement of securing points will depend on the load’s shape, weight, and distribution.

- Weight Distribution: The load’s weight should be evenly distributed to avoid imbalances that could lead to instability. This might involve adjusting the load’s position on the equipment or using additional supports.

- Center of Gravity: The center of gravity of the load should be kept as low and central as possible. High centers of gravity increase the risk of tipping or swaying.

- Appropriate Equipment: Using the correct type and size of equipment is crucial. The equipment’s capacity, stability, and maneuverability should match the load’s characteristics.

- Slow and Steady Movement: Operating the equipment slowly and smoothly minimizes the risk of sudden movements that could destabilize the load.

Think of it like stacking books – a tall, unstable stack is far more likely to topple than a shorter, broader one. Similarly, proper load securing, weight distribution, and a low center of gravity are crucial for maintaining stability during transport.

Q 21. What are the different types of forklift attachments and their uses?

Forklift attachments greatly expand the versatility of forklifts, allowing them to handle various materials and perform diverse tasks. Some common examples include:

- Side Shifter: Allows the operator to laterally shift the forks, enabling precise placement of loads in tight spaces.

- Clamp: Used for handling materials like paper rolls, lumber, and other long, cylindrical objects.

- Rotator: Enables the rotation of the load, making it easy to position materials at different angles.

- Fork Extensions: Increase the fork length, accommodating wider or longer loads.

- Carriage Spreader: Expands the fork spread, useful for handling oversized materials.

- Push-Pull Attachments: Used for pushing and pulling loads, useful in scenarios requiring more control or handling of materials not suitable for forklifts.

- Rotating Forks: Allow for easier placement of loads, especially in pallet racking.

- Bucket: Used to lift and transport loose materials such as sand, gravel, or soil.

The selection of the appropriate attachment depends on the specific material being handled and the task at hand. For example, a clamp would be ideal for handling large paper rolls, while a bucket is more suitable for moving loose materials.

Q 22. Describe your experience with computerized material handling systems.

My experience with computerized material handling systems is extensive. I’ve worked with Warehouse Management Systems (WMS) like Manhattan Associates and Blue Yonder, as well as various types of automated guided vehicles (AGVs) and robotic systems. For example, in a previous role, I implemented a WMS to optimize the picking and packing process in a large distribution center. This involved integrating the WMS with our existing conveyor system and RF scanners, significantly improving order accuracy and throughput. I’m also proficient in programming logic controllers (PLCs) and have experience troubleshooting and maintaining automated storage and retrieval systems (AS/RS). Understanding the intricacies of these systems – from their software interfaces to their mechanical components – is crucial for maximizing efficiency and minimizing downtime.

In another project, I helped design and implement a system using AGVs to transport materials between different production lines. This reduced labor costs and improved the flow of materials, resulting in increased productivity. My experience spans various aspects of these systems, including their initial design, integration, testing, and ongoing maintenance and optimization.

Q 23. How do you optimize the efficiency of material handling processes?

Optimizing material handling efficiency involves a holistic approach. It’s not just about the equipment; it’s about the entire process. I start by analyzing the current workflow, identifying bottlenecks, and areas for improvement. This often involves using techniques like value stream mapping to visualize the entire process.

Key strategies include: improving warehouse layout to minimize travel distances (more on this in the next question); implementing efficient storage methods like FIFO (First-In, First-Out) or LIFO (Last-In, First-Out) based on product characteristics; optimizing picking routes using technologies like slotting optimization software; and utilizing appropriate equipment, matched to the tasks at hand. For instance, using narrow aisle forklifts can significantly increase storage density in a warehouse. Finally, implementing real-time tracking and monitoring of materials allows for proactive problem-solving and adjustments to the workflow.

Data analysis is critical. By tracking key metrics such as order fulfillment time, inventory turnover, and equipment utilization, we can pinpoint areas needing improvement and measure the effectiveness of implemented changes. It’s a continuous improvement cycle.

Q 24. Explain your knowledge of different types of warehouse layouts.

My knowledge encompasses various warehouse layouts, each with its own strengths and weaknesses. These include:

- U-shaped layout: Efficient for processes with linear workflow. Ideal for small to medium-sized operations.

- I-shaped layout: Simple and straightforward, suitable for smaller operations with a single workflow.

- L-shaped layout: Offers flexibility and can accommodate various processes, balancing space and efficiency.

- Mixed layout: Combines elements of different layouts to optimize space and workflow depending on specific requirements of the facility.

