Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Laser Beam Characterization interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Laser Beam Characterization Interview

Q 1. Explain the concept of beam quality (M²).

Beam quality, often represented by the M2 factor (pronounced ‘M-squared’), is a crucial parameter describing how closely a laser beam’s divergence matches that of an ideal Gaussian beam. An ideal Gaussian beam is the benchmark, possessing the minimum possible divergence for a given beam waist. M2 is a dimensionless quantity; a value of M2 = 1 indicates an ideal Gaussian beam, while values greater than 1 represent beams with more divergence than an ideal Gaussian beam of the same waist diameter. The higher the M2 value, the poorer the beam quality, meaning the beam spreads out more rapidly.

Think of it like throwing a ball: an M2 of 1 is like a perfectly thrown ball that travels far with minimal spread. A higher M2 is like throwing a ball that disperses quickly in the air. In laser applications, good beam quality is essential for precision tasks like laser cutting, micromachining, or optical communication, as it ensures a tightly focused beam at the target.

Q 2. How do you measure beam diameter?

Measuring beam diameter isn’t straightforward because the intensity of a laser beam gradually decreases with distance from the center. We need a defined criterion to determine the beam’s edge. Common methods use the ‘D4σ’ method or the ‘knife-edge’ method.

- D4σ method: This method defines the beam diameter as the distance between points where the intensity falls to 1/e2 (approximately 13.5%) of the peak intensity. This is commonly used because many lasers have a Gaussian profile. A beam profiler with a camera directly measures the intensity profile and automatically calculates this diameter.

- Knife-edge method: A razor blade or similar sharp edge is scanned across the beam, and the power transmitted through the beam is measured. The derivative of this curve gives the intensity profile, from which the D4σ diameter can be derived. This is a simpler, albeit more manual, technique than using a beam profiler.

The choice of method depends on factors such as beam power, profile shape and accuracy requirements. For high-power lasers, the knife-edge method is safer than directly using a camera based beam profiler which might be damaged.

Q 3. Describe different methods for measuring laser beam power.

Measuring laser beam power involves capturing the entire beam’s energy and converting it into a measurable signal. Several methods exist:

- Power meters: These use thermal, photodiode, or pyroelectric sensors. Thermal sensors absorb the beam’s energy, causing a temperature rise that’s measured. Photodiodes convert light directly into electrical current, and pyroelectric sensors detect changes in their temperature caused by the absorbed light. Power meters offer a direct reading of power and are widely used.

- Calorimeters: For high-power lasers, calorimeters are preferred as they are less likely to be damaged. They measure the heat generated when the beam is absorbed by a known mass. The temperature increase is then used to calculate the power.

- Photodetectors and power meters combined with integrating spheres: Integrating spheres diffuse the incident beam so that it distributes evenly over the surface of the photodetector. This is advantageous for beams with a non-uniform profile. The uniform distribution over a large surface minimizes the risk of damage to the detector, improves the measurement accuracy and lowers the risk of detector saturation

The choice of method depends on the laser’s power level, wavelength, and pulse characteristics. For pulsed lasers, additional considerations such as pulse energy and repetition rate are essential.

Q 4. What are the common beam profiles (e.g., Gaussian, top-hat)?

Laser beams can exhibit various intensity profiles, describing how the power is distributed across the beam’s cross-section. Some common profiles include:

- Gaussian profile: This is the most common profile, characterized by a bell-shaped curve. The intensity drops exponentially as you move away from the center. Many lasers naturally produce Gaussian beams, and they are easy to model mathematically.

- Top-hat profile: This profile has a relatively uniform intensity across the beam’s central region, dropping sharply at the edges. This is desirable in many applications where uniform illumination is required. Often created by shaping the initial Gaussian profile, using spatial filters or beam shaping optics

- Flat-top profile: Similar to top hat but the intensity is relatively uniform across a wider area and the transition between the uniform core and the edges is gradual.

The beam profile significantly impacts the application. A Gaussian beam is best for focusing, while a top-hat beam is optimal for applications requiring uniform illumination.

Q 5. Explain the significance of beam divergence.

Beam divergence describes how quickly a laser beam expands as it propagates. It’s typically measured in milliradians (mrad) or degrees. A low divergence is crucial for applications requiring a tightly focused beam over a long distance, such as laser rangefinders or long-distance optical communication. A high divergence means the beam spreads quickly, making it less effective for precision work.

Imagine shining a laser pointer: a laser with low divergence will create a small, bright spot far away, while a laser with high divergence will create a larger, dimmer spot that spreads out rapidly. This is directly related to the beam quality M2; lower M2 means lower divergence.

Q 6. How do you characterize beam ellipticity?

Beam ellipticity refers to the deviation of the beam’s cross-section from a perfect circle. It’s quantified by the ratio of the beam’s major axis (longest diameter) to its minor axis (shortest diameter). An ellipticity of 1 indicates a circular beam. Ellipticity is often caused by asymmetries in the laser resonator or optical components. It can affect focusing ability and uniformity of illumination.

To characterize beam ellipticity, you measure the beam diameter along two orthogonal axes using techniques like the D4σ method mentioned earlier. The ratio of these diameters gives the ellipticity. Beam profilers often automatically provide these measurements.

Q 7. What are the limitations of different beam profiling techniques?

Different beam profiling techniques have limitations:

- Knife-edge method: Can be time-consuming and less accurate for complex beam shapes. The accuracy depends heavily on the sharpness of the knife edge and precision of the movement system.

- CCD camera based profilers: Can be damaged by high power lasers and are susceptible to saturation at high intensities. Also, the spatial resolution of the camera is a limiting factor in characterizing fine details of the beam profile.

- Pyroelectric detectors: Sensitive to ambient temperature variations affecting the measurement accuracy and are less suitable for continuous wave (CW) lasers than thermal sensors

Choosing an appropriate technique requires careful consideration of the laser’s characteristics and the desired accuracy. For instance, for high-power lasers, the knife-edge method or an integrating sphere-photodetector combination might be more suitable than a direct camera based measurement.

Q 8. Describe the principles behind beam propagation factor (M²) measurement.

