Cracking a skill-specific interview, like one for LEAN and Continuous Improvement, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in LEAN and Continuous Improvement Interview

Q 1. Explain the five principles of Lean.

Lean’s five principles are a foundational framework for eliminating waste and maximizing value. They guide the entire Lean methodology and are interconnected.

- Specify Value: Define value strictly from the customer’s perspective. What are they willing to pay for? This isn’t about internal perceptions of value, but about directly meeting customer needs. For example, in a car manufacturing plant, ‘value’ might be defined as a reliable, fuel-efficient vehicle that meets safety standards, not necessarily the fastest production time.

- Map the Value Stream: Analyze all steps involved in delivering that value, identifying those that add value and those that don’t. Imagine mapping the journey of a customer order – from initial placement to final delivery. This reveals bottlenecks and inefficiencies.

- Create Flow: Design the process to ensure a smooth and continuous flow of work, eliminating interruptions and bottlenecks. Think of it like a river; you want a consistent, uninterrupted current, not a series of stagnant pools.

- Establish Pull: Produce only what is needed, when it is needed, based on customer demand. This prevents overproduction, a major waste in Lean. A ‘pull’ system is responsive to actual demand, not forecasts.

- Seek Perfection: Continuous improvement is an ongoing process. Lean isn’t a destination; it’s a journey of constant refinement. This involves regularly reviewing and optimizing the value stream to eliminate further waste and enhance efficiency.

Q 2. Describe the seven wastes (muda) in Lean manufacturing.

The seven wastes (muda) are common sources of inefficiency in any process. Eliminating them is central to Lean’s goal of maximizing value.

- Transportation: Unnecessary movement of materials or information. Example: Moving parts across a factory unnecessarily instead of implementing a more efficient layout.

- Inventory: Excess raw materials, work-in-progress, or finished goods. Example: Holding large stocks of components that aren’t immediately needed, tying up capital and increasing storage costs.

- Motion: Unnecessary movement of people. Example: Employees walking excessively to gather tools or materials.

- Waiting: Idle time due to delays or bottlenecks. Example: Machines waiting for parts or operators waiting for instructions.

- Overproduction: Producing more than is needed or demanded. Example: Making products before customers order them, leading to excess inventory.

- Over-processing: Performing more work than necessary to meet customer requirements. Example: Adding unnecessary features to a product that don’t enhance its value for the customer.

- Defects: Producing flawed products or services that require rework or scrap. Example: Manufacturing faulty parts that need to be discarded, resulting in wasted materials and labor.

Q 3. How do you identify and prioritize improvement opportunities using Lean tools?

Identifying and prioritizing improvement opportunities requires a structured approach. Lean tools are crucial for this.

- Value Stream Mapping: This visually maps the current state of the process, highlighting bottlenecks and areas for improvement.

- 5 Whys: Repeatedly asking ‘why’ to drill down to the root cause of a problem. This helps move beyond superficial symptoms to address the underlying issue.

- Pareto Analysis (80/20 Rule): Identifies the vital few causes contributing to the majority of problems. This focuses improvement efforts on the most impactful areas.

- Data Collection: Gathering data on process performance metrics (e.g., cycle time, defect rates) to identify areas needing improvement. This can involve using tools like control charts.

- Prioritization Matrix: A matrix that ranks improvement opportunities based on factors like impact and effort. This helps to focus on those initiatives that deliver the greatest return with the least investment.

For instance, if a value stream map reveals a significant bottleneck at a particular machine, the 5 Whys can be used to find the root cause (e.g., frequent machine breakdowns due to poor maintenance). A Pareto analysis might then show that 80% of breakdowns are due to one specific component. This information helps prioritize improvements to that component, using data to justify the improvements.

Q 4. What is a value stream map, and how is it used in Lean?

A value stream map (VSM) is a visual representation of all steps involved in delivering a product or service from beginning to end. It’s a powerful Lean tool for understanding and improving the flow of materials and information.

A VSM shows not only the steps but also the time taken at each step, inventory levels, and other key process metrics. It helps to identify waste (muda) and bottlenecks. It’s typically created in two stages: a current state map and a future state map.

Current State Map: This maps the existing process, highlighting its inefficiencies. Future State Map: This shows how the process could ideally operate after improvements are implemented. The difference between the two reveals the potential for improvement. For example, a VSM for a manufacturing process might show excessive inventory at a specific workstation due to slow processing speeds, highlighting a need for improved machine capacity or worker training.

Q 5. Explain the difference between Lean and Six Sigma.

