Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Lifting and Moving Operations interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Lifting and Moving Operations Interview

Q 1. What are the different types of lifting equipment you are familiar with?

I’m familiar with a wide range of lifting equipment, categorized broadly by their power source and application. This includes:

- Overhead Cranes: These are ubiquitous in industrial settings, offering substantial lifting capacity and reach. I have extensive experience with both bridge cranes and gantry cranes, understanding their various control systems and safety mechanisms.

- Forklifts: A staple in warehousing and logistics, forklifts are crucial for moving palletized goods. My experience encompasses various types, including counterbalance, reach, and side-loader forklifts, and I am proficient in their safe operation and maintenance.

- Hoists: From chain hoists to electric hoists, these are versatile tools for lifting and moving loads vertically. I’m experienced in selecting the appropriate hoist for a given load and working height, considering factors like load capacity and lifting speed.

- Mobile Cranes: These are essential for larger projects involving heavy lifts in various locations. I’m knowledgeable about different types, including truck-mounted, crawler, and all-terrain cranes, as well as their operational limitations and required permits.

- Jacks: Hydraulic and mechanical jacks are critical for lifting heavy components in various situations. My experience includes using them in confined spaces and for supporting loads during maintenance.

- Lifting Beams and Slings: These are critical components of any lift, ensuring the load is evenly distributed and securely held. I have extensive knowledge of selecting appropriate slings (chain, wire rope, webbing) based on load type, weight, and lifting angle.

My experience covers both the practical operation and the maintenance aspects of these equipment types, ensuring they are always in safe working order.

Q 2. Describe your experience with safe lifting techniques.

Safe lifting techniques are paramount to prevent accidents. My approach is built on a foundation of careful planning and meticulous execution. It starts with a thorough risk assessment, identifying potential hazards like unstable ground, overhead obstructions, and the weight and center of gravity of the load.

I always ensure the correct lifting equipment is used, well-maintained and within its rated capacity. Proper rigging is crucial, using the correct type of slings and attaching them securely to both the load and the lifting equipment. This includes following the manufacturer’s guidelines and using appropriate safety factors. The lifting team undergoes thorough briefings, ensuring everyone understands their roles and responsibilities.

During the lift itself, I maintain constant communication with the team and visually inspect the equipment and load throughout the process. Smooth, controlled movements are essential, avoiding sudden jerking or abrupt stops. I’m also well versed in emergency procedures, knowing how to respond quickly and safely in unexpected situations. For instance, I once had to quickly shut down a crane operation when a strong gust of wind threatened to destabilize the load. Quick thinking and decisive action prevented a serious incident.

Q 3. Explain the importance of load charts and weight limits.

Load charts and weight limits are absolutely crucial for safety and preventing equipment failure. They provide the manufacturer’s specifications for a piece of equipment, outlining its maximum safe working load (SWL) under various conditions. This data is vital for selecting the right equipment for a specific job.

Ignoring these limits can lead to catastrophic equipment failure, potential injury, and significant property damage. For example, using a forklift rated for 2000 lbs to lift a 3000 lb load could cause the mast to collapse or the forks to bend, resulting in serious consequences. I always meticulously check load charts before initiating any lifting operation, ensuring the chosen equipment is adequately rated for the load’s weight and the specific conditions. I also consider factors like the load’s center of gravity and any environmental influences like wind or uneven terrain that might affect the SWL.

Q 4. How do you ensure the stability of loads during transport?

Ensuring load stability during transport is crucial and involves several strategies. Proper securing is key, using appropriate lashing, bracing, and other securing methods. This prevents shifting during transit. The choice of securing method depends on the type of load and the mode of transport.

For example, palletized goods on a forklift are secured using straps and the forklift’s stability, while a large piece of equipment on a lowboy trailer needs heavy-duty chains and potentially wooden blocking to prevent shifting during transport. The weight distribution is also critical; a poorly balanced load can easily tip over. I always ensure the load’s center of gravity is as low and centrally located as possible and use appropriate blocking and cribbing to further enhance stability.

Regular inspections during transport are essential, especially for longer journeys. I always check the securing mechanisms periodically to ensure they remain secure and adjust them as needed to compensate for shifting or settling of the load.