The beam propagation factor, also known as M², is a crucial parameter characterizing the quality of a laser beam. It quantifies how much the beam’s divergence differs from that of an ideal Gaussian beam. A Gaussian beam is the theoretical benchmark, exhibiting the minimum possible divergence for a given beam waist. The M² value is dimensionless and always greater than or equal to 1; M² = 1 represents a perfect Gaussian beam.

Measurement involves analyzing the beam’s width at various distances from the beam waist. This is typically done using a beam profiler that captures the beam’s intensity profile. By fitting the measured beam widths to a mathematical model that accounts for beam divergence, the M² value can be calculated. Several methods exist, including the second moment method and the ISO 11146 standard. The ISO 11146 method is widely accepted, outlining precise procedures for measuring beam parameters.

Imagine throwing a perfectly formed snowball (Gaussian beam). It travels a considerable distance before significantly spreading. Now, imagine throwing a clump of snow (non-Gaussian beam). It spreads much faster. The M² factor quantifies this difference in spreading, telling us how close our actual beam is to that ideal snowball.

Q 9. How do you compensate for beam wander during measurements?

Beam wander, the erratic movement of the beam’s centroid, is a major challenge during M² measurements. It introduces errors in determining the beam’s width at different propagation distances. Compensation strategies are crucial for accurate measurements. Several techniques are commonly employed:

- Averaging multiple measurements: Capturing multiple beam profiles and averaging the results reduces the influence of random wander. This is a simple yet effective approach, particularly for slower wander.

- Active beam stabilization: Employing a feedback system that actively corrects for beam drift using mirrors or other optical elements. This is ideal for significant or persistent wander.

- Using a fast beam profiler: A profiler with a high acquisition rate can capture many profiles rapidly, allowing for the detection and subsequent removal of wander effects through appropriate algorithms.

- Spatial filtering: Using a spatial filter prior to the beam profiler to remove high-frequency fluctuations which contribute to beam wander. This is not always feasible or desirable, though.

The choice of technique depends on the severity of beam wander and the available equipment. Often, a combination of approaches is most effective.

Q 10. What are the effects of atmospheric turbulence on beam propagation?

Atmospheric turbulence significantly affects beam propagation, mainly by introducing random variations in the refractive index of the air. These variations cause the beam to experience:

- Beam wander: The beam’s centroid shifts randomly.

- Beam broadening: The beam’s spatial profile expands due to the scattering effect of turbulence.

- Intensity fluctuations: The beam’s intensity fluctuates randomly, leading to scintillation (twinkling effect).

- Wavefront distortion: The wavefront of the beam becomes distorted, impacting its focusing ability.

These effects are particularly pronounced for long propagation distances and strong turbulence conditions. The strength of turbulence is often quantified using parameters like the refractive index structure parameter (Cn²). Mitigation techniques include adaptive optics (for wavefront correction), using shorter propagation paths, or employing techniques like spatial diversity (using multiple receiver points).

Imagine shining a laser pointer through a hot summer day. You see that the beam ‘wiggles’ and its brightness changes – that’s atmospheric turbulence in action.

Q 11. Explain the significance of the Rayleigh range.

The Rayleigh range (zR) is a critical parameter defining the length of a laser beam’s near-field region. It represents the distance from the beam waist (the narrowest point of the beam) where the beam’s cross-sectional area doubles. Beyond the Rayleigh range, the beam is considered to be in the far-field region, where it diverges significantly. It’s calculated as:

zR = πw0²/λ

where w0 is the beam waist radius and λ is the wavelength of the laser.

The Rayleigh range provides a measure of the beam’s depth of focus; a longer Rayleigh range indicates a longer depth of focus. This is crucial for applications requiring a tightly focused beam over a certain distance. For example, in laser material processing, a longer Rayleigh range ensures uniform material treatment over the desired area. In optical microscopy, a short Rayleigh range might be desired for high resolution.

Q 12. How do you calibrate a beam profiler?

Calibrating a beam profiler is essential to ensure accurate beam measurements. This typically involves two main steps:

- Spatial calibration: Determining the relationship between pixel coordinates on the profiler’s sensor and the actual physical dimensions of the beam. This is often achieved using a known object of precise dimensions, such as a calibrated slit or a precisely spaced array of pinholes. The profiler’s software then uses this information to convert pixel counts to real-world measurements.

- Radiometric calibration: Determining the relationship between the measured intensity values and the actual optical power of the beam. This often involves using a calibrated power meter to measure the total power of the beam and then comparing it with the integrated intensity value reported by the beam profiler. This allows you to convert the profiler’s readings into absolute power units.

The calibration procedures are specific to the manufacturer and the profiler’s model. It’s crucial to follow the manufacturer’s instructions closely. Regular calibration is necessary to maintain accuracy, especially for high-precision measurements.

Q 13. What are the safety precautions when working with high-power lasers?

Working with high-power lasers demands strict adherence to safety protocols. Here are some crucial precautions:

- Laser safety eyewear: Always wear appropriate laser safety eyewear with an optical density (OD) rating matching the laser’s wavelength and power.

- Controlled access: Restrict access to the laser area to authorized personnel only. Clearly mark the area with appropriate warning signs.

- Beam enclosure: Whenever possible, enclose the laser beam path to prevent accidental exposure. Use appropriate beam stops and beam dumps.

- Emergency shutdown: Ensure an easily accessible emergency shutdown mechanism is in place.

- Proper training: All personnel working with high-power lasers should receive adequate training in laser safety procedures.

- Regular maintenance: Regular checks of the laser system and safety equipment are paramount.

- Skin and eye protection: Protective clothing, including gloves and lab coats, should be worn to prevent skin exposure. Avoid any direct reflections.

Never underestimate the potential hazards. A high-power laser beam can cause serious and permanent eye damage or skin burns.

Q 14. What are the different types of laser beam profilers?

Several types of laser beam profilers exist, each with strengths and limitations:

- CCD-based profilers: These use a charge-coupled device (CCD) camera to capture the intensity profile of the laser beam. They are relatively inexpensive and versatile, but have a limited dynamic range.

- CMOS-based profilers: These use complementary metal-oxide-semiconductor (CMOS) cameras offering faster data acquisition rates than CCDs. They also tend to be more sensitive, particularly at lower light levels.

