Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Leather Manipulation interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Leather Manipulation Interview

Q 1. Describe your experience with various leather types (e.g., full-grain, top-grain, suede).

My experience encompasses a wide range of leathers, each with unique properties influencing its suitability for different projects. Full-grain leather, the highest quality, retains the original grain layer of the hide, resulting in a durable, richly textured material ideal for high-end goods like bags and jackets. It develops a beautiful patina over time. Top-grain leather, while still durable, has the top layer slightly sanded to create a smoother, more uniform surface. It’s a more affordable option often used in furniture and less expensive accessories. Finally, suede, made from the underside of the hide, is known for its soft, velvety texture and is often used in clothing and upholstery, requiring more delicate handling due to its absorbency. I’ve worked extensively with all three, understanding their strengths and limitations allows me to make informed decisions during the design process.

For instance, I recently crafted a bespoke briefcase. The client desired exceptional durability and a unique aesthetic. Full-grain leather, specifically bridle leather known for its strength, was the obvious choice. Contrastingly, for a pair of suede gloves, the soft, pliable nature of suede was essential for comfort and dexterity.

Q 2. Explain the process of selecting appropriate leather for a specific project.

Selecting the right leather is paramount. It’s not just about aesthetics; it’s about functionality and longevity. My process begins with understanding the project’s requirements: intended use (bag, belt, wallet), desired durability, budget, and aesthetic goals. I consider the leather’s thickness, weight, grain pattern, and finish. For example, a sturdy, thick full-grain leather is ideal for a work bag that will handle heavy loads, while a thinner, more supple leather might be perfect for a delicate purse. The desired level of formality also plays a role; a highly polished, smooth leather conveys sophistication, while a more rustic, textured leather lends itself to a rugged, casual design. I always factor in the client’s preferences, ensuring the final product aligns seamlessly with their vision. Often, I provide samples and swatches to aid the client in this decision-making process.

Q 3. What are the different leather finishing techniques you’re proficient in?

My finishing techniques are diverse, reflecting a dedication to achieving unique aesthetics and desired levels of protection. I’m proficient in numerous methods including hand-buffing to create a subtle sheen, applying waxes and oils to nourish and condition the leather, and using dyes and pigments for color customization. I also utilize specialized techniques like stamping, embossing, and tooling to add intricate designs or personalize the leather goods. Furthermore, I can apply protective coatings to increase water resistance and durability. Each technique alters the feel and look of the leather, influencing the final product’s character and durability. For example, a simple hand-buffed finish can enhance the natural beauty of full-grain leather, while tooling can add intricate details to a belt or wallet.

Q 4. How do you create accurate patterns for leather goods?

Creating accurate patterns is fundamental to successful leatherwork. I begin by sketching the design, carefully considering dimensions and functionality. Then, I create a paper template, utilizing precise measurements and accounting for seam allowances. I test the pattern on a scrap piece of leather before cutting the final material, making any necessary adjustments. This iterative approach ensures a perfect fit and prevents wasting precious leather. For complex designs, I may use digital design tools to create precise templates and scale them accurately. Regardless of the approach, the key is precision and patience. A poorly made pattern results in an ill-fitting and potentially ruined final product. I always double-check my measurements and patterns several times to minimize errors.

Q 5. Describe your experience with leather stitching techniques (e.g., saddle stitch, hand stitch).

I’m skilled in both hand stitching and machine stitching, choosing the appropriate technique based on the project’s requirements and aesthetic considerations. Saddle stitching, a durable hand-stitching technique using two needles, is my preferred method for high-end items; its strength and visual appeal are unmatched. Hand stitching allows for greater control and precision, especially on curved surfaces or intricate designs. Machine stitching provides efficiency for simpler items and production runs but lacks the same character and durability as saddle stitching. I’ve worked on projects ranging from intricately stitched leather journals to machine-stitched leather bags, always prioritizing the technique best suited to the specific piece.

Q 6. What tools and equipment are essential for your leatherworking process?