While both Lean and Six Sigma aim to improve processes, they have different focuses.

- Lean: Focuses on eliminating waste and improving flow to deliver value to the customer. It’s about speed and efficiency. It uses a variety of tools, including value stream mapping, 5S, and Kaizen events.

- Six Sigma: Focuses on reducing variation and defects in processes to achieve high levels of quality. It’s about consistency and precision. It relies heavily on statistical methods and data analysis, using tools like DMAIC (Define, Measure, Analyze, Improve, Control).

Think of it this way: Lean aims to make the river flow faster and smoother, while Six Sigma aims to make the river’s flow as consistent and predictable as possible.

In practice, Lean and Six Sigma are often used together, complementing each other. Lean provides the framework for streamlining processes and removing waste, while Six Sigma helps to achieve consistent quality levels within those streamlined processes.

Q 6. What are the key elements of a Kaizen event?

A Kaizen event is a short, focused improvement workshop involving a cross-functional team working together to solve a specific problem or improve a particular process. It’s a powerful tool for rapid improvement.

Key elements of a Kaizen event include:

- Clearly defined scope: Focus on a specific, well-defined problem or process area.

- Cross-functional team: Involve people from different departments with relevant expertise.

- Data-driven approach: Use data to understand the current state and measure the impact of improvements.

- Time-boxed event: Typically conducted over a short period (e.g., a few days).

- Implementation plan: Develop a plan for implementing and sustaining the improvements.

- Management support: Ensure that leadership provides necessary resources and support.

For example, a Kaizen event might focus on reducing lead times in a specific production line. The team would gather data, identify bottlenecks, brainstorm solutions, and implement changes. The improvements would then be measured to ensure they achieve the desired results.

Q 7. Describe your experience with 5S methodology.

5S is a methodology for workplace organization and standardization. It’s a foundational element of Lean, promoting a more efficient and safe work environment. I’ve used 5S extensively in various projects, improving efficiency and reducing waste.

My experience involves leading 5S implementations in several manufacturing settings, focusing on:

- Sort (Seiri): Eliminating unnecessary items from the workspace. This involved identifying and removing outdated tools, excess inventory, and anything that wasn’t essential for the tasks being performed. We used visual aids like labels and color-coding to identify items for removal.

- Set in Order (Seiton): Organizing the remaining items for easy access and use. This involved creating a systematic storage system, clearly labeling everything, and optimizing the layout of the workspace to improve workflow. We used shadow boards and visual cues to ensure that everything was in its designated place.

- Shine (Seiso): Cleaning the workspace regularly to maintain a clean and organized environment. This included establishing a cleaning schedule and assigning responsibilities to team members. We implemented regular inspections to ensure cleanliness was maintained.

- Standardize (Seiketsu): Establishing standard procedures for maintaining the 5S system. This involved creating visual work instructions, documenting best practices, and implementing regular audits to ensure adherence to standards. We developed checklists and training materials to ensure consistent application.

- Sustain (Shitsuke): Maintaining the 5S system over the long term. This involved incorporating 5S into daily routines, providing ongoing training, and regularly reviewing and updating the system. We implemented regular feedback mechanisms and reward systems to foster continuous improvement.

The results were significant: reduced search times for tools and materials, improved workplace safety, reduced waste, and increased employee morale due to a more organized and efficient work environment.

Q 8. How do you measure the success of a Lean improvement project?

Measuring the success of a Lean improvement project goes beyond simply looking at cost savings. A truly successful project delivers sustainable improvements across multiple key performance indicators (KPIs). We need a multifaceted approach, focusing on both quantitative and qualitative measures.

Quantitative Measures: These are easily measurable metrics. Examples include:

- Reduced Lead Time: How much faster are products/services delivered?

- Increased Throughput: Has the volume of output increased?

- Lower Defect Rates: Has the number of errors or defects decreased?

- Improved Inventory Turnover: How efficiently are we managing inventory?

- Reduced Costs: Are there demonstrable cost savings in materials, labor, or overhead?

Qualitative Measures: These focus on the softer, but equally important, aspects of improvement.

- Employee Engagement: Are employees more involved and empowered?

- Improved Morale: Has the overall workplace atmosphere improved?

- Increased Customer Satisfaction: Are customers happier with the improved product/service?

- Enhanced Safety: Has the workplace become safer?

- Improved Process Stability: Are processes more predictable and less prone to disruptions?