Q 5. What are your experience with rigging techniques?

Rigging is the art and science of safely attaching loads to lifting equipment. My experience encompasses various rigging techniques, always prioritizing safety and efficiency. I’m proficient in using different types of slings (chain, wire rope, webbing), shackles, hooks, and other rigging hardware.

I understand the importance of proper hitching and knot tying, ensuring the load is evenly distributed and securely attached. I carefully consider the load’s weight, shape, and center of gravity when selecting and using rigging equipment. I also adhere strictly to safety regulations and best practices, always using appropriate safety factors and regularly inspecting rigging gear for wear and tear. My experience includes handling complex rigging scenarios, such as lifting oversized or irregularly shaped loads, requiring precise calculations and careful planning.

Q 6. How do you identify and mitigate potential hazards in lifting operations?

Identifying and mitigating hazards is a crucial part of my daily work. It begins with a thorough pre-lift assessment that considers various factors: environmental conditions (wind, weather, ground stability), the load itself (weight, shape, fragility), the lifting equipment’s condition and capacity, and the proximity of obstacles and personnel.

Potential hazards can range from unstable ground to electrical hazards, and I use checklists and other standardized procedures to ensure nothing is overlooked. For instance, I might need to implement traffic control measures, establish exclusion zones, or employ additional safety personnel during the lift. Risk mitigation strategies may include using additional bracing, employing specialized lifting techniques, or using personal protective equipment (PPE) such as hard hats and safety harnesses. Regular communication within the team ensures everyone is aware of potential hazards and knows how to react appropriately.

I always document any hazards and mitigation strategies taken, contributing to a comprehensive safety record. For example, I once identified a potential electrical hazard near a crane operation; this required immediate adjustments to the lifting plan to ensure the safety of personnel.

Q 7. What is your experience with pre-lift planning?

Pre-lift planning is the cornerstone of safe and efficient lifting operations. It involves a detailed assessment of the entire operation before any lifting commences. This includes a thorough review of the load’s characteristics (weight, dimensions, center of gravity, fragility), the lifting equipment’s specifications and capabilities, the worksite conditions (ground stability, overhead clearances, access routes), and the sequence of operations.

I develop a detailed lift plan that includes a risk assessment, a step-by-step procedure for the lift, the selection of appropriate equipment and personnel, and emergency response plans. The plan details every aspect of the operation, including the rigging setup, the lift sequence, the positioning of personnel and equipment, and any necessary safety precautions. I always ensure the plan is reviewed and approved by relevant personnel before the lift is executed.

Careful pre-lift planning not only ensures safety but also improves efficiency by minimizing delays and rework. I’ve found that a well-defined plan significantly reduces the risk of accidents and streamlines the entire lifting process. For example, a detailed plan for lifting a heavy transformer for a power plant saved time and money by preventing delays and rework caused by unexpected issues.

Q 8. Describe your experience with different types of slings and their applications.

My experience encompasses a wide range of slings, each chosen based on the specific load and lifting environment. Understanding the properties of each type is crucial for safe and efficient lifting operations.

- Polyester Web Slings: These are incredibly versatile and commonly used due to their high strength-to-weight ratio and flexibility. I’ve used them extensively for lifting various materials, from building components to machinery, in construction and industrial settings. Their soft nature allows for easier handling of oddly-shaped loads. For instance, I once used a polyester web sling to carefully lift and position a delicate antique sculpture without causing any damage.

- Chain Slings: Ideal for heavy-duty applications and harsh environments, chain slings are exceptionally durable and resistant to abrasion. I’ve employed them in demolition projects and heavy manufacturing, where the strength and longevity are essential. However, careful inspection for wear and tear is critical to prevent failure. A specific instance involved lifting a large, heavy engine block using a properly rated chain sling.

- Wire Rope Slings: Offering high tensile strength, wire rope slings are frequently used for lifting extremely heavy loads. They are also good for applications demanding high-temperature resistance. My experience includes their use in lifting heavy steel beams in high-rise construction, with rigorous adherence to safety protocols. I once helped secure a wire rope sling to a load using proper hitches to avoid damage to the sling itself.

- Round Slings: Known for their conformability to irregularly shaped loads, these are effective in preventing load slippage and damage. They’re excellent for delicate loads where damage is a concern. I recall successfully utilizing round slings to relocate fragile laboratory equipment without incident.