My workshop is equipped with a variety of essential tools. These include cutting tools (sharp knives, swivel knives, and rotary cutters), various punches (for stitching holes and decorative elements), mallets and hammers (for tooling and shaping), stitching tools (stitching groovers, needles, and awls), and finishing tools (burnishers and edge bevelers). For more complex projects or large-scale production, I utilize a stitching machine and specialized leather-working equipment such as an embossing press. Properly maintained tools are crucial for precision and safety, ensuring high-quality work. I keep a well-organized workspace, allowing me to quickly locate and use the tools needed.

Q 7. How do you maintain and care for your leatherworking tools?

Maintaining my tools is a non-negotiable part of my process. Sharp blades are paramount for clean cuts and precision. I regularly hone and sharpen my knives and rotary cutters using appropriate stones and honing guides. I clean my tools after each use, removing any leather scraps or debris. Leatherworking tools, especially those made of metal, can rust if left uncared for; I regularly oil and lubricate my tools to prevent rust and prolong their lifespan. This preventative maintenance ensures that my tools remain in optimal condition, ensuring quality and efficiency throughout the leatherworking process. A well-maintained tool kit is an investment in the longevity and quality of my work.

Q 8. Explain your process for repairing damaged leather goods.

Repairing damaged leather goods requires a methodical approach, starting with a thorough assessment of the damage. I begin by identifying the type and extent of the damage – is it a scratch, a tear, a burn, or water damage? The material itself is also important; is it full-grain, top-grain, or a corrected-grain leather? This dictates the repair technique.

For small scratches, a leather conditioner and gentle buffing often suffice. Deeper scratches might require leather filler, carefully applied and blended to match the surrounding leather. Tears require more involved stitching, using thread that closely matches the leather’s color and a stitching technique that’s appropriate for the leather type and the tear’s location. For instance, a saddle stitch is strong and durable, suitable for structural repairs, while a blind stitch is better for cosmetic repairs where you want the stitches to be less visible. Water damage necessitates careful cleaning and conditioning to prevent mold and restore the leather’s suppleness. Sometimes, a complete section needs replacing with a patch of similar leather, meticulously stitched in place.

I always prioritize minimal intervention, aiming for a repair that’s both functional and aesthetically pleasing. Imagine repairing a vintage briefcase – the goal isn’t to make the repair blatant, but rather to seamlessly integrate it into the piece’s history.

Q 9. How do you address inconsistencies in leather thickness or texture?

Inconsistencies in leather thickness or texture are common, especially with natural leathers. Addressing these requires understanding the cause. Sometimes, it’s simply the natural variation inherent in the hide; other times, it’s due to manufacturing processes.

For thickness inconsistencies, I might use a leather skiving tool to carefully reduce the thickness of thicker areas, ensuring a uniform feel. For texture variations, the approach depends on the effect I want to achieve. If uniformity is key, I might use a smoothing tool or even lightly sand the surface, followed by conditioning to restore suppleness. However, if I’m aiming for a more rustic look, I might choose to embrace the natural variations, perhaps highlighting them with strategic tooling or finishing techniques.

Think of it like working with wood; you wouldn’t expect every piece of oak to be perfectly uniform. The beauty of natural materials often lies in their imperfections.

Q 10. Describe your experience with leather dyeing and finishing.

Leather dyeing and finishing are crucial for enhancing the leather’s appearance and durability. My experience encompasses a wide range of techniques, from hand-dyeing with aniline dyes for a natural look to using acrylic or water-based dyes for more vibrant and consistent results. I also utilize various finishing techniques, including glazing, burnishing, and stamping, to achieve a specific effect.

Hand-dyeing allows for a more artistic approach, achieving subtle shading and unique color variations. However, it requires more skill and time. Applying dyes using a spray gun or sponge provides more consistent color coverage. Finishing techniques like glazing add a protective layer and enhance shine, while burnishing compresses the leather fibers, creating a smooth, polished surface. Stamping adds texture and visual interest, creating embossed patterns or logos.

For example, I once dyed a saddle bag using a multiple-layer process of hand-dyeing with aniline dyes, creating depth and subtle shading variations to mimic a worn, aged appearance.

