Are you ready to stand out in your next interview? Understanding and preparing for Knowledge of Offset Printing Principles interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Knowledge of Offset Printing Principles Interview

Q 1. Explain the difference between sheetfed and web offset printing.

The core difference between sheetfed and web offset printing lies in how the paper is fed into the press. Think of it like this: sheetfed is like individually loading sheets into a printer, while web is like feeding a continuous roll of paper, like a giant receipt.

- Sheetfed Offset Printing: Uses individual sheets of paper, typically larger sizes. This offers high precision and quality, ideal for projects requiring exacting color accuracy and registration (perfect alignment of colors). It’s commonly used for brochures, business cards, and high-end publications. The process is slower and more labor-intensive because of the manual sheet handling.

- Web Offset Printing: Employs a continuous roll of paper (the ‘web’). This method is much faster and more cost-effective for large print runs, making it perfect for newspapers, magazines, and mass-market products. However, achieving the same level of precision as sheetfed can be more challenging, especially for intricate designs.

In short: Sheetfed is precise and flexible, suitable for smaller runs; web is fast and efficient, suited for large-volume printing. The choice depends on the project’s requirements and budget.

Q 2. Describe the process of platemaking in offset printing.

Platemaking is the crucial step where the image is transferred onto a printing plate. Imagine it as creating a stencil for the press. The process typically involves several stages:

- Image Preparation: The artwork is prepared digitally, ensuring it’s high-resolution and color-accurate. This often involves color management software to standardize the colors across different devices.

- Plate Creation: The image is sent to a platesetter, a device that exposes the image onto a photosensitive printing plate (commonly aluminum). Different methods exist, including Computer-to-Plate (CTP) systems which are now industry standard, eliminating the need for film. CTP systems use various technologies like thermal, violet laser, or UV exposure.

- Plate Processing: The exposed plate undergoes a chemical or thermal process to develop the image, making the image areas receptive to ink and the non-image areas water-receptive. This step ensures that ink only adheres to the desired areas.

- Plate Mounting: The developed plate is carefully mounted onto the printing cylinder of the press. Precise mounting is critical for accurate registration.

The entire process demands meticulous attention to detail to achieve quality print results. A flaw in any step can lead to printing errors.

Q 3. What are the key components of an offset printing press?

A modern offset printing press is a complex machine with many interconnected components, working together in a coordinated sequence. Key components include:

- Printing Units: These are the core units where the image is transferred from the plate to the blanket cylinder and then to the paper. Multiple units allow for multicolor printing.

- Feeders: These mechanisms feed the paper (sheets or web) into the press accurately.

- Delivery System: This system collects and stacks the printed sheets or rolls.

- Ink and Dampening Systems: These regulate the amount of ink and dampening solution (water) applied to the plate. The balance is crucial for achieving the desired color and preventing problems.

- Blanket Cylinder: This rubber-covered cylinder transfers the image from the plate to the paper. Its elasticity allows for even ink distribution.

- Impression Cylinder: This presses the paper against the blanket cylinder, transferring the ink to the substrate.

- Plate Cylinder: Holds the printing plate.

- Control System: This sophisticated system monitors and controls the press’s operations, allowing for adjustments to maintain quality and efficiency.

These components work in harmony to deliver high-quality printed materials.

Q 4. How do you maintain consistent color accuracy in offset printing?

Maintaining consistent color accuracy in offset printing is paramount. It requires a multi-faceted approach, starting even before the printing process begins:

- Color Management System (CMS): A CMS is crucial for standardizing colors across different devices and stages of production, from digital design to printing. Profiles are used to characterize each device’s color response, ensuring consistent color reproduction.

- Proofing: Producing accurate color proofs before printing is essential. These proofs act as a benchmark to verify if the colors on the printed output match the intended design.

- Ink Control: Precise control over ink density and dot gain (explained below) is necessary. This requires regular monitoring and adjustments of ink and dampening solution levels.

- Substrate Consistency: The type and quality of paper significantly affect color reproduction. Using consistent paper stock is vital for consistent color.

- Press Calibration: Regular calibration of the press is crucial to ensure proper ink distribution and color consistency across different printing units.

- Operator Skill: Experienced press operators play a crucial role, making subtle adjustments to maintain color accuracy throughout the print run.

Consistent color is a collaborative effort involving designers, prepress technicians, and press operators.

Q 5. Explain the significance of dot gain in offset printing.

Dot gain refers to the increase in the size of printed dots during the offset printing process. Think of it like this: you design a small dot, but after printing, it’s slightly larger. This happens because of the ink’s spreading on the paper and the compression during the printing process. While some dot gain is expected, excessive dot gain leads to undesirable effects.

- Impact on Color: Increased dot gain can lead to darker and muddier colors than intended, affecting the overall image quality. Imagine a vibrant yellow becoming dull.

- Importance of Control: Controlling dot gain is critical for achieving accurate color reproduction. Factors like ink type, paper, and press conditions influence dot gain.

