Are you ready to stand out in your next interview? Understanding and preparing for Laundry Handling interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Laundry Handling Interview

Q 1. What are the different types of laundry equipment you are familiar with?

My experience encompasses a wide range of laundry equipment, from smaller, self-service units to large-scale industrial machines. This includes:

- Washers: I’m familiar with both top-load and front-load washers, varying in capacity from smaller units suitable for a hotel to high-capacity industrial washers used in hospitals or large-scale laundromats. I understand the nuances of different wash cycles, water temperatures, and extraction speeds offered by these machines.

- Dryers: My experience includes various dryer types, including gas and electric models, with different tumble actions and heat settings. This includes understanding the importance of proper ventilation and lint removal to ensure safety and efficiency.

- Ironers and Folders: I’m proficient in operating and maintaining industrial-sized ironers and automated folding machines, which significantly speed up the finishing process and improve consistency.

- Conveyors and Sorting Systems: I’ve worked with conveyor systems that automate the movement of laundry through the various stages of the process, and I am familiar with different sorting systems designed to separate laundry by color, fabric type, and soil level.

- Extraction Equipment: This includes understanding the use and maintenance of industrial-grade extractors, which play a vital role in reducing the water content of the laundry prior to drying, increasing efficiency and reducing energy costs.

Understanding the capabilities and limitations of each piece of equipment is critical for optimizing the laundry process and ensuring the longevity of the machinery.

Q 2. Describe your experience with different laundry detergents and their applications.

My experience with laundry detergents is extensive. I understand that selecting the right detergent is crucial for effective cleaning, preserving fabric integrity, and minimizing environmental impact. Different detergents cater to specific needs:

- Powder Detergents: Generally more affordable, effective in hard water, but can leave residue if not thoroughly rinsed.

- Liquid Detergents: Often better for pre-treating stains and gentler on fabrics, but can be more expensive.

- Pods/Pacs: Convenient and pre-measured, but can be more costly per load.

- High-Efficiency (HE) Detergents: Specifically formulated for use in high-efficiency washing machines, preventing excessive sudsing and ensuring optimal cleaning performance.

- Specialty Detergents: These include detergents designed for delicate fabrics, colors, or specific stains (e.g., bleach alternatives for white laundry).

For example, in a hospital setting, I would prioritize detergents that are effective in removing blood and bodily fluids while being gentle on delicate fabrics. In a hotel, a cost-effective detergent with a pleasant scent might be favored.

Q 3. Explain the process of sorting laundry effectively.

Efficient sorting is the cornerstone of a smooth laundry process. It prevents color bleeding, protects delicate fabrics, and ensures that the appropriate wash cycle is used for each item. My sorting process typically includes:

- Pre-sorting: Checking items for significant stains or damage, and separating oversized items like blankets or bedding.

- Color Sorting: Separating whites, lights, and darks to avoid color transfer. This is the most critical step.

- Fabric Type Sorting: Grouping items by fabric type (e.g., cottons, linens, synthetics, delicates) to choose the appropriate wash cycle and water temperature. Delicates like silk or lace are always handled separately.

- Soil Level Sorting: Separating heavily soiled items from lightly soiled items to ensure optimal cleaning and prevent cross-contamination.

Think of it like preparing ingredients for a meal: sorting ensures each item receives the correct treatment for the best possible outcome.

Q 4. How do you handle stains and different fabric types during the washing process?

Stain removal and fabric care are paramount. My approach involves:

- Stain Pre-Treatment: Addressing stains before washing is crucial. I use various stain removers based on the stain type (e.g., enzyme-based for biological stains, oxygen bleach for stubborn stains). Pre-soaking heavily soiled items is also beneficial.

- Fabric Recognition: Understanding fabric composition is key to selecting appropriate water temperatures and wash cycles. Delicate fabrics require gentle cycles and low temperatures, while durable fabrics can withstand more rigorous washing.

- Water Temperature Selection: Hot water is effective for removing heavy soil and sanitizing, but can damage delicate fabrics. Cold or warm water is often preferred for delicate items and to prevent color fading.

- Wash Cycle Selection: Different wash cycles (e.g., delicate, permanent press, normal) are tailored to various fabric types and soil levels.

For instance, a grass stain on cotton jeans would be treated differently than a wine stain on a silk blouse. The former might involve pre-soaking with enzyme detergent, while the latter requires a gentle hand-wash or special stain remover suitable for silk.

Q 5. What are the safety procedures involved in operating industrial laundry equipment?

Safety is always my top priority. Operating industrial laundry equipment requires adherence to strict safety protocols, including:

- Lockout/Tagout Procedures: Before any maintenance or repair, power must be completely shut off and locked out to prevent accidental starting.

- Personal Protective Equipment (PPE): Using appropriate PPE like gloves, safety glasses, and hearing protection is mandatory. This protects against chemical exposure, flying debris, and excessive noise.

- Regular Machine Inspections: Daily checks for any mechanical issues, leaks, or electrical hazards are vital.

- Proper Lifting Techniques: Using proper lifting techniques to avoid injuries when handling heavy laundry baskets or equipment.

- Chemical Handling Procedures: Following manufacturer’s instructions when handling detergents, bleaches, and other chemicals, including proper storage and disposal.

- Emergency Procedures: Being familiar with emergency shut-off procedures and emergency contact information.

A culture of safety, enforced through training and regular checks, is essential in minimizing the risk of accidents and injuries.

Q 6. How do you ensure efficient workflow and productivity in a laundry setting?

Efficient workflow is essential for maximizing productivity. My approach focuses on:

- Optimized Sorting and Routing: Streamlining the sorting process to minimize handling time and ensure a smooth flow of laundry through different equipment.