Q 11. What are your preferred methods for edging leather?

Edging leather is a crucial detail that significantly impacts the overall aesthetic and durability of a leather good. My preferred methods depend on the project’s demands and the desired finish.

For a clean, polished edge, I often use a beveler to create a smooth, rounded edge, followed by sanding and burnishing for a professional finish. For a more rustic or decorative edge, I might employ techniques like stitching, painting, or antiquing. A stitch-in-the-ditch edge, where the stitching is neatly concealed in a groove, provides both strength and a refined appearance. For heavily used items, I might add a sealant to protect the edge from wear.

The choice of edging method often reflects the overall style of the piece. A meticulously burnished edge suits a fine handbag, while a raw, slightly frayed edge might be appropriate for a more rugged leather belt.

Q 12. How do you ensure consistent quality in your leatherwork?

Maintaining consistent quality in leatherwork requires meticulous attention to detail throughout the process. I begin with careful selection of high-quality leather, paying attention to its consistency, thickness, and overall quality. I then utilize precise measuring and cutting techniques to ensure accurate pattern placement and consistent component sizes.

I employ standardized procedures for each step of the process, from stitching to finishing, adhering to established best practices. Regular maintenance of my tools is essential to maintain their precision and efficiency. I also maintain detailed records of materials and processes used for each project, allowing for traceability and the identification of any potential variations. Regular quality checks throughout the project help me identify and correct any inconsistencies promptly.

Think of it as baking a cake; consistent results rely on precise measurements, adherence to the recipe, and the quality of ingredients. The same principle applies to leatherwork.

Q 13. Describe your experience working with different leather tooling techniques.

My experience spans various leather tooling techniques, including stamping, carving, and molding. Stamping involves using stamps to create embossed designs, adding texture and visual interest. Carving involves using specialized tools to cut and shape the leather, creating intricate designs with depth and relief. Molding involves pressing the leather into a mold to create three-dimensional shapes.

I am proficient in both traditional hand-tooling techniques, which provide a unique artistic touch, and machine-assisted tooling, which allows for faster and more consistent production for larger projects. The choice of technique depends on the desired design complexity and the project’s scale. For instance, a custom-made leather journal might benefit from intricate hand-carving, whereas mass-produced wallets might utilize machine-assisted stamping for efficiency.

I particularly enjoy the challenge of combining different tooling techniques to create unique textures and effects, adding layers of depth and artistry to my work.

Q 14. How do you handle complex leather patterns and designs?

Handling complex leather patterns and designs requires a systematic approach. I start by creating accurate patterns, often using digital design software to create precise templates. These templates are then carefully transferred to the leather, ensuring accurate placement and consistent dimensions.

Complex designs often require multiple pattern pieces that need to be carefully assembled. Precise stitching and careful alignment are crucial for achieving a seamless finish. For intricate designs, I might employ techniques like stitching guides or transfer paper to ensure accurate placement of stitching lines. The construction of complex projects, such as a highly detailed leather jacket, involves breaking the design down into manageable sections and assembling them methodically.

Much like solving a jigsaw puzzle, each piece plays a crucial role in the final outcome. Careful planning and execution are essential for success.

Q 15. How do you measure and cut leather accurately?

Accurate measurement and cutting are fundamental to successful leatherwork. It’s like baking a cake – precise measurements ensure a perfect result. I always start with a well-defined pattern, often created digitally and printed on a durable paper. Then, I transfer this pattern to the leather using a variety of techniques depending on the leather type and project complexity. For thinner leathers, I might use a tracing wheel and carbon paper. For thicker leathers, I may use a sharp awl to prick holes along the pattern lines, allowing for easier cutting.

Cutting itself is crucial. I use sharp, high-quality shears or a rotary cutter, ensuring a clean, straight cut to prevent fraying and uneven edges. A self-healing cutting mat protects both my work surface and the leather. For intricate shapes, a sharp utility knife and a metal ruler are invaluable. Regular sharpening and maintenance of my cutting tools are essential. I always double-check my measurements before cutting, and I work slowly and deliberately to avoid errors.