- Compensation: Prepress professionals use techniques like dot gain compensation to account for this phenomenon during the design stage, effectively ‘shrinking’ the dots digitally to ensure the printed result is accurate.

Understanding and managing dot gain is crucial for producing high-quality offset print jobs. Ignoring it leads to inaccurate color reproduction and overall dissatisfaction.

Q 6. What are the common causes of printing defects and how are they corrected?

Several common printing defects can occur during offset printing. Identifying and correcting them requires a systematic approach:

- Mottling: Uneven ink distribution, resulting in a blotchy appearance. This can be caused by inadequate ink or dampening solution balance or problems with the ink rollers.

- Set-off: Ink from one sheet transferring to the next, most common in high-volume printing. This is often addressed by using a slip sheet or adjusting the press’s delivery system.

- Hickies: Small specks of dirt or debris on the printed sheet, typically from rollers or the paper itself. Cleaning the press and using high-quality paper can mitigate this.

- Streaking: Long, continuous lines of ink or color inconsistencies, often due to problems in the inking or dampening systems.

- Ghosting: A faint imprint of a previous image appearing on subsequent prints. Caused by insufficient drying or transfer of ink to the next sheet.

- Slurring: Blurring of the printed image, often a result of incorrect pressure settings or worn printing plates.

Troubleshooting these defects involves careful observation, understanding their causes, and making appropriate adjustments to the press settings, cleaning equipment and replacing worn components. A detailed press log helps pinpoint causes and track solutions.

Q 7. Describe the different types of inks used in offset printing.

Offset printing uses various types of inks, each with unique properties:

- Conventional Inks: These oil-based inks are widely used and offer vibrant colors and good drying properties. They can be slow drying on porous substrates.

- UV (Ultraviolet) Inks: These inks cure instantly upon exposure to UV light, offering faster drying times and a wider color gamut. Excellent for faster turnaround and substrates that might not hold conventional inks well.

- Vegetable-Based Inks: Environmentally friendly alternatives to conventional inks, often used in eco-conscious printing. They can have limitations on color range and drying times.

- Hybrid Inks: Combine the attributes of different ink types, for instance, a combination of UV and conventional ink properties.

The choice of ink depends on factors such as printing speed, substrate, desired drying time, and environmental concerns. Ink selection plays a crucial role in the overall quality and efficiency of the printing process.

Q 8. Explain the role of pre-press in offset printing.

Pre-press in offset printing is the crucial preparatory phase before the actual printing begins. Think of it as the meticulous planning and preparation before building a house – you wouldn’t start constructing without blueprints, right? Similarly, pre-press ensures the printing process runs smoothly and produces high-quality results. It encompasses several key stages:

- Design and Artwork: Creating or adapting the artwork to fit the printing specifications.

- Image Setting: Converting the artwork into a digital format suitable for printing, often using high-resolution images and vector graphics.

- Color Management: Ensuring color consistency across different devices and media by using color profiles and standardized color spaces like CMYK.

- Imposition: Arranging pages in a specific order on the printing plates to optimize the printing process and minimize waste.

- Plate Making: Creating printing plates from the digital files. This involves exposing a photosensitive plate to the digital image, developing the plate, and preparing it for the press.

- Proofing: Producing a sample print to check the accuracy of colors, images, and text before proceeding with the full print run. This can involve soft proofing (on-screen) or hard proofing (physical prints).

A well-executed pre-press stage prevents costly errors during printing and ensures that the final product matches the client’s expectations. For instance, a mistake in imposition could lead to pages being printed in the wrong order, requiring a costly reprint.

Q 9. How do you troubleshoot common press problems, such as slurring or ghosting?

Troubleshooting press problems requires a systematic approach. Let’s consider slurring (blurred images) and ghosting (faint, unwanted image impressions):

Slurring: This usually indicates issues with the ink-water balance, dampening system, or roller settings.

- Check Ink-Water Balance: Too much water can cause the ink to spread and blur. Adjust the fountain solution (water) supply to find the optimal balance. Think of it like painting – too much water dilutes the paint, making it less vibrant and more spread out.

- Examine Rollers: Worn or damaged rollers can cause inconsistent ink transfer. Inspect for wear and tear and replace if necessary. They need to be in perfect condition for even ink distribution.

- Plate Problems: A damaged or improperly cleaned printing plate can also contribute to slurring. Inspect and clean the plate, or replace if necessary.

Ghosting: This usually points to problems with the inking unit, incorrect roller settings, or ink transfer issues.

- Ink Tack: Ink that’s too tacky can transfer to the non-image areas. Check the viscosity and adjust accordingly.

- Roller Settings: Improper roller pressure or spacing can lead to ink smearing and ghosting. Adjust the pressure and spacing for optimal ink transfer.

- Plate Cleaning: Ensure the printing plate is thoroughly cleaned between runs to prevent residual ink from transferring to the next sheet.