- Random storage layout: Provides flexibility but requires advanced WMS for efficient location management and retrieval. Useful when dealing with a wide variety of items with varying demand.

The optimal layout depends on factors like product volume, order frequency, storage requirements, and the available space. For example, a high-volume distribution center with fast-moving goods might benefit from a U-shaped or mixed layout to facilitate a smooth workflow, while a warehouse with a wide variety of low-volume items might be better suited to a random storage layout managed by a sophisticated WMS.

Q 25. How do you troubleshoot common issues with moving equipment?

Troubleshooting moving equipment involves a systematic approach. I start by identifying the symptoms of the malfunction. This often involves understanding the equipment’s operational parameters and using diagnostic tools. For example, if a forklift is experiencing reduced lifting capacity, I’d check hydraulic fluid levels, inspect the hydraulic pump, and look for leaks. Similarly, problems with automated equipment often require checking the PLC programming and sensor readings.

My troubleshooting methodology involves:

- Safety First: Securing the area and equipment before commencing any troubleshooting activity.

- Visual Inspection: Thoroughly checking for obvious signs of damage, leaks, or loose connections.

- Diagnostic Checks: Using diagnostic tools and software to identify specific faults.

- Testing and Verification: Testing individual components and verifying that repairs have resolved the issue.

- Documentation: Keeping detailed records of all troubleshooting steps and repairs.

A recent example involved an AGV that was repeatedly stopping unexpectedly. By analyzing the system logs and checking the sensors, I discovered a malfunctioning proximity sensor causing the AGV to prematurely halt. Replacing the faulty sensor resolved the problem immediately.

Q 26. What are the key factors to consider when selecting the appropriate equipment for a job?

Selecting the right equipment is crucial for efficiency and safety. Key factors to consider include:

- Payload Capacity: The weight the equipment needs to handle.

- Lift Height: The vertical distance the equipment needs to reach.

- Maneuverability: The space constraints and required agility.

- Power Source: Electric, propane, or diesel, depending on environmental and operational needs.

- Operating Environment: Indoor or outdoor, rough terrain or smooth surfaces.

- Budget: Initial cost, maintenance costs, and operating expenses.

- Safety Features: Operator protection systems and emergency stops.

For instance, choosing between a reach truck and a counterbalanced forklift depends on factors like warehouse layout, aisle width, and the types of goods being handled. Reach trucks are ideal for narrow aisles and high-stacking applications, whereas counterbalanced forklifts are more versatile for various tasks but need wider aisles. Careful consideration of these factors ensures the selected equipment maximizes efficiency and minimizes operational risks.

Q 27. Describe your experience working with different types of terrain or environments.

I have extensive experience working in various terrains and environments. This includes standard warehouse environments, outdoor loading docks, construction sites, and even challenging terrains such as uneven ground and steep inclines. I understand the specific considerations for each environment, including the type of equipment suitable for each and safety precautions to be taken. For instance, using specialized off-road forklifts on a construction site is crucial for safety and efficiency compared to standard warehouse forklifts.

My experience also extends to working in temperature-controlled environments, such as refrigerated warehouses, where specialized equipment and safety procedures are required to protect both personnel and the goods being stored. I’m familiar with the challenges posed by different environmental factors, such as dust, moisture, and extreme temperatures, and how to select and maintain appropriate equipment to counter these challenges.

Q 28. How do you stay updated on the latest safety regulations and best practices?

Staying updated on safety regulations and best practices is paramount in this field. I actively participate in industry conferences and workshops, attend safety training courses, and maintain memberships in relevant professional organizations such as OSHA (Occupational Safety and Health Administration). I regularly review and update my knowledge on current regulations and guidelines published by these bodies, and keep myself abreast of the latest industry standards and publications.

I also utilize online resources, such as industry publications and websites, to keep informed about emerging technologies and best practices in material handling safety. This proactive approach ensures I maintain a high level of competence in safety protocols and implement the most effective and up-to-date practices in my work.

Key Topics to Learn for Knowledge of Moving Equipment and Techniques Interview

- Equipment Operation and Safety: Understanding the principles of safe and efficient operation for various moving equipment (forklifts, cranes, conveyors, etc.). This includes pre-operational checks, safe operating procedures, and emergency protocols.

- Load Handling and Stability: Mastering techniques for secure load handling, weight distribution, and maintaining stability during transportation. Consider different load types and their specific handling requirements.