- Scanning slit profilers: These measure the beam’s intensity profile by scanning a narrow slit across the beam. They are generally more sensitive and offer a wider dynamic range than CCD or CMOS-based profilers, but tend to be slower.

- Pyroelectric profilers: These measure the thermal energy of the laser beam and are ideal for high-power lasers, where other technologies may be damaged by the high intensity.

The best type of profiler depends on specific application requirements, such as the laser’s power, wavelength, and required measurement speed and accuracy.

Q 15. Compare and contrast knife-edge and CCD-based beam profiling methods.

Both knife-edge and CCD-based methods are used to measure laser beam profiles, providing crucial information about the beam’s shape and intensity distribution. However, they differ significantly in their approach.

The knife-edge method is a simple and relatively inexpensive technique. It involves slowly scanning a sharp blade (the ‘knife-edge’) across the beam path, measuring the transmitted power as a function of the blade’s position. By differentiating this data, you obtain the beam profile. Think of it like slowly covering a light source with a razor blade – the rate at which the light dims gives you information about the intensity at each point.

- Advantages: Simple, inexpensive, robust to some environmental factors.

- Disadvantages: Lower resolution, susceptible to diffraction effects from the knife edge, requires careful alignment.

CCD-based beam profiling, on the other hand, utilizes a charge-coupled device camera to directly capture the beam’s intensity distribution. A lens focuses the beam onto the CCD array, and each pixel registers a corresponding intensity value. This creates a high-resolution 2D map of the beam’s intensity.

- Advantages: High resolution, fast measurement times, direct visualization of the beam profile, can capture various beam shapes.

- Disadvantages: More expensive than knife-edge methods, sensitive to saturation if the beam is too intense, requires careful calibration.

In essence, knife-edge is a scanning, indirect method suitable for simpler applications, while CCD-based profiling offers superior accuracy and detail for more demanding applications where precise beam characterization is critical.