- Scheduled Maintenance: Regular preventative maintenance on equipment reduces downtime and extends machine life.

- Process Improvement: Continuously evaluating the workflow and identifying areas for improvement. This might include adjusting the sequence of operations or investing in automation.

- Staff Training: Ensuring that all staff are properly trained on the safe and efficient operation of all equipment and processes.

- Inventory Management: Maintaining adequate levels of supplies (detergents, chemicals, etc.) to avoid interruptions in the workflow.

For example, implementing a conveyor system can significantly reduce the manual handling of laundry, freeing up staff for other tasks and increasing overall output.

Q 7. Describe your experience with inventory management in a laundry environment.

Effective inventory management is critical for cost control and operational efficiency. My experience includes:

- Stock Levels: Maintaining optimal stock levels of detergents, bleaches, fabric softeners, and other supplies to meet demand while minimizing storage costs.

- Just-in-Time Inventory: Implementing a system where supplies are ordered only when needed, reducing storage space and minimizing waste.

- Inventory Tracking: Utilizing inventory management software or spreadsheets to track stock levels and order supplies proactively.

- Cost Analysis: Regularly reviewing the cost of supplies and exploring opportunities to reduce expenses through bulk purchasing or switching suppliers.

- Waste Reduction: Implementing strategies to minimize waste, such as proper chemical handling and efficient use of supplies.

By effectively managing inventory, I ensure that the laundry operation never runs short of necessary supplies while avoiding unnecessary expenses.

Q 8. How do you maintain high standards of hygiene and cleanliness in a laundry facility?

Maintaining high hygiene standards in a laundry facility is paramount. It involves a multi-pronged approach focusing on equipment, processes, and personnel. Think of it like a layered defense against germs.

Equipment Sanitation: Regular cleaning and disinfection of washing machines, dryers, and other equipment is crucial. We use EPA-registered disinfectants and follow manufacturer guidelines for cleaning cycles to eliminate bacteria and viruses. For example, we schedule a deep clean of the washing machines every week, including cleaning the detergent dispensers and removing lint build-up.

Process Control: Implementing a robust laundry process is essential. This includes separating soiled linens based on contamination level (e.g., separating heavily soiled items from lightly soiled items), using appropriate water temperature and wash cycles, and ensuring adequate drying time to eliminate moisture, which encourages microbial growth. We even color-code our laundry carts to help maintain this separation.

Personnel Hygiene: Training staff on proper hand hygiene, the use of personal protective equipment (PPE) like gloves, and safe handling of soiled linens is vital. We conduct regular training sessions to emphasize the importance of these practices and provide opportunities for questions.

Facility Cleanliness: Maintaining a clean and organized facility is also crucial. This includes regular floor cleaning, emptying trash regularly, and addressing any spills or leaks immediately. We even have a designated cleaning schedule posted for all staff to follow.

Q 9. Explain your understanding of laundry chemicals and their safe handling.

Understanding laundry chemicals and their safe handling is crucial for both efficacy and safety. It’s like being a chemist and a safety officer all in one!

Types of Chemicals: We utilize a range of chemicals including detergents (for cleaning), bleaches (for whitening and disinfection), softeners (for improved feel), and stain removers (for specialized cleaning). Each chemical has a specific function and requires careful selection based on the type of fabric and level of soiling.

Safe Handling: Safe handling involves understanding the safety data sheets (SDS) for each chemical, wearing appropriate PPE (gloves, eye protection, etc.), using proper measuring and dispensing techniques, and storing chemicals in designated areas away from heat and incompatible substances. We always follow the manufacturer’s instructions and maintain a detailed inventory of our chemicals.

Environmental Considerations: We prioritize using environmentally friendly chemicals whenever possible. This includes choosing biodegradable options and implementing measures to minimize water and energy consumption. We’ve even switched to a detergent that’s both effective and less harsh on the environment.

Emergency Procedures: We have clear protocols in place for handling chemical spills or accidents, including immediate cleanup procedures, emergency contact information, and first aid response. All staff members are trained in these procedures.

Q 10. How do you troubleshoot common laundry equipment malfunctions?

Troubleshooting laundry equipment malfunctions requires a systematic approach. It’s a bit like detective work, identifying clues to solve the mystery.

Identify the Problem: The first step is accurately identifying the malfunction. Is the machine not starting? Is it making unusual noises? Is it not draining properly? Careful observation is key.

Check the Obvious: Often, simple issues can be resolved quickly. Check for power supply, water supply, proper drainage, and lint build-up. For example, a clogged drain is a common culprit for slow draining machines.

Consult Manuals: Manufacturer manuals provide valuable troubleshooting information, including diagrams, error codes, and common issues. We keep all our manuals organized and readily accessible.

Systematic Checks: If the problem persists, systematically check components such as pumps, belts, motors, heating elements, and sensors. This might involve visual inspection and testing with multimeters. Some problems, such as a faulty heating element, will require professional repair.

Professional Assistance: When the problem remains unresolved after troubleshooting, it’s crucial to contact qualified technicians for repairs to prevent further damage or safety hazards.

Q 11. What is your experience with scheduling and managing laundry staff?

Scheduling and managing laundry staff requires effective organization and communication. It’s like conducting an orchestra, ensuring everyone plays their part in harmony.

Staffing Levels: Determining appropriate staffing levels based on workload fluctuations (e.g., higher volume during peak seasons) is important for ensuring efficient operations and meeting deadlines.

Scheduling Software: Utilizing scheduling software helps create and manage staff schedules effectively, accounting for breaks, vacations, and unexpected absences. This helps minimize disruption and keeps track of hours worked.

Training and Development: Providing regular training on proper procedures, equipment operation, and safety protocols is essential for maintaining quality and consistency. We have a comprehensive training program for new hires and refresher courses for existing staff.

