Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Knowledge of Textile Manufacturing Processes interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Knowledge of Textile Manufacturing Processes Interview

Q 1. Explain the difference between weaving and knitting.

Weaving and knitting are both fundamental fabric construction methods, but they differ significantly in their structure and properties. Think of weaving like a basket, interlacing yarns at right angles, while knitting is more like chainmail, looping yarns together to create interconnected rows.

- Weaving: Involves interlacing two sets of yarns—the warp (lengthwise) and weft (crosswise)—at right angles. This creates a strong, durable fabric with a relatively stable structure. Examples include denim, linen, and cotton twill. The process is typically done on looms, ranging from simple handlooms to complex automated machines.

- Knitting: Uses a single yarn to create interlocking loops, forming rows of stitches. This yields a more flexible, stretchy fabric that drapes well. Examples include sweaters, socks, and jersey fabrics. Knitting can be done by hand or using various knitting machines, offering a wide range of textures and designs.

The key difference lies in the yarn arrangement: woven fabrics have distinct warp and weft yarns, while knitted fabrics consist of interconnected loops of a single yarn. This structural difference leads to variations in fabric properties like drape, elasticity, and durability.

Q 2. Describe the various stages involved in fabric finishing.

Fabric finishing transforms the raw, woven or knitted fabric into a marketable product. It enhances its appearance, feel, and performance. It’s a multi-stage process crucial for achieving the desired quality and functionality.

- Cleaning: Removing impurities like sizing agents (used during weaving) and dirt.

- Bleaching: Whitening the fabric to a uniform shade, particularly for lighter colors.

- Dyeing: Imparting color to the fabric using various methods (discussed in question 6).

- Printing: Applying designs and patterns to the fabric using screen printing, digital printing, or other methods.

- Finishing Treatments: This broad category includes many processes, such as:

- Calendering: Pressing and glazing the fabric for smoothness and luster.

- Mercerization: Treating cotton with caustic soda to increase luster and strength.

- Water Repellency: Applying coatings for water resistance.

- Flame Retardancy: Treating the fabric to make it less flammable.

- Softening: Improving the fabric’s handle and drape.

Each stage is carefully controlled to ensure consistent quality and meet specific performance requirements. The sequence and type of finishing processes used depend heavily on the fabric type, intended application, and desired properties.

Q 3. What are the common types of textile fibers and their properties?

Textile fibers are the basic building blocks of fabrics. They are categorized into natural and synthetic fibers, each with distinct properties impacting fabric performance.

- Natural Fibers:

- Cotton: Soft, absorbent, and comfortable; prone to wrinkling and shrinking.

- Wool: Warm, absorbent, and elastic; sensitive to moths and can shrink.

- Silk: Luxurious, smooth, and lustrous; delicate and expensive.

- Linen: Strong, absorbent, and durable; wrinkles easily.

- Synthetic Fibers:

- Polyester: Strong, wrinkle-resistant, and durable; can retain moisture and static electricity.

- Nylon: Strong, elastic, and water-resistant; can be prone to pilling.

- Acrylic: Soft, warm, and inexpensive; not as durable as other synthetics.

- Rayon: Smooth, drapable, and absorbent; weaker than many other fibers.

Understanding fiber properties is essential in selecting appropriate fibers for specific textile applications. For example, cotton’s absorbency makes it ideal for towels, while polyester’s wrinkle resistance makes it suitable for clothing that requires minimal ironing.

Q 4. How do you ensure quality control in a textile manufacturing environment?

Quality control in textile manufacturing is paramount to ensure consistent product quality and meet customer expectations. It’s a multi-faceted approach, involving inspections at every stage of production.

- Incoming Raw Material Inspection: Checking fiber quality, yarn count, and consistency.

- In-process Inspection: Monitoring weaving or knitting processes, checking for defects like broken yarns or mispicks.

- Finishing Stage Inspection: Ensuring consistent dyeing, printing, and finishing treatments.

- Final Product Inspection: Checking for defects, dimensions, and overall quality before packaging.

- Statistical Process Control (SPC): Using statistical methods to monitor and control the production process, identifying variations and potential problems early on.

- Regular Equipment Maintenance: Prevents malfunctions that can lead to defects.

- Employee Training: Well-trained personnel are crucial for identifying and preventing defects.

Implementing a robust quality control system, along with regular audits and continuous improvement efforts, is key to producing high-quality textile products and maintaining a strong reputation.

Q 5. Explain the concept of yarn count and its significance.

Yarn count refers to the fineness or thickness of a yarn. It indicates the number of units of length per unit of weight. Different systems exist, such as the English count (number of hanks of 560 yards per pound) and the metric count (number of kilometers per kilogram).