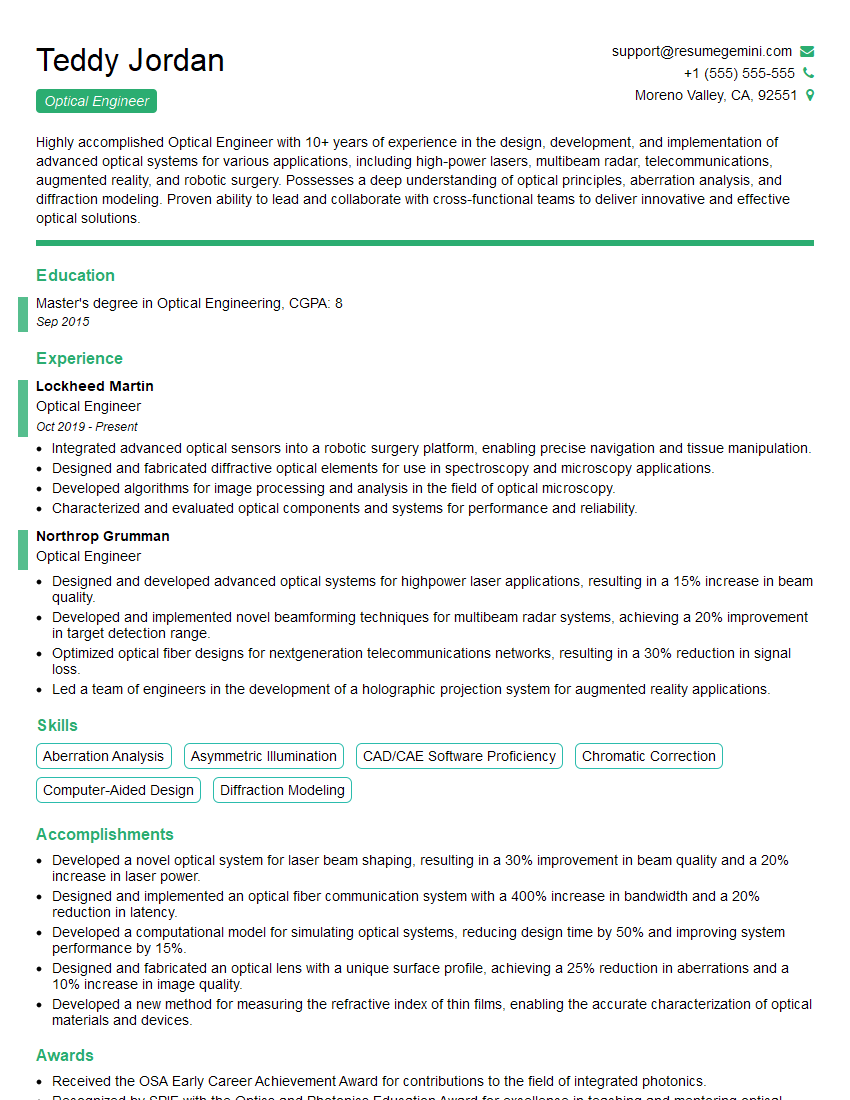

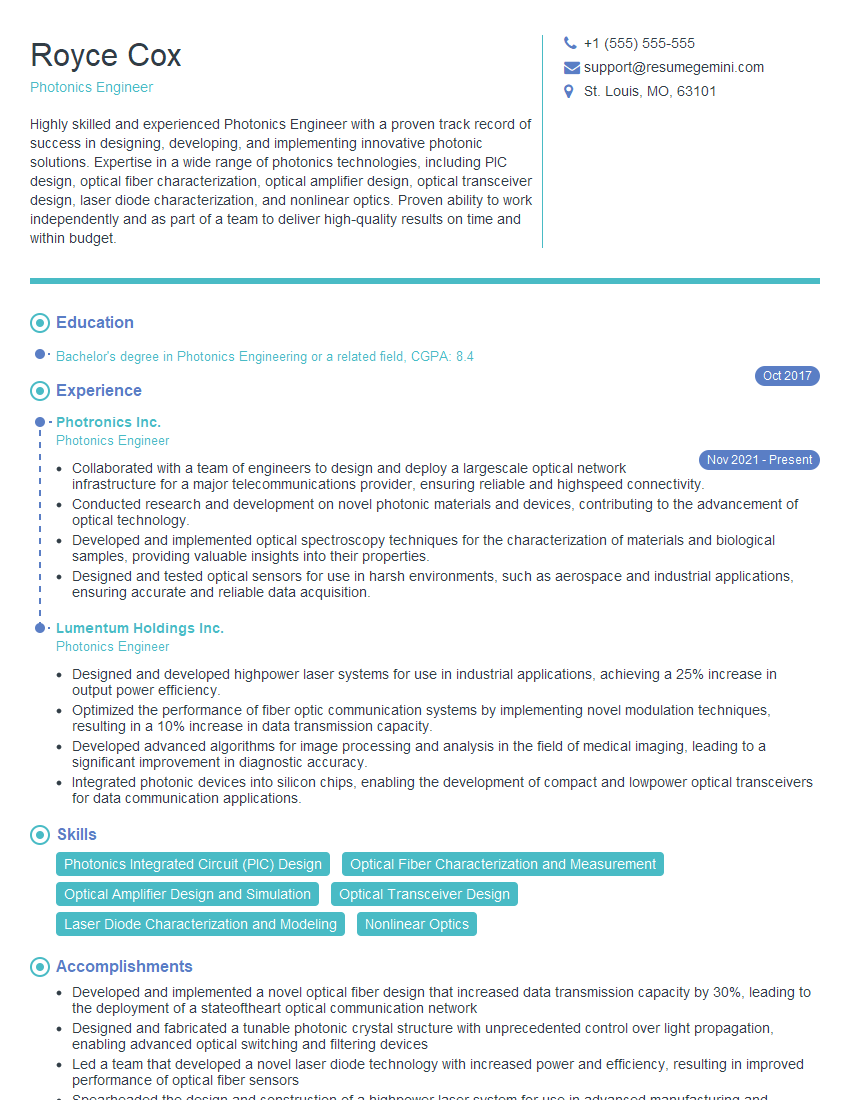

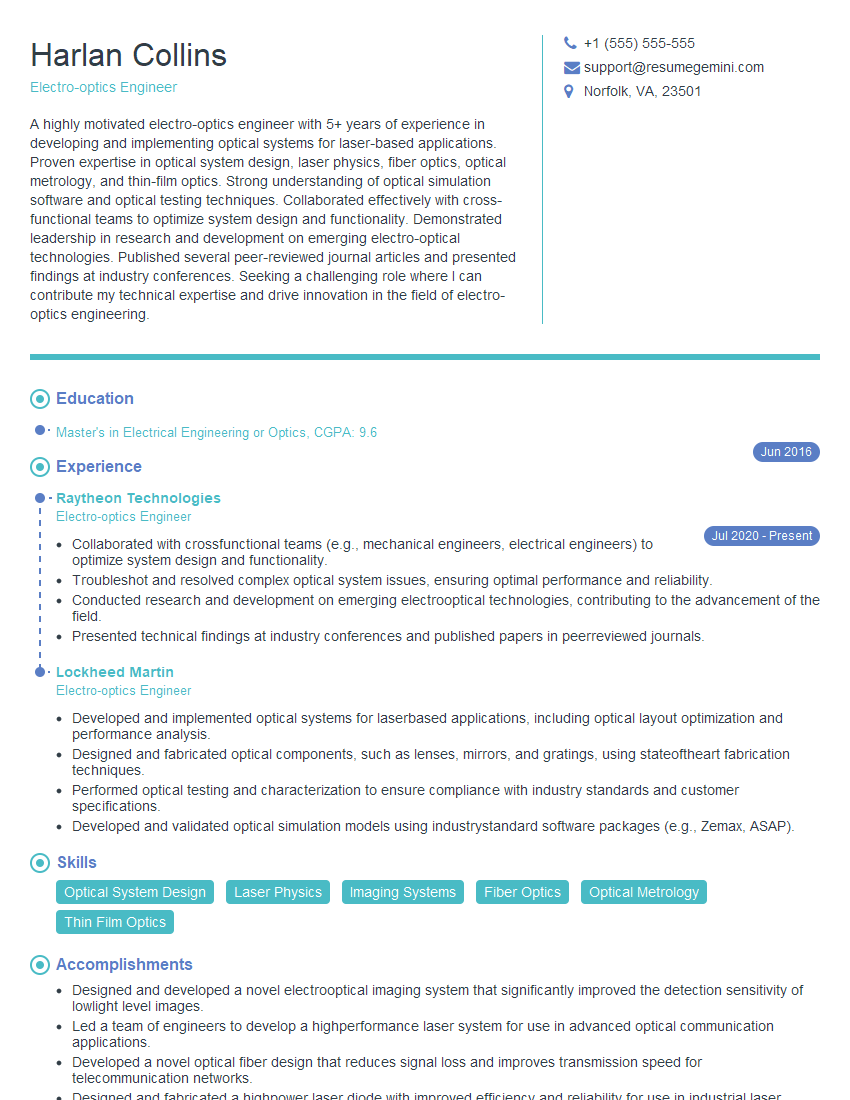

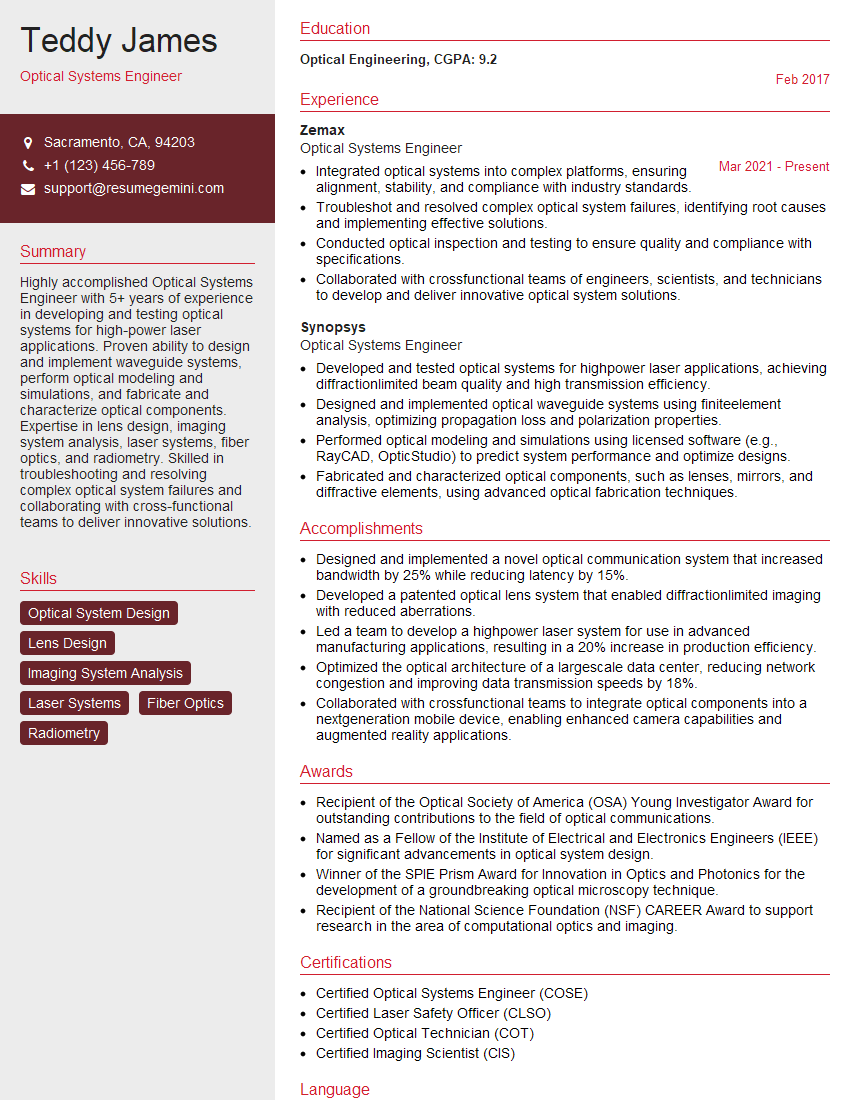

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you analyze and interpret beam profile data?

Analyzing beam profile data involves extracting key parameters to characterize the laser beam’s quality. This usually starts with generating a 2D intensity map from the measured data, whether it’s from a CCD camera or derived from a knife-edge scan. From this map, we extract various metrics.

- Beam Diameter: This is typically defined at a certain percentage of the peak intensity (e.g., 1/e2 diameter). It represents the beam’s size. Several methods exist to calculate this diameter, like using the second moment of the intensity distribution.

- Beam Shape: This assesses how closely the beam resembles an ideal Gaussian or other theoretical shapes (e.g., top-hat). Deviations indicate aberrations.

- Beam Power/Energy: Total power or energy carried by the beam, crucial for many applications.

- Beam Divergence: The rate at which the beam spreads out as it propagates, critical for applications that require a tightly focused beam.

- Beam Ellipticity: Ratio of major and minor axes of the beam, indicating astigmatism if not close to 1.

- Beam pointing stability: Measures the drift of beam center over time.

Software packages are commonly used to automate these calculations and provide visualizations. Interpreting the data involves comparing these parameters against specifications for the application. For example, if a high-precision material processing application requires a near-Gaussian beam with a tight focus, significant deviations could indicate the need for beam correction or adjustment of the laser system.

Q 17. Describe different methods for correcting beam aberrations.

Correcting beam aberrations is crucial for many laser applications demanding high beam quality. Aberrations distort the beam from its ideal shape, impacting its performance. Several methods exist to address this:

- Adaptive Optics: This sophisticated approach uses deformable mirrors or other adjustable optical elements to actively compensate for distortions in real-time. A wavefront sensor measures the aberrations, and a control system adjusts the mirror shape to correct them. This is commonly used in high-power laser systems or astronomical telescopes.

- Spatial Filters: These use pinholes to filter out high-order modes and improve the beam’s quality, leading to a more Gaussian-like profile. This is a simpler and often more cost-effective method but can reduce the beam’s power.