For example, when crafting a bespoke leather holster, a millimeter off in the cut could render it unusable. Accuracy guarantees a perfect fit and a professional finish.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with using leather-specific adhesives and glues.

My experience with leather adhesives encompasses a wide range of products, each suited to different applications. I use contact cement for strong, permanent bonds, particularly when joining large pieces or creating structural components. Contact cement requires careful application; I use a thin, even coat on both surfaces and allow it to become tacky before joining. This technique is ideal for items like the base and sides of a leather bag.

For more delicate work or where a less permanent bond is desirable, I use water-based glues, which allow for some repositioning. These are great for attaching smaller details, like decorative stitching or adding trim. I always test my adhesive on a scrap piece of the same leather first to ensure compatibility and avoid any unwanted reactions or discoloration.

I also have experience using specialized leather glues designed for specific leather types, like those formulated for suede or exotic skins. Choosing the right adhesive is as critical as choosing the right leather itself – the wrong glue can lead to failure and ruin a project.

Q 17. How do you ensure the durability and longevity of your leather creations?

Durability and longevity are paramount in leatherwork. It’s all about careful material selection, precise construction, and appropriate finishing techniques. I begin by choosing high-quality, durable leather – full-grain leather is my preferred choice due to its strength and resilience. The thickness of the leather is also important; thicker leather will withstand more wear and tear.

My stitching is always strong and even, using appropriate needles and thread for the leather type and project. Reinforcing stress points with additional stitching or rivets is common practice, especially on items like bags and belts. Proper edge finishing is also crucial; I use edge bevelers and burnishers to create smooth, protected edges that resist wear and tear.

Finally, regular conditioning keeps the leather supple and prevents cracking. I use high-quality leather conditioners specifically designed for the leather type, following the manufacturer’s instructions carefully. Think of it as moisturizing your skin – it keeps it healthy and prevents premature aging.

Q 18. Describe your experience with different types of leather closures (e.g., zippers, buckles, snaps).

I have extensive experience with a variety of leather closures. Zippers are a common choice for bags and wallets; I choose heavy-duty zippers designed for leather and carefully install them, ensuring a smooth, reliable operation. I meticulously measure and prepare the leather for zipper installation, paying close attention to alignment and stitching. This prevents any snags or binding.

Buckles are often used on belts and straps. I choose buckles that are sturdy and complement the style of the item. Attaching buckles requires precision and attention to detail; a poorly attached buckle can weaken the entire piece. I often reinforce the buckle’s attachment points with rivets or stitching.

Snaps, both magnetic and pressure, are convenient for smaller items like wallets or purses. I use high-quality snaps that are appropriate for the thickness of the leather. The installation involves careful marking and precise punching of the holes to ensure a secure and clean closure.

Q 19. How do you troubleshoot common problems during leather manipulation?

Troubleshooting is an integral part of leatherwork. One common problem is uneven stitching. This is often due to improper needle selection, inconsistent tension, or poor preparation of the leather. I address this by checking my needle size, adjusting my machine tension, and ensuring the leather is smooth and free from wrinkles before stitching.

Another issue is cracking or splitting of the leather. This could be due to using the wrong type of leather for the project, inadequate conditioning, or excessive stress on a particular area. I prevent this by selecting appropriate leather, regularly conditioning the finished item, and reinforcing stress points.

Glue problems are also frequent. If the glue isn’t bonding correctly, it’s crucial to check the compatibility of the adhesive with the leather, ensure proper surface preparation (clean and free of oils), and use the correct application technique. Often, a small amount of additional pressure applied during bonding time can solve the issue.

Q 20. How do you manage your time effectively when working on leather projects?

Effective time management is key to completing leather projects efficiently and to the highest standard. I begin by meticulously planning each project; this includes creating detailed patterns, sourcing materials, and estimating the time required for each step. This avoids unexpected delays and ensures a smooth workflow.

I prioritize tasks, focusing on the most crucial aspects first. For example, on a custom leather jacket, I will focus on pattern making and cutting the main pieces of leather before moving on to smaller details. I break down large tasks into smaller, more manageable chunks, making the overall project less daunting.