Example: A yarn count of 40s in the English system means that 40 hanks of 560 yards each would weigh one pound.

Significance: Yarn count directly influences fabric properties. A higher yarn count typically indicates a finer yarn, resulting in a smoother, more luxurious fabric, but potentially less durable. Lower yarn counts lead to coarser, heavier, and often more durable fabrics. Yarn count is therefore crucial for determining the final fabric characteristics and is carefully controlled during yarn production and fabric design.

Q 6. What are the different types of dyeing processes used in textile manufacturing?

Dyeing processes are crucial in imparting color to textiles. Several methods are used, each offering unique advantages:

- Piece Dyeing: Dyeing the finished fabric. It’s efficient for simple designs but less economical for complex patterns.

- Yarn Dyeing: Dyeing the yarn before weaving or knitting. This produces a more even and colorfast fabric, ideal for variegated patterns.

- Garment Dyeing: Dyeing the finished garment. This is useful for achieving unique effects, but requires careful control to prevent shrinkage or damage.

- Solution Dyeing: Adding the dye to the polymer solution before the fibers are formed (often used for synthetics). This results in exceptionally colorfast fabrics.

- Direct Dyeing: Dyeing with dyes that directly bond with the fiber, commonly used for cotton.

- Reactive Dyeing: Dyeing with dyes that chemically react with the fiber, creating exceptionally colorfast results, often for cellulosic fibers like cotton.

The choice of dyeing process depends on factors such as fabric type, desired colorfastness, cost, and design complexity. For instance, yarn dyeing might be preferred for high-quality, durable fabrics while piece dyeing is suitable for simpler, less expensive products.

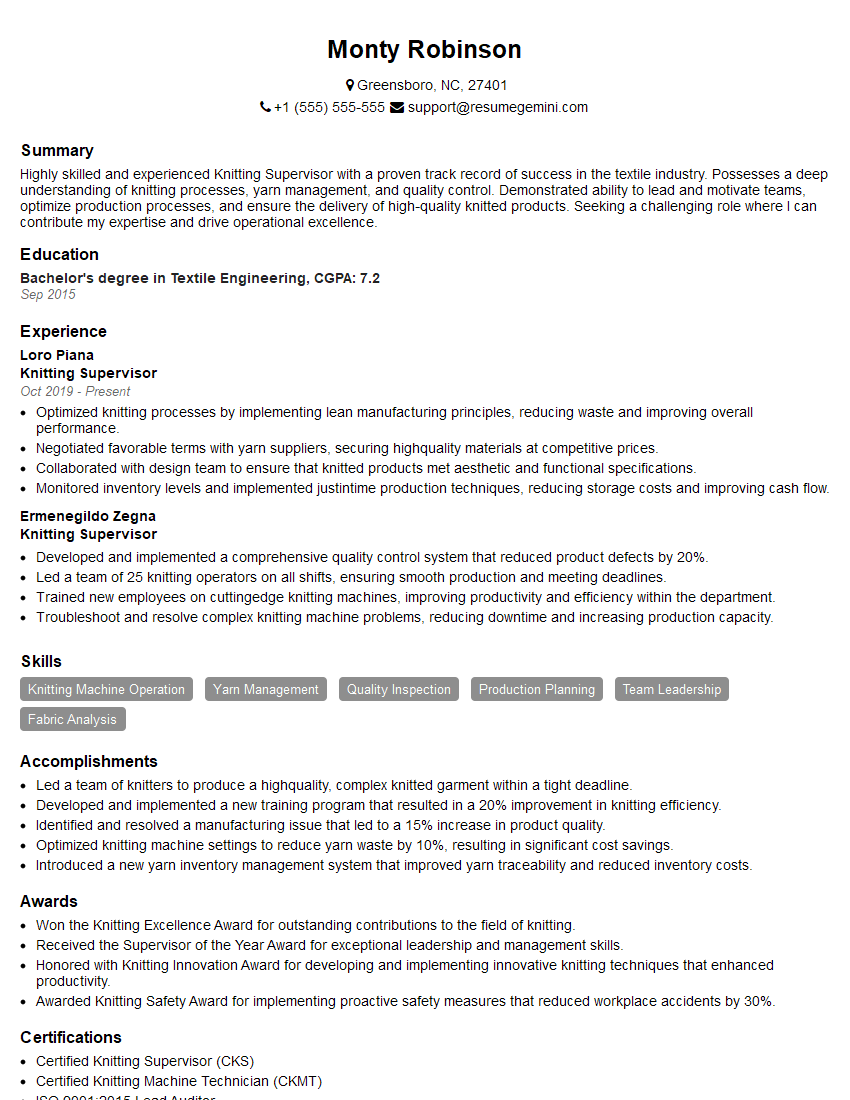

Q 7. Describe the various types of textile machinery used in your area of expertise.