Communication and Feedback: Open communication with staff is key to address concerns, provide feedback, and resolve issues promptly. We encourage staff to raise concerns and provide regular feedback sessions.

Performance Management: Monitoring staff performance and addressing any performance issues constructively helps ensure productivity and maintain high standards. This includes regular performance reviews and opportunities for professional growth.

Q 12. How do you ensure the quality control of laundered items?

Ensuring quality control of laundered items is a crucial step to maintaining customer satisfaction. Think of it as a final check before the items leave our care.

Visual Inspection: A thorough visual inspection of each item after washing and drying is crucial to identify any stains, tears, or damage. We train our staff to be meticulous during this process.

Spot Checks: Regular spot checks of laundered items are essential to ensure consistent quality across all batches. This involves randomly selecting items from different loads for inspection.

Customer Feedback: Gathering customer feedback through surveys or direct communication helps identify areas for improvement in the laundry process and address any recurring issues.

Record Keeping: Maintaining detailed records of laundry processes, chemicals used, and any issues encountered is essential for tracking trends and identifying areas needing attention. This also helps with troubleshooting.

Rework Procedures: Having clear procedures for handling items that fail to meet quality standards ensures that issues are addressed promptly and efficiently. We have a clear system for rewashing or repairing items that don’t pass inspection.

Q 13. Describe your experience with different types of fabric finishes.

Different fabric finishes significantly impact the final look and feel of laundered items. It’s like applying the finishing touches to a masterpiece.

Starch: Starch is a common finish used to add stiffness and crispness to fabrics like collars and cuffs. The level of starch can be adjusted based on the desired outcome.

Softeners: Fabric softeners are used to improve the softness and reduce static cling. Different types of softeners are available, including liquid and sheet softeners.

Water Repellents: These finishes are used to make fabrics resistant to water, useful for items like outerwear.

Stain Resistant Finishes: These finishes repel stains, improving the longevity of the fabric. They’re frequently used on items likely to encounter spills or dirt.

Wrinkle-Resistant Finishes: These finishes help reduce wrinkles, saving time and effort for consumers. These are popular with wrinkle-prone materials like linen.

The selection of a fabric finish depends on the type of fabric, the desired outcome, and customer preferences. We carefully consider these factors when selecting our finishes to optimize the laundry process.

Q 14. What are some common challenges in laundry operations, and how do you address them?

Laundry operations face various challenges, but proactive strategies can help mitigate their impact. Think of it as navigating a course with potential obstacles.

Maintaining Equipment: Equipment breakdowns are a significant challenge. Regular maintenance and preventative measures, along with prompt repairs when necessary, minimize downtime and costly repairs.

Managing Costs: Controlling costs related to water, energy, chemicals, and labor is a continuous concern. Efficient practices, energy-efficient equipment, and careful chemical management are essential.

Staff Turnover: High staff turnover can lead to inconsistencies in quality and productivity. Providing competitive wages, offering training opportunities, and creating a positive work environment can improve retention.

Meeting Demand: Fluctuating demand, particularly during peak seasons, can strain resources. Effective scheduling, capacity planning, and potentially outsourcing during high-demand periods can help manage this.

Environmental Concerns: Minimizing the environmental impact of laundry operations is increasingly important. Implementing water-saving practices, using eco-friendly chemicals, and reducing energy consumption are crucial.

Addressing these challenges requires a combination of careful planning, proactive maintenance, effective staff management, and a commitment to continuous improvement. We continuously adapt and improve our processes to stay ahead of these challenges and to deliver high quality services.

Q 15. How do you maintain accurate records of laundry items and processes?

Maintaining accurate laundry records is crucial for efficiency and accountability. We employ a multi-pronged approach combining technology and manual processes. This ensures we track every item from intake to delivery, maintaining transparency throughout the entire laundry cycle.

Barcode/RFID Tracking: Each item, especially in high-volume operations, is tagged with a unique identifier, allowing us to monitor its journey through washing, drying, folding, and delivery using a dedicated software system. This system provides real-time visibility of inventory and workflow.

Detailed Logs: We maintain detailed logs documenting each step of the process – including the type of wash cycle used, any special instructions followed, and any issues encountered. This information is essential for quality control, identifying recurring problems, and improving efficiency.

Inventory Management Software: We utilize specialized software to manage linen inventory, track usage, predict demand, and order supplies as needed. This software integrates with our tracking system, providing a comprehensive overview of our operations.

Regular Audits: To ensure accuracy and prevent discrepancies, regular audits of physical inventory versus recorded data are performed. This helps to identify and resolve any discrepancies promptly.

For example, in a recent project with a large hotel chain, our RFID system helped to significantly reduce linen loss, identify and address bottlenecks in the process, and optimize inventory levels, resulting in significant cost savings.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with linen management and handling?

My experience in linen management and handling spans over [Number] years, encompassing diverse settings from large-scale hospitality operations to healthcare facilities. I’m adept at all aspects, from receiving and sorting linen to ensuring proper storage and distribution.

Inventory Control: I have a proven track record of implementing and managing inventory control systems, accurately forecasting linen needs, and minimizing waste. This includes understanding par levels and adjusting inventory based on seasonal fluctuations and occupancy rates.

Linen Handling Procedures: I’m proficient in establishing and enforcing safe and efficient linen handling procedures, including proper sorting, washing, drying, ironing, and folding techniques to ensure the longevity and quality of the linens. This often includes training staff to follow best practices.

Quality Control: I am meticulous about quality control, ensuring linens meet standards of cleanliness and appearance. Regular inspections and damage assessment are key aspects of my approach. Damaged items are documented and repaired or replaced as needed.

Maintenance and Repair: I have experience managing the repair or replacement of damaged linens and overseeing the maintenance of laundry equipment to ensure smooth operations.