In my experience, a balanced scorecard approach, combining both quantitative and qualitative data, provides the most comprehensive picture of a Lean project’s success. For example, in a previous project implementing Lean manufacturing in a small batch production facility, we successfully reduced lead times by 40% (quantitative) while simultaneously observing increased employee satisfaction and reduced workplace injuries (qualitative). This holistic view gave us a much clearer picture of our accomplishments.

Q 9. Explain the concept of Poka-Yoke (error-proofing).

Poka-Yoke, often translated as ‘mistake-proofing’ or ‘error-proofing,’ is a Lean manufacturing methodology designed to prevent defects from occurring in the first place. It focuses on designing processes and systems that make it virtually impossible to make a mistake. This proactive approach is far more efficient than relying on inspection to catch errors later in the process.

Poka-Yoke methods employ various techniques, including:

- Checklists: Simple, structured lists ensuring all steps are followed.

- Visual Controls: Using color-coding, labels, or other visual cues to guide workers.

- Jigs and Fixtures: Guiding tools and devices to ensure parts are assembled correctly.

- Automation: Automating processes to minimize human error.

- Warning Signals: Alarms or indicators that alert operators to potential problems.

For instance, imagine a machine that only accepts a specific size of component. If you try to insert the wrong size, the machine simply won’t work. That’s Poka-Yoke in action. In a software development context, a form that automatically validates user input, preventing invalid data from being submitted, is another practical application. The key is to anticipate potential errors and build safeguards into the system to prevent them.

Q 10. What is Kanban, and how does it improve workflow?

Kanban is a visual workflow management system that helps teams manage and improve the flow of work. It’s particularly effective for managing tasks in a just-in-time manner, minimizing work-in-progress (WIP) and maximizing efficiency. Think of it as a visual representation of your workflow, making it easy to see what’s happening and identify bottlenecks.

A Kanban system typically uses a Kanban board, which can be physical or digital. This board displays the workflow stages (e.g., To Do, In Progress, Done) and the tasks within each stage. Cards representing individual tasks are moved across the board as they progress through the workflow. Limits are set on the number of tasks that can be in progress at any given time (WIP limits), preventing the system from being overwhelmed.

Kanban improves workflow by:

- Visualizing workflow: Provides a clear overview of the current state of work.

- Limiting work-in-progress (WIP): Prevents multitasking and improves focus.

- Improving flow: Identifies and addresses bottlenecks.

- Increasing efficiency: Reduces waste and improves productivity.

- Enabling continuous improvement: Facilitates regular review and adjustment of the process.

In my previous role, we implemented a Kanban system for our software development team. By limiting the number of tasks in progress, we reduced context switching and improved overall developer focus, leading to faster delivery times and higher-quality code. The visual nature of the board made it easy for the entire team to understand the workflow and identify areas for improvement.

Q 11. Describe your experience with root cause analysis.

Root cause analysis (RCA) is a structured problem-solving technique used to identify the underlying causes of problems, rather than just addressing their symptoms. It’s crucial in Lean environments because it helps to prevent recurring issues and create lasting solutions.

I have extensive experience using various RCA methods, including the ‘5 Whys,’ fishbone diagrams (Ishikawa diagrams), and fault tree analysis. The ‘5 Whys’ is a simple yet effective technique where you repeatedly ask ‘why’ to drill down to the root cause. Fishbone diagrams help visually organize potential causes, categorized by different factors (e.g., people, methods, materials, machines).

For example, in a previous project involving frequent machine downtime, we used the ‘5 Whys’ to investigate. The initial problem was ‘Machine X is frequently failing.’ By repeatedly asking ‘why,’ we discovered the root cause was a faulty component supplier providing inconsistent quality, leading to premature wear and tear. Addressing this supplier issue eliminated the recurring downtime.

My approach to RCA always involves:

- Data Gathering: Collecting relevant data to understand the problem.

- Team Collaboration: Engaging relevant stakeholders in the analysis process.

- Structured Methodology: Utilizing a chosen RCA technique to systematically investigate.

- Verification: Confirming the identified root cause before implementing solutions.

- Implementation of Corrective Actions: Developing and implementing effective solutions to prevent recurrence.

I prioritize a collaborative approach to RCA, ensuring that those directly involved in the process contribute their insights and knowledge. This collaborative effort leads to more thorough analysis and ownership of the solution.

Q 12. What is the role of data in Lean initiatives?

Data is the cornerstone of Lean initiatives. It provides the objective evidence needed to identify problems, track progress, and make informed decisions. Without data, Lean improvements become guesswork, lacking the rigor needed for sustained success.