I also avoid distractions. Creating a dedicated workspace, free from interruptions, and establishing clear working hours helps maintain focus. This minimizes errors and enhances my overall productivity.

Q 21. What are your preferred methods for cleaning and conditioning leather?

Cleaning and conditioning are essential for preserving the beauty and longevity of leather goods. For cleaning, I typically start with a soft, dry cloth to remove any loose dirt or debris. For more stubborn stains, I might use a specialized leather cleaner, always testing it on a hidden area first. Avoid harsh chemicals or excessive moisture, as these can damage the leather.

Conditioning is crucial to maintaining the leather’s suppleness and preventing cracking. I use high-quality leather conditioners, again testing on a hidden area first, applying them sparingly and evenly with a soft cloth. I avoid over-conditioning, which can leave the leather feeling greasy. The frequency of conditioning depends on the leather type, use, and environment – often every few months for regularly used items. Regular conditioning prevents the leather from drying out and becoming brittle.

Q 22. How do you adapt your techniques to different leather types and projects?

Adapting my techniques to different leather types and projects is crucial for achieving optimal results. Leather varies significantly in thickness, texture, and tannage (the process of preserving and treating hides). My approach involves a multi-step process:

- Assessment: I first carefully examine the leather’s characteristics. Is it full-grain, top-grain, or genuine leather? How thick is it? Is it supple or stiff? Knowing this informs my tool selection and stitching techniques.

- Tool Selection: For thicker leathers, I might use heavier needles and stronger thread. For delicate leathers, I opt for finer needles and lighter thread to avoid puncturing the material. Stitching techniques also adjust; for example, saddle stitching is better suited for thicker, tougher leathers, while a decorative stitch might be ideal for thinner, softer types.

- Technique Modification: Stiff leathers might require more conditioning or pre-treatment to make them more pliable. Delicate leathers need gentle handling to avoid tearing. For example, when working with suede, I take extra care to avoid scratching the delicate nap.

- Project-Specific Adjustments: The project itself also influences my technique. A sturdy belt requires strong stitching and durable leather, while a delicate bracelet demands precision and attention to detail. I might choose different dyes, finishes, or embossing techniques depending on the desired aesthetic.

For example, creating a rugged leather briefcase necessitates using thick, durable full-grain leather and robust stitching techniques, while crafting a refined leather wallet would involve thinner, softer leather and potentially more intricate hand-stitching or decorative tooling.

Q 23. Describe your understanding of leather grain and its impact on project design.

Understanding leather grain is fundamental to successful leatherwork. The grain refers to the natural outer layer of the hide, which has a unique texture and structure. Different grains impact design choices significantly:

- Full-Grain Leather: Retains the entire natural grain layer. It’s the strongest, most durable, and develops a beautiful patina over time. Its texture influences the design – a deeply textured full-grain leather might be best suited for a rustic-looking bag, while a smoother full-grain might work better for a more refined accessory.

- Top-Grain Leather: The top layer of the hide, but the outermost layer is sanded down. It’s smoother and more consistent than full-grain but less durable. This smoother surface lends itself well to embossing and stamping techniques.

- Genuine Leather: Often the lower layers of the hide, and is typically less durable. Designs should consider this leather’s limited strength, maybe using it for small items or linings.

For instance, when designing a belt, full-grain leather would be my preferred choice for its durability and natural look, whereas a smoother top-grain might be suitable for a more polished, less rugged look. The choice of grain dictates not only the final product’s appearance but also its longevity and suitability for intended use.

Q 24. Explain your experience with different types of leather stamps and embossing tools.

My experience encompasses a wide range of leather stamps and embossing tools. Different tools create distinct effects:

- Beveled Stamps: Create crisp, defined lines and create a shadow effect. They are excellent for lettering and intricate designs.

- Background Stamps: Used to create textured backgrounds and fill larger areas, adding depth and dimension. These often have repeating patterns.

- Fleuron Stamps: Decorative stamps used to add stylistic flourishes and details to designs.