Choosing the right sling involves careful consideration of factors like load weight, load geometry, lifting angle, and environmental conditions. Incorrect sling selection can lead to accidents and equipment damage. Therefore, I always prioritize proper sling selection based on manufacturer’s specifications and load charts.

Q 9. How do you handle unexpected situations during a lift?

Unexpected situations during a lift demand immediate, calm, and decisive action. My approach involves a structured response that prioritizes safety:

- Assess the Situation: Quickly identify the nature of the problem – is it a malfunction of the equipment, a shift in the load, or an environmental factor?

- Communicate Clearly: Immediately inform all personnel involved, clearly and concisely communicating the problem and the actions being taken. This might involve signaling a crane operator to stop, or issuing instructions to ground crew to secure the load.

- Implement Corrective Actions: Based on the assessment, initiate the appropriate corrective measure. This could range from securing the load with additional equipment, making adjustments to the rigging, or stopping the lift entirely. I once encountered a sudden gust of wind during a lift and immediately signaled the crane operator to lower the load. Safety of personnel and equipment was my highest priority.

- Investigate and Report: Following the successful resolution, a thorough investigation is essential to understand the root cause of the unexpected situation, so that similar incidents can be prevented in the future. I maintain detailed records of every lift, including any unexpected occurrences, for this purpose.

Maintaining a calm demeanor, effective communication, and a methodical approach are vital in successfully navigating these challenging situations.

Q 10. What safety precautions do you take when operating a forklift?

Forklift operation demands stringent adherence to safety protocols. My routine includes:

- Pre-Operational Inspection: Before each use, I thoroughly inspect the forklift’s tires, brakes, lights, horn, forks, and fluid levels. Any defect necessitates immediate reporting and rectification.

- Load Capacity Awareness: I never exceed the forklift’s rated load capacity. The load is carefully assessed and distributed evenly on the forks to maintain stability.

- Safe Operating Procedures: I maintain a safe speed and always keep a clear view of the path. I use appropriate signaling and communicate with other personnel to avoid collisions.

- Personal Protective Equipment (PPE): Safety glasses, steel-toed boots, and high-visibility clothing are worn at all times. Seatbelts are fastened while the forklift is in motion.

- Workplace Awareness: I am consistently mindful of my surroundings and potential hazards, such as pedestrians, obstructions, and uneven terrain.

- Load Securement: Loads are always secured properly using appropriate chains, straps, or other devices. Loads are lifted and lowered slowly and cautiously, ensuring stable movement.

Training and experience are vital for safe forklift operation. I am certified and regularly undergo refresher training to stay up-to-date with safety regulations.

Q 11. What is your experience with crane operations?

I possess extensive experience in crane operations, holding a valid certification and undergoing regular training. My experience covers various crane types including tower cranes, mobile cranes, and overhead cranes. I am proficient in assembling, disassembling, inspecting, and operating cranes according to established safety protocols and manufacturers’ guidelines. I’m comfortable with crane signaling and ensuring the safety of all personnel and the load at all times. A notable project involved operating a tower crane for a high-rise construction project, where careful coordination with other workers and adherence to strict safety regulations was paramount. My duties included accurate load positioning and ensuring that crane load charts were strictly adhered to for safe operations.

Q 12. Explain your understanding of load capacity and stability.

Understanding load capacity and stability is fundamental to safe lifting. Load capacity refers to the maximum weight a lifting device (crane, sling, etc.) can safely lift. Stability refers to the ability of the load to remain balanced and prevent tipping or falling during the lift. Factors impacting stability include the load’s center of gravity, the lifting method, and the environmental conditions.

For example, a heavy, irregularly-shaped object needs careful consideration of its center of gravity. The point of lift must be chosen carefully to prevent the load from tilting. If the center of gravity is miscalculated, the load could swing or overturn, resulting in serious injury or damage. Similarly, adverse weather conditions like high winds can impact stability. To counteract this, load capacity might need to be reduced and extra safety measures, such as additional rigging or wind monitoring, should be employed.

Always using certified equipment and verifying weight capacities before beginning any lifting operation is crucial. Misjudging either load capacity or stability can have catastrophic consequences.