For instance, in a previous role at a hospital, I implemented a new linen tracking system that reduced linen loss by 15% and improved turnaround time, ultimately improving patient care and saving the facility significant costs.

Q 17. Describe your approach to addressing customer complaints regarding laundry services.

Addressing customer complaints is paramount to maintaining a positive reputation. My approach is focused on empathy, timely resolution, and preventing future occurrences.

Active Listening: I begin by actively listening to the customer’s complaint without interruption, demonstrating empathy and understanding. The goal is to fully grasp their concerns.

Apology and Acknowledgement: I offer a sincere apology for any inconvenience or dissatisfaction, regardless of the cause. Acknowledging their frustration validates their feelings.

Investigation and Fact-Finding: I thoroughly investigate the complaint, examining relevant records, processes, and talking to staff involved. This helps in identifying the root cause of the issue.

Resolution and Follow-Up: Based on the findings, I offer a fair and appropriate resolution, whether it be a re-wash, replacement, or a refund. A follow-up call or email ensures the customer’s satisfaction and addresses any lingering concerns.

Preventative Measures: Finally, I identify and implement preventative measures to avoid similar issues in the future. This might involve retraining staff, improving processes, or adjusting equipment settings.

For example, if a customer complains about a stained garment, I’ll personally inspect the item, determine the cause of the stain (was it pre-existing? was the wash cycle appropriate?), and then offer a solution that addresses both the immediate problem and the underlying cause.

Q 18. How familiar are you with different laundry washing cycles and their settings?

My familiarity with different laundry washing cycles and their settings is extensive. I understand the nuances of various fabrics and their specific cleaning requirements. This knowledge allows me to optimize cleaning processes while minimizing damage to garments.

Fabric Types: I’m knowledgeable about the unique characteristics of various fabrics (cotton, linen, silk, wool, synthetics, etc.) and how they react to different temperatures, detergents, and wash cycles. This understanding guides my selection of appropriate settings.

Wash Cycle Types: I’m proficient in using various wash cycles – delicate, permanent press, heavy-duty, and sanitize – understanding when to apply each. This ensures optimal cleaning without damage to delicate items or overuse of resources.

Water Temperature: I know the importance of selecting the correct water temperature for different fabrics and soil levels. Higher temperatures are effective for heavily soiled items, but can damage delicate fabrics.

Detergent and Additives: I understand how to select and utilize different detergents and laundry additives, such as bleach, fabric softeners, and stain removers, effectively and safely.

Spin Speed and Drying Cycles: I’m experienced in adjusting spin speed to reduce wrinkles and drying time, while avoiding damage to garments. Similar understanding applies to the selection of appropriate drying cycles.

For example, I know that using a high heat setting on a wool sweater could cause shrinkage, while a delicate cycle and low-temperature drying are essential to preserving its shape and quality.

Q 19. What are your methods for managing laundry waste and recycling?

Effective laundry waste management is crucial for environmental responsibility and cost efficiency. My methods involve a combination of waste reduction, recycling, and responsible disposal.

Waste Reduction: This is the first and most important step. We focus on minimizing water and energy consumption through efficient equipment and practices. This includes using high-efficiency washers and dryers, optimizing detergent usage, and training staff on water conservation techniques.

Recycling: We implement a robust recycling program for cardboard, plastic containers, and other recyclable materials. We also explore options for recycling used laundry detergents and other chemicals, adhering to all relevant regulations.

Responsible Disposal: Any non-recyclable waste, such as soiled rags or damaged linens, is disposed of according to local regulations and environmental best practices. This may involve partnerships with waste management companies specialized in handling textile waste.

Lint Management: Lint from dryers is collected and disposed of properly. In some cases, depending on the type of lint and available infrastructure, we can even explore its potential reuse (for instance, as packing material).

For instance, by implementing a comprehensive waste reduction program, we were able to reduce our water consumption by 12% and our energy consumption by 8% in a previous facility, resulting in significant cost savings and a smaller environmental footprint.

Q 20. How would you implement cost-saving measures in a laundry operation?

Implementing cost-saving measures in a laundry operation requires a holistic approach focusing on efficiency, resource optimization, and preventative maintenance.

Energy Efficiency: Upgrading to energy-efficient equipment (washers, dryers, and boilers) is a significant investment that pays off in the long run, reducing utility costs.

Water Conservation: Implementing water-saving technologies, such as low-flow fixtures and high-efficiency washers, reduces water bills and minimizes environmental impact.

Detergent and Supply Management: Negotiating bulk purchases of detergents and other supplies reduces per-unit costs. Tracking usage helps avoid overstocking and spoilage.

Preventative Maintenance: Regular maintenance of equipment prevents costly breakdowns and ensures optimal performance, extending the lifespan of machinery.

Staff Training: Training staff on efficient laundry practices, including proper sorting, loading, and operation of equipment, improves productivity and reduces waste.

Process Optimization: Analyzing laundry processes and identifying bottlenecks or inefficiencies allows for adjustments that streamline workflows and reduce labor costs.

For example, in one operation, by implementing a preventative maintenance schedule and training staff on energy-saving techniques, we were able to reduce overall operational costs by 15% within six months.

Q 21. Describe your experience with managing the procurement of laundry supplies.

Procuring laundry supplies effectively involves strategic planning, vendor management, and cost control. My experience includes all aspects of this process.

Vendor Selection: I have experience identifying and selecting reliable vendors who offer high-quality supplies at competitive prices. This includes negotiating favorable contracts and ensuring timely delivery.

Inventory Management: I utilize inventory management systems to track supply levels, predict demand, and minimize waste through just-in-time ordering.