- Branding Irons: Electrically heated tools that burn a mark into the leather, often used for logos or monograms. This is best done on thicker leather.

- Embossing Mallets and Stamps: Used to create raised designs. These are great for creating delicate 3-D effects, such as floral patterns.

I’ve used these tools in diverse ways – from creating custom monogrammed wallets to designing intricate floral patterns on handbags. The selection of stamps and tools depends heavily on the project’s design, the type of leather being used, and the desired outcome. Careful consideration of the tool’s weight, size, and shape is essential for precise and consistent results. For example, working with a detail-oriented design on a small leather item requires smaller, more delicate stamps and a lighter hand.

Q 25. How do you maintain a safe and organized workspace?

A safe and organized workspace is paramount in leatherwork. My workspace is designed for both safety and efficiency:

- Safety First: I always wear appropriate safety gear, including safety glasses to protect against flying debris and leather dust, and gloves to avoid cuts and abrasions. Sharp tools are stored securely in designated areas and handled with extreme care.

- Organized Layout: My tools are arranged logically, with frequently used tools easily accessible and less frequently used tools stored neatly. This minimizes clutter and facilitates efficient workflow.

- Ventilation: I work in a well-ventilated area or use a dust collection system to minimize exposure to leather dust and fumes from dyes and finishes.

- Proper Storage: Leather hides and finished projects are stored properly to prevent damage and maintain quality. Leather needs to be kept away from moisture and direct sunlight. Finished pieces should be protected to preserve condition.

Maintaining a clean and organized workspace is not merely a matter of aesthetics, it’s a crucial safety and efficiency measure. A clear workspace prevents accidents, speeds up production, and improves the quality of the final product. For example, a cluttered workspace could lead to misplacing a tool and causing a cut. A well-organized system prevents such accidents.

Q 26. Describe a challenging leather project and how you overcame the challenges.

One challenging project involved creating a custom saddle for a client with very specific requirements. The client requested intricate tooling, a specific type of leather that was difficult to source, and precise measurements to fit their unique horse.

The challenges included:

- Sourcing the Leather: The required leather was a rare, high-quality, vegetable-tanned hide with a particular grain pattern. I had to contact several suppliers before locating a suitable hide.

- Precise Measurements: Accurately measuring the horse to create a perfectly fitting saddle required meticulous attention to detail. Any error could render the saddle uncomfortable for the horse.

- Intricate Tooling: The client requested elaborate tooling, which involved hours of careful work to create a balanced and aesthetically pleasing design.

I overcame these challenges by:

- Thorough Research: I researched various leather suppliers and thoroughly investigated the client’s specifications. This helped in finding the right materials and preparing detailed design plans.

- Careful Planning and Measurement: I utilized precise measuring techniques and created detailed patterns to ensure an accurate fit. I consulted with an equine professional to ensure that the saddle design would conform to best practices.

- Patience and Precision: The intricate tooling required immense patience and precision. I took breaks and approached the task methodically to avoid errors.

The final product was highly praised by the client and demonstrated my ability to overcome complex challenges using skill, patience, and planning.

Q 27. What are your strengths and weaknesses as a leatherworker?

My strengths as a leatherworker lie in my attention to detail, my ability to adapt to different techniques and materials, and my problem-solving skills. I’m also a quick learner and enjoy researching new techniques and materials to further expand my abilities.

One area I’m currently working on improving is my business management skills. While I excel at the creative and technical aspects of leatherwork, streamlining my business operations, such as marketing and pricing, requires further development. I’m actively seeking opportunities to learn more about these areas.

Q 28. Where do you see yourself in 5 years in the leather industry?

In five years, I see myself established as a respected and sought-after leather artisan. I envision having a thriving business, possibly with a small workshop, producing high-quality, custom leather goods. I’d like to mentor aspiring leatherworkers and share my knowledge and passion for the craft. Furthermore, I hope to be experimenting more with sustainable and ethically sourced materials, furthering my commitment to responsible craftsmanship.