- Beam Expanders: Used to increase the beam diameter, thereby reducing the effects of aberrations by increasing the Rayleigh range and reducing the angular spread.

- Optical Components Optimization: Careful selection of lenses, mirrors, and other components with low aberrations. This is a preventative measure rather than a corrective one.

- Software Correction: For some applications, software can mathematically correct distortions in the measured beam profile, although this doesn’t physically correct the beam itself.

The choice of correction method depends on factors like the type and magnitude of aberration, cost constraints, and the required level of beam quality. For example, in laser surgery, adaptive optics is often preferred for its precision, whereas in a simple laser pointer, careful component selection might suffice.

Q 18. Explain the concept of spatial coherence.

Spatial coherence describes the correlation between the phases of a light wave at different points across the beam’s cross-section. A highly spatially coherent beam, like a single-mode laser, has a well-defined phase relationship across its aperture, resulting in a well-defined direction of propagation and a tight focus. Think of it as a marching band; a highly coherent beam is like a perfectly synchronized band, whereas a low-coherence beam is more like a disorganized crowd, with each member going their own way.

In contrast, a spatially incoherent beam, like light from a light bulb, lacks a consistent phase relationship. This leads to a wider spread of directions, limiting the ability to focus the light to a tight spot. The degree of spatial coherence significantly impacts applications requiring tight focusing or long propagation distances. For example, high spatial coherence is crucial for holography and interferometry, while it’s less critical for flood lighting.

Spatial coherence is often quantified using parameters like the coherence length and the Michelson interferometer fringe visibility. The higher the coherence, the narrower the fringes will be in an interferometer setup.

Q 19. What are the advantages and disadvantages of using different laser sources?

Different laser sources offer distinct advantages and disadvantages depending on the application. The selection often involves trade-offs.

- HeNe Lasers: Offer good spatial coherence, stable output, but relatively low power and specific wavelengths.

- Diode Lasers: Compact, efficient, and widely tunable wavelengths. However, they can have less spatial coherence compared to HeNe and higher noise.

- Fiber Lasers: High power, good beam quality, and robust construction, making them suitable for industrial applications. Can be more expensive than diode lasers.