Data plays several crucial roles in Lean:

- Identifying Waste: Data analysis reveals areas of waste (e.g., excess inventory, unnecessary steps, defects) and their impact on the organization.

- Tracking Performance: Key performance indicators (KPIs) track progress towards Lean goals, providing insights into what’s working and what needs improvement.

- Measuring Improvement: Data is crucial to quantify the impact of Lean initiatives, demonstrating their value and ROI.

- Validating Hypotheses: Data allows testing assumptions and validating the effectiveness of implemented changes.

- Identifying Root Causes: Data analysis is vital in root cause analysis to uncover the underlying reasons for problems.

In practice, I utilize various data collection methods, including: process mapping, time studies, defect tracking, inventory analysis, and customer feedback surveys. These data sources are then analyzed using statistical process control (SPC) charts, Pareto charts, and other statistical tools to uncover trends and patterns. For example, tracking defect rates over time using a control chart helped us pinpoint a specific process step causing a large portion of our product defects, allowing us to implement targeted improvements.

Q 13. How do you handle resistance to change during a Lean transformation?

Resistance to change is a common challenge during Lean transformations. People are naturally resistant to changes that disrupt established routines or threaten their perceived security. Effective change management is critical to navigate this resistance.

My approach to handling resistance involves:

- Communication and Education: Clearly communicating the goals, benefits, and process of the Lean transformation to all stakeholders. This includes explaining how the changes will impact them, addressing concerns proactively.

- Employee Involvement: Engaging employees throughout the transformation process. Involving them in problem-solving, implementation, and decision-making builds ownership and reduces resistance.

- Building a Vision: Clearly articulating a shared vision and demonstrating how Lean principles will create a better future for the organization and its employees.

- Small, Incremental Changes: Introducing changes incrementally instead of implementing a massive overhaul all at once. This allows for adjustments along the way and reduces the feeling of being overwhelmed.

- Celebrating Successes: Recognizing and celebrating successes along the way helps build momentum and demonstrates the value of Lean principles.

- Addressing Concerns: Actively listening to and addressing concerns and anxieties of those resistant to change. It’s important to acknowledge and validate their feelings.

In one project, we overcame significant resistance from a group of experienced line workers by involving them in the design and implementation of new work processes. This fostered a sense of ownership and dramatically reduced their resistance. Their insights also contributed to the development of more practical and effective solutions.

Q 14. What is your experience with visual management tools?

Visual management is a cornerstone of Lean, making information readily available and easily understandable to all team members. It transforms data into actionable insights, promoting faster decision-making and improved communication.

My experience encompasses a wide range of visual management tools, including:

- Kanban Boards: As discussed earlier, these provide a clear visual representation of workflow and progress.

- Andon Systems: These visual signaling systems alert workers and managers to problems, enabling immediate action.

- Value Stream Maps: These diagrams illustrate the entire process flow, highlighting areas of waste and inefficiency.

- 5S Visual Aids: Visual cues (e.g., color-coding, labels) are used to maintain a clean, organized, and efficient workplace.

- Control Charts: These charts graphically display process data to identify trends and anomalies.

- Performance Dashboards: These present key performance indicators (KPIs) visually to monitor progress toward Lean goals.

I have utilized these tools in diverse settings, from manufacturing plants to software development teams. For example, in a manufacturing setting, we implemented an Andon system to instantly signal machine malfunctions, resulting in faster response times and reduced downtime. The visual nature of the system ensured everyone was aware of the problem immediately, creating a sense of shared responsibility for swift resolution.

Q 15. Describe a time you successfully implemented a Lean improvement project.

In a previous role at a manufacturing plant, we experienced significant bottlenecks in our assembly line due to inefficient material handling. We implemented a Lean improvement project focused on optimizing the flow of materials using the principles of 5S and Value Stream Mapping.

First, we conducted a thorough 5S audit, meticulously organizing the workspace, eliminating unnecessary items, standardizing processes, and cleaning up the area. This immediately improved accessibility and reduced wasted motion. Then, we created a detailed Value Stream Map to visualize the entire process, from raw material arrival to finished product shipment. This map helped us identify areas of waste, including excessive inventory, unnecessary movement, and waiting time.

Based on the Value Stream Map, we implemented several changes. This included: reorganizing the layout of the assembly line to reduce movement, implementing a Kanban system to manage inventory, and introducing standardized work instructions to improve consistency. The result was a 20% reduction in lead time and a 15% increase in overall equipment effectiveness (OEE).