Key Topics to Learn for Leather Manipulation Interview

- Leather Selection and Properties: Understanding different types of leather (e.g., full-grain, top-grain, corrected grain), their characteristics (strength, durability, texture), and suitability for various applications. Practical application: Justifying leather choices for a specific project based on budget and desired aesthetic.

- Cutting and Pattern Making: Mastering accurate pattern creation, efficient cutting techniques, and minimizing material waste. Practical application: Describing your process for creating patterns from designs and adapting them for different leather thicknesses.

- Stitching and Sewing Techniques: Proficiency in various hand and machine stitching methods, understanding stitch types (e.g., saddle stitch, backstitch), and selecting appropriate needles and thread. Practical application: Explaining how to choose the right stitching method for different leather types and project requirements.

- Finishing and Treatments: Knowledge of leather finishing techniques (e.g., dyeing, staining, sealing, embossing) to achieve desired aesthetics and protect the leather. Practical application: Troubleshooting common finishing problems and explaining the impact of different finishes on leather durability.

- Tooling and Embossing: Understanding and applying various tooling techniques (e.g., stamping, carving, molding) to create decorative or functional elements. Practical application: Demonstrating understanding of different tooling methods and their suitability for specific designs.

- Repair and Maintenance: Knowledge of leather repair techniques (e.g., patching, stitching repairs) and maintenance procedures to extend the lifespan of leather goods. Practical application: Describing approaches to repairing common leather damages while maintaining aesthetic integrity.

- Health and Safety: Understanding and adhering to safety protocols when working with leather and associated tools and chemicals. Practical application: Describing your approach to maintaining a safe workspace and handling hazardous materials responsibly.