- Solid-State Lasers: High power, good beam quality, and tunable wavelengths. Often used in scientific research and high-power industrial applications. Can be expensive and require significant cooling.

- Excimer Lasers: Produce ultraviolet light, used in micromachining and medical applications. Their operation is more complex and requires special safety measures.

For instance, HeNe lasers are preferred for interferometry due to their excellent spatial coherence, whereas high-power fiber lasers are favored for material processing applications due to their robustness and efficiency. The choice should consider power requirements, wavelength, coherence needs, beam quality, budget, and safety.

Q 20. How do you choose an appropriate beam profiler for a given application?

Selecting the appropriate beam profiler is crucial for accurate and meaningful results. The choice depends on several factors:

- Beam Power: High-power lasers require profilers with high damage thresholds. The profiler needs to withstand the intensity without being damaged.

- Wavelength: The profiler’s sensor needs to be compatible with the laser’s wavelength. Different sensors have different spectral sensitivities.

- Beam Size and Shape: The sensor area should be large enough to capture the entire beam, while the resolution should be sufficient to resolve the details of the beam profile.

- Measurement Speed: Applications requiring fast measurements necessitate a high-speed profiler. This is especially critical for dynamic processes.

- Budget: The cost of the profiler varies widely, from relatively inexpensive knife-edge devices to high-end CCD-based systems.

- Required Accuracy: The precision of the measurement is crucial. Some applications might require a profiler with higher accuracy than others.

For example, a simple laser pointer might only need a basic knife-edge setup, while a high-precision laser cutting application demands a high-resolution CCD-based profiler with a high dynamic range and precise calibration. Careful consideration of these factors ensures the selection of a profiler suitable for the application’s specific requirements.

Q 21. Describe your experience with beam shaping techniques.

I have extensive experience with various beam shaping techniques, crucial for optimizing laser performance in different applications. The goal is often to transform a Gaussian or other standard beam profile into a desired shape, such as a uniform top-hat profile or a specific intensity distribution.

- Diffractive Optical Elements (DOEs): These utilize micro-structured surfaces to diffract the beam into a desired shape. DOEs offer flexibility in creating complex shapes and are often used for creating flat-top beams or structured light patterns.

- Axicons: These conical lenses create a long, non-diffracting Bessel beam, useful in optical trapping and microscopy.

- Multimode Fiber Coupling: Coupling a laser beam into a multimode fiber mixes and homogenizes the beam, resulting in a more uniform intensity distribution at the output. This is a straightforward method, often preferred for its simplicity.

- Spatial Light Modulators (SLMs): These programmable devices can dynamically shape the beam in real-time, offering great control over the profile. This is particularly useful in adaptive optics and dynamic beam shaping applications.

- Microlenses Arrays: Arrays of small lenses are used to create a beam with a uniform distribution from an initial Gaussian profile.

The choice of technique depends on factors like the required beam shape, accuracy, cost, and complexity. For instance, in laser material processing, a uniform top-hat profile is often desired for even ablation, which can be achieved using DOEs or microlenses arrays. In optical trapping, Bessel beams created by axicons provide a long depth of focus. My experience spans designing, implementing, and characterizing beam shaping solutions for various applications, tailoring the techniques to meet the specific requirements of each project.

Q 22. How do you handle noisy or corrupted beam profile data?

Noisy or corrupted beam profile data is a common challenge in laser beam characterization. It can stem from various sources, including detector noise, environmental vibrations affecting the beam path, or even errors in data acquisition. Handling this requires a multi-pronged approach.

Firstly, understanding the source of the noise is crucial. Is it random noise (e.g., thermal noise in the detector), or systematic (e.g., a periodic vibration)? This dictates the appropriate filtering technique.

For random noise, I typically employ smoothing algorithms like moving averages or Savitzky-Golay filters. These algorithms average data points over a small window, reducing the impact of random fluctuations. The choice of window size is critical; a larger window smooths more aggressively but can also blur sharp features in the beam profile.

For systematic noise, more sophisticated methods might be necessary. For example, if the noise is periodic, a Fourier transform can identify and remove the offending frequencies. Alternatively, if the noise is correlated with another measured parameter (such as temperature), regression analysis can be used to remove the systematic effect.

Outlier rejection is also essential. Data points that significantly deviate from the overall trend can be identified and removed or replaced using interpolation techniques. Robust statistical methods, such as median filtering, are particularly useful here because they are less sensitive to outliers than the mean.

Finally, it’s important to validate the processed data. Comparing the processed profile with raw data helps assess whether the chosen method effectively removed the noise without significantly distorting the underlying beam shape. Visual inspection and quantitative metrics, like the signal-to-noise ratio, are invaluable in this verification step.

Q 23. Explain the role of beam steering in laser systems.

Beam steering is the controlled manipulation of a laser beam’s direction and position. It’s a critical function in many laser systems, enabling precise targeting, scanning, and beam alignment. Imagine trying to use a laser pointer without being able to aim it – that’s the significance of beam steering.

Several techniques achieve beam steering, including:

Mechanical steering: This involves physically moving mirrors or lenses to deflect the beam. This method is robust but can be slow and may introduce mechanical vibrations.

Electro-optical steering: This uses electro-optical devices like acousto-optic deflectors (AODs) or piezoelectric mirrors. AODs use sound waves to change the refractive index of a crystal, deflecting the beam. Piezoelectric mirrors use voltage to precisely control the mirror’s angle. These methods offer fast and precise beam steering.

The choice of steering technique depends on the application’s speed requirements, accuracy needs, and budget constraints. For example, high-speed laser scanning applications might favor AODs, while applications requiring high accuracy and stability might opt for precision mechanical systems.

Q 24. Describe your experience with different types of laser beam diagnostics.

My experience with laser beam diagnostics is extensive, encompassing various techniques. I’ve worked extensively with:

Beam profilers based on CCD/CMOS cameras: These are widely used for their versatility and relative ease of use. They provide direct images of the beam intensity profile, which are then analyzed to extract parameters like beam diameter, beam divergence, and beam quality factor (M2).