Q 13. How do you perform a pre-operational inspection of lifting equipment?

A pre-operational inspection is a non-negotiable step before any lifting operation. My procedure involves a systematic check of all equipment involved:

- Visual Inspection: I thoroughly examine the crane, slings, hooks, shackles, and other equipment for any visible damage, wear, corrosion, or defects. This includes checking for cracks, frayed wires, bent hooks, or any other signs of potential failure.

- Functional Check: I verify the operational functionality of each component. This involves testing brakes, hydraulic systems (if applicable), and other crucial mechanisms to ensure they are working correctly. The smooth operation of the crane is essential, such as its hoisting, lowering, and slewing capabilities.

- Documentation Review: I check all necessary certifications and documentation, ensuring that all equipment is within its rated capacity and has undergone proper inspections and maintenance.

- Load Capacity Verification: The weight of the load is carefully verified, ensuring it does not exceed the capacity of the equipment being used. I always use load charts and follow the manufacturer’s specifications.

- Communication: Before initiating the lift, I ensure clear communication with the crane operator and ground crew to confirm everyone’s understanding and readiness.

A detailed checklist is used for consistency, and any defects are immediately reported and addressed before proceeding.

Q 14. What are the regulations and standards you follow for safe lifting?

Safety is paramount. My work adheres strictly to several regulations and standards, including but not limited to:

- OSHA (Occupational Safety and Health Administration) regulations: These provide comprehensive guidelines for safe lifting practices in the workplace, covering equipment, personnel, and procedures.

- ASME (American Society of Mechanical Engineers) standards: These standards cover the design, manufacturing, and inspection of lifting equipment, ensuring quality and safety.

- Manufacturer’s guidelines: Each piece of equipment has specific operating instructions and safety precautions provided by the manufacturer; these are meticulously followed.

- Local and national regulations: I remain informed about any relevant local regulations and laws pertaining to lifting and moving operations.

Continuous professional development and staying abreast of the latest industry best practices are essential for maintaining a high standard of safety. Understanding and following these regulations is not just a matter of compliance; it is a commitment to the safety of my colleagues and myself.

Q 15. How do you communicate effectively with your team during lifting operations?

Effective communication is paramount during lifting operations. It’s not just about giving instructions; it’s about ensuring everyone understands the plan, the risks, and their roles. I utilize a multi-pronged approach. Firstly, I conduct thorough pre-lift briefings. These cover the load details (weight, dimensions, center of gravity), the lifting plan (including equipment, rigging, and personnel assignments), potential hazards, and emergency procedures. I make sure everyone is actively involved in the discussion and any questions are addressed. Secondly, during the lift, I use clear, concise hand signals and verbal communication, constantly monitoring the team’s actions and providing adjustments as needed. Clear communication avoids misunderstandings that could lead to accidents. Think of it like conducting an orchestra – each member plays a crucial part, and the conductor (me) needs to ensure everyone is in sync and responding to the signals correctly. Lastly, post-lift debriefs allow for feedback and learning from both successful and challenging lifts. We analyze what worked well and identify areas for improvement, fostering a continuous improvement culture within the team.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of lifting machinery.

My experience encompasses a wide range of lifting machinery, including mobile cranes (rough terrain, all-terrain, and crawler cranes), overhead cranes (both bridge and gantry), forklifts (various capacities and types), and specialized lifting equipment such as vacuum lifters and air-powered hoists. I’m proficient in operating and inspecting these machines, understanding their limitations, and selecting the appropriate equipment for different tasks. For example, when lifting a very heavy load over long distances, a crawler crane with its superior stability would be preferred over a rough-terrain crane. Conversely, for tight spaces, a smaller forklift or even a vacuum lifter might be the safest and most efficient solution. My experience also extends to understanding the relevant safety regulations and certifications needed to operate each type of machinery.

Q 17. What are the signs of damaged or malfunctioning lifting equipment?