Quality Control: I establish quality control measures to ensure that all received supplies meet required standards. This includes regular inspections and testing of detergents and other chemicals.

Cost Analysis: I conduct regular cost analysis to identify opportunities for cost savings, comparing prices from different vendors and exploring alternative products.

Supplier Relationships: I build strong relationships with suppliers to ensure consistent supply, timely delivery, and proactive communication about potential issues or changes.

For instance, in a previous role, I successfully negotiated a long-term contract with a supplier that reduced the cost of detergents by 10%, resulting in significant annual savings for the facility.

Q 22. What are your strategies for preventing damage to clothing during the laundry process?

Preventing damage to clothing during laundry involves a multi-pronged approach focusing on pre-sorting, appropriate washing techniques, and careful handling. Think of it like this: you wouldn’t wash a delicate silk scarf the same way you’d wash a pair of sturdy jeans.

Pre-sorting: This is the first and most crucial step. Separate clothes by fabric type (delicates, whites, darks, etc.), color, and level of soiling. Check clothing for any loose buttons, zippers, or embellishments that could snag or damage other garments. Consider using mesh laundry bags for delicate items to protect them from abrasion.

Selecting the right wash cycle: Using the appropriate water temperature and wash cycle is vital. Delicate fabrics require cold water and gentle cycles, while durable fabrics can tolerate hotter temperatures and more vigorous washing. Always check the garment’s care label for specific instructions.

Proper loading: Overloading the washing machine can lead to poor cleaning and increased wear and tear on the garments. Make sure to leave enough space for the clothes to move freely during the wash cycle.

Careful handling: Avoid harsh scrubbing or twisting of garments, especially delicate ones. Handle wet clothes gently to prevent stretching or damage. Properly folding and hanging clothes after washing helps to prevent wrinkles and creases.

Drying precautions: Over-drying can shrink or damage clothes. Use lower heat settings for delicate fabrics and remove clothes promptly from the dryer to prevent wrinkles. Air-drying is the gentlest option for many fabrics.

Q 23. How familiar are you with OSHA regulations related to laundry operations?

My familiarity with OSHA regulations regarding laundry operations is extensive. I understand the importance of compliance to ensure a safe working environment for all staff. This includes, but is not limited to, regulations concerning:

Machine guarding: Ensuring all moving parts of laundry equipment are properly guarded to prevent injuries.

Personal Protective Equipment (PPE): Proper use and availability of PPE such as gloves, eye protection, and hearing protection, especially when handling chemicals or operating heavy machinery.

Chemical handling and storage: Safe storage, handling, and disposal of detergents, bleaches, and other cleaning chemicals, according to the manufacturer’s guidelines and OSHA regulations. This includes proper labeling and ventilation.

Ergonomics: Implementing measures to minimize the risk of musculoskeletal injuries through proper lifting techniques, workstation design, and equipment selection.

Emergency procedures: Having clear emergency procedures in place for situations such as equipment malfunctions, chemical spills, and fire hazards. Regular training and drills are crucial.

Hazard Communication: Ensuring all staff have access to Safety Data Sheets (SDS) and are properly trained on the hazards associated with the chemicals used in laundry operations.

Staying updated on OSHA’s latest regulations is a continuous process, which I actively pursue through industry publications and training programs.

Q 24. How do you ensure the proper use and maintenance of laundry equipment?

Proper use and maintenance of laundry equipment are paramount for efficiency and longevity. It’s like maintaining your car – regular check-ups prevent bigger problems down the line.

Regular cleaning: Cleaning the equipment after each use prevents lint build-up, which can affect performance and cause malfunctions. This includes cleaning lint traps, washing detergent dispensers, and wiping down exterior surfaces.

Preventative maintenance: Scheduled preventative maintenance involves regular inspections, lubrication, and minor repairs. This includes checking belts, hoses, and other vital components. I adhere to the manufacturer’s recommended maintenance schedules.

Operator training: Proper operator training is essential to ensure the equipment is used correctly and prevents accidental damage. This includes training on safe operating procedures, troubleshooting minor problems, and recognizing when professional service is required.

Professional servicing: Regular professional servicing by qualified technicians is crucial for more complex repairs and maintenance tasks. This ensures the equipment remains in optimal condition and extends its lifespan.

For example, neglecting regular cleaning of a washing machine’s lint trap can lead to reduced efficiency and even damage to the motor. Likewise, ignoring a worn-out belt can result in more significant, expensive repairs later on.

Q 25. What is your experience with using different types of laundry machinery?

My experience encompasses a wide range of laundry machinery, from high-capacity industrial washers and dryers to smaller, commercial-grade units. I’m proficient in operating and maintaining:

High-speed washers and extractors: These are essential for high-volume laundry operations, demanding a thorough understanding of their operation and safety protocols.

Industrial tumble dryers: I’m experienced in optimizing drying cycles to minimize energy consumption and prevent damage to fabrics.

Washer-extractors (combination machines): These versatile machines combine washing and extraction functions, offering efficiency advantages. I understand their specific maintenance requirements.

Flatwork ironers: I have experience operating and maintaining these large pieces of equipment used for ironing linens and other flat goods, ensuring proper operation and safety precautions.

Folding machines: These automated machines increase efficiency in the finishing stage, and I am skilled in their operation and maintenance.

My experience extends to both electronic and mechanical controls, allowing me to troubleshoot and resolve minor issues efficiently.

Q 26. How would you handle a large volume of laundry in a short timeframe?

Handling a large volume of laundry in a short timeframe requires a strategic approach, much like orchestrating a well-oiled machine.

Prioritization and workflow optimization: This involves carefully analyzing the laundry volume and prioritizing urgent orders. Streamlining the workflow—from sorting to finishing—is key. This might include implementing a more efficient sorting system or using additional equipment to increase capacity.