The textile industry employs a wide array of machinery, each specialized for a particular stage of production.

- Spinning Machines: Convert fibers into yarn (e.g., ring spinning, open-end spinning, air-jet spinning).

- Weaving Looms: Interlace warp and weft yarns to create woven fabrics (e.g., shuttle looms, air-jet looms, rapier looms).

- Knitting Machines: Produce knitted fabrics using interlocking loops (e.g., weft knitting machines, warp knitting machines).

- Dyeing Machines: Apply dyes to fabrics or yarns (e.g., jet dyeing machines, pad dyeing machines).

- Printing Machines: Apply designs to fabrics (e.g., screen printing machines, rotary printing machines).

- Finishing Machines: Perform various finishing processes (e.g., calenders, sanforizing machines).

- Cutting and Sewing Machines: Used in the garment manufacturing process.

My specific area of expertise focuses on weaving and finishing machinery, particularly the advanced automated looms and finishing equipment used in high-volume production environments. Technological advancements continue to drive improvements in efficiency and precision, leading to the development of even more sophisticated machines.

Q 8. How do you troubleshoot common problems encountered during textile production?

Troubleshooting in textile production involves a systematic approach. It starts with identifying the problem – is it a yarn issue, a machine malfunction, a process flaw, or something else? I typically use a structured approach, similar to a detective investigating a crime scene. I gather evidence (e.g., inspecting the fabric, checking machine logs, talking to operators) and then analyze the data.

For example, if we’re seeing excessive yarn breakage on a spinning machine, I would first check the machine’s settings (tension, speed), then examine the quality of the raw fiber (length, strength, cleanliness). If the problem persists, I’d move on to checking the machine components for wear or damage and consider whether the lubricant needs replacing. A similar methodical approach is used for issues in weaving, knitting, dyeing, or finishing. Root cause analysis techniques like the 5 Whys are invaluable.

- Visual Inspection: Closely examine the fabric for defects like broken ends, slubs, or mispicks.

- Machine Logs: Review machine data to identify patterns or anomalies.

- Operator Feedback: Consult with the operators who work with the machinery to understand their observations and insights.

- Testing: Conduct laboratory tests (strength, colorfastness, etc.) to verify the quality of the materials and finished product.

Q 9. What are the key performance indicators (KPIs) used to measure efficiency in textile manufacturing?

Key Performance Indicators (KPIs) in textile manufacturing track efficiency and productivity across various stages. They provide a quantifiable measure of success and help identify areas for improvement. Some crucial KPIs include:

- Production Output: Measured in meters of fabric produced per hour or day, this reflects the overall production rate.

- Machine Efficiency (OEE): Overall Equipment Effectiveness combines availability, performance, and quality rate to assess how effectively machines are utilized.

- First Pass Yield: Percentage of defect-free products produced without rework, reflecting quality control effectiveness. A high FPY means fewer resources are wasted on fixing errors.

- Waste Reduction: This tracks the amount of raw materials, energy, and water used per unit of output. Minimizing waste is crucial for sustainability and profitability.

- Defect Rate: The percentage of defective products produced helps identify weak links in the production process. This KPI often ties directly to customer satisfaction.

- Lead Time: The time it takes to complete the entire production process from raw materials to finished goods. Shorter lead times translate to faster delivery and increased responsiveness to customer needs.

- Inventory Turnover: The rate at which inventory is sold or used, showing how efficiently raw materials are transformed into finished products.

By monitoring these KPIs, manufacturers can make data-driven decisions to optimize processes, reduce costs, and improve overall performance.

Q 10. Explain the importance of sustainability in modern textile manufacturing.

Sustainability is no longer a ‘nice-to-have’ but a necessity in modern textile manufacturing. Consumers are increasingly demanding environmentally and socially responsible products, and regulations are becoming stricter. A sustainable approach encompasses several key areas:

- Eco-Friendly Materials: Using organic cotton, recycled fibers, or innovative materials like Tencel, which have a lower environmental impact throughout their lifecycle.

- Water Conservation: Implementing water-efficient dyeing and finishing processes, such as closed-loop systems, to minimize water consumption and reduce pollution.

- Energy Efficiency: Utilizing energy-saving machinery, renewable energy sources, and optimizing production processes to reduce energy consumption and carbon footprint.

- Waste Management: Implementing strategies to reduce textile waste through recycling, upcycling, or innovative solutions, reducing landfill burden.