Identifying damaged or malfunctioning lifting equipment is crucial for preventing accidents. Regular inspections are essential, and I always follow a comprehensive checklist. Signs of damage can include: obvious physical damage like dents, cracks, or bends in the structure; worn or frayed ropes, chains, or slings; leaking hydraulic fluids; unusual noises during operation; faulty safety mechanisms (e.g., a non-functional overload device); and inaccurate readings on gauges or indicators. For example, a crack on a crane’s boom could indicate a serious structural weakness, and frayed slings could lead to catastrophic load failure. If any of these signs are observed, the equipment should be immediately taken out of service for inspection and repair by qualified personnel. Never compromise on safety; even seemingly minor issues could escalate into a major accident.

Q 18. How do you handle lifting operations in confined spaces?

Lifting in confined spaces presents unique challenges. Careful planning and risk assessment are crucial. This involves choosing the right equipment – often smaller, more maneuverable cranes or specialized lifting tools. Detailed spatial analysis is necessary, considering not just the load dimensions but also the swing radius of the crane, access points, and potential obstacles. Communication becomes even more critical, with team members needing to maintain close coordination in limited space. We often utilize specialized lifting techniques such as using smaller capacity equipment and employing experienced riggers capable of handling the limitations of the space. Thorough planning, including risk assessments and detailed spatial mapping, is essential to mitigate the risk of collision with the surrounding structure or other obstacles.

Q 19. What are your experience with load securing methods?

Secure load handling is paramount to prevent accidents. My experience covers a variety of load securing methods, tailored to the specific characteristics of the load and the means of transportation. This includes the proper use of different types of slings (chain, wire rope, webbing), ensuring correct angles and attachment points. I understand the importance of considering the load’s center of gravity and how it impacts stability during transportation. For example, securing a long, narrow load requires careful consideration to prevent shifting or swaying. Different securing methods are used for different loads, from simple cargo nets for smaller items to complex lashing systems for heavy machinery. I also have experience with load restraint systems such as tensioners and winches to ensure the load remains secure throughout transit. I adhere strictly to industry standards and best practices when securing a load, ensuring it is immobile and safe. Proper documentation and inspections are also critical parts of the process.

Q 20. Describe your experience with emergency procedures in lifting operations.

Emergency procedures are an integral part of any lifting operation. We conduct regular training drills to ensure the team is well-prepared to handle unexpected situations. Our procedures cover a range of scenarios, from equipment malfunctions to medical emergencies. Clear communication channels are established to rapidly disseminate information and coordinate actions. We have designated emergency response personnel and pre-determined evacuation routes, specific to each site. For example, if a crane malfunctions, the operator has a pre-determined procedure to lower the load safely and shut down the equipment, while other personnel are responsible for securing the area and providing assistance. Regular review and update of these procedures are essential to ensure effectiveness and adaptation to the changing needs of the work environment.

Q 21. How do you ensure compliance with safety regulations?

Compliance with safety regulations is non-negotiable. I ensure adherence to all relevant local, national, and international standards, including OSHA (or equivalent) regulations. This starts with pre-job planning, where a thorough risk assessment identifies potential hazards and determines appropriate control measures. We maintain detailed records of equipment inspections, operator certifications, and training programs. Regular audits of our procedures and equipment are conducted to ensure continued compliance. We also stay updated on any changes in regulations and incorporate them into our practices promptly. Non-compliance can lead to serious consequences, so maintaining a robust compliance program is a top priority, ensuring safety for the team and the public.

Q 22. What is your understanding of risk assessments in lifting operations?

Risk assessments in lifting operations are crucial for preventing accidents and injuries. They involve a systematic examination of all potential hazards associated with a lift, evaluating the likelihood and severity of each hazard, and then implementing control measures to mitigate the risks. This isn’t just a checklist; it’s a dynamic process that should be adapted to the specific circumstances of each lift.

A thorough risk assessment considers factors like the load’s weight, dimensions, and center of gravity; the lifting equipment’s capacity and condition; the environment (e.g., weather, ground conditions); the competency of the personnel involved; and the procedures being followed. For example, lifting a heavy piece of machinery in a confined space with limited visibility presents significantly higher risks than lifting a smaller, lighter object in an open area with ample space. The assessment might identify risks such as equipment failure, load instability, collision with obstacles, or personnel injury and then detail preventative actions, like using a secondary lifting device, improving lighting, or implementing a traffic management plan.

Q 23. How do you calculate the center of gravity of a load?