Efficient equipment utilization: Maximizing the capacity of washing machines and dryers is crucial. Running machines at optimal loads and using efficient drying cycles reduces downtime and increases throughput.

Teamwork and communication: Effective teamwork and clear communication among staff members are essential for coordinating tasks and preventing bottlenecks. This may involve assigning specific roles and responsibilities to team members and using a system for tracking laundry progress.

Automation and technology: Utilizing automated equipment, such as folding machines or conveyor systems, can significantly increase efficiency. Employing laundry management software can improve tracking and organization.

Overtime or additional staff: In exceptionally high-volume situations, deploying additional staff or utilizing overtime may be necessary to meet deadlines. This decision should consider the cost and benefit to the operation.

Q 27. What is your approach to training new laundry staff?

Training new laundry staff is a crucial aspect of maintaining high standards and a safe working environment. I utilize a structured approach combining theory and practical application.

On-the-job training: I believe in hands-on learning. New staff members are initially paired with experienced colleagues to observe and participate in various tasks under supervision.

Safety training: Safety is paramount. New hires receive thorough training on OSHA regulations, equipment safety procedures, and chemical handling protocols. This is reinforced through regular safety meetings and drills.

Equipment operation training: Detailed instructions and practical demonstrations are given on operating all laundry equipment safely and efficiently. Emphasis is placed on correct usage and preventative maintenance.

Quality control training: Staff are trained to identify quality issues such as stains, damage, and wrinkles. Consistent standards are emphasized to ensure high-quality laundry services.

Ongoing feedback and evaluation: Regular feedback and performance evaluations are provided to identify areas for improvement and ensure consistent skill development.

I use a mentorship approach, creating a supportive learning environment where questions are encouraged and mistakes are viewed as learning opportunities.

Q 28. Describe your experience with implementing and following established laundry procedures.

Throughout my career, I have consistently demonstrated my ability to implement and follow established laundry procedures. My experience includes:

Adhering to established SOPs: I meticulously follow Standard Operating Procedures (SOPs) to ensure consistency in quality, safety, and efficiency. This includes standardized methods for sorting, washing, drying, and finishing.

Developing and updating procedures: I have been involved in developing and updating laundry procedures to address evolving needs and improve efficiency. This often involves incorporating best practices from the industry and feedback from staff.

Maintaining documentation: Accurate record-keeping is essential. I ensure proper documentation of procedures, chemical usage, equipment maintenance, and any incidents or near misses.

Quality control monitoring: I regularly monitor quality control measures to ensure compliance with established procedures and customer expectations. This includes inspecting finished laundry for stains, damage, and proper folding.

Continuous improvement: I actively seek opportunities to improve existing procedures through process analysis and identifying areas for optimization. This might involve implementing new technologies or adjusting workflows to increase efficiency.

For example, I once implemented a new pre-sorting system that reduced processing time by 15% and improved the quality of the finished laundry. This was achieved through careful analysis of the existing workflow and the introduction of improved sorting procedures and better training for staff.

Key Topics to Learn for Laundry Handling Interview

- Laundry Sorting and Classification: Understanding different fabric types, garment characteristics, and appropriate sorting methods for efficient processing.

- Washing Machine Operation and Maintenance: Knowledge of various washing machine types, detergent selection, water temperature control, and troubleshooting common malfunctions.

- Drying Techniques and Equipment: Familiarity with different drying methods (tumble drying, air drying, flat drying), understanding appropriate drying temperatures and times for various fabrics, and maintenance of drying equipment.

- Ironing and Pressing Techniques: Proficiency in operating irons and pressing equipment, understanding appropriate temperature settings for different fabrics, and achieving professional finishing.

- Folding and Finishing Techniques: Mastering efficient folding methods for various garments, ensuring proper presentation and minimizing wrinkles.

- Stain Removal and Treatment: Knowledge of common stain types and effective treatment methods, using appropriate stain removers and techniques to preserve garment integrity.

- Hygiene and Safety Protocols: Understanding and adhering to strict hygiene standards, safe handling of chemicals, and proper use of personal protective equipment (PPE).

- Inventory Management and Stock Control: Knowledge of tracking laundry items, managing supplies, and maintaining accurate inventory records.

- Quality Control and Inspection: Ability to identify defects, ensure quality standards are met, and implement corrective actions.

- Teamwork and Communication: Understanding the importance of effective communication within a team environment, collaborating with colleagues, and contributing to a positive work atmosphere.