- Ethical Labor Practices: Ensuring fair wages, safe working conditions, and responsible sourcing of materials to protect workers’ rights and uphold ethical standards.

Embracing sustainability not only benefits the environment but also enhances brand reputation, reduces costs in the long run (through waste reduction), and increases customer loyalty. It’s a win-win situation.

Q 11. What are the different types of fabric defects and how are they identified?

Fabric defects can occur at various stages of production, from fiber preparation to finishing. Identifying these defects requires a keen eye and understanding of the manufacturing process. Here are some common examples:

- Yarn Defects: Slubs (thick places in the yarn), neps (small tangled fibers), broken ends (yarn breakage), uneven thickness.

- Weaving Defects: Broken ends, mispicks (incorrectly interlaced weft yarns), floats (length of yarn on the surface), holes, barre (uneven width).

- Knitting Defects: Run stitches, dropped stitches, laddering (vertical split in the fabric), holes, fabric distortion.

- Dyeing and Finishing Defects: Uneven color, shading, stains, creases, shrinkage issues.

Identification typically involves visual inspection under controlled lighting conditions, sometimes using magnification tools. For subtle defects, specialized testing equipment might be required, such as microscopy or image analysis systems.

Q 12. Describe your experience with different types of textile testing equipment.

Throughout my career, I have worked extensively with various textile testing equipment. This includes:

- Tensile Strength Tester: Measures the strength and elongation of yarns and fabrics. This is crucial for ensuring the durability and performance of textiles.

- Bursting Strength Tester: Determines the resistance of fabrics to pressure, relevant for applications requiring high strength like airbags or protective clothing.

- Colorfastness Tester: Assesses the resistance of dyed fabrics to fading from washing, light exposure, or rubbing. This ensures color consistency and longevity.

- Abrasion Tester: Measures the fabric’s resistance to wear and tear, predicting the fabric’s life cycle.

- Microscope: Used for detailed analysis of fiber structure, yarn properties, and fabric defects at the microscopic level.

- Spectrophotometer: Accurately measures and compares the color of fabrics, critical for consistency and matching across production batches.

My experience with these instruments allows me to perform thorough quality control, assess material suitability, and troubleshoot production problems effectively.

Q 13. How do you manage production schedules and meet deadlines in a fast-paced environment?

Managing production schedules in a fast-paced environment requires meticulous planning and effective communication. I employ several strategies:

- Detailed Production Planning: Creating a comprehensive schedule that takes into account machine capacity, material availability, and order deadlines. Software tools like ERP systems are often used for this purpose.

- Capacity Planning: Evaluating available resources and allocating them efficiently to different production lines. This anticipates potential bottlenecks and allows for proactive adjustments.

- Real-time Monitoring: Using digital dashboards to track production progress, identify delays, and implement corrective actions. Any deviation from the plan triggers immediate attention.

- Effective Communication: Maintaining clear and consistent communication with production teams, management, and clients to ensure everyone is aligned and informed of any changes or issues.

- Contingency Planning: Developing backup plans to handle unexpected delays or disruptions, ensuring we can still meet deadlines. This could involve prioritizing critical orders or adjusting resource allocation.

Proactive monitoring and communication are key. I’ve often used Kanban boards or other visual management systems to visualize workflow, identify bottlenecks, and streamline the production process. It’s about being flexible and adaptable in a dynamic setting.

Q 14. Explain your experience with different types of textile finishing agents.

Textile finishing agents are crucial for enhancing fabric properties like softness, durability, water resistance, and wrinkle resistance. My experience encompasses a wide range of agents:

- Softeners: Improve the hand feel of fabrics, making them softer and more comfortable. These can be silicone-based, cationic, or non-ionic depending on the desired effect.

- Water Repellents: Provide water resistance without compromising breathability, often used in outdoor apparel or upholstery. Fluorocarbon-based agents are common, but more eco-friendly alternatives are being developed.

- Wrinkle Resist Finishes: Reduce fabric creasing and enhance their wrinkle recovery properties, improving ease of care and appearance. These can be resin-based or other chemical treatments.

- Flame Retardants: Increase the fabric’s resistance to ignition, crucial for safety in various applications. The specific type used depends on the regulations and the application (e.g., children’s sleepwear).

- Antimicrobial Finishes: Incorporate antimicrobial agents to inhibit the growth of bacteria and fungi, preventing odor and improving hygiene. These are commonly found in sportswear or medical textiles.

The selection of finishing agents depends on the fiber type, the intended application of the fabric, and environmental considerations. I prioritize using sustainable and eco-friendly agents whenever possible, aligning with modern industry best practices.