Systematic troubleshooting involves observing the print defects, testing different adjustments, and carefully monitoring the results. Keeping detailed records of adjustments made is crucial for future reference.

Q 10. What are the different types of paper used in offset printing and their suitability?

Offset printing uses a wide variety of papers, each with its own characteristics and suitability for different applications. The choice depends on factors such as the desired print quality, budget, and end-use of the printed material. Here are some examples:

- Coated Paper: Offers a smooth, glossy surface ideal for high-quality images and vibrant colors. Commonly used for magazines, brochures, and high-end packaging.

- Uncoated Paper: Has a matte or slightly textured surface, suitable for applications where a more natural feel is desired. Often used for books, stationery, and business cards. This absorbs ink differently, impacting the appearance.

- Gloss Coated Paper: Provides the highest gloss and vibrancy, perfect for high-impact marketing materials.

- Matte Coated Paper: Offers a less glossy finish but still provides good image quality and is less prone to glare.

- Recycled Paper: An environmentally friendly option made from recycled fibers. It may have a slightly rougher texture.

- Speciality Papers: Includes a range of papers with unique textures, colors, and finishes, such as linen paper, textured board, or metallic papers.

Consider the weight (grams per square meter or gsm) of the paper, as this influences its thickness and durability. Heavier papers are generally more durable but may be more expensive. The paper’s porosity also influences ink absorption and drying time.

Q 11. Describe the process of setting up a printing job on an offset press.

Setting up a printing job on an offset press is a multi-step process that requires precision and attention to detail. Imagine it like preparing a complex recipe – each step is essential for the final product’s success.

- Plate Mounting: Carefully attach the printing plates to the press cylinders, ensuring proper alignment and registration.

- Ink and Water Settings: Adjust the ink and water levels to achieve the desired ink-water balance. This is crucial for achieving the correct color density and preventing slurring.

- Roller Settings: Adjust the rollers to ensure consistent ink transfer across the printing surface. This requires fine-tuning to avoid streaks or uneven ink distribution.

- Blanket Cylinder Cleaning: Clean the blanket cylinder to remove any debris that could interfere with printing. This ensures consistent print quality.

- Paper Feeding: Ensure the paper is correctly fed into the press and aligned to avoid misfeeds and waste.

- Test Prints: Run test prints to check the alignment, color accuracy, and overall print quality. Adjust the settings as necessary until the desired results are achieved.

- Makeready: This process involves preparing the press for a print run. It covers all aspects from initial setup to quality checks before full production.

Once the setup is complete and test prints are satisfactory, the press can begin the full production run. Thorough setup is critical for avoiding waste and ensuring consistent, high-quality prints.

Q 12. How do you perform quality control checks during and after printing?

Quality control is paramount in offset printing. It’s an ongoing process, not just a final step.

During Printing:

- Regular Monitoring: Constantly inspect printed sheets for color consistency, registration accuracy, and any defects such as smudging, slurring, or ghosting.

- Color Measurement: Use a densitometer or spectrophotometer to measure the color density and ensure it aligns with the specifications. This provides objective measurements for consistent quality.

- Regular Adjustments: Make small adjustments to ink, water, and pressure settings as needed to maintain optimal print quality.

After Printing:

- Final Inspection: Conduct a thorough inspection of the entire print run for any defects. This may involve a visual check, or using specialized software for digital analysis of the quality.

- Sampling and Testing: Take random samples to verify color accuracy, image sharpness, and overall print quality. This allows verification of the whole print run quality.

- Documentation: Maintain detailed records of the printing process, including any adjustments made and the results obtained. This helps in troubleshooting and improving future print jobs.

Efficient quality control procedures minimize waste, ensure client satisfaction, and uphold the reputation of the printing establishment.

Q 13. Explain the importance of maintaining proper makeready procedures.

Proper makeready procedures are essential for efficient and high-quality offset printing. Think of it as the foundation of a building – if the foundation is weak, the whole structure will be compromised. Makeready includes all the steps taken to prepare the press for a specific job.

The importance lies in:

- Minimizing Waste: Careful setup reduces the amount of paper wasted during the initial test prints and adjustments.

- Ensuring Consistency: Proper makeready ensures that the print quality remains consistent throughout the entire run. Consistent quality means less need for reprinting and rework.

- Reducing Setup Time: A well-defined makeready process speeds up the setup time, allowing for more efficient production. Reduced setup time increases efficiency and productivity.

- Improving Quality: Correctly executed makeready procedures result in high-quality prints with accurate colors and registration. Higher quality output leads to client satisfaction and positive brand image.

- Preventing Equipment Damage: Following correct procedures safeguards the printing press and other equipment from damage caused by improper use.

By adhering to established makeready protocols, printing companies enhance overall efficiency, reduce costs, and maintain a high standard of print quality. Neglecting makeready can lead to significant financial and reputational losses.