Calculating the center of gravity (CG) of a load is vital for safe lifting because it determines the load’s stability and how it will react to forces. For simple, regularly shaped objects, the CG is often at the geometric center. However, for complex or irregularly shaped loads, more sophisticated methods are needed.

One common method involves suspending the load from two different points. The intersection of the plumb lines dropped from each suspension point marks the CG. Another approach involves using specialized software or engineering tools that take into account the load’s dimensions and weight distribution. Imagine lifting a large metal beam: if the CG is not correctly identified, the load could swing unexpectedly during the lift, creating a hazardous situation. Accurate CG determination is essential for preventing tipping, sway, and other potential accidents.

Q 24. Describe your experience with using personal protective equipment (PPE).

Personal Protective Equipment (PPE) is non-negotiable in lifting operations. My experience includes consistent and correct use of safety helmets, high-visibility clothing, safety footwear with steel toes, and appropriate gloves depending on the task (e.g., cut-resistant gloves when handling sharp objects). I’ve also used harnesses and lanyards when working at height or near potential fall hazards, and hearing protection when operating noisy equipment.

Beyond simply wearing the PPE, I emphasize proper maintenance and inspection to ensure its effectiveness. A damaged helmet or worn-out gloves are useless and could even increase risk. I’ve also participated in regular training sessions on the correct use and limitations of various PPE items, reinforcing the importance of a proactive safety culture.

Q 25. What is your experience with different types of hoists?

My experience encompasses a range of hoist types, including overhead cranes, jib cranes, mobile cranes, and chain hoists. Each has its advantages and limitations, making selection dependent on the specific lifting task. For instance, overhead cranes are ideal for heavy loads within a defined workspace, while mobile cranes offer flexibility for lifting in different locations. Chain hoists are better suited for smaller, lighter loads and precise positioning. I’m proficient in the safe operation, inspection, and maintenance of each type, ensuring regular checks for wear and tear, proper lubrication, and adherence to load capacity limits.

I’ve also worked with different control systems, from manual lever-operated hoists to advanced radio-controlled systems, ensuring appropriate selection based on the complexity and demands of the task. Experience with each type translates directly to understanding its operational limits and safe operating procedures. For example, I would never use a chain hoist to lift a load exceeding its specified weight capacity.

Q 26. How do you manage multiple simultaneous lifting operations?

Managing multiple simultaneous lifting operations requires meticulous planning and coordination. Clear communication is paramount. We use pre-lift meetings to discuss the sequence of lifts, the designated areas for each operation, and potential conflicts. A designated signaler is crucial for communicating instructions to crane operators, ensuring everyone understands their responsibilities and potential hazards.

We employ a system of permits and check lists to authorize each lift, ensuring that all safety protocols are followed. This prevents accidental collisions, load interference, and other potential hazards. Detailed site surveys, including identifying overhead obstructions and access routes, are key to mitigating the risk of accidents during the combined operations. For example, lifting heavy materials on a construction site with multiple cranes requires a traffic management system, designated lifting zones and robust communication between crane operators and ground personnel.

Q 27. How do you handle difficult or heavy loads?

Handling difficult or heavy loads requires a multi-faceted approach prioritizing safety. First, a comprehensive risk assessment, considering factors like load instability and environmental conditions. Then, appropriate lifting equipment is selected, ensuring its capacity exceeds the load weight. This frequently involves using specialized equipment like spreader beams to distribute the load more evenly or heavy-duty slings and shackles. For particularly awkward shapes, additional rigging may be necessary to provide stability.

The lifting process is then meticulously planned and executed, using techniques like progressive lifting to ensure controlled movement and minimize stress on the equipment and load. Extra personnel are often deployed for guiding and spotting the load, and communication remains critical throughout. In my experience, careful planning and execution, combined with the right equipment and personnel, allows for the safe and efficient handling of even the most challenging loads. For instance, lifting a large transformer requires a detailed plan, specialized rigging, and a highly skilled team.

Q 28. Explain your understanding of different types of lifting hooks and their uses.

Lifting hooks are vital components in lifting operations, and their selection depends on the specific load and rigging configuration. Common types include:

- Standard hooks: These are general-purpose hooks used for lifting various loads.