- Maintenance and Troubleshooting: Demonstrate knowledge of routine maintenance procedures, recognizing potential mechanical issues, and basic troubleshooting techniques to prevent equipment malfunctions.

- Regulations and Compliance: Familiarity with relevant safety regulations, industry standards, and best practices related to moving equipment operation and workplace safety.

- Logistics and Planning: Understanding the logistical aspects of moving equipment, including route planning, scheduling, and coordinating with other personnel to ensure efficient and safe operations.

- Problem-solving and Decision-Making: Ability to analyze situations, identify potential hazards, and make informed decisions to ensure safe and efficient movement of materials.

- Technological Advancements: Awareness of modern technologies used in moving equipment, such as automation, remote control systems, and data monitoring tools.

Next Steps

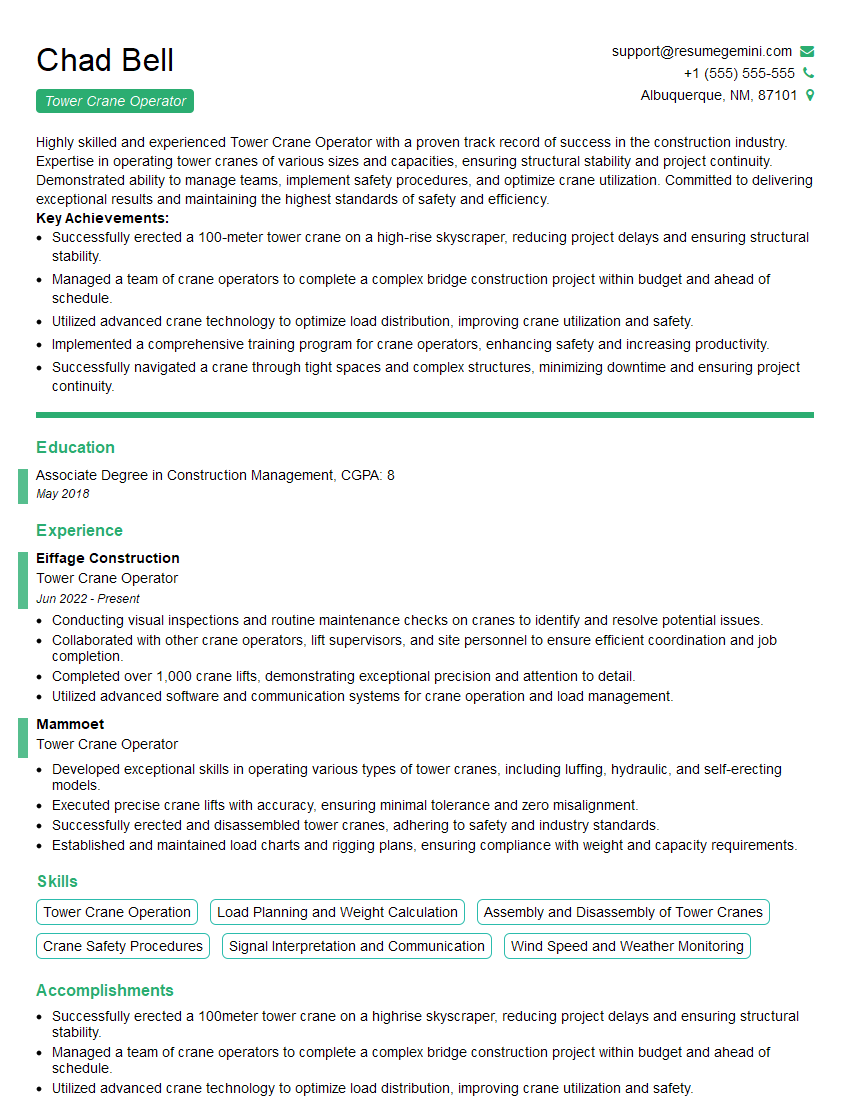

Mastering Knowledge of Moving Equipment and Techniques is crucial for career advancement in logistics, warehousing, manufacturing, and construction. A strong understanding of these principles demonstrates your commitment to safety and efficiency, making you a highly valuable asset to any organization. To significantly boost your job prospects, it’s essential to create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini can help you build a professional and compelling resume tailored to the specific requirements of your target roles. We provide examples of resumes specifically designed for candidates with expertise in Knowledge of Moving Equipment and Techniques to guide you in crafting your own standout application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good