Q 15. Describe your experience with different types of looms or knitting machines.

My experience encompasses a wide range of weaving and knitting machinery. In weaving, I’ve worked extensively with both conventional shuttle looms and advanced air-jet looms. Shuttle looms, while simpler, offer excellent control over complex patterns, ideal for high-quality, intricate fabrics. Air-jet looms, on the other hand, are significantly faster and more efficient for mass production of simpler designs. I’m also familiar with rapier looms, known for their versatility in handling various yarns. In knitting, I have experience with both circular knitting machines, perfect for creating seamless tubular fabrics like socks and sweaters, and flat knitting machines, which allow for greater design flexibility and the creation of flat panels. My experience includes troubleshooting, maintenance, and optimizing the performance of these machines to maximize efficiency and minimize downtime. For example, I once identified a recurring jam in an air-jet loom by carefully analyzing the yarn feed mechanism, ultimately saving the company significant production time and reducing waste.

- Shuttle Looms: Ideal for intricate designs, slower production speed.

- Air-Jet Looms: High-speed production, suitable for simpler designs.

- Rapier Looms: Versatile, handles various yarns.

- Circular Knitting Machines: Produces seamless tubular fabrics.

- Flat Knitting Machines: Allows for greater design flexibility and flat panels.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle customer complaints or quality issues?

Handling customer complaints and quality issues requires a systematic approach. My first step is always to listen carefully to the customer and understand their concerns completely. This involves gathering all relevant information, including photographs, fabric samples, and order details. Then, I initiate a thorough investigation to pinpoint the root cause of the problem. This might involve inspecting the production process, analyzing fabric samples in our lab, or even consulting with our suppliers. Once the root cause is identified, I work with the relevant team to develop and implement corrective actions. This might involve adjusting machine settings, improving quality control procedures, or retraining personnel. Finally, I communicate the findings and the corrective actions to the customer, offering appropriate compensation or solutions. For instance, we once received a complaint about inconsistencies in the dyeing of a large batch of fabric. Our investigation revealed a problem with the dye bath temperature regulation. After correcting the issue, we re-dyed the affected fabric and compensated the customer for the delay.

Q 17. What are the health and safety regulations relevant to textile manufacturing?

Health and safety regulations in textile manufacturing are crucial for worker well-being and legal compliance. These regulations cover a broad range of areas, including:

- Machine guarding: Ensuring all moving parts of machinery are properly guarded to prevent accidents.

- Noise control: Implementing measures to reduce noise levels to safe limits, including the use of hearing protection.

- Dust and fiber control: Utilizing ventilation systems and personal protective equipment (PPE) to minimize exposure to dust and fibers, which can cause respiratory problems like byssinosis.

- Chemical handling: Safe storage, handling, and disposal of chemicals used in dyeing and finishing processes.

- Ergonomics: Designing workstations and work processes to minimize strain and injury.

- Personal Protective Equipment (PPE): Providing and ensuring the correct use of PPE such as gloves, eye protection, and respiratory masks.

- Emergency procedures: Establishing clear emergency procedures and training employees on how to respond to emergencies.

Compliance with these regulations is paramount. Regular safety inspections, employee training, and adherence to best practices are essential to maintain a safe and healthy work environment.

Q 18. Explain your experience with Lean Manufacturing principles in a textile setting.

Lean manufacturing principles have been instrumental in optimizing our textile production. We’ve implemented several key Lean techniques, including:

- Value Stream Mapping: Identifying and eliminating waste in the entire production process, from raw material to finished product. This helped us streamline our processes and reduce lead times.

- 5S Methodology (Sort, Set in Order, Shine, Standardize, Sustain): Creating a cleaner, more organized, and efficient workspace. This led to a reduction in errors and improved productivity.

- Kaizen (Continuous Improvement): Regularly reviewing and improving our processes to identify and eliminate inefficiencies. This is an ongoing process that involves all team members.

- Kanban: Implementing a visual system to manage the flow of materials and work in progress, reducing inventory and preventing bottlenecks.

For example, by implementing Kanban, we reduced our work-in-progress inventory by 30%, leading to significant cost savings and faster turnaround times.

Q 19. How do you manage inventory and reduce waste in textile production?

Inventory management and waste reduction are critical in textile production, where raw materials and finished goods can be costly. We utilize several strategies:

- Just-in-Time (JIT) Inventory: Receiving raw materials only when needed, minimizing storage costs and reducing the risk of obsolescence. This requires close collaboration with suppliers.

- Demand Forecasting: Accurately predicting future demand to optimize production schedules and avoid overproduction. This minimizes waste and storage costs.