The success of this project wasn’t just about the numbers; it was also about empowering the team. By involving the assembly line workers in the problem-solving process, we fostered a sense of ownership and commitment to the improvements, ensuring long-term success.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What Lean tools are you most proficient with?

My proficiency spans a range of Lean tools, but I’m particularly adept at Value Stream Mapping, 5S, Kanban, and Poka-Yoke.

- Value Stream Mapping: I excel at using this tool to visualize and analyze the flow of materials and information, identifying bottlenecks and opportunities for improvement. I’ve used it successfully in both manufacturing and service environments.

- 5S: This methodology, focusing on Sort, Set in Order, Shine, Standardize, and Sustain, is fundamental to Lean. I’m experienced in conducting 5S audits, implementing improvements, and ensuring long-term sustainability.

- Kanban: I’m skilled in designing and implementing Kanban systems to manage workflow, limit work in progress (WIP), and improve flow. I understand how to adjust the Kanban system based on actual demand and process constraints.

- Poka-Yoke (Mistake-Proofing): I’m proficient in identifying potential errors and implementing simple, cost-effective solutions to prevent them from occurring. This includes using visual cues, jigs, and fixtures.

Q 17. How do you ensure sustainability of Lean improvements after a project is completed?

Sustainability of Lean improvements is crucial. It’s not enough to just implement changes; we need to embed them into the culture and processes of the organization.

My approach involves several key strategies:

- Standardization: Documenting improved processes and creating standardized work instructions ensures consistency and prevents regression to old habits.

- Training and Empowerment: Training team members on new processes and empowering them to own and maintain the improvements is vital. This often includes creating a culture of continuous improvement.

- Visual Management: Using visual cues like dashboards, charts, and Kanban boards helps track progress and identify potential problems early. This transparency keeps everyone informed and engaged.

- Regular Audits and Gemba Walks: Conducting regular audits and Gemba Walks (explained below) allows for early detection of deviations from standard work and facilitates prompt corrective actions.

- Continuous Improvement Culture: Fostering a culture of continuous improvement where employees are encouraged to identify and propose improvement ideas is essential for long-term success.

Q 18. Explain the concept of Gemba walks.

Gemba walks are structured observations conducted at the actual place of work, the ‘Gemba’. They’re not just casual visits; they’re purposeful observations aimed at understanding the work process firsthand, identifying improvement opportunities, and gathering data.

A typical Gemba walk involves:

- Planning: Defining the purpose and scope of the walk, identifying key areas to focus on, and preparing questions.

- Observation: Observing the work process, paying attention to details, and documenting findings. This may involve taking photos or videos.

- Data Gathering: Collecting data related to cycle times, waste, and other relevant metrics.

- Interaction: Engaging with employees, asking questions, and gaining their insights and perspectives.

- Analysis and Action Planning: Analyzing the data and observations to identify improvement opportunities and create an action plan.

Think of it as a detective investigating a crime scene, but instead of solving a crime, the goal is to identify and solve process inefficiencies.

Q 19. What is your understanding of Total Productive Maintenance (TPM)?

Total Productive Maintenance (TPM) is a holistic approach to equipment maintenance that aims to maximize the effectiveness and lifespan of equipment by engaging all employees in maintenance activities.

Unlike traditional reactive maintenance, which only addresses problems after they occur, TPM focuses on preventing problems through proactive maintenance, employee involvement, and continuous improvement. Key elements of TPM include:

- Autonomous Maintenance: Empowering operators to perform basic maintenance tasks on their own equipment.

- Planned Maintenance: Scheduling and performing regular maintenance tasks to prevent equipment breakdowns.

- Preventive Maintenance: Implementing measures to prevent equipment failures before they occur.

- Early Failure Detection: Implementing systems to detect potential failures early on.

- Training and Education: Providing operators and maintenance personnel with the necessary training and education to perform maintenance tasks effectively.

The benefits of TPM include reduced downtime, improved equipment reliability, increased productivity, and reduced maintenance costs. It’s a crucial component of any Lean manufacturing or service operation that relies heavily on equipment.

Q 20. How do you apply Lean principles in a service industry?

Lean principles are just as applicable in service industries as they are in manufacturing. While the ‘product’ is different (a service instead of a tangible good), the core concepts of eliminating waste and improving flow remain the same.

In a service industry, ‘waste’ might manifest as:

- Waiting time: Customers waiting for service.

- Unnecessary movement: Employees moving unnecessarily between tasks.

- Overprocessing: Performing more work than necessary.

- Inventory: Holding excessive files or paperwork.