Q 14. What is the difference between CMYK and Pantone color systems?

CMYK and Pantone are two distinct color systems used in printing, each with its own advantages and disadvantages:

CMYK (Cyan, Magenta, Yellow, Key/Black): This is a subtractive color model used for four-color process printing. It works by layering cyan, magenta, yellow, and black inks to create a wide range of colors. It’s like mixing paints – the more you mix, the darker the result becomes. This is the most common system for commercial printing because it’s economical and versatile.

Pantone (PMS): This is a spot color system using pre-mixed inks with specific formulations. Each Pantone color has a unique number, allowing for precise color matching across different print jobs and printers. Think of it as using pre-mixed paint colors instead of mixing them yourself. This is ideal for achieving specific brand colors or very vibrant colors that might be difficult to reproduce using CMYK.

The main difference lies in the method of color reproduction. CMYK relies on combining four basic inks, while Pantone uses pre-mixed inks with specific formulas. CMYK is cost-effective for large print runs, while Pantone is better for ensuring consistent brand colors or achieving very specific color tones across multiple printing projects. A logo printed using Pantone colors will always be the same, regardless of where it is printed.

Q 15. How do you manage color consistency across multiple printing runs?

Maintaining color consistency across multiple printing runs is crucial for brand identity and project success. It relies on a multi-faceted approach, starting even before the press runs. We use a standardized color management system, typically based on ISO coated v2 or a similar profile, to ensure everyone – from designers to pre-press operators – works with the same color space. This involves utilizing color profiles embedded within the digital files, and carefully calibrating all our monitors and proofing devices to this standard.

During pre-press, we create color separations using a color management software such as GMG ColorProof or similar. These separations dictate the precise ink percentages for each color plate (Cyan, Magenta, Yellow, and Black – CMYK). We also produce a proof, often a digital proof for client approval and a contract proof for our internal quality control. This proof serves as the benchmark against which the final prints are compared.

On the press itself, we carefully monitor ink densities using a densitometer at regular intervals. This involves measuring the ink density on the printed sheets and making adjustments to the ink keys as needed to maintain consistency throughout the run. We also regularly check dot gain, which is the tendency of the dots in the printed image to spread during printing. Maintaining consistent dot gain is critical for accurate color reproduction. Additionally, maintaining a stable press environment, including temperature and humidity, is crucial, as these factors can influence the drying and color characteristics of the inks. We record and track all these measurements to ensure traceability and quality control. Finally, we use color bars (control strips) on each sheet to visually compare the printed color to the pre-press standards. This ensures that the color consistency is maintained throughout the run. Any deviations from the target are noted and corrective actions are taken to regain the desired consistency.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of offset printing presses.

My experience encompasses a range of offset printing presses, from smaller sheet-fed presses suitable for shorter runs and specialized projects to larger, web-fed presses designed for high-volume production. I’ve worked extensively with Heidelberg Speedmaster presses, known for their reliability and precision. These presses allow for versatile printing on various substrates, and I’m comfortable operating and maintaining their different modules including inking systems, dampening systems and perfecting units.

I’m also proficient with Komori Lithrone presses, renowned for their advanced automation features and sophisticated color control capabilities. These presses, through their advanced automation, significantly increase efficiency in high-volume print production. Furthermore, I have hands-on experience with smaller format presses like Ryobi and Roland presses, useful for shorter runs and quick turnaround jobs that require agility and quick setup times. My experience extends to understanding the nuances of each press type, including their strengths and limitations, allowing me to select the optimal press for each project based on factors like print quality, run length, and substrate.

Q 17. Explain your understanding of imposition and its importance.

Imposition is the strategic arrangement of pages on a printing sheet to optimize the printing process. Think of it like a complex jigsaw puzzle, where each piece (page) needs to be placed precisely to minimize waste and maximize efficiency. It’s crucial because it dictates how the printed sheets will be folded, cut, and bound into the final product. Improper imposition can lead to significant issues, including incorrect page sequencing, wasted paper, and increased production costs.

For example, a 24-page brochure might be imposed on a single sheet in a way that allows for efficient folding. A skilled pre-press operator uses specialized software to create an imposition plan. This plan takes into consideration factors like sheet size, the number of pages, and the final product’s binding style (e.g., saddle stitch, perfect binding). The software generates a customized layout that maximizes sheet usage and minimizes waste, which translates to cost savings and efficiency. I’m proficient in using various imposition software such as pre-press imposition software to create efficient and accurate imposition plans for a variety of print projects.

Q 18. How do you ensure proper registration during the printing process?

Ensuring proper registration is paramount for high-quality offset printing. Registration refers to the precise alignment of the different color plates (CMYK) and any special printing elements (e.g., varnish, coatings). Misregistration, where the colors are not perfectly aligned, leads to blurry images and unacceptable print quality. Several steps are crucial to maintaining perfect registration.