- Clevis hooks: These hooks have a clevis (a U-shaped fitting) that allows for easy attachment to shackles or other lifting components.

- Grab hooks: These hooks are designed to engage with specific load shapes or features.

- Eye hooks: These are typically welded to load-bearing components and provide a secure attachment point.

The choice depends on factors like load type, weight, and the required method of attachment. For instance, a grab hook is ideal for lifting prefabricated components with specific lifting points, while a clevis hook offers flexibility for connecting multiple components. Regular inspections for damage, cracks, or deformation are essential, as a failed hook can lead to catastrophic accidents. Each hook is also rated for a maximum load capacity, which should never be exceeded.

Key Topics to Learn for Lifting and Moving Operations Interview

- Safety Regulations and Procedures: Understanding and applying relevant safety regulations, including OSHA guidelines and company-specific protocols. This includes proper use of Personal Protective Equipment (PPE).

- Lifting Techniques and Mechanics: Mastering proper lifting techniques to minimize risk of injury to both the worker and the load. This includes understanding center of gravity, leverage, and body mechanics.

- Equipment Operation and Maintenance: Familiarization with various lifting and moving equipment (cranes, forklifts, hoists, etc.), including their safe operation, maintenance procedures, and limitations.

- Load Securing and Transportation: Understanding techniques for safely securing loads during transport, preventing shifting or damage, and complying with weight and balance regulations.

- Risk Assessment and Mitigation: Identifying potential hazards associated with lifting and moving operations, and developing strategies to mitigate risks before they occur. This involves pre-job planning and hazard identification.

- Communication and Teamwork: Effective communication with team members, supervisors, and other stakeholders to ensure safe and efficient operations. This includes clear signaling and coordination.

- Emergency Procedures: Knowledge of emergency procedures to handle accidents or unexpected situations, including reporting protocols and first aid response.

- Weight and Balance Calculations: Understanding how to calculate and verify the weight and balance of loads to ensure stability and prevent tipping.