Scanning slit methods: These offer high spatial resolution, especially for very small beams. A slit scans across the beam, and the transmitted power is measured as a function of position. This data then reconstructs the beam profile.

Pyroelectric detectors: These are useful for high-power lasers where other detectors might be damaged. They measure the heat generated by the beam, providing an integrated measure of power and enabling beam profile measurements indirectly.

Wavefront sensors: These advanced systems measure the phase distribution of the laser beam, enabling analysis beyond intensity profiles. This is invaluable for understanding aberrations and improving beam quality.

Each technique has its strengths and weaknesses. My expertise lies in selecting the most appropriate technique based on the specific laser characteristics (power, wavelength, coherence), measurement requirements (accuracy, spatial resolution, speed), and budget constraints.

Q 25. How do you ensure the accuracy and repeatability of beam characterization measurements?

Ensuring accuracy and repeatability in beam characterization is paramount. It involves careful attention to both hardware and software aspects.

Calibration: Regular calibration of the measurement equipment is crucial. This involves using traceable standards to verify the accuracy of the detector, optics, and the entire measurement system.

Environmental control: Environmental factors like temperature and air currents can affect beam propagation and measurement accuracy. Controlling these factors within a stable environment is essential.

Measurement procedure: A standardized measurement procedure minimizes variations between measurements. This includes specifying the measurement distance, beam sampling method, and data acquisition parameters.

Data analysis techniques: The choice of data analysis techniques directly affects the accuracy and repeatability of the results. Using well-established algorithms and validation methods is key.

Statistical analysis: Performing statistical analysis on multiple measurements helps quantify the uncertainty and assess the repeatability of the results.

By implementing these rigorous procedures, we can ensure the quality and reliability of beam characterization data, vital for applications ranging from laser manufacturing to medical laser therapy.

Q 26. What software packages are you familiar with for beam profile analysis?

I am proficient in several software packages for beam profile analysis, including:

BeamGage (DataRay): This is a widely used commercial software package for analyzing beam profiles from various detectors. It provides tools for calculating beam parameters, generating reports, and performing statistical analysis.

MATLAB: I utilize MATLAB extensively for custom data analysis and algorithm development. Its flexible environment allows for complex processing tasks and the creation of tailored analysis workflows.

Python (with libraries like SciPy and NumPy): Python offers a powerful and open-source alternative for beam profile analysis. Libraries like SciPy provide robust numerical algorithms, while NumPy enables efficient array manipulation.

My familiarity with these packages allows me to adapt to different situations and choose the most suitable tools based on the data format and analysis requirements.

Q 27. Describe a challenging beam characterization problem you solved.

A challenging problem I encountered involved characterizing the beam profile of a high-power, pulsed laser with significant spatial and temporal variations. The laser’s high power made standard CCD-based profilers susceptible to damage. Furthermore, the short pulse duration and non-uniform energy distribution across the beam profile complicated measurements.

To address this, I employed a combination of techniques. Firstly, I used a high-speed, non-destructive pyroelectric detector array to capture the beam’s energy distribution. This provided an initial characterization of the beam’s spatial intensity profile. To account for the temporal variations, I incorporated a fast pulse acquisition system.

Next, I developed a custom algorithm in MATLAB to compensate for the pyroelectric detector’s slower response time and the non-uniformity of the sensor elements. Finally, I compared the results from this method with simulations, which were crucial in validating the measurements and understanding the limitations of the technique. The outcome was a robust and accurate characterization of the beam’s spatial and temporal profile despite its challenging nature, contributing significantly to the laser system’s optimization and control.

Q 28. How do you stay updated on the latest advancements in laser beam characterization?

Staying current in the rapidly evolving field of laser beam characterization necessitates a multifaceted approach.

Conference attendance: I regularly attend conferences like CLEO and SPIE Photonics West to learn about the latest research and technological advancements from leading experts.

Journal publications: I subscribe to leading journals in optics and photonics, including Optics Letters, Applied Optics, and Optics Express. I carefully review relevant articles to stay informed about new techniques and applications.

Professional networking: Engaging with colleagues and experts through professional organizations like OSA and SPIE provides invaluable insights and opportunities for collaboration and knowledge sharing.

Vendor engagement: Staying connected with leading vendors of laser beam diagnostics equipment ensures that I’m familiar with the latest hardware and software advancements.

This continuous learning ensures that I can apply the most current and efficient methods to solve the challenging problems encountered in beam characterization.

Key Topics to Learn for Laser Beam Characterization Interview

- Beam Propagation and Gaussian Beams: Understanding fundamental beam parameters like beam waist, divergence, and Rayleigh range. Practical application: Designing optical systems for optimal beam delivery.

- M2 Factor and Beam Quality: Defining and measuring beam quality; its impact on laser system performance. Practical application: Selecting appropriate lasers for specific applications based on beam quality requirements.

- Beam Profiling Techniques: Familiarity with various methods like knife-edge scanning, CCD cameras, and quadrant detectors. Practical application: Characterizing the spatial distribution of laser intensity.

- Wavefront Aberrations: Understanding the impact of aberrations on beam quality and methods for correction. Practical application: Improving the performance of high-precision laser systems.

- Laser Beam Shaping Techniques: Exploring methods for transforming beam profiles (e.g., using diffractive optical elements). Practical application: Optimizing laser beam profiles for specific applications like material processing or microscopy.

- Measurement Uncertainty and Error Analysis: Critically evaluating the accuracy and precision of beam characterization measurements. Practical application: Ensuring the reliability of experimental results.

- Specific Laser Types and Their Characteristics: Understanding the beam properties of different laser types (e.g., diode lasers, fiber lasers, solid-state lasers). Practical application: Matching laser selection to application needs.