Firstly, careful plate mounting is essential. Each plate must be precisely positioned on the press cylinder. We use precision registration tools and techniques to ensure accurate plate placement. Secondly, during the makeready process, we carefully align the plates using the press’s registration controls. This involves printing test sheets and making fine adjustments to ensure all colors are perfectly aligned. Thirdly, regular monitoring is critical. Throughout the printing run, we monitor registration using registration marks printed on each sheet. Any misalignment is immediately addressed by adjusting the press controls. Maintaining consistent press conditions such as temperature and humidity is another key step. Environmental fluctuations can affect the paper’s size and can therefore lead to registration issues. Lastly, the use of high quality printing plates is crucial in maintaining accurate and consistent registration.

Q 19. What are the safety precautions involved in operating an offset printing press?

Safety is the utmost priority when operating an offset printing press. The machinery is powerful and potentially dangerous, and stringent safety procedures must be followed at all times. Before operating the press, it is necessary to undergo mandatory safety training and receive certification.

Safety precautions include proper lockout/tagout procedures before any maintenance or cleaning is done. The use of Personal Protective Equipment (PPE), such as safety glasses and gloves, is mandatory. We strictly enforce the avoidance of loose clothing or jewelry that could get caught in the machinery. Furthermore, regular equipment inspections and maintenance are conducted to identify and resolve potential hazards before they occur. Press operators should be thoroughly trained on emergency shutdown procedures. We maintain a clean and organized workspace to minimize tripping hazards, and proper ventilation is crucial to reduce exposure to inks and solvents. Finally, we adhere to all relevant OSHA guidelines and regularly conduct safety meetings to reinforce safety protocols and address any concerns.

Q 20. Explain your experience with different finishing techniques (e.g., cutting, folding).

My experience with finishing techniques is extensive, encompassing a wide range of processes that add value and enhance the final printed product. I’m proficient in various cutting techniques, from simple guillotine cutting for straight cuts to die-cutting for more complex shapes and designs. Die-cutting allows for intricate shapes and designs, adding a creative element beyond basic rectangular prints. I’ve also worked with several folding methods including different types of folding for brochures, leaflets and booklets, choosing the optimal method depending on the project’s requirements and the number of pages involved. The precision folding of pages is crucial for a professional and accurate final product.

Beyond cutting and folding, I’m experienced in other finishing operations such as binding (perfect binding, saddle stitch, wire-o binding), lamination (gloss, matte), embossing, and UV coating. These finishing techniques are selected based on the specific project requirements. For instance, perfect binding is ideal for books and magazines, while saddle stitching is perfect for brochures. Lamination adds durability and enhances the visual appeal, while UV coating protects the print from wear and tear. My understanding encompasses the entire workflow, from the design phase where the ideal finishing techniques are determined, to the execution phase where precision and accuracy are key factors.

Q 21. How do you handle customer complaints related to print quality?

Handling customer complaints related to print quality is a critical aspect of my role. My approach is professional, solution-oriented, and empathetic. The first step involves active listening to fully understand the customer’s concern. Then, I analyze the complaint carefully. A thorough investigation is conducted to determine the root cause of the problem. This could involve reviewing the original artwork, examining the printing plates, checking press settings, inspecting the printing conditions, and analyzing the finished product. Different quality-control checks are implemented at various stages of the production process to minimize such issues.

Depending on the nature of the complaint, several solutions might be implemented. If a printing error is identified, we may reprint the affected sections or the entire job, depending on the scale and the severity of the issue. If the problem lies in the design or the pre-press stage, we may work with the client to make necessary corrections and reprint. In some cases, a partial refund or discount might be offered as a gesture of goodwill. It is vital to maintain open communication with the customer throughout the process, keeping them informed of the investigation’s progress and the proposed solutions. The goal is to resolve the issue efficiently and professionally while maintaining a strong customer relationship. Ultimately, each complaint represents a learning opportunity, enabling us to refine our processes and prevent similar issues in the future.

Q 22. Describe your experience with print estimating and costing.

Print estimating and costing is crucial for profitability in offset printing. It involves meticulously calculating all direct and indirect costs associated with a printing job, ensuring a fair price that covers expenses and yields a healthy profit margin. My experience encompasses a detailed understanding of various cost components, including:

- Material Costs: This includes paper (considering weight, grade, and size), inks (type and quantity), plates, and other consumables.

- Labor Costs: Estimating time for pre-press (design, platemaking), press operation (run time, makeready), and post-press (finishing, binding).

- Equipment Costs: Depreciation, maintenance, and operating costs of the printing press, binding machines, and other equipment.

- Overhead Costs: Rent, utilities, salaries of support staff, and other indirect expenses.

- Profit Margin: Adding a percentage markup to ensure profitability.

I utilize sophisticated estimating software that incorporates these cost elements and allows for quick and accurate job pricing. For example, I’ve successfully managed estimating for large-scale projects, such as printing brochures for national campaigns, accurately forecasting costs and delivering projects on budget. I’m proficient in analyzing client briefs, understanding their requirements, and translating them into precise cost estimates. I also consider potential unforeseen issues and build contingency into estimates to mitigate risks.