- Inventory Tracking Systems: Utilizing software to track inventory levels in real-time, providing insights into usage patterns and enabling proactive ordering.

- Waste Reduction Initiatives: Implementing programs to reduce waste at each stage of production, including optimizing cutting patterns to minimize fabric scraps and recycling wastewater.

For instance, we implemented a new cutting pattern optimization software that reduced fabric waste by 15%, resulting in significant cost savings.

Q 20. Describe your experience with Six Sigma or other quality improvement methodologies.

My experience with Six Sigma methodologies has been invaluable in improving quality and reducing defects. We’ve used DMAIC (Define, Measure, Analyze, Improve, Control) to address several quality challenges. For example, we once used DMAIC to address a problem with inconsistent thread count in our woven fabrics. We defined the problem, measured the current defect rate, analyzed the root causes (which included variations in machine tension and yarn quality), implemented improvements (such as recalibrating the machines and improving yarn selection), and established control measures to prevent recurrence. This resulted in a significant reduction in defects and improved customer satisfaction.

Q 21. How do you stay up-to-date with the latest advancements in textile technology?

Staying current in the dynamic textile industry requires continuous learning. I actively participate in industry conferences, workshops, and trade shows, where I learn about the latest technologies and innovations. I also subscribe to industry publications, journals, and online resources, keeping abreast of advancements in areas such as sustainable materials, smart manufacturing, and automation. Furthermore, I engage in online courses and professional development programs to enhance my knowledge and skills. Networking with colleagues and experts in the field is also crucial, fostering collaboration and sharing best practices. For instance, I recently attended a conference on sustainable textile manufacturing, learning about new eco-friendly dyeing techniques and biodegradable materials that could significantly reduce our environmental impact.

Q 22. What are the different types of fabric structures?

Fabric structures are essentially the way yarns are interwoven or interlooped to create a textile. Understanding these structures is crucial for determining the fabric’s final properties like drape, strength, and texture. There are three main categories:

- Woven Structures: These are created by interlacing two sets of yarns at right angles – the warp (lengthwise) and weft (crosswise). Think of a traditional tapestry or a simple cotton shirt. Variations include plain weave (the simplest, like a checkerboard), twill weave (diagonal lines, like denim), and satin weave (smooth, lustrous surface, like satin sheets).

- Knit Structures: Instead of interlacing, yarns are interlooped to form a continuous fabric. This creates more stretch and flexibility than woven fabrics. Examples include jersey (used in t-shirts), rib knit (with vertical ribs), and purl knit (more textured).

- Non-Woven Structures: These fabrics aren’t made by weaving or knitting. Instead, fibers are bonded together mechanically, chemically, or thermally. Examples include felt (made from matted fibers), and some types of geotextiles used in construction.

The choice of fabric structure is dictated by the end-use application. For instance, a strong twill weave is ideal for workwear, while a soft jersey knit is preferred for comfortable clothing.

Q 23. Explain the importance of colorfastness in textiles.

Colorfastness refers to a textile’s ability to retain its color despite exposure to various factors like light, washing, rubbing, and perspiration. It’s paramount for several reasons:

- Maintaining Appearance: A colorfast fabric will look new for longer, preventing fading or discoloration that diminishes its aesthetic appeal.

- Customer Satisfaction: Poor colorfastness leads to dissatisfied customers and potential returns. Imagine buying a vibrant red shirt that washes out to pink!

- Brand Reputation: Consistent and reliable colorfastness is crucial for maintaining a brand’s reputation for quality and durability.

- Safety and Regulations: In certain industries (e.g., children’s clothing), strict regulations govern the allowable colorfastness levels to prevent harmful dyes from leaching.

Testing for colorfastness is done using standardized methods and scales, ensuring consistency and meeting industry requirements. The results are often expressed as a rating, indicating the level of colorfastness achieved.

Q 24. Describe your experience with different textile dyeing techniques.

My experience encompasses a wide range of dyeing techniques, from traditional methods to advanced technologies. I’ve worked extensively with:

- Vat dyeing: A process used for deep, vibrant colors on cellulosic fibers like cotton. It involves reducing insoluble dyes into a soluble form, dyeing the fabric, and then re-oxidizing the dye to make it insoluble again. It’s known for its excellent colorfastness.

- Reactive dyeing: Another method for cellulosic fibers, reactive dyes form a chemical bond with the fiber, resulting in exceptional colorfastness and wash durability. This is often used for bright, highly saturated colors.

- Disperse dyeing: Suitable for synthetic fibers such as polyester, disperse dyes are finely dispersed in water and absorbed by the fiber. It’s commonly used for bright, lively colors in sportswear and other synthetic garments.