- Defects: Errors in service delivery.

Applying Lean in a service industry often involves streamlining processes, reducing customer wait times, improving employee efficiency, and reducing errors. Tools like Value Stream Mapping, 5S, and Kanban can all be effectively used to identify and eliminate waste.

For example, a hospital could use Lean to optimize patient flow, reducing wait times in the emergency room and improving overall patient experience. A bank could use Lean to streamline its loan processing, reducing processing times and improving customer satisfaction.

Q 21. What are the key performance indicators (KPIs) you would track in a Lean project?

The specific KPIs will vary depending on the Lean project’s goals, but some common examples include:

- Lead Time: The time it takes to complete a process from start to finish. A reduction in lead time indicates improvement in efficiency.

- Cycle Time: The time it takes to complete one unit of work. Similar to lead time, shorter cycle times signify efficiency gains.

- Throughput: The amount of work completed within a specific time period. An increase in throughput demonstrates improved productivity.

- Inventory Levels: Tracking inventory levels to identify and reduce excess stock.

- Defect Rate: Measuring the number of defects or errors to improve quality.

- Overall Equipment Effectiveness (OEE): Measures the effectiveness of equipment by considering availability, performance, and quality. This is particularly relevant in manufacturing settings.

- Customer Satisfaction: Measuring customer satisfaction through surveys or feedback is vital for service-based Lean projects.

- Employee Engagement: Tracking employee engagement to ensure that Lean initiatives don’t negatively impact morale.

It’s important to establish baseline measurements before starting the project to track improvements accurately. Data visualization through dashboards and charts is key to effectively monitoring these KPIs and making data-driven decisions.

Q 22. How do you use A3 reporting in Lean projects?

A3 reporting is a powerful Lean tool for problem-solving and improvement project management. Think of it as a one-page summary of a problem, its analysis, proposed solutions, and implementation plan. It’s designed for clear communication and facilitates collaborative problem-solving.

The structure typically includes:

- Problem Statement: Clearly defines the problem being addressed, often using metrics to quantify its impact.

- Background: Provides context and relevant background information.

- Current State: Describes the current situation, often using data visualization like charts or graphs.

- Data Analysis: Presents data analysis to support understanding the root cause of the problem. This could include Pareto charts, fishbone diagrams, or 5 Whys analysis.

- Proposed Solutions: Outlines potential solutions and their anticipated impact.

- Implementation Plan: Details the steps required to implement the chosen solution, including timelines and responsibilities.

- Results: Tracks the progress and outcome of the implementation, demonstrating the impact of the solution.

Example: Imagine a manufacturing plant experiencing high defect rates in a particular product line. An A3 report would document this problem, analyze root causes (perhaps through a fishbone diagram showing factors like equipment malfunction, operator error, or material defects), propose solutions (e.g., improved training, equipment upgrades, or process changes), and track the improvement in defect rates after implementation. This allows everyone involved to stay focused and understand the progress at a glance.

Q 23. Explain the concept of Andon.

Andon is a visual signaling system used to immediately alert team members and management of abnormalities in a process. Think of it as a visual alarm system. It’s crucial for stopping production when a problem occurs, preventing defects from moving downstream, and enabling rapid problem-solving. This prevents small issues from becoming larger, more costly problems.

A typical Andon system might use lights, horns, or digital displays to signal various situations:

- Production Stoppage: Indicates a major problem requiring immediate attention.

- Quality Issue: Signals a quality defect requiring inspection and corrective action.

- Machine Malfunction: Alerts maintenance personnel to a machine problem.

Practical Application: In an assembly line, an Andon system could immediately halt the line if a worker detects a defective part. This prevents potentially hundreds of faulty products from being produced, saving time, resources and improving quality. It also emphasizes a culture of immediate problem-solving and empowers workers to address issues proactively.

Q 24. What are the challenges in implementing Lean in a large organization?

Implementing Lean in large organizations presents several challenges, often stemming from size, complexity, and established cultures:

- Resistance to Change: Employees accustomed to old ways of working may resist new methods and processes. Overcoming ingrained habits requires strong leadership and effective change management strategies.

- Siloed Departments: Large organizations often have departmental silos, hindering cross-functional collaboration, crucial for Lean’s success. Breaking down these silos requires clear communication, shared goals, and incentivizing collaboration.

- Data Acquisition and Analysis: Gathering and analyzing data across a large organization can be challenging. Implementing robust data collection systems and developing data analysis skills are vital.

- Lack of Management Support: Lean implementation requires top-down support and commitment. Without buy-in from leadership, the effort is likely to fail.