Q 23. Explain your knowledge of different types of substrates and their compatibility with offset printing.

Substrate selection is paramount in offset printing as it directly impacts print quality, durability, and overall project success. Different substrates possess varying properties influencing ink absorption, smoothness, and printability. My knowledge encompasses a wide range, including:

- Paper: Coated (gloss, matte, silk), uncoated (offset, text, cover), recycled, and specialty papers (like textured or metallic papers). Coated papers provide sharper images and brighter colors, while uncoated papers offer a more natural feel.

- Cardboard: Used for packaging, displays, and heavier applications. Thickness and surface treatment (e.g., coated or laminated) affect print quality.

- Films: Including various plastics, vinyl, and synthetic materials, used for labels, banners, and flexible packaging. These require specific inks and printing techniques.

Choosing the right substrate involves considering factors like the project’s end use (e.g., a glossy brochure versus a matte business card), budget, desired aesthetic, and the printing press’s capabilities. For example, printing fine details on a highly textured paper might be challenging and could require adjustments to the printing process. I have extensive experience evaluating substrate properties and recommending optimal choices based on the project’s needs and budget.

Q 24. How familiar are you with color management software (e.g., GMG, X-Rite)?

I am highly proficient in color management software, particularly GMG ColorProof and X-Rite i1Profiler. These tools are essential for ensuring consistent color reproduction across different stages of the printing process, from design to final output. My expertise includes:

- Profile Creation: Generating ICC profiles for various devices (printers, monitors, scanners) to accurately represent colors.

- Color Proofing: Creating soft proofs that closely match the final printed output, minimizing surprises and ensuring client approval.

- Color Correction: Adjusting color values to achieve consistency and match specific color standards (Pantone, etc.).

- Workflow Integration: Seamless integration of color management software into the pre-press workflow for optimized color accuracy.

I use these tools daily to ensure the colors seen on screen closely match the final print, reducing costly reprints due to color discrepancies. For instance, I’ve used GMG ColorProof to create soft proofs for high-end packaging projects, ensuring accurate color reproduction across multiple print runs and guaranteeing client satisfaction.

Q 25. What are your strategies for improving productivity in a printing environment?

Improving productivity in a printing environment requires a multifaceted approach focusing on efficiency and optimization at every stage. My strategies include:

- Process Optimization: Analyzing workflows to identify bottlenecks and streamline operations. This might involve implementing lean manufacturing principles to eliminate waste and improve efficiency.

- Automation: Leveraging automation technologies wherever possible, such as automated platemaking and pre-press systems, to reduce manual labor and improve speed.

- Preventive Maintenance: Regular maintenance of printing equipment minimizes downtime and extends machine lifespan. A well-maintained press runs faster and more efficiently.

- Employee Training: Investing in training programs to enhance employee skills and knowledge. A well-trained team is more efficient and makes fewer mistakes.

- Data-Driven Decision Making: Using MIS (Management Information Systems) to track key performance indicators (KPIs), enabling informed decision-making and continuous improvement.

For example, in a previous role, I implemented a new workflow management system that reduced production time by 15% by streamlining the pre-press process. By meticulously tracking and analyzing data, we were able to pinpoint areas for improvement and optimize our processes.

Q 26. Describe your experience with MIS (Management Information Systems) in a printing company.

My experience with MIS in printing companies involves utilizing software systems to manage various aspects of the business, from job tracking and costing to client management and production scheduling. I’m proficient in using MIS to:

- Job Tracking: Monitor job progress in real-time, from order entry to delivery. This ensures timely completion and efficient resource allocation.

- Cost Accounting: Accurately track costs associated with each job, enabling precise pricing and profit analysis.

- Inventory Management: Manage paper, ink, and other consumable stocks to optimize inventory levels and minimize waste.

- Client Relationship Management (CRM): Track client information, past orders, and communication history for better customer service and targeted marketing.

- Reporting and Analysis: Generate reports on various aspects of the business, enabling data-driven decision-making for improvements in efficiency and profitability.

I’ve used MIS systems to streamline operations, reduce errors, and improve overall business efficiency. For instance, using real-time job tracking, I’ve been able to proactively address potential delays and ensure on-time delivery for clients, leading to improved customer satisfaction.

Q 27. What are some common environmental concerns related to offset printing, and how can they be addressed?

Offset printing, while efficient, presents several environmental concerns. These include:

- Waste Generation: Paper waste during printing and finishing, as well as ink and chemical waste.

- Water Usage: Significant water consumption in the washing of printing plates and blankets.

- Energy Consumption: Offset presses require substantial energy to operate.

- Chemical Emissions: Volatile organic compounds (VOCs) released from inks and cleaning solutions.