Next Steps

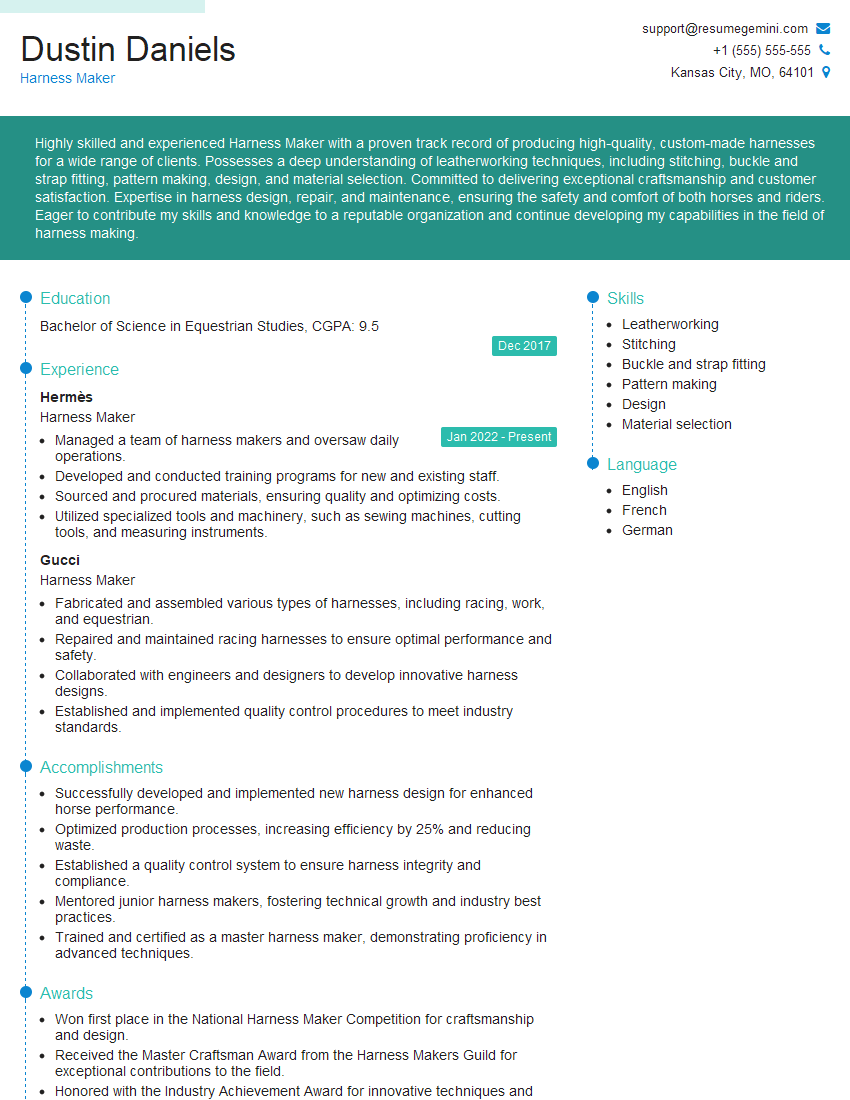

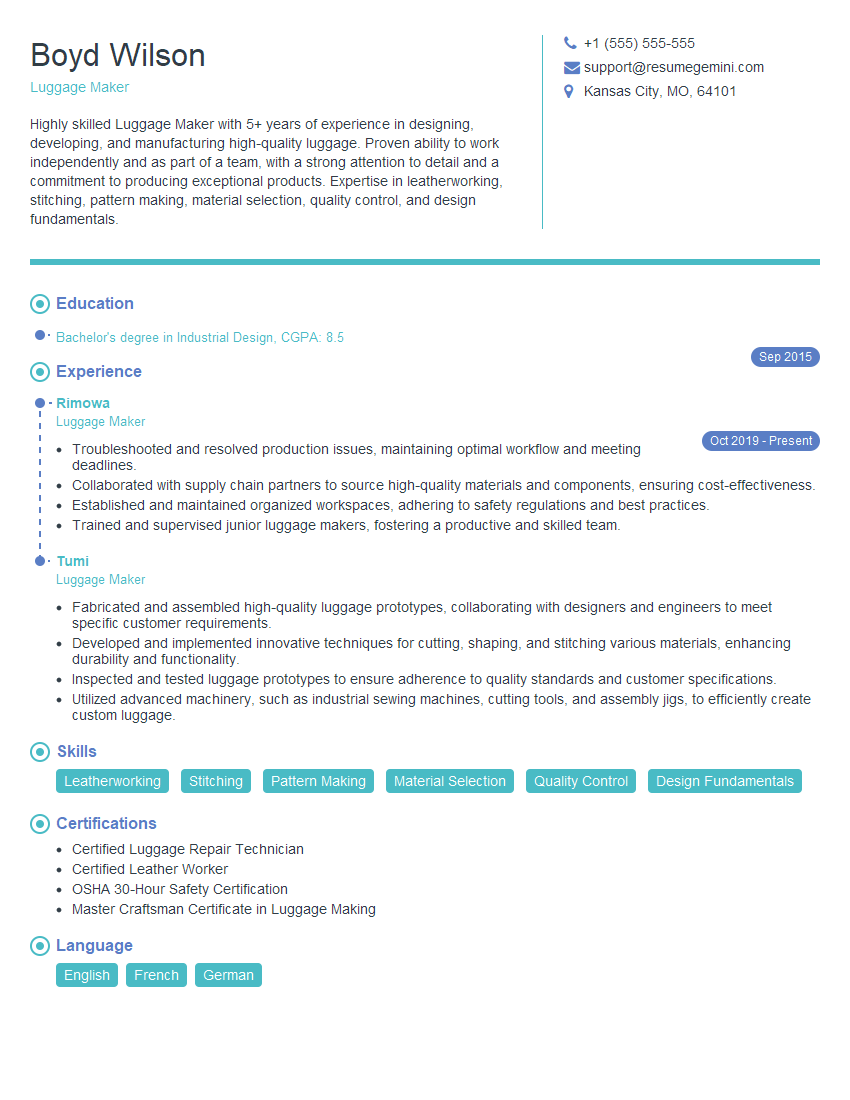

Mastering leather manipulation opens doors to exciting and rewarding careers in various industries, from high-end fashion and bespoke goods to furniture restoration and automotive upholstery. To maximize your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource that can help you build a professional resume that showcases your abilities and experience in leather manipulation. Examples of resumes tailored to this field are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good