Next Steps

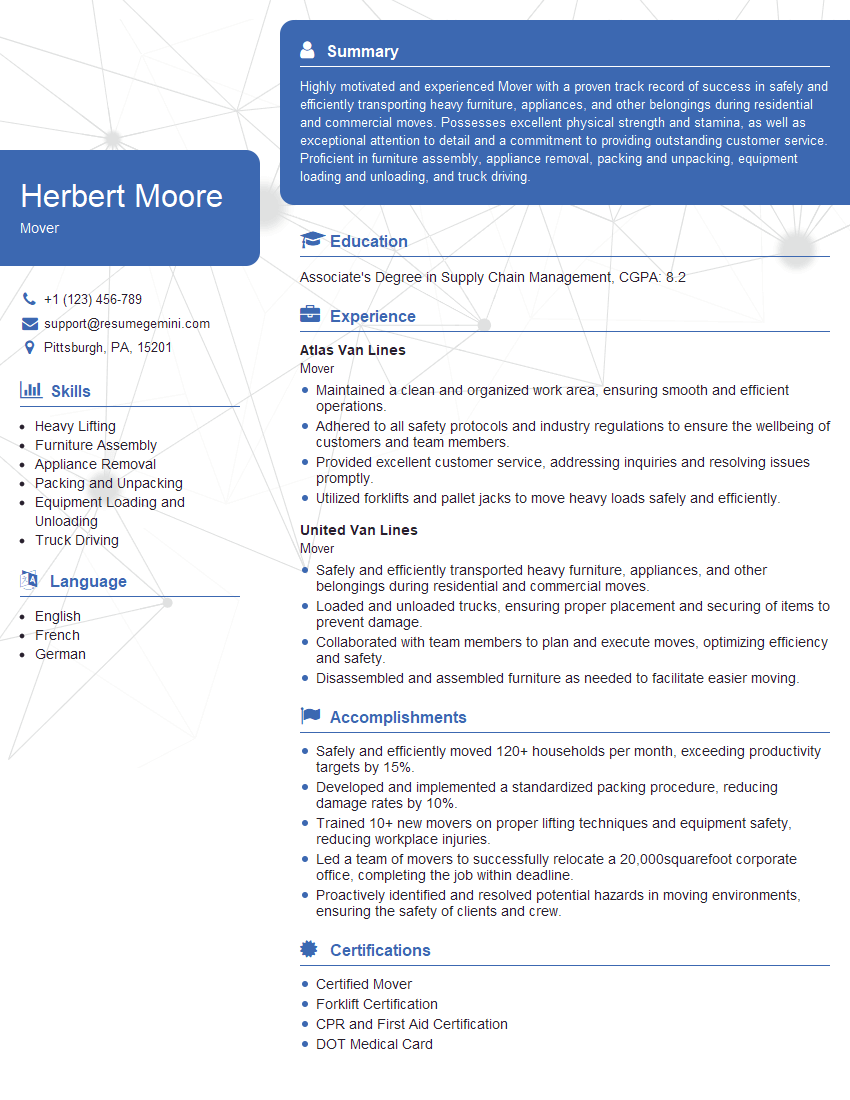

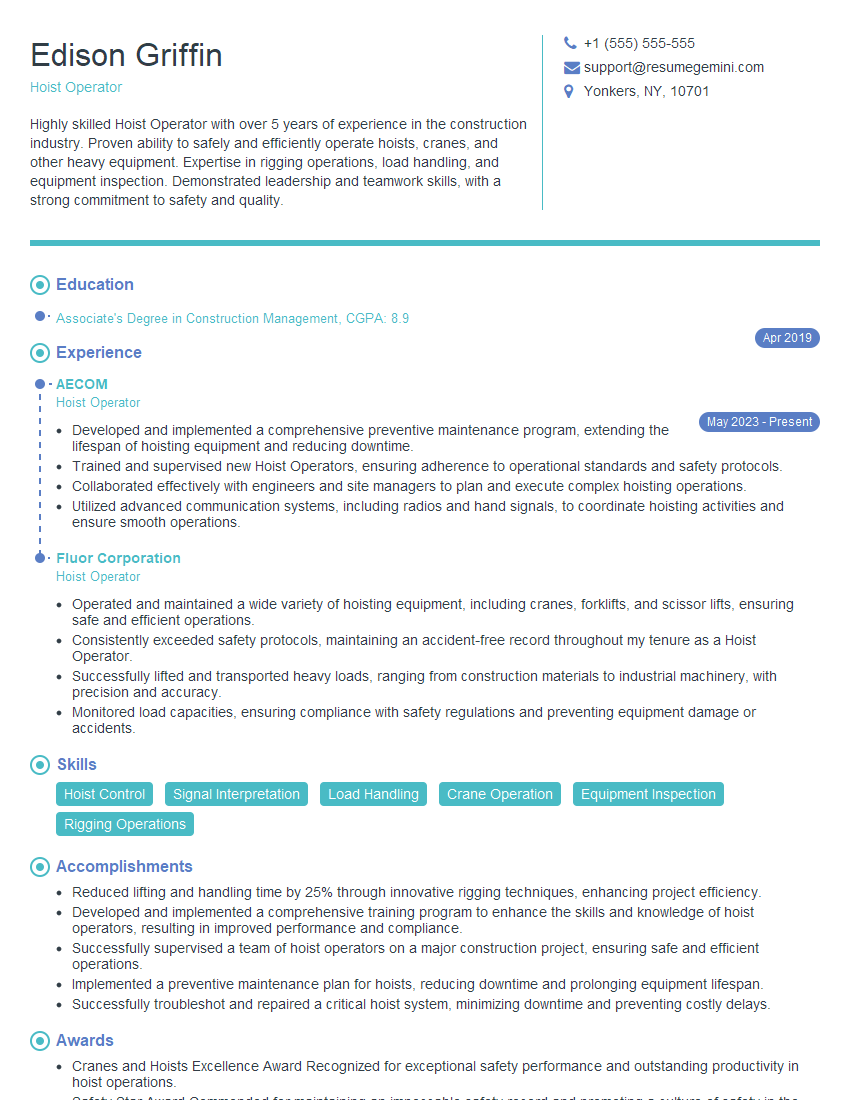

Mastering Lifting and Moving Operations opens doors to a rewarding career with excellent growth potential in diverse industries. A strong understanding of safety and efficiency is highly valued by employers. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We offer examples of resumes tailored to Lifting and Moving Operations to guide you in crafting a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good