Addressing these concerns requires a multi-pronged approach:

- Waste Reduction: Implementing efficient waste management systems, including recycling programs for paper and responsible disposal of chemicals.

- Water Conservation: Using water-saving technologies, such as closed-loop systems for washing, and adopting more water-efficient processes.

- Energy Efficiency: Utilizing energy-efficient equipment and practices, such as using LED lighting and optimizing press settings.

- Sustainable Inks: Switching to vegetable-based or low-VOC inks to reduce harmful emissions.

- Sustainable Substrates: Using recycled paper and other eco-friendly materials.

Adopting these strategies not only reduces the environmental impact but also improves the company’s image and can lead to cost savings in the long run. For example, implementing a closed-loop washing system significantly reduced water consumption and chemical waste in a previous workplace.

Q 28. Explain your understanding of the latest advancements in offset printing technology.

Recent advancements in offset printing technology are focused on increasing efficiency, improving print quality, and reducing environmental impact. Key advancements include:

- Automation and Digitization: Increased automation in platemaking, press operation, and finishing processes through digital workflows and automated systems.

- Improved Ink Systems: Development of low-migration inks, UV and LED-curable inks, and eco-friendly inks for better print quality and environmental responsibility.

- Enhanced Press Technology: Development of higher-speed presses with more sophisticated controls and inline finishing capabilities. This includes features like automatic plate changing and color registration systems.

- Data-Driven Optimization: Utilization of sensors and data analytics to optimize press settings and reduce waste. This allows for real-time monitoring and adjustment of print parameters for consistent and high-quality results.

- Sustainable Materials: Increased availability of sustainable substrates (recycled paper, bio-based materials) and printing processes minimizing waste.

These advancements are transforming the offset printing industry, leading to higher productivity, better print quality, and more environmentally responsible printing practices. I’m actively engaged in keeping up-to-date with these changes to ensure that I can utilize the latest technology to provide clients with the best possible print solutions.

Key Topics to Learn for Knowledge of Offset Printing Principles Interview

- The Offset Printing Process: Understand the fundamental steps involved, from platemaking to final output. Be prepared to discuss the mechanics of ink transfer and the role of each component (plates, blankets, cylinders).

- Color Management and Separation: Explain the concepts of CMYK, color profiles (e.g., ICC profiles), and how accurate color reproduction is achieved. Discuss practical applications like color proofing and adjustments.

- Pre-press Preparation: Detail your knowledge of file preparation, including image resolution, trapping, and imposition. Be ready to discuss different file formats and their suitability for offset printing.

- Press Operation and Maintenance: Describe your understanding of press setup, ink adjustments, and common troubleshooting techniques. This includes familiarity with different types of offset presses and their capabilities.

- Paper Selection and Handling: Explain the importance of choosing the right paper stock for different projects and how paper properties influence the printing process. Discuss paper feeding and handling techniques.

- Quality Control and Troubleshooting: Describe methods for identifying and resolving common printing defects (e.g., slurring, dot gain, mottle). Discuss quality assurance procedures throughout the printing process.

- Sustainability and Environmental Impact: Demonstrate awareness of eco-friendly printing practices, including responsible ink and paper choices, and waste reduction strategies.