Next Steps

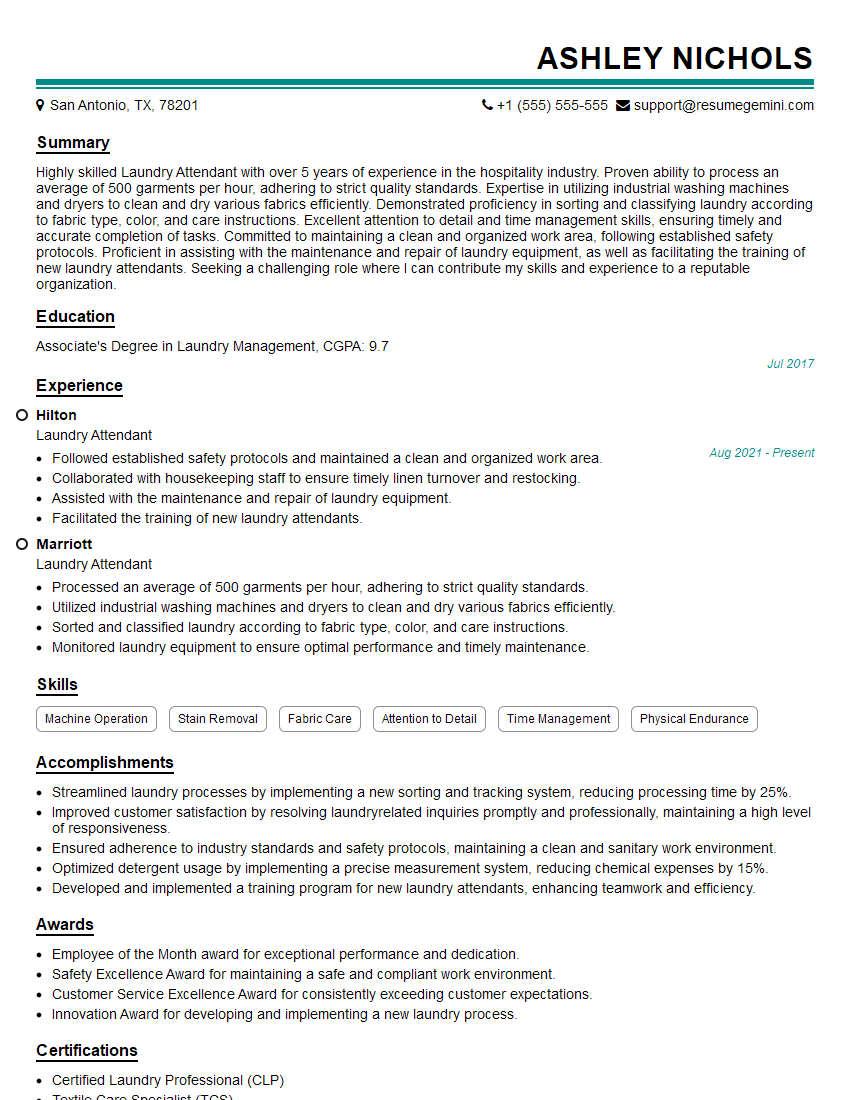

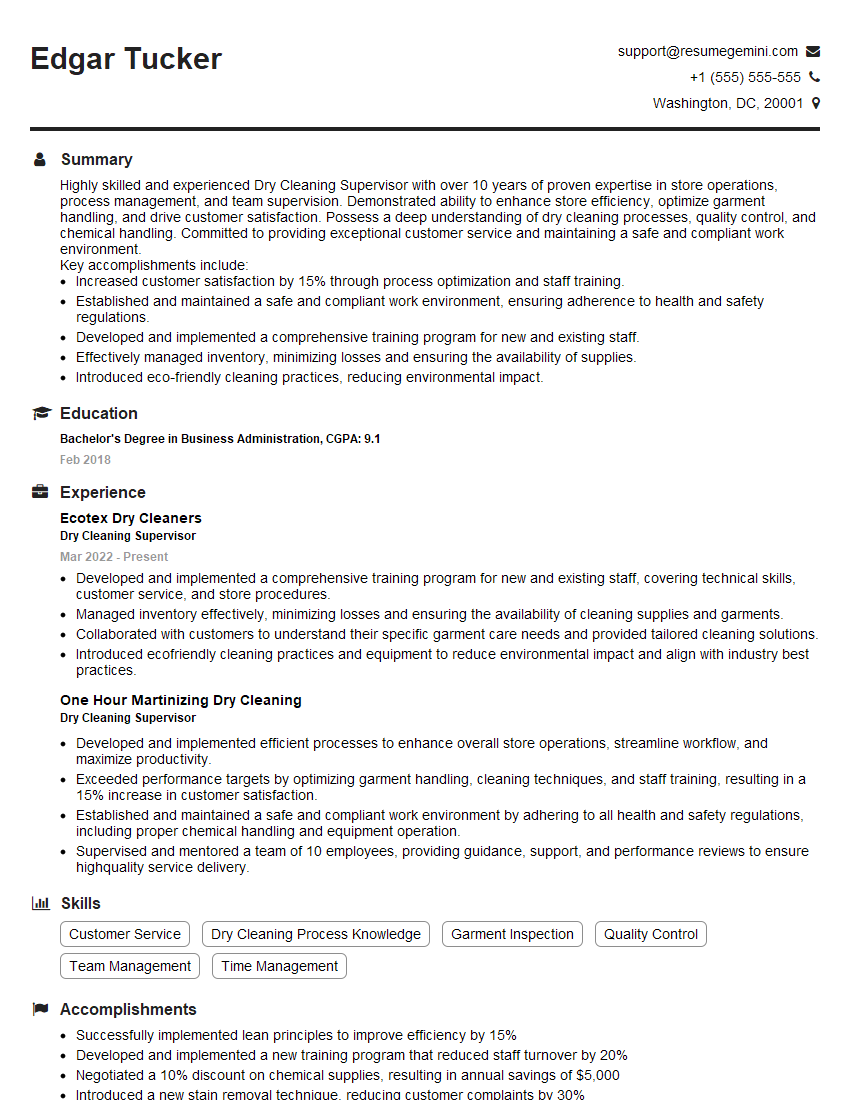

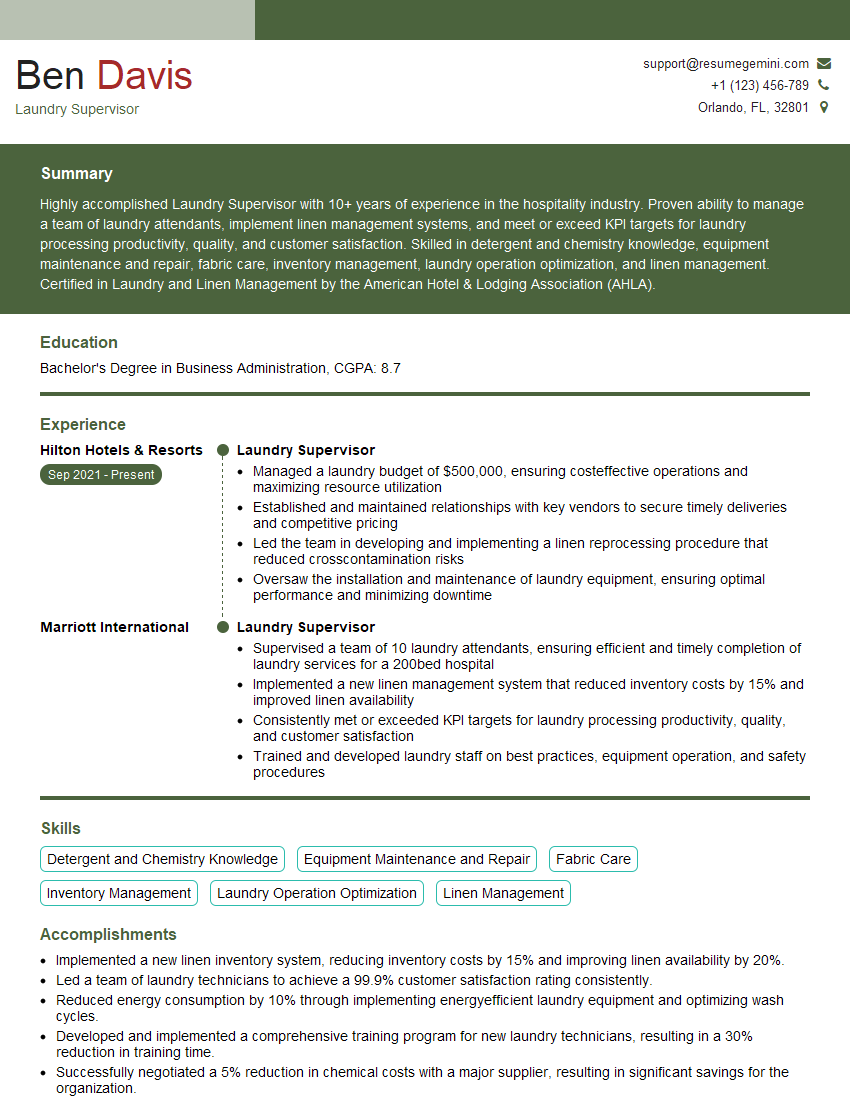

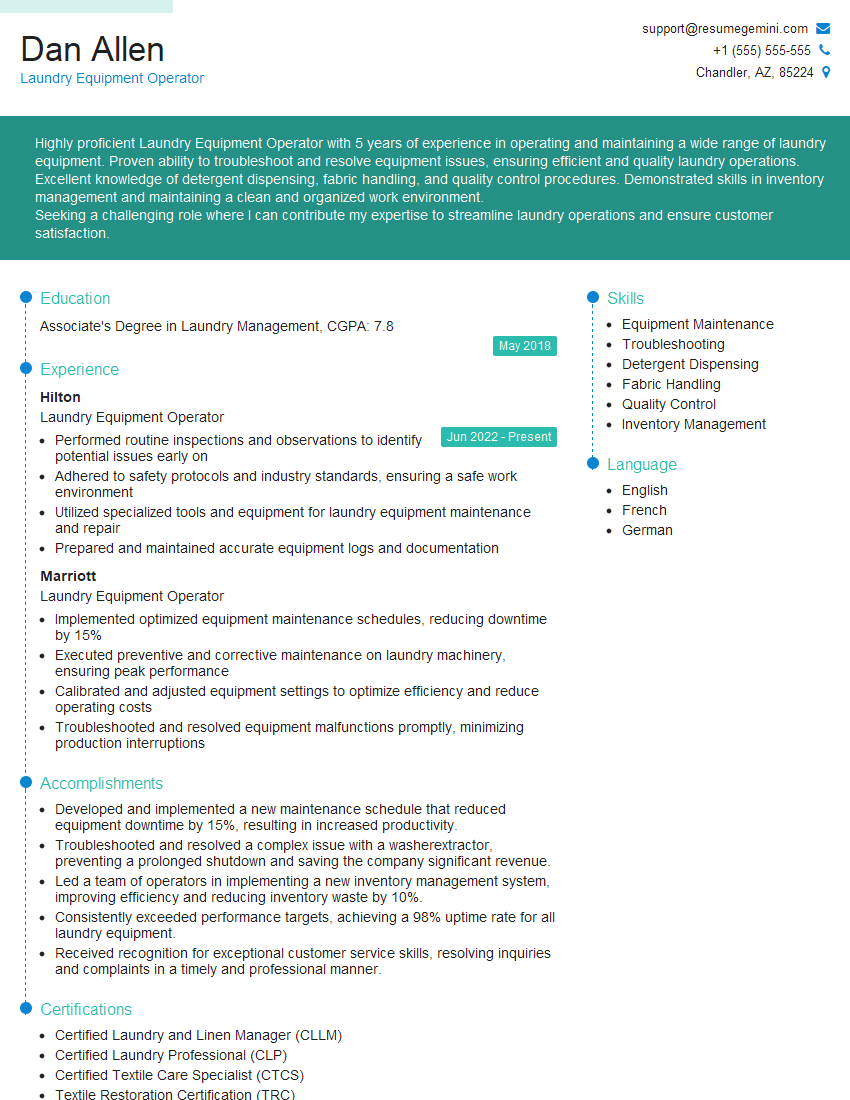

Mastering laundry handling techniques opens doors to diverse career opportunities in hospitality, healthcare, and commercial laundry services. To accelerate your job search, crafting a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume tailored to highlight your skills and experience. Examples of resumes specifically designed for Laundry Handling roles are available to guide you. Invest time in creating a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good