- Measuring Success: Defining and tracking appropriate metrics is crucial to demonstrate the value of Lean initiatives and maintain momentum. This often requires adapting traditional KPI frameworks to align with Lean principles.

- Training and Development: Upskilling the workforce in Lean principles and tools is essential. This requires significant investment in training programs and ongoing support.

Overcoming these challenges requires a phased approach, focusing on pilot projects to demonstrate success, securing leadership buy-in, and fostering a culture of continuous improvement.

Q 25. How do you prioritize improvement projects based on business value?

Prioritizing improvement projects based on business value requires a systematic approach. I typically use a framework that considers several factors:

- Financial Impact: Estimate the potential cost savings, revenue increases, or other financial benefits of each project.

- Strategic Alignment: Assess how well each project aligns with the organization’s overall strategic goals.

- Customer Impact: Evaluate how each project will improve customer satisfaction, reduce lead times, or enhance product quality.

- Feasibility: Assess the likelihood of successful implementation, considering resource availability, technical challenges, and potential risks.

- Urgency: Consider the time sensitivity of addressing each problem. Some issues require immediate attention while others can be tackled later.

Prioritization Matrix: I often use a prioritization matrix, plotting projects based on their business impact and feasibility. This allows for a clear visual representation and easier selection of high-impact, feasible projects.

Example: A project reducing production downtime by 10% might have a higher priority than one that improves employee morale, even if both are valuable. The downtime reduction directly translates to significant cost savings and revenue improvement.

Q 26. What are your strengths and weaknesses related to Lean principles?

Strengths: I possess a deep understanding of Lean principles and tools, including Kaizen events, Value Stream Mapping, 5S, and A3 reporting. I’m highly proficient in data analysis and using metrics to track progress. I excel at facilitating cross-functional collaboration and coaching teams to adopt a continuous improvement mindset. I have a proven track record of successfully implementing Lean projects across diverse industries.

Weaknesses: While I am adept at guiding and mentoring teams, I can sometimes be too focused on the details, potentially slowing down the decision-making process. To mitigate this, I actively work on delegating tasks more effectively and trusting the expertise of team members.

Q 27. How do you stay updated on the latest trends in Lean and Continuous Improvement?

Staying updated on Lean and Continuous Improvement trends involves a multi-faceted approach:

- Professional Networks: I actively participate in Lean-focused professional organizations and attend conferences and workshops to connect with other practitioners and learn about the latest innovations.

- Publications and Journals: I regularly read industry publications and journals focused on Lean, operations management, and continuous improvement.

- Online Resources: I utilize online platforms and communities to access articles, case studies, and webinars related to Lean and CI.

- Benchmarking: I regularly study how leading companies are applying Lean principles and adapting them to modern contexts.

This proactive approach ensures my knowledge remains current and relevant, allowing me to effectively apply best practices to my work.

Q 28. Describe your experience with implementing Lean in a cross-functional team.

In a previous role, I led a cross-functional team tasked with improving the order fulfillment process. The team consisted of representatives from operations, logistics, sales, and customer service. Initially, there were challenges in aligning priorities and communication. We overcame this by:

- Establishing clear goals and metrics: Defining shared targets for order fulfillment time, accuracy, and customer satisfaction.

- Utilizing Value Stream Mapping: Visually mapping the entire process, identifying bottlenecks and areas for improvement. This helped all team members understand the process holistically.

- Facilitating Kaizen events: Conducting workshops with the team to identify and implement small, incremental improvements. This fostered a culture of continuous improvement and ownership within the team.

- Regular communication and feedback: Maintaining open communication channels through regular meetings and progress reports. This ensured everyone was informed and involved.

The result was a 20% reduction in order fulfillment time, a 15% decrease in errors, and significant improvements in customer satisfaction scores. This experience solidified my understanding of the importance of effective cross-functional team dynamics in implementing Lean improvements.

Key Topics to Learn for LEAN and Continuous Improvement Interview

- Lean Principles: Understand the core principles of Lean manufacturing (Waste Reduction, Value Stream Mapping, Just-in-Time, etc.) and how they apply across various industries.

- Value Stream Mapping (VSM): Learn to create and analyze VSMs to identify bottlenecks and areas for improvement. Be prepared to discuss practical applications and examples from your experience.

- Kaizen and Continuous Improvement methodologies: Explain the philosophy of Kaizen and its role in fostering a culture of continuous improvement. Discuss tools like 5S, PDCA cycle (Plan-Do-Check-Act), and A3 problem solving.