Next Steps

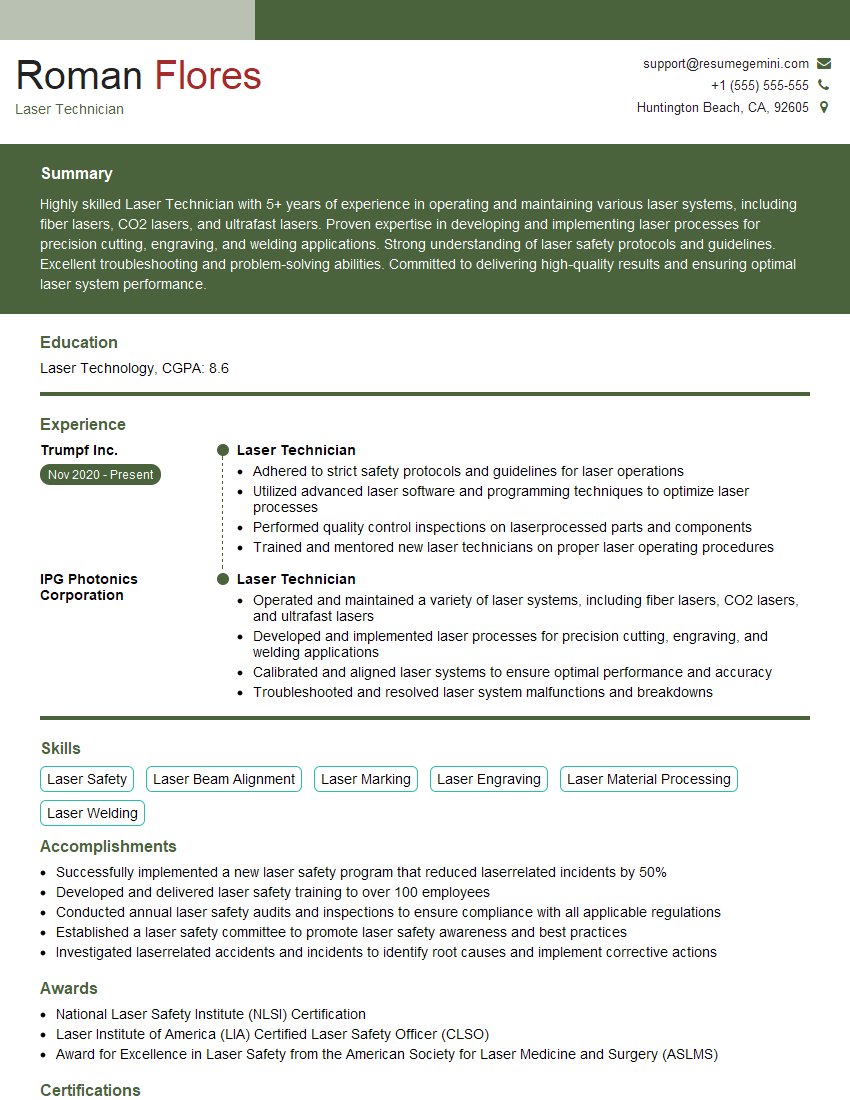

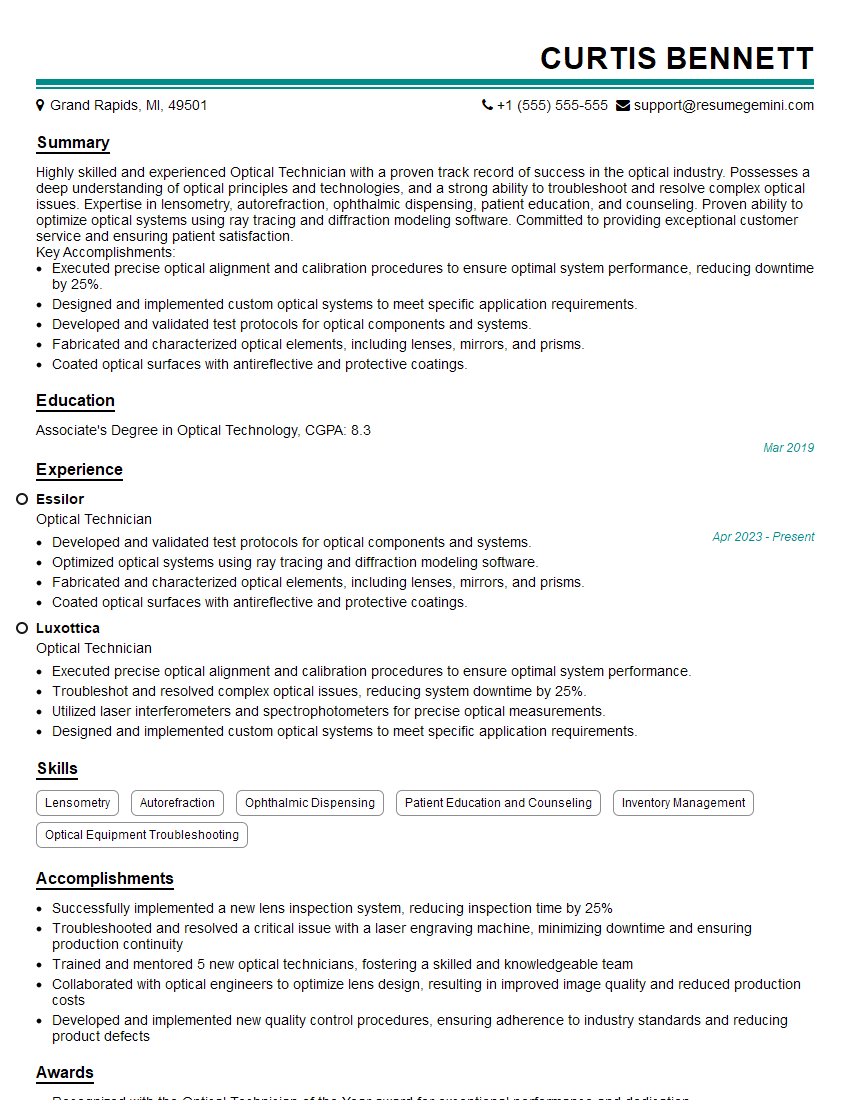

Mastering laser beam characterization opens doors to exciting career opportunities in diverse fields like photonics, laser manufacturing, biomedical optics, and scientific research. A strong understanding of these concepts is highly valued by employers. To maximize your job prospects, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and effective resume, significantly increasing your chances of landing your dream job. Examples of resumes tailored to Laser Beam Characterization are available within ResumeGemini to guide your creation. Take the next step toward your career success today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good