- Acid dyeing: Used for dyeing wool and silk, acid dyes are applied in an acidic bath, creating a good wash fastness. The shades obtained are usually softer and less intense.

My experience also includes optimizing dyeing processes to minimize water and energy consumption, aligning with sustainable manufacturing practices. I’m adept at troubleshooting issues related to dye uptake, color consistency, and achieving desired color shades.

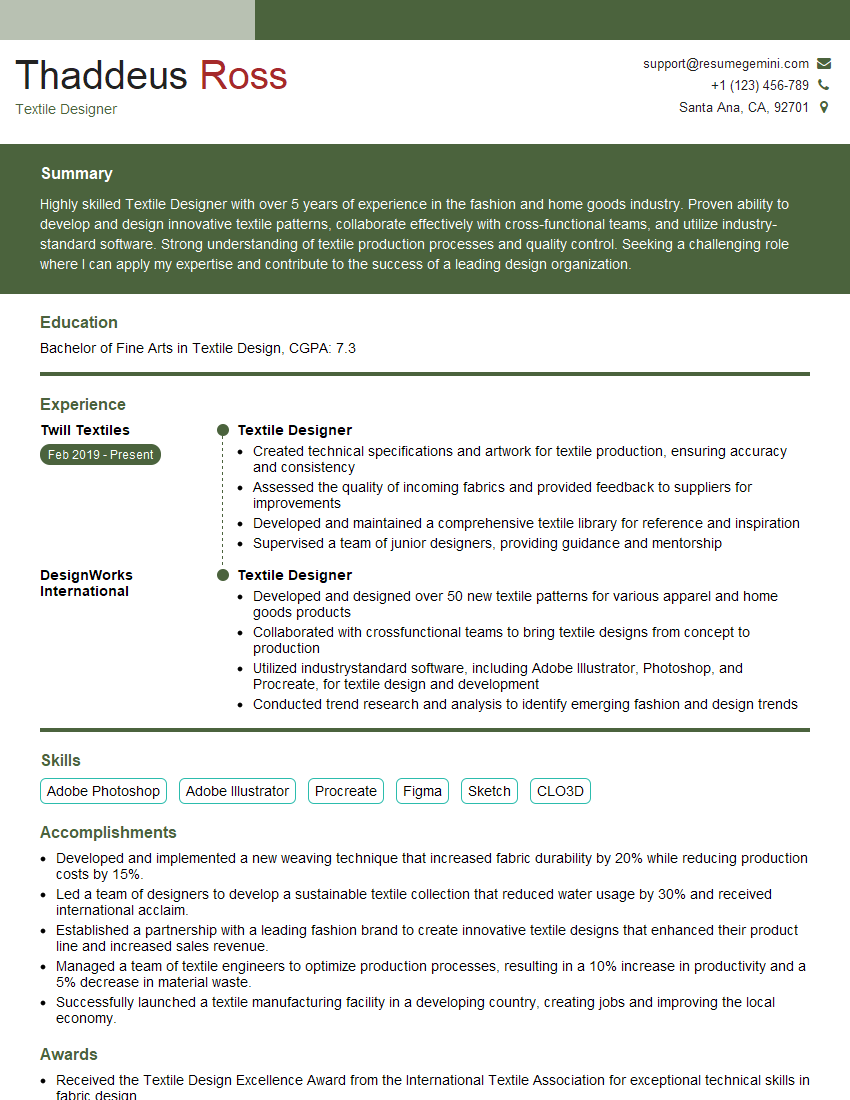

Q 25. What software programs are you proficient in for textile design or manufacturing?

I’m proficient in several software programs commonly used in textile design and manufacturing. This includes:

- Adobe Illustrator: For creating intricate designs and patterns.

- Adobe Photoshop: For image manipulation and color correction.

- CAD software (e.g., Lectra, Gerber): For pattern making, grading, and marker making, optimizing fabric usage and minimizing waste in the cutting process.

- ERP systems (e.g., SAP): For managing inventory, production planning, and order tracking.

My ability to integrate these tools allows me to streamline the design and manufacturing process, ensuring accuracy and efficiency.

Q 26. Explain the process of developing a new textile product, from concept to production.

Developing a new textile product is a multi-stage process, involving careful planning and execution. Here’s a typical workflow:

- Concept and Design: This begins with identifying market needs, trends, and developing initial design concepts (sketches, mood boards, color palettes).

- Material Selection: Choosing the appropriate yarn, fabric structure, and dyeing/printing methods based on the design requirements and target market.

- Prototyping and Sampling: Creating small samples to test the feasibility of the design, fabric properties, and assess the overall quality.