- Problem-Solving Frameworks: Master various problem-solving methodologies like DMAIC (Define, Measure, Analyze, Improve, Control) and 8D problem solving. Be ready to discuss their application in real-world scenarios.

- Metrics and KPIs: Understand key performance indicators (KPIs) used to measure Lean initiatives and continuous improvement efforts. Be prepared to discuss how these metrics are used to track progress and demonstrate success.

- Waste Elimination (Muda): Go beyond simply listing the seven types of waste. Discuss how to identify and eliminate waste in different contexts, using practical examples from your own experience or case studies.

- Lean Six Sigma: Understand the synergy between Lean and Six Sigma methodologies and how they complement each other in driving efficiency and quality improvements.

- Change Management: Discuss strategies for effectively implementing Lean initiatives and managing change within organizations. Consider the importance of communication, training, and leadership in successful transformations.

Next Steps

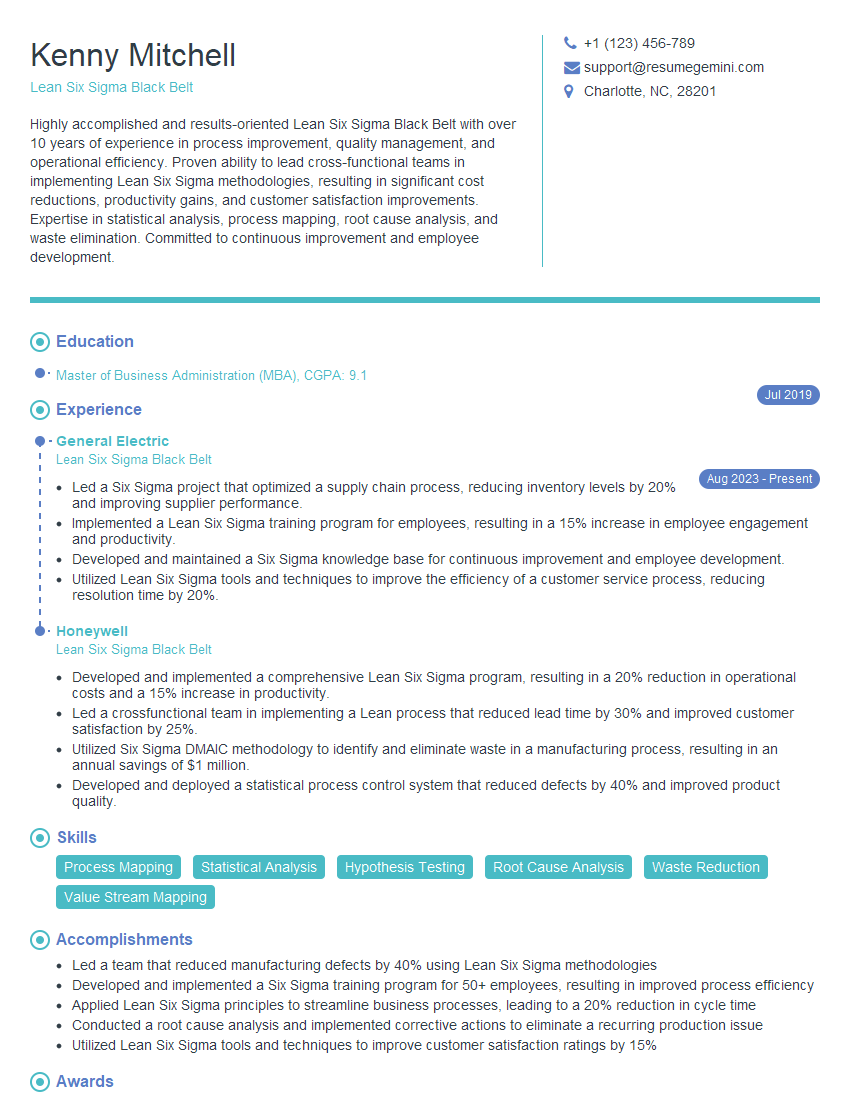

Mastering Lean and Continuous Improvement principles significantly enhances your career prospects across various industries. These skills are highly sought after, demonstrating your ability to drive efficiency, reduce costs, and improve overall organizational performance. To maximize your chances of landing your dream role, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to highlight your Lean and Continuous Improvement expertise. Examples of resumes specifically designed for this field are available to guide your efforts. Invest the time to craft a compelling narrative that showcases your skills and experience – it’s an investment in your future career success!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good