Next Steps

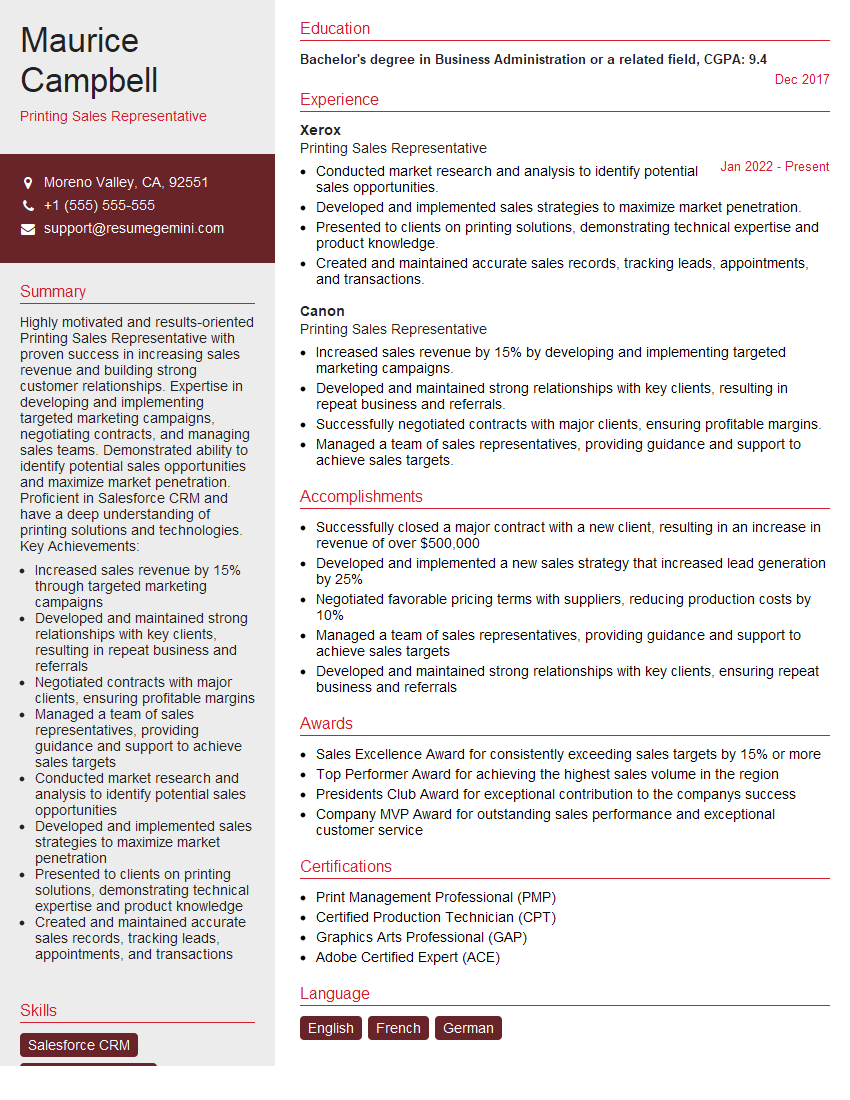

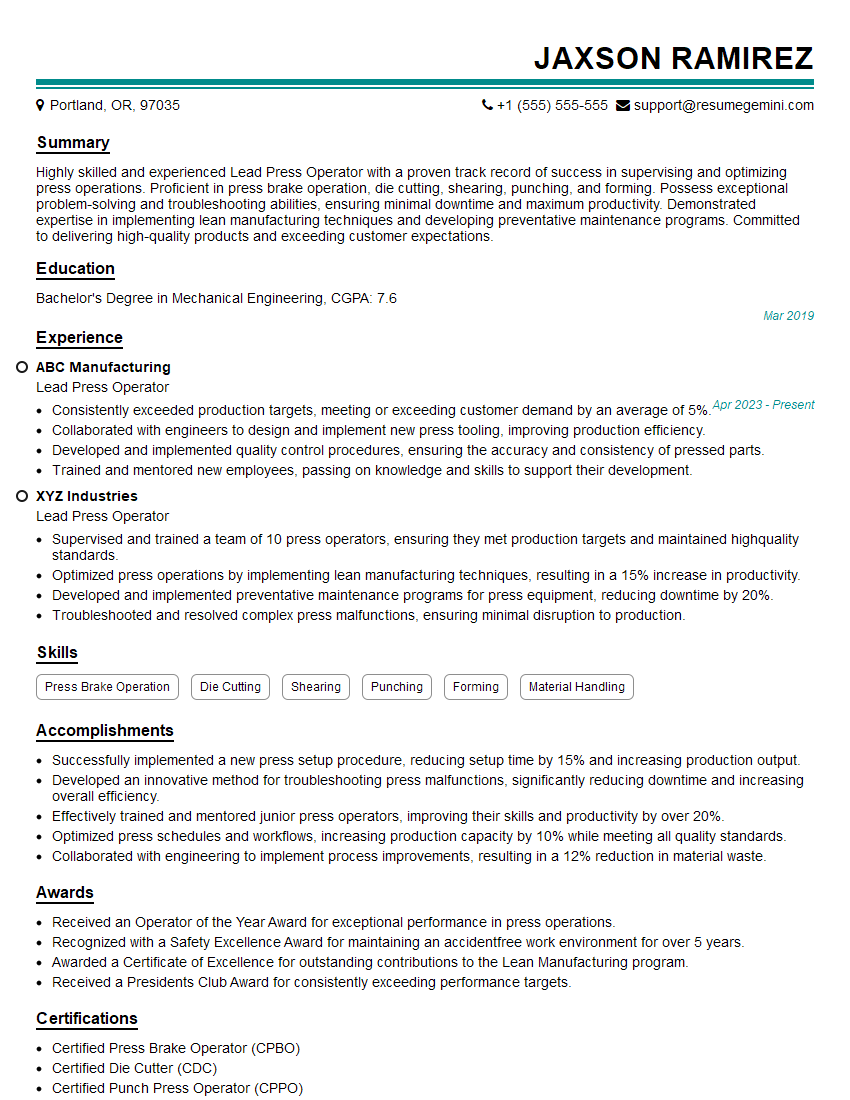

Mastering the principles of offset printing is crucial for career advancement in the graphic arts industry. A strong understanding of these concepts will significantly enhance your interview performance and open doors to exciting opportunities. To maximize your job prospects, crafting an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to highlight your skills and experience. Examples of resumes tailored to showcasing expertise in Knowledge of Offset Printing Principles are available through ResumeGemini, giving you a head start in your job search.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good