- Testing and Quality Control: Rigorous testing is crucial to ensure the product meets quality standards for colorfastness, durability, and other relevant properties.

- Production Planning: Developing a production plan that outlines the manufacturing process, timelines, and resource allocation.

- Manufacturing: The actual production process, including yarn preparation, weaving/knitting, dyeing/printing, finishing, and inspection.

- Quality Assurance: Final inspection of the finished product to ensure it meets the quality standards set earlier.

- Launch and Marketing: Once the product meets the required standards, it’s launched into the market with appropriate marketing strategies.

Throughout this process, close collaboration between design, production, and quality control teams is essential for successful product development.

Q 27. How do you manage a team of textile workers effectively?

Effective team management in the textile industry requires a blend of strong leadership, communication, and understanding of the specific demands of the work. My approach focuses on:

- Clear Communication: Maintaining open and transparent communication channels with team members, ensuring everyone understands their roles and responsibilities.

- Motivation and Empowerment: Creating a positive and supportive work environment where employees feel valued and empowered to contribute their best.

- Training and Development: Providing opportunities for skill enhancement and professional growth, keeping the team updated on industry best practices and technological advancements.

- Problem-Solving and Collaboration: Encouraging teamwork and collaboration in problem-solving, providing support and guidance to overcome challenges.

- Performance Monitoring and Feedback: Regularly monitoring team performance, providing constructive feedback, and recognizing individual achievements.

I believe in leading by example and fostering a collaborative culture where everyone feels comfortable sharing ideas and contributing to the team’s overall success. I have consistently demonstrated the ability to build strong, high-performing teams in demanding production environments.

Q 28. Describe your experience with different types of textile printing methods.

My experience with textile printing methods includes a variety of techniques, each with its unique advantages and applications:

- Screen Printing: A traditional method that uses stencils to apply inks to fabric. It’s versatile, suitable for large-scale production, and cost-effective for simple designs.

- Rotary Screen Printing: A more advanced screen printing technique using a rotating cylinder, allowing for faster and more precise printing, ideal for high-volume production.

- Digital Printing: Uses inkjet technology to directly print designs onto fabric. It’s ideal for intricate designs, small production runs, and rapid prototyping. However, the initial investment can be significant.

- Heat Transfer Printing: Involves transferring pre-printed designs onto fabric using heat and pressure. It’s efficient for producing customized designs or small quantities.

Selecting the appropriate printing method depends on factors such as design complexity, fabric type, desired quality, and production volume. My experience allows me to choose and optimize the best method for any given project.

Key Topics to Learn for Knowledge of Textile Manufacturing Processes Interview

- Fiber Properties and Selection: Understanding natural (cotton, wool, silk) and synthetic (polyester, nylon, acrylic) fiber characteristics, their suitability for different textile applications, and the impact on final product quality.

- Yarn Manufacturing: Familiarize yourself with spinning processes (ring spinning, open-end spinning, air-jet spinning), their advantages and disadvantages, and how yarn properties influence fabric construction.

- Fabric Construction: Master the various weaving (plain, twill, satin) and knitting (weft, warp) techniques. Understand how fabric structure affects drape, durability, and aesthetic qualities. Be prepared to discuss different fabric finishes.

- Dyeing and Finishing: Learn about different dyeing methods (reactive, disperse, acid), their applications, and environmental considerations. Understand various finishing techniques like bleaching, mercerizing, and water-repellent treatments.

- Textile Testing and Quality Control: Become familiar with common textile testing methods used to assess strength, colorfastness, shrinkage, and other crucial quality parameters. Understand the importance of quality control throughout the manufacturing process.

- Textile Machinery and Equipment: Develop a basic understanding of the machinery involved in different stages of textile production. This includes spinning machines, weaving looms, knitting machines, and finishing equipment.

- Sustainability and Ethical Considerations: Demonstrate awareness of sustainable textile practices, eco-friendly materials, and ethical sourcing. This is increasingly important in the industry.

- Troubleshooting and Problem-Solving: Be prepared to discuss how you would approach common challenges encountered in textile manufacturing, such as fabric defects, production bottlenecks, and quality issues.

Next Steps

Mastering Knowledge of Textile Manufacturing Processes is crucial for career advancement in this dynamic industry. A strong understanding of these processes demonstrates your technical expertise and problem-solving abilities, making you a highly desirable candidate. To maximize your job prospects, it’s essential to create a compelling and ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We provide examples of resumes tailored to Knowledge of Textile Manufacturing Processes to guide you through the process. Take advantage of these resources to present yourself in the best possible light and achieve your career goals.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good